- Work technology

- Possible connection methods

- Briefly about the main

- How to start replacing a gas pipe

- Process description

- Connection of metal systems

- Cutting into a plastic pipe

- Work rules

- Specifications

- What are the tie-ins

- Some math and numbers

- Third stage

- Video description

- Final stage

- Video description

- Briefly about the main

- Final stage

- Video description

- Briefly about the main

- Methods of tapping into a polyethylene gas pipeline under pressure

Work technology

When you have a cast-iron sewer pipe in front of you, the next step is to fix the shut-off valve to the flange outlets of the saddle. Through the first and have to start a crown. The cast-iron pipe is drilled, while it will be necessary to cool the work site and change failed crowns from time to time. In this case, you need to use a special cutting tool that has carbide inserts. It will not be possible to cut the material using other equipment. At the final stage, the crown is removed, the water flow is blocked, and the installation of the external branch is carried out according to standard rules.

Possible connection methods

The connection of the new blue fuel supply network to the existing one is carried out by tie-in or welding.

In the first case, the operation of the main pipeline is not subject to fundamental changes, since the process of cold tapping into a gas pipe is carried out without the use of welding. The volume of the pumped substance and its pressure do not change and are still kept in the operating range of the network.

This method is used to connect new consumers. To perform work related to the central network, you must have a permit and permit to carry out gas hazardous activities.

Without special training, it is absolutely impossible to interfere with the functioning of the main pipeline. Violation can result in tragic consequences, including death or imprisonment.

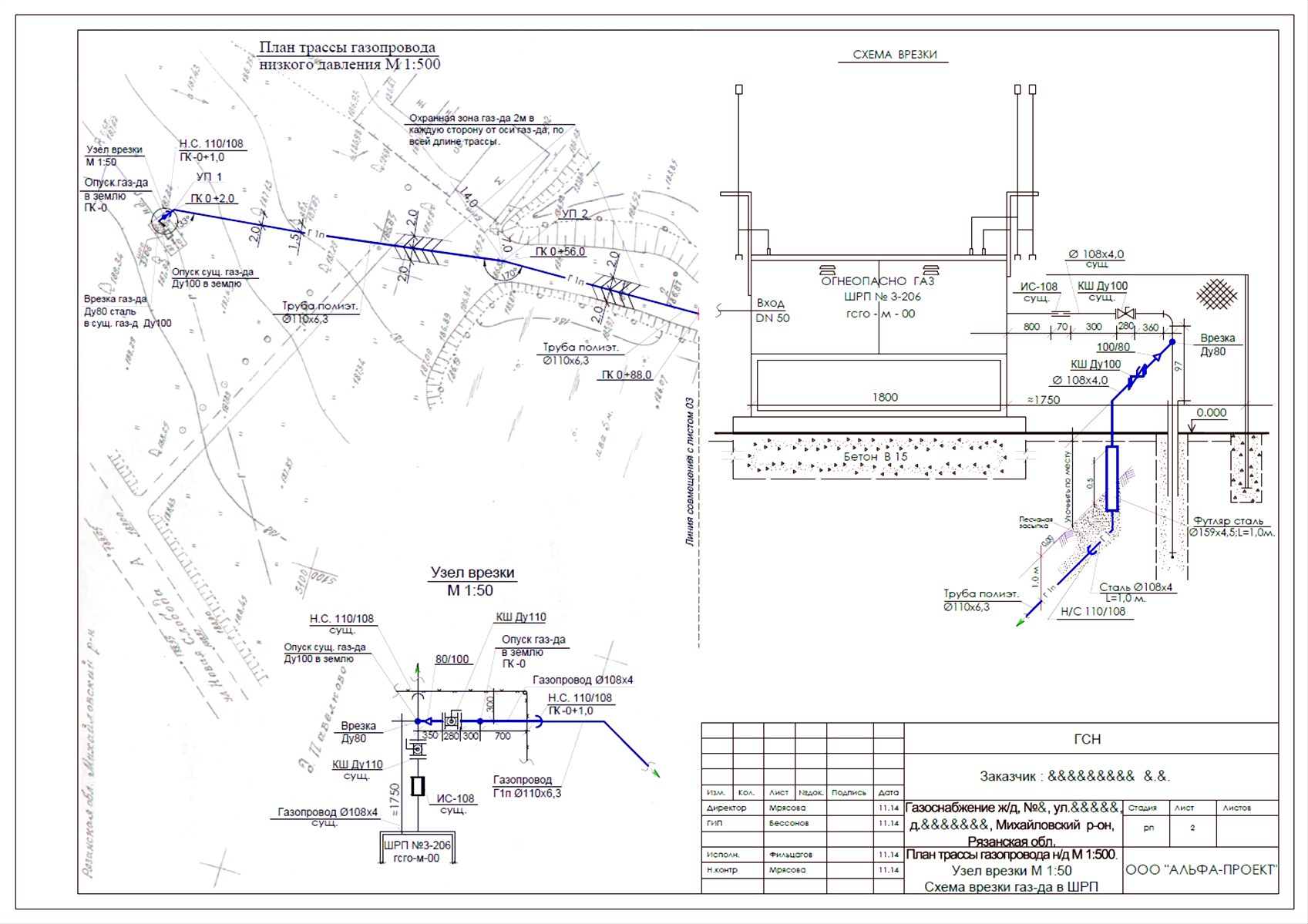

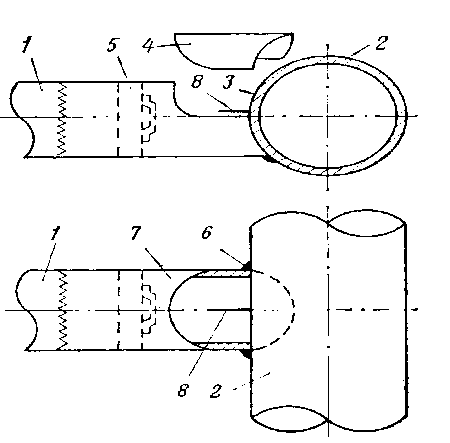

In some cases, tie-in into the gas pipeline should be performed with the intersection of the axes of the networks. Explanations to the diagram: 1 - connected pipe, 2 - labor of the working gas pipeline, 3 - "window" (cut out wall), 4 - visor, 5 - wooden disk, 6 - welded shock, 7 connecting pipe, 8 - rod for extraction, 9 – overlay (+)

The second option of joining is more familiar to most inhabitants. It is reliable and has stood the test of time. However, a specialist conducting a tie-in in this way must necessarily have a high level of professional qualifications, as well as have a special permit.

The methods of joining are:

- tie-in to a gas pipeline under low pressure;

- under medium and high pressure gas, when special devices are used;

- with shutdown of gas and complete release of pipes from it.

The choice of connection method to the gas pipeline depends on a number of factors. Therefore, the decision must be made by the people making the connection on a case-by-case basis.

As for the contractor, there may be 2 options: representatives of the gas service or employees of a private company who have the legal right to perform actions, as well as the necessary equipment and permission to carry out gas hazardous work.

Moreover, in the second case, the office can assume obligations for the preparation and execution of a package of documents for a legal tie-in to the main gas network. True, all additional services will affect the final cost of connection.

Not only the perfect performance of the gas pipeline depends on the correct choice of pipes, but also the safety of the operation of the entire gas transmission system.

Briefly about the main

On the websites of local GDOs, the procedure and the necessary papers are usually presented. Briefly, the process of paperwork can be represented as follows:

- contacting the local administration to clarify the address of the GDO, obtaining a situational and topographical plan of the site, if necessary, obtaining a permit for a tie-in into the gas pipeline (a sample is presented above) - free of charge;

- contacting the GRO to obtain technical conditions and sign a connection agreement - 30,000–50,000 rubles;

- development of a gas supply project - 10,000–60,000 rubles;

- work on the installation of internal equipment and networks on the site - 100-200 thousand rubles;

- connection of the pipeline at the site with the main one - 5000–10000 rubles per excavation pit;

- conclusion of contracts for the supply of gas and maintenance of equipment, the launch of blue fuel.

The total costs are approximately 150-250 thousand rubles, but it is worth preparing for additional small expenses.

Source

How to start replacing a gas pipe

A gas pipeline is a system that simultaneously serves both for transporting and storing gas.Designs of this type vary depending on the mission they perform. For example, networks intended for the transmission of blue fuel over long distances are characterized by high pressure. In view of this, experimenting with such systems is dangerous, since this can provoke trouble for the neighbors, and not just for you. Let the relevant organizations take care of it. After all, knowing how to make a tie-in into a high-pressure gas pipe is part of the professional responsibilities of their employees. Moreover, according to the regulatory documents in force in our country, persons without permission are prohibited from carrying out such work. Therefore, you should call the master and wait for his arrival.

Most likely, at the first visit, the gas service employee will not change the pipe for you. He will need to inspect the system, measure the length of its elements and, based on the data obtained, draw up an estimate for the work, including the price of new pipes needed to modify the domestic gas pipeline.

Process description

Naturally, the work begins with the preparatory phase, regardless of whether you will crash into the system yourself or choose a specialized service. If the latter, then you need to contact the appropriate authority, fill out an application, perhaps provide a package of documents prescribed by law. Decided to connect a new pipe with your own hands? This means that you need to buy the appropriate materials, prepare the system and yourself for the planned work. So, if the preparatory stage is completed successfully, we start the sidebar.

Connection of metal systems

- Surface cleaning. Remove from the place where you planned to make a frame, paint, debris, rust.

- Markup.Determine where the connection will be, put the marks.

- Making holes (with the coil method - 1, with the tee method - 2).

- Well treatment. The cracks should be treated with clay, and it is recommended to start this process even during the cutting of the surface in order to minimize the risk of burning / igniting the leaked blue fuel. Finished holes should be closed as quickly as possible with a special (made of asbestos and clay) plug. The treated area must be cooled.

- Installation of the disconnect device. When the metal has cooled, the plug can be opened to remove a fragment of the cut pipe from the structure. After removing a piece of metal, a disconnecting device is placed in the slot, which is a set of disks made of wood and rubber, as well as small bowls with viscous clay. If you stick to the tee method, then there will be two such slots.

- Pipe installation. When the disconnect device has covered the gap, it's time to start making the main hole - under the attached (new pipe). Check the correct diameter, it is possible that the markings will have to be corrected. Make a hole, install a pipe. Weld the joints of the pipe on both sides, then close the valve on it.

- Closing the hole. So, the pipe is welded, now you need to weld a new pipe. To do this, first remove the remains of the metal that appeared as a result of making the main slot. Put them in their place, work with clay, and brew them too. Check if the welding seam is leaking gas (using soap).

- Attaching a new pipe.

Cutting into a plastic pipe

Increasingly, plastic structures are used for the installation of engineering networks. If you need to connect to such a system, what should you do? First, be glad that the process will not be more complicated than in the case of metal. Secondly, strictly adhere to such recommendations.

Buy high-quality - factory-made, GOST-compliant connecting elements (fittings), ideally - metal. Use a socket joint and special glue to increase the reliability of the seam. Make sure that the junction is perfectly sealed, has a maximum density. Before installation, treat the insert with an anti-corrosion compound.

How is the tie-in itself carried out in the case of plastic networks? The connection is made by creating inserts perpendicular to the working system. The length of the inserts can vary within 70-100 cm. The extension should take place with the help of plastic pipes - on the basis of a socket-contact connection. What is this technology? The steel insert is heated (approximately to the level of 60 degrees). And a plastic structure is already being put on it, moreover, instantly and with force. If you crash into a system with medium pressure, experts advise connecting powdered polyethylene to the “case” in order to make the connection as strong as possible.

Crashing into a gas pipe is certainly better with the help of professionals, however, knowing the theory, you can experiment, meanwhile, it's up to you.

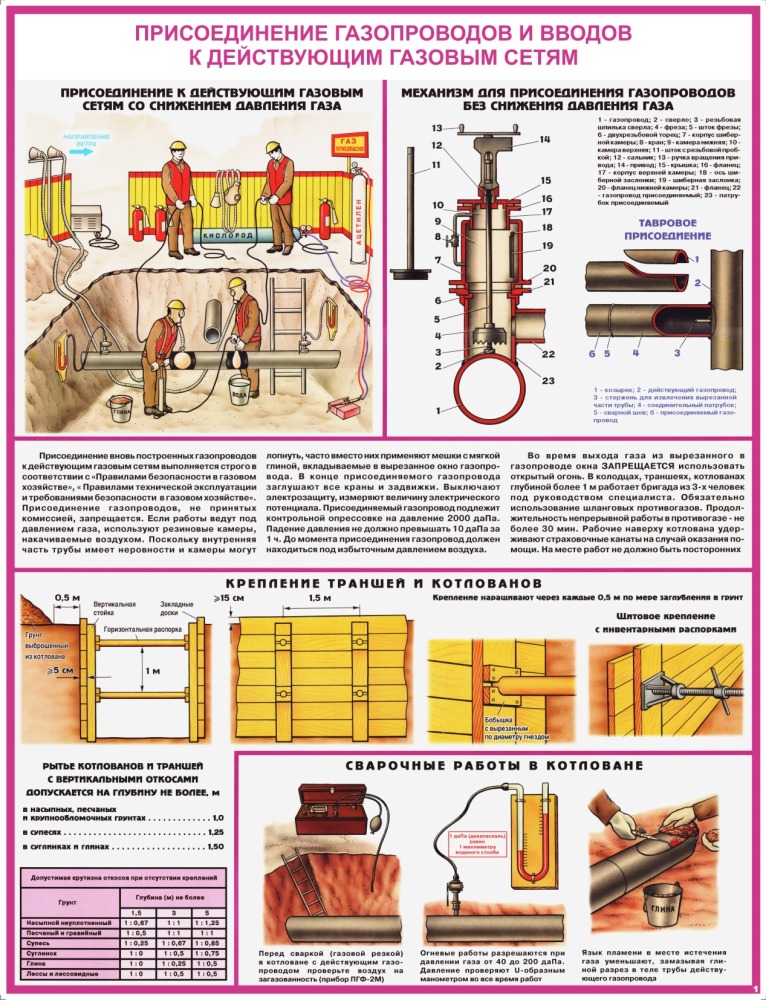

Work rules

The replacement procedure begins with the fulfillment of safety requirements. The master must take care of the absence of sources of open fire and remove smokers and unauthorized persons from the site.

The method and technology of tapping into a gas pipe depends on the pressure in this gas pipeline

In addition, at the entrance to the work site, it is necessary to post a warning sign “No access!”, “Caution, gas!”, “Smoking is prohibited!” etc. These are generally accepted requirements.

However, the implementation of a tie-in into a gas pipe provides for compliance with certain rules for handling such systems. The main ones are formulated as follows:

- tapping into a low-pressure network is allowed if the value of this parameter does not exceed 80 millimeters of water column, but not less than 20;

- connection to networks or highways with medium / high pressure is possible only if it is reduced to an acceptable level;

- gas cutting and welding is allowed in areas with pressure within 40≤P≤150. Compliance with this corridor must be monitored throughout the operation.

According to the law, only organizations that have permission for such activities have the right to carry out work without reducing pressure (sometimes it is even necessary to obtain a special outfit).

Specifications

Uninterrupted gas supplies to consumer homes directly depend on the throughput of gas pipes. In this regard, the calculation of this parameter is made especially carefully. Moreover, this process is mandatory regardless of the material used products - polymers or steel.

To determine the maximum throughput of each specific pipe, the following formula is used:

QMax = 196.386 T×(P/Z)×(Dat/2),

where P is the value of the constant working pressure in the gas pipe, increased by 0.1 MPa; Dat - the size of the conditional passage of the pipe; T is an indicator of the temperature of the gas passing through the pipe in degrees Kelvin; Z is the compression factor.

Based on the formula, we can conclude that the higher the temperature of the gas transported through the pipes, the greater their throughput should be in order to prevent leaks, loss of tightness or even explosions.

Although in their professional activities, craftsmen often use more complex formulas for calculating throughput, nevertheless, the above calculation method is more than enough for self-selection of pipes of the desired diameter.

What are the tie-ins

To connect a new pipe to a house, you need to know how to combine a new network with an already working one.

The tie-in requires precise movements and the right equipment, so the whole process can be carried out using the following technologies:

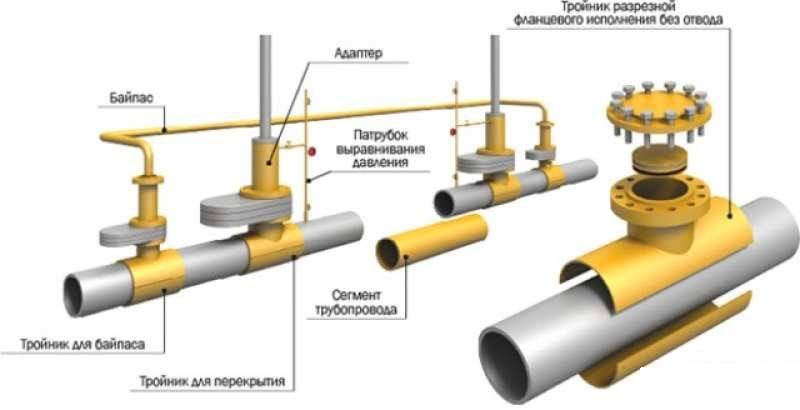

No welding or cold tapping. With this method, the object remains to work at the same level, that is, without significant changes in structures and pressure. Using the method without welding, gas workers connect new users to the networks. The technology for carrying out such work is quite simple, and therefore is popular among workers. You can watch a quick guide on the video from the network.

Punch device

Welding. This method for conducting gas into the house is considered traditional. A new gas pipe cuts into a working network by welding it. This method is dangerous, but reliable, so it can only be carried out by specialists with permission.

Welding tie-in method

The tie-in is carried out by the coil and tee method.The coil method - a new pipe is connected to the end of the operating system, and the tee - the tie-in is carried out with the intersection of the axes of the network. You can visualize the differences between these techniques using a photo from the Internet.

Some math and numbers

One of the main factors ensuring uninterrupted gas supply is the throughput of the gas pipeline. Therefore, special requirements are imposed on the calculation of this parameter. Such calculations must be made regardless of the type of gas pipes that are planned to be used - steel or plastic.

The maximum value of the pipe throughput is determined by the formula:

Qmax \u003d 196.386T × (P / Z) × (DN / 2) , where

P - absolute gas pressure or operating pressure in the gas pipeline system plus 0.1 MPa; Du - the value of the conditional passage of the pipe; T is the temperature of the transported gas in degrees Kelvin; Z is the compressibility factor. An analysis of this formula indicates that the larger T, the higher the throughput must be, otherwise the gas pipeline will depressurize, which can lead to an explosion.

Useful information! There is a more complex formula. But even this is quite enough to select a gas pipe according to the “throughput” parameter.

Not only the performance of the gas pipeline, but also the safety of the entire system depends on the correct choice of pipes.

However, you can make a choice using the data from the table below. It presents the capacity of the pipes depending on the pressure created by the gas.

Table 1

Third stage

The price of the contract with the GDO includes the fact that they will lay a pipe to the site. Work on your territory is a separate issue.An agreement on them can be concluded with Oblgaz or a third party that has a permit to perform work.

Installation of gas equipment in the house

The work includes pipe laying, installation of equipment, valves, meters for a gas supply project. The cost of the gas pipeline and installation of equipment inside the house in this case is not regulated. Typically, the costs are 100-200 thousand rubles, but prices may vary by region

When purchasing gas appliances for the home, it is important to make sure that you have certificates of conformity with the vehicle and fire certificates. So the oblgas will not have reasons to refuse to start gas

During the installation of the equipment, the GDO can check whether you meet the technical conditions. After the work is completed on your part, an act of readiness of networks and equipment is signed. If a grid is already passing through your land, from the moment the act is signed, oblgaz will complete its part (insert) within:

- 10 working days if the pipe diameter is less than 250 mm and the pressure in it is less than 0.3 MPa;

- three months if the pipeline diameter exceeds 250 mm and the pressure exceeds 0.3 MPa.

If the pipeline to the site needs to be laid, then the tie-in time increases. They are counted from the day the connection agreement was signed and are relevant for private traders:

- 9 months, if it is not necessary to issue permits for the construction of a gas pipeline (with a capacity of 0.6 MPa);

- 1 year if a permit is required.

Video description

This video shows the intricacies of connecting a house to gas, and what documents will be needed for this:

It is important to take into account that GDO employees will not excavate a pit for a tie-in. You need to find workers on your own for a fee (5000-10000 rubles)

Final stage

The networks of the house are connected to the highway - it's time to get permission for commissioning. After that, the fuel will be allowed through the pipes. The following documents are attached to the application:

- act of acceptance of the house (if any);

- act of acceptance of gas consumption networks;

- an act of acceptance of the input of networks into the building (drawn up by an organization that performs the installation of pipes and equipment on the site);

- an act of the state of ventilation and chimneys (this act can be VDPO, the cost is 2000-3000 rubles);

- connection agreement (from our second stage);

- an agreement for the maintenance and repair of in-house equipment (concluded with the GRO or other organization);

- contract for technical and emergency maintenance of the gas pipeline (concluded with GRO);

- contract for the supply of natural gas (signed with GRO).

Checking the pressure in the gas pipeline

At the first start-up, the operability of the system is checked, there should be no leaks and pressure drops. Upon successful completion of the check, oblgaz employees instruct the owners and issue documents:

- acts on the delimitation of property liability and operational liability;

- act on the start of gas supply (connection).

Video description

Clearly about the cost of connecting a house to gas is shown in the video:

Briefly about the main

On the websites of local GDOs, the procedure and the necessary papers are usually presented. Briefly, the process of paperwork can be represented as follows:

- contacting the local administration to clarify the address of the GDO, obtaining a situational and topographical plan of the site, if necessary, obtaining a permit for a tie-in into the gas pipeline (a sample is presented above) - free of charge;

- contacting the GRO to obtain technical conditions and sign a connection agreement - 30,000–50,000 rubles;

- development of a gas supply project - 10,000–60,000 rubles;

- work on the installation of internal equipment and networks on the site - 100-200 thousand rubles;

- connection of the pipeline at the site with the main one - 5000–10000 rubles per excavation pit;

- conclusion of contracts for the supply of gas and maintenance of equipment, the launch of blue fuel.

The total costs are approximately 150-250 thousand rubles, but it is worth preparing for additional small expenses.

Source

Final stage

The networks of the house are connected to the highway - it's time to get permission for commissioning. After that, the fuel will be allowed through the pipes. The following documents are attached to the application:

- act of acceptance of the house (if any);

- act of acceptance of gas consumption networks;

- an act of acceptance of the input of networks into the building (drawn up by an organization that performs the installation of pipes and equipment on the site);

- an act of the state of ventilation and chimneys (this act can be VDPO, the cost is 2000-3000 rubles);

- connection agreement (from our second stage);

- an agreement for the maintenance and repair of in-house equipment (concluded with the GRO or other organization);

- contract for technical and emergency maintenance of the gas pipeline (concluded with GRO);

- contract for the supply of natural gas (signed with GRO).

Checking the pressure in the gas pipeline

At the first start-up, the operability of the system is checked, there should be no leaks and pressure drops. Upon successful completion of the check, oblgaz employees instruct the owners and issue documents:

- acts on the delimitation of property liability and operational liability;

- act on the start of gas supply (connection).

Video description

Clearly about the cost of connecting a house to gas is shown in the video:

Briefly about the main

On the websites of local GDOs, the procedure and the necessary papers are usually presented. Briefly, the process of paperwork can be represented as follows:

- contacting the local administration to clarify the address of the GDO, obtaining a situational and topographical plan of the site, if necessary, obtaining a permit for a tie-in into the gas pipeline (a sample is presented above) - free of charge;

- contacting the GRO to obtain technical conditions and sign a connection agreement - 30,000–50,000 rubles;

- development of a gas supply project - 10,000–60,000 rubles;

- work on the installation of internal equipment and networks on the site - 100-200 thousand rubles;

- connection of the pipeline at the site with the main one - 5000–10000 rubles per excavation pit;

- conclusion of contracts for the supply of gas and maintenance of equipment, the launch of blue fuel.

The total costs are approximately 150-250 thousand rubles, but it is worth preparing for additional small expenses.

Source

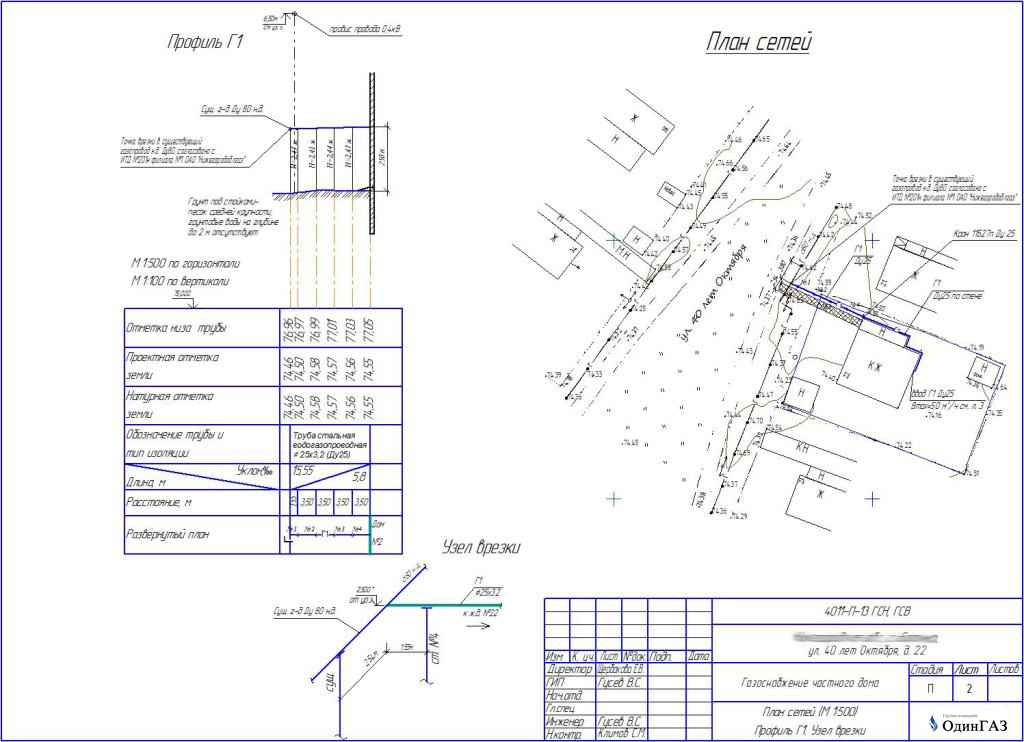

Methods of tapping into a polyethylene gas pipeline under pressure

Very often a situation arises when it is necessary to carry out repair work, work to connect additional networks to an existing gas pipeline, crash without creating inconvenience for consumers, i.e. without turning off the gas

This is especially important in cases where gas is the only available source of energy for heating systems of residential and public buildings, technological units of industrial enterprises.

There are several main ways to carry out such work, which have their own specifics and certain areas of application:

1) The method of crushing polyethylene pipes.

2) The method of locking balls.

3) Mechanical method of tapping under pressure through a polyethylene tap using a special device with a cutter.

At the same time, the first method is recommended (according to various independent estimates of domestic and foreign experts) for pipelines with a diameter of no more than 160 mm and a wall thickness of no more than 10 mm. After carrying out the work, it is mandatory to apply repair amplifying electric-welded couplings to the place of overpressure.

At the same time, the first method is recommended (according to various independent estimates of domestic and foreign experts) for pipelines with a diameter of no more than 160 mm and a wall thickness of no more than 10 mm. After carrying out the work, it is mandatory to apply repair amplifying electric-welded couplings to the place of overpressure.

In the event of emergency situations, squeezing can also be carried out on large diameter gas pipelines. The second method allows you to carry out work on existing gas pipelines at a maximum allowable pressure of not more than 1 bar. The diameter of the gas pipeline blocked by balls can be from 63 to 400 mm, and the diameter of the hole for introducing the ball can be from 50 to 90 mm.

Tapping into an existing gas pipeline in the third way is carried out by milling the wall of a polyethylene pipe with an annular cutter, the diameter of which is slightly smaller than the inner diameter of the outlet. It is known that existing saddle branches for tapping under pressure make it possible to connect branches with a maximum diameter of up to 63 mm to an existing pipeline. In the new technology, the range of diameters of embedded pipes has been expanded and amounts to 50-63-90-110-125-160 mm. The maximum allowable pressure when tapping on a gas pipeline is 10 bar (on a water pipeline - 16 bar).

Connection of gas pipelines without pressure reduction should be carried out using special equipment that ensures the safety of work.The “Perfect” device, manufactured by the German company Hutz+Baumgarten, is designed on the basis of new achievements in the field of mechanics and, thanks to a special milling cutter, allows plunging with minimal effort and virtually no chips.

The equipment is certified and has permission from Rostekhnadzor for use. To carry out tapping using this equipment, a polyethylene overhead care, a polyethylene ball valve, an electrofusion socket and a welding machine for welding fittings with embedded heating elements are required.

The technological process of tapping into an existing pipeline consists of the following operations:

- overhead care is welded onto the existing polyethylene pipe;

- through an electro-welded coupling, the overhead maintenance is connected to a polyethylene ball valve;

– the equipment for the “Perfect” tie-in is removed from the package and assembled according to the instructions;

– the assembled equipment is installed through an open polyethylene valve on the free shank of the valve and fixed;

- the assembled structure is pressure tested through a special side valve, while the test pressure must be 1 bar higher than the pressure level in the pipeline;

- by rotating the ratchet lever installed at the end of the rod, the tie-in is carried out with a stable horizontal position of the equipment;

- after the tie-in, the bar is retracted until the cutter stops in the clamping device;

- the polyethylene valve is closed and the gas is bled from the internal space of the equipment by carefully opening the side valve;

- after that, the equipment is dismantled and the polyethylene plug is removed from the cutter.The design of the cutter is such that all the chips remain in it and do not enter the operating pipeline.

Thus, another reliable way has appeared to carry out tapping under pressure on existing gas pipelines without shutting down consumers.