- A few tips for quality welding

- Choosing the right electrodes

- Choice of electrodes

- Punch methods without welding

- Carrying out work

- How butt welds are welded

- The need for work

- Main difficulties

- What is needed for electrical welding?

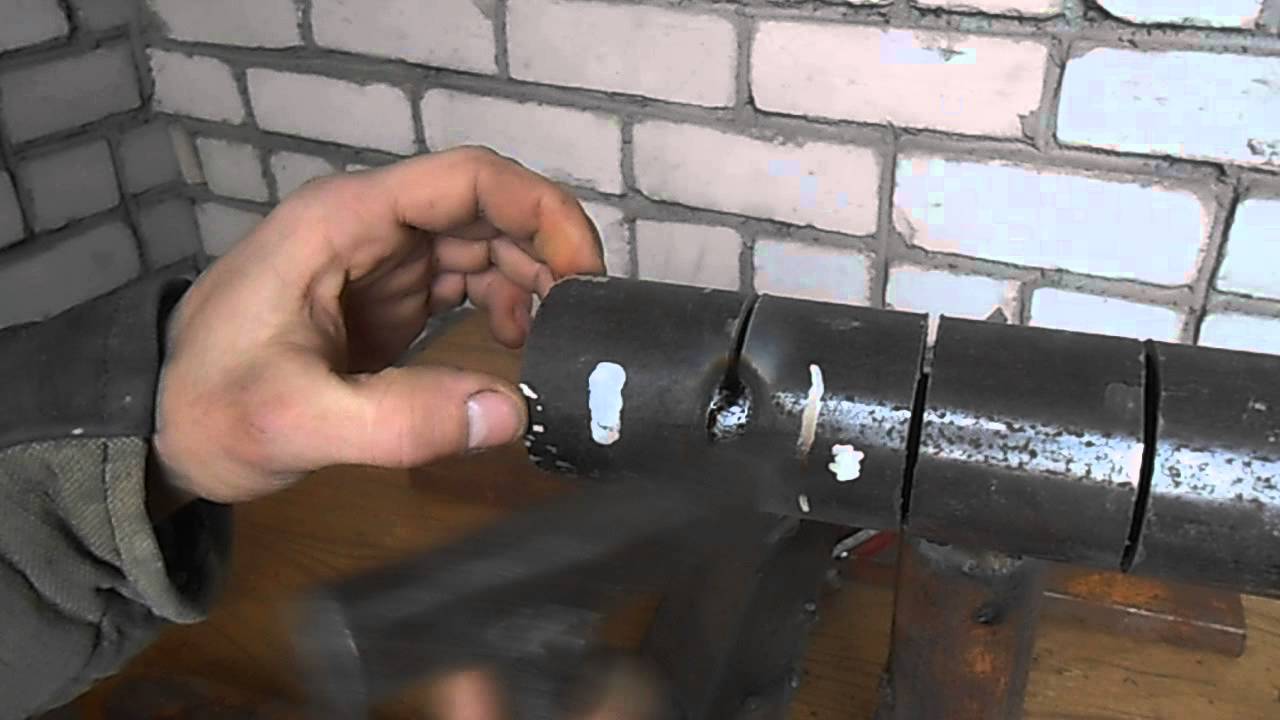

- Welding of steel pipes

- Pipeline assembly

- Preliminary work with details

- Welding process

- A few tips for quality welding

- Choosing the right electrodes

- Quality control of the welded joint

- Welding

- Welding process technology

- Gas welding

- Manual arc welding

- Selection of electrodes for electric-welded pipes

- How to weld profile pipes at 90 degrees

- Video

- Selection of welding electrodes

- How to weld a spur to a heating pipe? - Window Guru's Handbook

- Types of pipe welds

- Range of welding electrodes

- Welding step by step

A few tips for quality welding

The quality of welding depends on the correct preparation for welding, the choice of electrodes and the technology of the process, which is somewhat different when connecting joints.

Choosing the right electrodes

The quality of the weld depends largely on which electrode is used for welding. It is a thin metal rod with a special coating.The inside of the electrode serves as a conductor for creating an electric arc, and the coating ensures its stability, and also participates in the creation of a weld.

According to the type of core, the electrodes are divided into consumable and non-consumable. In the first case, the basis of the product is a steel wire, in the second - a tungsten, carbon or graphite rod.

According to the type of protective coating, the electrodes are divided into:

- cellulose - marking "C" - are used for labor-intensive and complex welding work with large diameter pipes, on long technological highways;

- rutile-acid - "RA" - the most used type of electrode for welding engineering networks of water supply and heating;

- rutile - "RR" - can also be used for welding pipes for water supply and heating, they are thicker and have better weld quality;

- rutile-cellulose - "RC" - give a stronger seam when using a vertical connection method;

- universal - "B" - suitable for welding pipes of various diameters and thicknesses, in a wide temperature range.

Another classification of electrodes for welding is the diameter of the rod. The strength of the electric arc, which can cope with pipe rolling of a certain thickness, depends on it:

- 3 mm - electrodes are suitable for welding pipes up to 5 mm thick;

- 4 mm - electrodes allow welding up to 10 mm thick, as well as making multi-layer metal seams.

Attention! In addition to the thickness and material of the electrode for high-quality welding, it is also necessary to take into account the current strength, which depends on the method of connecting the pipes. For example, for a simple butt joint, an arc from 80 to 110 amps is suitable, and for overlap welding, you will need to switch the machine to 120 amps

Choice of electrodes

The preparatory stage includes the selection of the most suitable electrode. The tightness of the resulting system, as well as the complexity of welding, depend on the quality of this consumable. Today, electrodes are used, which are represented by a conductive rod with a special coating. Due to the use of a special composition, the arc is stabilized and a more attractive, high-quality welding seam is formed. In addition, in some cases, the included chemicals reduce the likelihood of metal oxidation.

On sale there is a fairly large number of different options for the execution of such consumables. According to the type of core, there are:

- With a core that does not melt. In their manufacture, graphite or tungsten is used, as well as electrical coal.

- With melting rod. In this case, a wire is used in the manufacture, the thickness of which can vary over a wide range. When conducting electric welding, the thickness of the electrode is the most important parameter to be considered.

Hot rod electrodes

Classification is also carried out according to what substance is used as a coating. The following versions are most widely used:

- Rutile acid are often used to create a heating pipeline system or domestic water supply. During electric welding, slag can form, which is not difficult to remove.

- Cellulose are more suitable for working with products that have a large cross section. An example is the case of manufacturing a pipeline for supplying gas and water.

- Rutile are used when you need to get a neat seam. Slag can be easily and quickly removed from the surface.In addition, it is suitable for welding on a second or subsequent seam.

- Rutile-cellulose are suitable for welding in almost any plane. This point determines their frequent use when creating a vertically located seam of great length.

- The main coating is considered a universal coating, which is suitable for electric welding of a wide variety of parts, including thick-walled products. The resulting fastening is characterized by plasticity and high strength.

Rutile electrodes

It is recommended to pay attention to products of well-known manufacturers, the declared performance of which will correspond to the real ones. In addition, when choosing consumables, you need to pay attention to the expiration date of the product.

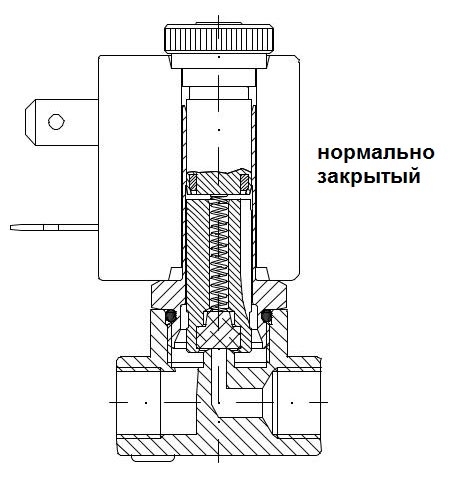

Punch methods without welding

It is possible to cut into the main pipeline without using welding. This technology is used by many specialists, since welding work requires compliance with safety rules. In this case, special equipment is required for welding. Welding work is considered complex and time-consuming.

From non-welding tie-in technologies, there are:

- installing a collector is the best solution for a large private house. A compact collector system is also installed in the apartment. A water pipe is installed to the inlet of such a system. The collector has several outlets. Their number depends on the system model. The pipeline connects to any outlet. Adapters are used to fix the hoses;

- installation of a tee - this tie-in method is used if a single outlet is provided. The water supply connection is pre-untwisted, and then a tee is mounted in this place. The pipeline is expanded or shortened by threading;

- the process of cutting the pipe itself - the technique is optimal if there is no connection from the outside. To perform cutting, a grinder is used. A pre-threaded tee is installed;

- the use of a thin pipe - a hole is prepared in the system, on which a sealant, clamp is fixed. Lag screws are used to mount the outlet.

Carrying out work

Before starting welding you need to put on overalls, prepare a welding mask and gloves. Prepare the area for welding. Remove all flammable items. You will need a metal brush to clean the surface of the pipe and a hammer to beat the slag. And, of course, the welding machine itself, and correctly selected electrodes.

During the purchase of electrodes, read the instructions on the package. The manufacturer shows on his product the rules of operation and the purpose of this type of electrode. Electrode diameter and the current strength is selected by the calculation method. For any 1 mm of electrode thickness, a current of 30 to 40 amperes is required. As for inverter welding machines, in this case, for a 3 mm electrode, the required current strength will be 80 A. These parameters are suitable for welding metal, and for cutting it, you need to increase the current strength to 100 A.

You need to start work from fixing both pipes in order to avoid displacement of the seam. Light the arc with the electrode inserted into the holder and try to weld a small area. The electrode must have an angle of inclination 70? in relation to the surface to be welded and a gap of about 2–4 mm. Immediately, you need to make a reservation that these indicators are of a very approximate temperament and only experience will advise the optimal values in a particular case.

Before you decide to carry out work, you need to prepare as much as possible. It will not be superfluous either to study the theoretical side of the issue, or to watch the relevant videos, or to consult with experts individually.

How butt welds are welded

If the edges are not chamfered, the applied bead should have a slight expansion on each side of the joint. To prevent lack of fusion, it is necessary to create a uniform distribution of molten metal.

Only the correct setting of the current and the competent selection of electrodes will make it possible to weld 6 mm metal well if the parts do not have beveled edges. The current value is selected empirically. Why weld several test strips.

If the parts have V-bevels, the butt weld can be a single layer or multiple layers. The main role in this matter is played by the thickness of the metal.

When one layer is welded, arc ignition should take place at point "A", at the edge of the bevel, according to figure 67a. Then the electrode is lowered down. The root of the seam is completely boiled, then the arc is sent to the next edge.

When the electrode moves along the bevels, its movement is deliberately slowed down to ensure good penetration. At the root of the seam, on the contrary, they accelerate the movement in order to prevent a through burn.

On the reverse side of the welding joint, professionals advise applying an additional backing seam.

In some cases, a steel 2-3 mm lining is mounted on the opposite side of the seam. To do this, increase the welding current by about 20–30% relative to the standard value. Through penetration in this case is completely excluded.

When the bead is created, the steel backing is also welded. If it does not interfere with the design of the product, it is left. When welding very important structures, the opposite side of the weld root is welded.

If it is necessary to weld a multilayer butt weld, the root of the weld is first boiled. For this purpose, electrodes with a diameter of 4-5 millimeters are used. Then, the following layers are deposited with expanded beads, for which large electrodes are used (See Figures 67, b, c).

The need for work

Welding a pipe with water may be required in the following cases:

- Leaks formed as a result of exceeding the standard loads or poor-quality installation work. Shutdown in such cases is not welcome, especially when it comes to main pipelines that supply water to large residential areas.

- The need for a cut. Draining fluid from the entire system involves significant temporary losses, so the matter is often limited to turning off the circulation pumps. This measure helps to reduce the pressure in the circuit, the work is simplified.

Main difficulties

Welding pipes under pressure is not an easy task, not every specialist will undertake its implementation.

The problems are related to the following phenomena:

- the pressure of the liquid does not allow reaching the required temperature of the weld pool, it is extremely difficult to achieve the required coefficient of adhesion of the deposited metal to the base;

- when water contacts hot material, large volumes of steam are produced. The welder has to work in conditions of limited visibility, the mask fogs up, you have to constantly wipe it, get distracted, waste time;

- it is very difficult to work in the case when the pipes are located at a height, under the ceiling.Water can drip onto the welder, and holding heavy equipment is inconvenient.

What is needed for electrical welding?

To weld pipes using electric welding, you will need a welding machine. Today, there are two types of such devices: devices made on the basis of a step-down transformer, and inverters that operate at high frequencies. The first type is used extremely rarely, since it is considered obsolete. The inverter is a more modern device that is simple and portable. It is possible to adjust the welding mode with high accuracy. True, inverters are considered less reliable in use. Therefore, to work with such equipment, it is necessary to have a certain qualification.

To weld pipes using electric welding, you will need a welding machine. Today, there are two types of such devices: devices made on the basis of a step-down transformer, and inverters that operate at high frequencies. The first type is used extremely rarely, since it is considered obsolete. The inverter is a more modern device that is simple and portable. It is possible to adjust the welding mode with high accuracy. True, inverters are considered less reliable in use. Therefore, to work with such equipment, it is necessary to have a certain qualification.

In addition, heating welding involves the presence of other auxiliary equipment:

- special mask with a light filter. It reliably protects the eyes and face from sparks and particles of molten metal during welding;

- overalls for body protection;

- suede gloves. With their help, the device in the hand will hold securely;

- electrodes;

- metal brush. Necessary for cleaning the pipe section before welding, to remove scale;

- a special hammer that is used to knock down scale.

Welding of steel pipes

Welding of round pipes is carried out with a continuous seam. That is, if the process started from one point, then it must end on it, without tearing the electrode from the surface to be welded. When welding pipes of large diameter (over 110 mm), it is impossible to fill the seam with one electrode. Therefore, it is necessary to use multilayer welding, where the number of layers is determined by the thickness of the pipe walls. For example:

- If the wall thickness is 6 mm, then two layers of metal are sufficient.

- 6-12 mm - welding is done in three layers.

- More than 12 mm - more than four layers.

Attention! Multi-layer welding is made with one requirement. Allow the previous layer to cool before applying the next layer.

Pipeline assembly

Before welding pipes, in order to simplify the task, it is necessary to assemble the welding joint. That is, install the pipes according to the design of the assembly, clamp them so that they do not move or move. Then the tack is made. This is when spot welding is done in one place, if the pipeline is assembled from products of large diameter, then tack welding can be done in several places.

In principle, everything is ready, you can cook the pipeline. It would seem that this conversation about welding could be completed. But for novice welders, it is just beginning, because the welding process associated with the assembly of pipelines is a large number of nuances. Here are just a few of the ones you need to take into account.

- Pipes with a thickness of more than 4 mm can be welded with a radical seam, this is when the metal fills the space between the edges to the full depth, and with a roll, when a roller 3 mm high is formed on top of the seam.

- When connecting pipes with a diameter of 30-80 mm with a vertical seam, the technology is slightly different from the bottom location of the seam. First, the volume of 75% is filled, then the rest of the space.

- With multi-layer welding technology, a horizontal seam is welded in two layers so that the next one is applied in the opposite direction than the previous one.

- The connection point of the lower layer must not coincide with the same point of the upper layer. The lock point is the end (beginning) of the seam.

- Usually, when welding pipes, the latter must be turned all the time. They do it manually, so you need to know that the optimal turning sector is 60-110 °. Just in this range, the seam is located in a convenient place for the welder. Its length is the maximum, and this allows you to control the continuity of the suture connection.

- The most difficult thing, according to many welders, is to turn the pipeline immediately by 180 ° and at the same time maintain the quality of the weld. Therefore, with such a turn, it is recommended to change the welding technology. That is, first the seam is boiled to a depth of up to 2/3 in one or two layers. Then the pipeline is rotated 180°, where the seam is filled completely in several layers. Then again there is a turn of 180°, where the seam is completely filled with the metal of the electrode. By the way, such joints are called rotary.

- But there are also fixed joints, this is when the pipe is welded to the pipe in a fixed structure. If the pipeline is located horizontally, then it is necessary to weld the joint between its parts, dividing it into two parts. Welding starts from the bottom point (ceiling) and moves to the top. The second half of the joint is welded in the same way.

And the last stage in pipe welding technology is the quality control of the seam. It must be tapped with a hammer to bring down the slag. Then visually check for cracks, gouges, chips, burns and no penetrations. If the pipeline is intended for liquids or gases, then after assembly, water or gas is launched into it to check for leaks.

The welding process is actually a responsible event. And only the experience of a welder can guarantee the quality of the final result the first time. But experience is a thing. We invite you to watch the video - how to cook steel pipes.

Preliminary work with details

According to the instructions, the following conditions must be met:

- Geometric dimensions.

- The presence of a quality certificate, in particular, if it is a pipeline for drinking water.

- Perfectly round pipe shape - no end defects in the form of a flattened or oval section are allowed.

- The same thickness of the walls of the pipes along their entire length.

- The chemical composition of products must comply with the State Standards of the Russian Federation for certain systems. This information is obtained from the technical documentation or laboratory tests.

Then you can proceed, in fact, to the preparation of pipes for docking and welding.

The preparation process includes the following stages:

- check the evenness of the cut at the end of the pipe - it should be equal to 90º;

- the end and a section of 10 mm from it must be carefully cleaned until a metallic sheen appears;

- all traces of oils, rust, paints should be removed and the surface at the end of the pipe degreased.

Such work can be done with a beveler, trimmer or grinder. Professionals working with large diameter pipes use milling machines or gas and plasma cutters.

Welding process

When all the preliminary preparation is over, you can start welding. If you do not have the necessary skills, and you have never done such work before, we recommend that you first practice on extra pieces of pipe so as not to ruin the entire system.

A few tips for quality welding

The quality of welding depends on the correct preparation for welding, the choice of electrodes and the technology of the process, which is somewhat different when connecting joints.

Choosing the right electrodes

The quality of the weld depends largely on which electrode is used for welding. It is a thin metal rod with a special coating. The inside of the electrode serves as a conductor for creating an electric arc, and the coating ensures its stability, and also participates in the creation of a weld.

According to the type of core, the electrodes are divided into consumable and non-consumable. In the first case, the basis of the product is a steel wire, in the second - a tungsten, carbon or graphite rod.

According to the type of protective coating, the electrodes are divided into:

- cellulose - marking "C" - are used for labor-intensive and complex welding work with large diameter pipes, on long technological highways;

- rutile-acid - "RA" - the most used type of electrode for welding engineering networks of water supply and heating;

- rutile - "RR" - can also be used for welding pipes for water supply and heating, they are thicker and have better weld quality;

- rutile-cellulose - "RC" - give a stronger seam when using a vertical connection method;

- universal - "B" - suitable for welding pipes of various diameters and thicknesses, in a wide temperature range.

Another classification of electrodes for welding is the diameter of the rod. The strength of the electric arc, which can cope with pipe rolling of a certain thickness, depends on it:

- 3 mm - electrodes are suitable for welding pipes up to 5 mm thick;

- 4 mm - electrodes allow welding up to 10 mm thick, as well as making multi-layer metal seams.

Quality control of the welded joint

After completing the electric welding, an external examination determines the presence of burns, pores, fistulas and other visible defects. To identify microcracks that are invisible to the naked eye, the mounted area is usually connected to the heating system. If water droplets do not appear on the seams, the work was carried out with high quality. This method of verification is acceptable in a private home, where the system can be filled at any time.

In apartments with central heating, the quality of welded joints is checked in summer using a compressor. Plugs are placed at the ends of the pipes, the joints are coated with soapy foam, air is pumped under pressure. Places where there are flaws are determined by the bubbles on their surface.

It is better to replace or install new heating pipes in the summer so that most of the welding operations can be performed outdoors. There should be no flammable materials in the vicinity of the place of work. If the experience of welding pipes is still not enough, you can first weld a few unnecessary scraps, so as not to spoil the new workpieces later.

Welding

Experts believe that the easiest way to tie into a steel external network is welding. A prerequisite for tie-in is the ability to turn off the water supply through the system.

Autogenous make a hole of suitable diameter. Then the pipe is welded, the valve is mounted. The last element of the system is covered in the process of further work. If the tie-in is completed, it will be necessary to restore the anti-corrosion protection.

If the pipeline is laid from polyethylene pipes, then welding work is not carried out.Taking into account the diameter of the consumable material, the clamp is fixed.

Welding process technology

To weld pipes, the following connection methods are used: electric arc (manual, semi-automatic and using flux) or gas (using acetylene).

Gas welding

Since it is not always possible to weld pipes by electric welding, in such cases a gas burner is used. This method is applicable in the field. At the same time, the quality and fullness of the seams is higher. The risk of internal stress in the metal is reduced, since it is less susceptible to temperature effects.

To carry out the work, a gas generator or acetylene is required. In the second case, the temperature in the working area is higher. The filler wire must be fed so that it is located on the hot metal. If welding of galvanized material is required, then a flux is taken, and the oxygen concentration in the gas increases. At the same time, it is not necessary to treat the seams with anti-corrosion agents after work.

Manual arc welding

When welding pipes by manual arc welding, the number of penetrations depends on the thickness of their walls. The composition of the electrodes is also important. If the diameter of the products is large, then by applying the next layer, scale is knocked off, and the connection is forged. During the application of the first seam, you can not rush. After that, the metal is checked for cracks. If there are uneven areas on the seam, they are cut down. Work in these places is carried out again with an offset (1.5-3 cm). The final layer is made with thickly coated electrodes.

Selection of electrodes for electric-welded pipes

There are many types of electrodes suitable for the implementation of various tasks and differing in the material of manufacture, thickness and characteristics.Before buying electrodes, you need to understand their features in order to avoid errors during operation. In addition, it is worth asking how to distinguish a fake product from a real one, and get ready for the costs - good electrodes are not cheap.

When connecting pipes, it is necessary to achieve not only high strength, but also tightness of the connection, for which you can use a simple method consisting in the following steps:

- The seam is not boiled in a circle, but in the shape of a figure eight or a horseshoe;

- With such welding, the slag from the metal is gradually squeezed out;

- Each piece of slag must be removed, as a result, not only a reliable, but also quite nice weld will be obtained.

How to weld profile pipes at 90 degrees

To get a perfectly right angle when welding, the performer needs to have similar experience and follow the technology exactly. There are several important points that will help determine how to weld a profile pipe at 90 degrees:

- First of all, the pipes must be cut;

- work must be carried out on a flat surface;

- to fix the angle, you can use special devices (magnetic squares) or improvised means (corners or scarves);

- welding is carried out in stages: first, a rough connection is made; then the performer makes sure that the 90 degree angle is observed; after welding is carried out cleanly.

Video

Here is a video of the simplest fixture for welding at an angle of 90 degrees.

And here's another, three-dimensional.

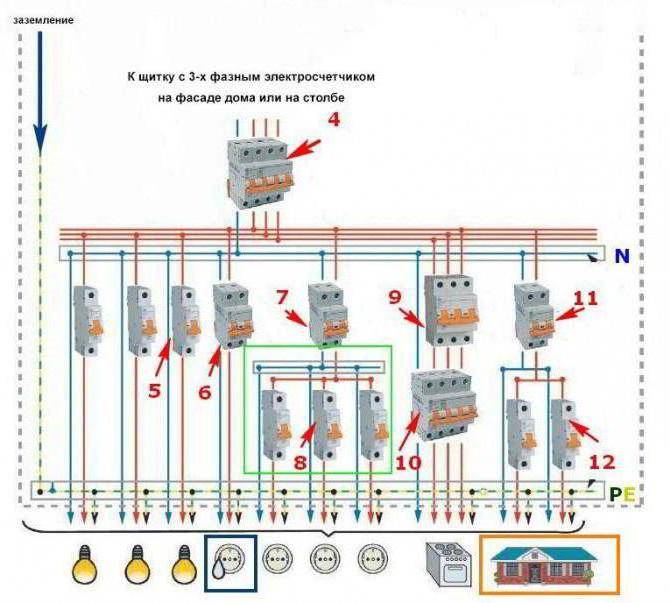

Selection of welding electrodes

In order to choose the right electrode correctly, several important parameters must be taken into account:

- workpiece thickness;

- Mark became.

Depending on the type of electrode, the value of the current strength is selected. Welding can be performed in a variety of positions. The lower one is divided into groups:

- horizontal;

- Tavrovaya.

Vertical type welding can be:

- Upwards;

- Ceiling;

- Tavrovaya,

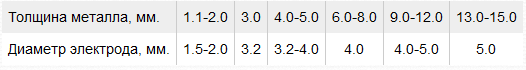

Each manufacturer in the instructions for the electrodes, be sure to report the value of the welding current at which they will work normally. The table shows the classic parameters used by experienced welders.

The magnitude of the current strength is influenced by the spatial position, as well as the size of the gap. For example, to work with a 3 mm electrode, the current must reach 70–80 amperes. This current can be used to perform ceiling welding. This will be sufficient for welding parts when the gap is much larger than the diameter of the electrode.

To cook from below, in the absence of a gap and the corresponding thickness of the metal, it is allowed to set the current strength to 120 amperes for an ordinary electrode.

Welders with extensive experience recommend using a certain formula for calculation.

To determine the current strength, 30–40 amperes are taken, which must correspond to one millimeter of the electrode diameter. In other words, for a 3 mm electrode, you need to set the current to 90-120 amperes. If the diameter is 4 mm, the current strength will be 120-160 amperes. If vertical welding is performed, the amperage is reduced by 15%.

For 2 mm, approximately 40 - 80 amperes are set. Such a “two” is always considered very capricious.

There is an opinion that if the electrode diameter is small, then it is very easy to work with it. However, this opinion is erroneous. For example, to work with the "two" you need a certain skill.The electrode burns quickly, it starts to get very hot when a high current is set. Such a “two” can weld thin metals at low current, but experience and great patience are needed.

Electrode 3 - 3.2 mm. Current strength 70–80 Amps. Welding must be carried out only on direct current. Experienced welders find that above 80 amps it is impossible to perform normal welding. This value is suitable for cutting metal.

Welding should be started with 70 amperes. If you see that it is impossible to boil the part, add another 5-10 Amps. With a lack of penetration of 80 amperes, you can set 120 amperes.

For welding on alternating current, you can set the current strength to 110-130 amperes. In some cases, even 150 amperes are installed. Such values are typical for a transformer apparatus. When welding with an inverter, these values are much lower.

Electrode 4 mm. Current strength 110-160 Amps. In this case, a spread of 50 amps depends on the thickness of the metal, as well as your experience. "Four" also requires special skill. Professionals advise starting with 110 amps, gradually increasing the current.

Electrode 5 mm or more. Such products are considered professional, they are used only by professionals. They are mainly used for surfacing metal. They practically do not participate in the welding process.

How to weld a spur to a heating pipe? - Window Guru's Handbook

Pipeline installation is a serious and responsible undertaking. The welding process for connecting pipes is used quite often.

In this way, pipes from various materials can be connected, however, the technology of the process will differ in individual specific cases.

In industrial and private construction, welding of metal pipes by electric welding is very widely used.

This method is characterized by simplicity, mobility and economic profitability, since it can be carried out both manually and automatically. In private construction, manual arc welding of pipes is most often used, for which it is enough to have welding equipment and electrodes.

Types of pipe welds

In construction and industrial production, the following methods of welding steel pipes are used:

- butt welding;

- overlap welding;

- welding of tee joints;

- welding of corner joints.

When making connections by welding, the following positions are used, depending on the conditions: horizontal, vertical, bottom and ceiling. The most advantageous and convenient welding position is the lower position, which is possible if the pipe is rotated, so this technology should be preferred.

In the construction of large diameter pipelines, butt joints are most often used.

It is extremely important in such cases to ensure that the edges are welded through the entire thickness.

For thick-walled pipes, double welds are used - external and internal.

To reduce the formation of metal sagging on the inner surface of the pipes, it is necessary to hold the electrode at an angle of 45 degrees relative to the horizontal plane during the welding process.

Range of welding electrodes

Before welding a pipe to a pipe, it is necessary to choose the right electrodes, which are available with different types of coatings, and each type is capable of performing a specific task, which should be followed when choosing them.

- Cellulose coating.Large diameter pipes are welded with this type of electrodes, they are able to create circular and vertical seams.

- Rutile coating. Electrodes with such a coating have easy ignition, as well as repeated ignition, and the slag crust is characterized by a high degree of brittleness. It is very convenient to install tacks, fillet welds and weld root seams from above to create a presentation.

- Rutile cellulose coating. Such electrodes are convenient for making seams in any position in space, vertically, including in the direction from above, the most difficult for experts to determine.

- Rutile acid coating. Provides easy separation of the slag crust and economical consumption of electrodes when welding pipes.

- Basic coverage. Electrodes with such a coating provide the weld with high viscosity. Such seams are not subject to cracking, they are used for thick-walled pipes with difficult operating conditions. It is recommended to apply also when using pipelines at low temperatures.

Sections: Welding - how to cook

welding, do-it-yourself welding, Welding - basics

Welding step by step

The thermal process that occurs during electric welding connects the parts with a strong seam, which will be better in terms of mechanical properties, unlike gas welding.

So, how to learn to cook? When it comes to a pipe in an accessible place and with the possibility of rotation, then two sections of the pipeline are end-to-end connected by one or three points of electric welding. Then:

- continuously (if you can rotate);

- with a separation, starting from the bottom, if the pipe is in an uncomfortable position and it cannot be rotated, a seam is made.

Welding is carried out in two passes.First, the "root" is filled - the first seam that closes the very joint of the pipes (2-3 mm), then the excess sagging and scale are cleaned off, and the second seam is made, and then it is also cleaned.

The general instructions for the entire process look like this.

- Before directly starting work, a comfortable stable position is taken. The space must have good lighting.

- Strike to ignite the arc, if it does not ignite, slightly increase the amperage.

- Move the electrode to the beginning of the seam and start the weld pool, keeping the arc gap constant.

- By setting a sufficiently high current, the straightened metal will follow the heat.

It is necessary to monitor the quality of welding directly in the process of performing work, paying attention to the edges of the “bath”, how evenly the filling is

- Put an end, leaving some metal.

- Extinguish the arc along the seam.

You can learn how to make seams correctly and with high quality, if you wish, but you can master all the steps easier and faster if you have ever watched the process of electric welding from the outside or were a participant as an assistant.