- The best gas stoves according to buyers

- Recent Articles:

- Oven

- Gas burner selection options

- Battery type

- Gas used to power the burner

- How to choose the power of a gas burner

- Ignition type

- Troubleshooting Color Changes

- How to light a fire

- A few words about the internal structure of gas burners

- How to achieve security

- Injector diameter

- Power

- fittings

- Gas stove burner device

- Rules for the use of gas in everyday life

- If jet replacement is required

- Rules for operation and repair

- How to increase the power of a gas burner in a gas stove? Example.

- How to clean nozzles

- Gas stove burner device

- The burner burns weakly or goes out

- Conclusions and useful video on the topic

The best gas stoves according to buyers

Plate GEFEST 1200C7 K8 on Yandex Market

Stove GEFEST 900 on Yandex Market

Plate GEFEST 5100-02 0010 on Yandex Market

Stove Gorenje GI 62 CLB on Yandex Market

Stove Electrolux EKG 95010 CW on Yandex Market

Recent Articles:

- Power Tool Safety Power Tool Safety Precautions The following power tool safety precautions are universal and will apply…

- Fire safety of a private house Every person at least once in his life had to break some rules - cross the road on red ...

- How to hang a sink on drywall? Installing a Sink on Drywall in 3 Ways IntroductionMost bathroom sinks are wall-mounted. Enough…

- Provence hood Types of hoods and their photos in the interior The right hood in the interior of the kitchen works great when…

Oven

Gas stove ovens are:

- gas;

- electrical;

- combined (with electric grill).

The best choice of the last two types of ovens, since heat is evenly distributed in them. However, with this choice, it is imperative to consult with an electrician whether the wiring can withstand the load received.

Gas ovens can be of 2 types:

- without convection;

- with forced air circulation.

The best choice is a gas oven with forced air circulation, since in this case the probability of cooking underdone or burnt food on one side is minimal.

Gas burner selection options

After the type of device and its functional features, as well as the operating conditions, are determined, it is necessary to carefully study its characteristics and compare it with the closest analogues.

Pay attention to the following technical points

Battery type

All of the above models of burners operate on liquefied gas - propane or butane, which, in turn, can be supplied in completely different containers.

The most compact and portable burners used in domestic and tourist purposes use compact collet gas cartridges as a battery.Some devices have a separate compartment for such a cartridge, others are fixed on top of it.

Classic tourist burners with one or two burners are powered by five-liter gas cylinders connected through a special gearbox. Such devices are widely used for both cooking and heating;

! Preference should be given to models that allow the use of several power sources with the same efficiency, and also have the ability to connect to a stationary gas pipeline.

Gas used to power the burner

- Isobutane blend is the most common and versatile type of fuel. Provides clean combustion without a large amount of emissions and high heat transfer;

- Propane is a gas that burns cleanly and does not emit harmful substances during combustion. It is found on sale less often than the isobutane mixture;

- Butane is similar in properties to propane, but the process of its combustion is less clean, in addition, it is quite unstable in the cold season.

How to choose the power of a gas burner

The power of a gas burner is a parameter that displays the efficiency of its operation and efficiency. It is impossible to achieve a 100% effect from gas combustion, however, many modern models have an efficiency index of 80-90%. Power is traditionally measured in kilowatts and is indicated in the technical specifications. In the field, the power of the burner is calculated quite simply - one kilowatt of energy is enough to cook one liter of food.For example, for a company of four people, it is necessary to cook about 2-2.5 liters of food, and therefore the burner capable of delivering power of 2.5-3 kilowatts will be the most suitable. The same principle is also used to determine the power of a gas burner used for other needs - heating a tent, water heating.

Ignition type

- Inexpensive gas burners in this regard are deprived of all amenities - the valve opens the gas supply to the nozzles, while ignition is carried out using matches or a lighter. This principle is both reliable and not at the same time - there are no mechanical elements that can fail, however, matches tend to get damp, and the lighter fails at the most inopportune moment;

- Piezo ignition is used in advanced devices. It is a compact piezoelectric element that emits a spark and ignites the gas-air mixture when a button is pressed. It should be remembered that such ignition requires careful handling and periodic maintenance, and that it may not work at an altitude of over 4 kilometers. Even if your burner is equipped with a piezo ignition, matches will never be superfluous;

Troubleshooting Color Changes

The most common mistake often made by users of gas equipment is the purchase of unsuitable equipment.

Some products are only suitable for one type of gas, but may be used differently. Then it is also possible to change the color of the flame.

In everyday life, propane stoves are often used, which require a slightly different ratio of gas and air. If they are connected to the main gas supply system, the color of the flame will change

In everyday life, propane stoves are often used, which require a slightly different ratio of gas and air. If they are connected to the main gas supply system, the color of the flame will change

For example, a home appliance can run on propane.It requires a slightly different proportion of gas and air than natural gas.

Therefore, before purchasing a stove, it is important to ask if it is intended for the gas mixture that you will use.

So, if the color of the gas flame has changed to yellow, orange or red, first of all, it is necessary to recognize the presence of danger. Many begin to attribute everything to low-quality gas, to problems with the supplier, but most often the reason is in the burners themselves.

It is important to find the source of the color change and troubleshoot it. If you cannot do this on your own, it is recommended to contact the company with which you have an agreement for the maintenance of gas equipment

They will diagnose and repair the device if necessary.

Most often, the problem is solved after a simple cleaning of your gas equipment. Sometimes it may be necessary to replace the burner nozzles or other actions to fine-tune the air-fuel mixture to the burner.

Most often, the problem is solved after a simple cleaning of your gas equipment. Sometimes it may be necessary to replace the burner nozzles or other actions to fine-tune the air-fuel mixture to the burner.

It is also important to take preventive measures. Most often, the gas changes its color due to the fact that the burners inside are clogged with household dust, food debris.

If you use the stove more carefully, do regular cleaning, you can avoid getting unnecessary objects inside the burner. These are efforts that absolutely every user can make.

Cleaning can be done using special detergents. This must be done when the burners have completely cooled down.

Try to follow these cleaning rules:

- clean enameled and metal surfaces without using abrasive cleaners;

- do not use chlorine-containing cleaners;

- clean glass-ceramic surfaces with soapy water;

- use a stiff-bristled brush for the holes themselves.

In conclusion, they wipe the cleaned stove with a dry rag, wait until it dries, and try to light the gas.

If cleaning the burners did not correct the situation, and the gas is still orange, then there is only one way out. Immediately you need to contact a specialized service center that deals with the repair of gas equipment.

Burners should be kept clean after every cooking. Use improvised means and high-quality detergents to achieve the desired effect.

Burners should be kept clean after every cooking. Use improvised means and high-quality detergents to achieve the desired effect.

If you do not know how to disassemble and clean them, you can look at the instructions for your gas stove. It should describe how to clean these mechanisms.

In addition, it is important to keep the entire stove clean, even its most remote parts from the fire. Indeed, in some cases, pollution from those places can be accidentally transferred and fall under the damper.

Most of the recommendations described above may seem elementary and frivolous at first glance. A lot of people think they're fine with their stove and in control. In fact, completely different processes can occur inside the plate.

Dust that you did not immediately remove then gets inside the burner, where it melts and chars. And in this case, it becomes very difficult to clean it. And if the household appliance continues to be used in this spirit, its condition will deteriorate more and more. Ultimately, this will lead to complete failure.

Do not delay contacting gas services and specialists. If the stove is constantly malfunctioning, it needs repair.Preventive examinations from specialists will also be useful.

In addition, you should not neglect the rules for the safe operation of gas equipment, because even the slightest mistake can lead to sad consequences.

How to light a fire

If you have never encountered gas stoves before, then the question of how to light a gas stove can be very relevant. To do this, you need to follow a certain algorithm. First of all, you need to ventilate the room. Next, follow these steps step by step:

- Open the valve on the pipe or the valve if a gas cylinder is used.

- Light the burner.

This process occurs in different ways, depending on the type of stove and the source of fire. The stove can be ignited in the following ways:

- from an open source of fire - matches;

- using an electric or silicon lighter;

- electric ignition.

Modern models of gas stoves are equipped with a built-in electric ignition system. This function can be displayed on a separate button, or it can be built into the burner tap. This is the only case when the burner can be ignited at the same time when the stove valve is turned on. In other models, you must first provide a fire (spark), and then open the burner valve. The faucet opens clockwise with slight indentation. For information on how to light a gas stove oven, read here.

The flame should be a distinct blue color and evenly distributed around the burner. If it slips inward, close the tap and re-ignite the burner. The optimal flame height should not exceed 2-2.5 cm and is adjusted by turning the valve knob.If there is a draft in the room, the flame will tend to break away from the burner, which is dangerous in terms of fire safety. With an excess of air, it is necessary to close the window. With a lack of air, the color of the flame will clearly change from blue to yellow, and carbon monoxide will be released, which is dangerous to human health.

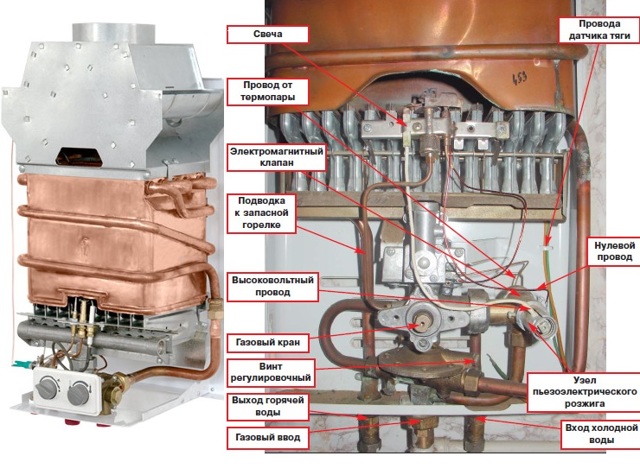

A few words about the internal structure of gas burners

Gas is blown into the burner cavity through an injector, which is often called a jet. But, you don't have to start with that.

In modern kitchen appliances, burners consist of several parts:

- the divider is a flanged sleeve with teeth, thanks to which the gas is distributed in a circle and forms a uniform flame;

- divider cover - this piece complements the design and is located at the top of the burner. In modern cookers, covers can be made of different materials, but most often, it is stainless steel.

In more sophisticated devices, all this is complemented by an electric ignition candle, which is placed on the side. If you remove the divider and cover, you can see the jet. In fact, this is a small bolt with a tiny through hole, made of brass or bronze. The hole is engraved with numbers indicating its diameter. Passing through his hat, the fuel enters the divider and burns. When the stove smokes, the hole is too big.

Therefore, it makes sense to check whether the type of nozzles matches the raw material used. Most gas stoves have jets designed for city main gas - methane. Here the pressure is less and the hole should be larger. Conversely, in a propane tank, the pressure is higher, which means that the hole in the jet should be smaller.

Externally, nozzles operating on mains or liquefied gas are no different. The difference is only in the holes. If during inspection it is clear that the nozzle is not the same, it should be replaced. I note that the jets must be suitable for a specific stove model, otherwise they will not work correctly or you will not be able to install them at all. In addition, an improperly installed assembly is a direct path to gas leakage and explosion.

How to achieve security

Here the matter is in the so-called. the Reynolds number Re, showing the relationship between the flow rate, density, viscosity of the current medium and the characteristic size of the area in which it moves, for example. pipe cross section diameter. According to Re, one can judge the presence of turbulence in the flow and its nature. If, for example, the pipe is not round and both of its characteristic dimensions are greater than some critical value, then vortices of the 2nd and higher orders will appear.

Not all homemade gas burners are accurately calculated according to the laws of gas dynamics. But, if you arbitrarily change the dimensions of parts of a successful design, then the Re of fuel or sucked air can jump beyond the limits that it adhered to in the author's product, and the burner will become smoky and voracious at best, and quite possibly dangerous.

Injector diameter

The determining parameter for the quality of a gas burner is the cross-sectional diameter of its fuel injector (gas nozzle, nozzle, jet - synonyms). For propane-butane burners at a normal temperature (1000-1300 degrees), it can be approximately taken as follows:

- For thermal power up to 100 W - 0.15-0.2 mm.

- For a power of 100-300 W - 0.25-0.35 mm.

- For a power of 300-500 W - 0.35-0.45 mm.

- For a power of 500-1000 W - 0.45-0.6 mm.

- For a power of 1-3 kW - 0.6-0.7 mm.

- For a power of 3-7 kW - 0.7-0.9 mm.

- For a power of 7-10 kW - 0.9-1.1 mm.

Power

In no case should you make a gas burner with a power of more than 10 kW. Why? Let's say the efficiency of the burner is 95%; for an amateur design, this is a very good indicator. If the burner power is 1 kW, then it will take 50 watts to self-heat the burner. About 50 W soldering iron can get burned, but it does not threaten an accident. But if you make a 20 kW burner, then 1 kW will be superfluous, this is an iron or electric stove already left unattended.

fittings

The third factor determining the safety of the burner is the composition of its fittings and the manner in which it is used. In general, the scheme is as follows:

- In no case should the burner be extinguished with a control valve, the fuel supply is stopped with a valve on the cylinder;

- For burners with a power of up to 500-700 W and high-temperature ones (with a narrow injector that excludes the transition of the gas flow Re beyond the critical value), fed by propane or isobutane from a cylinder up to 5 liters at an outside temperature of up to 30 degrees, it is permissible to combine the control and shut-off valves in one - regular on the cylinder;

- In burners with a power of more than 3 kW (with a wide injector), or powered by a cylinder of more than 5 liters, the probability of a “breakthrough” of Re beyond 2000 is very high. Therefore, in such burners, between the shut-off and control valves, a gearbox is also required to maintain pressure in the supply gas pipeline within certain limits.

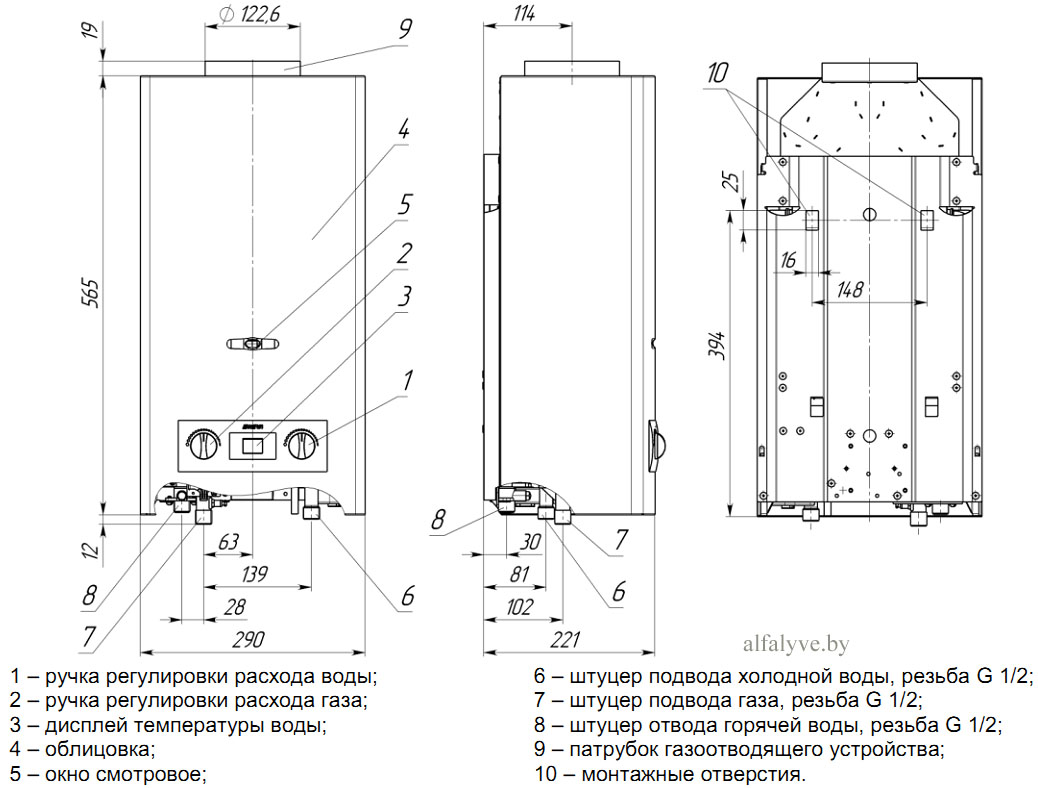

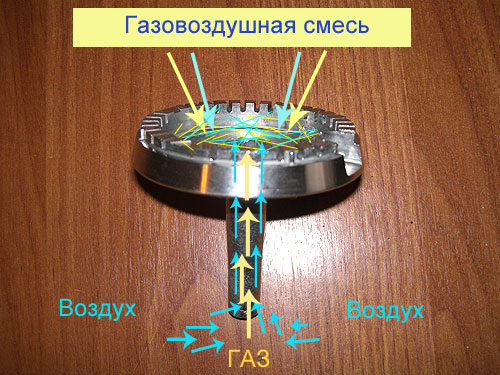

Gas stove burner device

To understand how you can increase the flame in a household gas stove, you should familiarize yourself with the structure of the burner itself, the principle of supplying and burning gas.

The first thing to remember once and for all: not just pure gas burns in the stove, but a gas-air mixture. It is from its final composition, the ratio of gas and air, that the size and effectiveness of the fire that the consumer receives from the burner largely depend.

Burners in burners, depending on the method of air intake, are of three types:

- Diffusion is usually used in ovens. There is no air leakage in such structures; mixing with gas occurs naturally.

- Kinetic burners use line pressure to capture the right amount of air to create the right fuel mixture.

- Combination burners successfully use both methods of adding air to the gas. It is these devices that are used in most household gas stoves.

The burner design itself has a simple, but precisely calibrated configuration.

The pipeline ends with a tip in which a jet is mounted. Its through hole has a certain calculated diameter. It is through it that gas is supplied to the mixer, in which the fuel is mixed with air. From the mixer, the combustible composition enters the burner, in which a flame is produced.

It is worth focusing on the area between the nozzle and the mixer. While the gas overcomes this segment, exactly the amount of air that is necessary to obtain the optimal combination of fuel and oxygen is mixed with it.

This distance is also strictly calculated, due to which the gas burns completely and with the highest possible efficiency.

Rules for the use of gas in everyday life

- Perform unauthorized gasification of a house or apartment, rearrangement, replacement and repair of gas appliances, cylinders and valves.

- Carry out redevelopment of the premises where gas appliances are installed, change the area of \u200b\u200bheated premises without agreement with the local government.

- Make changes to the design of gas appliances. Change the arrangement of smoke and ventilation ducts; seal ventilation ducts, wall up and seal "pockets" and hatches intended for cleaning chimneys.

- Disable safety and regulation automation. Use gas with faulty gas appliances, safety automation, shut-off devices (taps) and gas cylinders, especially if a gas leak is detected.

- Use gas in violation of the integrity and density of masonry, plaster (if cracks appear) of gasified stoves and their chimneys.

- Install and use the valve (gate) on the smoke channel, chimney, chimney. If there is a valve (gate) in the design of the furnace, ensure its extraction and sealing from the outer side of the wall of the smoke channel of the resulting hole (slot).

- Use, install gasified stoves in the premises of apartment buildings.

- Use gas appliances in the absence of draft in the smoke and ventilation ducts, closed windows (transoms), the closed position of the louvre on the ventilation duct. At the same time, in the lower part of the door or wall leading to an adjacent room, it is necessary to provide a grate or a gap between the door and the floor, as well as special supply devices in the outer walls or windows.

- Use forced ventilation devices (hood, fan) when gas boilers or water heaters are running.

- Leave working gas appliances unattended (except for appliances designed for continuous operation and having appropriate safety automatics for this).

- To allow children of preschool age, persons who do not control their actions and do not know the rules for using these devices to use gas appliances.

- Use gas and gas appliances for other purposes. Use gas stoves for space heating.

- Use rooms where gas appliances are installed for sleep and rest.

- Dry laundry over or near a gas stove.

- Check the operation of ventilation ducts, tightness of gas equipment connections using open flame sources, including matches, lighters, candles and others.

- Store empty and filled cylinders with liquefied gas in rooms and cellars. Arbitrarily, without special instruction, replace empty cylinders with gas-filled ones and connect them.

- Have in a gasified room more than one cylinder with a capacity of more than 5 liters, not connected to a gas stove.

- Place cylinders at a distance of less than 0.5 m from a gas stove, 1 m to heating appliances, 2 m to stove burners, less than 1 m from an electric meter, switches and other electrical appliances and equipment.

- Expose LPG cylinders to the sun and heat.

- Allow damage to gas equipment and theft of gas.

- Twist, crush, kink, stretch or pinch the gas hoses connecting the gas equipment to the gas pipeline.

If jet replacement is required

There are some things you can do yourself too.To work, you will need a set of keys and a Phillips screwdriver: if the nozzles for bottled gas are 8 mm, for the burners - 14 mm, for the pipeline - 17 mm. Don't forget to turn off the faucet.

In the plates of the old sample, the jets are hidden in depth. To begin with, dividers, burners, and a table cover are removed. The type of fasteners depends on the type of stove, however, in most cases it is necessary to unscrew a couple of screws. Here you can see traverses - metal strips on which burners are fixed. All of them are made in the same design and differ only in the length of the aluminum pipeline connecting the nozzle and the divider. For every two burners, there is one metal frame. The body of each burner is rigidly fixed on the traverse, and the pipes are fastened in pairs with ears inside the body.

As I said, at the end of each pipeline is a nozzle where gas is supplied. Further, through the hole in the nozzle, it goes to the burner and is fed to the divider. To replace in older models of plates, it is necessary to release the tip with the jet by bending the special lock. In the new ones, everything is done much easier, you don’t need to bend anything. When you have found what to replace, you can start repairing. Assembly is carried out in reverse order.

Rules for operation and repair

The serviceability of equipment and your personal safety largely depends on how you treat the equipment. This includes proper installation, careful operation, regular maintenance and replacement of parts with a limited lifespan.

Here are the basic rules for using a gas stove:

- regularly clean the grate, stove surface, burners, control knobs;

- keep in touch with representatives of Gorgaz and regularly carry out maintenance of equipment;

- ventilate the room, even if you use the hood;

- in case of a long absence, close the shut-off valve;

- make sure that the knobs are in the "off" position when the hob is not in use.

Care must be taken in the operation of the oven. He, like any equipment, requires cleanliness and serviceability of all parts.

It is not recommended to use the oven as an ordinary cupboard for storing dishes, especially cluttering it with flammable or melting objects.

Inside the oven should be only "working" accessories: baking sheets, grates, grilling tools and utensils or forms, if they are used in cooking

Inside the oven should be only "working" accessories: baking sheets, grates, grilling tools and utensils or forms, if they are used in cooking

If the ventilation is faulty and it is not possible to open the window or window, it is forbidden to use gas equipment.

If a specific smell of gas appears, it is necessary to open the fuel supply valve, open the windows and call the emergency service. During the waiting period, you can not turn on electrical appliances, light a flame, but it is better to leave the room altogether. Even the call is recommended to be made from the landing or from the street.

Repair of gas equipment should be carried out either by invited specialists from a service organization, or by employees of a specialized service center.

How to increase the power of a gas burner in a gas stove? Example.

How to increase the power of a gas burner in a gas stove?

A woman came to us, a great lover of hiking and all kinds of rafting on the river. She brought with her a small PGT1 model 802 single-burner travel stove and asked, "Is it possible to increase the power of the burner in such a stove?"

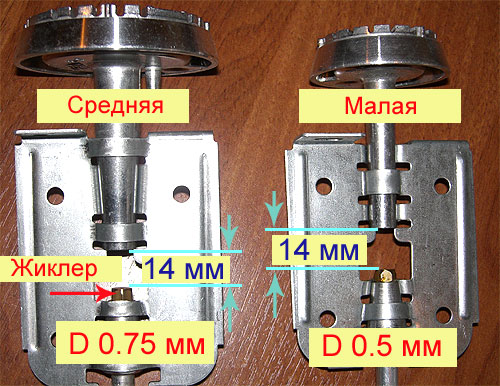

Let's take two assembled Hephaestus burners and consider these two designs.

Put together it looks like this:

The pipeline, which ends with a tip, into which a jet with a through hole of a certain diameter is screwed, directing the gas flow to the mixer mounted on the burner body.

It is worth noting the following:

- the distance from the jet to the inlet of the burner mixer tube is approximately the same, - about 14 mm, - the holes in the jets are different (small burner 0.5 mm, medium burner 0.75 mm jet hole diameter, i.e. 25% more gas is supplied to medium burner than small)

Do you know, for example, that in order to take and burn 1 cubic meter of natural gas, we need to add 10 cubic meters of air to it and burn it in the same way? standard formula.

The idea is

The gas from the jet in a thin stream beats inside the mixer (burner) tube in a straight line 14 mm long, sucking in or taking with it, as you like, a certain amount of air, where in this tube, or rather, in its outlet, the gas and air are mixed (hence we have the factory name of the burner is the mixer name).

What is the secret meaning?

The distance of 14 mm was taken by the factory for a reason!

one . If you start to increase this distance, then there will be an excess of air and the power during the combustion of the resulting gas-air mixture will drop.

2. And if we reduce this distance, we will get an excess of gas, and the air will not have time to mix in the required amount. We get a red flame, soot that the kettle cannot be washed, but the power, of course, will increase by some value.

3. And the distance between the jet and the inlet to the mixer tube cannot be infinitely increased either, since the gas jet simply breaking into the air will not enter the mixer tube at all.

Based on the data obtained, we see that simply increasing the diameter of the jet in order to increase the power of the burner will not be entirely correct. But we did just that, although for good, it would be necessary to increase the diameter of the burner, so that there was more mixture. But the case did not allow to insert a mixer of greater power.

As a result, we gave the lady two types of nozzles with a diameter of 0.85 and 0.95 mm M6 pitch 0.75. According to the state in the tile there is a jet with a diameter of 0.75 mm. Until I called. Usually, if they don't call us, then everything is fine)))

Below is a burner and nozzles to increase power for PGT 1 (gas tourist)

Source

How to clean nozzles

First, turn off the gas and check if the stove has cooled down. To clear the blockage, remove the cover and divider. As I said, there is a small hole inside. Take a sewing needle and clean it gently. It's not worth pushing and pushing him. It is enough to insert the tip and gently rotate the needle between your fingers.

Care and operation of gas stoves

At the same time, if there is dirt, it is useful to clean the divider itself and the cover. You can use a toothbrush, washing-up gel for dishes and a stream of warm water. It is impossible to pick with wire, carnation. Today's burners are not the ones used 50 years ago. They can't handle that kind of vandalism. Then wipe the whole thing dry, dry for half an hour or a little longer, collect and put in place. When assembling, make sure that the grooves and protrusions of the burner match. The cover must be in place evenly, without displacements and distortions.

Gas stove burner device

To understand how you can increase the flame in a household gas stove, you should familiarize yourself with the structure of the burner itself, the principle of supplying and burning gas.

The first thing to remember once and for all: not just pure gas burns in the stove, but a gas-air mixture. It is from its final composition, the ratio of gas and air, that the size and effectiveness of the fire that the consumer receives from the burner largely depend.

Evidence that the optimal amount of air is mixed into the gas is the blue color, the absence of soot and obvious yellow “flies”

Burners in burners, depending on the method of air intake, are of three types:

- Diffusion is usually used in ovens. There is no air leakage in such structures; mixing with gas occurs naturally.

- Kinetic burners use line pressure to capture the right amount of air to create the right fuel mixture.

- Combination burners successfully use both methods of adding air to the gas. It is these devices that are used in most household gas stoves.

The burner design itself has a simple, but precisely calibrated configuration.

The diagram shows the device of a gas burner. Only at first glance, the design seems simple. However, a failure in any node can affect the quality and composition of the gas-air mixture and reduce the efficiency of the stove.

The pipeline ends with a tip in which a jet is mounted. Its through hole has a certain calculated diameter. It is through it that gas is supplied to the mixer, in which the fuel is mixed with air. From the mixer, the combustible composition enters the burner, in which a flame is produced.

It is worth focusing on the area between the nozzle and the mixer.While the gas overcomes this segment, exactly the amount of air that is necessary to obtain the optimal combination of fuel and oxygen is mixed with it.

This distance is also strictly calculated, due to which the gas burns completely and with the highest possible efficiency.

The burner burns weakly or goes out

The burner of the table or oven burns weakly when the tap is open at full tap and the oven is cold. If there are problems with only one burner (the rest are working normally), then the reason is that the jet of the corresponding burner is clogged. Repair is easy. It is necessary to clean the nozzle (jet, nozzle). This is done with a thin wire or needle. At first, you can try to clean the nozzle without removing it. The burner nozzles of the table are installed under the burners (fig. 1. A). The oven burner nozzle is installed on the side of the stove (fig. 2. A). Getting to the oven nozzle is not always easy. Then you need to remove the bottom wall of the oven, unscrew and remove the burner (it is attached there with one or two screws). The nozzle can be accessed from the oven.

If it is not possible to clean the nozzle without removing it, then it can be easily unscrewed with a suitable key.

If all burners burn poorly, then the reason is low gas pressure. The combustion of the burner of an oven with a thermostat must be checked when the oven is cold. Otherwise, the thermostat may reduce the gas supply when a certain temperature is reached. This is, in fact, its regular function.

Conclusions and useful video on the topic

It is not always possible to figure out the first time how to clean the gas burner from scale and dirt. The video below offers detailed instructions on how to do this:

So, the normal color of a gas flame is blue.If your burners burn differently, this is a reason to clean them or call a specialist for a more complete diagnosis. Do not delay with this question, because not only the color of the flame changes, but the composition of the combustion products.

The accumulation of carbon monoxide can lead to undesirable consequences. Therefore, gas safety issues must be addressed first.

Have you ever encountered a change in the color of the flame? How did you act in such a situation? Leave your comments, share your experience, ask questions - the contact block is located under the article.