- Safety rules for every day

- Elements of safety and comfortable operation

- Do I need to turn off the gas heating boiler at all?

- The principle of operation of the boiler

- Tips and advice for care

- Step-by-step installation of the heat generator and chimney

- Operation features

- Setting the boiler automation and pressure

- Installation

- Winter mode

- Does not start - causes and solutions

- Possible malfunctions when starting the boiler and methods for their elimination

- Unable to turn on the igniter

- Water does not heat up

- Clocking occurs

- dangerous situations

- Specifics of application and operation

- Tips and tricks for choosing

- BUILDING THE BOILER UNIT

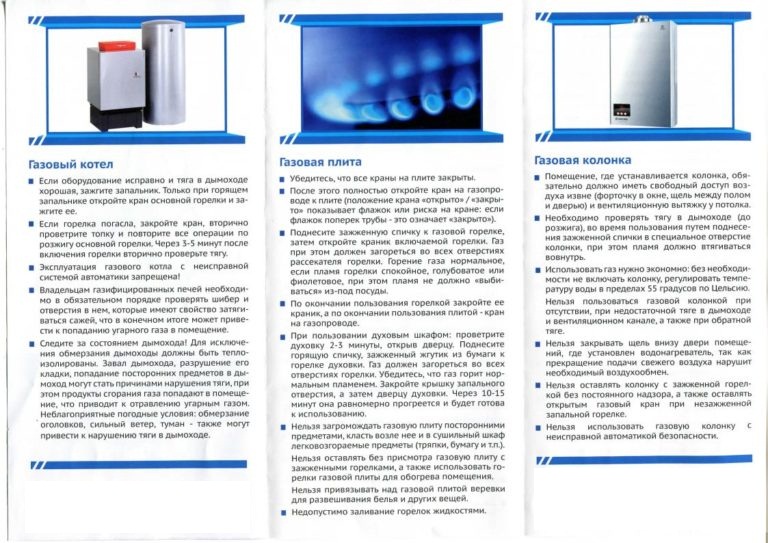

- Basic rules for using gas at home

- Gas boiler startup technology

- How often should it turn on?

- Basic recommendations for the operation and repair of gas boilers

- Distinctive abilities

Safety rules for every day

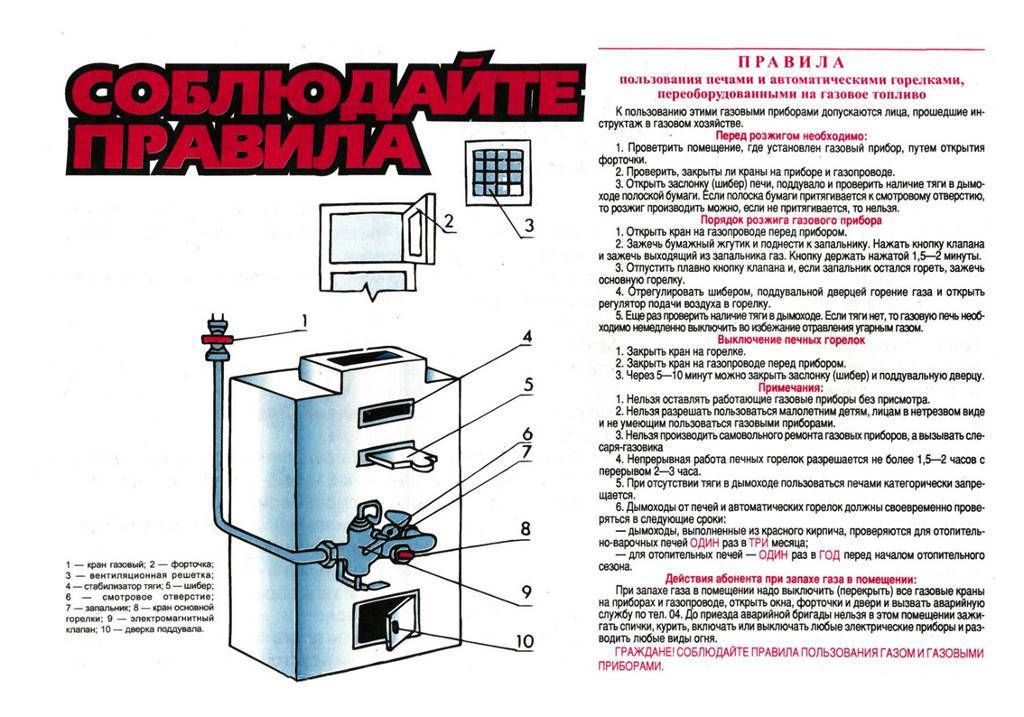

Before any use of the gas appliance, a number of mandatory steps must be performed.

Namely, it is necessary:

- Make sure there is no smell of gas.

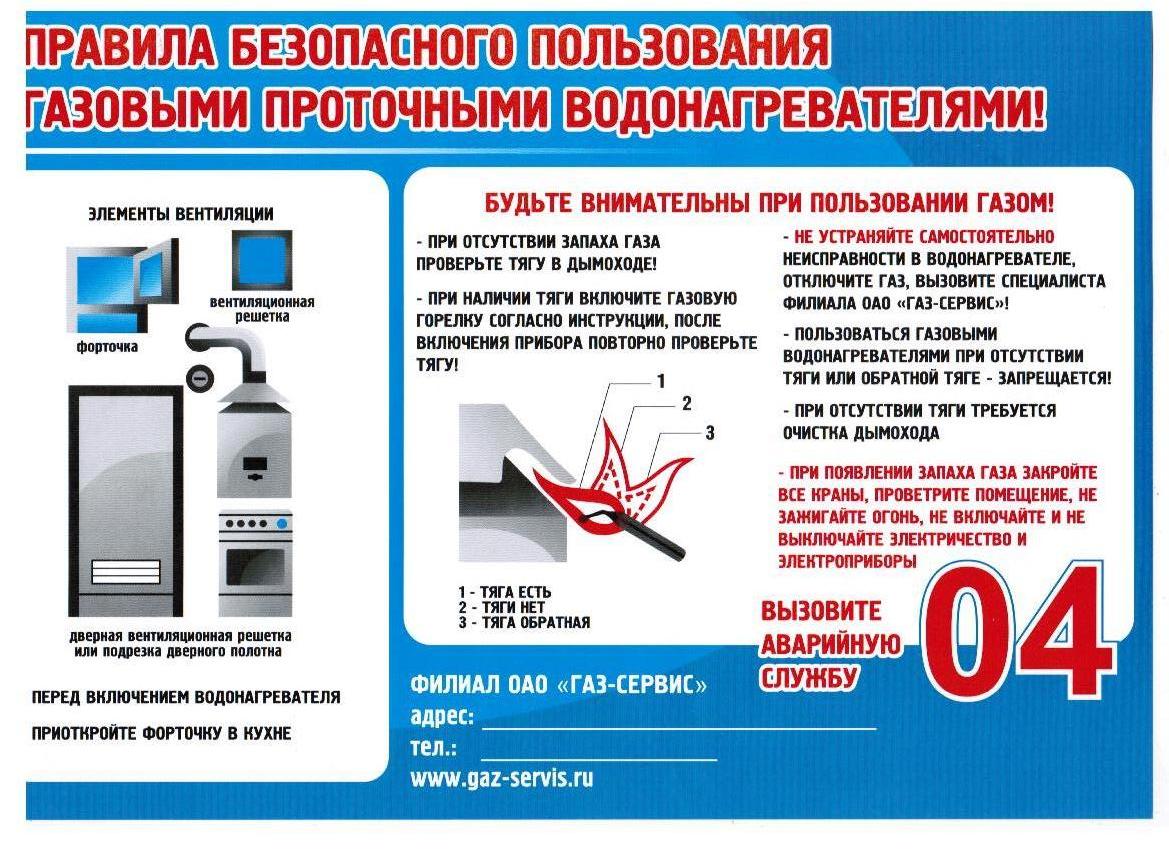

- Check for traction. It should be remembered that its absence is a direct threat to life.

- Open window. Modern metal-plastic products can be set to ventilation mode. Which should occur during the entire process of burning the energy carrier.

- Control the operation of the gas appliance. That is, the equipment should not be left unattended.

- Turn off the taps of the gas appliance when it is no longer necessary to use it.

And also it should be remembered that the electric hood located above the gas stove must be turned on before the gas combustion process begins. If the sequence is not followed, then the use of the specified equipment should be refrained.

It is important to remember that only people who have the appropriate skills and knowledge are allowed to operate gas appliances.

Elements of safety and comfortable operation

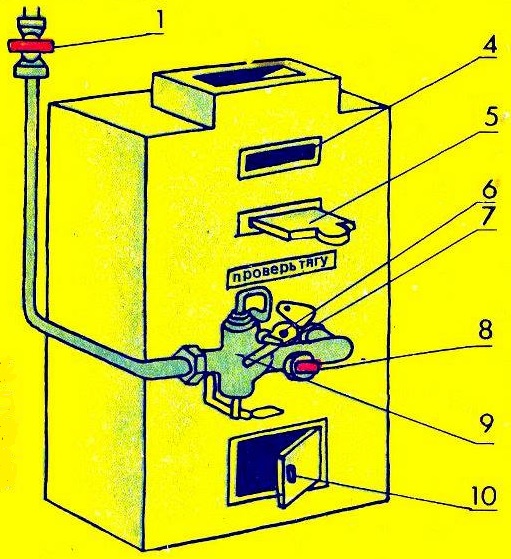

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure the safety of work, and devices that contribute to the comfortable operation of the boiler.

The following parts are responsible for safe operation:

- thermostat;

- draft and flame control sensors;

- safety valve.

The flame control sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

The flame temperature regulator (thermostat) maintains the required temperature of the coolant, and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical level (maximum or minimum).

The draft control module stops the gas supply to the burner as soon as the location of the bimetallic plate changes due to elevated temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

The safety valve regulates, distributes and shuts off the gas flow

In a heating system, a safety valve is an inseparable component of pipeline fittings, which is important in controlling the volume of coolant involved in the circuit. The hole in the valve through which the gaseous fuel flows is called the seat.

To turn off the device, it must be covered with a disk or piston

The hole in the valve through which the gaseous fuel flows is called the seat. To turn off the device, it must be covered with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as simulating:

- Single stage devices have only two operating positions: on/off.

- The two-stage device is equipped with one inlet and two outlets, while the valve opens when it is turned to an intermediate position, due to which the switching on occurs more smoothly.

- Boilers with two power levels are supplied with a three-stage device.

- Modulating valves are used to smoothly change the power rating of devices.

Automation used for convenience includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

Do I need to turn off the gas heating boiler at all?

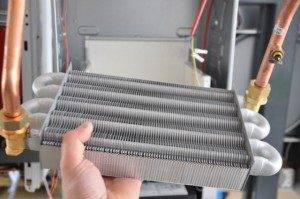

The start-up after the coolant has completely cooled has a particularly detrimental effect on the system. For example, if you turned off the boiler for the weekend and the coolant (water) has completely cooled down during this time.In this case, after ignition, condensation may form on the heat exchanger and burner. And over time, it can provoke equipment failure.

Many owners, in an effort to save money, do not turn off the floor or wall-mounted boiler, but only screw on the gas valve. Firstly, this is inefficient, and secondly, it also has a bad effect on the operation of the equipment. Gas burners can only work correctly at a certain level of gas pressure. If the pressure drops, the burner can continue to work, but the fire will come much closer to it, reducing the service life.

The principle of operation of the boiler

Gas is used not only for space heating, but also for heating water. For this, either water columns or double-circuit boilers are used. The equipment that is used today is equipped with highly effective security systems - they keep the gas combustion process under control. But, nevertheless, there are mandatory rules for the use of gas equipment and their observance can become a guarantee of safety.

Before putting the equipment into operation, the user must ensure:

- In the presence of the required amount of working fluid in the heating system.

- That the burner, safety valve, are in working order.

- Measuring instruments show correct data.

- The operating temperature of the boiler device should not fall below 65 degrees. This may lead to condensation.

Tips and advice for care

Competent maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break down even in the first year of operation.Performing several operations will prevent the following outcome of events:

- even during normal operation of the boiler, you need to contact one of the organizations that carry out work in this area, so that the master inspects the device for gas and water leaks, the condition of the sensors and the chimney, and, if necessary, makes repairs;

- it is always necessary to control the water pressure inside or at the outlet of the system. If it falls below 0.8 bar, then water must be added;

- water is usually added to the system directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of the water from the boiler. The refilled water should only be cold (up to 35°C).

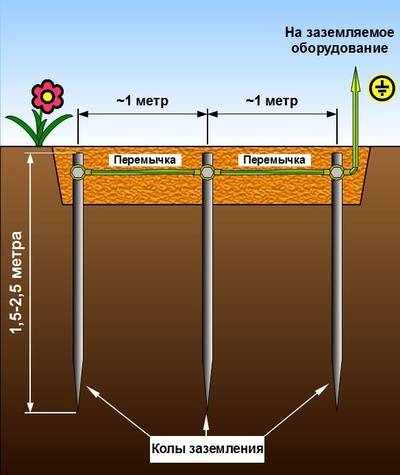

Step-by-step installation of the heat generator and chimney

Do-it-yourself installation of elements of the heating system is not difficult, especially with proper preparation of the room and the place where the structure will be installed.

Step-by-step installation instructions consist of several steps:

- Installing the device and leveling it vertically using metal pads or special feet. It is necessary to take into account the ratio of the pipe and the hole prepared for the installation of the chimney.

- Prepare several insulated pipes or take ordinary ones by wrapping them with basalt fiber.

- Make a hole in the wall that will be 35-38 cm wider than the chimney.

- Install a metal passage box, pass a pipe through it, fill the remaining space with basalt wool.

- Outside, the chimney is installed vertically, parallel to the wall. A kind of umbrella is attached from above, preventing the ingress of a large amount of water, from below - a collection for condensate.

- The part of the chimney coming from the heat generator is mounted at a slight angle towards it.

After completing the work, you should make sure that the chimney is not under the roof ridge and water will not drain into it during rain or snow melt.

Operation features

Boilers "KoreaStar", being productive and reliable, have advantages and disadvantages typical for any equipment with a closed firebox:

- Noise. The reason is the operation of the fans. With their help, air is injected and removed from the coaxial chimney. A distinctive feature of all forced draft burners is their noisy operation. It is advisable to install such heaters away from living rooms.

- The water in the hot water supply is heated separately from the coolant. The three-way solenoid valve increases the heating rate, ensures a uniform supply of water at any pressure in the water pipes.

- When the coolant cools down to +5 °C, the boiler starts automatically, preventing the heating system from defrosting.

- Energy dependence. The instructions for use of KoreaStar heaters say that they are able to function with voltage surges up to 15% of the nominal value. But in practice, there are problems, the controller board fails. Installing an uninterruptible power supply will help prevent breakdowns.

- Before connecting the device, you need to obtain permission, order project documentation from the gas service.

Setting the boiler automation and pressure

Reconfiguration is performed if the automation works too often. This problem is called clocking, and it occurs due to an excessive increase in the temperature of the coolant.Reduce the gas supply to the main burner, so you protect the boiler from wear.

The method also has a fallback - just twist the tap in front of the boiler. Remember that incomplete combustion of fuel leads to an increase in the volume of flue gases and burning.

The installation location of the boiler in the kitchen: gas can be turned off with a tap after the connection, as well as on the lowering, if this does not interfere with the operation of the stove and other gas appliances

The installation location of the boiler in the kitchen: gas can be turned off with a tap after the connection, as well as on the lowering, if this does not interfere with the operation of the stove and other gas appliances

To get rid of clocking, move the room thermostat (if any) to a colder place or lower the air temperature at the installation site. Increase the amount of coolant in the heating system. Replace the main burner if cycling occurs due to its increased power.

Problems with automation and frequent shutdown are observed under such circumstances:

- voltage dropped or jumped;

- a strong wind extinguished the burner;

- the patency of the chimney has decreased;

- decreased gas pressure.

To improve the operation of automation, point the handle of the autoblock (gas valve) to the “spark” position. The igniter (pilot burner, pilot burner) will light up. Leave the knob for 30 seconds in this position, then return to the “off” position - a white circle.

Boilers are produced with thermostats (temperature controllers), daily and weekly programmers. The thermostat turns off the boiler when the set temperature is reached, then the device turns on automatically. While the hosts are away, they can rely on the regulator with a 7-day work period. The daily device eliminates the need for constant monitoring of the boiler.

Weekly programmer for gas boilers Computherm Q7, on which you can select the sensitivity threshold, set the parameters for the transition between heating and cooling and block the buttons

Weekly programmer for gas boilers Computherm Q7, on which you can select the sensitivity threshold, set the parameters for the transition between heating and cooling and block the buttons

Pressure is adjusted on the autoblock. For example, take Eurosit 630. The unit maintains the temperature of the water in the heating circuit and stops the gas supply in a dangerous situation. Eurosit 630 has a knob that rotates and has 7 flame modes - point it to position "1", remove the cover and screw the screw on the left under the handle. Turn clockwise - the gas supply will be less and smoother, the automation will work better.

Set also the maximum mode. Move the knob to "7" and tighten the screw on the bottom of the unit, now counterclockwise. By reducing the flame level, the gas pressure and the efficiency of the boiler burner will decrease at the same power setting.

First determine the desired sides on the autoblock. The surface with the handle is considered lateral. The unit is installed in different ways: sometimes this side is on the side, sometimes on top. Do not confuse the desired screws (gold plated) with the fasteners.

The pressure must be reduced in such cases:

- the flame goes out shortly after ignition; 2

- there is cotton when ignited;

- the flame goes beyond the limits allotted to it;

- red or red-orange color of fire.

Pressure usually rises in winter: gas distribution companies raise the value from 200 to 280 mm of water column. Install a pressure regulator or reduce the flow through the drop.

Installation

Before installing the machine, make sure it is powered by natural gas. If LPG is to be used, the heater must be readjusted by a specialist.Power supply with 220 V/50 Hz parameters must be supplied to the place of installation of volatile models. Deviation of parameters from the norm leads to a decrease in productivity, a reduction in service life.

It is forbidden to connect other electrical appliances to the boiler power supply. It is also forbidden to use extension cords and adapters when connecting. Failure to comply with safety regulations may result in a fire.

Winter mode

In winter mode, the gas boiler operates at full capacity. It can be conditionally divided into the operating mode "heating only" and "hot water priority". In the first case, the device turns on and off on its own, bringing the room to the desired level of air temperature.

A cycle is created. It depends on the cooling rate of the room, square meters, the power of the boiler itself

Set a comfortable temperature, paying attention to cycling. Regulate to reduce load and save on gas consumption

In heating mode, adjust the temperature from 35 ºС to 85 ºС, gradually achieving optimal performance. After adjusting the temperature, elements such as water pressure, pressure switches, NTC sensors and others are checked.

Does not start - causes and solutions

The start of the boiler may be unsuccessful for various reasons:

- The complete absence of indication and signs of the unit's performance. Here, the cause is most often a lack of power, or an illiterate power connection. Bosch boilers are phase-dependent, i.e. need the correct connection of each electrode. In addition, high-quality grounding is necessary, otherwise the operation of the unit will not be stable and stable.

- The boiler cannot be ignited. Often the cause is a factor such as condensate that has fallen on the control board.The protective case is not always able to completely eliminate the ingress of moisture. Most often it passes inside through the wires. In addition, you should check the condition of the burner nozzles, check the gas valve and check the operation of the turbo blower. All defective components should be replaced with new, working items.

- The unit does not work only in any particular mode. In this case, the problem lies either in the control board, or in the incorrect setting of the operating modes.

IMPORTANT!

All repair work or adjustment of the control board mode should be entrusted to specialists from the service center. Self-performing such procedures can cause the opposite effect.

Possible malfunctions when starting the boiler and methods for their elimination

Breakdowns of gas equipment with electronic controllers are eliminated only by a specialist. If, subject to all the rules, a new gas boiler does not start, the user can independently eliminate the simplest malfunctions.

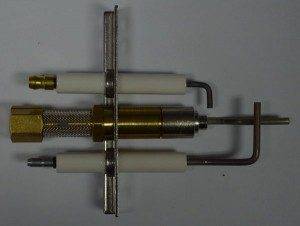

Unable to turn on the igniter

Failure occurs for several reasons:

Failure occurs for several reasons:

- the insulator is dirty. To eliminate damage, wipe it with a clean, dry cloth. Severe contamination is removed with solvents. The element is wiped dry;

- the formation of soot deposits in the space between the body and the candles. In this case, no spark appears. It is necessary to knock on the gas supply channel.

If the gas is not supplied when the igniter is on when the knob is turned, there is a risk of a malfunction of the solenoid valve, thermocouple, thermostat, or supply valve. These breakdowns are eliminated by a specialist.

Advice! If you find a web, you need to unscrew the nut and carefully remove it.

Water does not heat up

The complexity of the breakdown depends on the type of boiler:

The complexity of the breakdown depends on the type of boiler:

- deposits form on the walls of contour models with mechanical control. The DHW circuit is flushed with hot water and detergents;

- electronic gas boilers do not heat water due to breakdowns of electronics or duct sensors.

Important! Troubleshooting electronic equipment should only be a master

Clocking occurs

The failure is typical for devices that heat the coolant at high power. To prevent the cost of paying for gas fuel, premature wear of automation, the supply rate is reduced. You need to adjust it according to the instructions by turning the screw on the valve or using the buttons on the control panel.

The failure is typical for devices that heat the coolant at high power. To prevent the cost of paying for gas fuel, premature wear of automation, the supply rate is reduced. You need to adjust it according to the instructions by turning the screw on the valve or using the buttons on the control panel.

Proper and consistent inclusion of a gas boiler will create a comfortable temperature. Following the recommendations of experts, you will easily carry out the first start-up of equipment that will be effective in cold and wet weather.

Watch a video on how to properly turn on and start a gas boiler

dangerous situations

The greatest danger is the failure associated with the operation of the burners. If the flame goes out, gas can accumulate in the room, which subsequently causes an explosion. Causes of fire extinguishing:

- the gas pressure has fallen below the permissible norm;

- no draft in the chimney;

- the supply voltage is gone;

- the igniter went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automation devices necessary for the prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent the accumulation of gas in the room

Modern safety standards provide for the installation of gas analyzers in boiler rooms; they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, which automatically stops the flow of fuel to the burners.

Specifics of application and operation

Judging by the feedback from consumers, Koreastar boilers are productive and reliable equipment that have their own specific disadvantages that are inherent in all equipment with closed combustion chambers.

The range of Koreastar gas wall-mounted boilers has the following characteristics:

- High noise during operation - is a consequence of the operation of the burner fans. The intake of air and the output of combustion products is carried out using a coaxial chimney, in a forced way. All pressurized burners are noisy, so the stations must be installed away from living quarters.

- DHW heating - hot water heating is performed independently of the heating system. The presence of a three-way solenoid valve significantly increases the heating rate. A uniform supply of hot water is provided, regardless of the pressure in the water supply system.

- Safety group - when the coolant cools down to a temperature of + 5 ° C, the boiler automatically starts, preventing the heating system from defrosting.

- Connection to the power supply - although the manufacturer indicates the ability of the equipment to work, despite voltage drops in the network up to 15% of the rated power, practice shows that this is not always the case. The controller board can fail with any electrical surge. The installation and installation of a UPS can provide protection.

Tips and tricks for choosing

Coreastar boilers can operate with a gas drop of up to 4 mbar, they are resistant to voltage drops. Models are characterized by stable heating of hot water and are intended for domestic use.

Koreastar products should be chosen for rooms with a maximum heated area of up to 320 m² and the need to provide domestic hot water.

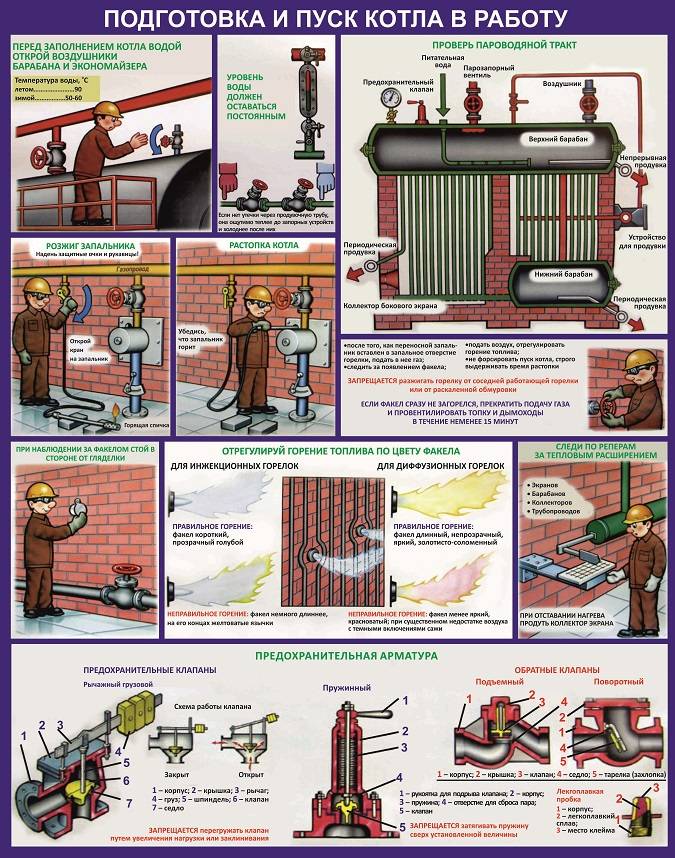

BUILDING THE BOILER UNIT

3.2. When starting to receive gas into the gas pipeline, they check whether the valves of the gas pipeline to the boiler and the valves (valves, taps) of the gas burners are closed, and then open the candle at the end of the gas pipeline. Then the valve on the gas pipeline is opened and the gas is released, observing its pressure on the pressure gauge. After gas comes out of the candle, close its valve (faucet).

3.3. If all burners go out during ignition, immediately stop the gas supply to them.

3.4. When igniting gas burners, one should not stand against peepers (lighting hatches) so as not to suffer from a flame accidentally thrown out of the furnace.

3.5. Ignition of boiler furnaces equipped with automatic control of the combustion process and safety automatics or complex automatics must be carried out in accordance with the requirements of the production instructions for their start-up, adjustment and operation.

3.6. Before turning on oil burners, you must:

- check the presence of diesel fuel in the supply tank;

- drain the settled water from the tank;

- open the shut-off valves on the fuel supply line;

— check the fuel filter, if necessary, replace the filter element;

- when starting the burner, make sure, visually, that the fuel is free to circulate through the filter element and the deaeration chamber.

3.7.When kindling, it is necessary to control the movement of the boiler elements during thermal expansion according to the established indicators (benchmarks).

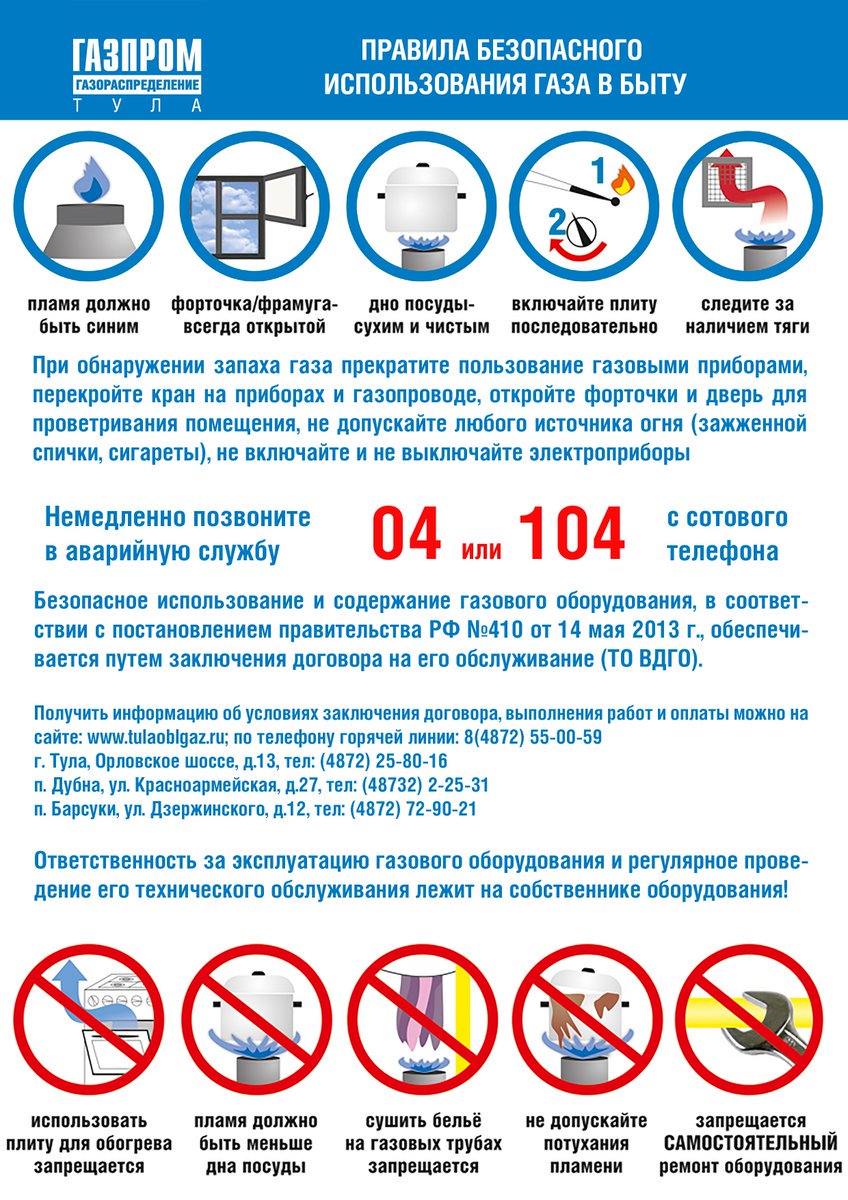

Basic rules for using gas at home

Understanding and remembering the rules for operating gas equipment in residential buildings will not be difficult. They are simple, to achieve and maintain the proper level of security, you need to make a minimum of effort.

- Use of serviceable devices of factory production. The connection of the equipment should only be carried out by an experienced gas service specialist.

- Providing controllers and inspectors with free access to equipment and communications at any time of the day. Fulfillment of all requirements of authorized persons.

- Regular cleaning of ventilation grilles from dust, and channels from dirt, deposits and foreign objects.

- The use of gas only for its intended purpose, in accordance with the attached instructions - heating water in circuits, cooking on burners.

- Timely payment of invoices for consumed fuel. Prevention of debt formation.

- Cleaning of devices with minimal physical pressure, without the use of active chemicals that can cause metal corrosion and destruction of gaskets.

- Use of products only with constant presence in order to prevent accidental ignition or extinguishing of fire by spilled liquid.

Gas boiler startup technology

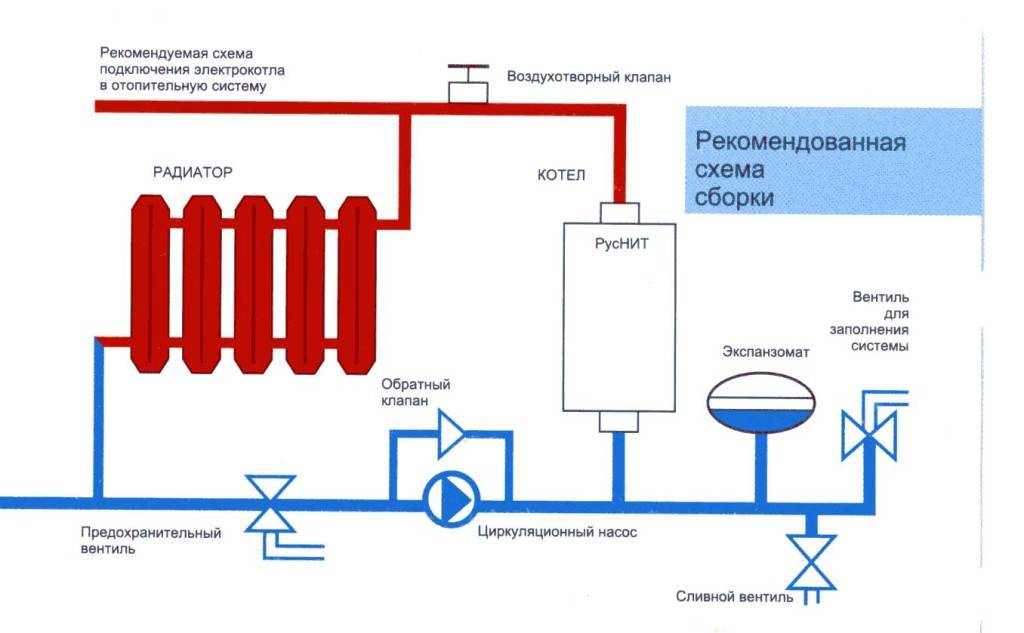

Scheme of installation of a gas boiler.

The first start-up of the equipment involves filling the system responsible for heating with water.The initial start-up should focus on setting up and checking not only the unit itself, but also the heating system, which serves as the basis. How correctly the launch will be made will determine how efficient the heating of the house has become.

Initially, the system should be filled with water. At the bottom of the equipment, where the pipelines are connected, you can find a valve. Its shape may vary between models, so it may look like a rotating pin, for example. The faucet should not be fully open. Otherwise, the pipes may form free air in the interior.

The gas boiler must have a pressure gauge that represents the pressure indicator. The equipment should be started by creating a pressure of approximately 2.5 atm. At the moment the arrow reaches the corresponding value, the pressure pump should be turned off, which is true if it is present. After that, you can close the tap and start bleeding air, which is done using an automatic or manual Mayevsky tap, it must be applied to each of the heating devices. At that moment, when the water starts to flow, the tap can be closed. The boiler pressure gauge should show a pressure of 1.5 atm, this figure will have to catch up to 2 atm. This level will be the optimal pressure for a double-circuit boiler.

How often should it turn on?

The frequency of turning on the boiler depends on several factors:

- Unit power.

- Correct boiler settings.

- Presence of a room thermostat.

With excessive power, the installation quickly heats up the OB and turns off.The circulation pump ensures the supply of new portions of the cooled coolant, the temperature sensor is triggered and starts the boiler again.

Power can be reduced by software. It is also necessary to reconfigure the boiler, in particular, increase the F11 parameter (waiting time before restarting) to a maximum of 10 minutes.

Using a thermostat allows you to significantly increase the time between unit starts, since the air cools down and heats up much more slowly.

Basic recommendations for the operation and repair of gas boilers

Never open the gas valve. All work related to gas must be carried out by a specialist. Don't put your life in danger. As a last resort, if you have basic knowledge of the operation of gas boilers, you can check the filter at the gas pipeline inlet. Before this, be sure to turn off the tap, unscrew it and check the gasket. 80% of problems during the operation of a gas boiler occur due to zeroing of the phase when the wire plug is incorrectly connected to the outlet. For example, one of the family members turned off the boiler from the socket and unknowingly put the plug back in the wrong position.

First of all, you should pay attention to this, and try to put the plug in the correct position. If this is the problem, the system will reset the error, the boiler will start working

This completes the repair of the gas boiler. In order not to get confused in the correct establishment of the phases, you can make marks on the plug and socket with a marker, mark the pin and the hole corresponding to it. It is necessary to check the gas pressure, this can be done visually, for example, by the time the kettle boils.If the kettle boils longer than usual, half an hour instead of ten minutes, then the pressure is low. coolant circulation. On the input are put boiler protection filters from debris and scale falling into it from old or low-quality systems during the operation of a gas boiler. A layer of dirt forms inside the pipes, circulation is disturbed in the boiler. In this case, you need to make sure that the system is not clogged with debris - unscrew the filter and check it. In case of contamination, the filter and rinse thoroughly and reinstall. Be sure to check your chimney. Various contaminants may appear inside the pipe during the operation of a gas boiler, for example, wasps can comfortably settle in it, build a hive right in the chimney. In addition, if water enters the chimney from the outside, ice can form, preventing air from escaping. A sign that the problem is in the chimney will be a strong spread of flame when the boiler is turned on. In this case, the pipe must be cleaned, and the ice must be knocked down. Regularly clean the chimney pipe. Before the first use and during the entire operation of the gas boiler, it is worth scrolling the rotor of the circulation pump as follows: unscrew the washer, put a piece of cloth and turn the rotor clockwise with a screwdriver. Due to the tightness of the pump, movement will be difficult, but after work will be restored. Check the operation of pressure sensors, temperature sensors, etc., after turning off the boiler. Make sure the contacts are connected - disconnect the wire from the sensor and insert it back, this will restore the electrical connection. Inside the boiler there is a burner that requires regular cleaning.This can be done with sandpaper, carefully clean the ionization and ignition contacts and the burner field from plaque. If during the operation of a gas boiler, loud noise and vibrations come from it, it is necessary to check the fan, which can become clogged from dust entering it. If there is dirt on the fan blades, the operation will be disrupted. Pollution must be removed to restore normal air circulation and normal operation of the gas boiler. Lubricate bearings. If the fan continues to spin poorly, then the bearings need to be replaced. The system has a press control - a mechanism that closes the circuit when the fan is turned on, which protects the boiler from fire. Two tubes supply pressure and vacuum to it. This element also needs to be checked. When the fan is turned on, a click is heard, indicating that the contacts in the press control are closed. If the fan is faulty, the press control will also be faulty accordingly.

Distinctive abilities

According to reviews of Ariston gas wall-mounted double-circuit boilers, they have 4 distinctive features that are useful for their owners:

- All models of this company are equipped with automatic protection systems.

- The presence of a water pump, which is necessary for the constant circulation of water through the pipes.

- Possibility to choose a model with an expansion tank. With its help, automatic pressure control will occur inside the heating system.

- Ariston equips its equipment with various types of ignition. It can be automatic, which will greatly facilitate the life of the owner of a particular boiler.Otherwise, each time the unit is started, a person will need to press a special button.