- How to insulate the ceiling in a cold attic

- Where to insulate the ventilation pipe?

- Why is it needed

- A special case

- Methods and materials for ventilation insulation

- Application of roll materials

- Shell application

- Misconceptions about ventilation

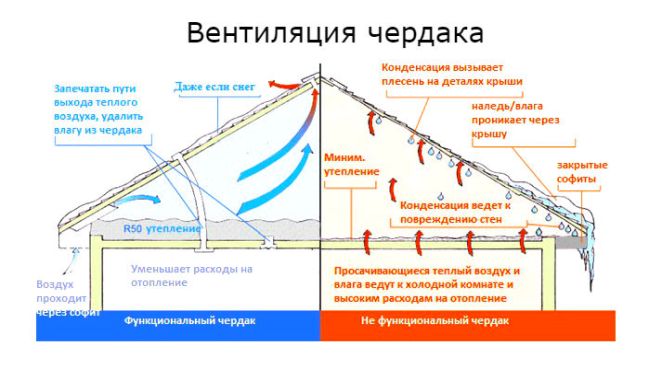

- Attic space: the need for ventilation

- Installation of thermal insulation on ventilation pipes

- Expanded polystyrene insulation

- Polypropylene and polyurethane foam

- Polyethylene foam insulation

- Do-it-yourself thermal insulation installation technology

- Necessary calculations

- Preparatory work

- Warming with mineral wool

- Insulation with polyurethane foam

- Foam insulation

- The nuances of installing self-adhesive thermal insulation

- Thermal insulation with special cylinders

- What is the meaning of ventilation insulation

- Shell for thermal insulation

How to insulate the ceiling in a cold attic

Today, there are many options for insulating the attic floor with your own hands. The following thermal insulation materials are most widely used:

- mineral wool. This includes glass, stone and slag wool. Available in slabs and mats;

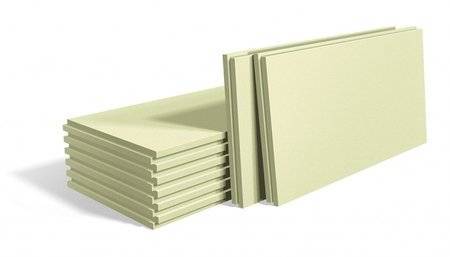

- expanded polystyrene and polystyrene. Expanded polystyrene is a higher quality material than polystyrene. It has greater strength and density, less moisture absorption;

- polyurethane foam (PPU).One of the most technologically advanced, high-quality and expensive heaters;

- bulk materials (sawdust, expanded clay, slag, etc.).

Before insulating the attic of a private house with one of the above heaters, it is necessary to decide which of them will be the most rational. For example, it is simply impossible to fit well mineral wool boards. For such a case, it is better to use loose insulation, which will fill all the voids and irregularities.

Do-it-yourself insulation with mineral wool is quite common due to its good heat-insulating and sound-proofing properties. Before laying the mineral wool, a vapor barrier is laid on the attic floor to prevent moisture from entering the lower rooms.

Most often, mineral wool is laid in two layers. A vapor barrier is also laid on top and only then a subfloor is made for moving around the attic.

Insulation with expanded polystyrene (polystyrene) is also recommended to be done with a lining under it of a layer of vapor barrier membrane. The moisture permeability of these materials, although insignificant, is better to play it safe and get rid of possible future difficulties. For self-insulation in a cold attic, it is better to use polystyrene foam boards, as they are stronger than polystyrene.

Insulation of a non-residential attic with polyurethane foam (PPU) is the most effective and high-quality way for a wooden private house. The main advantages of polyurethane foam are as follows:

- absolute seamlessness. After applying PPU, a monolithic layer of thermal insulation is created;

- environmental friendliness. The material does not contain volatile components that may be released during its operation;

- high adhesion.PPU adheres to almost any surface except for polyethylene and fluoroplastic surfaces;

- PPU has one of the lowest thermal conductivity coefficients;

However, it should be borne in mind that the material must be applied to dry surfaces with a temperature of +10 °C. In addition, self-applying PPU will not work. This will require equipment and specialists who can correctly select the content of the components and configure the equipment. Therefore, to insulate the attic with this material, significant financial investments will be required.

The oldest and most proven way to insulate an attic floor with your own hands is thermal insulation with bulk materials. Before backfilling the material, a lining layer is laid - glassine, vapor barrier membrane, etc. It all depends on the specific type of insulation and the technology of its preparation before direct laying on the attic floor.

When insulating walls in the attic, if any, you can use all of the above materials. The only exceptions are bulk materials, which, for obvious reasons, are not suitable for thermal insulation of walls.

Where to insulate the ventilation pipe?

Mandatory insulation is necessary in places where there is a temperature difference. In areas where warm and cold air come into contact, condensate appears most abundantly. Here is the dew point. When designing the insulation of exhaust ducts, the position of this point is calculated first of all.

The task is to move it as close as possible to the outlet of the ventilation pipe. An ideal option when the mixing zone of cold and warm air flows is moved outside the house.

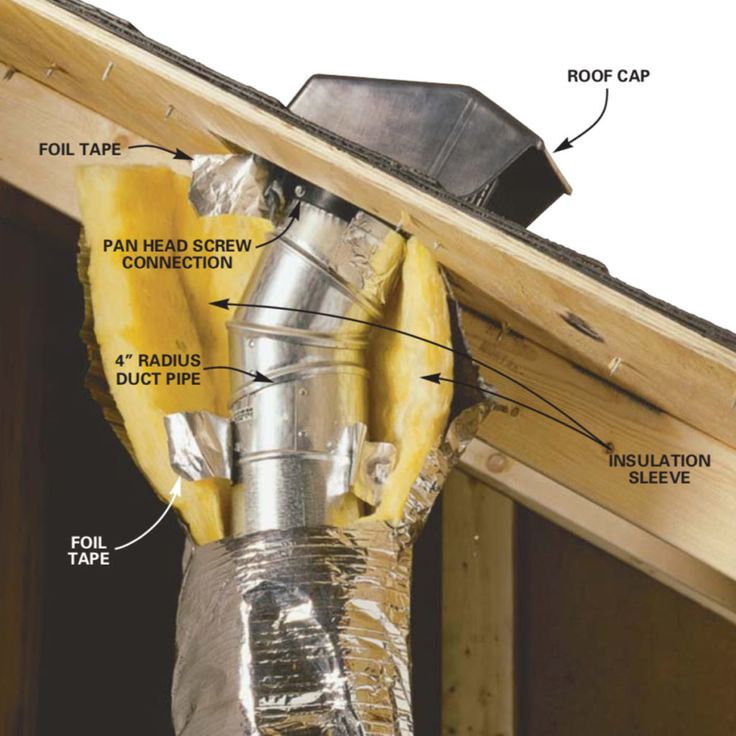

Since this is rare, on the ventilation pipe that crosses the cold attic and then goes to the roof, the zone of passage through the ceiling of the upper floor or attic is subject to insulation. The pipe itself is insulated along its entire length to the very outlet to the roof.

In the case of supply ventilation, the amount of condensate falling out on the outer walls of the ventilation duct is directly proportional to its length. This phenomenon is influenced by the installation feature. In large areas, in addition to pipes, valves are also insulated.

In order not to create prerequisites for the occurrence of a dew point, i.e. the transformation of water vapor contained in the air into water, air ducts in a cold attic must be insulated and ventilation equipment must be installed

In order not to create prerequisites for the occurrence of a dew point, i.e. the transformation of water vapor contained in the air into water, air ducts in a cold attic must be insulated and ventilation equipment must be installed

The insulated valve has the form of blinds with adjustment. The latter limit the passage and somewhat increase the temperature of the air supplied from outside, because. in the design there are tubular heaters.

The speed of the air supplied through the valve is controlled by means of levers or an electric drive system. Heating of the valve blades with heating elements is necessary to prevent their icing. This changes the temperature of the supply air masses slightly.

Why is it needed

The key word is condensation. Without insulation, it will inevitably form on the inner surface of the ventilation duct and flow down the inner walls, flowing through leaky joints into the main walls and ceilings. The consequences are obvious: dampness of walls and ceilings, the appearance of mold and their gradual destruction.

The effect of condensate on the ventilation duct itself depends on what material it is made of:

- Galvanization can suffer if the protective anti-corrosion layer is violated. Which, however, is inevitable when cutting a sheet.

- PVC and corrugated aluminum pipes tolerate contact with moisture without any consequences.

Another trouble associated with moisture condensation is the gradual freezing of frost on the inner walls of the ventilation duct outside a warm room. For several weeks of operation in severe frosts, the pipe clearance can decrease from 100 - 150 millimeters to zero.

Where does the condensate come from?

There are two reasons for its appearance.

- Human life is associated with excessive moisture in the air. When washing dishes, cooking, washing, even just breathing, the atmosphere is saturated with water vapor.

- Meteorologists have long used the concept of relative humidity. The higher the air temperature, the more water vapor it can hold. 100% relative humidity is the maximum amount of water that can be contained in the air in vapor form. However, it is worth changing the temperature - and with the same amount of vapor in the air, the relative humidity will change. With significant cooling, it can exceed 100%, after which excess water will inevitably begin to condense on surfaces with a low temperature. In our case, on the inner surface of the ventilation duct.

Consequences of moisture condensation in the ventilation duct.

A special case

In production, there is often a need for forced ventilation with a high air flow rate. In particular, to remove harmful volatile products of production, sawdust, shavings, etc.

The noise of the air and what it carries becomes a serious problem in some cases. In factory premises, ventilation insulation often aims not so much to combat condensate as to simply soundproof. The methods, however, apply the same.

Methods and materials for ventilation insulation

Warming methods are as follows:

-

The use of roll materials (mineral wool insulation, foamed polyethylene, foamed rubber).

-

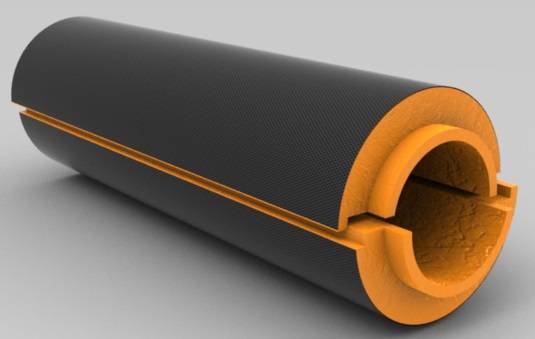

The use of "shell" (cylinders for pipes, can be made from mineral wool, polyethylene foam or rubber, polystyrene or XPS, polyurethane foam).

Sheet materials (foam plastic, extruded polystyrene foam, sheet polyurethane foam) - they can be used to insulate air ducts, but only for rectangular and square ones. This option is used very rarely, since it is inconvenient to mount it, it takes much more time, and a large number of joints are obtained between the sheets.

First of all method and material of insulation is selected based on the shape of the ventilation duct:

-

For round ducts: roll insulation and "shell" can be used. Sheet material for a round duct will not work, because it cannot be bent.

-

For rectangular and square ducts: only roll insulation can be used.

Round and rectangular insulated air ducts

Additionally, over the insulation layer on the pipe can be put on:

-

Galvanized casing.

-

Plastic casing.

In private homes, such protection is not necessary, since it is designed to prevent mechanical damage to the insulation.

Application of roll materials

This option for duct insulation is used simply:

-

The air duct is tightly wrapped with insulation.

-

So that the insulation does not fall off, it is fixed with soft wire in equal steps.

If we are talking about air ducts of large diameter, which are insulated with mineral wool, then in addition to the wire, pins are used for fastening. For this:

-

The pins are welded to the outer surface of the ventilation duct using a contact welding machine.

-

Mineral wool is tightly wound around the air duct, pricking on the pins.

-

From above, the wound insulation is fixed with clamping washers, which are attached to each pin.

-

Further, for additional fixation, a wire is used, which is wound over the insulation.

Roll of foiled mineral wool

The method using rolled insulation is good for the following reasons:

-

simple and quick to use;

-

allows you to create a layer of insulation without seams and joints;

-

if necessary, it allows you to quickly remove the heat insulator in the desired area (for example, to repair a pipe, or to replace a heater).

The following materials may be used:

Mineral wool heaters. The most common, cheapest and most effective option. A common thickness is 5 cm, on sale you can find rolls with a thickness of 4 to 8 cm. Thicker mineral wool is convenient to use only for large diameter pipes, which are not used in low-rise residential construction. There are insulators with an outer foil layer (increases efficiency and serves as additional mechanical protection)

Of the minuses - mineral wool eventually cakes and crumbles, and it is necessary to work with it carefully.

Foamed polyethylene. The option is simpler and cheaper, but also less effective.

The thickness of such a heater is small (from 2 to 40 mm), so it will have to be wound in several layers.

Foamed rubber.Almost the same as polyethylene foam.

When it comes to choosing an insulator for an air duct, it is easiest to choose the first option.

Shell application

The shell is a cylinder that is put on the insulated area. That is, in fact, it is a pipe made of insulating material. It could be:

-

mineral wool;

-

foamed rubber;

-

foamed polyethylene;

-

foam/EPS;

-

polyurethane foam.

The shell can be either solid (it can be put on the pipe only when laying the air duct) or separate (it can be put on a ready-made and working ventilation system).

Polyurethane foam shell for pipe insulation

The use of the shell is ideal for sections passing through the wall: it is very difficult and inconvenient to wind the rolled insulation there. It is also convenient to use the shell on straight sections. But where the pipe turns, it will no longer be possible to put on the cylinder, and you will have to use a mat.

The very process of using the shell for ventilation insulation looks like this:

-

The shell is put on the pipe.

-

If the shell is separate, its parts are fastened together with glue (reliably, but it will be more difficult to separate them if necessary) or wire (an easier and more convenient way).

-

The joints between the cylinders are glued with construction tape.

Misconceptions about ventilation

little to do attic ventilationit is important that it is done correctly. However, among people who are going to deal with this issue, there are several common misconceptions. They should be considered in more detail.

They should be considered in more detail.

- The need for ventilation is only in the summer. In fact, the attic needs not only to be ventilated in the heat, but also to smooth out the large temperature difference inside and outside the attic in winter. If this is not done, then humidity will inevitably rise - an excellent environment for the existence of mold, fungus. It is extremely difficult to deal with these phenomena, and in advanced cases, mold can penetrate into the rooms - then there is no need to talk about any comfort.

- Ventilation removes warm air from the room in winter. In fact, if heat is poorly retained in the house, then it is not the ventilation that should be blamed, but poor-quality thermal insulation. It is because of it that conditions are created under which moist and cold air enters the attic.

- The size of the ventilation holes does not matter. In fact, the area of these holes is important. With a small ventilation area, the effect of it will be almost zero. So that the room is well ventilated, and at the same time heat leakage is not allowed, by 500 sq.m. the area needs 1 sq.m. ventilation holes.

Attic space: the need for ventilation

The device of the ventilation system is the most important part of the design. Ventilation is involved in the heat exchange processes of the entire residential building.

The device of the ventilation system is the most important part of the design. Ventilation is involved in the heat exchange processes of the entire residential building.

In the hot season, the roof is able to heat up over a hundred degrees, and heated hot air enters the house, aggravating the heat in it. In cold weather, other problems may appear. The cooled air forms drops of condensate on the insulated ceilings: this moisture negatively affects the wooden elements.

Even elementary ventilation can prevent premature damage to the rafters.

Attic ventilation ensures the mixing and equalization of the temperatures of the roof structure and the external environment. It prevents the formation of ice during the melting of the snow cover, the descent of "avalanches" and the appearance of large icicles.

Arrangement of a high-quality air exchange system actually extremely important

Installation of thermal insulation on ventilation pipes

Expanded polystyrene insulation

Insulated ventilation pipes expanded polystyrene are less susceptible to corrosion, which greatly increases their service life.

To install the polystyrene shell, you do not need special skills. For its installation:

- Determine the size of shell you need.

- Cut the shell with a saw or knife.

- Install the parts of the shell on the pipe with an offset of several centimeters between each other, carefully close the side joints.

From the ventilation pipes, which are insulated with polystyrene foam shells, in the event of an emergency, they are quite easy to dismantle and just as easy to install back.

Polypropylene and polyurethane foam

These materials have significantly lower thermal conductivity and high refractoriness. Ventilation pipes are insulated with polyurethane foam and polypropylene as follows:

- Determine the required size.

- Cut material into semi-cylinders.

- Provide an allowance for the cover layer.

- Install half-cylinders on the ventilation pipes.

- Securely fasten the joints with bandages.

PPU (polyurethane foam) shell for pipes

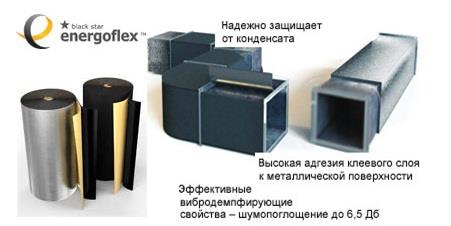

Polyethylene foam insulation

This material insulated pipe for ventilation is the most popular today. Foamed polyethylene is a ready-made shell that completely encloses and insulates pipes.

For pipe insulation:

- Take material measurements.

- Divide the insulating sheath along a special seam.

- Fix the shell on the pipe.

- Using mounting tape or glue, fix the joints and seams of the insulating shells.

For square-section air ducts, polyethylene foam is produced in rolls (for example, Energoflex Star Duct)

Regardless of how to insulate the chimney, the location of the heat-insulating material, the main thing is to prevent cold bridges, which reduce the effectiveness of insulation, and ensure high vapor resistance

To do this, special attention should be paid to the places where the channels join the building structures, where there is the greatest probability of the appearance of cold bridges.

Do-it-yourself thermal insulation installation technology

When planning the thermal protection of the duct, you should prepare the right amount of insulation and fasteners based on preliminary measurements.

Necessary calculations

If you plan to use ready-made shells, you need to determine the length of the treated areas and prepare the material with some margin. In the case of roll insulation, you should additionally calculate the desired width of the product. To do this, determine the diameter of the pipe, add the double parameter of the thickness of the insulator, multiply the result by 3.14 (Pi number).

Preparatory work

Before starting work on insulating the outer section of the ventilation duct, the deflector should be removed if you have to work with a finished casing that is pulled over the pipe. In other cases, there is no need to dismantle the protective umbrella

It is also important to prepare clamps and other fasteners in the required quantity.

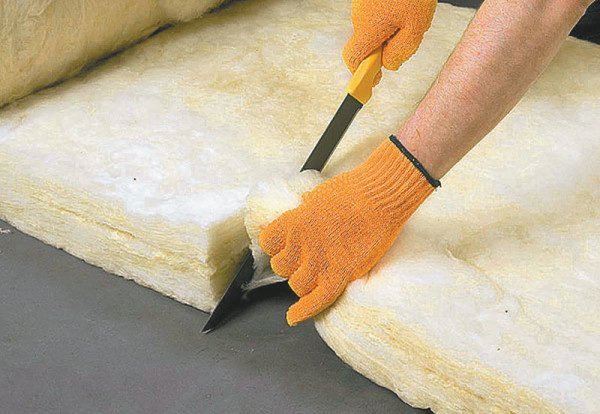

Warming with mineral wool

For the installation of roll insulation, the following set of tools and materials is required:

- construction knife;

- stapler;

- aluminum tape;

- roulette;

- rubber spatula.

Aluminum tape will be needed to insulate air ducts with mineral wool

Aluminum tape will be needed to insulate air ducts with mineral wool

Foiled mineral wool is used, which leads to reliable waterproofing of the fibrous base of the insulation. Insulation in the form of stone wool with Isover brand foil is especially in demand.

Stages of work:

- perform marking on the canvas with an aluminum coating, taking into account overlapping, cut the required number of blanks. Moreover, an incision should be made along the length of the end, retreating from the edge by 7-8 cm. Next, the cotton wool is removed along the incision line, leaving a layer of foil;

- wrap the pipe with insulation so that the protrusion of the foil along the edge closes the joint seam;

- the connecting line is fixed with a stapler in 10 cm increments, glued on top with aluminum tape.

To isolate the corner elements of the ventilation duct, curvilinear fragments of insulation are used, cut according to the parameters of the base. The street section of the duct must be strengthened with clamps over the mineral wool. It is also required to build a protective box of tin.

Insulation with polyurethane foam

Polyurethane foam insulation is sprayed using special equipment. Due to the high cost of installation work with the participation of professionals, PPU is mainly used in the arrangement of industrial exhaust air systems. Manufacturers also offer compact units for mixing foam insulator components for insulating air ducts in private housing construction. The complete set weighs within 30 kg and allows you to foam a small piping in the attic and on the roof.

Foam insulation

Plate material is used in the arrangement of rectangular ventilation systems. The expanded polystyrene layer is completed with special waterproofing products in the form of a membrane or foil. Billets are cut from the plates to the required dimensions, fragments are mounted using clamps, adhesive tape, a stapler or metal wire. To eliminate gaps at the outer corners, the joints are additionally sealed with mounting foam.

Waterproofing is required depending on the density parameters of the boards. For example, for PPS-60 there is no need to protect against moisture, and PPS-40 should be used complete with a waterproofing membrane.

The nuances of installing self-adhesive thermal insulation

Self-adhesive insulation - penofol brand "C" - is valued for ease of installation. The outer surface of the material based on polyethylene foam is finished with an aluminum coating. Glue is applied to the back of the insulator, which is covered with a film. The canvas is cut to the required size in accordance with the parameters of the air duct, the film is removed and glued to the selected pipe surface. The edges of the self-adhesive thermal insulation are folded with an overlap of at least 5 cm and secured with aluminum tape.

Thermal insulation with special cylinders

The shell is used only for round pipes, selecting a model of the appropriate size. One-piece cylinders with a longitudinal section are relevant for the arrangement of ventilation ducts of small diameter. The shell is opened along the gap line, put on the pipe and fastened with tape or a clamp. Collapsible models of finished cylinders are also in demand for thermal insulation of air duct outlets outside the heated room and outdoor segments of the ventilation duct with the obligatory construction of a protective box.

What is the meaning of ventilation insulation

Actually, the insulation itself is necessary to prevent the conditions for the occurrence of the so-called dew point. According to the building code SP-50.1333-2012, this term refers to the temperature at which the water vapor contained in the air falls out in the form of water on surrounding objects, that is, it condenses. Naturally, the dew point directly depends on the humidity of the air, the higher it is, the closer the dew point is to the ambient temperature.

Table for determining the dew point.

Let's start with the fact that on an unprotected pipe in the attic floor, condensate can fall both from the inside and from the top of the duct. This moisture is dangerous in its own way in both cases. So the water constantly flowing down the pipe will naturally be absorbed into the ceiling.

And here it does not matter whether it is concrete, wood or any other material, sooner or later it will begin to collapse. Add to this the unpleasant stains around the pipe on the ceiling of the last floor;

More than half of ventilation ducts and pipes are now made of galvanized iron

Zinc coating is a good thing, but if it is damaged, which is inevitable during cutting and installation, a thin iron sheet will begin to rust and it will take a little time for holes to appear on the pipe, no more than 2 - 3 years;

Cutting mats from cotton wool insulation.

- In addition to domestic ventilation, fan ventilation for the sewer system is installed in houses from 2 floors and above. Simply put, this is a continuation of the sewer riser brought to the roof. So, with the extreme humidity that is in the sewer, the attic sector of such a pipe with a diameter of 100 mm freezes tightly already at a temperature of -5ºС or -7ºС for a week.And this already entails problems with the operation of the sewer;

- In addition to its direct function, insulation for ventilation pipes is a good sound insulator. By setting up such a system, you do not have to listen to the howl of the wind in your pipes;

- But a rotten ceiling, a damaged ceiling, constant wind music, an unpleasant smell from the sink and a sewer frozen in winter are still “flowers”, the appearance of mold and fungus inside the household ventilation system is much more dangerous. The fact is that such "vegetation" is spread by aerosol, in other words, mold spores are carried by air currents. Naturally, once they get into the ventilation system, they will regularly irrigate the whole house, and the people living in the house will constantly breathe all this bouquet. The consequences can be very different, from mild malaise, to chronic headaches and allergies.

Wrapping a glass wool cocoon with a waterproofing sheet.

Now weigh the pros and cons and decide for yourself whether it is necessary to insulate the ventilation pipes in your house. I think the answer is obvious and further we will dwell in detail on common materials and methods for their installation.

Shell for thermal insulation

The shell can be monolithic (in this case it is strung on a pipe) or prefabricated. The latter option is used for ready-made operating systems. The shell can help out in those places where the pipe is passed through the wall. When winding roll insulation in such cases, it may be difficult. Pretty good results can be achieved in outdoor open areas. However, those points where the duct turns cannot be closed with a cylinder. In such conditions, it is recommended to use insulating mats.

The shell can be made from:

- Styrofoam.

- mineral wool.

- extruded polystyrene foam.

- Polyethylene.

- rubber.

There is a lot of noise in the supply and exhaust air ducts during operation. With an increase in the cross section of the pipe, the throughput becomes higher, but the resistance also increases. Interior finishing allows you to make the surface as smooth as possible, which slows down the air flow less.