- Improvement of the stove to increase efficiency

- Ways to increase efficiency

- Why is there bad draft in the oven?

- warm brick

- What is a potbelly stove

- How to make a homemade potbelly stove?

- Chimney for potbelly stove

- Material for the manufacture of the chimney

- Making a metal chimney for a potbelly stove

- Pipe installation

- Pipe Care

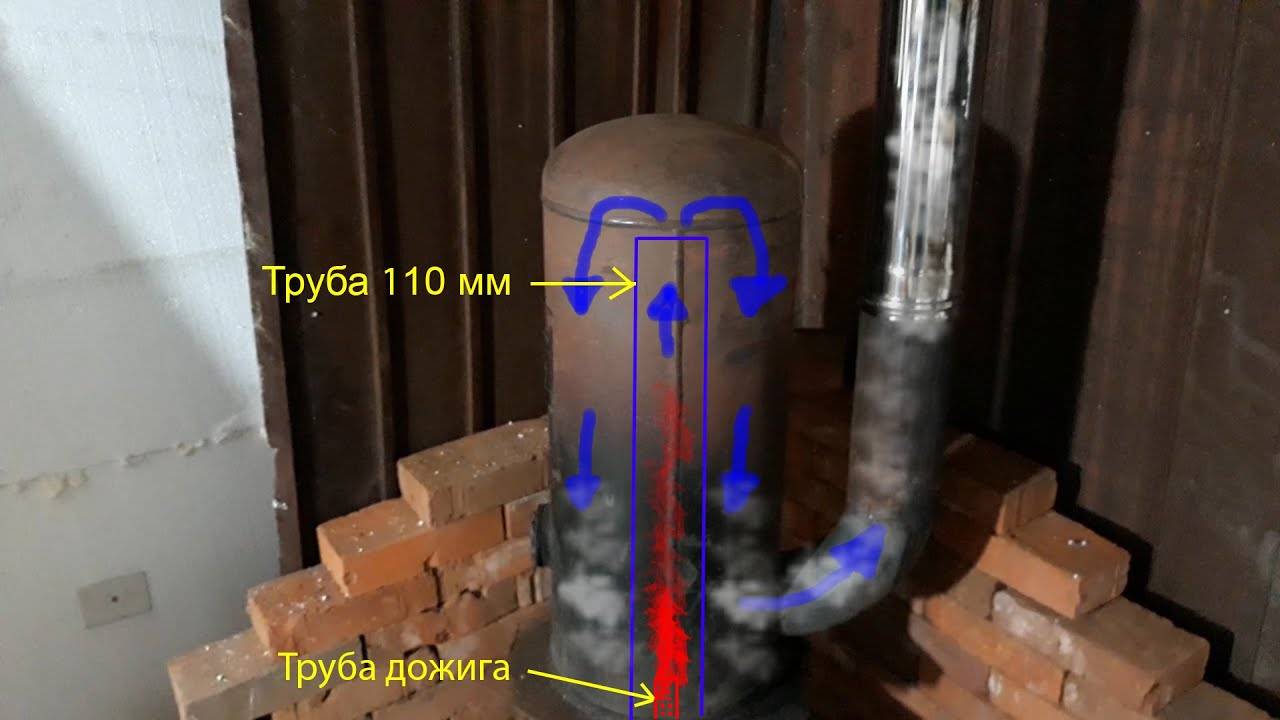

- Device and principle of operation

- Modification

- The third type of stove-potbelly stove

- What are the advantages of bourgeoisie?

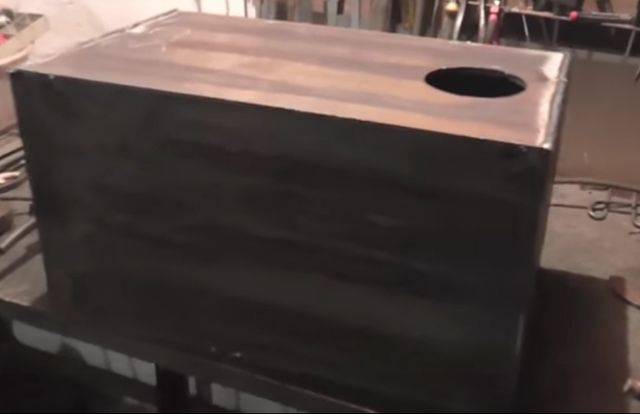

- How to make a potbelly stove from steel

- Manufacturing sequence

- How to increase draft in a potbelly stove with a chimney

- The main stages in the manufacture of potbelly stoves

- Requirements for the construction of bourgeois

- Ensuring heat removal

- asbestos chimney size

- Step-by-step instructions for assembling a potbelly stove with your own hands

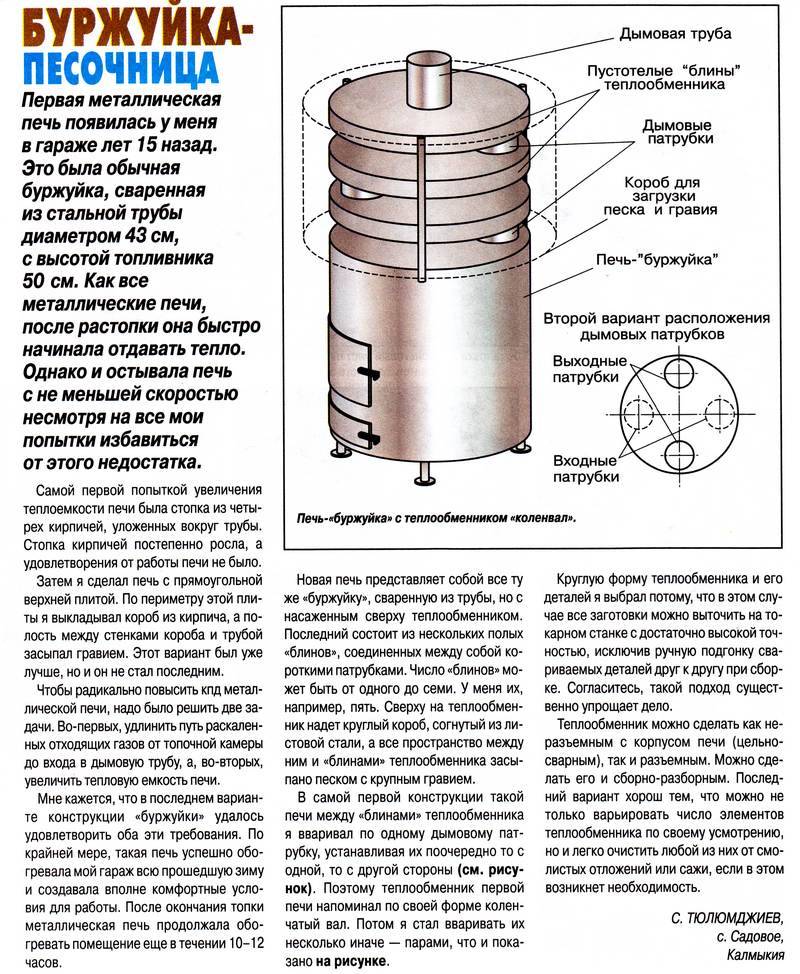

Improvement of the stove to increase efficiency

Suitable for garage heating

To increase the performance of the potbelly stove, the chimney can be built in not at the back, as is traditionally done, but at the front directly above the combustion chamber. In this case, the walls of the stove will first heat up, increasing the heat output. And if the furnace itself and the pipe are overlaid with bricks, then the cooling time will increase significantly, which will lead to fuel savings. In addition, if the dimensions of the structure allow, it is possible to make the inner walls in the furnace compartment itself from fireclay bricks, that is, to carry out the lining of the furnace.

Another method of increasing the heat capacity of a potbelly stove is the installation of additional fins. To do this, strips of thick metal located perpendicular to the walls are welded to the side walls of the furnace from the outside. This increases the heated area, which warms up the surrounding air faster. If you install a container with water on the stove, this will also contribute to long-term preservation of heat after the fire is stopped.

A furnace with welded fins can be protected by a special casing made of metal or heat-resistant materials. This will reduce the risk of burns during the firing of the stove.

Another way to increase the efficiency of a potbelly stove is to weld large-diameter hollow metal pipes to it. Their ends at the top of the stove will be directed in opposite directions according to the principle of buleryan stoves.

Ways to increase efficiency

Potbelly stoves are made in various shapes and sizes. But they are united by one drawback - low efficiency. More than half of the thermal energy, in the truest sense of the word, flies out into the pipe. The irrational use of heat has led the owners of these heaters to think about possible changes in the design of the furnace to increase its efficiency. The solution to this problem could be a partial modernization of the potbelly stove. There was no single concept for solving this issue, and each owner of the furnace began to independently, by trial and error, solve the problem.

An increase in the efficiency of a potbelly stove is the receipt of an additional amount of heat from a heater with a constant amount of fuel burned. This can be achieved in several ways:

- changing the heat transfer surface,

- increase in heat removal;

- using more high-calorie fuel;

- an increase in the heat capacity of the furnace.

The potbelly stove gives off heat to the surrounding space not only with its body, but also with a metal chimney. You can increase the heat transfer surface of the device by revising its dimensions upwards. This option is possible when creating a furnace with your own hands. Having already made a potbelly stove, it can be done in another way. Usually a corner is welded to the chimney from a metal pipe. Position it with the top to the element along the entire length. The installation of the corner is carried out around the pipe. Thus, the area of the heat transfer surface can be increased by 3-4 times, depending on the size of the corner.

Another option to increase the heat transfer surface is to manufacture a chimney that runs inside a large area. To do this, make a chimney with turns. They are performed in the form of smooth transitions. It is undesirable to create turns at right angles, since the potbelly stove may begin to smoke. The last section of the chimney is installed vertically. A pocket is made on it with a hatch for cleaning soot.

If it is impossible to lengthen the pipe, its design is changed. Cylinders made of a pipe with a diameter of 300-400 mm are welded onto the branch pipe coming out of the furnace body. Between themselves, they are connected by pipe segments with a diameter of at least that of the chimney. Their welding is carried out out of alignment to increase the smoke path.

Why is there bad draft in the oven?

Poor or weak traction most often causes reverse traction as a consequence. The reasons can be quite different from each other. As for the main one, these are the mistakes that people made when they designed the heating system. In this case, there is a possibility of improper use of building materials.Let us also consider in more detail the possible sources of the problem and what to do in such cases:

The defect may lie in the design of the chimney. The proportions between height and firebox are sometimes calculated incorrectly. And because of the low, for example, pipes, most often the stretching is worse. However, if the parameter for this component was greater, then the reverse thrust would not have formed.

REFERENCE

Therefore, it is so important to take into account the universal size - about five meters.

- Do not forget about the ratio of the diameter. A narrow value contributes to the difficulty for the output of combustion products.

- In addition, if the product is a square shape, then most likely the movement of smoke will not be as free as it would be with rounded corners.

- Natural conditions also significantly affect the presence of weak traction. In rainy climates, in high humidity or with strong winds, the level tends to decrease.

- If there are various damages or scratches, bumps on the pipe, then there is a high probability of obstacles for attraction with a good coefficient.

- Oven maintenance. It is not uncommon for the user to forget about cleaning, thereby accumulating pollution - collapsed building materials.

- The reason is very similar to the previous one. Only this time the blockage is soot.

- The ventilation process is broken. Because of this, there is a shortage or even absence of supply air mass.

warm brick

A potbelly stove on wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to build a screen of baked clay bricks around it with your own hands.If you look closely at the drawings of such a mini-building, you can see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and if desired, around the chimney.

Brick screen for potbelly stove

Brick screen for potbelly stove

Bricks need a foundation. Do you want the masonry to last a long time? Then pour the base at a time to form a monolith. The material for the foundation is better to take concrete, which should be reinforced with steel reinforcement with your own hands. It is desirable to make a reinforcement layer at a distance of approximately 5 cm from the surface of the concrete pad.

Ventilation holes are made at the bottom and top of the brickwork, which will ensure the movement of air (heated masses will go up, cold air flows from below). Ventilation also prolongs the life of the metal walls of the potbelly stove, postponing the moment of their burnout due to cooling by circulating air.

Bricks laid around the stove accumulate heat, and then give it away for a long time, warming the air in the room even after the potbelly stove goes out. In addition, brickwork additionally protects the objects surrounding the stove from fire.

If desired, the stove can be completely laid out of brick. Such a structure is beneficial in that it will last for many years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite laborious and is suitable only for those people who have experience in masonry with their own hands;

- a brick potbelly stove is quite expensive, as it requires the use of refractory materials, including fireclay bricks and special clay for mortar.

In order to get a small potbelly stove on wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber, 2-4 rows are laid out from fireclay bricks. Ordinary clay baked brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or a potbelly stove with your own hands, you make them according to a drawing or by eye, the main thing is that at the output you get an effective heater, and in an expanded configuration also a hob for cooking. Look around for suitable materials (barrels, sheet metal, etc.) and go to your own homemade stove or even a potbelly fireplace!

What is a potbelly stove

For those who have never seen such stoves, you need to tell what a potbelly stove is. This is a firebox made of metal, with a straight chimney and a hole into which firewood is laid. These fireboxes are often made from any suitable metal object or welded from scrap metal. A potbelly stove can be round, for example, made from an old metal barrel, square or rectangular from iron boxes. The stove is placed on metal legs or just on bricks. The pipe exits through the roof. A potbelly stove is good because it is cheap, and you can heat it with any waste.

The operation of such a furnace is based on constant combustion. Thin metal quickly heats up and gives off heat to the room. Everything would be fine, but you just have to constantly keep the fire in the furnace, because when the flame becomes smaller, the stove begins to cool.It cools down quickly, and the room becomes cold again. But craftsmen have learned how to get out of the situation by upgrading the stove with their own hands. Having such a stove and upgrading it a little, you can get a very cheap heating device that will retain heat even after the fire goes out. And when burning, the converted potbelly stove will give much more heat than before.

How to make a homemade potbelly stove?

- The first type of potbelly stove

- The second type of stove-stove

- The third type of stove-potbelly stove

- Step-by-step device of a potbelly stove

The stove, popularly known as a "potbelly stove", is a barrel- or box-shaped metal structure equipped with a pipe and a door. As a rule, the chimney was led directly into the window of the room. "Burzhuyka" literally saved people in the cold season, if the house was not equipped with a large Russian stove or there was simply not enough firewood for heating.

Schematic diagram of a sawdust stove.

This stove got its name because of its high efficiency; she could heat the room in a short time by burning several birch branches.

Until now, home-made potbelly stoves with a similar design have been successfully used for heating garages, temporary houses and small country houses.

In addition, urban residents of apartments should also resort to such unpretentious equipment if the heating is turned off in winter.

Potbelly stoves bribe with the simplicity of their device and high efficiency. To date, there are several different types of baby stoves, let's look at some of them.

Chimney for potbelly stove

Material for the manufacture of the chimney

Before proceeding with the manufacture of the chimney pipe, which will be installed on the potbelly stove, it is necessary to determine the material that will be used.

Taking into account the fact that the potbelly stove is a portable stove, we immediately refuse brick chimneys. In this case, we have few options: either asbestos-cement or metal pipes. Most heating experts still recommend using metal chimneys: they are both lighter and easier to manufacture.

It is about them that we will talk in more detail.

Most heating experts still recommend the use of metal chimneys: they are both lighter and easier to manufacture. It is about them that we will talk in more detail.

Cast iron stove with steel chimney

Making a metal chimney for a potbelly stove

So, we decided on the material - we will make a chimney from a metal (stainless steel) pipe. However, it is not enough just to stick the chimney pipe into the corresponding hole in the potbelly stove - the chimney must be correctly installed and optimally located.

Potbelly stove on the street

As a rule, a simple chimney for a potbelly stove installed indoors consists of two parts - internal and external. These parts are connected in the attic or at the level of the roof space.

Such a "double-knee" design makes it relatively easy to replace the lower burned-out segment of the chimney without dismantling the entire system.

By the way, you can not buy steel pipes, but bend them from a steel sheet, but this will require certain skills from you. On the other hand, then you can make a pipe for a potbelly stove of exactly the diameter that you need.

Pipe installation

To install a chimney of standard dimensions, we need the following materials:

- Knee 100x1200mm (1 pc.)

- Knee 160x1200 mm (2 pcs.)

- Butt elbow 160x100 mm (3 pcs.)

- Tee 160 mm with plug

- Mushroom 200 mm

Also, depending on the characteristics of the room in which the potbelly stove with our chimney will be installed, you may need a passage glass, a rain visor, thermal insulation, etc.

Also, to seal the joints between pipes, we may need an asbestos cord or a special sealant.

After all the materials are ready, we proceed to assemble the pipe for the potbelly stove:

- We fix the first section of the pipe on the chimney or the furnace pipe.

- We build up the pipe elbow to the overlap.

Chimney hole

- In the floor slab we make a hole with a diameter of at least 160 mm for the chimney outlet. We remove the thermal insulation along the edges of the hole to prevent its ignition.

- We insert a passage glass into the hole, and then we pass the potbelly stove pipe through it.

- We join the pipe with an external chimney.

- To ensure optimal operation of the chimney, we provide thermal insulation of the outer part of the chimney, wrapping it with thermal insulation and coating it with bitumen.

Chimney outlet through the window

We strengthen the fungus on top of the chimney, which protects the pipe from precipitation and small debris getting inside.

Pipe Care

In order for the chimney (and with it the potbelly stove itself) to work properly, it must be looked after:

- At least once a year, we check the outer surface of the pipe for defects - burnouts, rust, cracks.

- Similarly, the pipe must be cleaned annually.To do this, you can either use special chemical compounds that are burned in the furnace along with firewood, or simply burn a few aspen logs in a potbelly stove. Aspen gives a very high temperature, which perfectly burns out soot.

- It is unlikely that it will be possible to use mechanical cleaning agents (ruff, weight, etc.), because the chimney of the potbelly stove is not very durable.

The manufacture and arrangement of both the furnace itself and the pipes for the potbelly stove is a difficult task only at first glance. Of course, you will have to sweat and carefully study the proposed instructions - nevertheless, it is quite possible to do this without resorting to the help of specialists. So keep it up!

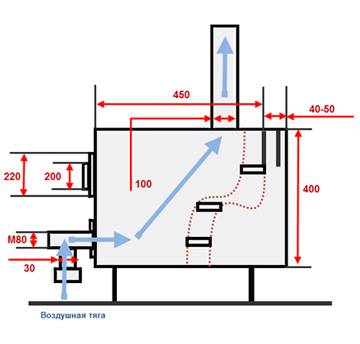

Device and principle of operation

What is the difference between Loginov's Potbelly stove from other metal stoves? The bottom line is the L-shaped blower. The ash pan door is replaced with pipes welded perpendicularly. The edge of the horizontal pipe is tightly welded, and the edge of the vertical pipe is threaded for a plug. Holes are made on the thread - by screwing the plug, you can reduce the air flow, thereby regulating the combustion process.

Loginov's original potbelly stove

It is important to make a plug with a little play, so the expansion of the metal when heated will not cause problems. A screen is welded on the sides and back on the stiffening ribs to increase efficiency

Without such screens, it is extremely uncomfortable to be near the stove - the temperature is too high and fraught with burns. The firebox door is also threaded. A 200mm pipe serves as the firebox opening, and a plug with a handle with a diameter of 220mm is screwed onto this pipe.

You can see more details about Loginov's potbelly stove in this video:

Modification

The N. Pyankov model is distinguished by the presence of an additional combustion chamber.Unlike more complex designs of slow-burning stoves, the Pyankov potbelly stove is made even faster, the model proposed by Loginov. It is enough to weld steel sheets 140-160 mm long to the rear and front walls of the furnace at different distances from the top. The distance between sheets should be 80mm. The grate is installed 80mm from the bottom. Loginov's firebox door, Pyankov transferred to the upper part of the furnace and began to use it as a hob.

It will not be difficult for a good master to evaluate all the advantages and disadvantages of two drawings. If desired, you can make a new model of a potbelly stove using only these two developments, changing the rectangular shape to a round one.

An example of a home-made design (in this photo is a modernized Pyankov oven), but there is practically no difference in the manufacturing process.

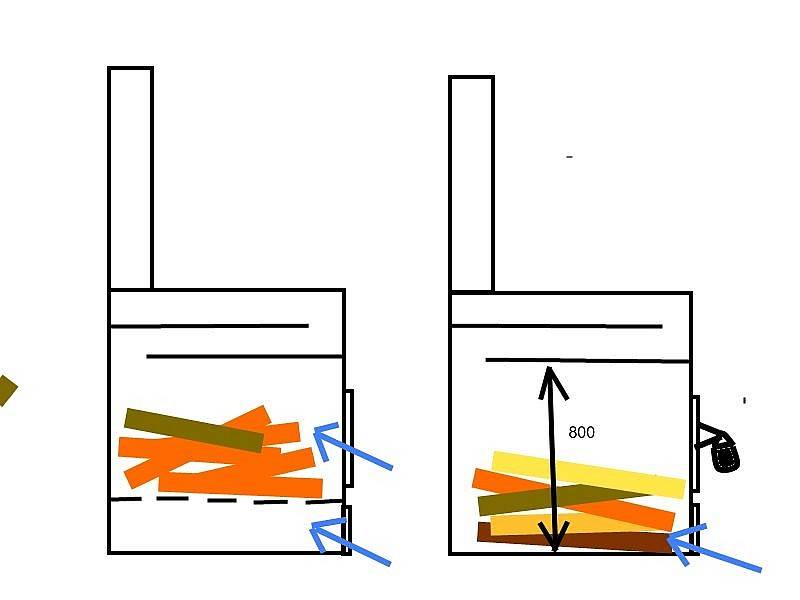

The third type of stove-potbelly stove

Now let's figure out how a home-made potbelly stove with a square body with thin walls and adjustable draft is designed. The main advantage of a square-shaped potbelly stove is a larger surface area of interaction with air, that is, a greater efficiency compared to a stove based on a pipe.

The most optimal dimensions for a homemade stove would be a construction height of 800 mm and a base of 450 × 450 mm. A potbelly stove of this size will not take up much space and easily accepts almost any piece of wood.

Chimney installation diagram.

You should also determine how thick the metal will serve as the material for the stove.Here, as in everything, the golden mean should be observed: very thick walls (about 1 cm) warm up for too long, thin-walled metal sheets swell after the firebox, the stove will become shapeless.

Choose for these purposes the average wall thickness - approximately 0.3-0.5 cm. Then the potbelly stove will retain its original appearance and will perfectly warm the room.

What are the advantages of bourgeoisie?

First of all, such long-burning devices are characterized by low profitability. After all, for their manufacture, as a rule, containers that were in use are used. They can be purchased completely free of charge or at a minimal cost. The same can be said about the price of fuel.

Besides:

- You can make a potbelly stove with your own hands if you find successful and understandable drawings of its design.

- With a small size of the stove, it has sufficient efficiency.

- It does not need to build a strong foundation.

- You do not need to issue a bunch of permits.

- Easy maintenance and free installation.

- A potbelly stove, in addition to the function of heating, can serve as a cooking stove.

firebox door

But despite all the advantages of such do-it-yourself furnaces, they have such disadvantages as the rapid burning of fuel, as well as rapid cooling due to the inability to accumulate heat. All these shortcomings can be eliminated if improved types of furnaces are used and heat-accumulating structures are built.

How to make a potbelly stove from steel

Stove potbelly stove convection type.

If you need to heat a house in the country and cook food, you should definitely know how to weld a potbelly stove yourself from sheet steel. This design will not require a lot of fuel.This is achieved through the installation of partitions in the furnace, reliable fastening of the doors and the ability to adjust the air flow. To make such a device with your own hands, you will need to prepare the following elements:

- metal sheet with a thickness of 4 mm or more;

- metal with a thickness of 8-12 mm, from which partitions will be made;

- lattice;

- chimney;

- corners from which the legs will be built;

- welding device.

Manufacturing sequence

From the steel sheet, the first step is to cut out the elements for the body and several partitions that will be mounted on the top of the firebox. They will be able to make a labyrinth for the smoke, as a result of which the efficiency of the stove will increase. In the upper part, you can make a recess for the chimney structure. The recommended recess diameter is 100 mm. Next, you will need to make a recess for the hob with a diameter of 140 mm.

Stove potbelly stove made of sheet steel.

Using a welding device, you need to attach the side elements to the bottom of the structure. To the side walls you will need to attach strips of metal of great thickness. As a result, it will be possible to attach the grate. It can be a sheet of metal with recesses with a diameter of about 20 mm. The lattice can be made of reinforcing bars. At the next stage, supporting elements from a metal strip must be attached to the side walls. After that, the installation of partitions is carried out.

Doors for the firebox and ash pan should be cut out of metal. They can be installed on ordinary hinges. However, a more reliable option is to use curtains made of steel pipes and rods. They can be fixed on wedge hecks.The elements are cut from a stainless steel sheet, after which they are fixed with bolts. In order to be able to adjust the intensity of fuel combustion, on the door that closes the ash pan, it is necessary to make a recess for mounting the damper.

To the recess for the chimney structure, you need to attach a sleeve 200 mm high, on which the pipe will be mounted. A damper in the tube will help keep the heat in. For her, it will be necessary to cut a circle from a metal sheet. One extreme part of the steel rod must be bent. After that, several parallel holes will need to be made in the tube. Next, a rod is mounted, after which a round damper is welded to it.

Diagram of a brick fence for a potbelly stove.

The flue pipe must be installed at an angle of 45°. If it passes through a recess in the wall, in this place the part must be wrapped with fiberglass, and then fixed with a cement mixture.

To prevent the occurrence of burns from touching a red-hot stove, it will be necessary to build a steel protection screen from several sides and place it at a distance of 50 mm. If there is a desire to increase the heat transfer coefficient, the structure can be overlaid with bricks. After the firebox is finished, the brick will heat the house for some time. Laying should be carried out at a distance of 12 cm from the metal body.

The air cushion can become heat protection.

For its implementation, holes for ventilation must be made in the masonry above and below.

How to increase draft in a potbelly stove with a chimney

The design of the chimney potbelly stove with high efficiency should have the following features:

- The chimney should be made high enough.So, the optimal distance from the furnace itself to the top of the pipe is about 5-6 m.

- In the form of a pipe, horizontal and inclined sections of less than 45 degrees should not occur, or their number should be minimized.

An increase in the efficiency of the potbelly stove will also be facilitated by the creation of thermal insulation on the pipe, which will significantly reduce the harm from condensation.

- When setting the cross section of the chimney, you need to choose the optimal size. If at the time of establishing the efficiency of the potbelly stove there is already a too narrow chimney, you can put a deflector on top, which will protect the structure from precipitation and increase traction.

- The height of the pipe should also be affected by the level of the ridge. If the chimney is below it, you need to build up the pipe.

↓ Be sure to read the recommended material on the topic ↓

How to make an economical do-it-yourself potbelly stove with increased heat transfer

Tip: The thrust in the furnace is determined by the color of the flame: if there is not enough air, it is red with dark stripes, if it is in excess, it is bright white, and the chimney often makes a buzz. If the color of the flame is golden-orange, then the potbelly stove draft is normal.

The main stages in the manufacture of potbelly stoves

1. All details are marked on a sheet of metal: 6 steel rectangles for the walls of the furnace, 1 rectangle for creating a smoke reflector, plates for the grate and a latch for the door. 2. cut out a sheet of metal is possible at any metal base. The guillotine, unlike the grinder, allows you to cut (chop) it more accurately. In this case, straightening (alignment of sheets) will not be necessary.3. The furnace body is made in the form of a rectangle. Their sides are joined together at an angle of 90 ° and welded together.

four.To avoid mistakes, the oven box is first only tacked by welding in several places, and only then, after checking its horizontal and vertical positions, its seams are welded.

Important! All connections in the body are carefully welded; to check the joints for tightness, you can coat the joints with chalk or kerosene. 5

Welding seams are cleaned with a metal brush.6. The internal space of the potbelly stove is divided into three parts: a firebox, a smoke chamber and an ash pan. To separate the firebox from the ashpit, a grate is laid between them, on which the fuel will be placed. To do this, at a height of 10-15 cm from the bottom of the furnace, 5x5 cm corners are welded on the sides and on the back of the box. On which the grate will be located

5. Welding seams are cleaned with a metal brush.6. The internal space of the potbelly stove is divided into three parts: a firebox, a smoke chamber and an ash pan. To separate the firebox from the ashpit, a grate is laid between them, on which the fuel will be placed. To do this, at a height of 10-15 cm from the bottom of the furnace from the sides and on the back of the box are welded corners 5x5 cm. on which the grid will be located.

Advice. The grate is best made from 2-3 detachable parts. Otherwise, when replacing a burned-out grate, it will be difficult to get it out of the furnace.

7. The grating is welded from thick steel bars or strips 30 mm wide. They are attached to 2 stiffeners - rods with a diameter of 20 mm. Since the grate burns out over time, it is better to make such a grate removable.

Making a grate

Making a grate

eight.At a distance of 15 cm from the top of the box, two strong rods are welded on which will be placed one or two removable reflectors - thick-walled metal sheets that will delay the flow of hot gases and send them for afterburning. However, they should not completely block the oven. In order for hot smoke to be able to enter the pipe, about 8 cm is indented from the front (for the first sheet) and the back of the furnace.

Scheme of the passage of gases in the simplest potbelly stove and a furnace with an installed reflector

Scheme of the passage of gases in the simplest potbelly stove and a furnace with an installed reflector

9. Next, the upper part of the box is welded, and then cut out in it pipe hole .

pipe hole

pipe hole

10. The front part of the stove with holes cut out in it for the doors of the furnace and ash pan, is welded last. 11. The size of the firebox door should be sufficient so that it is possible to load fuel and change the grate without effort. The hole for the ash pan is made a little smaller. 12. The hinges are first welded to the door, and then to the potbelly stove body. They can be bought ready-made or welded from two tubes of different diameters. Door handles can be made from a strip of metal or a bar.

Important! When fastening the doors, they should be adjusted to the body as tightly as possible; for this, they are straightened (aligned) and cleaned with an emery wheel. The wedge locks that close the doors are fitted to the body as tightly as possible

13. On such an oven you can cook food or warm water. To do this, a hole of the required diameter is cut in the upper part of the box. Burner for oven. which will be inserted into this hole, can be purchased at any hardware store.14. For ease of use, the design mounted on legs or a welded pipe stand.15.The chimney is connected to the stove using a sleeve. 16. For inserting a slide gate. regulating the exit of smoke, two holes are drilled in the pipe. A metal rod is inserted into the holes and bent at 90 °. A “penny” made of metal is attached to it in the center of the pipe - a gate, the diameter of which should be slightly less than the diameter of the pipe itself by 3-4 mm.

Smoke damper

Smoke damper

Requirements for the construction of bourgeois

An economical long-burning wood-burning stove must meet certain requirements and device rules:

- Without fail, such a structure is equipped with a chimney, and the room is equipped with a supply and exhaust ventilation system.

- Given that the design of the potbelly stove, when heated, will heat up to very high temperatures, it is necessary to comply with fire safety requirements when installing it indoors.

The oven must be located away from flammable wall, ceiling and floor structures, and also have a fence to prevent fire and the risk of burns during its operation. The potbelly stove, fenced with a wall of heat-resistant brick, not only becomes safe during operation, but also creates additional heating areas.

Ensuring heat removal

It is possible to increase heat removal by creating devices that promote natural and forced convection. To ensure natural air circulation, screens are made with a guide vane, which allows you to create a powerful convection flow and distribute it throughout the room. The guide apparatus is made in the form of curved metal strips welded to the screen and directing warm air not only upwards, but also to the sides. The prepared device is attached to the furnace.

The device for heat removal can also be made from scraps of water and shaped pipes. The distance from the floor to the lower cut of the elements should be at least 15-20 cm. The pipes are welded to the body of the stove and are covered with a screen on the sides to protect against accidental contact. A traditional potbelly stove heats the air around it by 0.5-1.0 m, and the use of this design allows you to increase not only the radius, but also the rate of temperature rise in the room. When the body of the heating device is heated above 60 ° C, a stable convection draft arises in the device, the power of which increases as the temperature of the furnace increases.

Heat removal can be increased by using fans to blow the heat transfer surface. Use both household and old car fans. Particularly well proven devices with a variable speed of rotation. They allow you to adjust the temperature and time of heating the room in various modes of operation of the furnace.

For more efficient blowing of the elements of the furnace, special casings are arranged that allow cold air to be directed to the hottest parts of the heating device, while it can be taken from various places in the room. A potbelly stove with pipes welded into the firebox for heating air has proven itself well. A multi-speed car fan installed on a common supply manifold allows you to effectively heat the room.

asbestos chimney size

When choosing pipes for an asbestos chimney, you need to be guided by the following considerations:

- The use of this material is possible only for gas boilers and pyrolysis heating units, which are characterized by a low flue gas temperature.It should be borne in mind that the smoke of pyrolysis furnaces is oversaturated with products that contribute to the formation of condensate, and therefore soot.

- The diameter of the asbestos chimney pipe should not be less than the outlet pipe of the thermal unit.

- The total length of the chimney must be at least 5 meters, while the excess over the roof ridge - at least 0.5 meters.

- A significant excess of this indicator will also lead to undesirable consequences due to a decrease in the speed of movement of gases in the pipe. This will increase the amount of condensate formed.

The effectiveness of a chimney of any material depends on its proper installation on the roof of the house.

Step-by-step instructions for assembling a potbelly stove with your own hands

The first step is the preparation of the drawing and the necessary materials. As for the drawing, it should reveal in as much detail as possible the design features and subtleties of all elements.

For experienced craftsmen, this stage can be skipped, but for those who are just starting out as a bourgeois designer, it is recommended to assemble a cardboard layout. Modeling, in this case, will cost much less than miscalculations immediately embodied in the metal.

The next step is the selection of tools and materials. Here it is recommended to use as much as possible ready-made components and housings produced in an industrial way. So you can not only reduce the cost of work, but also find new more effective technical solutions. Another piece of advice regarding this stage is the proper organization of the workplace. When working with sheet metal, it is recommended to assemble a slipway from wood so that the structures to be welded can be easily installed in the desired position.

During assembly, you need to remember that all connections must be as accurate and durable as possible, especially for the body and supports of the potbelly stove. And of course, after assembly, it is necessary to make a test firebox to check the performance of the assembled structure.