- How to remove air pockets?

- Circulation pump

- Conclusion

- Why does the gas boiler go out and what to do

- Circulation pump

- Conclusion

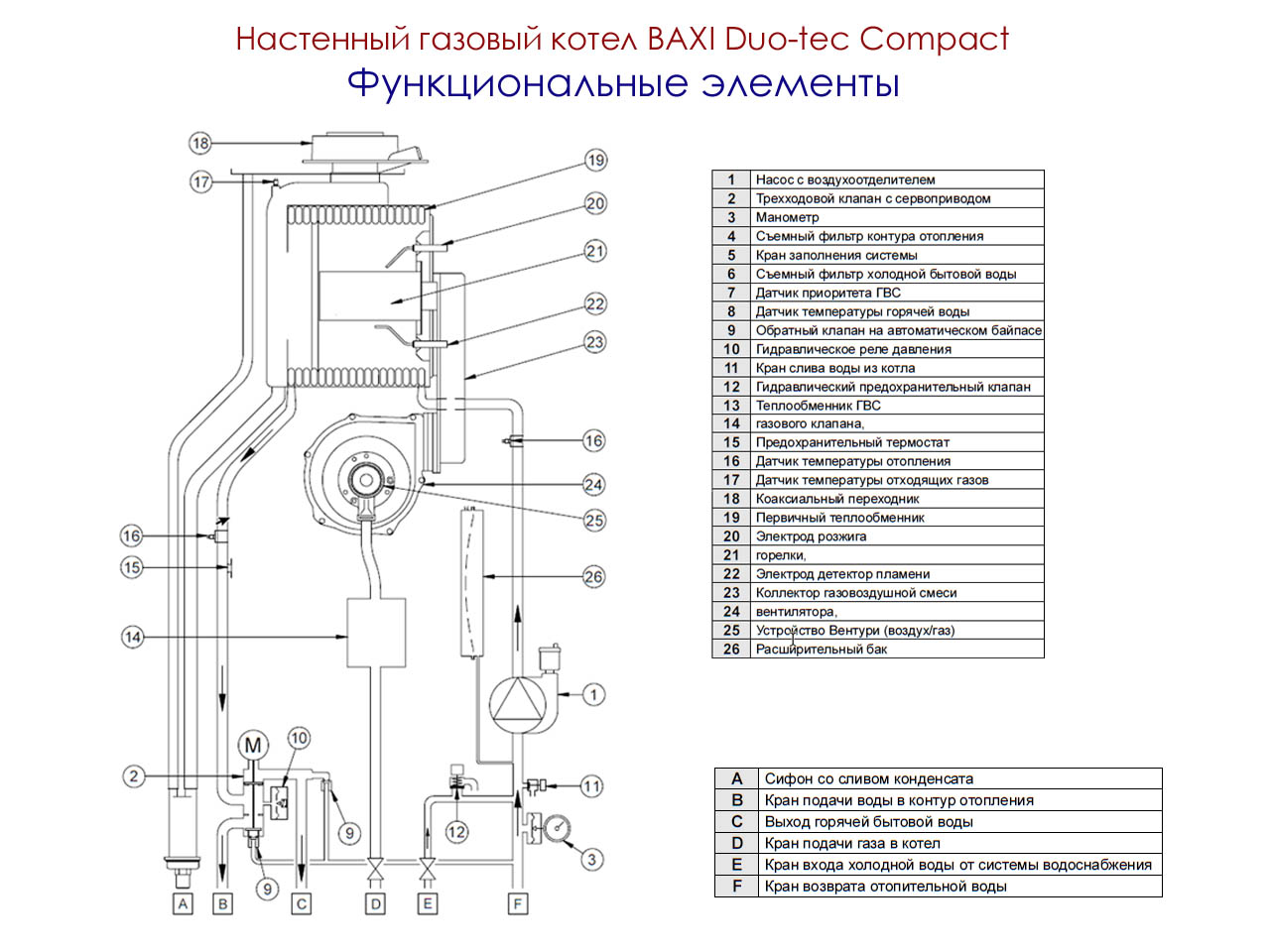

- Recommendations for turning on the Baxi gas boiler

- Heating boiler settings and why they are needed

- Procedure for replacing an obsolete boiler

- What documents are needed when replacing a gas boiler

- Do I need a new project when replacing a gas boiler

- Features of replacing a boiler of the same power

- Is it possible to replace a gas boiler with an electric one

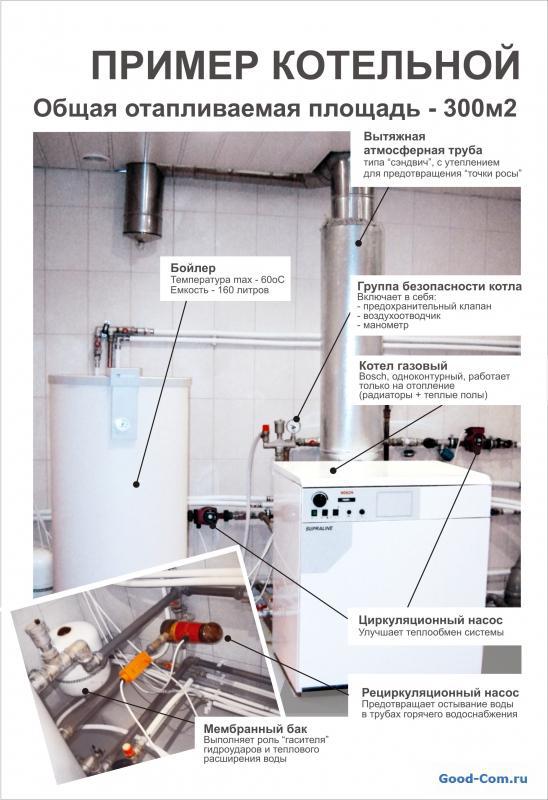

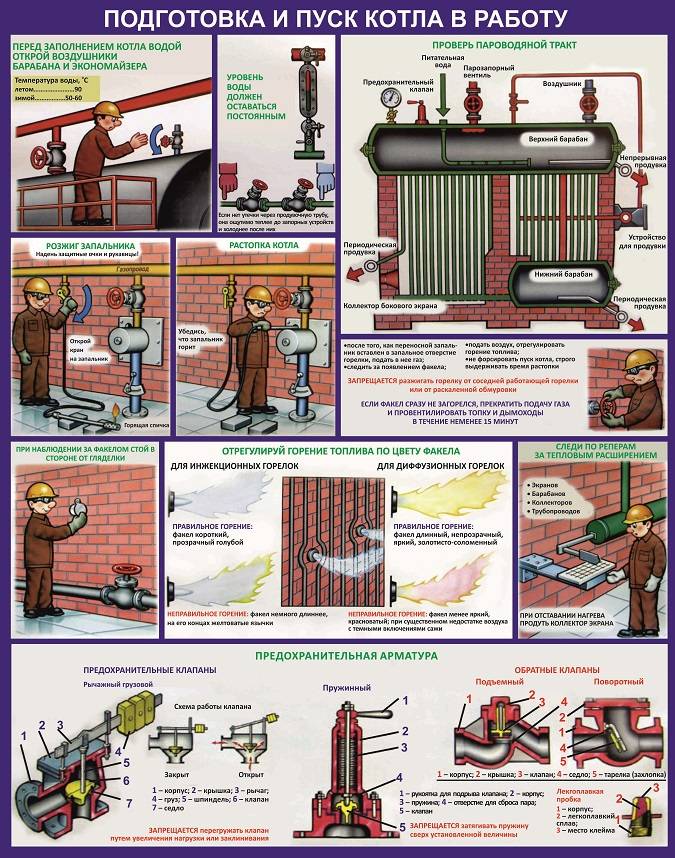

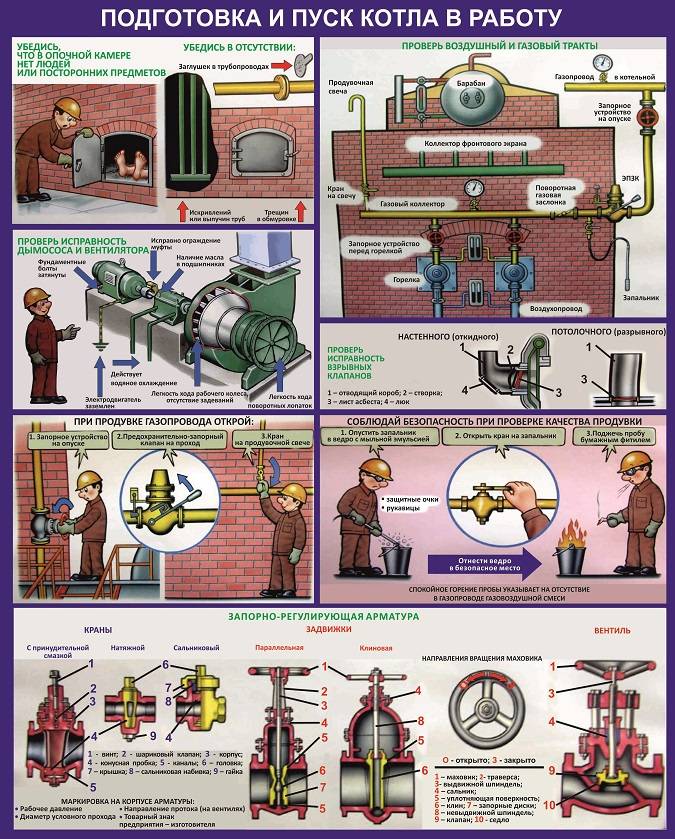

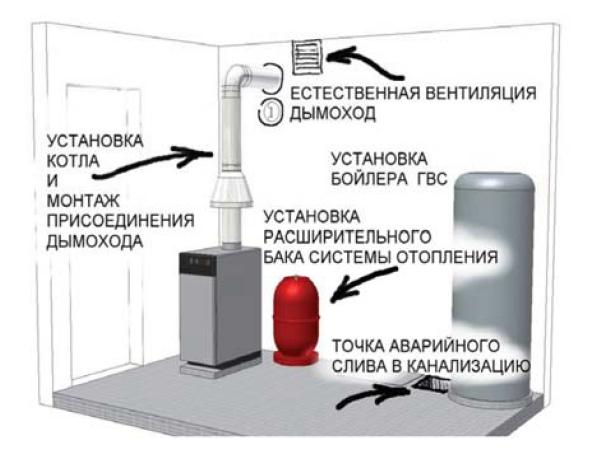

- Checking the boiler room before starting

- What is checked during verification:

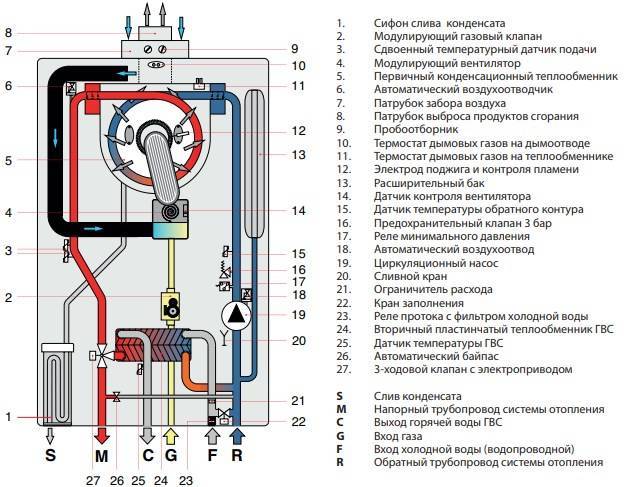

- Classification

- Table: types of gas boilers

- Operating recommendations

- What are the other safety rules?

- Basic error codes and their interpretation

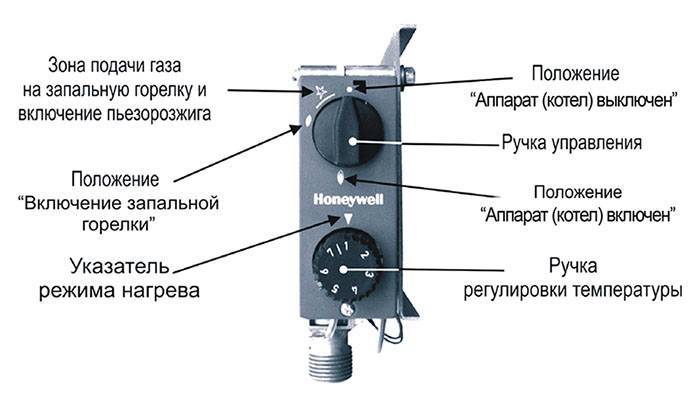

- 4 Starting the instrument

- What to do if there are malfunctions

- Removing air pockets before lighting a gas boiler

- Preparation before turning on the Ariston brand gas boiler for the first time

- Possible breakdowns of the gas boiler

- Radiator network: 4 ways of piping

- One-pipe connection option

- Two-pipe circuits ring and dead end

- Collector system

- About the terms of operation of gas equipment

How to remove air pockets?

Simply connecting the system by filling it with water is not enough. It will not work or its efficiency will become extremely low.To carry out a full-fledged first start-up of the equipment, it is necessary to drain all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically venting air when filling, but the efficiency of such systems is low. This means that manual venting of the main and other systems is required during connection. Only then can you start.

Removal of air locks during connection is carried out not only at the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this, they are equipped with the so-called Mayevsky cranes, which you just need to open by substituting a basin under them. At first, a slight whistle will be heard - this is air gradually leaving the system. If the plugs are removed, then water begins to flow. If the batteries are freed from air masses, then the valves must be closed. Such a simple procedure is carried out with each radiator, it must be checked and cleaned of plugs. When air is removed from all radiators, the pressure gauge needle will be set to the desired value. Before turning on the gas boiler, it is necessary to add a coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air plugs from the circulation pump, which requires disassembly of some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a cover in the middle of the body, it has a slot for a screwdriver. The boiler must be started, that is, turn on the power, set the heating regulator to the required operating position.After that, a weak hum will be heard - this will earn the circulation pump. You can hear gurgling, other sounds. Using a screwdriver, the cover in the found part must be slightly unscrewed, this should be done until water flows. As soon as the liquid begins to seep, the cap must be screwed back. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, and the sounds and gurgling will disappear, the pump will start to work quietly. Immediately after this, the electric ignition of the equipment will work, the gas boiler will start its work on its own.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up, begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. From properly performed preparation, start-up, adjustment of the system depends on how efficient the heating will be.

The first start-up of the heating system is a crucial moment, on which the serviceability of its elements, coherence and uninterrupted operation depend.

How to turn on a gas boiler, fill the radiators with coolant, bleed air, check everything and not forget anything.

Consider the procedure and rules for commissioning the heating system.

If the boiler is new and you do not want to lose the possibility of warranty service, you will have to invite service employees. They will make an appropriate note in the passport that the first launch was carried out in accordance with all the rules.

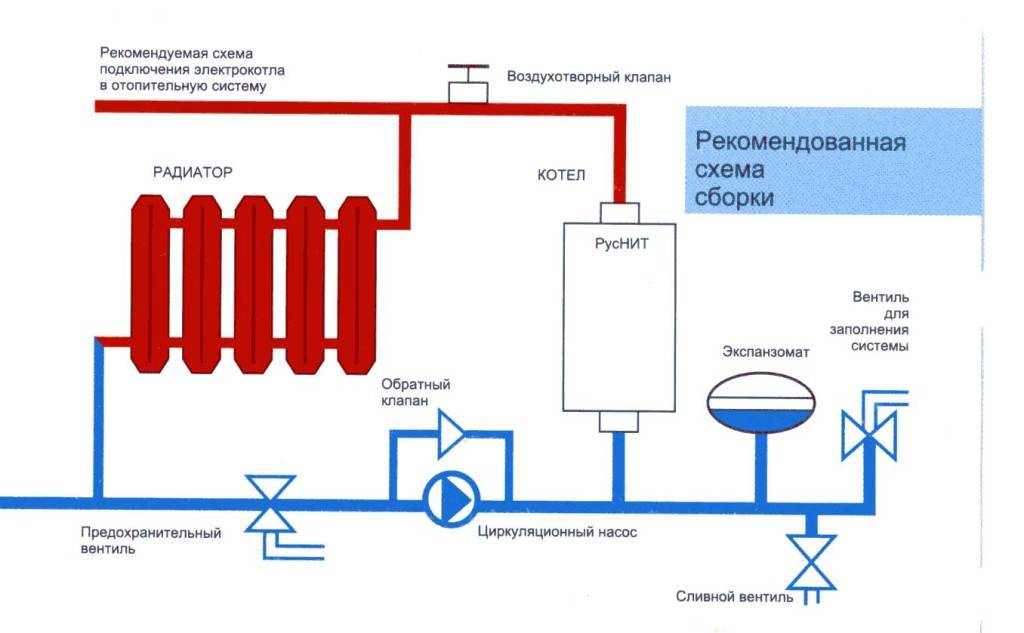

Before the boiler is turned on, it must become part of a single heating system.

All its elements, such as:

- pipes;

- radiators;

- pumps;

- filters;

- expansion tank;

- thermostats;

- security group;

Must be installed in accordance with the diagram. Once again, everything should be visually inspected and proceed to filling the system with coolant.

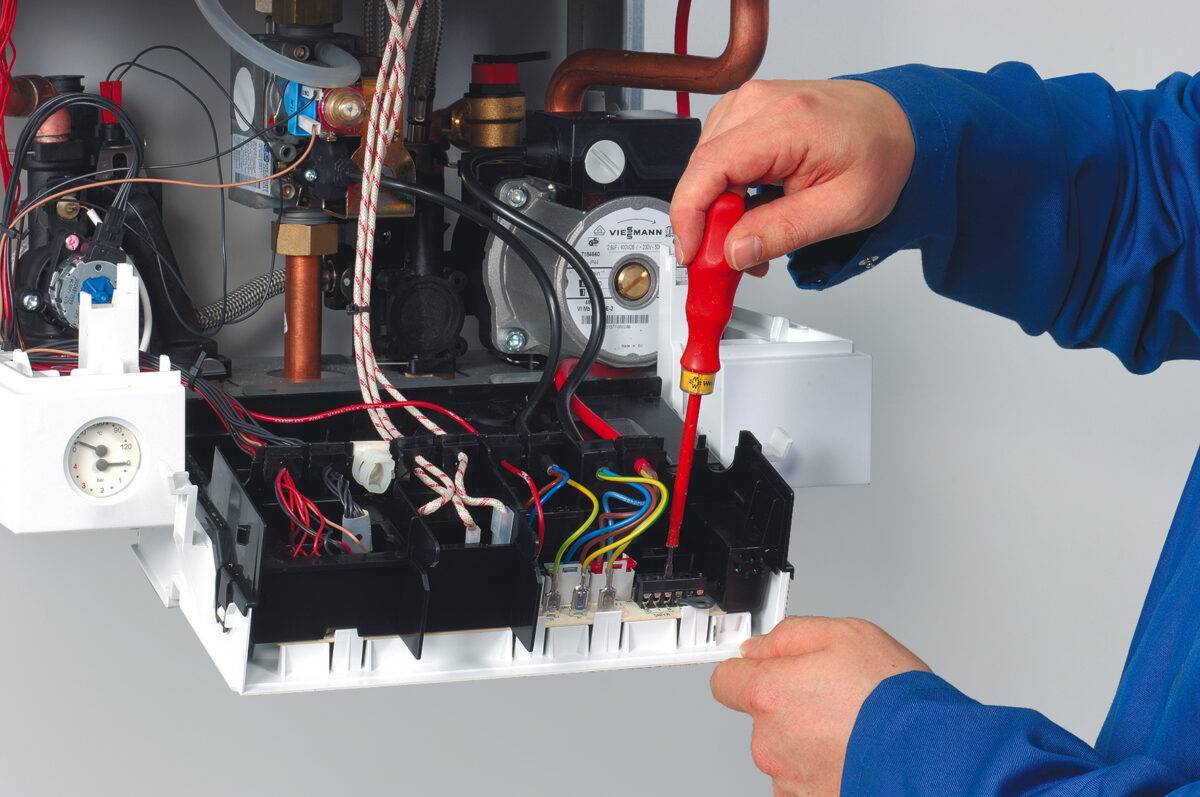

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will give a corresponding error).

To do this, remove the front panel of the housing, unscrew the central bolt on the pump and turn the shaft in the direction indicated by the arrow with a slotted screwdriver.

An air vent is installed above the pump. The bright cover must be pulled up and let the air escape.

Floor boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. — review of design options and models.

Conclusion

At first, the system may make gurgling sounds, all because it is impossible to bleed air to the last atom during start-up. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the normal range.

Temperature adjustment and other boiler settings are described in the instructions for each model.

Why does the gas boiler go out and what to do

There can be many reasons for the extinction of a flame. They largely depend on the design of the boiler, in particular, on the type of combustion chamber.

For closed burners, typical reasons may be:

- Shutdown of gas supply in the highway.

- Failure of the gas valve, problems with gas equipment.

- Clogged burner nozzles with soot.

Open burners are subject to the same problems, but there are additional ones:

- The occurrence of reverse draft in the chimney.

- Strong gust of wind outside.

- Drafts in the room.

The solution of these problems occurs in accordance with the nature and properties of the causes that caused the attenuation. If the flame suddenly goes out, first of all, turn off the gas supply and call the gas service.

If the problems lie in the boiler itself, it is urgent to call a technician from the service center.

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will give a corresponding error).

It is recommended to rotate the shaft manually before starting.

To do this, remove the front panel of the housing, unscrew the central bolt on the pump and turn the shaft in the direction indicated by the arrow with a slotted screwdriver.

An air vent is installed above the pump. The bright cover must be pulled up and let the air escape.

Conclusion

At first, the system may make gurgling sounds, all because it is impossible to bleed air to the last atom during start-up. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the normal range. Temperature adjustment and other boiler settings are described in the instructions for each model.

Recommendations for turning on the Baxi gas boiler

If you wondered how to turn on the Baxi floor-standing gas boiler, you must follow a certain technology. In the first step, you must open the gas cock, usually located under the equipment itself.

It is important to make sure that the system has the right pressure, only then can power be supplied to the device. Then you should press the "Start" button and set the device to the "Winter" or "Summer" mode

The panel has special buttons with which you can set the desired temperature values in the boiler and hot water circuits. This will turn on the main burner. If you have purchased a gas boiler, how to turn it on, you need to ask before unpacking the goods. After you have carried out all the above actions, you need to make sure that the boiler is working, this will be indicated by a special symbol of a burning flame on the display.

Heating boiler settings and why they are needed

Imagine you bought a gas boiler and successfully connected it. Winter is coming, you want to be ready for the heating season. As soon as there is a need for heating the room.

When hot water is needed, the boiler automatically switches to hot water. In other cases, the boiler is in standby mode and performs other functions so as not to freeze itself.

The boiler operating modes give the user an understanding of how the boiler works, what tasks it performs, how the priority is built. They help to understand concepts such as cyclicity, temperature and warming up. Knowing these concepts, you can guess how profitable it is to save on resources for the boiler.

Basic settings of the gas boiler:

- work only for heating;

- hot water priority;

- summer mode of operation;

- "warm floor" mode;

- frost protection.

Individual models of boilers have their own modes. Basically, they are focused on marketing and emphasize their "zest". But the standard set is always the same.

To choose a boiler, watch this video:

Procedure for replacing an obsolete boiler

Gas equipment is considered a device of increased danger.

Therefore, all work on the installation and maintenance of gas appliances is also classified as work with increased danger. The existing rules unequivocally answer the question - how to replace a gas boiler in a private house - it is forbidden to install or replace boiler equipment on your own. Installation of boilers can only be carried out by special authorities (gorgaz, rygaz, oblgaz) through enterprises that have a license for such work.

To start replacing the boiler, you need to do the following:

- Write an application to the gas service for permission to replace the boiler. You need to know that when replacing an old boiler with a similar one, you do not need to create a new project, but if changes have occurred - a boiler of a different type, the location or gas supply scheme changes, then a new project is created.

- After receiving a response, you need to hand over a construction passport to the gas service. Collect and submit DVK inspection certificates, and if an imported boiler is installed, a certificate of conformity.

What documents are needed when replacing a gas boiler

Before replacing a gas boiler, it is necessary to collect a lot of documents and obtain permits for such work.

You will need the following documents:

- If the equipment is from foreign manufacturers, then you need to provide a certificate in accordance with our safety standards;

- If the boiler is double-circuit, then it is necessary to have a sanitary and hygienic certificate for supplying hot water for domestic needs. Usually such a document is provided immediately with the warranty card;

- Document on checking ventilation and smoke ducts;

- Warranty contract for at least 1 year, which is concluded with a service company;

- A document with the results of connecting equipment to engineering networks.

- Act on hidden work when installing a coaxial chimney through the wall;

- Project with changes. The main condition: the new boiler must be legalized.

You must collect all the documents yourself. If you do not have such an opportunity, then you can contact a special installation company. But in this case, additional costs must be calculated.

Do I need a new project when replacing a gas boiler

The project specifies the model, type and power of the heating unit. In addition, each boiler has its own serial number, indicated in the data sheet and included in the project documentation. Therefore, when replacing, you will need to make a new project with new data.

You need to go through the following steps again:

- Obtain specifications for the replacement of a gas boiler. At this stage, the gas distribution company can change the capacity of the unit based on the actual living area of the house.

- Make a new project.

- Obtain approval by submitting a gas distribution project, specifications, and the results of checking the chimney channel.

- Replace the old unit with a new one.

When replacing an old gas boiler with a new one, the following documents are needed:

- The passport.

- Documents of the owner of the dwelling.

- Technical passport for gas equipment.

- Specifications.

Standard prices for the replacement of already installed gas equipment are 1000-1500 rubles, depending on the region.

Features of replacing a boiler of the same power

If the gas consumption per hour of the new boiler is similar to the gas consumption of the old one, then this greatly simplifies the task.Since all that is needed from the owner is to submit a notification of the replacement to Gorgaz.

And to it should be attached:

- Boiler connection certificate.

- The act of inspection of ventilation, chimney.

- Contract for at least one year maintenance of gas equipment.

After consideration, the application is granted permission. After that, the equipment is replaced, tested and its operation begins. Thus, the RF GD No. 1203 p. 61(1) allows to operate.

Is it possible to replace a gas boiler with an electric one

Replacement is quite possible, but for this you will have to obtain permission from another organization involved in power supply. Documents are needed only if the electric boiler has a power of more than 8 kW. Up to this performance limit, the unit belongs to ordinary household water heaters by the type of boiler, therefore, it is installed without permits and approvals.

For productive electric boilers, a separate power supply line will be required. You will need to make a project and obtain permission to increase the amount of electricity generated. Separately, it is necessary to write a statement about disconnecting the gas boiler from the main.

Checking the boiler room before starting

Usually the check is made within one to two days. But if any inaccuracies or equipment malfunctions are identified, the process can take up to several weeks or even months.

The Commission pays great attention to safety in the use of electrical and thermal systems, chimneys, smoke exhausters, fans, gas installations of overpressure or atmospheric pressure.The inspection of the boiler room is carried out by the inspector very carefully, carefully, in order to avoid serious undesirable consequences as a result of poor-quality study of all details

Only after making sure of 100% suitability of the equipment, its safety, a license is issued

The inspection of the boiler room is carried out by the inspector very carefully, carefully, in order to avoid serious undesirable consequences as a result of poor-quality study of all the details. Only after making sure of 100% suitability of the equipment, its safety, a license is issued.

What is checked during verification:

- whether the applied citizen really has the right to use the land area;

- report on safety briefings, etc.;

- Is there a registration for this project?

- the presence of a fuel regime card;

- list of job descriptions, etc.

There should also be logs - accounting, shift, repair, documents on labor protection, safety precautions, plans for evacuation and fire fighting in the event of equipment failure. These papers can be officially approved only with the help of qualified specialists. In this case, you can save not only on personal time, but also on finances.

This is the procedure for starting the boiler plant in normal mode, which follows installation and commissioning. Based on the commissioning results, a document is being prepared stating that the launched boiler room complies with the rules and regulations that allow its further use.

Classification

There are a huge number of types of this equipment, which allows you to choose the one that suits you in all respects.

Table: types of gas boilers

| Number of circuits | According to the way of traction | By type of ignition | By installation method | By power modulation | |||||

| Single circuit: heating only | Double-circuit: heating and DHW | Natural traction | Ventilation draft | Electronic ignition | Piezo ignition | floor standing | wall | single stage | two stage |

The gas boiler can be located on the floor and wall

Floor boilers differ from wall-mounted boilers in a wide range of power adjustment. Such equipment can heat a room of 200 m2. If you connect a boiler to it, then you can also provide yourself with hot water.

Wall-mounted gas boiler will fit perfectly into any interior

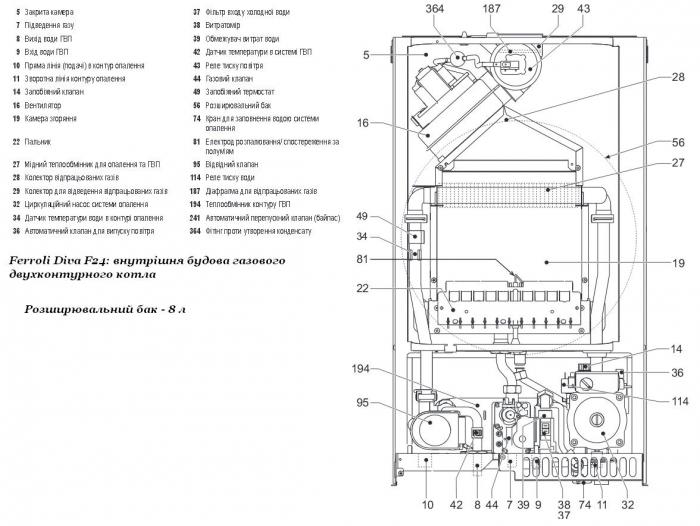

A single-circuit boiler can heat one thing: either a coolant, or a heating system, or hot water supply. When using a double-circuit, it is possible to simultaneously connect space heating and hot water supply.

Boilers with natural draft are distinguished by the fact that the products of combustion are removed using constant influxes of street air. They often heat non-residential premises and small houses. In boilers with ventilation draft, it is forced. In them, combustion takes place in a closed chamber. A special chimney is equipped with external and internal pipes through which air is taken. They do not burn the oxygen of the room, do not need an additional air supply to maintain combustion.

In the room where the gas boiler is located, the ventilation system should be well thought out.

For equipment with an electronic ignition, the activation process is automated. Such models are more economical than piezo ignition boilers, since they do not have a special part with a constantly burning flame.If the power supply is interrupted, the equipment ceases to function, but automatically resumes operation when power returns.

Boilers are also classified according to energy efficiency:

- condensation;

- convection.

The latter do not form condensate, which can dissolve the acids that are on the walls of the device. But the heat transfer in it is lower.

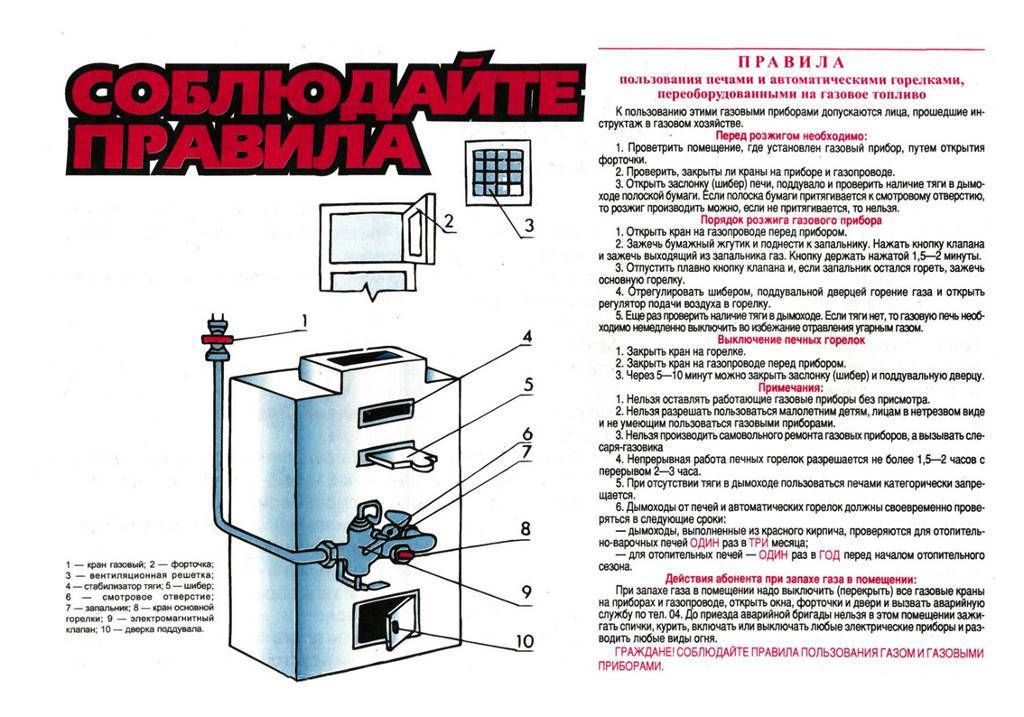

Operating recommendations

- In case of malfunctions of the gas valve, it is necessary to check it and adjust the settings. If the heat exchanger covers a large layer of scale, then this greatly reduces heat transfer and significantly increases fuel consumption. In such a situation, the boiler makes a crack or noise. This is due to the accumulation of salts, which slowly crumble from the surface over time, which is why noise is heard. You can remove them with the help of special reagents.

- Often you have to deal with too rapid wear of the nodes. The main reason for this is clocking. In this case, the gas boiler can automatically turn on and off. When the water in the circuit cools, a signal is received from the thermostat that the water has cooled, in this case the boiler turns on.

How to choose a gas boiler, see the following video.

What are the other safety rules?

- Do not disassemble or dismantle gas appliances yourself.

- Handle the power cord with care.

- Do not place any foreign objects on the device.

- Don't step on the boiler. Do not stand on chairs, tables or other unstable objects to clean the wall-mounted boiler.

- Keep an eye on the coolant, top it up in time in the system.

- Be careful - in some modifications, the use of antifreeze is prohibited.

- If you smell gas, immediately turn off the gas, open windows and doors. Exit the boiler room and call the gas service.

In order for the operation of a domestic gas boiler to be safe and uninterrupted, the user must read the instructions for it in advance. By choosing models equipped with automation, the consumer increases the comfort of use and safety. By following the rules for the use of gas appliances in everyday life, for their installation and maintenance, the number of emergencies can be minimized.

Basic error codes and their interpretation

The list of standard errors, which are displayed as an alphanumeric code, is quite large.

For convenience, we provide it in the form of a table:

| Error code | Decryption (problematic element) |

| E00 | Control board failure |

| E01 | Flame control sensor failure |

| E02 | Overheating thermostat |

| E03 | Draft sensor on pneumatic relay or thermostat |

| E04 | Burning mode control electrode |

| E05 | RH temperature sensor |

| E06 | DHW temperature sensor |

| E09 | Control board failure |

| E10 | Pressure switch or pump operation sensor (pressure switch) |

| E12 - 13 | Hydraulic pressure switch |

| E21 | Damage to the elements of the control board |

| E22 | Low supply voltage |

| E25 - 26 | Heating medium temperature sensor |

| E31 | No communication between control board and remote control |

| E32 | DHW and RH temperature sensors |

| E35 | Flame sensor |

| E40 - 41 | Combustion gas pressure sensor (draft sensor) |

| E42 | Flame control sensor |

| E97, 98, 99 | Malfunction of the electronic control board |

The appearance of this or that code is not always able to say something to an unprepared person.A list of errors with decoding is available in the user manual, which should be kept at hand for prompt clarification of the causes or source of the malfunction.

NOTE!

Troubleshooting can be done independently, but in most cases, the participation of a specialist from the service center is necessary.

It is especially important to use it during the warranty period.

4 Starting the instrument

These models have a hot water mode. When switching to it, the electronic burner will automatically light up. For piero ignition, you will need to press the flame regulator and hold it for a few seconds, then activate the piezo button. Sometimes the ignition can be blocked due to the presence of air in the system. To unlock, just press the "Restart" key. The inclusion of parapet models of the ATON type occurs according to the same scheme. If the kit includes a remote control, you can set fire to the boiler with it.

The algorithm for launching outdoor devices will be somewhat different. Before lighting a floor-standing gas boiler such as Baxi, Siberia, Buderus, Lemax, Conord, you need to ventilate the room, check the presence of draft and the position of the control and temperature selector. It should be in "Off" mode. Then open the gas valve, switch the selector to the pierre ignition mode and press it for 5 seconds. At the same time, press the piezo button. After the burner lights up, you can adjust the temperature.

Gas heating installations must not be switched off for a long time, especially during the cold season. The action of low temperatures will provoke freezing of the heating system and failure of its components (pipes, radiators, boiler).If a long-term non-use of the gas installation is planned, it is not recommended to turn it off, but to set the minimum temperature indicators. Thus, with a minimum fuel consumption, it will be possible to avoid defrosting the heating circuit.

What to do if there are malfunctions

Consider situations with breakdowns on the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may occur that require prompt elimination.

In Baksi models, the following problems may appear:

- the burner does not ignite;

- during operation, pops are heard in the furnace;

- the boiler has overheated;

- the device is very noisy;

- the sensor has failed.

The probable causes of breakdowns are associated both with violations of the operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality of the coolant;

- decreased pressure in the gas pipeline;

- in the power supply voltage drop;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

Removing air pockets before lighting a gas boiler

Air vents must be installed in the upper fitting of each radiator. These can be Mayevsky taps, or automatic valves.

Automation will cope with everything itself, you just need to give it a little time (the pressure drop will tell you that the air has come out).

To release air with a Mayevsky crane, you need to prepare a bucket, a rag, a special key from the installation kit (or a screwdriver and pliers).

A container is alternately substituted for each radiator, the tap is unscrewed, and the air comes out with a hiss.Then the battery will begin to "spit" air mixed with water. You can close the air vent when a trickle of water flows out of it.

Approximately 5-7 minutes at each radiator - and the first air plugs are removed. The readings of the pressure gauge are checked (they should go down), and the water supply tap is turned on again. It would be good to repeat the procedure for lowering the air again.

Ultimately, the pressure should be above average, but not the maximum, because when the water heats up, the pressure will rise even more.

By the way, in order not to splatter furniture and walls when the air is released, you can hang a rag on the faucet, through which water will drain into a bucket.

Preparation before turning on the Ariston brand gas boiler for the first time

The gas boiler "Ariston" should be started for the first time, as soon as the installation and piping of the equipment elements is completed

It is important to check the respective installations. The unit must be installed following safety standards, and you must completely exclude the possibility of fire

The boiler must be away from the wall, there must be no flammable objects and materials nearby. Once the installation is complete, you can connect the equipment to a cold water source. To do this, plugs are removed from the nozzles, and a filter with a ball valve is located at the inlet. The last device must be present on all nozzles when piping.

Particular attention must be paid to the piping from the gas main. These works are carried out by specialists, and if necessary, a gas meter will have to be installed.

If you purchased the Ariston gas boiler, then before turning it on, you need to lay the power line for the heating unit.The equipment must be supplied with an electrical cable with a plug, and there must be a separate socket near the appliance. Then the boiler is connected to the chimney, the draft and operation of which must be checked before connection.

Preparation for starting the boiler involves disconnecting it from the electrical network before filling the device and the heating system with water

It is important to exclude leaks, for this the thermostat turns on to the maximum value so that the switch works automatically

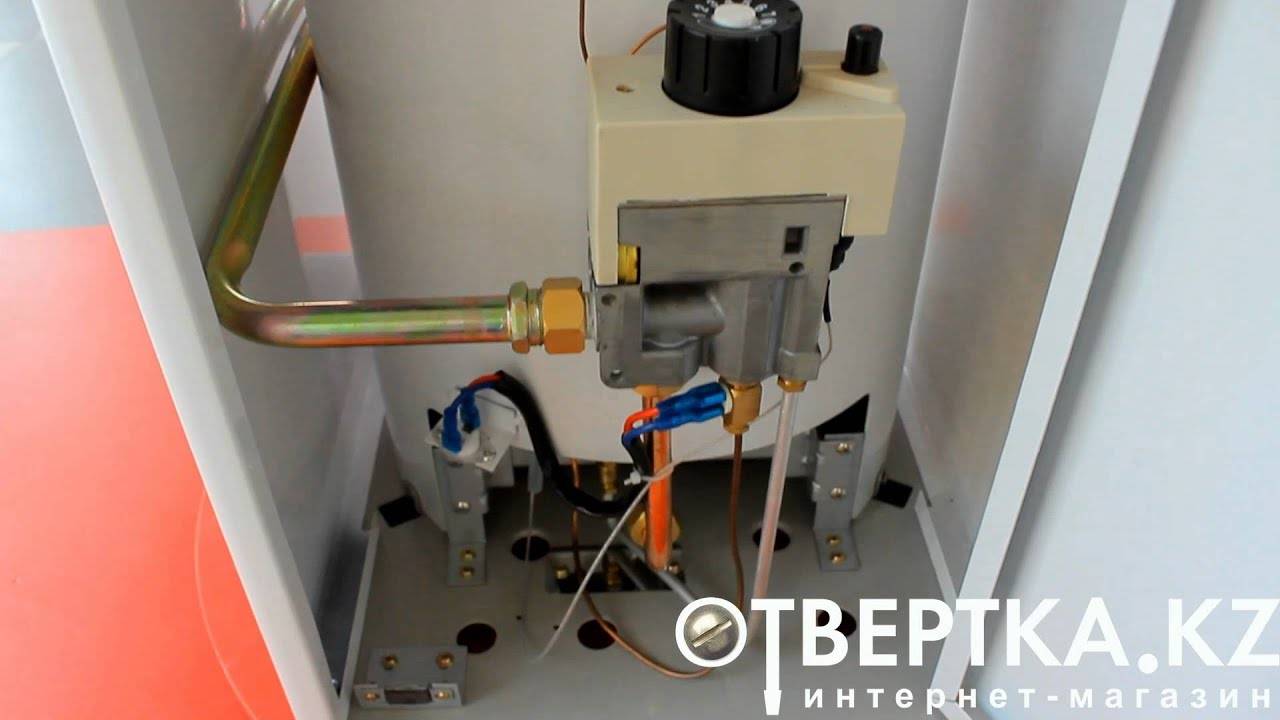

Possible breakdowns of the gas boiler

There is such a problem: after you release the start button, the igniter goes out. Such a malfunction is associated with a breakdown of the gas boiler automation system. But in no case should you use the boiler with the automation turned off. This is due to the fact that when the flame goes out due to a strong air flow or in the event of an unexpected cessation of the gas supply, the gas supply to the room may begin.

Thus, the igniter flame begins to come into contact with the thermocouple. The thermocouple heats up in 30-40 s, and EMF appears on its outputs. It is enough to trigger the electromagnet. Thus, the stem is fixed in the lower position. After that, you can release the start button.

The draft sensor is located in the upper part of the gas boiler, next to the pipe for removing combustion products into the environment. Such a device consists of a contact and a bimetallic plate.

If the pipe is clogged, then there is a sharp increase in its temperature. The bimetallic plate begins to heat up and the voltage supply circuit to the electromagnet breaks.Thus, the stem cannot be held by the electromagnet and the valve closes. This means that the gas supply will stop.

Radiator network: 4 ways of piping

Before you make heating, explore all possible arrangement options to choose the best option. The choice is influenced by the needs of the family and the features of the building. Now the following types of heating distribution for private houses are used:

- "Leningrad". It consists of a single pipe into which the batteries are embedded.

- Two-pipe. It is also called a dead end.

- Two-pipe associated, ringed.

- Collector.

If the building is two-level, it makes sense to use a combined heating scheme for a private house. This is when the system is collector on the lower floor, and associated on the upper floor. Leningradka and two-pipe works autonomously without connecting pumping equipment. The driving force is the convection movement of the liquid through the pipeline, when hot water is squeezed up, and after cooling it goes down.

One-pipe connection option

Along the outer load-bearing wall of each of the rooms, a route is laid along which the coolant from the boiler is launched. Radiators crash from time to time. Most often they are placed under the windowsill.

The peculiarity of such water heating is that the spent coolant from the battery is returned to the general circuit, mixed with hot water and sent to the next one. Therefore, the further the room, the more sections will be required, as the liquid cools down.

Also, when choosing, keep in mind that:

- The minimum diameter of pipes is 20 mm if they are made of metal. For metal-plastic, the cross section is from 26 mm, and for polyethylene - 32 mm.

- The maximum number of batteries is up to six.Otherwise, it is necessary to increase the cross section of the pipeline, which will increase the cost by 15-20%.

- It is difficult to regulate the temperature in the rooms. Turning the regulator knob on one radiator leads to a change in the temperature regime throughout the circuit.

This is an efficient heating of a country house with a total area of 60 to 100 square meters. But this is the most inexpensive way to heat, say, a dacha. Even if the building is two-story, there will be no problems if two circuits are assembled, on a separate branch per floor.

Two-pipe circuits ring and dead end

These two ways of organizing heating are different in that there are two circuits: direct and reverse. The first is designed to supply heated coolant to the batteries. The second is the withdrawal. Through it, water after cooling flows back to the boiler. And these systems differ from each other in the following ways:

- In the case of a dead-end option, the liquid flows to the last consumer through the previous ones, and then it is sent through a separate pipe for heating.

- The Tichelman ring loop assumes the simultaneous flow of supply and discharge in one direction along the radiators in series with a return to the boiler room.

Moreover, in the first case, the shoulder may not be one, but several. The second scheme involves two circuits interacting within a single line.

Despite the fact that the cost of such a system is higher than that of a single-pipe system, its popularity is due to a whole list of advantages:

- All batteries warm up the same way.

- The connecting pipes have a small diameter (15-20 mm).

- The number of points of consumption is not limited.

- The temperature regime is set for each room.

Self-assembly of dead-end branches is not difficult even for a novice builder.The ring system is mounted a little more difficult, since you have to “circle” the doorways. The track is mounted in the walls on top or in the floor under the threshold.

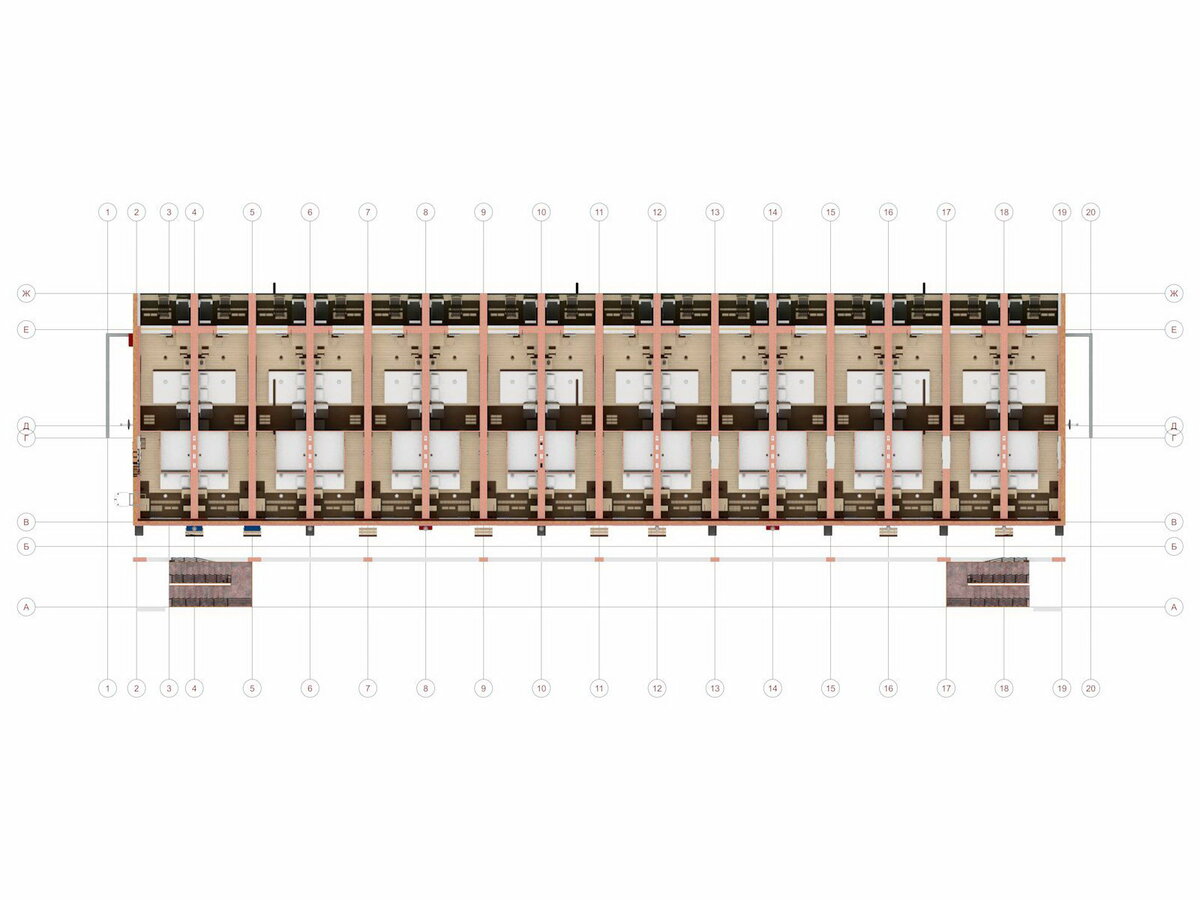

Collector system

To supply the coolant to consumers, a ray principle and a distribution comb are used. The latter is arranged under the floor in the depths of the building closer to the center. Two pipes are laid from the comb to the boiler. The same amount is carried out to each radiator. You can hide the wiring under a cement screed or between the lags in the ceiling

It is important that the comb is equipped with an air release valve.

In addition to the main advantages that are inherent in dead-end systems, this heating method has a number of additional advantages:

- Whatever the interior, the pipeline does not spoil it, because everything is hidden in the floor.

- Adjustment is simple and convenient, as the valves are mounted in a common distribution cabinet.

- Installing an electronic control unit fully automates the system, making it completely autonomous.

About the terms of operation of gas equipment

Replacement of gas equipment is carried out in the following cases: the expiration of the standard operating periods established by the manufacturer and prescribed in the technical passport or the operating periods established by the design documentation approved for gas pipelines.

If the life of the gas equipment has not expired, then one visit of the master in three years will be enough

It is important to note that the appearance is not an indication of the good condition of the equipment. Therefore, a performance check every three years is necessary.

If the service life of the equipment has expired, then the service organization must either issue an order to replace it, or offer the owner to send the equipment for diagnosis in order to extend the service life. The owner has the right to replace gas equipment that has worked out its service life, without preliminary technical diagnostics.

Diagnosis of gas equipment can only be carried out by specialized organizations that have received a license from Rostekhnadzor, therefore, before giving equipment for diagnostics, make sure that the organization has the appropriate license for this.

Based on the results of technical diagnostics, the issue of the possibility of further use of the equipment or the need to replace it is decided. At the same time, diagnosis does not give a 100% guarantee that the period will be extended. But the owner must take into account that if the service life is extended, then it is necessary to check such gas equipment at least once a year, respectively, the price for maintenance will triple.

New gas equipment can be selected and ordered from the City Engineering Service company, or purchased independently. But it must be remembered that, according to paragraph 10 of the Rules for the use of gas, approved by Decree of the Government of the Russian Federation of May 14, 2013 N 410, “the replacement of equipment that is part of the in-house and (or) in-house gas equipment is carried out by a specialized organization as part of the execution of an agreement on maintenance and repair of in-house and (or) in-house gas equipment.Independent replacement of the specified equipment by its owner without the involvement of a specialized organization is not allowed.”

Modern manufactured gas appliances and equipment are constantly being improved in terms of various degrees of protection.

To save your own and others' lives, health and property, it is important to update and repair gas appliances in a timely manner. In the pursuit of economic gain, never neglect safety