- Best before date

- Options for using induction

- Heating rate

- Incandescent lamp device

- What kind of light do plants need to grow?

- Industrial induction luminaires

- Scope of application

- Kinds

- What is the difference between induction and electric hobs

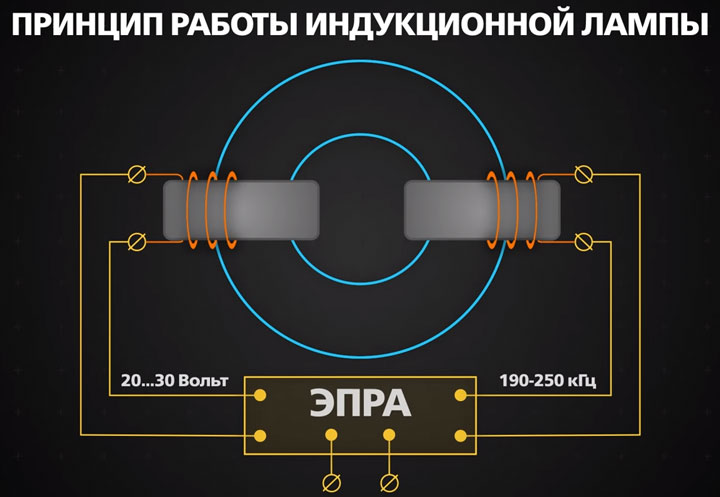

- Operating principle

- Suitable cookware

- Price

- Complexity of care

- Heat consumption

- Pros and cons of induction meters

- Characteristics

- Ammeter internal resistance

- Applications

- Malfunctions of induction cookers

- Comparison of induction cookers and other cooking devices

- Differences

- It's all about the principle

- Efficiency

- Pros and cons of induction devices

- Advantages

- Flaws

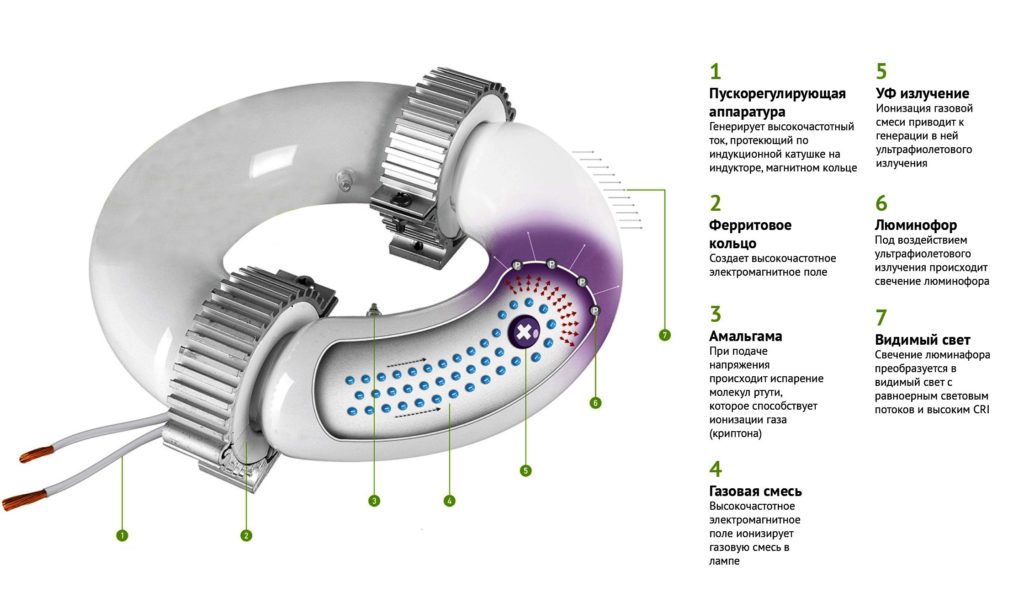

- Features of devices with an integrated generator

- CHARACTERISTICS OF DIFFERENT TYPES OF SODIUM LAMPS

- Conclusion

- conclusions

Best before date

The service life of a product depends on its quality. LN must be stored in a cardboard box. This is necessary in order not to accidentally break it or so that it does not give an imperceptible crack that will ruin all the work. Due to such a crack, the gas will evaporate, as a result, after the light bulb is screwed into the ceiling, it will work no more than 2-3 hours. It is necessary to follow the safety rules when screwing the lamp into the ceiling. Children should not be allowed to this process, and it is also advisable to completely turn off the electricity supply in the room.

Note! Used light bulbs must be properly disposed of, they are not allowed to be thrown away with food waste. Each city has special bins for such waste.

If you follow all the rules of storage and use, then the lamp will last as long as possible, without defects.

Vintage Edison Bulb

Vintage Edison Bulb

Options for using induction

Lamp appearance

These lamps are available in different types and shapes. Models with the most common plinths are offered, so replacement should not be a problem. What distinguishes them from most analogues is only the massive design of the luminous element itself - a braided bulb and large ferrite rings, which actually provoke magnetic induction.

Sufficiently dimensional induction lamps are ideal for interior lighting of large objects (production shops, warehouses, storage facilities, etc.). Industrial induction lamps provide high luminosity with relatively low energy consumption. As already mentioned, in terms of consumption, such systems are comparable to LEDs. But LED-lamps of similar power will cost the owner many times more.

In addition, induction lighting systems spread light in all directions, as a result, it is scattered throughout the room more evenly. For diodes, the dispersion angle is much narrower. Therefore, with comparable power, the luminescence efficiency of LED systems will be lower.

Due to their resistance to temperature changes, they can also be successfully used for outdoor lighting - illumination of roads, industrial sites, recreation areas and common areas.

An induction street lamp will provide a uniform high-intensity luminous flux, and even with adequate color reproduction. Thanks to the contactless energy exchange scheme, it is able to work for many years without human intervention. And this is an important component of the overall economy. After all, it is known that the maintenance of high street lamps is not cheap. It requires the involvement of special equipment and a team of workers with access to work at heights.

Bispectral flasks

Another plus of such lamps is that they emit ultraviolet, which is as similar as possible to the natural one emitted by the sun. Therefore, such systems are ideal for artificial illumination of plants. There is even a separate line - phyto - lamps. It is recommended to regularly illuminate covered greenhouses with them, since even through the transparent glass of the partitions, the natural flow of ultraviolet radiation does not reach the seedlings.

Such lamps are successfully used to ensure the normal flow of photosynthesis in seedlings in greenhouses or in house plants located in shaded areas or in apartments on the north side of the building.

Under the influence of radiation from induction phyto-lamps, the vegetation of plants improves noticeably, a noticeable increase in yield is observed. Crops get sick less and become more resistant to pests, as the ultraviolet light coming from the lamps gently disinfects the upper soil layer.

Since such systems practically do not heat up during operation, they do not dry out the air. This means that you can use less powerful lamp models and install them closer to the planting sites (hang them on long wires, for example).

Light therapy

For illumination of plants it is ideal to use bispectral induction flasks. They generate a light flux simultaneously with two spectra: warm red and cold blue. This creates optimal conditions for the growth of stems and leaves (at a temperature of 6400 K) and for flowering (2700 K). These phyto-flasks look like this:

This combination allows you to liken their glow to the sun's rays. Under their influence, photosynthesis in plants occurs as efficiently as possible. Normal vegetation is achieved even in fully enclosed greenhouses. So it’s not without reason that such a line of lamps in the name has the postscript “phyto” - this is a kind of light growth stimulator.

We recommend installing an induction over a home greenhouse, and observe the result. We are convinced that in the near future you will reap the benefits of "light therapy" with your own hands.

The choice of induction lamps for greenhouses is justified in many ways:

- they generate the most acceptable type of radiation for plants;

- they shine very brightly and at the same time are very economical, therefore they can be used over large areas and work continuously;

- they do not heat up, which means they do not affect the temperature regime inside the greenhouses;

- can work for a very long time, without any human intervention;

Heating rate

Meticulous users, in order to find out which stove heats up faster, carried out real measurements. For this, two pots of the same type were taken with the same temperature of the water and the walls of the body.

Next, it was necessary to find out which stove will boil water faster? Induction has always coped with this task several times faster than a simple electric one.

This is again explained by the exclusion of an extra intermediary from the process.Everything is elementary.

Fewer elements in heat transfer, faster heating. Is it always convenient? It turns out that it doesn't.

For example, when heating something liquid with solid pieces, the liquid will boil quickly, but these same pieces will not warm up immediately. With such food, it is better to initially set the power a little less.

By the way, manufacturers of cheap inductions often deceive their customers. A burner circle of the same size is drawn on the surface, but in fact there is an inductor coil of a much smaller diameter inside.

Hence the lower heating rate and greater overheating of the central zone. As a result, all the food that gets into the center of the pan will burn, and vice versa along the edges.

How to find out at home without disassembling the panel? Elementary. Put a frying pan much larger than the drawn circle on the stove, pour water into it and turn it on to the maximum.

After a minute, you will see the real diameter of the heating zone by the formed bubbles.

Each housewife in such a simple way can find out how good and high-quality the induction panel was sold to her. Remember that a small inductor on a large pot gradually leads to uneven heating and deformation of the bottom.

Incandescent lamp device

The main parts that make up the design of the LN are a base, a vessel, electrodes, holders for incandescent threads, an incandescent body, contacts and insulation. In Figure 10, you can see the structure of the light bulb.

Before buying a lamp, it is advisable to consult a specialist. It is not recommended to give the choice to an unknown manufacturer, as defective products may come across that will not work for the prescribed period, or even break under voltage.Quality manufacturers always give a guarantee of at least 30 days for incandescent lamps. The buyer has the full right to exchange the product or return the funds if the lamp was less than 10 hours old or it burned out instantly.

In conclusion, it should be noted that incandescent lamps have long ceased to be popular among people. However, it must be emphasized that among such products there is a huge choice, for cars, street lighting, aircraft and so on. Unfortunately, LN cannot be used near products made of wood. Since sometimes there is a strong heating and rupture of the spiral, which may cause an emergency.

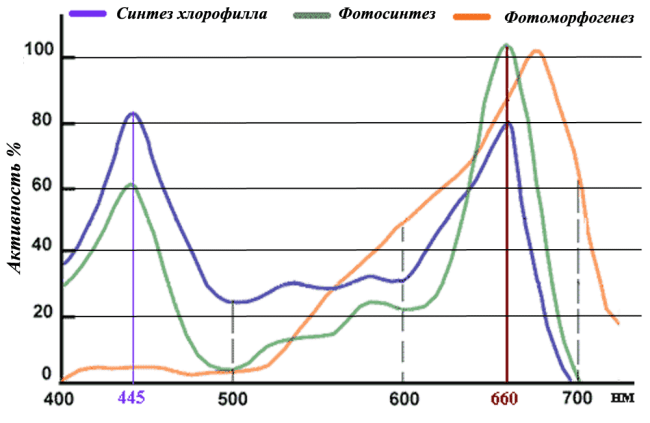

What kind of light do plants need to grow?

Artificial garden lighting

Artificial garden lighting

When choosing a greenhouse lamp, gardeners pay the main attention to the light spectrum and illumination in lux (lx). The second indicator is selected depending on the plants grown in the greenhouse:

- 1000-3000 lux - for shade-loving beets or cabbage;

- 3000-4000 lux - for shade-tolerant cucumbers and zucchini;

- 4000-6000 lux - for light-loving nightshade and tropical fruits.

Each light range affects plants differently. At the same time, the influence practically does not depend on the type of vegetation, for all it is largely the same:

- 280–320 nm - only harms crops;

- 320-400 nm - has a minimal effect;

- 400-500 nm - "blue" light is involved in photosynthesis;

- 500-600 nm - "green" is needed for photosynthesis of the lower leaves;

- 600-750 nm - "red" affects the development and regulation of cultivated crops.

The activity of growth processes depends on the spectrum of light

The activity of growth processes depends on the spectrum of light

UV (less than 380 nm) and IR (more than 780 nm) radiation is not required for photosynthesis. They have a greater effect on the color and rate of aging of the leaves.

Plants grown in greenhouses and greenhouses require "blue" and "red" light. It is they that are emitted by a bispectral induction lamp, which was specially developed for use in greenhouses.

Industrial induction luminaires

Special requirements are imposed on the lighting of premises and territories of industrial enterprises. It should be:

- reliable;

- quality;

- lighting fixtures should be easy to install.

Rice. 3 - Induction spotlight with IP65 protection

Rice. 3 - Induction spotlight with IP65 protection

When choosing a light source, the expediency of its use should be justified.

All these indicators correspond to industrial lamps of induction type. They are easy to install, save up to 80% of energy resources, have excellent color reproduction and comply with the requirements of the PUE and sanitary standards.

They are classified according to the following criteria:

- degrees of protection (standard design, moisture resistant, dust and moisture resistant, explosion-proof;

- mounting method (wall, ceiling, suspended, built-in, cantilever);

- power;

- dimensions.

Induction floodlights and induction lamps with high luminous efficiency, fast payback period, color temperature, approaching natural light, create a comfortable working environment, as well as in the office and at home. Diverse in design and degree of protection, they are used in various premises, as well as on the street. It remains only to choose the right ones for specific needs.

Scope of application

Manufacturers produce products with common bases, so replacing an induction lamp with your own hands is not difficult. They differ only in size: the bulb is braided with strong ferrite rings, which create an electromagnetic field. Dimensional devices are suitable for lighting large industrial premises, because they provide bright light without significant energy costs.

Manufacturers produce products with common bases, so replacing an induction lamp with your own hands is not difficult. They differ only in size: the bulb is braided with strong ferrite rings, which create an electromagnetic field. Dimensional devices are suitable for lighting large industrial premises, because they provide bright light without significant energy costs.

A significant scattering angle allows the rays to gently envelop the entire room completely, for LEDs the light slope is narrower, so the efficiency of such devices is lower. Lamps are highly resistant to different temperatures, they are installed outdoors: they illuminate streets, roads and subways with their help. Induction appliances provide adequate light transmission and high performance for many years without the intervention of specialists.

Phytolamps that emit ultraviolet light illuminate houseplants and greenhouses. They allow you to accelerate the growth and development of flowers, greenery and seedlings. This will increase yields, eliminate all pathogenic microbes from the soil and increase the resistance of crops to bacteria and pests. The luminaires do not dry out the air, so they are mounted as close as possible to the seed planting site.

Devices have a number of advantages regarding the use in greenhouses:

- the most suitable type of lighting is generated for different types of plants;

- very bright light quickly, but gently spreads over the entire area of \u200b\u200bthe room;

- the case does not heat up, so there is no effect on the temperature regime;

- work has been going on for quite some time.

Kinds

Induction cookers are usually divided into:

- Freestanding - combined with an oven. Equipment of this type is characterized by increased power, with extensive functionality. Usually, manufacturers make freestanding induction cookers with an oven with four or more burners.

- Built-in - hob panels of low height. The dimensions of built-in induction cookers are standard 60x50 cm and non-standard - there are oval devices, with various smooth transitions from one shape to another, rectangular. Installation is not difficult and is usually done in kitchen furniture with appropriate cutouts.

- Portable induction hobs are available with 2 or 3 burners, but there are models with one or four heating zones. The dimensions and design features allow you to move the device and are ideal for small rooms or summer cottages. The main advantages of portable models are their mobility, convenience, the ability to connect to any outlet and low cost.

Plates are distinguished by type of heating:

With heating zones - burners. Induction coils are placed in certain places and heat up only their area. Places of placement are marked with markings on the surface of the plate.

Combined combine induction hobs with TEN or gas hobs. Appliances usually have two inductive and two conventional burners. The device is relevant for users who prefer to cook in ordinary dishes that do not have ferrimagnetic properties.

Depending on the number of dishes supplied, data about each object appears on the electronic control panel and available for control - the degree of heating of each separately.

What is the difference between induction and electric hobs

First, let's figure out what we're dealing with. It must be understood that both types of hobs essentially electrical as they work from the networkand not on gas. They differ only in the type of burners and the way heat is transferred to the dishes.

Operating principle

Modern electrical panels in many ways similar to old stoves with metal burners and work on the same principle: the stove has a heating element that generates heat for cooking. Heaters are most often hidden under a glass-ceramic panel, which is easy to clean and looks attractive. The picture below is a typical electric hob. It marks the areas under which the heating elements are located.

Externally induction panels very similar to electric ones, but they use a completely different principle of operation. In them, the dishes play the role of a conductor of induction current, due to which they heat up. This current is created by high-frequency generators located under each burner. The hob itself does not heat up on induction cookers.

Suitable cookware

And now we have come to another difference between induction and electric stoves: different kitchen utensils are suitable for them. With conventional electric ones, you can use any frying pans and pots, and with induction - only those that have ferromagnetic properties, that is, they can conduct current and heat up from induction. If you decide to cook something in ordinary dishes, even good and high-quality ones, the stove will not work.

Suitable containers usually have a reel symbol (small spiral).You can also check the compatibility of the dishes and the hob using an ordinary magnet: if it sticks to the saucepan, feel free to put it on the burner.

So that when buying a new hob, you do not have to change all the pans, they came up with special adapters: steel discs that serve as a heat conductor for dishes. But with such an adapter, your brand new induction hob will turn into a regular electric hob.

Price

Induction stoves appeared much later than electric ones, and they are more complicated - that's why they are more expensive than traditional counterparts. For example, the cheapest induction for two burners costs 7,200 rubles on Yandex.Market - this is DARINA P EI523 B. For four burners - already from 13,000 rubles. You can also find small built-in panels for one pan - they will cost from 4500 rubles.

You won’t have to choose an electric panel for a long time: they are much cheaper - you can buy a standard four-burner surface for 7,000 rubles.

Complexity of care

Both electric and hobs are usually coated with glass-ceramic, which is easy to clean with standard hob cleaners. Another thing is that some electrical surfaces are still equipped with metal pancakes: this design is a little more difficult to maintain.

Also, due to the fact that the electric panel heats up, if during the cooking process something boils or drops onto the burner, the liquid will evaporate, and the escaped product will be welded to the stove - it will be quite difficult to wash it off.

Heat consumption

Induction panels have a higher efficiency: they heat the dishes directly, not the air.Electric ones heat the burner, and therefore throw out part of the heat during cooling. Even a gas stove is much more convenient in this regard, as it gets cold faster.

Pros and cons of induction meters

Electricity metering devices are only single-tariff, because they do not have a system remote reading in automatic mode, that is, the meter cannot operate at day and night rates. This is a significant drawback that an induction electric meter has, since the payment for current will be much higher than that of electronic ones.

Induction meters have a number of advantages and disadvantages. Among the advantages can be noted:

- They have a relatively low price.

- High level of reliability.

- Not dependent on power fluctuations.

- They have a long service life.

- Suitable for such manipulations as rewinding readings and stopping the counter.

- Sold at most electrical outlets.

However, against this background, there are also negative aspects, and in particular:

- Low accuracy class.

- A large percentage of error at small loads.

- Only one tariff can be used.

Manufacturers of induction meters are working to improve their products, increasing the accuracy class and service life, but the design that induction meters have does not allow to significantly improve these indicators. It is because of this that electronic metering devices have replaced, which are more stable and have many positive aspects.

Characteristics

One of the main parameters of light bulbs with a body of heat will be the power indicated in watts. The purpose of the lamps is different, so the range of choice is large - from 0.1 W "lamp" to 23 thousand.W searchlights for airfields.

In everyday life, low-power light bulbs are used, usually from 15 W to 200 W, and in production, lamps with a power of up to 2000 W are used.

The quality of the light beam and the level of scattering are regulated by the material used to manufacture the vessel.

car light bulb

car light bulb

The highest light transmission is inherent in products with transparent glass, because they do not absorb light. The matte surface of the lamp absorbs 5% of light rays, and the white surface absorbs 15%.

The size of incandescent bulbs can be from 60 mm to 130 mm. Depends on the scope.

Ammeter internal resistance

It should be less than the resistance of the circuit itself. The indicator is calculated after measurements with a voltmeter, which is connected in parallel with the ammeter. Then the readings of the second are divided by the readings of the first, the result is the internal resistance. A small value is necessary so that the voltage drop across the instrument does not affect the measurement accuracy.

This device is one of the simplest and most common. They also talk about how to use ammeters in physics lessons, so there should not be any special problems during operation, especially with the advent of digital ammeters, which greatly simplified the nuances of working with the device and expanded its scope.

Applications

The fields of application of these lamps are very diverse. Due to its optimal technical characteristics, rather high light output with a minimum level of energy consumption, the lamp can be used for high-quality street lighting, lighting of large workshops of industrial enterprises, shopping centers and other facilities. Suitable for creating optimal light balance even in the most inaccessible places.

Induction lamps in street lighting are widely used today. Often such lamps are used to illuminate streets, parks, squares and similar objects. These lamps do not need to be changed frequently, and they are well suited for any lighting equipment. Such models quickly pay off and are the most wear-resistant.

Induction lamps in street lighting

Induction lamps are also used to illuminate shopping malls. This product emits natural, natural light that does not strain your eyesight. This quality is simply indispensable both in terms of practical application and for creating an aesthetic effect. Induction lamps help to give supermarket windows and shopping areas a very beautiful and expensive look. Among other things, induction lamps are used in workrooms, workshops, factories, factories and greenhouses.

Summing up, it can be noted that induction lamps have a number of distinctive features that contribute to the increase in their popularity. The areas of application where this type of product can be used are as wide as possible, and in the future, this type of lighting fixture may replace many similar types of lighting.

The minimum price, fast payback periods, long life and easy maintenance - all this makes induction lamps very popular.

Malfunctions of induction cookers

The electromagnetic principle of operation of the induction cooker implies high reliability and durability of the device.

Despite this, during operation, some breakdowns are possible:

Low burner power. The likely cause is improper installation of dishes that are not in the center of the work surface.It is possible that the diameter of the pot (frying pan) is smaller than the diameter of the heated zone. Also, the reasons include the incomplete fit of the dishes to the surface or overheating of the induction winding;

The burners on the left side of the oven do not work. The probable cause is a breakdown of the control unit or power board;

Failure of one of the working areas

Before cooking, it is important to follow a certain switching sequence. First, the hotplate is selected (using the touch panel), and then the power is set

If everything is done correctly, check the cookware used for the fact that it matches the induction cooker (in diameter and material). If the cookware complies with the rules, but the comfort still does not work, activate the test check of the temperature sensor and replace it (if necessary). If the sensor is working, make sure that the dishes fit snugly against the surface;

The two burners on the right side are not working. The cause of the malfunction often lies in poor contact of the terminal box or blown fuse. It is worth checking the quality of the connection between the control unit and the power board. In extreme cases, a replacement block is required;

The residual heat indicator is out of order. Actions - conducting a test check, the results of which conclude that the temperature sensor is in good condition. If the part is serviceable, the control unit changes. In case of display malfunctions, it is worth checking the quality of the connection between the panel and the control unit;

The hotplate does not turn on and there are no messages on the screen. Check the power switch, fuse, as well as the quality of the connection of the control unit with the power board and the touch panel;

Cooling fan failure

Pay attention to the installed power. If it is minimal, the fan will not work immediately, but after reaching an air temperature of 50 degrees Celsius

Do a test check. If the fan fails, replace it. If this node is serviceable, replace the control unit;

The induction cooker beeps continuously. The probable cause is the failure of the control unit;

The maximum power burner (3 kW) does not work. The activation of the cooking zone is sometimes blocked to prevent overheating of the induction hob unit. If the problem appears for no reason, the control unit changes;

Automatic switch off of the hob. The principle of operation of the induction cooker is designed so that the shutdown is performed in three cases. First, if the time was set by a timer. Secondly, if the burner has been running for more than two hours. Thirdly, when after 10 seconds after turning on, no action occurs.

Comparison of induction cookers and other cooking devices

Induction units are high-tech devices that use different physical principles than other devices. Induction current opens up new horizons for consumers in cooking and allows you to fully control this process.

Differences

It's all about the principle

The main difference between different cooking devices relates to the principle of their operation.

We will not linger on gas units for a long time. Here the differences are obvious: they are in different types of fuel, thanks to which the device functions.

Electric stoves in this respect, it would seem, do not have differences, but similarities.After all, in these designs everything is based on electricity. But there is a difference nonetheless!

When switched on, the electric stove heats up to the set heating temperature. Then the hot surface of the device transfers heat to the dishes and thereby heats the container and its contents.

An induction hob activates magnetic currents that heat pots or pans, but the hob does not change its temperature.

Efficiency

Let's compare the efficiency of using different devices.

heating efficiency:

- electric stove with glass ceramics - 50-60%;

- gas stove - 60–65%;

- induction panel - 90%.

Pros and cons of induction devices

Advantages

- Increasing the heating rate. During switching on, the dishes and, accordingly, the products are heated, while the panel itself practically does not heat up.

- Saving electrical energy. The physical principles that have become the basis of this kitchen technique allow you to cook food with minimal energy consumption. This is because energy is expended to create a magnetic field. The coil does not need to be heated.

- Increased safety of induction cooking appliances. It is impossible to get burned on its surface. The operation of such a device eliminates the occurrence of fire, even if the burner is left for a long time. As soon as the dish is cooked and the stove is turned off, it will not be hot, but warm.

- Auto power off. The hob automatically recognizes the presence of dishes on its surface and turns off automatically.

Flaws

In fairness, it should be noted that such a panel is not without flaws.

Some consumers are wary of this new kind of kitchen appliance because cooking on an induction cooker requires the use of special utensils. It must have certain ferromagnetic properties. And dishes made of aluminum or glass should not be used.

Equipment of this class is strongly not recommended to be installed next to household appliances made of metal.

The panel of these devices requires careful handling. A lid or knife that has fallen on it can cause a crack.

Care must also be taken when placing dishes on the hob, otherwise the hob may break.

But the key drawback of this household appliance is the high cost in comparison with stoves operating on other principles.

Features of devices with an integrated generator

Luminaires powered by an external separate generator are often not supplemented with a phosphor coating. For this reason, they only scatter the light produced by the ionized gaseous plasma. According to the general classification, such models can be attributed to gas-light lamps. By the way, street induction lamps are often made exactly according to this principle - with an external placement of an electric generator. This is due to the high service life and increased reliability of such devices - accordingly, they are more resistant to damage and other external influences.

CHARACTERISTICS OF DIFFERENT TYPES OF SODIUM LAMPS

In the technical literature, sodium lamps are commonly referred to by the following abbreviations:

- DNaT - a general definition, deciphered as Arc Sodium Tubular;

- NLND - Low Pressure Sodium Lamp;

- HPS - High Pressure Sodium Lamp.

HPS are one of the most efficient light sources due to their high light output. Low pressure sodium lamps can produce more than 200 lumens per 1 W of power, the maximum light output of high pressure devices is in the range of 140 lm / W.

The second advantage of sodium light sources is their high efficiency: for NLVD this figure is about 30%.

The third plus of HPS is long service life with insignificant losses in the quality of the luminous flux (10-15% of the initial power for 15,000 hours of operation) with a significant time of use.

At the same time, the service life of modern lamps often exceeds 25,000 hours. Studies have shown that the main decline in light flux (up to 13%) occurs during the first 6000 hours of operation. Further, the flow rate changes slightly.

Sodium lamps also have disadvantages:

- their effectiveness is significantly reduced at low ambient temperatures;

- the light emitted by the NLND significantly affects the color perception of the human eye, distorting it.

Based on the foregoing, we can conclude that it is preferable to use sodium light sources in those places where color accuracy fades into the background, and the economic effect comes to the fore (for street lighting and in gardening).

Types of sodium lamps.

According to their design, sodium lamps can be divided into:

- tubular;

- soffit;

- mirror.

At the same time, tubular designs can be divided into:

- traditional (with one burner);

- two-burner (increased service life).

Conclusion

Equipping large areas with induction lighting can be expensive - especially when compared to traditional spotlights. Nevertheless, in the long term, such lamps justify themselves both in terms of financial performance and ease of maintenance. In addition, the induction lamp provides high-quality light. If standard halogen or even energy-saving devices are not ideal in terms of the perception of their radiation by the eye, then gas-discharge induction models can adjust the glow parameters for specific needs. Moreover, both the color rendition and the degree of radiation intensity are regulated.

conclusions

One of the main disadvantages of IL is its high price. Such lamps cost from 1000 rubles. Manufacturers give a long warranty period - as much as 5 years. Calculations show that the cost of purchasing one IL pays off within 1-1.5 years, depending on the capacity and duration of operation.

Induction lighting significantly reduces electricity consumption. Therefore, the load on the wiring will be minimal. This is especially true for lighting large areas: urban, industrial, etc.

In general, it can be noted that the most promising field of application of IL is the illumination of large spaces. The use of IL in everyday life is limited by dimensions and harmful radiation: electromagnetic and ultraviolet. And for industrial enterprises, the national economy, induction lamps are a good way to illuminate large areas with high quality and relatively inexpensively.