- Features of insulation of chimneys of various shapes

- Ways to insulate chimneys from various materials

- Thermal insulation of a brick chimney

- With plaster

- With fiber insulators

- Video: sheathing a brick pipe with tin

- How to insulate an asbestos chimney

- How to insulate a metal chimney

- Do-it-yourself warming - procedure

- Plastering

- Video: plaster and chimney insulation

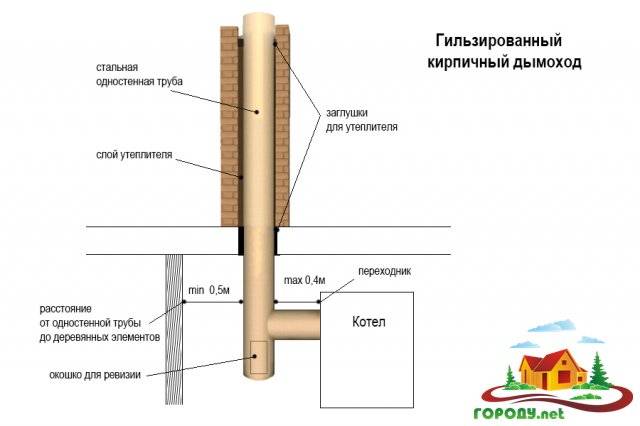

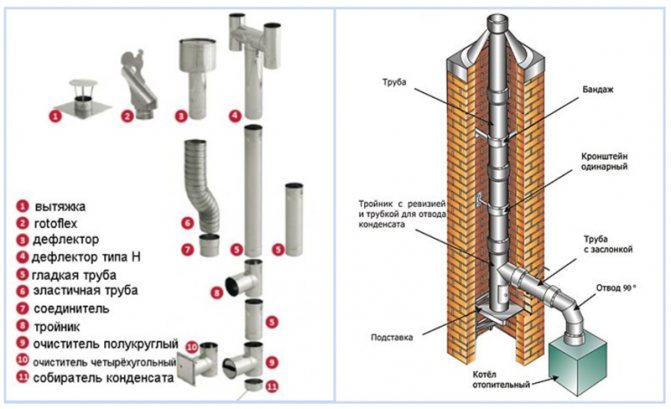

- Sleeve or sandwich chimney

- Lining a brick chimney

- Bulk insulation

- How and with what to insulate other structures?

- Thermal insulation for brick construction

- Use of cotton

- Application of plaster

- Insulation of metal pipes

- Requirements for a metal chimney

- Winding of stove and chimney metal pipes

- Gas boiler pipe insulation

- Choosing a heater

- How to insulate a chimney or fireplace chimney

- Chimney collapse

- How to insulate a chimney with your own hands?

- brick chimney

- Asbestos-cement chimney

- steel chimney

- Chimney insulation in the attic

- Heaters for thermal insulation of a chimney

- Which heater is better to choose

- Benefits of chimney insulation

- Brick work

- Method one

- Method two

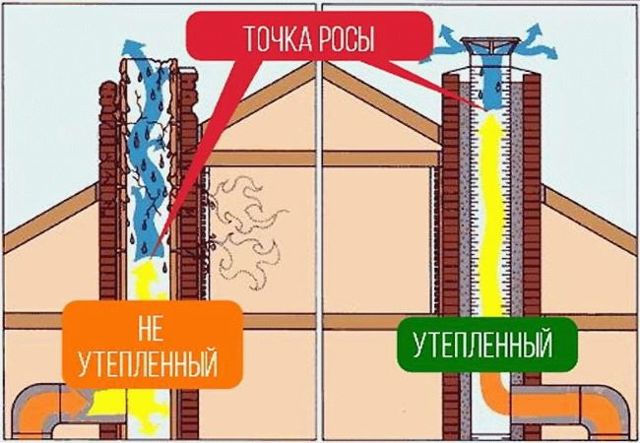

- Why insulate chimneys?

- Materials and methods of chimney insulation.

- How to choose a heater

- Summing up

Features of insulation of chimneys of various shapes

When arranging chimneys of square or rectangular shapes, thermal insulation is performed using a frame. Using the same technology, it is possible to insulate smoke channels of a circular cross section. For example, to insulate an asbestos chimney from several pipes, the construction of a frame box is required.

Subsequence insulation works smoke shafts of square or rectangular configuration:

- maintaining an interval of 10 cm from the perimeter of the object being equipped, they assemble a frame from metal profiles or a wooden block. Fastening is carried out using galvanized nails and self-tapping screws 30-50 mm long;

- the space between the crate and the walls of the gas outlet shaft is filled with mineral insulation;

- the outer perimeter of the frame is sheathed with asbestos panels 10-12 mm thick.

At the final stage, the butt joints are filled with heat-resistant plaster, as well as the upper perimeter of the frame, to ensure the tightness of the structure.

Ways to insulate chimneys from various materials

The method of thermal insulation of a pipe primarily depends on the material from which it is made. Now chimneys are made of asbestos, steel, etc., but brick is still the most common.

Thermal insulation of a brick chimney

Brick pipes must be additionally insulated: this significantly extends their service life. It is most convenient to provide protection against condensate at the design stage of the house. For example, if you maintain the required thickness of the walls of a brick pipe during its construction, moisture will not settle. However, for objective reasons, this is not always possible, and often the chimney has to be equipped already in the completed building.

Currently, two main options for insulating a brick chimney are used: simple plastering and lining with mineral wool.

With plaster

The most common way is to plaster a brick chimney, starting with the part in the attic and ending with the part protruding above the roof. The procedure for this is as follows:

- First, the surface of the pipe is cleaned of dust, primed and covered with a reinforcing mesh so that the fastener does not pass through the chimney through.

- Then apply up to five layers of plaster, alternating with priming. The solution must have heat-resistant properties, so it includes lime, finely sifted slag and a little cement. The first layer (a thin batch) should cover the mesh (about 3 cm), after it dries, the rest are applied (up to 6 cm in total).

- In conclusion, the pipe is whitewashed with lime or covered with paint that does not wash off with water.

The efficiency of the chimney with such insulation increases by 25%.

With fiber insulators

You can insulate a brick chimney with your own hands using fiber heat insulators as follows:

The outer surface of the pipe is covered with mineral wool with a layer of 5 cm or more, using special fasteners (a hairpin with a wide hat) or scotch foil.

The second layer of insulation should cover the joint of the first layer so that there is no exposure of the pipe

It is important to prevent the insulation from sliding down.

Then everything is lined with metal profiled sheets or asbestos-cement slabs. The upper part of the structure is isolated.

In this way, it is possible to reduce condensation by half and reliably protect the chimney from heat loss and external influences even in severe frosts.

Insulated chimney helps reduce heat loss and saves fuel

If necessary, depending on the size of the chimney, guides are lined up, between which sheets of insulation will fit tightly, so that it is convenient to fasten materials.

You can also build a metal or asbestos-cement box around the pipe, and place a heater (mineral wool, dry sand, expanded clay, brick breakage) in the void between the pipe and the box.

Video: sheathing a brick pipe with tin

How to insulate an asbestos chimney

It is quite simple to insulate an asbestos-cement pipe on your own. The material will be a fiber heat insulator and galvanized metal sheets or pipes. The work plan is as follows:

- Clean the outside of the chimney from dust.

- Cover (wrap) the entire length of the pipe with insulation with a uniform layer of 5–7 cm, fix it with tape-foil or soft thin wire.

- Make a cylindrical casing of galvanized steel with a larger diameter so that the pipe, together with the insulation, is hidden.

- For ease of installation, divide the casing into several parts of one meter.

- Place the casing pieces on top of each other so that they overlap.

- Protect the top of the structure from moisture ingress (isolate with cement mortar).

Thermal insulation must be carried out to the very top of the pipe

You can first install part of the cylindrical casing, and then tamp the insulation into the void around the pipe, then install the next part with an overlap and continue tamping the insulation, and so on to the very top. The design is simple and reliable, it will be enough for this type of pipes, since their service life is short.

How to insulate a metal chimney

Metal chimneys are mainly made of stainless steel with a wall thickness of 0.5–1.2 mm.A second, larger one is put on the main chimney, and the space between them is densely filled with a mineral heat insulator.

Insulation will protect the metal chimney from corrosion

The main thing is that the axis of symmetry is not violated. The annular gap should be at least 5 cm, and in regions with a cold climate - at least 8 cm. Pipes are purchased ready-made, the outer one can consist of several segments that fit together conveniently.

"Sandwiches" made of stainless steel and insulation are convenient for installing the chimney and durable in operation

Do-it-yourself warming - procedure

Before proceeding with the thermal insulation device, prepare everything you need for work. Clean the pipe from dust, repair cracks and chips

It is important that the surface is dry, otherwise the quality of thermal insulation will decrease.

Plastering

The mixture is mixed with water using a construction mixer in the proportions specified by the manufacturer. It is more correct to first pour water into the container, and then add the dry mixture.

With a spatula or trowel, the solution is applied in spots over the entire surface of the pipe and leveled.

Plaster mortar is leveled over the entire surface of the pipe

The pipe is covered with a reinforcing mesh along the spots of the solution, which will fix it on the surface. The mesh is necessary to strengthen the plaster layer, it plays the role of a frame.

The first layer of plaster is applied over the reinforcing mesh

It is important that it covers the entire surface without gaps.

In order for the plaster layer to stay on the surface of the chimney, a reinforcing mesh is used.

The plaster is leveled and left to dry.

After that, several more layers are applied, each of which needs to be dried.For good thermal insulation, you need 3-5 layers.

After drying the last layer, the pipe is painted in the color of the roof for aesthetics.

Video: plaster and chimney insulation

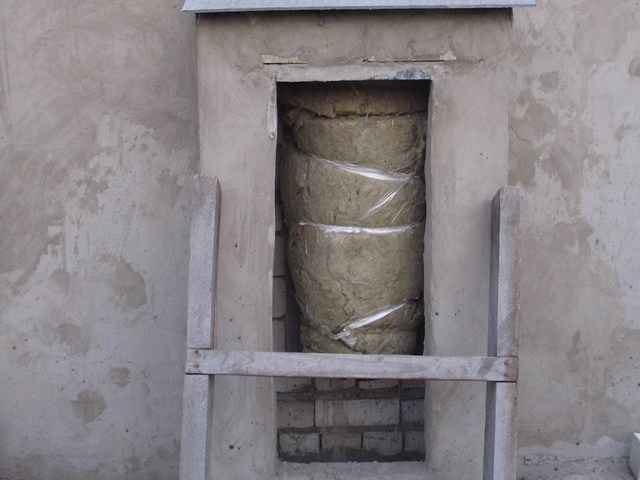

Sleeve or sandwich chimney

- To do this, you need a steel or galvanized pipe with a diameter larger than the chimney by 6-10 cm and mineral or basalt wool.

- The chimney is wrapped with a layer of insulating material. The layer thickness must be at least 5 cm, the winding is overlapped.

- The layer of cotton wool is fixed with coils of wire or foil tape.

The sleeve is made using a heater and larger diameter pipes

- A protective cover is put on top of the insulation. It is recommended to fix the thin metal sleeve with adhesive tape and tightening straps.

- A gap is left between the upper edge of the protective casing and the insulation, which is filled with cement mortar to protect the wool from moisture.

Lining a brick chimney

The above method is suitable for metal and asbestos chimneys, brick will require a lot of effort and time.

- Insulation mats are cut to the size of the chimney walls and attached to them with a knitting wire or adhesive tape. In some cases, a crate may be needed.

To insulate a brick pipe, a crate is sometimes required.

- Outside, the chimney is lined with bricks, cinder blocks, sheathed with metal siding or asbestos concrete slabs.

Bulk insulation

- A casing is built around the chimney. Depending on the material, it can be round or rectangular.

- The gap between the casing and the pipe is filled with sand, expanded clay or broken bricks.

- Cement mortar is poured on top to prevent moisture from getting inside.

For insulation with expanded clay and other bulk materials, a casing is required

Such simple work will not only save the chimney from destruction and extend its life, but will also help save a lot by minimizing heat loss.

How and with what to insulate other structures?

The most difficult work is for the owners of a brick chimney; metal may not require additional manipulations at all. But in any case, the main requirement for a heater is its incombustibility.

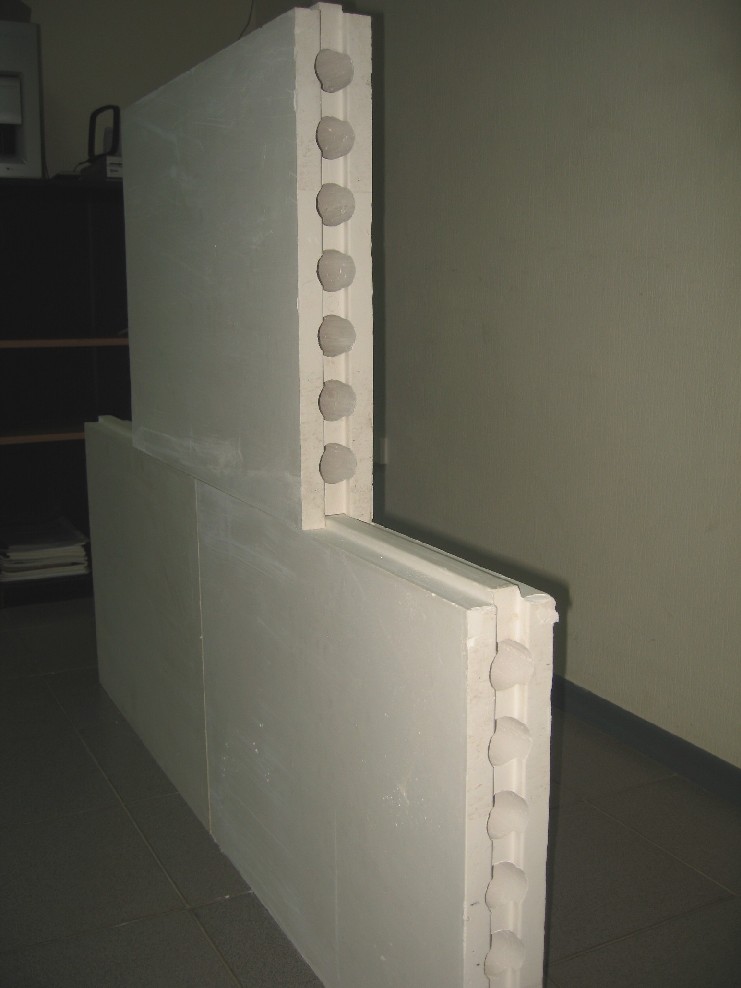

Thermal insulation for brick construction

There are two options. It is possible to insulate with mineral wool (or cotton varieties) or plaster, but in the latter case, the work will take more time and require effort from the master.

Use of cotton

The easiest option is to fix mineral wool (glass wool, basalt) with adhesive tape. After wrapping, the insulation is “hidden” under cinder-concrete or asbestos-cement slabs. Or even left open. This is not the best option, even for the attic.

Application of plaster

All work consists of several stages, very stretched in time.

- First, a reinforcing mesh is fixed on the walls of the chimney pipe with dowels, then a solution consisting of fine slag, cement and lime is thrown onto it. The maximum layer thickness is 30 mm. Cover all surfaces at once.

- Mineral wool is attached to a slightly dried solution, then the solution is again thrown in, which is pressed in with a fiberglass reinforcing mesh. Then they wait for the complete drying of the plaster layer.

- After setting the solution, the surfaces are leveled, this time the layer of the solution is made thinner. The dried walls are treated with a primer: at least twice with a break for drying the composition.

The last step is painting the chimney. Often, facing bricks, stone, artificial or natural, decorative plaster or porcelain tiles are used to decorate chimneys.

Insulation of metal pipes

Many iron structures do not need additional manipulations, because there are products on sale that can be called semi-finished products. They consist of two pipes, heat-insulating material has already been laid between them.

If there is no such design, then such a product is not too difficult to create on your own. To implement the plan, they buy a pipe that is 60-80 mm more than the chimney diameter. It is put on the channel, then fixed on the base. The space between the elements is filled with light loose or fibrous insulation.

An alternative is to use the same mineral wool as the sandwich filling. If the roofing system is reliable enough to withstand the additional load, then a heavy “stuffing” can be used as a heat insulator: for example, screened slag or broken brick.

Requirements for a metal chimney

Before you insulate the chimney, you must familiarize yourself basic rules and requirements to him:

- The pipe must have a height of at least five meters. Only in this way can one be sure that the thrust will not function worse over time;

- The distance between the ceiling and the pipe must be at least 300 millimeters;

- If materials such as roofing felt, slate, ondulin (combustible) were used as a finishing material for the roof, the pipe must be equipped with a special spark arrester.

Sealing metal pipes

Sealing metal pipes

Non-combustible chimney heaters

Non-combustible chimney heaters

Winding of stove and chimney metal pipes

Before insulating an external chimney, it is necessary to select the most suitable material and calculate its exact amount.

Winding instructions and materials:

- The easiest option is to use a special solution. As a mixture, special powders are used, which must be diluted in a certain proportion with water;

- You can buy the mixture at any specialized hardware store;

- First, a special glass fiber stack must be fixed to the surface of the pipe, which will prevent the solution from rolling and spreading.

Gas boiler pipe insulation

In order to choose a heater for the chimney of a gas boiler, it is necessary to choose and use no less high-quality, non-combustible materials. The most common option is to use sandwich pipes. The design of which consists of two pipes with different diameters. This is necessary so that a product with a large cross section enters the second one, and thereby forms an additional protective layer.

How to insulate metal chimney pipe- materials and guidance:

- On the roofing it is necessary to make small holes. Their cross section should exceed the diameter of the chimney by approximately 25-30 centimeters;

- We produce insulation using basalt wool.After winding, there should be no gaps;

- Insulation is additionally fixed with wire;

- The casing of the pipe with a large size must be fixed with tapes and ties;

- A metal sheet located near the riser must also be insulated with asbestos, expanded clay or clay.

Chimney insulation with mineral wool

Chimney insulation with mineral wool

Non-combustible chimney insulation

Non-combustible chimney insulation

Gas boiler chimney insulation

Gas boiler chimney insulation

One of the most important elements of any stove and fireplace is the chimney, which you learned from this article. Following the instructions and recommendations, you can do all the work on your own, with minimal time and money.

Choosing a heater

Mineral wool

So we got to the question - how to insulate the chimney pipe. In general, there are many types of thermal insulation materials that builders use for chimneys. An example is:

- fibrous insulation;

- mineral wool (for example, Rockwool insulation);

- broken brick;

- glass wool;

- concrete slabs, etc.

Cinder concrete slabs (although the photo shows too large slabs for the chimney, there are fewer)

The price, in its essence, does not play any significance here - the more convenient and convenient it is for you, the warmer it is. However, general advice choice of heater it would still be useful to know:

- Perhaps the most important advice is that in no case should you use combustible materials to insulate the chimney, because the entire structure (including the chimney) and a small piece of the roof (near the chimney) are under constant high temperature;

- It is better to choose a material that can be easily put alone with your own hands, for example, glass wool;

- Before using the selected material, do not rush to mount it. In each package of insulation there is an instruction from the manufacturer, in which you can learn a lot of useful information.

How to insulate a chimney or fireplace chimney

Chimneys and chimneys are laid out of brick, forming a network of winding channels inside the chimney that trap heat inside the house. Direct-flow chimneys made of steel, asbestos-cement or ceramic pipes are mounted mainly on decorative or temporary stoves and fireplaces that are not used as the main heating device. Therefore, optimal thermal insulation for chimneys of stoves and fireplaces - This is a special plaster mixture applied over brickwork as follows:

- First, a plaster solution is prepared. To do this, you need to combine water and a dry mixture, whipping the resulting substance with a construction mixer. Moreover, water is first poured into the container for preparing the solution and only the mixture is poured into the field. The proportions of the solution are determined by the manufacturers of warm plaster.

- Next, you need to throw several lumps of mortar onto the surface to be insulated, picking it up with a spatula and breaking it against the wall with a sharp movement of the brush. Moreover, such spots must be distributed over the entire surface of the pipe.

- At the next stage, a fiberglass plaster mesh is attached (pasted) to the spots scattered along the chimney. With the help of mesh, we create a reinforcing frame for a thick layer of warm plaster, since coatings with a depth of more than 5 millimeters need to be reinforced to prevent cracking of the insulating layer.

- Next, a rough layer of plaster is thrown onto the surface of the chimney, covering the entire reinforcing mesh with lumps of the mixture. Moreover, the thrown portion of the plaster should break on the surface of the duct, sticking to the bricks.

- The next step is the formation of a finishing (finishing) layer of plaster. To do this, you need to trim with the rule all the bumps of rough plaster lumps that have crashed against the chimney and smooth the plastered surface with a wide spatula, on which a portion of fresh mortar is collected.

An alternative technology involves insulating the chimney or chimney with flat panels (mats) made of mineral wool. The insulation is cut according to the dimensions of the pipe and placed from the bottom up, fixing it with adhesive tape.

However, such a barrier can only be installed on top of the inner section of the chimney located in the attic.

Chimney collapse

Broken chimney

So, the destruction of the chimney occurs for several reasons, which we will now consider, and based on the information received, we will try to take a number of measures:

- The main reason for the destruction of the chimney is dampness. Where does it come from if the chimney itself is a warm place? It's simple: not all the moisture that rises with warm air goes out into the atmosphere. Part of the steam deposits settles on the inner walls of the pipe (metal, brick, etc.), thereby condensing (transforming) into permanent moisture.

- The second reason is the formation of aggressive substances that appear during the combustion of fuel. Many experts compare their action with the effect of acids and alkalis.With prolonged inactivity of the chimney, aggressive "acids" that have settled on the walls of the structure begin to be absorbed into the structure of the chimney walls, gradually destroying them and making them completely unsuitable for further operation.

Can help in both cases. chimney pipe insulation, capable of delaying (or suspending) destructive chemical processes.

How to insulate a chimney with your own hands?

Chimneys of houses have a different design and are made of various materials. The most common: brickwork, asbestos-cement slabs, metal tubular chimneys. Each design has specific properties and requires an individual approach during installation.

brick chimney

Warming a brick chimney with your own hands can be done in several ways.

- The first way is plaster. On the outside of the brickwork chimney, a steel reinforcing mesh is fixed. A layer of plaster mortar 30 mm thick is applied on top of it. The solution is a mixture of lime and slag with the addition of a small amount of cement. After the first layer has dried, a second layer is applied from the same solution, and then another 2-3 layers. The last coating is carefully rubbed, puttied, and after complete drying, painted or whitewashed with lime.

- Another method involves the use of mineral heaters. A basalt sheet is fixed to the pipe from all sides (adhesive tape can be used for fastening). Outside, a lining of asbestos-cement slabs with a thickness of more than 40 mm is mounted on the cotton wool coating. Instead of such slabs, you can build another brickwork. A leveling layer of plaster is applied over the cladding.

The main advantages of such a complex design:

- heat losses are reduced by 2 times;

- significantly reduces the likelihood of condensate accumulation;

- significantly increases the strength and durability of the structure.

Asbestos-cement chimney

If the chimney pipe is made of asbestos cement, then the insulation is carried out in the following order:

- The design of the insulation with a metal casing, which is made of galvanized steel, is used. In the case when the chimney is long, the casing is mounted from several sections in the form of a cylindrical pipe no more than 1.5 m long (the sections are put on top of each other with an overlap of up to 10 cm).

- The gap between the chimney and the casing must be more than 60 mm. It is filled with mineral wool gradually with careful tamping.

- After the gap is completely filled, the top of the structure is poured with a thick concrete solution.

You can apply a simplified design. 3 layers are wound around the pipe mineral basalt wool, then a polymer film and foil are applied. Strengthening of the structure is provided by metal brackets, which are attached over the foil layer.

steel chimney

Steel chimneys are used, which are made of stainless steel pipes of the required diameter. The insulation of such a chimney is carried out using another larger stainless pipe. The inner diameter of the outer casing must exceed the outer circumference of the chimney by at least 10 cm. The gap between the pipes is filled with thermal insulation material - best of all basalt wool. Filling is carried out gradually, in parts, with sufficient compaction.

Modern steel chimneys are made in the form of a sandwich structure, i.e. in finished form they have a layered system with thermal insulation.Such a chimney does not require the installation of additional insulation and is reliable in operation.

Chimney insulation in the attic

The need to insulate the chimney in the attic is determined by the type of room: cold or heated in winter. If the temperature here is the same as outside, then you need to install a heater on the pipe.

To insulate a pipe in a cold attic, you can use any of the considered structures, taking into account that the likelihood of direct exposure to precipitation is excluded. Therefore, it is recommended to insulate with wooden shields, and the outer side of the frame must be aesthetically processed.

Heated attics are characterized by such a design - a frame made of wooden boards or chipboard with a thickness of at least 18 mm, the gap between the chimney and the pipe is at least 50 mm. As a filler, it is recommended to use basalt wool or felt.

In the manufacture of chimney insulation with your own hands, you will need the following standard tool:

When planning private construction, people do not think about the special role of chimneys and the need to isolate them. In fact, insulation is an important element that allows you to increase the durability of the entire furnace system.

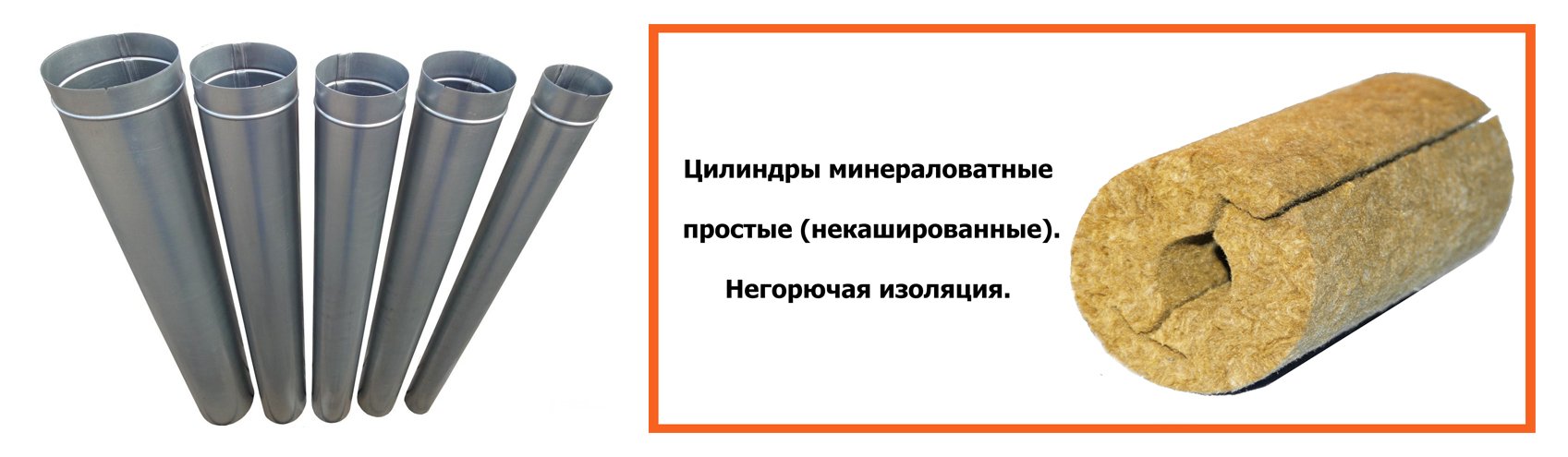

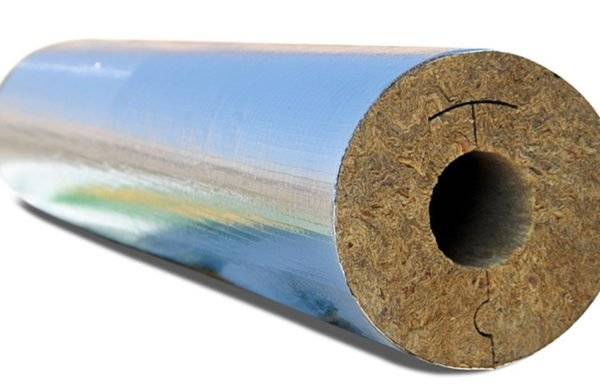

Heaters for thermal insulation of a chimney

To insulate the stove chimney, materials are used that provide a high degree of insulation, coupled with low thermal conductivity. This eliminates the risk of cold bridges, icing and condensation.

Among the most effective and popular materials for insulation are the following:

-

plaster - used for insulation of brick and stone chimneys. The plaster mortar is applied to the previously prepared reinforced surface.In terms of the ratio of labor costs and quality, this method is the least justified;

-

broken brick - used for thermal insulation of brick and steel structures. The material is poured into a casing, which is fixed around the chimney. The minimum distance from the chimney is 60 mm. Sometimes slag is used instead of broken brick;

- basalt wool is a modern heat-insulating material produced in the form of mats or cylinders with various internal sections. The material is wrapped around the chimney and fixed to steel clamps. In terms of price-quality ratio, this method is the most effective.

In fact, all the methods described above have some similarities - the insulation is applied or fixed on the outer surface of the chimney. After that, the heat-insulating material is protected by a steel casing.

In order to save money, the outer steel pipe can be replaced with wooden or cinder-concrete slabs. For example, a rectangular frame can be fixed around the chimney using wooden shields at hand, and the space between the pipe and the shields can be filled with any heat-insulating material.

Which heater is better to choose

The first thing to remember when choosing a material for chimney insulation is that the insulation must be made of non-combustible components. During the operation of the chimney, the insulation will heat up to 100–150 ° C, and at the point where the pipe exits through the ceiling, the temperature can be even higher.

For self-insulation of the chimney, it is better to use basalt thermal insulation. The shape and thickness of the product is selected taking into account the existing design of the chimney.

The basalt cylinder can be matched exactly to the size of the chimney pipe

To the benefits heaters based on basalt wool can be attributed to:

- high thermal insulation qualities;

- good vapor permeability;

- resistance to chemicals;

- immunity to the formation of fungus and mold;

- high thermal stability when heated above 100 °C;

- environmental friendliness and safety.

Before using ready-made thermal insulation from the manufacturer, you should carefully study the technology of its installation. As a rule, high-quality products are completed with a paper insert or instructions that describe in detail how they are cut and installed.

Benefits of chimney insulation

When designing a home heating system, there is an important stage that is often not taken into account - this is the insulation of the chimney pipe. Furnace, boiler chimney of any design and from any material should be thermally insulated to avoid its destruction.

During the operation of the furnace, a difference in temperature and pressure is created in the chimney, forming a draft. Under the action of draft, hot smoke rises outside the building. This process inevitably leads to the formation of condensate inside the pipe, which, combining with the chemical composition of the flue gas (soot), forms an aggressive acidic environment (sulfuric, nitric, hydrochloric, carbonic acids). In such an environment, the chimney is covered with microcracks, after which the temperature difference and caustic condensate cause progressive destruction up to the interior decoration.

If you allow the accumulation of condensate, it will gradually destroy the chimney

Now in houses where a large living space is heated, automated boiler equipment is installed with transition mode from start to heating, stopping and restarting.With the constant use of such a system, condensate is formed several times more, as a result of which a major overhaul of the pipe must be carried out after 3-4 years. Brickwork chimney it warms up for a long time, does not have a smooth surface, soot abundantly settles on its walls, reducing the clearance, and a large amount of condensate can lead to the formation of an ice jam in the pipe.

Condensation is especially dangerous at low temperatures

To avoid these problems, the built chimney should be insulated and thus:

- minimize condensation;

- reduce heat loss;

- prevent destruction;

- protect from climatic factors;

- extend the service life;

- protect roofs and ceilings from fire.

Of course, the best result of chimney insulation will be achieved only during the initial design of the building, when all the nuances can be taken into account. Often, the desire to correct the situation arises already with the heating system in use, when only part of the heat transfer reduction technology can be applied.

Brick work

Brick as a building material is still out of competition: in brick houses, chimneys are also made of brick. Brick chimney insulation can be done in different ways.

Method one

The first method is plastering, which is easy to do with your own hands. A solution is prepared from lime and slag - it is applied to the brickwork from the outside with a layer of 3-4 cm. A layer of plaster will reduce heat loss by 25%. But in order for the plaster to hold well under the influence of cold and moisture, it should be applied to the mesh.

The sequence of work can be described as follows:

- a reinforced mesh is attached to the brick surface;

- a slag-lime mortar is being prepared;

- 3-5 layers of plaster are applied to the grid: the first layer is the most liquid, the subsequent ones are thicker.

Method two

A more effective material for a brick structure is a chimney slab insulation.

The sequence is as follows:

- the brick pipe is sewn up with insulation boards (mats of basalt or mineral wool);

- the insulation is lined with asbestos cement slabs or brickwork;

- the structure is plastered.

This method is more complicated, but the efficiency of this design allows you to retain up to 50% of heat.

Why insulate chimneys?

To exclude conditions condensation on walls of the chimney. This is due to the fact that flue gases, touching the cold walls of the pipe, deposit a wet film on it, which, interacting with soot (unburned waste), forms harmful chemical compounds that destroy the walls and have an unpleasant odor.

The phenomenon of condensation in nature manifests itself when the moisture content in the air is supersaturated as a result of its cooling, it is compressed, density increases and, having reached the “dew point”, moisture falls out in the form of precipitation (small droplets, fog).

Smoke vapor also has a “dew point”, this point can be located and change its position along the entire length of the pipe. So, for example, when the furnace is ignited, it can be located directly in the furnace and, as the pipe channel warms up, rise higher and higher until it “flies into the pipe”.

By the way, this expression tells us that the oven must be fired correctlyin order not to waste extra firewood: the most optimal option is that the temperature at the beginning of the pipe channel should be in the range of 250-300 ° C, and at the outlet from 100 ° C to 150 ° C.

It is necessary to strive to reduce the time for the formation of condensate, and this can be achieved by quickly heating the inner surface of the pipe. That is why it is necessary to insulate chimneys. In homes with year-round use, this must be done to minimize the amount of condensate formed, since its chemical composition contains dissolved harmful substances, including sulfuric acid, which destroys the pipe channel.

Materials and methods of chimney insulation.

If the chimney passes from the outside of the building, then it must be insulated along the entire length. Brick pipes can be insulated by plastering using fiberglass mesh and basalt wool insulation. This method was widely used during the overhaul of "Khrushchev" and was called - a thermal coat. Materials for a thermal coat can be purchased at any construction market. The fur coat includes:

- fasteners (dowel and nail with a pressure washer);

- plaster mesh (durable glass fabric woven in a special way - best known as SSSH - 160)

- insulation (plates, mats made of mineral wool or expanded polystyrene)

- polymer-mineral adhesive (SARMALEP)

- plaster (special finishing composition - SARMALIT)

- paint (special paint for plaster - SOFRAMAL)

The insulation technology is simple: with the help of dowels and nails, the mats are attached to the outer wall of the pipe, the surface of the mat is glued with a mesh overlay, then a layer of plaster is applied and paint is applied to it. This design is very light, does not require additional reinforcement of the walls and emphasis on the foundation.

It happens that it is necessary to install a pipe to additional equipment installed in the utility room or basement. Here you can apply the assembly system from pipes in the form of a sandwich, which do not require insulation and allow installation through the wall. This is a prefabricated system consisting of heat-resistant stainless pipes (pipe in pipe), the annular space of which is filled with non-combustible material with very low thermal conductivity. You can select pipes of the optimal cross section for your heating system by studying the installation and operating instructions.

How to choose a heater

In order for the pipe insulation material to perform its functions, it must have the following characteristics:

- High temperature resistant. If the insulation cannot withstand the elevated temperature, it may begin to break down or catch fire during the heating of the house.

- Tightness.

- Light weight.

- The resistance of the material to the formation of moisture.

- Plastic.

- Long service life of the material. If the insulation does not have a long service life, it will often have to be replaced.

- Low temperature resistant.

To choose the right material, you need to find out what types of insulation exist and which ones are suitable for the pipe of your house.

Often plaster is used for insulation. The advantages of this method of warming include:

- relatively low cost;

- aesthetics;

- accessibility for every home owner, since plastering work can be done independently.

But it is also worth remembering that the plaster will often have to be changed. At the same time, it is exposed to moisture and quickly collapses.

Some owners of country houses create an additional layer of brickwork. This method has several advantages. An example is a pleasant appearance and a long service life.

But many refuse this method, as it involves the performance of complex work and the presence of construction experience. Often this method is combined with the laying of heat-insulating materials such as polystyrene foam or expanded polystyrene.

If the pipe is made of stainless steel or asbestos, sandwich pipes are often installed. Such products are two pipes, between which a heater is located. Condensation does not form on such sleeves. However, they cannot cause a fire. A pipe that is qualitatively insulated in this way can be used for a long time without the appearance of defects and a decrease in traction.

Summing up

So, we learned how to insulate the chimney with our own hands. Conducted thermal insulation significantly extends the period. The thrust increases, the amount of condensate decreases, which means that the amount of soot deposited on the walls decreases.

If you need to extend the chimney (for example, when replacing the roof), trust it only to professionals. Otherwise, you can get what can you see on video.

Therefore, be sure to brick pipe insulationso that in winter there are no problems with heating the house.

At the end, be sure to watch the video in which the well-known builder blogger Andrey Terekhov explains the principles and methods of how to insulate a chimney pipe with your own hands.