- Work Permit

- Making miniature offset hooks

- Possible connection methods

- Insertion into the central highway

- no pressure

- No line block

- Features of the tie-in

- Obtaining a work permit

- Plumbing structure made of metal

- With non-pressure welding equipment

- With a special pressure device

- Options for inserting into a plastic pipe

- Mounting the crimp collar of the lining

- Clamp or manifold device

- Electric welding saddle attachment

- Insertion by means of a branch pipe

- Choosing the Best Solution

- Tapping into a pipe under water pressure

- Punch methods

- Construction of a well for arranging a node

- Video about tie-in to plastic pipes

Work Permit

Work on tapping into water mains, both by welding and without it, cannot be carried out without obtaining the appropriate permits.

Illegal tapping traditionally ends with bringing the owner to material and administrative responsibility.

Image gallery

Photo from

The pipeline is cut

Small diameter pipe insert

Insertion equipment

Insertion is performed by the master

Water connection

Connection to the water supply in the well

Surface water connection

Summer water connection

A site plan can be obtained from the Federal Center for Land Registration, and technical conditions from the central department of the water utility.

The technical conditions for connection will indicate:

- connection point;

- main pipeline diameter;

- data required for embedding.

In addition to the local structure of Vodokanal, the development of design estimates is carried out by specialized design organizations that have the appropriate license.

Then the documentation for the tie-in should be registered at the local branch of the SES. Simultaneously with the submission of the collected package of documents to the SES branch for registration, it is required to leave an application for issuing an opinion on the need to connect to the water supply.

To carry out the work, you should have a site plan in hand, as well as obtain technical conditions and permission to tie in the local water utility

According to generally accepted standards, the execution of pipe tapping under pressure and installation of metering devices must be carried out by qualified and authorized personnel. It is prohibited to carry out such work on your own.

Save money by making your own efforts to connect, it will turn out only in the production of earthworks during the development and backfilling of the trench.

Conditions under which tapping is not allowed:

- if the main network pipeline has a large diameter;

- if the property is not connected to the central sewer system;

- if the tie-in is supposed to bypass metering devices.

Even in the presence of all permits, only qualified specialists should carry out the tie-in of the pipe to the existing network.

You can save only if you do some of the work on your own, the implementation of which does not require a license

These include: earthworks (digging and backfilling of trenches), delivery of material and other types of ancillary work that are not directly related to the tie-in procedure.

Of course, no one can forbid the owner to perform the sidebar on his own. Therefore, the article describes in detail the sequence of actions.

This is interesting: Insulation of external water supply in the ground: work technology + video

Making miniature offset hooks

In the summer, it is almost impossible to catch fish with a regular spinning rod. This is explained by the fact that in summer the fish usually gather in places with an overgrown bottom or where there are snags. This is where the offset hook comes in handy. Such a hook has a bent shank, which reduces the likelihood of an unexpected hook.

Offset can be made from a regular hook. Any hook with a long shank will do for this. But you should choose such hooks that are made of high-quality steel. Such a hook, when bent, will break if it is released over the flame.

In order to prevent the entire hook design from being released, it is best to take it with pliers. We take for the part that does not need a "vacation" and hold over the flame, for example, a gas burner. It should be pointed out that the shank of the hook will never change its properties. As a result, we get a strong hook, the strength of which is very high.

Possible connection methods

The connection of the new blue fuel supply network to the existing one is carried out by tie-in or welding.

In the first case, the operation of the main pipeline is not subject to fundamental changes, since the process of cold cut in gas pipe carried out without the use of welding. The volume of the pumped substance and its pressure do not change and are still kept in the operating range of the network.

This method is used to connect new consumers. To perform work related to the central network, you must have a permit and permit to carry out gas hazardous activities.

Without special training, it is absolutely impossible to interfere with the functioning of the main pipeline. Violation can result in tragic consequences, including death or imprisonment.

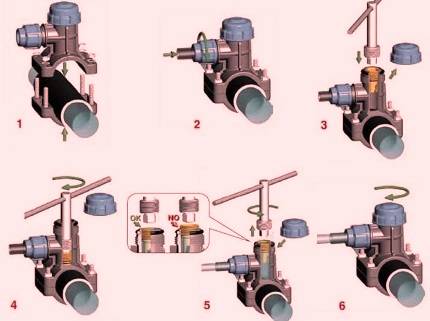

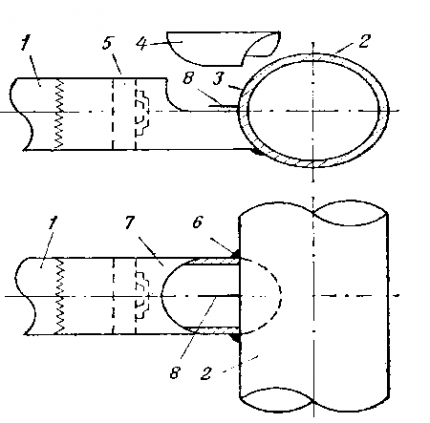

In some cases, tie-in into the gas pipeline should be performed with the intersection of the axes of the networks. Explanations to the diagram: 1 - connected pipe, 2 - labor of the working gas pipeline, 3 - "window" (cut out wall), 4 - visor, 5 - wooden disk, 6 - welded shock, 7 connecting pipe, 8 - rod for extraction, 9 – overlay (+)

In some cases, tie-in into the gas pipeline should be performed with the intersection of the axes of the networks. Explanations to the diagram: 1 - connected pipe, 2 - labor of the working gas pipeline, 3 - "window" (cut out wall), 4 - visor, 5 - wooden disk, 6 - welded shock, 7 connecting pipe, 8 - rod for extraction, 9 – overlay (+)

The second option of joining is more familiar to most inhabitants. It is reliable and has stood the test of time. However, a specialist conducting a tie-in in this way must necessarily have a high level of professional qualifications, as well as have a special permit.

The methods of joining are:

- tie-in to a gas pipeline under low pressure;

- under medium and high pressure gas, when special devices are used;

- with shutdown of gas and complete release of pipes from it.

The choice of connection method to the gas pipeline depends on a number of factors. Therefore, the decision must be made by the people making the connection on a case-by-case basis.

As for the contractor, there may be 2 options: representatives of the gas service or employees of a private company who have the legal right to perform actions, as well as the necessary equipment and permission to carry out gas hazardous work.

Moreover, in the second case, the office can assume obligations for the preparation and execution of a package of documents for a legal tie-in to the main gas network. True, all additional services will affect the final cost of connection.

Not only the perfect performance of the gas pipeline depends on the correct choice of pipes, but also the safety of the operation of the entire gas transmission system.

Insertion into the central highway

The tie-in process can be primarily divided into two types:

| no pressure | In this case, the flow in the central line is blocked for the duration of the work. |

| Tapping under pressure | It is performed in cases where it is not possible to turn off the water. |

Below, we will take a look at both options for performing this work.

no pressure

This process largely depends on the material from which the pipes are made, however, the principle is always approximately the same. Therefore, as an example, consider a tie-in into a steel line.

So the instruction looks like this:

- First of all, you need to expose the section of the highway on which the tie-in will be carried out. To do this, you need to dig a pit measuring approximately one and a half meters by one and a half meters.

As a rule, at first the pit is dug with the help of an excavator, but upon reaching a special metal tape, the workers take up the shovels. After the tape, it usually remains to dig another 30-50 centimeters. - Further, a trench is usually dug to the object that will be connected.

- Then the water in the system is turned off.

Welded elbow

- After all earthworks have been completed, a hole is cut out in the main pipe with the help of an autogen and a branch pipe with cut pipe threads is welded to it.

- Then a valve is attached to the pipe, which allows you to shut off the flow for further work.

- At the end of this operation, a well is installed above the tie-in.

If the pipe is made of polyethylene or another type of plastic, then there is no need for welding. In this case, special devices are used - saddles for tapping into the water supply. This fitting is a tee, the nozzles of which are disassembled into two halves.

Saddle for pipeline tie-in

After installing the saddle, a hole is made in the plastic pipe. Further work looks the same as when working with a steel pipeline.

In the photo - tie-in of a branch into a steel line under pressure

No line block

The pressure relief device is a fairly efficient and productive method.

However, this work requires precise compliance with technology and all the nuanceswhich are given below:

First of all, in the area where the pipe will be drilled, it is necessary to remove the insulation and thoroughly clean the surface.

Pressure line drilling pattern

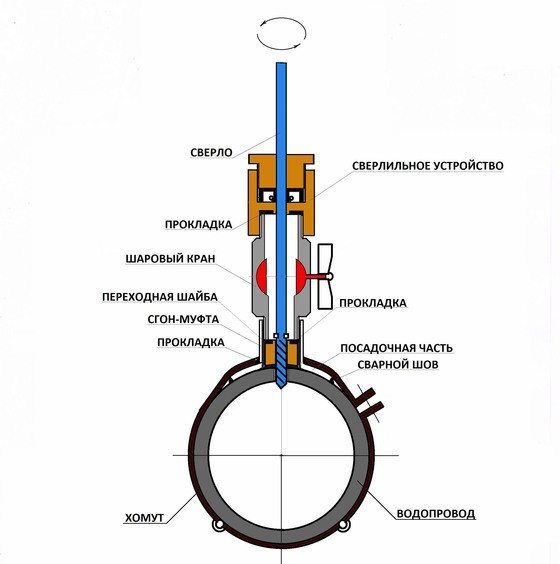

- Next, a saddle is installed on the main pipe for tapping into the water supply.

- Shut-off valves and a special device for drilling are attached to the branch pipe.

- Then, a cutter of the required size is inserted through the open valve and the stuffing box of the fixture.

- After drilling the hole, the cutter is pulled out and the valve is closed.

- At the end of the work, the drilling device is dismantled.

If the pipe is steel, then a pipe can be welded to it and then the same steps can be performed. As in the previous case, a well must be installed at the outlet.

Features of the tie-in

The material of which the centralized pipeline consists determines how the tie-in will be carried out into it. Less often it is cast iron, but more often it is metal-plastic, plastic or metal. When creating a hole, water will naturally flow out of the pipeline, but without this, of course, it is impossible to make a tie-in. In order for everything to work out correctly and in good quality, you need to use specialized clamp systems.

The material of which the centralized pipeline consists determines how the tie-in will be carried out into it. Less often it is cast iron, but more often it is metal-plastic, plastic or metal. When creating a hole, water will naturally flow out of the pipeline, but without this, of course, it is impossible to make a tie-in. In order for everything to work out correctly and in good quality, you need to use specialized clamp systems.

Main tie-in rules:

- The diameter of the inner surface of the pipe to be connected must match the diameter of the drill to be used.

- The outer diameter of the pipe should be slightly smaller than the diameter of the hole into which it is inserted.

How the tie-in is made depends on the type of water supply. To prevent the descent of water, special clamps and welding are often used. If there is no possibility of cutting the line, clamps must also be used. Welding must not be used if the pipes are made of polyethylene.

At the end of the pipe to be inserted, there must be a thread for a root tap or a coupling; when welding is used, it will be necessary to drain the water from the system.

The main tool for these works is a drill specially designed for this, with the help of which a hole with the required diameter can be made in a pipeline with water inside.In order for the device to have good performance, safety precautions must be observed.

First you need to free the pipe from insulation and clean it at the point of insertion. Then it is necessary to install a flange, which is displayed on the main pipeline. Secure it with a clamp. Install a drill on the valve closing the flange. The clamp is not used when inserting into a steel pipe, it uses a pipe welded in advance.

First you need to free the pipe from insulation and clean it at the point of insertion. Then it is necessary to install a flange, which is displayed on the main pipeline. Secure it with a clamp. Install a drill on the valve closing the flange. The clamp is not used when inserting into a steel pipe, it uses a pipe welded in advance.

It is necessary to check if there are any defects in the seam after welding has ended. If available, it is necessary for greater reliability to weld again along the contour of this seam.

It is necessary to introduce a cutter of the desired diameter after the pipe (coupling) is ready, and make a hole for the pipe. The valve will block the flow of water in the nozzle after removing the equipment. Upon completion of welding, everything can be insulated and coated with a composition against the occurrence of corrosion. So work is done with pipes made of metal and cast iron.

For use in tie-in work, there are several types of clamps on the market:

- electrowelded clamp-saddle is used when working with plastic pipes. The kit includes a cutter of the required diameter. But for its installation, you will need a few more tools;

- drilling - in its design, a rotary-gate mechanism is used, which, like an adjusting or gate valve, remains on the pipe;

- saddle - this type of clamp is used when working with plastic, metal, asbestos-cement pipes; the locking plate present in its design will block the flow of water;

- clip - can not be used when tapping a valve into a pipe under pressure.Suitable for empty pipes, because it has an inexpensive price and ease of use. The composition of the material is metal or plastic.

A polyethylene pipe insert is made with the first two types of clamps.

Obtaining a work permit

Given the importance of the water main as an object of providing a vital product, a permit for the production of a tie-in must be obtained from the local water utility department. The method of execution is not important - with or without welding. An approved copy of the site layout is issued by the Federal Center, which registers land ownership, and the technical conditions for connection are formulated by the Vodokanal department

They must contain the following information:

An approved copy of the site layout is issued by the Federal Center, which registers land ownership, and the technical conditions for connection are formulated by the Vodokanal department. They must contain the following information:

- location of the insertion;

- the size of the pipe of the main water supply;

- data that may be needed in the production of the insert.

Such a document can be executed in a specialized design organization, but this does not cancel its approval in the water utility.

The document for the production of the tie-in will be registered at the local department of the sanitary and epidemiological station. A set of documents submitted to the SES is accompanied by a statement about the need to connect to the central water supply network.

Given all sorts of restrictions, it is obvious that savings through the application of one's own efforts is possible only when excavation is performed. The rest can only be carried out by specialists with special approvals.

Connection to the water supply under pressure is prohibited under the following conditions:

- the pipeline is made of a large diameter pipe;

- in the absence of connection to the central sewerage scheme;

- if the tie-in does not provide for the installation of water metering devices.

Plumbing structure made of metal

Today, such pipelines are irrelevant and impractical. They are replaced by more modern and cheap materials, as they are quite expensive and resistant to corrosion. One of the competitive materials are plastic pipes

Sometimes there are steel products, so you should also pay attention to them.

With non-pressure welding equipment

For this you need to have

For this you need to have

:

1. Welding equipment for creating connecting sections on metal products;

2. An autogen is used to cut a hole with the desired diameter;

3. Extensions with a threaded section as an auxiliary element for attaching an additional outlet element;

4. Fittings for blocking the flow of water into a new one.

It is worth noting that such devices have a rather high price, therefore, it is for such tasks that it is better to use the services of professional welders who will come on call with personal welding equipment and tools.

Stages of work

:

1. Initially, it is necessary to block water movements in the wire.

2. Using an autogen, it is necessary to make a hole of the required diameter.

4. Fittings must be installed on the threaded sections to shut off the water supply.

5. Finally, turn on the water supply.

Do not forget that after the completion of the entire process, it is imperative to protect the joints from corrosion, since welding work, most likely, such protection has been reduced to zero.

As an alternative, you can cut out the desired section of the product and replace it with a tee with an auxiliary outlet.

With a special pressure device

This method involves the use of special devices for drilling pipes under pressure.

How to crash into a pressurized water pipe

:

1. To begin with, it is worth removing the insulating materials and cleaning the surfaces of the plumbing product. The cross section of the product that drains water should not be larger than the pipe that acts

If done without taking into account these facts, you can tear it when drilling holes

2. It is necessary to install a flange part (see) with an outlet on the active element and fix it yourself with the help of .

3. Attach a special drilling tool to the flange part and install it.

4. In the valve in the open state, you need to insert a cutter of the required diameter and cut a hole.

5. Finally, remove the device from the extension, before doing so, be sure to turn off the water.

These methods involve cutting into a steel plumbing system without using welding. Now more about how to crash into a polypropylene water pipe.

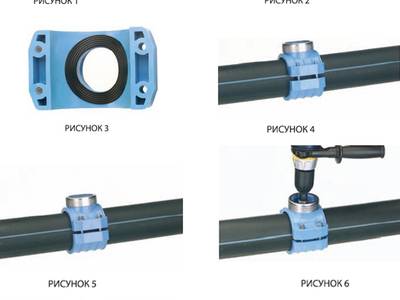

Options for inserting into a plastic pipe

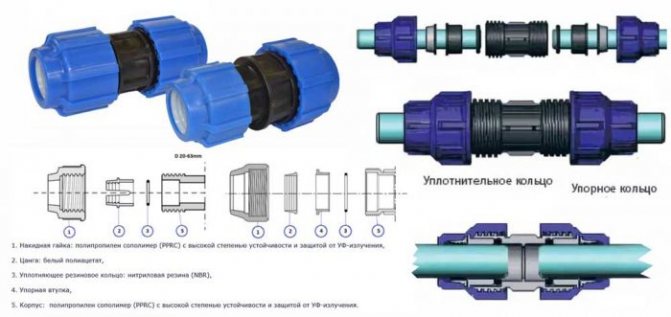

Consider how to embed into a plastic water pipe in different ways: by crimping a clamp with an overlay, connecting a manifold or a tee, installing an electric welding saddle, providing a tie-in through a pipe.

Mounting the crimp collar of the lining

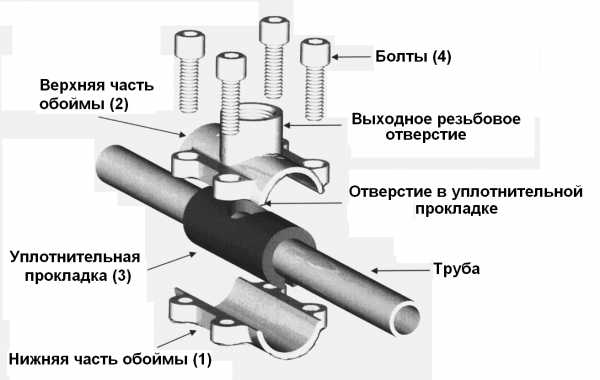

This assembly consists of two parts with bolts tightened with clamps. The upper part is attached to the pipe through a sealing gasket that prevents water leakage. For good clamping, both parts of the lining must be matched to the appropriate size according to the marking.

In the first upper part there is a technological hole for connecting a new water supply line.

Possible connection via:

- stopcock element,

- the presence of a built-in cutter and a protective valve,

- metal end in the form of a flange,

- the possibility of a plastic end for gluing.

After placing the clamp with overlays, I direct the upper part towards the planned branch of the new line. The assembly is fixed with bolts, which are pre-selected in size, taking into account the diameter of the assembly. With a special device, a hole is drilled in the line through the pipe of the mounted fitting.

This method also allows you to connect to a plastic pipe under pressure with water. For this, a built-in valve is installed in the assembly, by turning which a hole is drilled. After obtaining the desired result, the valve closes and the cutter rises.

This is a very profitable way to solve the problems of connecting to water in cases where it is not possible to stop the water supply or it is extremely inconvenient. This solution simplifies the procedure and makes it possible to carry it out online.

Clamp or manifold device

Installing a tee can be called a classic solution to the problem. Instead of the installation, prepared by removing part of the pipe from both sides, a separate part is mounted in the form of a tee or manifold. Next is soldering.

Electric welding saddle attachment

This mechanism resembles the above described method of attaching the lining, but with differences. It, like a tee, provides a tight and reliable fastening by soldering at the molecular level of the material.

This is achieved due to the device in plastic overlays of electric heating coils, which are a special welding device that has a program configured for each node to prevent overheating. After that, the plastic, warming up to a certain temperature, not exceeding the critical one, sticks to the plastic and provides a tight and strong contact.

Insertion by means of a branch pipe

A good way on low pressure pipes. The principle of fastening is that with the help of a branch pipe and a girth, without welding, it is installed on pipes. The elements of the device of the required diameter are selected, otherwise the assembly may leak water. The fastener allows you to quickly and easily install the outlet.

Choosing the Best Solution

Without a doubt, it is possible that the most versatile and effective way, given the complexity of mounting the assembly, is lining. Compared to other methods, it provides reliability and flexibility in installation.

This is interesting: What can replace soldering iron at home – practical advice

Tapping into a pipe under water pressure

To crash into a pipe under pressure, you need one

compression connection - saddle. This connection can be purchased at

plumbing stores, but before buying, check what diameter your pipe is,

in which to crash.

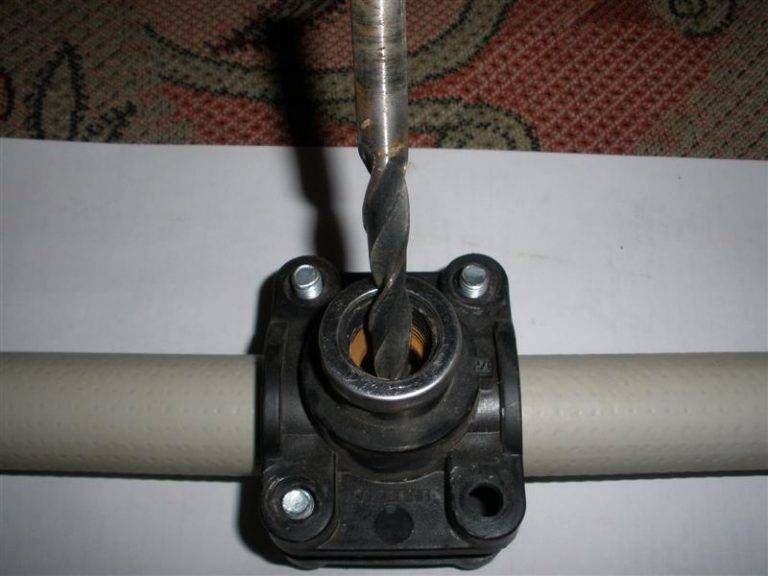

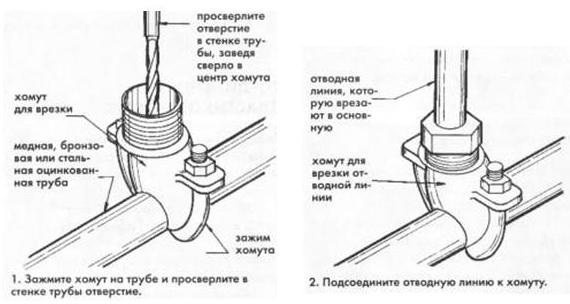

We install the clamp on the pipe and tighten the bolts connecting its halves. When tightening the bolts, distortions between the halves of the saddle must be avoided. It is desirable to tighten the bolts crosswise.

Installation of a compression joint on a pipe under water pressure.

After that, an ordinary ball valve of suitable diameter must be screwed into the thread of the saddle. How to choose a high-quality ball valve and open it if it is jammed can be found in this article.

It remains only to drill a hole in the pipe through the open

ball valve.

First, we determine the diameter of the drill. For getting

good water flow, it is desirable to drill a hole as large as possible

diameter. But in this case, the ball valve has its own hole. it

the hole is smaller than the inside diameter of the faucet thread. Therefore, the drill will have to

pick up this hole.

During drilling, it is important not to hook the fluoroplastic

seals inside the ball valve. If they damage the crane will stop holding

water pressure

For drilling plastic pipes, it is best to use

pen drills for wood or crowns. With these drills, PTFE seals

cranes will remain intact and such drills will not slip off the pipe in the very

start of drilling.

During drilling, you do not need to worry about the chips, it will be washed

water flow when the hole is drilled.

To drill holes safely and easily, there are several

tricks.

Since in the process of making a hole there is a high probability of pouring water over it, it is not advisable to use a power tool. You can of course use a mechanical drill or a brace. But they will be difficult to drill metal pipes. You can use a cordless screwdriver, even if it is flooded with water, then the electric shock will be insignificant. But a screwdriver at one important point may not have enough power.When the hole is almost drilled and the drill bit has almost passed the pipe wall, it can get stuck in the metal pipe wall. And then the situation will turn out that water is already flowing under pressure on the tool, and the hole has not yet been drilled to the end. This may not necessarily happen, but it is worth remembering.

Particularly desperate people use an electric drill, but the work is done with a partner who turns off the drill from the outlet when water appears.

To protect the instrument from the flow of water, you can put it in a plastic bag.

A plastic bag wrapped around a screwdriver.

Drilling a hole in a pipe through a ball valve.

Or put a circle with a diameter of 200-300 mm of thick rubber directly on the drill, which will act as a reflector. You can even use thick cardboard instead of rubber.

Cardboard-reflector, dressed on an electric drill drill.

There is another simple and affordable way. Plastic is taken

1.5 liter bottle. A part with a bottom of about 10-15 cm is cut off from it, and in

a hole is drilled in the bottom. We dress this bottom on the drill with the cut off part

from a drill and with such a device we drill a pipe. The bottle should cover

a crane. The flow of water will be reflected by a semicircular bottom.

Punch methods

Often the material of the water supply pipeline determines both the material of the branch line pipe and the method of tie-in. If the central or secondary pipe is steel, then it is also better to use a steel layer. In extreme cases, make a transition section in the form of a fitting from a steel pipe with a valve, to which then connect a pipeline from another material.

Insertion of steel pipes is carried out in two ways, such as:

- using a welding machine by welding the fitting to the water supply;

- by means of a steel collar without welding.

Both methods are used both for tapping into a pipeline that is under pressure and without pressure. But on high-pressure pipelines, welding is recommended only in emergency, emergency cases, as well as when organizing additional safety equipment. In the normal mode of work, actions are needed to completely turn off the section of the water supply system where the tie-in is made using welding.

The algorithm of work using welding on an existing pipeline is as follows:

- a pit is dug out by an excavator to a level above the laid pipeline by about 50 cm;

- the section of the pipe into which the tie-in is planned is manually cleared of the soil;

- the tie-in place is freed from the anti-corrosion coating and other protective layers, and the specific area for connecting the fitting or branch pipeline is cleaned to a shiny metal;

- a fitting with a tap is welded;

- after the metal heated by welding has cooled, a drill is inserted through the tap into the fitting and a hole is drilled in the wall of the water pipe;

- when water flows through the fitting, the drill is removed and the tap is closed (the insert is made, further laying of the water supply line starts from the valve on the fitting).

Mortise Clamp It is an ordinary part, consisting of two halves of semicircular shapes. These halves are put on the pipe and pulled together with bolts and nuts. They differ from ordinary clamps only in the presence of a threaded hole on one of the metal parts. A fitting is inserted into this hole, which serves as part of the bypass line.You can position the hole for the pipe anywhere in the water supply, and when screwing in the fitting, it will always be at right angles to the linear plane of the pipeline surface.

The rest of the process is similar to tie-in by welding: a drill is inserted into the fitting through a tap and a hole is drilled. If the outlet is of small diameter and the pressure in the water supply is within 3–4 kgf / cm², then the tap can be screwed on without problems even after drilling (if it is threaded and not welded). Connection of additional lines to the cast-iron line is also carried out using clamps.

Tapping into pipes made of plastic or polyethylene occurs with the help of plastic clamps or saddles (half-clamp with fasteners). Clamps and saddles are simple and welded. Working with simple devices is not much different from tie-in with a clamp into a steel pipe. And in welded saddles or clamps there is all the equipment necessary for welding. Such a saddle assembly is installed on the pipe in the intended place, the terminals are connected to electricity and after a few minutes the tie-in will be automatically performed.

Construction of a well for arranging a node

To simplify the insertion into an existing water supply, it is convenient to use a manhole. The diameter of the structure should be about 70 cm. This space is enough to accommodate the shut-off valve (in the form of a valve or gate valve), as well as perform all the necessary manipulations for the tie-in.

In the future, during the period of operation, the presence of such a structure will facilitate the repair of home plumbing.

The tie-in unit used to turn off the input for the period of repair work will be located right inside the mine in the area of the connection point with the external water conduit

To build a well, they dig a new pit of the appropriate size. The bottom of the pit is covered with a gravel "cushion", forming a layer 10 cm high.

To make a reliable foundation, cuts of roofing material are spread over the leveled gravel dump and a concrete screed 10 cm thick is poured. When creating the fill, concrete grades M150 and M200 are used.

After three or four weeks, when the concrete has acquired the necessary strength, a shaft is erected above the slab. To do this, the walls of the pit are lined with bricks, cement blocks or reinforced concrete rings. The neck of the structure should reach the zero level.

If the well is supposed to be installed in a site where the groundwater level rises to one meter during the flood period, it is necessary to build a waterproof structure.

It is most convenient for this purpose to purchase a ready-made plastic container. From below it is anchored to a concrete slab, from above such a structure is covered with a cast slab equipped with a hole for installing a hatch.

Video about tie-in to plastic pipes

There are many nuances in connecting a branch to a plastic pipeline. There are different types of plastics, and fittings in design, and tie-in methods. To avoid gross mistakes, we recommend that you watch the videos below on this topic.

Insert in pressure HDPE pipe using a saddle with a cutter:

Features of mounting an electric welded saddle:

The nuances of tie-in to a polyethylene water pipe:

Crashing into existing plastic plumbing is rare.But sometimes you need to change pipes, install water meters, or simply connect additional plumbing. To do this, there are several different types of fittings and tie-in technologies.

For any case, there is an optimal option so that the installation can be carried out independently. It is obligatory to entrust these works to professional plumbers only in a situation of connection to a common water supply, where preliminary approvals are required.