- What is efficiency and how to calculate it

- Choosing a soldering torch

- Success Statistics Rule

- Heat transfer within the system

- Installing a gas burner in a solid fuel boiler

- What determines the efficiency of the boiler

- Save money with programmable thermostats

- What determines the efficiency of the boiler?

- Which tanks do you prefer?

- Hardware setup

- How to increase the efficiency (efficiency) of a solid fuel boiler

- What is efficiency - coefficient of performance

- How to increase the efficiency of a solid fuel boiler

- Manufacturing features and choice of materials

- Materials and tools for the manufacture of equipment

- Recommendations for the manufacture of equipment

- 5 Ways to Increase the Efficiency of Your Heating System

- Boilers with pyrolysis type of combustion

- Output of combustion products

- Output of combustion products

What is efficiency and how to calculate it

The heat output of heating devices, which include batteries or radiators, is the sum of the quantitative indicator of heat that is transferred by the battery over a certain period of time and is measured in watts. The process of heat transfer by batteries takes place as a result of processes that are known as convection, radiation and heat transfer. Any radiator uses these three types of heat exchange. As a percentage, these types of heat transfer can vary for different types of batteries.

What will be the efficiency of heaters, in the vast majority of cases, depends on the material from which they are made. Consider the advantages and disadvantages of radiators made from different types of material.

- Cast iron has a relatively low thermal conductivity, so batteries made from this material are not the best option. In addition, the small surface of these heating devices significantly reduces heat transfer and occurs due to radiation. Under normal apartment conditions, the power of a cast iron battery is no more than 60 watts.

(See also: Which is better to choose a heating radiator)

Steel is slightly higher than cast iron. More active heat transfer occurs due to the presence of additional ribs, which increase the area of heat radiation. Heat transfer occurs as a result of convection, the power is approximately 100 watts.

Aluminum has the highest thermal conductivity of all the previous options, their power is about 200 watts.

In addition, for the most efficient heating, it is necessary to take into account how much power may be required. When calculating the power of heating devices required for a room, the number of walls facing the street and windows is used. For every 10 m2 of floor with 1 outer wall and window, about 1 kW of battery thermal power is required. If there are 2 external walls, then the required power is already 1.3 kW. (See also: Water-heated stoves)

The bottom connection is used if the heat-conducting pipes are hidden under the floor screed and does not exclude heat loss up to 10% of the original value. The single-pipe connection is considered the least effective, since the power loss of the heating device with this method can reach 45%.

Choosing a soldering torch

Soldering or cutting with ordinary gas burners will not work. For this purpose, powerful and productive devices equipped with an air blower or an injector are needed. By adjusting the composition of the supplied mixture, it is possible to achieve the flame of the desired strength and perform the necessary work regarding the soldering of metals or other materials. Professional torches used for soldering are expensive, and therefore they are needed by a narrow circle of specialists. The power of such devices is 10-15 kW.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to buying

Success Statistics Rule

What is the meaning of bringing the tank to the field? Of course, in order to remain in a combat-ready state as long as possible and at the same time do something useful, for example, inflict incredible damage, illuminate enemy tanks, prevent the capture of a base, and so on.

You should not immediately merge, even if your nickname is at the end of the list. You need to be patient and wait. As soon as it becomes clear what positions the tanks occupy, you can begin to plan your actions.

It also happens that team players merge, and you have to stay one on one with enemy vehicles. Just don't give up right away, even if it seems like you can't handle it, keep playing. Sometimes such tactics help to get the number of unfinished tanks, recapture HP.

Heat transfer within the system

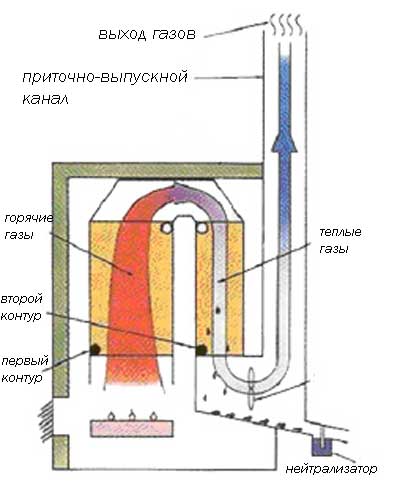

The burning gas heats a container with water (coolant), which in turn heats the radiators. The latter affects the efficiency of the boiler only how quickly and without loss the energy is transferred to the coolant.The most successful form of a heat exchanger for this is a cylindrical one, inside of which the same burner is located. The coolant moves around them in a spiral, guaranteed to have time to heat up to the required temperature.

The material of the heat exchanger is different - from steel to cast iron and depends on the model of the boiler, each of which is calculated in its own way.

The principle of operation of the condensing boiler in the video below:

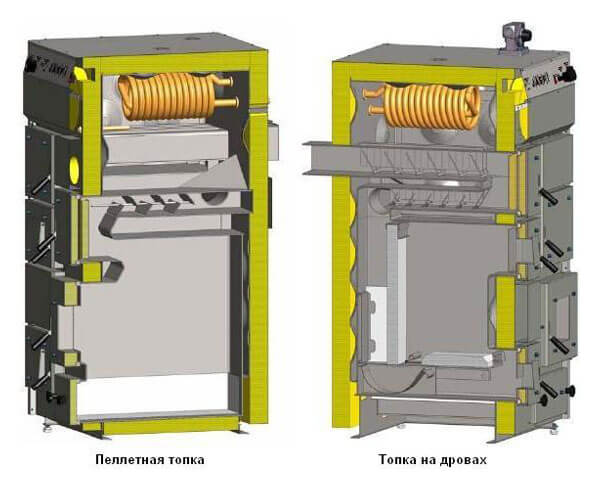

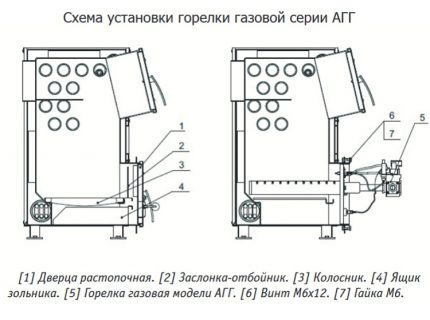

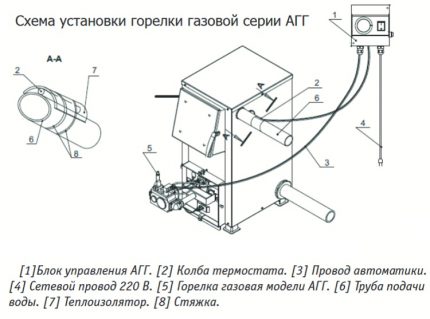

Installing a gas burner in a solid fuel boiler

After common sense and a real assessment of their capabilities, most home craftsmen still prefer the modernization of solid fuel boilers that previously processed wood or coal. They simply put a factory-made gas burner in their firebox.

For the arrangement of suburban property, you can purchase a solid fuel unit, which can be converted into a gas one. For example, the Teplodar stove, in which a gas burner is mounted

Consider the installation steps of the burner brand Teplodar AGG:

- Dismantling the firebox door, ash pan damper (or the ash pan itself, if it is made in the form of a retractable lattice box with a monolithic door), a chipper and a grate. In short, you need to remove all structural parts located within the firebox and ash pan.

- Fixing the burner. A burner block is mounted in the firebox channel freed from the above elements. If the Teplodar stove is designed to change fuel, then the burner module is fixed in the channel through standard ears with screws and nuts threaded into them.

- Connecting automation to the remote control. The devices available in the design of the burner block that ensure automatic operation of the boiler are connected to the control panel.

- Mounting the thermostat sensor.It is installed on the supply pipe, wrapped in insulation to protect against external mechanical and thermal influences, and on top with ties.

- Start to work. It is carried out after checking the draft and volley ventilation of the room with a modernized boiler. With the help of a simple handle, the most suitable mode is selected.

We remind you that according to the requirements specified in the “Safety Rules for Gas Distribution and Gas Consumption Systems”, all work on installing equipment, replacing burners, servicing equipment and connecting to the network supplying blue fuel must be carried out by gas workers.

The technical documentation attached to the Teplodar stove contains a detailed description of the process of installing a gas burner for converting a solid fuel unit into a gas one.

In accordance with federal regulations and standards, it is necessary to conclude an agreement with representatives of the gas services for the supply of gas and related services. It is clear that not all remote settlements will be able to serve employees of gas organizations. However, it is desirable to adhere to the requirements in order to avoid catastrophic consequences.

With a decrease and a sharp extinction, the current from the electric element is weakened, as a result of which the gas supply channel is blocked. Overheating of water in the boiler is fixed by a temperature sensor, which transmits a signal to open the contact pair blocking the burner

Take risks or value and protect the health with the well-being of your loved ones? It's up to you to decide. It is wiser to refuse threatening measures, but it is very useful to know about the process of their implementation in order to monitor how well and honestly gas workers work.

What determines the efficiency of the boiler

The efficiency factor is a percentage of the calorific value of the fuel. In other words, the efficiency indicates how much of the heat of combustion of the fuel the boiler manages to use for heating. At the same time, any calculations are based on the properties of natural gas, which complies with accepted state standards.

Equipment performance depends on several main factors:

type of burner - closed models demonstrate higher efficiency than atmospheric ones;

heat exchanger design - the maximum amount of energy is transferred to the coolant by wall and floor condensing models;

control system - sensors, automatic solutions, built-in or separately mounted pump guarantee rational use of fuel;

type of ignition - with an electric ignition device, there is no need to install a constantly working igniter, which saves a resource;

third-party factors - correct installation, chimney design, etc.

The most energy-efficient boilers are classified as expensive, but the cost of their purchase and installation is more than paid off due to minimal fuel consumption and a long service life.

Save money with programmable thermostats

Many modern boilers support the ability to connect thermostats to themselves. You can place the thermostat in the room that can be taken as a reference. (Just never put thermostats in the kitchen. Due to the operation of the stove, it is always warmer there) According to the reference room, you set the temperature and the boiler already starts working from the thermostat signal.Practice shows that this method already makes gas heating a little more economical.

In addition to simple thermostats, there are so-called programmable ones. They are wired, wireless, mains powered or battery operated. Options start from 2000 rubles and go up to infinity. Such thermostats allow you to set weekly operating modes.

How does it work in practice? Let's say you are a worker. And the whole family is often absent from home. Study, work, etc. In fact, in your absence, there is no need to heat the house to a comfortable temperature. It is enough just to maintain an adequate positive mode so that furniture, decoration and other parts of your home do not suffer. With a programmable thermostat, you can set the temperature by the hour.

Let's say you all leave for work at 9 o'clock and return home at 6 o'clock. You set the thermostat to go down from 9 a.m. and up from 5 p.m. so that the house is warm when you arrive.

In fact, in your absence, heating will work in economical mode. Savings in such scenarios can reach up to 30%.

We talked about this in more detail in the video:

There are many programmable thermostats. There are even some that can be controlled remotely from a smartphone. Here you already choose everything according to your taste and color. The main thing is that all of them can change their temperature depending on the time and day of the week.

The only important thing is that your boiler has the ability to connect thermostats. If you are using a simple boiler, then most likely there may not be such an opportunity there.

All modern wall-mounted boilers support the connection of thermostats. This also applies to many floor standing boilers.

Here is such a simple and uncomplicated way to make your gas heating more economical.

Read also:

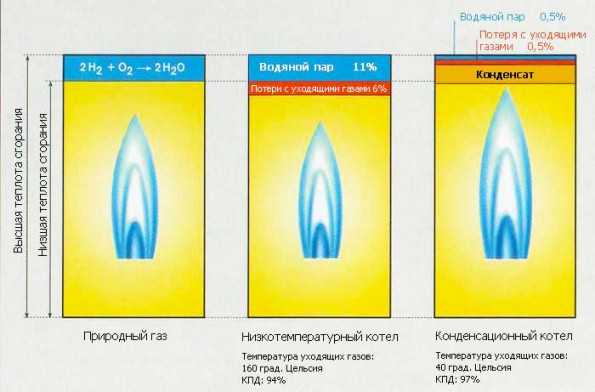

What determines the efficiency of the boiler?

The main indicator of the efficiency of the boiler is its efficiency - efficiency. The average efficiency of various models is in the range of 90-94%. A much higher efficiency, more than 100%, is possessed by condensing heat generators, which are used to heat the coolant and the condensate that forms during the combustion of gas.

The type of combustion chamber also affects efficiency - open or closed. In a closed combustion chamber, the gas burns completely, a minimum amount of carbon monoxide enters the air. The correct choice of power is also an important factor in the efficiency of the boiler. If you put a boiler that is too powerful, it will turn on and off at very short intervals, as a result, it will consume more gas.

With insufficient power, the heat generator will work for wear, which will significantly reduce its service life. The economical operation of the boiler will be ensured by automation, which will respond to changes in the temperature in the room. And, most importantly, the insulation of the house, because no matter how economical your boiler is, heating the street will nullify everything.

Video about a homemade gas boiler:

Which tanks do you prefer?

Many are sure that it is better to use imb tanks, which have excellent characteristics. In different periods of the game, such cars were different, but soon the authors themselves nerfed them. Therefore, give preference to those tanks that you like the most. Even if he does not bend, but you get the pleasure of the fight.

What is a potbelly stove every owner of a country house, garage or utility room knows. This oven appeared a long time ago, but to this day it is in demand. Decades ago, it was even used to heat food, now it is a source of heat for various rooms. You can assemble such a stove yourself from improvised means, which are not a problem to find in the garage or even on the street.

Owners of garages or small houses choose this type of heating because they have significant advantages over other types of stoves. For example, having a small area, it will either not work to install a stove, or it will simply not be rational, but you want the room to be warm all year round. Therefore, the installation of any heating device is simply necessary.

In the case of using a potbelly stove, a problem may arise that an increase in efficiency will be required. And for this you do not need to resort to the help of specialists, such work can be done with your own hands. Let's see what is needed for this.

Each device can be found pros and cons in the process of use. In the case of a potbelly stove, we highlight the following positive aspects:

- The design of the furnace is simple and does not require large financial costs. Everything you need to make a stove with your own hands can be easily found in the utility room.

- If necessary, the potbelly stove is easily transported to another house or garage. Its weight usually does not exceed 30 kilograms and small dimensions will only be a plus.

- The oven can be quickly heated up regardless of weather conditions.

- In fact, almost everyone can heat a potbelly stove. That is, it can be both coals and sawdust, firewood branches, or even household garbage.

As for the negative characteristics, we highlight the main ones:

- The area of the heated surface is quite small, in connection with this, a small amount of heat enters the room.

- The room, even after prolonged use of the stove, cools down quickly.

Given such shortcomings, we are talking about a low efficiency, that is, the level of efficiency of the stove.

To organize the heating systems of a private house, owners often use gas boilers. This is due to their good performance, a wide range of equipment, and the cheapness of the fuel itself. Gas-powered devices are reliable and durable, easy to operate.

The issue of heating in the winter season is especially relevant. Problems in the functioning of heating equipment affect not only the comfort, but also the health of the inhabitants of the house. The design of the heating system is carried out even at the stage of construction or repair work. It was at this time that the issue of choosing a boiler was decided. The main parameter on which they rely when buying equipment is its power. The quality of the heating system depends on it.

Checking the efficiency of a gas boiler

Over time, gas boilers can reduce their power, which is due to wear of parts, non-compliance with operating rules, and inappropriate care. If you do not plan to purchase new heating equipment in the near future, you should look for ways to improve the operation of a gas boiler.

Hardware setup

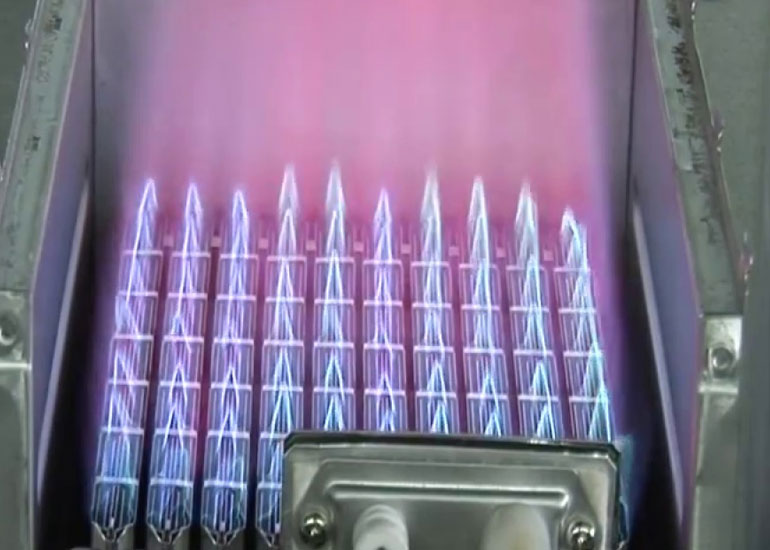

An open chamber is a fairly simple combustion device. It looks like this: above the burner there is a heat exchanger in the form of a coil of thin copper tubes.Due to the open design, the air necessary for the combustion reaction is supplied to the place of ignition of the gas from the environment.

As a rule, there is enough air from the room (provided that good ventilation is organized). But there are wall-mounted models with air intake from the outside, for which a special hole is mounted in the wall. Open combustion chambers require a chimney.

It is most often installed for models of floor gas boilers, and was also used to complete an old-style boiler (in this case, the ignition was performed by an ignition burner).

Schemes of the device of the combustion chamber

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional settings.

Scheme of actions when setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a manometer, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers, phases are connected correctly.

- Install a gas analyzer in the chimney.

- Start device.

- Use a manometer to read the pressure at the outlet of the burner block. The pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow with an air damper.

- The readings of the gas analyzer must also comply with all standards for the installation of gas equipment.

Setting up gas equipment should be carried out by specialists.The simplest open-type boilers can be configured independently if you have certain skills, knowledge of the burner block device. The efficiency of the boiler, its level of efficiency, fuel consumption depend on the quality of the burner. It is superficially possible to determine that the equipment is malfunctioning by the changed burner flame.

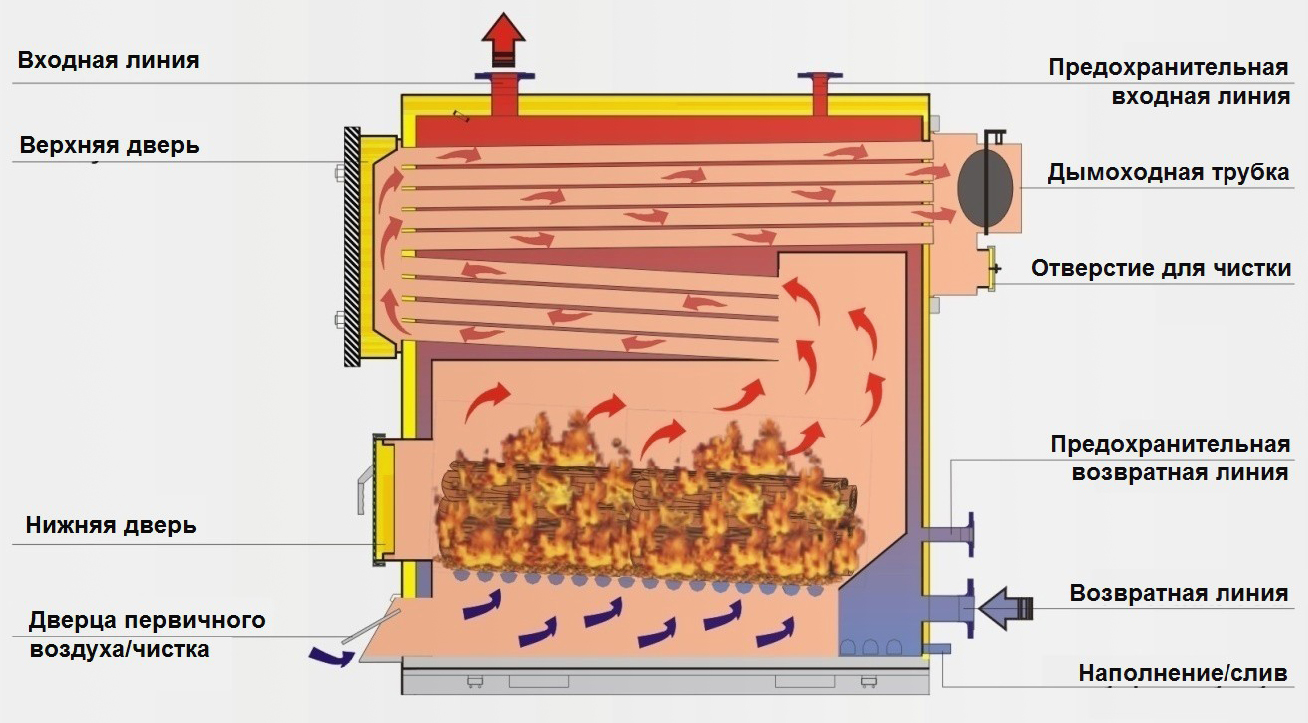

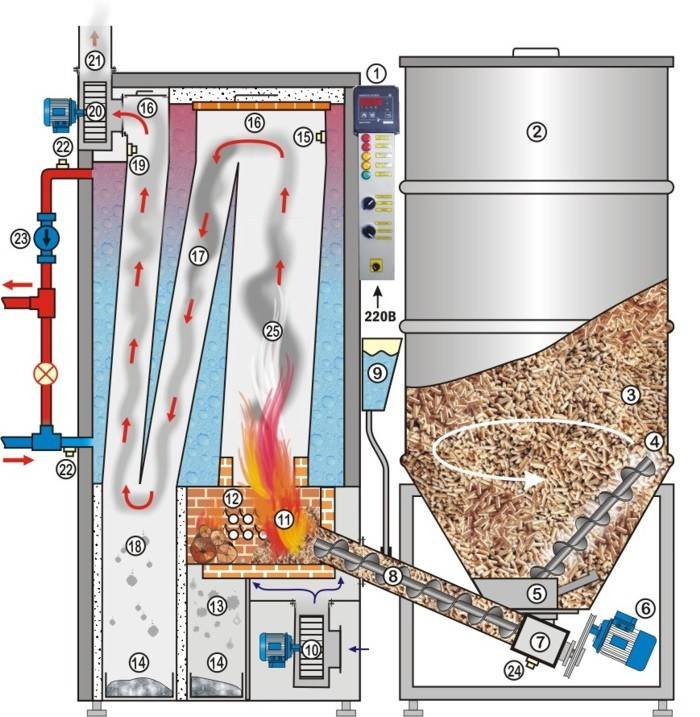

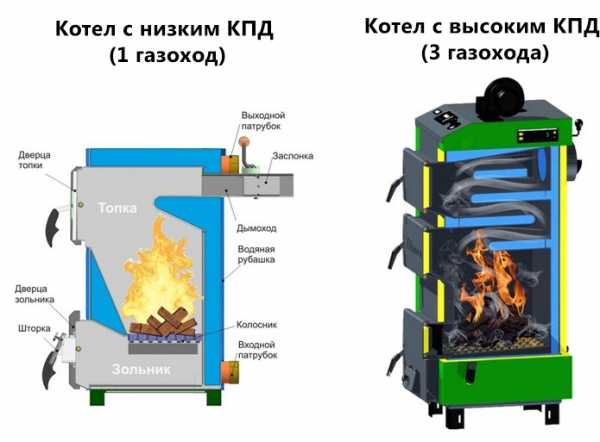

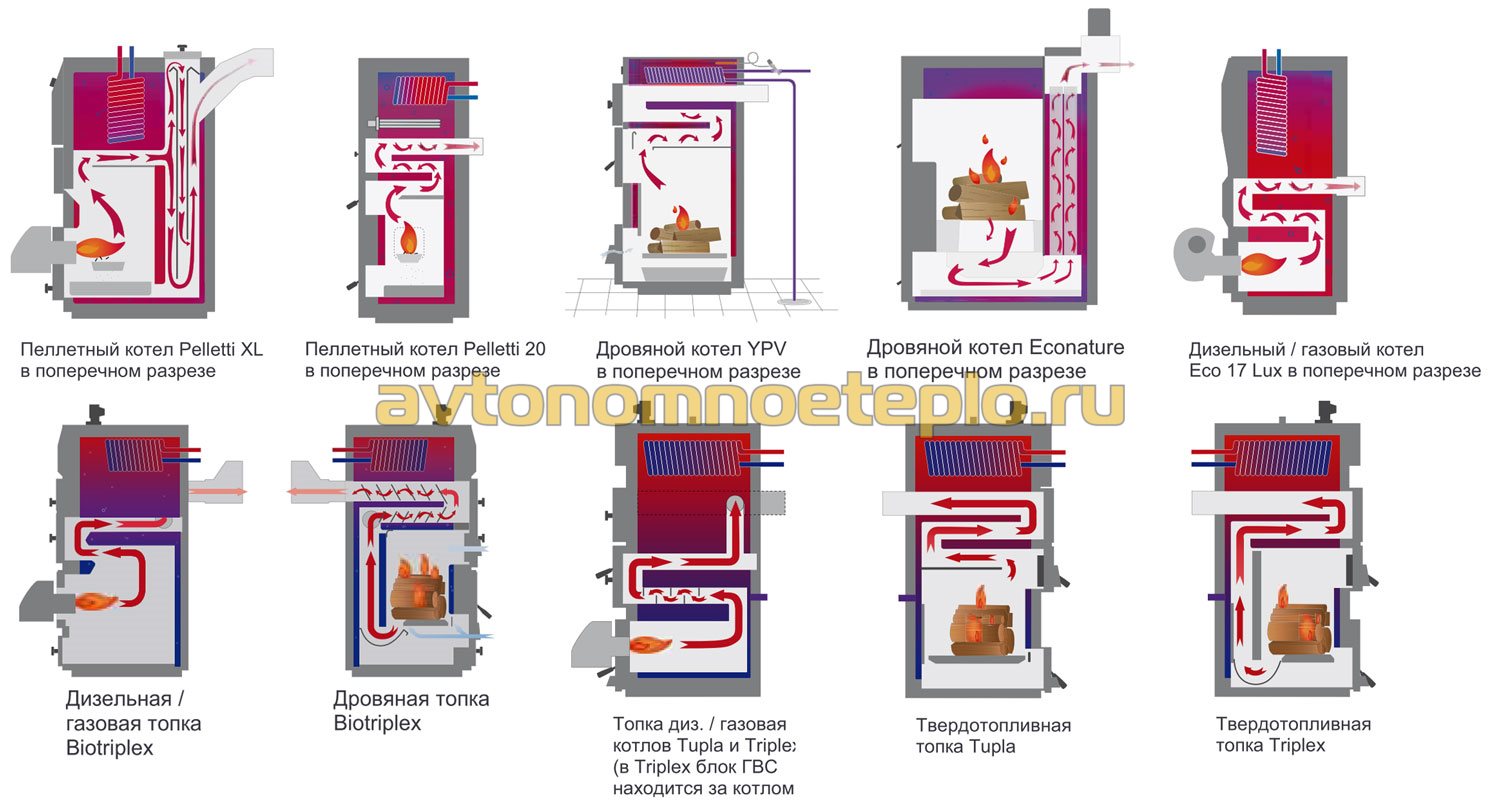

How to increase the efficiency (efficiency) of a solid fuel boiler

Solid fuel boilers (hereinafter referred to as SPH) have a sufficient percentage of efficiency compared to other heating units (gas boilers, for example) to be competitive and lead the market. The latest TTH models are equipped with the latest automation systems to optimize performance.

Solid fuel boilers operate on the principle of stove heating: heat is transferred to the coolant (water) by generating energy during the combustion of coal, firewood, pellets in the furnace. The coefficient of performance or efficiency for each boiler is different and depends on many conditions: the choice of fuel, operating rules, installation quality, etc. Let us consider in more detail what is the efficiency of heating appliances, and how to increase this coefficient for solid fuel boilers.

What is efficiency - coefficient of performance

For the correct selection of the boiler power relative to the square of the room to be heated, we recommend paying attention to the efficiency of the unit, its efficiency, especially when it comes to solid fuel boilers. The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when products are burned in the furnace) and useful heat - which enters the heating system for transmission to the room

After calculating a simple formula, we get the percentage of efficiency

The coefficient of performance or efficiency is an indicator that is calculated based on the ratio between the energy expended (thermal - when products are burned in the furnace) and useful heat - which enters the heating system for transmission to the room. After calculating a simple formula, we get the percentage of efficiency.

q1 + q2 + q3 + q4 + q5 = 100%

Deciphering:

q1 is an indicator of the heat that was transferred to the coolant - water.

q2 - physical underburning - heat loss with exhaust gases.

q3 - chemical underburning - heat loss during incomplete combustion of fuel.

q4 - heat loss during heat dissipation.

The percentage of efficiency increases when the boiler is optimized.

The key point that affects the efficiency indicator is how well the solid fuel boiler was installed. In addition, the choice of fuel (coal, firewood, pellets), the presence of ventilation, and operating conditions are taken into account.

Let's take an example.

If the passport of the purchased boiler indicates an efficiency of 90%, it should be noted that this is an indicator that can be achieved if the unit operates in nominal mode, high quality fuel and low ash content is burned. With other factors during operation, the efficiency of a solid fuel boiler can be reduced to 60% or 70%.

How to get closer to the ideal and squeeze out the heat as much as possible during the operation of the heat pump?

How to increase the efficiency of a solid fuel boiler

Consider some recommendations on how to make a solid fuel boiler work at its maximum, work economically, consuming a minimum of wood, coal or pellets.

- Load only dried fuel into the fuel pump.If you burn wet wood or coal, part of the energy is spent on drying them.

- Do not use fuel with a large amount of debris, impurities, dust, because these inclusions will quickly clog both the heat exchange channels of the boiler, and the grate and chimney.

- Solid fuel boilers require mandatory periodic cleaning of the chimney and internal surfaces of the boiler, because any heat pump becomes clogged incomparably more than another gas boiler.

- Ensure proper draft in the chimney channel: it should not be too strong, but not too weak. If we exclude the moment of correct design of the chimney, then for this there is a throttle valve on the chimney or on the TPH, which regulates the air draft in the chimney - it should be set to the correct value. In order to load a solid fuel boiler once or twice a day and ensure the efficient operation of heating in general, it is necessary to design a buffer tank (heat accumulator).

- Purchase a solid fuel boiler only with a draft fan that can accurately regulate the combustion process in the boiler and control the temperature of the flue gases.

Manufacturing features and choice of materials

In addition to knowledge, skills, drawings and diagrams, for the manufacture of heating equipment, it is necessary to stock up on materials and tools. What is needed for the manufacture of equipment?

Materials and tools for the manufacture of equipment

Materials:

- Plates made of heat-resistant steel 4-5 mm thick to create a firebox.

- Steel sheets with a thickness of 2-3 mm for the manufacture of the body.

- Steel pipes for the heat exchanger, the length and diameter of which are calculated individually.

- Metal pipes for the chimney.

- Arched plate and grate.

- Ash pan combustion chamber door.

- Fire resistant brick.

- cement solution.

Tools

- Welding equipment with a supply of electrodes.

- Device for gas cutting.

- Bulgarian with disks.

- Pipe bender.

- Level, tape measure, marker.

Recommendations for the manufacture of equipment

Homemade boilers for heating a private house are usually made of metal. At home, it is almost impossible to make a cast-iron firebox; buying a new one will be expensive. Many homeowners order them from craftsmen who specialize in the manufacture of heating equipment. In order not to encounter defects in the operation of heating in the future, it is recommended to take part in the process. The purchase of materials and components, the assembly of the heating boiler, the installation and testing of the finished device must take place in your presence.

Since the temperature in the combustion chamber of a solid fuel device is very high, it is made of expensive alloyed heat-resistant steel (stainless steel) 5 mm thick. In order to save money and simplify welding work, ordinary thick sheets of steel are often used instead of stainless steel. Such products are short-lived, and steel walls can be deformed from temperature changes.

A reliable and efficient home-made solid fuel installation will cost less than a factory one

The water jacket is made of ordinary metal St 20 3 mm thick. Such steel is used in the production of pipes for hot water and steam. Therefore, fire tubes with a diameter of 48-76 from the same steel grade are suitable for the heat exchanger. The design of the shirt should be as rigid as possible. This quality is ensured by welding stiffeners to the outer walls of the furnace in increments of 120-150 mm.The outer walls of the tank are also welded to the ribs.

Blower doors and fireboxes should be double-layered. Between the metal layers, it is necessary to put a heat-insulating layer made of asbestos, basalt fiber, or a combination of both. The same materials can be used to insulate the body. The hinges on the doors are made adjustable, and the porches are sealed with an asbestos cord. In order not to burn your hands, the locking handles are equipped with ebonite or textolite nozzles.

5 Ways to Increase the Efficiency of Your Heating System

There are several simple ways to increase the efficiency of a heating battery without much material and labor costs. Let's consider them in detail. (See also: Autonomous heating systems)

Keeping the surface of heating devices clean.

No matter how incredible this statement may seem, even a thin layer of dust on radiators leads to a decrease in heat transfer. For example, the efficiency of aluminum radiators contaminated with a layer of dust can decrease by 20-25%. In addition, the inside of the battery also needs regular cleaning. The first problem can be dealt with on your own by ordinary wet cleaning, but for the second you will have to contact a qualified specialist. Plumbers are armed with knowledge and skills that will help in a short time to clean the radiator from scale and other contaminants accumulated during operation.

Painting radiators with paint appropriate for their purpose.

First, for coloring it is necessary to select paint of dark colors.Thanks to this, it will be possible to achieve not only good heating of the batteries, but also a significant increase in heat transfer. Secondly, you need to choose the right paint for coloring. As a coating for cast-iron heating radiators, it is better to use enamels known to everyone, and acrylic, alkyd and acrylate enamels are more suitable for aluminum and steel batteries.

Why the issue with painting is this way and not otherwise, can be explained quite simply: cast-iron radiators are quite easy to paint with any kind of enamel due to their structure. The thin fins of aluminum heatsinks can be clogged with too much paint. At the factory, radiators with a thin body and many plates are painted with powder paints that do not pose a threat to the quality characteristics of the radiator and do not change the type of heat transfer. Coloring the battery in a dark color allows you to increase the efficiency of heating elements up to 15% of the usual value. (See also: Comparison of heating systems)

Use of reflective screens.

The heat that the battery radiates spreads in all directions. Therefore, at least half of the useful thermal radiation goes into the wall located behind the heating devices. You can reduce unnecessary heat loss by placing a screen behind the radiator, for example, from ordinary foil or ready-made, bought in a store. When using even a home-made screen made of a thin metal sheet, not only does the heating of the wall stop, but an additional source of heat is created, since, when heated, the screen itself begins to give off heat to the room. When using a reflective screen, the efficiency of cast iron batteries, and many others, can be increased up to 10-15%.

Increasing the surface area of the batteries.

There is a very direct relationship between the surface area that radiates heat and the amount of this heat. To increase the heat transfer of radiators, you can use an additional casing. The material from which it will be made must be carefully torn out. For example, aluminum casings have the highest heat dissipation. They are used as an addition to cast iron radiators. With frequent interruptions in the operation of heating systems, it is worth considering purchasing steel casings, which retain the heat received from radiators for a very long time. Accordingly, this type of battery case gives off heat to the surrounding space much longer than others.

Create additional air flows in the room.

If you direct the air flow to the heating devices, for example, using a conventional household fan, then the air in the room will be heated much faster. In this case, it should be borne in mind that the direction of the air flow should be vertical and directed from the bottom up. With this method, the increase in the efficiency of radiators can reach 5-10%.

Using even one way to improve the heat transfer of batteries, you can significantly increase the temperature in the room and reduce the cost of additional heating. Before you begin to improve the performance of the radiators, make sure that they are connected to the heating network correctly and that the heat regulators on the latest generation appliances are set to the required value.

In addition, with a constant problem with heat supply, attention should be paid to the thermal insulation of walls and windows, through which heat usually escapes. It is necessary to insulate not only the outer walls, but also those that go to the stairwell

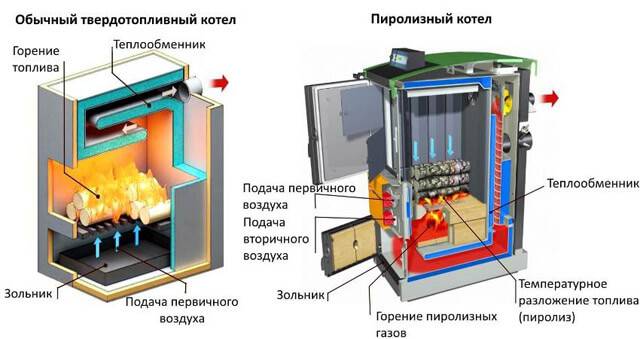

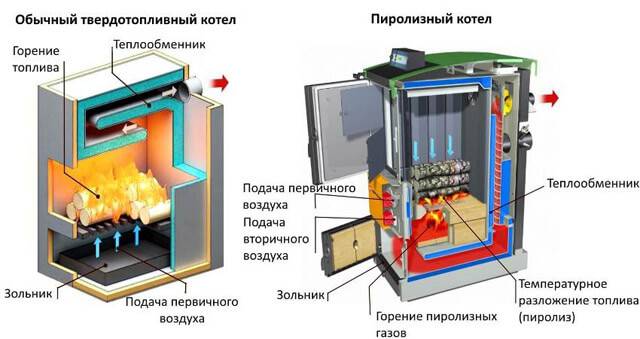

Boilers with pyrolysis type of combustion

Solid fuels are also used for pyrolysis boilers, in particular firewood, however, the principle of their operation is fundamentally different from the installations described above. They are able to heat the house much longer and more efficiently, and consume fuel more economically. In this regard, the cost of such units is approximately 1.5-2 times higher than the rest.

The secret of gas-generating (pyrolysis) boilers is that under the influence of high temperature and with a lack of air, wood is converted into charcoal, releasing pyrolysis gas.

This reaction requires a temperature of 200℃ to 800℃. At the same time, a large amount of energy is released, which dries the wood and heats the air. Pyrolysis gas moves through pipes to the combustion chamber, where it ignites when mixed with air - this is how most of the heat is generated.

Active carbons are involved in oxidative processes during the combustion of pyrolysis gas, so the smoke coming out of the chimney consists mainly of carbon dioxide and steam - the content of harmful components is negligible. In addition, pyrolysis boilers, in principle, emit much less smoke than classical installations. Since the fuel burns almost without residue, gas-fired boilers rarely need to be cleaned.

Thanks to automation, the intensity of combustion in such a boiler can be adjusted in order to save fuel and create the optimum temperature in the room.

Output of combustion products

The latest implemented ways of saving concern this point.The logic of the solution - if the temperature of the combustion products at the outlet of the chimney was 200-250 ° C, then why not use them to heat the coolant? To do this, additional heat exchangers made of steel or cast iron (with a large heating inertia) are installed on the exhaust gas path.

Additionally, work is underway to extract heat from the evaporated water obtained as a result of the combustion reaction - this is done by "condensing" boilers, which set records in terms of efficiency - the temperature of the exhaust gases is about 50 ° C, and the amount of heat used for its intended purpose reaches 98%.

Output of combustion products

The latest implemented ways of saving concern this point. The logic of the solution - if the temperature of the combustion products at the outlet of the chimney was 200-250 ° C, then why not use them to heat the coolant? To do this, additional heat exchangers made of steel or cast iron (with a large heating inertia) are installed on the exhaust gas path.

Additionally, work is underway to extract heat from the evaporated water obtained as a result of the combustion reaction - this is done by "condensing" boilers, which set records in terms of efficiency - the temperature of the exhaust gases is about 50 ° C, and the amount of heat used for its intended purpose reaches 98%.