- Valve plumbing repair

- Types of needle valves

- What is a gate valve

- Types and benefits

- Gate valves of large diameters

- Mounting

- How to adjust the temperature in the apartment

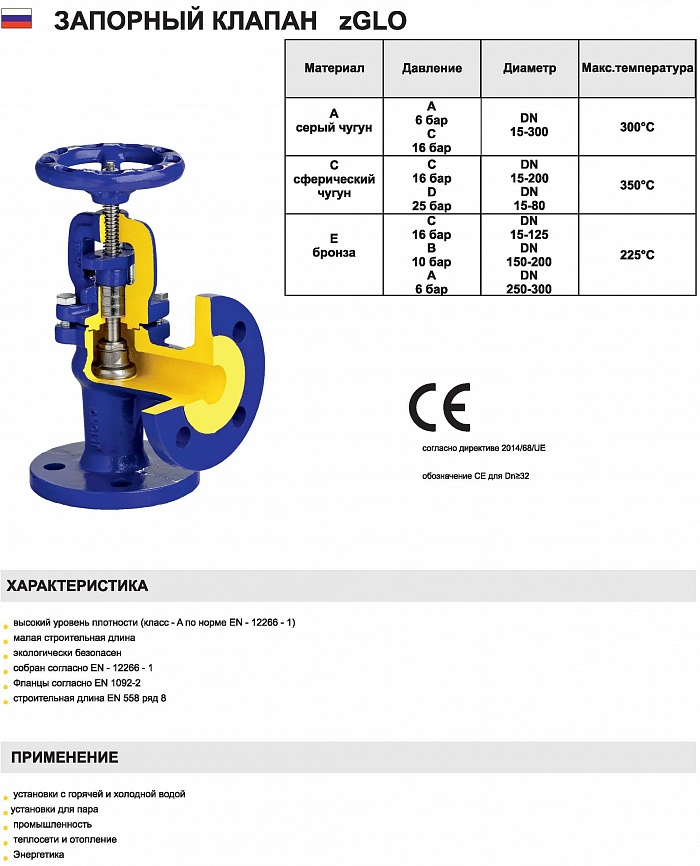

- valve material

- What is a ball valve for?

- Disadvantages of ball valves

- What are locking devices made of?

- How does a wheel valve work - what elements does it consist of

- Frame

- spool

- Cap

- Ways to adjust the heating system

- Valves and ball valves for connecting VALTEC plumbing

- How to choose a ball valve

- Device and principle of operation

- What kind of faucets/mixers are there?

- valve

- Single lever

- with thermostat

- Contactless

- Ball valve design and application

Valve plumbing repair

If the shut-off element of the valve is damaged, it is replaced with a similar, unworn or new assembly. To do this, the pipeline section is freed from liquid, blocking it from both sides. Then the valve-type shut-off element is dismantled. The ball valve is removed completely open-ended or On the flanges, the nuts are twisted in parallel and gradually - 3-4 turns on each.

First, you should check the serviceability of the seals, which are replaced when worn. Most leaks are due to deformation of gaskets and thread stripping due to improper installation. Then the body and seat are inspected.In the absence of cracks, the assembly is assembled again. The case cannot be repaired if mechanical damage appears on it. Growth to the pipeline requires its cutting and the need for further welding.

In this case, you will have to install a new or repaired water valve. An unprepared person should not undertake complex repairs because of ignorance of its features.

Shut-off valves create additional resistance, so blockages can form at the joints. It is not always necessary to remove the valves. Sometimes it is enough just to flush the pipelines by opening all the taps.

Replacing the oil seal can be done carefully with your own hands. To do this, turn off the water supply from the riser, disassemble the locking mechanism, replace the gaskets and lubricate the moving parts.

Types of needle valves

Shut-off needle valves according to the principle of operation are of the following types:

- shut-off, completely blocking the flow;

- regulating, providing precise adjustment of the passage of the working substance;

- balancing, used to redirect flows between connected pipe branches, allowing you to change the hydraulic pressure.

The locking type of structures is able to withstand extreme operating conditions, but their service life is minimal. Due to negative factors, corrosion processes can occur in them. They are used on the main canals.

Regulating products are installed on communications with low or medium operating pressures. Differ in the increased reliability, maintainability.

Balancing valves are used in complex communications with a complex branched network, where it is required to maintain a balance in terms of pressure, volume, flow rate and temperature. Used in heating systems.

Sealing type:

bellows, in which vacuum is used as a sealant, are distinguished by reliability and durability;

stuffing box, a special seal is used, while the location of the stem inside the valve is not important.

By design:

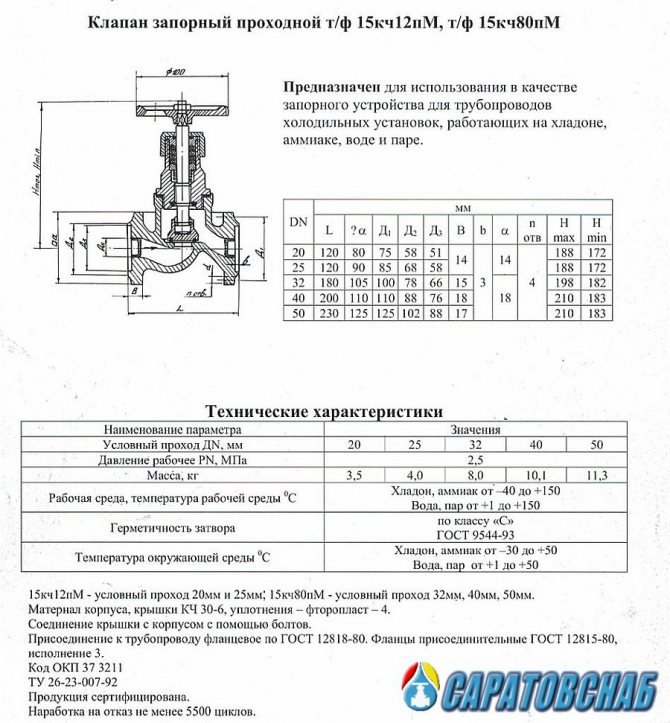

- through passage, installed on a straight section of pipes;

- angular, used to connect communications at a certain angle;

- poppet, for systems with transported liquid under pressure up to 340 bar, temperature up to +600C;

- straight-through, for transporting viscous media with minimal hydraulic resistance.

Body material:

- carbon steel - designed for pressure 160-400 bar, flow temperature from -400C to +2000C;

- stainless steel - used for gas and liquid media with temperatures up to + 4000C;

- high-carbon steel - medium pressure from 16 to 40 MPa, temperatures from -600C to +2000C.

Shut-off needle valve

What is a gate valve

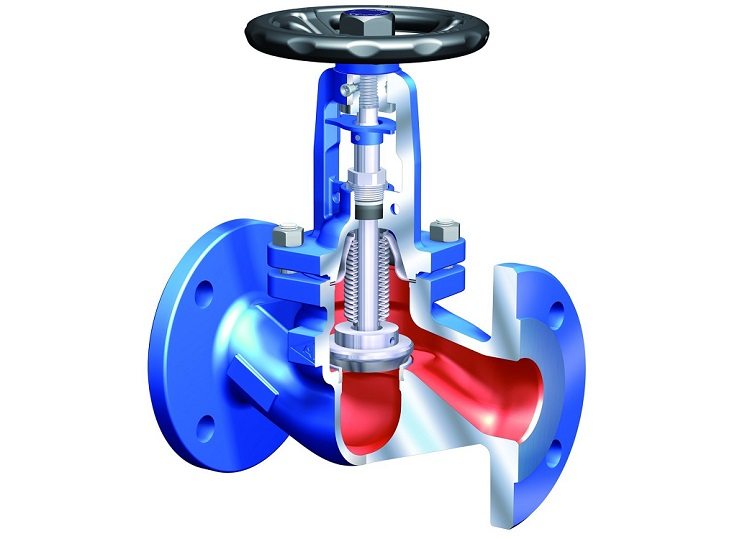

A gate valve is one of the types of valves that blocks, directs or regulates the flow inside the pipeline, preventing movement in part or in full, depending on the type of device and its tasks; while the locking element moves in a plane perpendicular to the flow.

According to the material used (whole or only body), valves are divided into five types:

1. Cast iron;

2. Steel (their subtype is stainless steel valves);

3. Aluminum;

4. Bronze;

5. Titanium.

This is interesting: How to unscrew the tap from the metal-plastic pipe

Types and benefits

These products are classified according to several criteria.

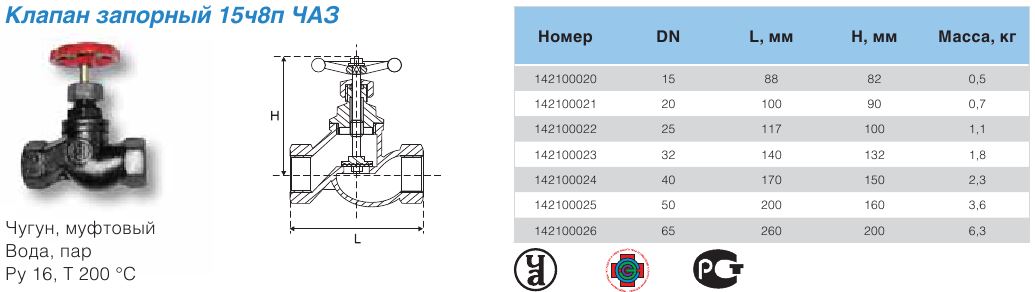

Depending on the method of installation in the system, shut-off valves are divided into:

Coupling. Designed exclusively for threaded mounting. Therefore, the ends of the shut-off valve are designed for internal or external threads. This type of valve is made of brass or steel. In the first case, it is used only in domestic pipelines. Moreover, both brass and steel valves are installed in pipelines with low working environment pressure - up to 15.792 atmospheres (1.6 MPa). There is another design of such sanitary fittings. So, today you can buy a brass shut-off coupling valve for installation on threaded compression fittings;

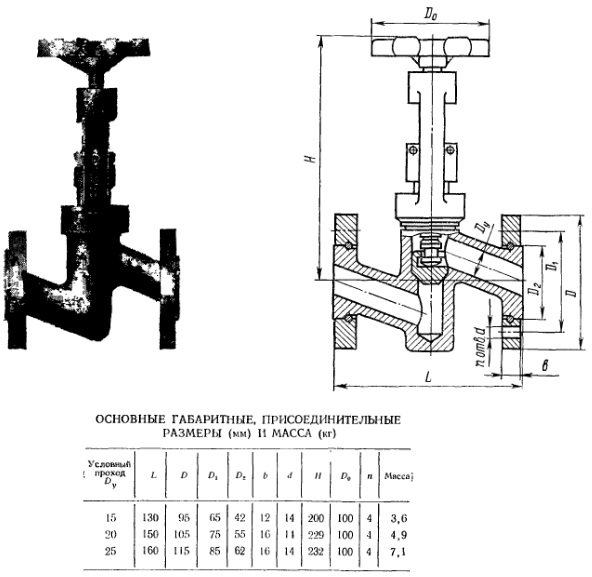

Flanged. The body of the flange part is made of steel or cast iron. Its installation is carried out according to a completely different scheme. The main ends of the body of this valve end with flanges. This design is more durable. Therefore, engineering communications with an average pressure level of 10 MPa are a priority area for application of a flanged shut-off valve. This feature allows the use of these devices in industrial and municipal main pipelines. Flange mounting is practiced on pipes with a diameter of 10 ≤ D ≤ 1600 mm.

The design of the ends is not the only difference between the above types of valves. A flanged valve is much larger than its boxed counterpart. In numbers, it looks like this: the size of a flanged valve can reach 300 mm, while the size range of coupling products ends at 63 mm.

Valves differ in the way of connection - threaded, coupling, flanged

In addition to these two groups of locking parts, there is also a third type - valves, the design of which is designed for welded installation. Their main ends are designed in the form of smooth branch pipes. The scope of the welded shut-off valve is industrial pipelines operating under pressure of more than 10 MPa.

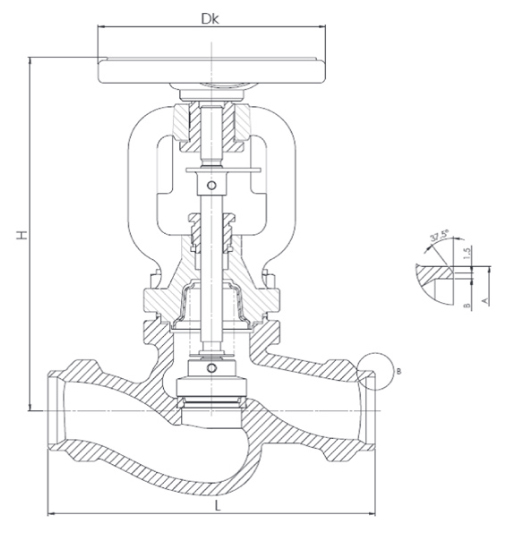

Depending on the design of the body, the valves are:

Corner. Connect two pipes perpendicular to each other. Angle stop valve has the following advantages:

- the efficiency and simplicity of the design make it easy to operate and repair the product.

- compared with the valve - a small building height;

- blocking the flow of working media is provided by a slow stroke of the valve.

Checkpoints. Such products are mounted on a horizontal or vertical pipeline assembly. The design of the shut-off valve is of two types: bellows (with a high degree of tightness) and stuffing box. Among the shortcomings of such a detail, experts distinguish:

- high hydraulic resistance;

- quite a lot of weight;

- the complexity of the hull design. This leads to the fact that, to facilitate manipulation, the through valve is often equipped with an electric drive;

- large building dimensions;

- the presence of a zone of stagnation. Rust particles can accumulate there, which usually leads to corrosion.

The bellows valve design provides a higher degree of tightness than stuffing boxes

The body of the stop-and-go coupling valve has 2 fittings, on which an internal or external thread is cut.In the latter case, the coupling is screwed onto the body, and its free end is mounted in the pipeline run. If there is an internal thread on the shut-off valves, the connection to the pipe is made by screwing the spur into the body of a straight-through steel or brass shut-off valve.

Direct-flow. In appearance, a device of this type is similar to a through valve, but longer and much larger in size. Its design is characterized by the fact that the nozzles are opposite to each other. The flow control in this shut-off valve is carried out due to the transverse movement of the passage element, when the seat of the device is aligned with the borders of the passage opening. The undoubted advantage of such valves is the absence of stagnation zones and low hydraulic resistance.

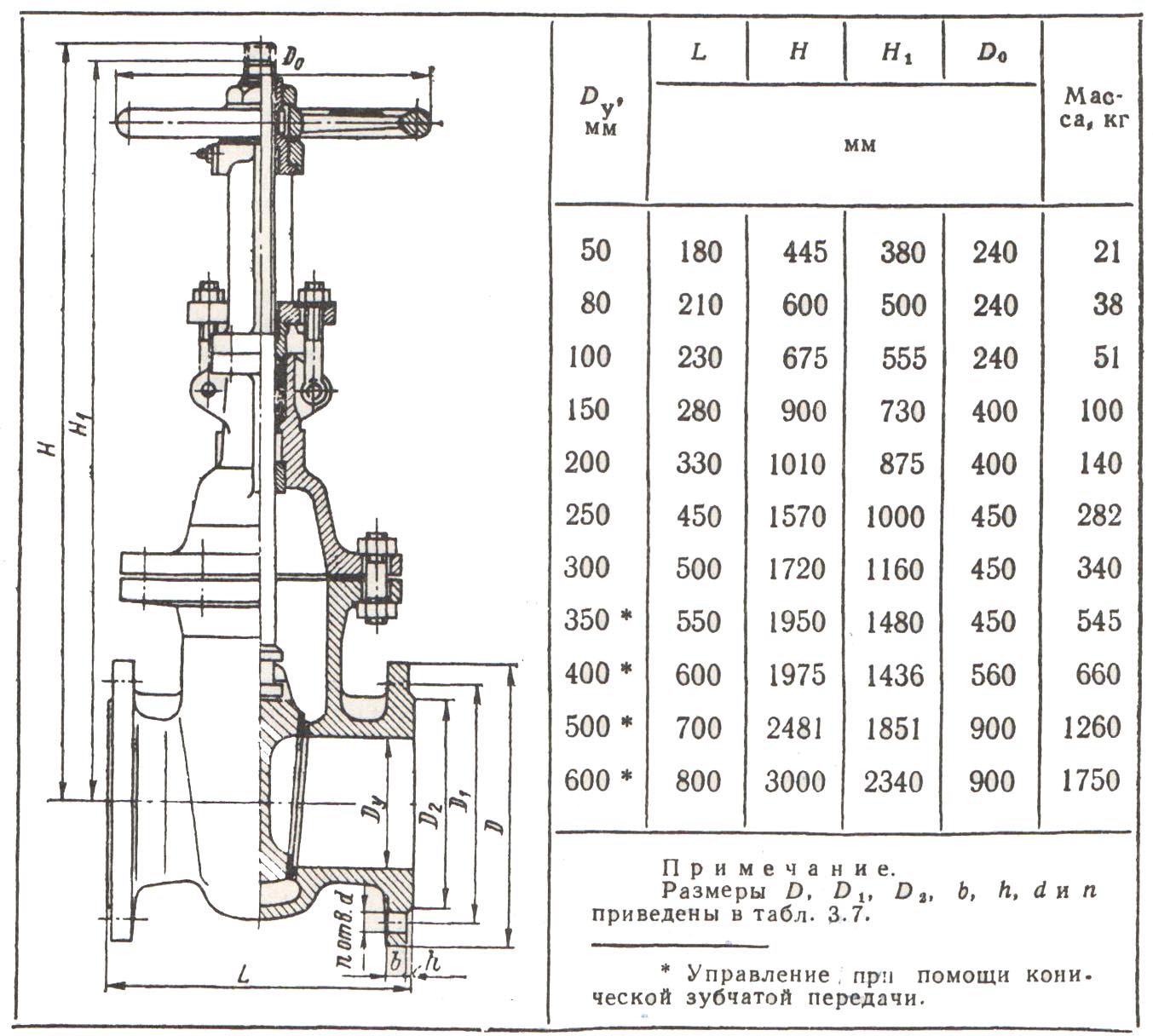

Gate valves of large diameters

Traditionally, pipes from 200 mm to 2000 mm are considered to be large diameter pipes, and appropriate valves are needed for these. These are used at large events where the flows are very strong, or in large cities and metropolitan areas for the same water supply or sewer system. Such locking devices are necessarily equipped with an electric drive or at least a gearbox. Unlike small valves, you won’t be able to simply close or open such a deadbolt with your hands, therefore, a system of mechanical movement of the valve is provided. It is the length of wide pipes, with a large diameter, that such valves fit perfectly and will be absolutely appropriate than in small ones.

Regardless of the valve diameter, they all have their own symbols, thanks to which you can find out all the information in a compressed form. For example, the diameter is designated as Du, and the climatic version as HL or U.

There are only two types of climate modification. Yes, the choice is small, but this is quite enough. "HL" is used at low temperatures (below -50 degrees Celsius). Gate valves of this type are not widely used, most often in permafrost zones or at great depths of cold seas. Type "U" has a wider application, as it is designed for moderate temperatures (from -30 to +30 degrees Celsius). It is these valves that can be seen in industries and enterprises throughout our country.

Cheap gate valves - the possibility of unstable operation of the equipment

Some of the prices for valves in good companies can be truly surprising, but you should not look for a much cheaper option. Prices directly depend on the material from which they are made, the country of origin, diameter and other parameters. The proverb has been circulating among the people for a long time: “Expensive, but cute, cheap, but rotten”, so here, if you buy a locking device for a much lower price than from other sellers, then do not be surprised that this equipment will not last long and can bring a lot of problems. Moreover, there were many cases when valves of a different material or inappropriate climatic design were sold and they failed after a couple of weeks, as they were used for other purposes, the fault was both inattentive buyers and deceiving sellers.

The most important thing when choosing and buying shut-off valves, as well as, in fact, any product, is to pay attention to the quality and the manufacturer, check all the data and documents. The main criterion when choosing a valve should be the diameter of the pipe on which it will be installed, otherwise the locking device may simply not suit you, and you will spend a decent amount of money and a lot of effort

Just be careful when choosing or contact specialists who understand this field and will help you make the right choice.

Mounting

The installation of a shut-off sleeve valve is carried out as follows:

- choose a place, preferably accessible from all sides;

- shut off the water supply in the pipeline. If the tie-in is carried out in a water pipe, then the network can be stopped using a valve on the riser of the building. For installation of the device in the heating system, temporary interruption of heat supply and water drain must be agreed with the management company;

- cut out in the intended place a section of the pipe, equal in size to the length of the valve;

- threads are cut at the ends of the pipes, with a diameter and pitch matching the same parameters of the valve nozzles;

- remove the remnants of chips;

- compact the prepared sections of the thread with linen thread;

- screw the valve onto the thread. When mounting, take into account the direction indicated on the device case;

- check the performance of the fittings and the tightness of the connections.

How to adjust the temperature in the apartment

- If the apartment is often hot enough to make you want to turn off the radiators, consider installing temperature controllers on the radiators.If the battery has a bypass, you can put a thermostat at the battery inlet that will control the temperature in the room.

- If there is no bypass, it is forbidden to install control devices, since with such devices you will set the temperature not only in your apartment, but also for all neighbors in the riser. In this case, you can replace the heating battery and install a bypass.

To shut off the heater, ball valves are required

For those who live in houses with central heating, questions about how to shut off the radiator usually arise in two cases:

- if warm weather has settled on the street, and the central heating has not yet been turned off, since the heating season has not officially ended;

- if necessary, replace, repair or paint the radiator, repair the wall behind the battery.

In this case, the following point should be taken into account: a coolant is constantly inside the battery. It is drained only in case of repair work in the system. This is due to the fact that the main part of the heating devices installed in old houses, as well as the house wiring, are made of steel.

This is due to the fact that the main part of the heating devices installed in old houses, as well as the house wiring, are made of steel.

The liquid inside the radiator contains a certain amount of oxygen in dissolved form, which eventually completely reacts with the metal, as a result of which corrosion stops.

It is impossible to leave the system or a separate heater unfilled for a long time - moisture remains on the inner surface of a steel or cast iron battery, which does not evaporate for a long time in a confined space. This significantly accelerates the corrosion process. Thus, the coolant is drained only in exceptional cases.

valve material

Here it is necessary to divide the valves into those that will be used in internal water supply networks, and those installed outside.

For internal networks, devices are made of bronze, brass, stainless steel and plastic. For outdoor use models from all of the above materials, as well as from steel and cast iron.

- Devices made of brass and bronze are the most expensive, but at the same time, the most durable. They have a small specific gravity, small dimensions, they can be installed both on a water supply system with cold water and hot water. More recently, only they were used in the heating system, because scale does not settle on the surfaces of brass and bronze appliances.

- Stainless steel valves also boast a long service life. But they are much cheaper than the first two models.

- Plastic valves are the cheapest with good technical characteristics. It is now used in all types of plumbing and heating networks.

What is a ball valve for?

This valve can not only block the flow of the internal medium, but also regulate its parameters - flow rate, pressure, speed, and even mix various media in the required proportions. However, there is an opinion that such a device cannot be operated with a partial rotation of the ball due to its increased abrasive wear.Plumbers advise owners of their own apartments to turn the handle of this locking element more often in order to avoid souring of its internal parts.

Ball valves for plumbing with a cantilever handle have a so-called "dead" zone, but this disadvantage is easily compensated by a faucet with a lamb handle. In the people it is also called "butterfly" or "bow". However, this does not in any way reduce the popularity of such plumbing equipment in everyday life. A ball valve is readily purchased and installed on heating radiators, dryers, underfloor heating systems, and so on.

Disadvantages of ball valves

- Due to the specifics of the design, ball valves have significant limitations in installation and use - such mechanisms can effectively and safely operate in a working environment with a temperature not exceeding 200˚С;

- Valves with a cantilever closing handle have a so-called "dead zone" when turning, which is not always convenient when installing equipment in a limited space. The use of a device with a butterfly handle will help to avoid this inconvenience;

- The water in the pipeline of cold or hot water supply cannot be perfectly clean, and contains all kinds of impurities. Most often these are mineral salts, rust and scale from welding. This debris and deposits begin to accumulate in the chamber of the mechanism if the valve has not been used for a long time. As a result, when you try to open or close the device, the handle may break, as plaque inside the tap will not allow the ball to rotate around its axis. It is easy to prevent this trouble - once every 2-3 months, turn the handle so that it does not become slagged;

- The most common phenomenon after some time of operation is that water leaks even when the mechanism is closed. This means that the surface of the ball was covered with salts or rust got into the chamber. In this case, the device is disassembled, cleaned, gaskets and seals are changed;

- Manufacturer's guarantees are not always a guarantee of quality, but you cannot check the product itself in the store under working conditions. The early appearance of a leak in new fittings often appears due to the poor quality of the stuffing box material. Replacing the stuffing box solves the problem, but it is better to operate the ball mechanisms at positive temperatures, preventing them from overcooling so that the stuffing box does not deform from temperature changes. In addition, when the body freezes, it can simply break.

What are locking devices made of?

Before you find out what valves are made of, you need to divide them into two types:

- installed in internal water supply networks;

- mounted on external water supply and gas pipelines.

If the product is intended for internal water supply networks, then brass, bronze, stainless steel and plastic devices are used. If the products are used for outdoor work, then the above materials are used for this, as well as additionally steel and cast iron.

- Plumbing devices made of brass and bronze are expensive options. However, their cost is justified by the quality and durability. Such devices are lightweight, small in size, and can also be installed not only on a water supply system for supplying cold water, but also hot. Such products are also used in heating systems, since scale does not settle on their surfaces.

- Stainless steel valves.Another good option that has a long service life. They are several times cheaper than brass and bronze devices.

- Plastic products are among the cheapest, but they are in no way inferior in quality to the above models. Their disadvantage is the possibility of installation only in plastic pipelines.

Cast iron and steel valves are popular for outdoor installations. For the manufacture of such products, cast iron and steel are used, which will significantly reduce the price of the device. After all, similar products made of brass and bronze will cost ten times more.

How does a wheel valve work - what elements does it consist of

Frame

Valves can be produced in several types of housings. In total, there are three options for sale:

- rubber;

- collapsible;

- hidden.

Let's analyze the types of valves in more detail.

The most common rubber "nipples". They can be installed on both stamping and alloy wheels. Usually withstand up to 4.5 atm. There are models of different lengths. Not afraid of temperature changes.

Collapsible consist of several components that are assembled during installation. Gaskets are included with the kit. Made of steel and chrome plated. Practically not afraid of exposure to reagents, temperature changes, water. Since they are made of metal, they can withstand heavy loads perfectly.

The hidden valve is made of metal. Technically similar to collapsible. Differs in the absence of a rod for pumping. The spool is located inside the element that secures the "nipple" to the rim. They are used on high-speed cars, recommended for installation on alloy wheels.

spool

The locking device in the valve is the spool.It is worth understanding how this constructive element is arranged. Technically, it allows you to connect cavities with different pressures, while not letting air through from one side to the other. The wheel nipple of a passenger car is somewhat different from a similar device for bicycles, although it has a general principle of operation.

The spool operates due to the displacement of the movable element relative to the main part. As a result, it can let air into the tire when inflated, but does not let it back at all once the inflation is stopped. If necessary, by pressing the spool, you can bleed some of the air.

There are the following types of spool.

- for chamber tires;

- standard for tubeless tires;

- reinforced, recommended for use on sports cars.

Cap

The cap is often considered a decorative element, although it has an important function. The cap protects the nipple from dirt. Cleanliness allows the valve to perform significantly longer. Therefore, be sure to look for the presence of caps on the wheels. They are attached by simply screwing onto the “nipple” bar.

Now on sale you can find plastic and metal caps. Often drivers prefer to buy metal caps, especially if the rim is chrome plated. In fact, it is better to choose the plastic option. Metal can freeze to the valve in winter, or simply boil under the influence of reagents. This will necessitate a complete replacement of the nipple.

Ways to adjust the heating system

Heating system with control valves

There are several ways to change the characteristics of heat supply.Timely hydraulic adjustment of the heating system is necessary to stabilize the pressure in certain areas and the entire scheme as a whole. Temperature correction serves as a tool for changing the degree of air heating in a particular room. Most often, a crane is used for this. for adjusting the heating temperature.

All of the above characteristics largely depend on the operation of the boiler. However, to normalize the system parameters, it is necessary to install additional components. Depending on the function, they are divided into the following types:

- Temperature. Serve for partial or complete blocking of the coolant flow in radiators or in a separate circuit. With the help of taps, a thermostat or mixing units, the heating batteries in the apartment are adjusted;

- Pressure. Temperature differences between flow and return can cause pressure surges. This will unbalance the system, which will worsen its performance. To eliminate this problem, hydraulic arrows are mounted, as they do collector pipework.

In practice, timely adjustment of taps on heating radiators reduces energy costs. Also, with the help of control valves, you can change the degree of heating of the air in the room.

The actual performance of the heating system must match the calculated ones. In this way, the number of adjustment elements can be reduced.

Valves and ball valves for connecting VALTEC plumbing

In the modern plumbing market, the VALTEC brand stands out for its well-established service for information and technical support of its products and the widest range of valves for water supply and heating systems.Especially popular are VALTEC valves and ball valves, which will help solve a huge range of problems in connection and comfortable use of plumbing fixtures, provide the necessary conditions for an urgent interruption of water flow.

Brass, resistant to dezincification, is used as a structural material, which provides excellent resistance to abrasive and corrosive processes even in the presence of a poor-quality working environment. Nickel and chromium plating give valves and ball valves for connecting VALTEC sanitary ware an attractive appearance, high performance and additional protection against the influence of aggressive factors of the external and internal environment.

VALTEC valves and ball valves are equipped with convenient threaded connections of various types ½", ¾" or 1". To solve special engineering problems, there are models with a union nut and mini taps with a flag handle for internal or external threads. Household tee valves will create a reliable hermetic connection with any plumbing fixture, help to shut off or regulate the flow of water, provide the connection of household and heating appliances (washing machines, dishwashers, instantaneous water heaters, etc.). A significant advantage of these products is their good maintainability. VALTEC also offers a wide range of household tees based on ball locking mechanism.

The ball valve design makes it easy to completely shut off or open the flow of water with a simple 90 degree turn of the handle.For reliable sealing and long service life of the tap, the ball is covered with a durable layer of chrome and additionally polished to give the surface an ideal shape and smoothness. Installation of plumbing fixtures to a cold or hot water supply network is conveniently carried out with the help of flexible pipes and VALTEC corner household taps with a built-in strainer. Aesthetic and ergonomic corner valve will allow you to conveniently install the faucet on an open sink, organize the necessary direction of the flow of water to the drain tank and, if necessary, reliably interrupt it.

How to choose a ball valve

When starting the construction of a water supply or heating system, you should know exactly the sizes of pipes and fittings, which ball valve is better. You should start by creating a pipeline layout. According to it, you need to calculate the number of valves. Then buy valves or ball valves.

In places where the flow is blocked, at the beginning of the branches of the heating system, valves are used. They simply block the flow at the right time. At the end points of the pipes, at the outlet of the water, it is better to install ball valves.

The choice starts with the diameter. Fittings for the house fit threaded. Then you should choose the material of the case and the color of the handle:

- yellow, black - gas;

- blue, blue - cold water;

- red - hot water.

Faucets usually have shiny steel or decorative handles.

Large selection of ball valves

Device and principle of operation

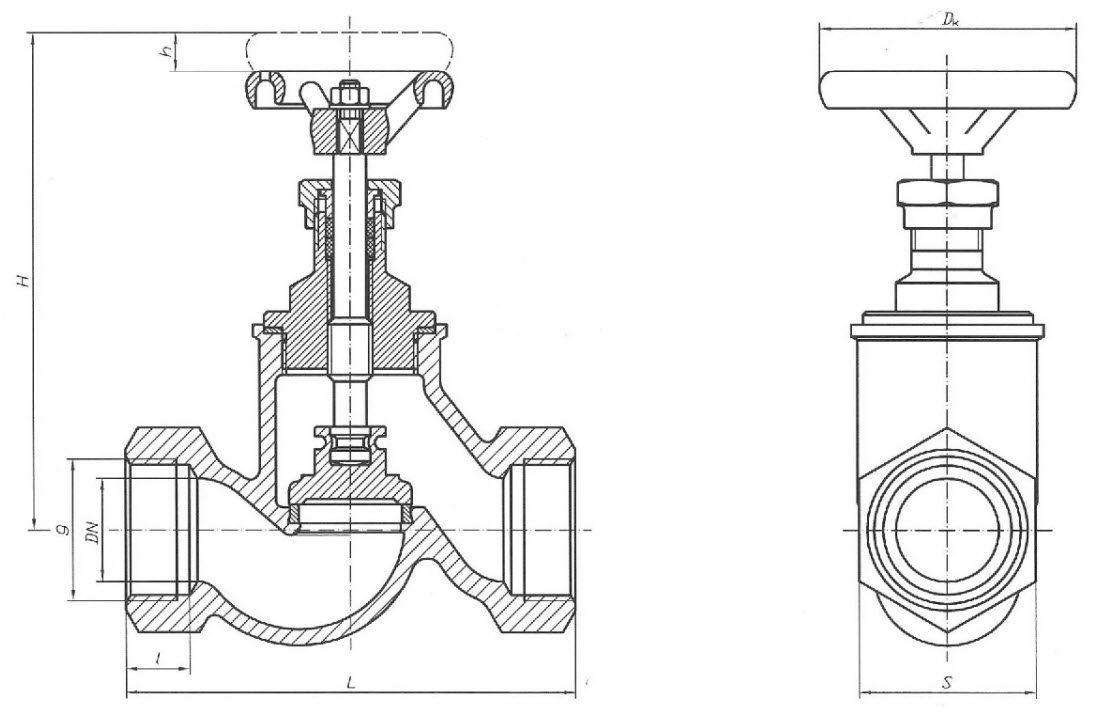

The needle valve structurally consists of the following parts:

- cast body;

- rod with a tip in the form of a cone;

- handle fixed on the rod with a nut;

- screw cap on the case;

- seals;

- adjustment screw.

Device and principle of operation: when the handle is turned counterclockwise, the rod moves along its axis along the thread cut inside the body, upwards, opening the through hole. In reverse rotation, the flow is blocked. Due to the conical end of the stem, a large area of contact with the seat is provided, the flow is regulated smoothly and precisely.

Inside the zigzag channel inside the body there is a saddle, which includes the stem end when the spindle is turned clockwise. A needle faucet can have not only a hard tip, but also a soft one.

To increase the service life of the stem thread, a special chrome coating is applied to its surface.

Crane control can be manual or mechanical. To automate control, it is enough to connect the rod to the electric drive.

What kind of faucets/mixers are there?

Depending on the purpose, there are 4 main types of water taps: valve, single lever, thermostatic and sensory.

valve

These mixers are considered the most common appliances.

They are of two types:

- with one valve. Such faucets can supply only one type of water - cold or hot. It is mainly used for installation in the kitchen or washbasin. The body of a single-valve faucet is made of an alloy of copper or brass. The locking mechanism - in the form of a ceramic or worm valve - axle box is driven by a valve;

- with two valves. Their device includes a chrome-plated brass body, two valves that control the cartridges (faucet - bushing).

Due to the operation of the cartridges, the pressure and temperature of the water are regulated.The spout, depending on the modification of the mixer, can be integral with the body (not swivel) or freely rotate in different directions. Two-valve mixers are designed for mixing hot and cold water;

Single lever

In a single-lever mixer there is only one handle (lever), with which the intensity of the supply of cold and hot water is regulated. The pressure can be increased by lifting the handle up.

with thermostat

This is an innovative type of device. Adjustment of temperature and intensity of water inflow occurs when a certain indicator is set on a special thermostat scale.

Contactless

The device of such mixers includes special sensors, the principle of operation of which is based on the reaction of infrared rays to heat and movement.

Therefore, as soon as hands are brought close to this mixer, it immediately works. Most often they can be seen in public places: bathrooms of airports, railway stations, entertainment centers, healthcare facilities, etc.

Ball valve design and application

Having dealt with the design features, you can understand the principle of its operation, which determines the operational characteristics. The ball valve consists of the following elements:

- Body part. The locking mechanism is a continuation of the gas supply pipeline system, therefore it must have a sealed housing. Most often, the body is made of steel or brass.

- The structure has a connection pipe section. This element may be threaded or welded to the pipeline.

- The throat part of the structure is designed to pass the rod.

- The connecting rod is designed to provide connection between the handle and the movable locking element, represented by a ball.

- Washers contraindications.

- The main element is the locking ball. It is this element that directly shuts off the gas supply.

- Saddle. In order for the locking ball not to move, a saddle is installed. It is held in place with a ring stop.

- There is an o-ring and a spring, a flange and a ring. All these structural elements are responsible for tightness.

- The locking mechanism is controlled using a special handle. It can have a variety of sizes, as a rule, it is painted red.

- The handle is fixed with a special nut.

- In order for the ball to be set with high accuracy in two positions, closed and open, a stopper is installed, represented by a handle stroke limiter.

Pretty simple design easy to use. The locking mechanism is represented by a steel hollow ball. This structural element has a through hole, which has a diameter equal to the diameter of the connecting segment of the two parts of the locking mechanism. The principle of operation is as follows:

- The movable structural element is represented by a handle that can be rotated around an axis.

- The handle transmits motion to the ball.

- The ball has a through hole; when rotated 90 degrees, the solid wall is replaced by a hole.

It should be borne in mind that manufacturers do not recommend putting the handle in a half-open position. The half-open state causes accelerated wear of the main locking element of the structure.