- Control and measurement of rarefaction in the chimney

- Thrust calculation

- What is a fireplace extractor, and why is it needed?

- When should it be applied?

- Pros and cons of application

- What chimneys are suitable for?

- Description of the ventilation system in the toilet

- Forced

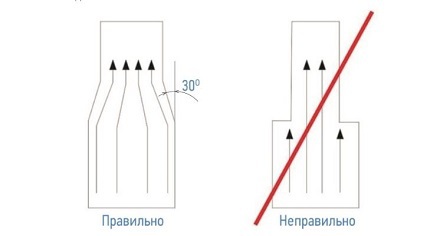

- Installation of a chimney on the roof

- Norms according to GOST

- Required Tools

- deflector mount

- Chimney options

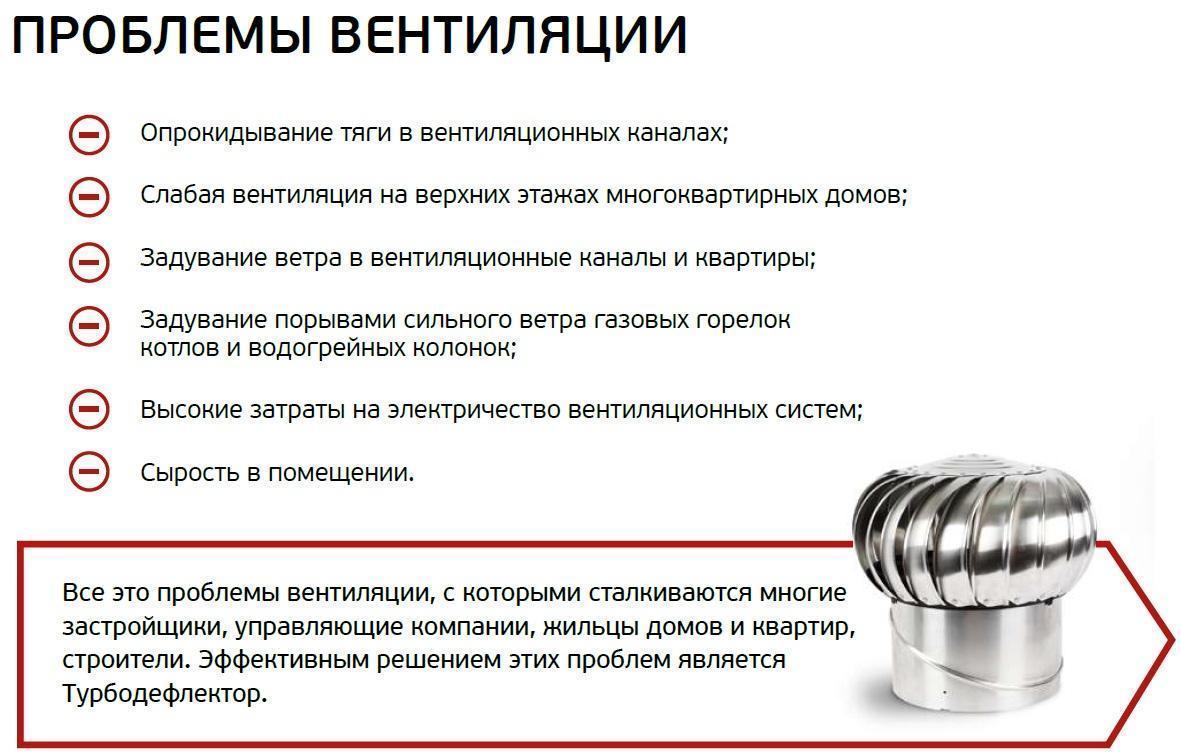

- Pros and cons of turbo deflectors for ventilation

- System with recuperation and processor control

- How to make a traction stabilizer with your own hands

- How to increase traction in an already mounted channel

- We recommend reading:

- Independent construction of the foundation. What needs to be considered?

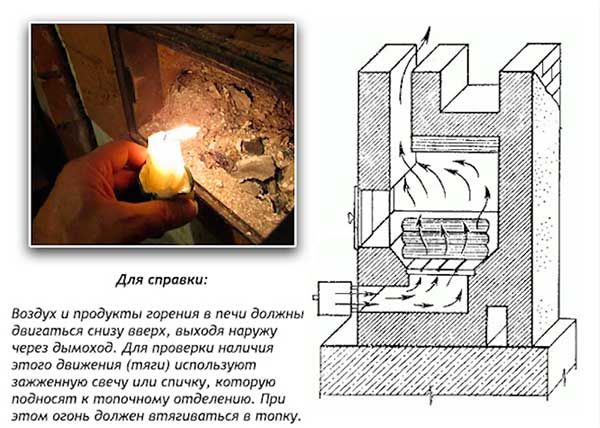

- Where to start checking the furnace

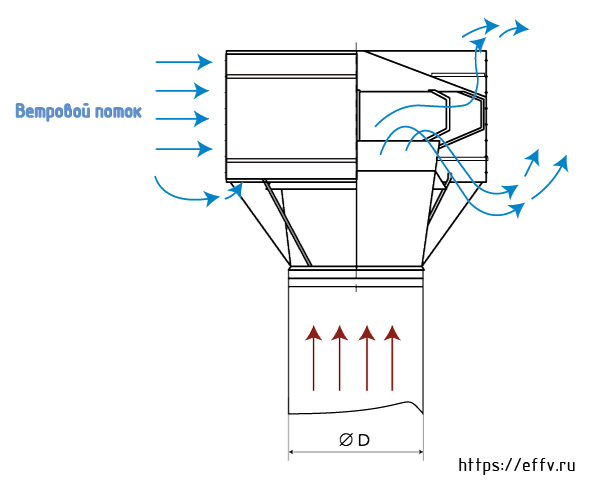

- Special adjustment devices

- Photo gallery: draft control devices

Control and measurement of rarefaction in the chimney

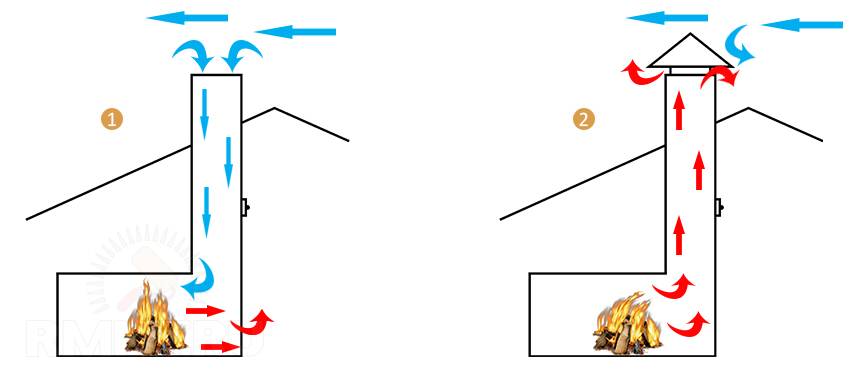

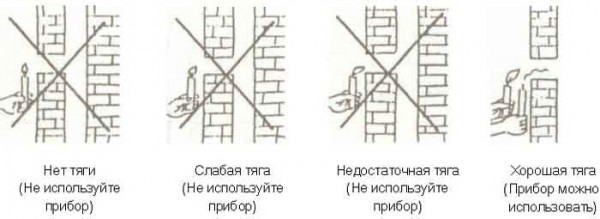

The usual way to check if the chimney is functioning is to substitute a lit match or lighter to the chimney channel. Sometimes a piece of toilet paper and a smoking cigarette are used instead.

If a light or smoke is directed inside the chimney, there is a rarefaction of the air. If the flame is completely motionless, then this means that there is no thrust.

Too much traction can even extinguish a burning match

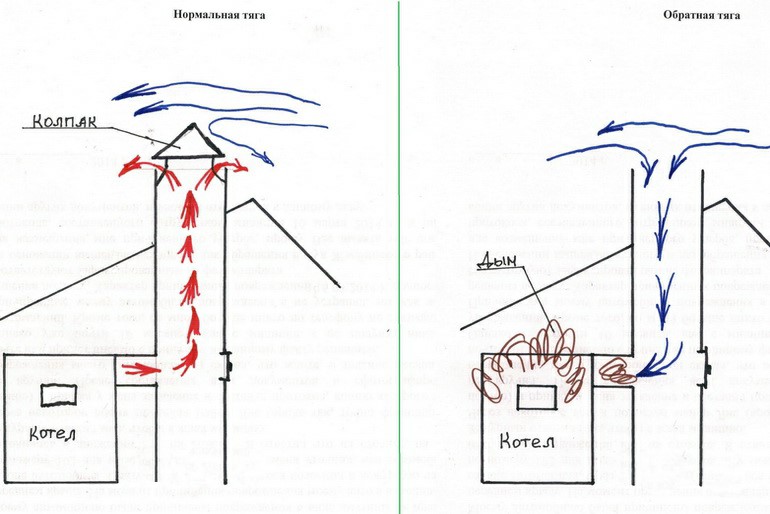

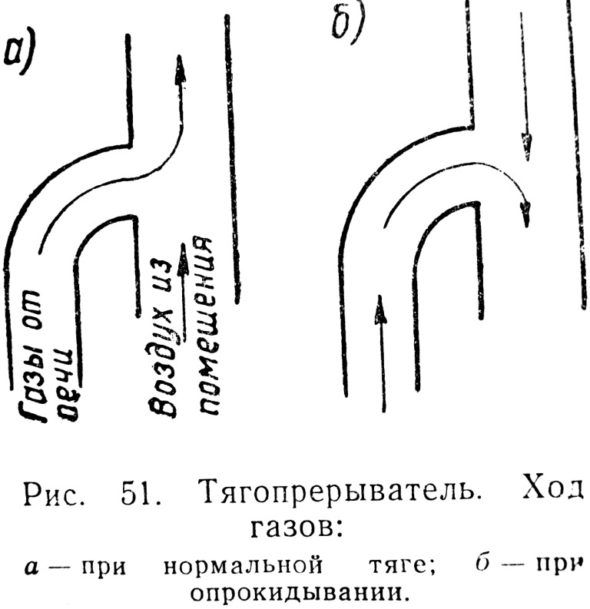

If a light or smoke is directed away from the channel, that is, into the house, it is recognized that there is rarefaction of the air, but it is violated. This phenomenon is called overturned draft, which adversely affects the operation of the heating system.

The normal course of gases when the thrust is overturned is violated

Thrust calculation

Since the thrust is created due to the pressure difference, it is calculated by the formula ∆P = C∙a∙h (1/T0 - 1/Ti), where ∆P is the pressure difference in Pa, a is the atmospheric pressure in Pa, h is the height of the pipe in metres, T0 is the absolute outside temperature in K, and Ti is the absolute inside temperature in K. C is a coefficient which is assumed to be 0.0342 in the calculations.

Depending on the obtained value of ΔP, the following levels of air rarefaction are distinguished:

- less than 2 Pa - 1st, 2nd or 3rd;

- exactly 2 Pa - 4th;

- more than 2 Pa - 5th or 6th.

Trying to find out for yourself what the traction force is is not worth it. It is better to use heating equipment so that there is no need to check according to formulas and devices.

What is a fireplace extractor, and why is it needed?

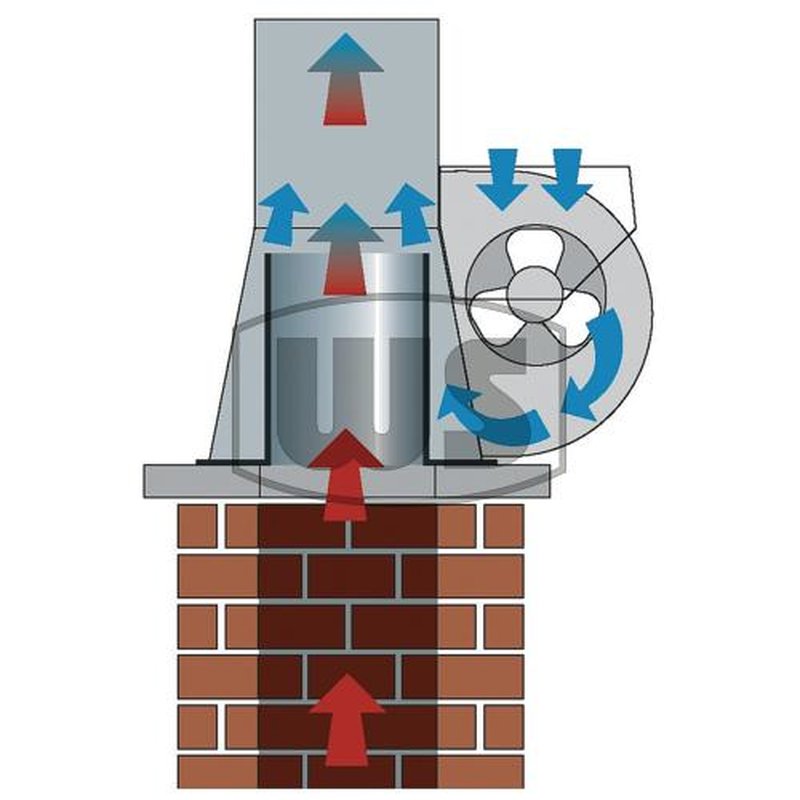

This device is a duct fan with an electric motor, which is mounted at the outlet of the chimney. The principle of operation of the device is simple - during the operation of the fan, draft in the chimney increases.

Simply put, this device is a forced exhaust system, but they are not designed for full exhaust. They are used only to improve the (episodic) natural draft in the pipe, or for the duration of its repair.

Chimney hoods

Chimney hoods

For example, a fireplace smoke exhauster is started as needed - for a time when natural draft drops to a certain value.

When should it be applied?

There are several indications for the use of a chimney exhauster, which are somehow related to draft disturbances in the chimney.

Indications for use:

- When there is no draft in the chimney at all (for example, due to errors in the construction of the chimney, or because of its weakness in terms of exhaust). This often happens with the wrong selection of the height of the chimney.

- In cases where the chimney is not correctly positioned relative to the roof ridge.

- If a taller building was built nearby and, accordingly, the draft dropped because of this (due to the obstruction of wind flows).

- In cases where the chimney needs repair work (slots, cracks, any protruding elements have appeared).

- In cases where the diameter of the chimney was chosen not large enough, or vice versa - too large.

Pros and cons of application

Any device of this type has both a number of undeniable advantages and a number of disadvantages. This is also true for smoke exhausters.

Among the advantages of such a device, it is worth noting:

- you can not repair the chimney "right now" - the smoke exhauster allows you to postpone repair work indefinitely;

- the ability to create the necessary traction due to its amplification, in any weather;

- it is possible to significantly reduce the harm from the formation of condensate due to the fact that the thrust will be increased, and as a result, less condensate will form;

- the ability to turn off the fan at any time when there is sufficient natural exhaust from the chimney.

List of disadvantages of using such a device:

- it is not always possible to install a smoke exhauster;

- additional consumption of electrical energy (however, in fairness, such fans consume relatively little electricity).

What chimneys are suitable for?

You can use a smoke exhauster on chimneys for a stove, fireplace, various boilers (gas and solid fuel)

But there is one important condition - you can mount such a product only on chimneys in which the temperature does not exceed +600 degrees

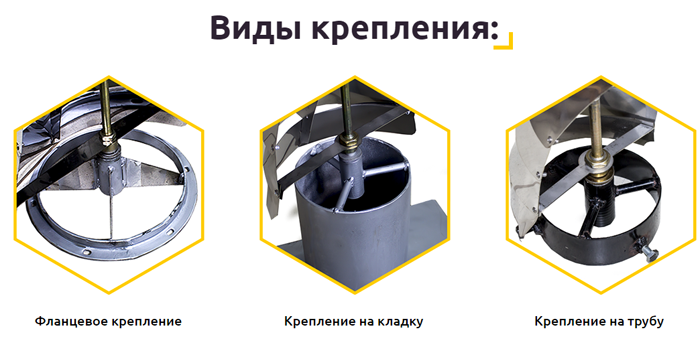

Types of fastening of chimney hoods

Types of fastening of chimney hoods

This also applies to heat-resistant models. Although they are designed for high-temperature operation, they are not too large (therefore, they are used for a stove or fireplace, but not for industrial purposes). Moreover, +600 degrees is a very good indicator, many heat-resistant smoke exhausters are even designed for temperatures up to +350 degrees (average value).

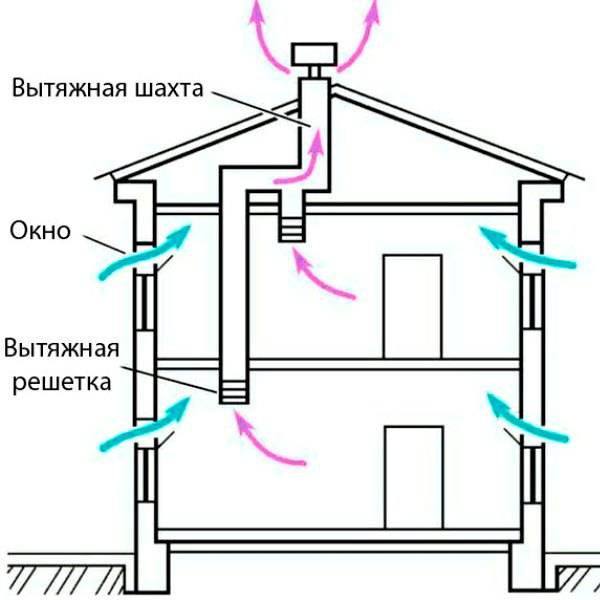

Description of the ventilation system in the toilet

For best results, it is necessary to equip ventilation in both the booth and the cesspool.

There are two types of hood:

- natural;

- forced or mechanical.

Natural works thanks to the draft formed by the air flow. Warm air rises and cold air accumulates at the bottom. If you make two holes: one from above, the second from below, then the flow of cold air coming from the street will displace warm air with methane vapor through the upper passage.

To ensure the best traction, it is necessary to use a pipe, while its diameter must be at least 15 cm and a height of 2–2.5 meters. In general, it is considered optimal when the pipe protrudes at least 1.5 meters beyond the roof level.

Ventilation in the country toilet

Forced ventilation involves the connection of a fan that will promote air circulation inside the cabin. In order for the toilet to have fresh air, it is necessary to have a window for ventilation.You can combine both types of hood in the booth for best results, but it is strictly forbidden to install a fan in a cesspool - only a chimney.

Forced

It is possible to increase the temperature throughout the entire volume of the material only when fuel is burned. But this must be done according to a strictly defined algorithm in order to avoid breaks in the structure of the solution. Before you dry the stove after laying, you need to stock up on dry hardwood firewood. Logs should be even and no more than 4 cm wide.

The algorithm by which the first firebox will pass is represented by just a few points.

- The blower door opens slightly so that its maximum gap is 1 cm.

- The damper in the chimney, which blocks the movement of the flow, must be open ½. It is impossible to open it “to the whole”, since we need to get warm. With the valve fully open, we will burn firewood “for nothing”.

- The channels through which the secondary air circulates are not used. All relevant doors are closed.

After complete combustion of firewood, close the main valve, leaving a gap of 1 cm. The blower door does not need to be touched, and the secondary supply doors also open slightly. In this position, the oven dries until the next day. The subsequent stages follow an identical scenario. The difference lies only in the mass of fuel burned. At the first start, you can heat the stove with two kilograms of firewood, with each subsequent session, the mass increases by 1 kg.

Fire in the furnace

It is impossible to determine exactly how many days forced drying should be carried out. Its effectiveness can be checked by the absence of condensate on the firebox door. This will mean that all the moisture has come out.Many craftsmen notice that it takes about 10 days to prepare a brick oven for full use, and in winter these periods may increase.

Good to know: Which brick oven is the best and most economical

Installation of a chimney on the roof

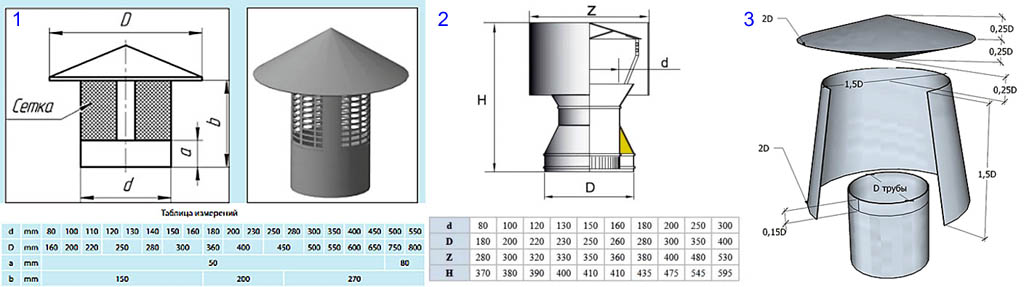

There are two options for installing the deflector: connecting directly to the chimney and mounting on a piece of pipe, which is later put on the chimney. The second method is considered the best in terms of convenience and safety, because the most troublesome stage of work is done on the ground, and not on the roof.

Norms according to GOST

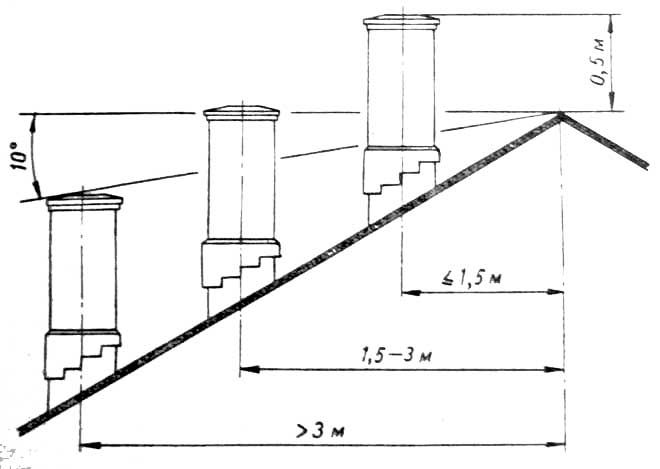

Excerpts from the current regulatory documents regarding the installation of a deflector on a pipe inform about the following:

- any nozzles on the smoke channel must be mounted in such a way that they do not block the path to the combustion products of the fuel;

- on a flat roof, the mouth of the pipe is supposed to be placed above the fences;

There must be free space around the mouth of the pipe

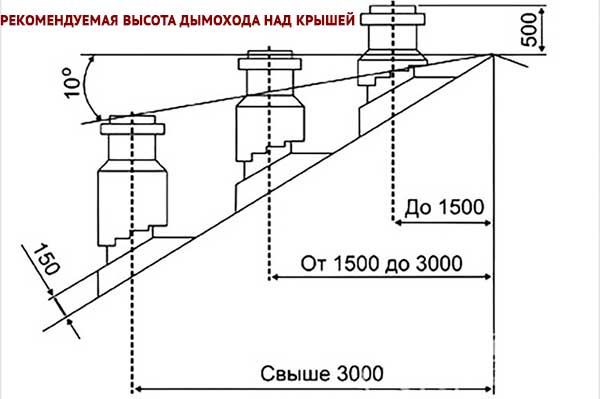

- on a roof with slopes, the chimney head must be located above the ridge, if the space between them is less than one and a half meters, or at the level of the ridge, when the gap from the pipe to the highest point of the roof varies within three meters;

- the deflector must not be mounted on a site where an aerodynamic shadow is created due to neighboring buildings;

- the body of the device must be well ventilated regardless of the direction of the wind;

- rotating deflectors are not suitable for stove chimneys in houses built in areas with cold winters;

- installation of a round deflector on a brick chimney involves the use of special adapter pipes.

Required Tools

To install the deflector on the smoke channel, you need to find some tools and fasteners:

- electric drill;

- open-end wrenches;

- threaded studs;

- nuts;

- clamps;

- two ladders (one for climbing to the roof, and the other for moving along the roof).

In addition, to install the device on the chimney, you will need a piece of pipe. Its diameter should slightly exceed the size of the smoke channel.

deflector mount

The chimney is connected to the pipe, performing certain tasks:

- On the prepared pipe section 10 cm from the edge, the points are marked where you need to drill holes for the fasteners. Similar marks are left on a wide section of the diffuser.

- Holes are made in the pipe section and diffuser with a drill. The parts are temporarily connected to each other, checking if the top and bottom holes match. If this is not observed, then the products are recognized as defects, because the fasteners cannot be inserted evenly.

- Studs are inserted into the holes. On both sides, both on the diffuser and on a piece of pipe, the fasteners are fixed with nuts. They are twisted evenly in order to protect the product from deformation.

- With the manufactured device sent to the roof. The structure is put on the smoke channel and tightened with clamps.

In the case of mounting the deflector on a brick chimney, you will have to arm yourself with nails and a hammer

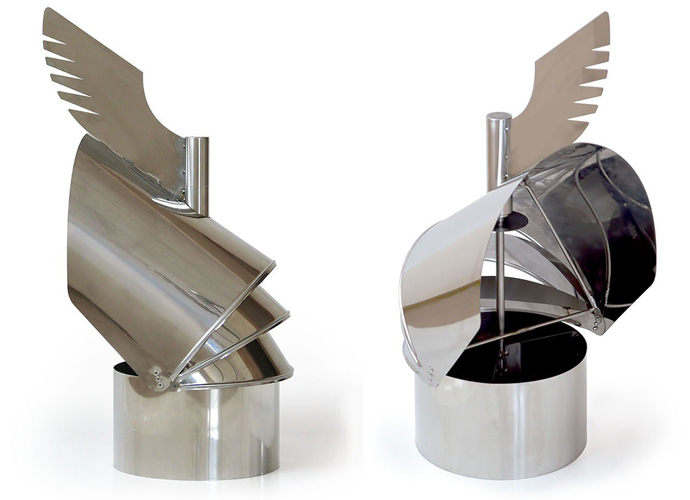

Acting as described above, you can mount any device, except for the weather vane deflector, since its design is rather non-standard.

In the case of using a device with a wind rose, 3 holes are created in the smoke channel with a drill. The holes are made at the same level in order to insert bolts into them a little later. These fasteners are immersed in holes when the annular part of the deflector-weather vane is placed in the chimney section.An axle is inserted into the bearing in the form of a ring, a cylinder, a device web and a cap are alternately attached to it. The weather vane deflector elements are combined with brackets or rivets.

The deflector can be confidently called a useful device that has a positive effect on the draft force in the chimney and the functioning of heating equipment. It is relatively simple to make and connect a fixture to a pipe, you just need to be “savvy” in choosing the type of deflector.

Chimney options

If all chimneys are very similar in principle, then the greatest and most obvious difference is found in the material.

The traditional material for chimneys was and remains brick. It is still popular, although other solutions have appeared.

If you are installing a brick oven, then the chimney will most likely be made of brick too. But nothing prevents a brick slab from making a transition for a chimney from a pipe.

Chimney pipes are:

- metal;

- Multilayer sandwiches;

- Asbestos-cement;

- From ceramics.

Chimney sandwiches are gaining popularity. The structure consists of 2 steel pipes, one inside the other, and the gap is filled with heat-insulating material, usually basalt. During operation, a neat pipe is obtained from the outside. Such a chimney is very quickly erected.

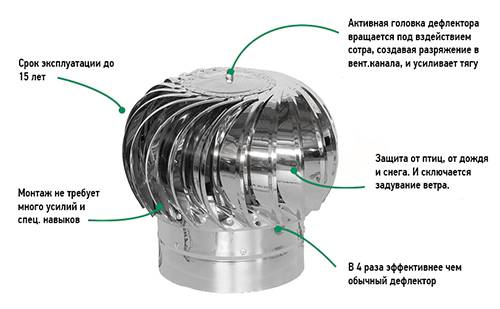

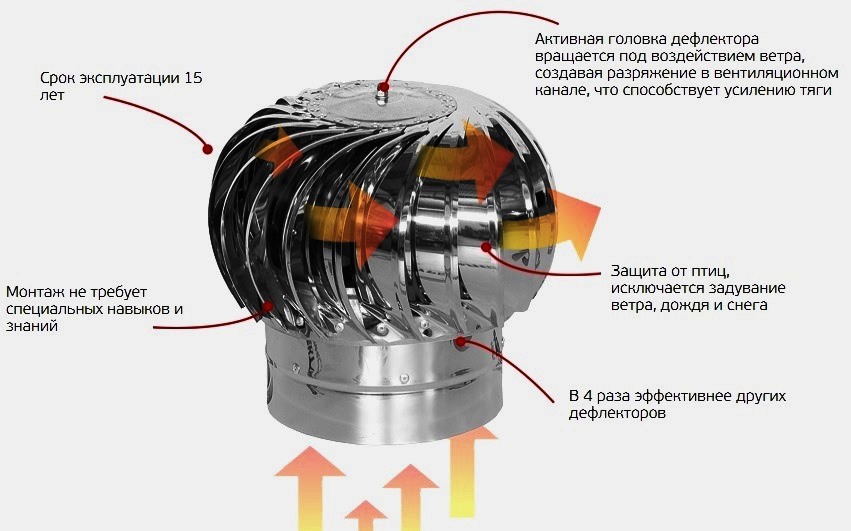

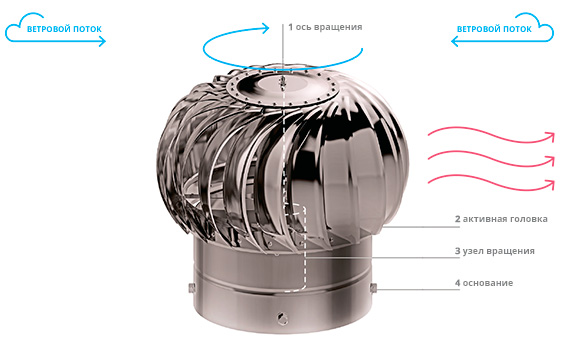

Pros and cons of turbo deflectors for ventilation

The device does not require connection to electricity, as it works under the influence of wind

The device does not require connection to electricity, as it works under the influence of wind

Devices help to increase air exchange, prevent the appearance of condensate in the space between the elements of the roof.

The turbofan on the chimney has advantages in application:

- does not require connection to electricity;

- has a long service life, depending on the material, it works from 10 to 15 years;

- the channels where the rotary deflector is located are less often cleaned due to the exclusion of accidental ingress of objects;

- compact and lightweight devices do not put a load on the pipe;

- installation does not require special skills;

- equipment almost does not freeze in frost due to constant mobility.

There are some drawbacks to using a turbo deflector. Due to the strong draft in the channel, the burners of the gas boiler are sometimes blown out. The turbine stops in completely calm weather, with increased relative humidity to the limit or severe frosts.

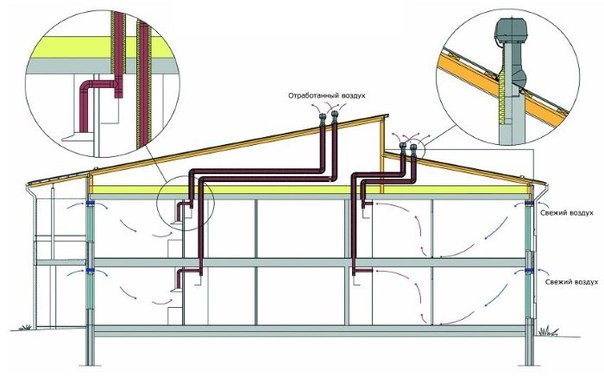

System with recuperation and processor control

Today you can inexpensively purchase all the components for home ventilation, which will be controlled by a computer. You can program the mode of operation of such a system, even when you are far from your dacha.

Most often, recuperators are installed in each room, drilling through the outer wall as close to the ceiling as possible, and the supply channel is lowered lower to the floor, hiding it with a decorative box. Fans to ensure air exchange are installed strictly vertically inside the channels

Particular care should be taken when installing a unit with the thinnest membrane, which ensures efficient heat exchange between air flows that are removed outside and drawn into the room. Supporters of the installation of recuperators insist that modern building materials are incompatible with the effective functioning of natural ventilation, since its normal operation requires air from the street, which was previously provided by cracks in windows and doors, but today is practically absent.The disadvantages of modern ventilation systems include:

The disadvantages of modern ventilation systems include:

- noise from the fans;

- high cost of arrangement;

- constant need for electricity.

The latter problem is most often solved by installing solar panels and installing an autonomous system for all components of the "smart lady".

Enjoying the fresh warm air, you will surely praise yourself more than once for the fact that, thanks to self-education, you were able to make a strip foundation for the house with your own hands, build walls, cover the roof, and managed to correctly calculate and skillfully execute the ventilation system.

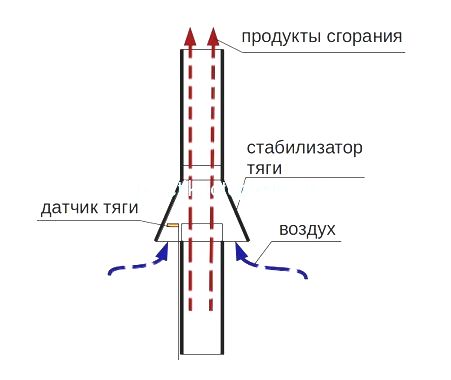

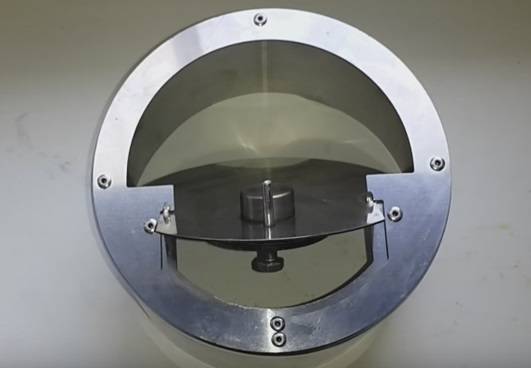

How to make a traction stabilizer with your own hands

To make a draft stabilizer with your own hands, you will need to prepare tools for working with stainless metal and material for making the regulator itself.

For work you will need:

- Welding machine for working with stainless steel. It can be a gas welding machine or an inverter machine that runs on direct current.

- Electrodes on a stainless steel diameter 4 or argon for gas welding.

- Bulgarian, cutting and grinding wheel.

Materials for the manufacture of a traction stabilizer:

- Metal sheet made of AISI 304 steel (similar to 08X18H10) or AISI 321 (similar to 08X18H10T). Metal thickness 10 mm.

- Bolts, nuts, metal rod with a diameter of 10 mm - all made of stainless, heat-resistant steel.

The installation scheme is as follows:

- From a sheet of metal, it is required to weld a branch pipe - the regulator body. Calculate the diameter based on the diameter of your chimney. You will need to put the stabilizer on a tee or branch pipe extending from the main pipe. Therefore, the inner diameter of the stabilizer must match the outer diameter of the tee.Usually it is 115 mm, but it can be more.

- The metal for the body should be cut with the calculation of overlap welding with a seam width of 1 cm.

- The cut sheet is twisted and welded. The seam is cleaned to smoothness from the outside and inside.

- At a distance of 40 mm from the edge at the end of the housing, roll a restrictive barrier. It will serve as a stopper when mounting the device on the pipe.

- At the other end of the body, in the lower part, weld limiters to prevent the damper from tipping inward. In the upper part or in the middle (depending on the shape of the damper), fasteners for the rotary axis are welded.

- A shutter is cut out of metal. Its size is equal to the internal diameter of the outlet of your case or corresponds to the contours of the outlet if you decide to reduce it.

- A hole is drilled at the bottom of the damper for the adjusting bolt.

- In the middle (for a symmetrical damper) or in the upper part (for an expanding form), a rotary axis is welded.

- Install the shutter on the body.

- Install the traction stabilizer on the pipe.

When installing the stabilizer on the pipe, grease the contact points of the nozzles with a heat-resistant sealant. This will make the connection stronger and tighter.

How to increase traction in an already mounted channel

The above calculations make it possible to build a chimney with optimal parameters to obtain a normal level of natural draft. But what if there is a reverse thrust? Is it possible to increase the indicator and how to increase traction on your own? There are several ways:

- cleaning the chimney. When soot and other types of deposits settle, the working diameter of the pipe is significantly reduced, which leads to a decrease in traction. You can clean up:

Usage chimney cleaner

special means such as log "Chimney sweep";

Special soot cleaner

When using special products, it is necessary to strictly follow the instructions provided on the packaging of the product or a special insert.

folk remedies. For example, peel from raw potatoes, aspen firewood, and so on;

- elimination of design flaws made during the construction of the pipe (elimination of cracks, lengthening or shortening, elimination of excessive bends, insulation, and so on);

- installation of additional equipment.

As additional equipment to enhance traction, you can use:

regulator. The device is installed on the pipe and by opening / closing the damper allows you to adjust the traction force in the heating system;

Traction control device

deflector-amplifier. The increase in thrust occurs due to the redirection of air flows formed due to an increase in the diameter of the device;

Device for redirecting air flows

vane. The draft stabilizer, as well as the deflector, is installed at the end of the chimney and serves to enhance draft due to the streamlining of air flows. In addition, the weather vane helps to stabilize the level of traction during strong gusts of wind;

Traction stabilizer

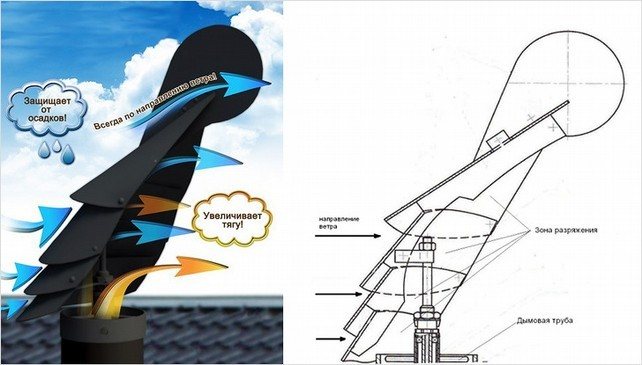

rotary turbine. When exposed to wind, the device begins to rotate, creating a low pressure area around itself, contributing to an increase in traction.

wind traction booster

Unlike other devices, a rotary turbine performs its functions only in the presence of wind.In addition, the device does not protect the chimney from clogging with leaves, small birds and other pollutants.

All additional devices require periodic maintenance: cleaning in the warm season and cleaning from ice in winter. If you do not clean it in a timely manner, then the performance of the device will be minimized and the desired effect will not be achieved.

We recommend reading:

Independent construction of the foundation. What needs to be considered?

All about country life and real estate

Where is Moscow expanding? And what does this threaten summer residents? 294265

Will the Central Ring Road be able to unload the highways near Moscow? 163312

What metro stations will be built in the suburbs? 155012

What areas of the Moscow region are the cleanest and dirtiest in terms of ecology? 140065

The best cottage settlements of the Moscow region 106846

Where is it better to live in the suburbs? District rating 82935

How much does it cost to connect the house and land to communications? 79441

How many acres of land do you need to build a house? 72106

Districts of New Moscow. What are their advantages and disadvantages? 68760

How to calculate acres of land? 65390

Building norms and rules for the development of land plots 64414

What are the exhibitions of finished houses in Moscow and Moscow region? 62492

What houses are currently being sold in the Moscow region? 60956

What is land without a contract? 58012

What are the restrictions on building near rivers and water bodies? 55623

Do basements and basements count as floors? 51221

What taxes need to be paid for a house, garage, sauna and other buildings? 51086

Which home heating is more profitable: gas or electric? 48237

Is it profitable to build a house for sale? 44774

The best places for fishing in the suburbs 43577

Landscaping from scratch. Where to begin? 43110

Pitfalls when buying a house

What do you need to pay attention to? 42219

How to bargain for a house? 42096

Is it possible to get out of SNT? 42017

Where will the gas be soon? Plan for gasification of settlements near Moscow 37860

Life in a cottage village. Pros and cons 37039

Do I need a permit to build a house on my property? 34080

The largest and most expensive cottages in Russia 33652

How much does it cost to build your house? 32879. Is it worth buying a house in SNT for permanent residence? 32261

Is it worth buying a house in SNT for permanent residence? 32261

What is the best way to build a house for permanent residence? 31142

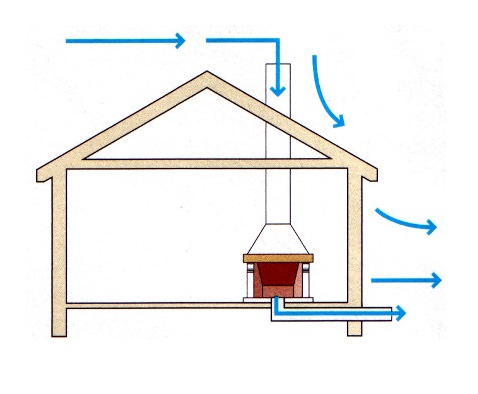

Where to start checking the furnace

Smoke comes out in the house, and you need to start checking from the roof - from the chimney. If the draft was good, but stopped abruptly, the cause may be an object that blocked the pipe. This happens especially often if there is no cap above the chimney, and tall trees are located nearby. Any object can mechanically narrow the chimney channel: a nest made by birds, a brick that has fallen out of the chimney, an accumulation of branches, debris. In the absence of a cap, traction also disappears during strong winds. The air mass creates a vortex in the pipe and blocks the path of smoke. He comes back and exits through the latches and doors. In calm weather, there is no smoke in the house, and already by this sign one can understand its cause.

Special adjustment devices

Modern instrument makers have taken care of the release of special devices that regulate draft in the chimney:

- Regulators. They are installed on the chimney outlet to normalize the draft in the heating system, and also as a means of influencing the heating efficiency.

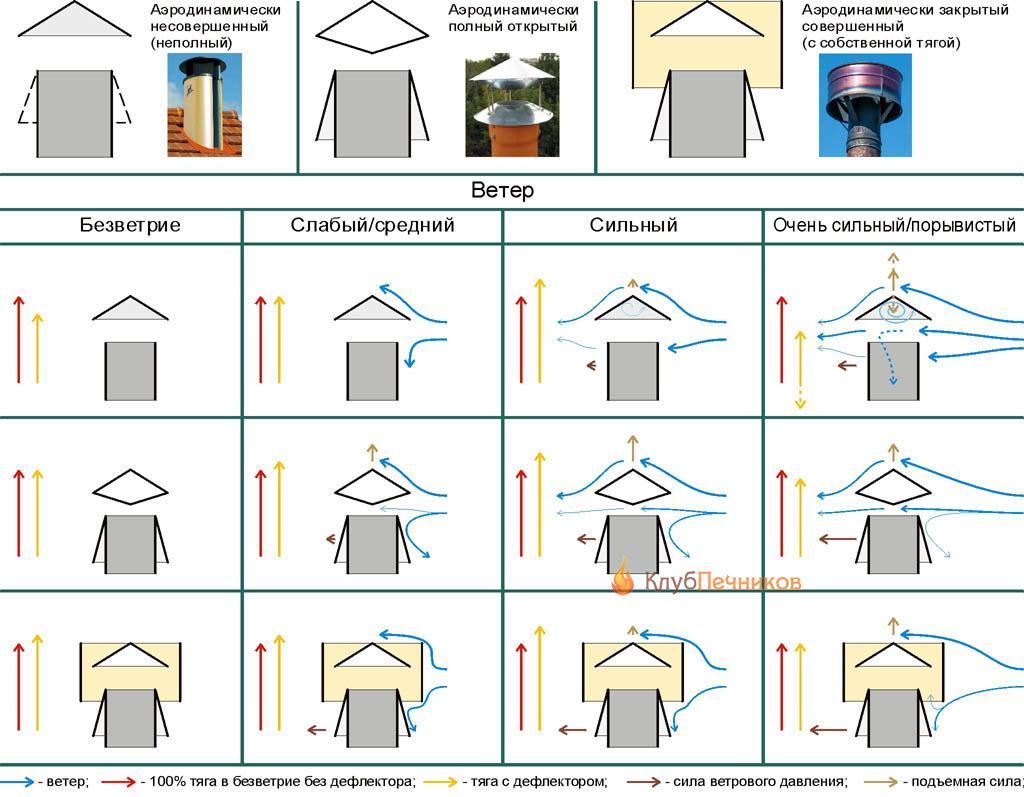

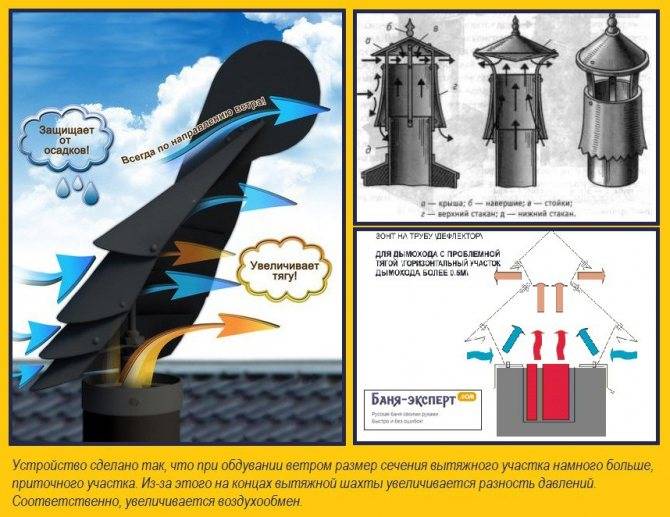

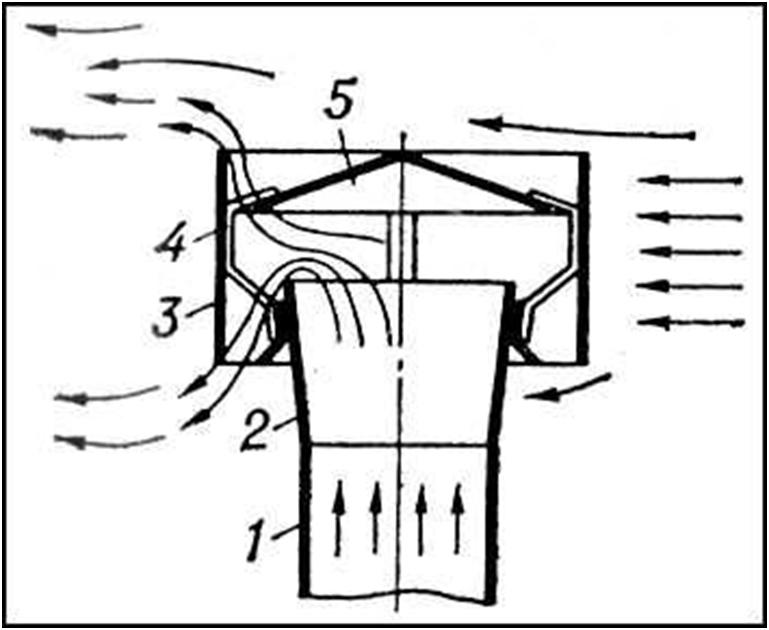

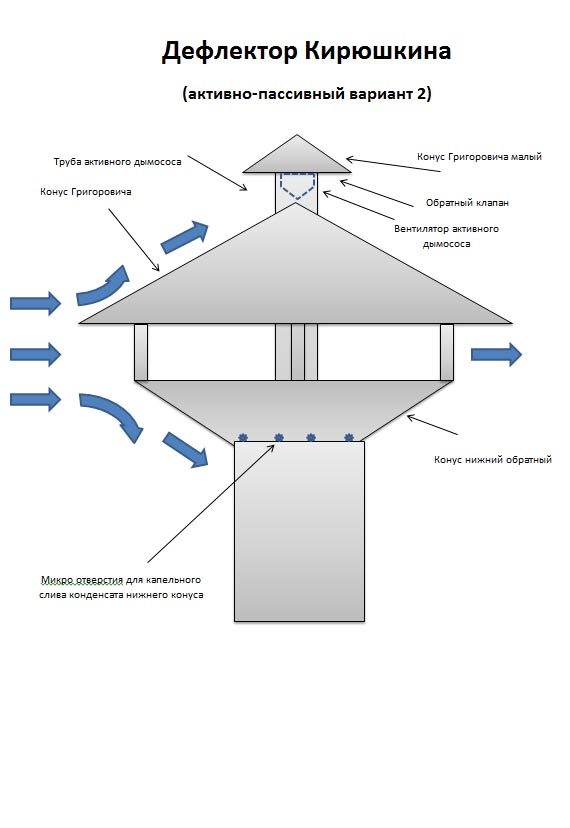

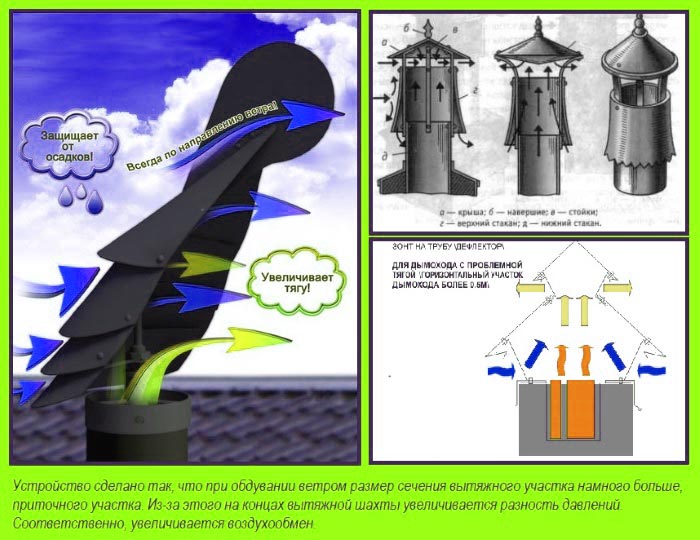

- Deflectors.Such devices are fixed on the chimney from the outside. The draft speed is improved due to the fact that the diameter of this device is much larger than the chimney pipe, and, therefore, a low pressure area appears in it when air flows around it.

- Chimney flue. It is a special design that performs several functions at once: improves traction, protects the pipe from raindrops and snow whirlwinds. The operation of the device is similar to the operation of the deflector; the thrust speed is normalized by reducing the external air resistance.

- Smoke fan. It is very popular among owners of houses with a heating system. An artificial air vortex is created inside the chimney due to the operation of the ventilation system, which requires electricity to connect. Compliance with all necessary safety measures is a prerequisite for the installation and operation of such a device to improve chimney draft.

All devices installed on the chimney pipe to improve draft require mandatory control, especially in winter. This is due to the fact that additional appliances attached to the chimney from the outside can clog, freeze (in winter) and thereby prevent the chimney from working properly. A blockage obtained "with the participation" of devices can cause back draft and the penetration of carbon monoxide into living quarters.

Do not forget to regularly inspect along with the chimney and devices that help increase traction.

Photo gallery: draft control devices

The most common device among users of stove heating

Such a device is especially relevant for improving the operation of stoves and fireplaces.

Useful and beautiful device

By installing such a device, you can increase the performance of the entire heating system.