- 2 Mineral wool - cheap, but not very effective

- Features of laying the heat-insulating layer in buildings made of different materials

- The order of operations in panel and monolithic buildings

- Installation of insulation materials in a brick building

- Moisture resistant drywall

- Mineral wool

- Vapor permeability

- Vapor permeability is the most important factor

- Where to insulate, inside or outside

- Thermal insulation of concrete - features

- Conditions for the use of internal thermal insulation

- The case for technology

- List of major disadvantages

- Options for insulating the walls of panel houses

- List of materials for effective insulation

- What does "corner apartment" mean?

- External insulation

- Preparatory stage

- Insulation installation

- Reinforcement preparation

- Finishing

- New generation thermal insulation

- One-Stop Solution

2 Mineral wool - cheap, but not very effective

It is possible to insulate the wall from the inside with rolled (foamed polyethylene, mineral wool), sheet (extruded polystyrene foam - EPPS, polystyrene - foam plastic) and sprayed (foamed polyurethane foam - PPU, keramoizol, astratek) materials. All of them have their own characteristics. Their installation is carried out according to certain technologies.

Mineral wool for thermal insulation is rarely used.It has only two advantages - low cost and no need for careful alignment of surfaces protected from cold. But she has a lot of shortcomings:

- the complexity and complexity of working with rolls;

- tendency to form lumps during operation, accumulation of moisture and loss of initial heat-shielding characteristics because of this;

- the need to create a crate;

- low sound insulation.

Installation of mineral wool during the insulation of the apartment from the inside is carried out in several stages. The old finish is removed from the wall (to the state of the bare surface). The cleaned base is inspected for cracks, gaps, holes. If any, they are sealed with a plaster mixture. Roll thermal insulation is cut into pieces of the required dimensions.

Wooden slats (metal profiles) are stuffed onto the wall, creating a frame. The material fits (as tightly as possible) between the elements of the latter. Cotton wool is attached directly to the laths of the crate.

A vapor barrier film is glued onto the bars and the mounted protective layer. Without it, the heater will quickly become unusable. There will always be a smell of dampness in the room, and microorganisms will actively multiply on the wall, which will require repairs and replacement of mineral wool.

A more effective home protector from the cold is polyethylene foam in rolls. It is a product of small (4–5 mm) thickness with a foil layer on one of the sides (directed into the room). They are recommended to insulate vertical surfaces in panel high-rise buildings.

Polyethylene is fixed on the wall (it is prepared according to the principle described above) using special glue. Finishing is done over the protective layer.

Features of laying the heat-insulating layer in buildings made of different materials

Experts give several recommendations on how to insulate walls from the inside in a private house. They note that work should begin at the construction stage of the project. In a city apartment, this is not always possible, so the sheathing is done after construction work.

The order of operations in panel and monolithic buildings

If the wall in the panel house is very cold, the heat-insulating layer is laid according to the following scheme:

- Training. From the room you will need to remove the furniture, remove the trim and plaster.

- Application of waterproofing coating. All surfaces are treated with polymers or glued with a film on construction tape.

- Installation of a crate with guides made of wood or metal. The step of the product corresponds to the dimensions of the heat-insulating material.

- Wall insulation from the inside by laying the insulator in the openings of the crate.

- Installation of vapor barrier without gaps and gaps. Joint points and gaps must be treated with sealants.

At the last stage, the GCR is attached according to the manufacturer's instructions. They will be lined.

Installation of insulation materials in a brick building

Polystyrene is best for insulating walls inside a brick house. Work is carried out in stages:

- Removed all top trim.

- The surface is plastered, all cracks are sealed and covered with a primer.

- The adhesive composition is prepared and applied to the wall with a spatula. Serrated tool go through to create stripes.

- Heat insulator sheets are installed starting from the bottom. They need to be pressed down, then tightly join the edges and cut off the excess.

- Finishing in progress. To fix the GKL, you do not need to prepare the surface.When priming or painting on polystyrene, they pass with a primer, put a reinforcing mesh and plaster or putty on it.

Moisture resistant drywall

- Installation of the crate on the supporting structure.

- Creation of corner posts from beams with a section of 50x100 mm with a height equal to the height of the room.

- Reinforcement of the crate with a 50x50 beam along the edge.

- Sheathing the structure with plasterboard sheets with a moisture-repellent surface.

Mineral wool

- All surfaces inside the premises are smeared with fire and rotting agents.

- A crate is made of timber with a step of 50 cm.

- Preliminary cutting of mineral wool sheets along the height of the wall and width, 2 cm more than the verticals of the crate.

- Fixation of the 1st layer of mineral wool with anchor bolts.

- Laying vapor barrier film.

- Fastening of the second layer and additional reinforcement with bars 30x40 mm.

- Sheathing of the finished structure with clapboard.

Before you insulate the house from the inside, you should choose the right material and carry out surface treatment. Do-it-yourself installation work is not difficult if you understand the nuances of the technology.

Vapor permeability

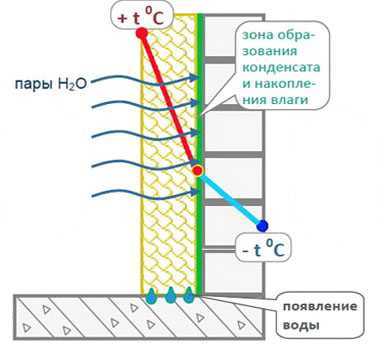

In a residential building, the vapor permeability of the walls should increase in the direction of the street. The main reason lies in the different humidity in winter inside and outside the house. The reasons for high humidity in the house are as follows:

The house is inhabited by people who breathe, cook, wash floors and dishes, and do laundry.

All these habitual operations make the air more humid. And with closed windows, air exchange is difficult and is carried out only by the forces of the ventilation system. From the course of physics, we know that heated air is able to retain more moisture than cool air.For this reason, condensation occurs from the "excess" moisture during the cooling of the air.

Sweating windows and dampness in the corners of the building are a practical example of this. But water vapor leaves the house not only through ventilation, but also through the pores of the wall. If the wall outside is more permeable to steam, then it can easily pass through it. Otherwise, having met an obstacle, water vapor begins to condense right in the wall, which leads to its dampening.

Vapor permeability is the most important factor

It is very important that it increases from layer to layer from the inner wall to the outer. This factor is very important because in the non-warm season, the humidity in residential premises is significantly higher than outside them. Everyone living in the house breathes, which means that the air is filled with moisture.

Household processes from cleaning to cooking also play their role, as a result, the air is humidified, but does not go outside.

Everyone living in the house breathes, which means that the air is filled with moisture. Household processes from cleaning to cooking also play their role, as a result, the air is humidified, but does not go outside.

This factor is very important because in the non-warm season, the humidity in residential premises is significantly higher than outside them. Everyone living in the house breathes, which means that the air is filled with moisture. Household processes from cleaning to cooking also play their role, as a result, the air is humidified, but does not go outside.

The warmer the air, the more moisture it can hold.

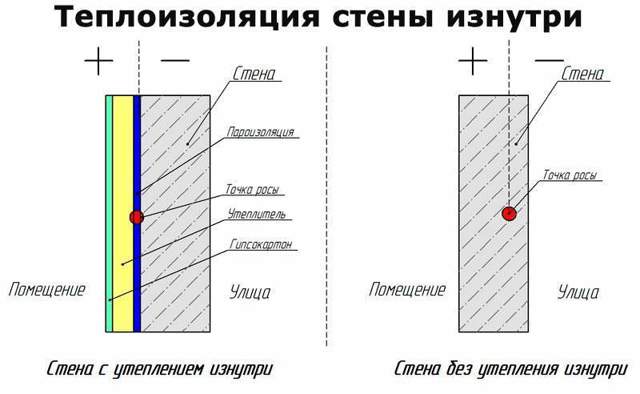

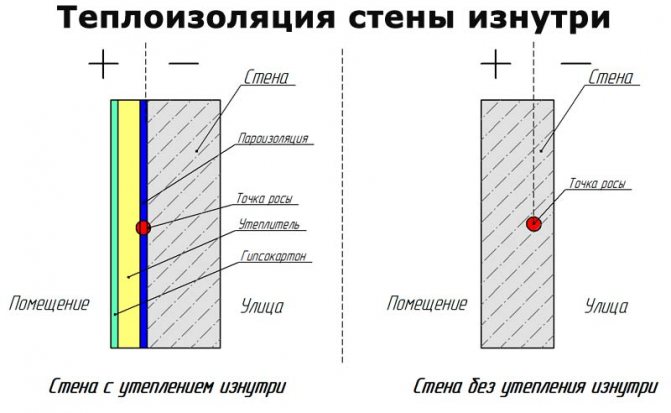

So that the walls do not sweat, there is no condensation and dampness in the corners, it is important to correctly resolve the issue of the vapor permeability of the materials used in the insulation.If the insulation of brick walls does not imply a vapor-permeable outer layer, the wall is guaranteed to be damp. The location of the insulation of a wall-brick house from the inside is not the most effective type of insulation, since the situation is ideal when the house is insulated from the outside

If everything is not done correctly, the dew point will fall on the brick wall itself, which will accelerate the destruction of the structure, especially buildings made of silicate solid brick, which is most afraid of moisture. If your house is built from this, in addition to insulating the brick wall from the inside or outside, protect the walls with roof peaks, but do not forget about the outflow of steam, which in this case becomes even more important!

The location of the insulation of a wall-brick house from the inside is not the most effective type of insulation, since the situation is ideal when the house is insulated from the outside. If everything is not done correctly, the dew point will fall on the brick wall itself, which will accelerate the destruction of the structure, especially buildings made of silicate solid brick, which is most afraid of moisture. If your house is built from this, in addition to insulating the brick wall from the inside or outside, protect the walls with roof peaks, but do not forget about the outflow of steam, which in this case becomes even more important!

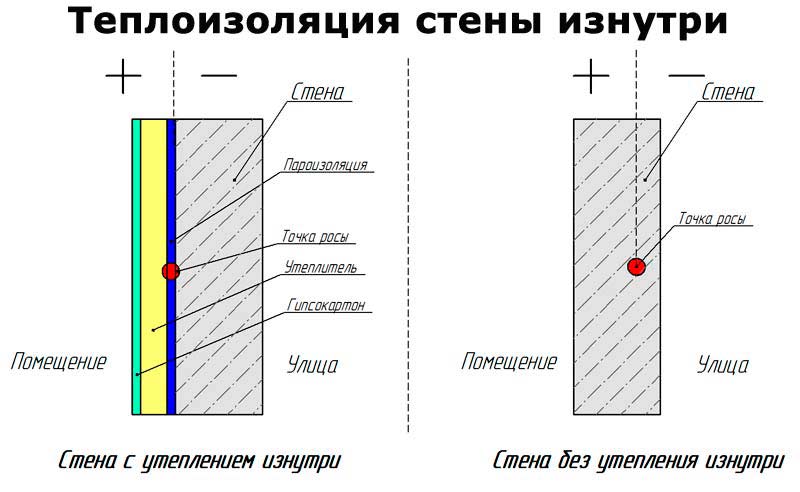

Insulation of brick walls from the inside leads to the fact that the dew point is located directly behind the insulation, a violation of technology is fraught with dampness and mold. External insulation, of course, will ensure the heating of the entire wall, the release of steam to the outside, and the absence of excess moisture.

But all of the above does not mean that it is impossible to insulate inside. There are many reasons why outdoor insulation may not be possible. For example:

- We cannot insulate architectural monuments from the outside. A high-rise building is insulated, the upper floors are insulated, but there are no towers. The neighboring walls are so close that there is no place for the exterior thermal insulation to be done correctly.

These and other reasons make us accept the fact that external insulation is impossible. And if you have chosen the internal option to insulate your house, you just need to understand well how to properly insulate a brick wall from the inside in order to be sure to comply with the technology. The most important principle of which is as follows: we should separate the wall and its insulation from the room, make them airtight.

And there are two solutions here:

Internal insulation with a material whose vapor permeability will be extremely low.

These can be considered penofol, which is a heater with a layer of foil applied to polyethylene foam. Also, extruded polystyrene foam has low vapor permeability if its surface is denser on one side. Mandatory condition: both the foil side of the foam and that side of the extruded polystyrene foam, which is denser, must be laid towards the inside.

- The following solution to the problem is also possible: wall insulation from the inside should assume the presence of a vapor-tight film, which will be located on the inside of the housing and hermetically cut off the insulation from the inner wall. If you go this route, you should not leave a single tiny gap for moisture, be sure to overlap the vapor barrier and carefully tape the seams

Where to insulate, inside or outside

The first question that arises before the start of insulation. The answer to it is ambiguous, since these options have their pros and cons.For example, insulation from the inside is often done in an apartment larger than 3 floors, especially in high-rise buildings, since working outside is dangerous. In addition, inside the heat insulator will not be adversely affected by the street, and the insulation process itself can be performed in any weather and season. But, there are also disadvantages: a decrease in living space, the formation of condensate, the release of harmful substances.

External insulation is a more common option, as it allows you to protect the concrete wall, clad it. It is more convenient to work outside and living space is not lost. There is no human contact. And the insulation inside contributes to the fact that the wall freezes itself. There is a phenomenon in which the wall on the one hand is isolated from the heat of the rooms, and on the other hand is constantly exposed to sub-zero temperatures. That is why it is better to insulate concrete walls from the outside. But, it is up to the owner to choose the methods of insulation of concrete structures.

Thermal insulation of concrete - features

The peculiarity of concrete walls is that for their insulation you need to calculate everything and plan in advance. The task is not easy when compared with walls made of brick or wood, but doable. Insulation of a concrete wall outside and inside has the following features:

- The surface must be treated with antiseptic agents.

- Communications and wiring are laid even before thermal insulation work.

- When insulating the facade, the entire area is processed, it is impossible to make only certain sections or a wall.

- The areas behind the radiators are treated with a foil insulation. This is a thin aluminum layer on the insulation. It will reflect heat energy.

If we talk about internal insulation, then there are also some nuances.For example, condensation will accumulate inside, since moisture has nowhere to go

Therefore, it is important to ensure good ventilation. In addition, an environmentally friendly insulation is selected that will not harm health.

Conditions for the use of internal thermal insulation

The exterior walls of an apartment building are now finished using building materials that retain heat. In private houses, thermal insulation along the facade is also not uncommon. If this method is not enough for you, you can insulate the walls from the inside.

The case for technology

By simply laying the insulation, you will save up to 30% of the heat in the rooms that leaks out into the street. Other advantages of the technique include:

- ease of laying materials from the inside with your own hands - no need to make scaffolding, use special equipment;

- work is carried out all year round, in any climate;

- independent cost planning - if there are no funds for a full-scale repair, you can make thermal protection room by room;

- a wide range of thermal insulators.

List of major disadvantages

Some masters consider wall insulation inside the house to be problematic for the following reasons:

- cracking of the external supporting structure during its interaction with the environment;

- protection from the cold of the building on one side only;

- formation of condensate as a result of dew point displacement between materials and surface;

- reduction of the usable area of the room by 10 cm on each side;

- risks of the appearance of "cold bridges" during the arrangement of the frame and reduce the efficiency of work.

Options for insulating the walls of panel houses

Modern technologies present two options for insulating the surfaces of the walls of an apartment building: from the inside and outside. Both options will solve the problem of low room temperature and rapid heat loss.In prefabricated houses, more cast-iron radiators with excellent heating qualities were installed, but due to the thinness of the walls and their direct contact with frosty air, the efficiency of radiators is significantly reduced.

Both options are suitable for this, but their implementation is radically different, so you need to determine a simpler and more economical one that you can do yourself.

List of materials for effective insulation

The list of vapor-tight materials recommended for use in internal thermal insulation is small:

- extruded polystyrene foam;

- slab polyurethane foam (PPU);

- Styrofoam;

- foam glass.

When performing thermal insulation, the following rule must be observed: with each layer, the vapor permeability of the material increases. In a situation with internal insulation, it is best to let air through and water molecules should be walls.

Polyurethane foam plates have the same characteristics as the sprayed composition:

- do not support combustion;

- environmentally friendly;

- service life up to 25 years;

- thermal conductivity - 0.022;

- moisture resistance and complete vapor tightness;

- sheet thickness - 35-70 mm.

The material is an effective insulation for private and multi-storey buildings, warehouse and industrial buildings. To increase the thermal insulation properties, a layer of foil is applied to the plates, reflecting infrared radiation back into the room. At the ends of the PPU panels, grooves are made for docking without cold bridges.

Due to its strength and moisture resistance, extruded polystyrene foam is used as a heater in all areas of construction: individual, industrial and civil.It has optimal characteristics for internal thermal insulation:

- vapor permeability - 0.013;

- low water absorption allows use in damp rooms;

- plate thickness - 40 mm;

- thermal conductivity - 0.028-0.03.

The material can be used to insulate walls made of concrete, wood or brick.

The thermal insulation sequence includes the following steps:

The plates are mounted directly on the wall, so it is important to check the plane of the structure. It should not have protrusions and depressions.

The old finish is carefully cleaned. The surface of the wall must be dry and even. To prevent the appearance of mold, it is primed with an antiseptic composition.

For fastening the plates, a special adhesive composition is used, applied to the entire surface with a notched trowel. Installation of insulation starts from the bottom of the corner. The joints of the panels are blown with mounting foam, which is cut off after drying.

There are two ways to finish the heat-insulating layer with your own hands: stick a reinforcing mesh on the surface of the extruded polystyrene foam and apply plaster or fix a foil film on the material, fill the crate and sew it with drywall sheets. The second option will take up more space in the room, but the effect of insulation will increase significantly.

Foam glass has many positive characteristics:

- vapor permeability - 0.005;

- excellent sound insulation;

- low water absorption;

- thermal conductivity - 0.04-0.06;

- environmental friendliness;

- strength and lack of deformation;

- does not burn, does not emit toxins;

- The material is resistant to microorganisms and rodents.

Foam glass is a universal heat insulator, it has not become popular due to the high cost and difficulties in installation.The rough surface of the material does not allow for tight joining of the plates, the joints must be sealed with liquid rubber. This takes time and requires additional costs.

Styrofoam is an affordable and popular insulation, but when choosing a material, you should pay attention to its density. Its indicator must be at least 35 kg / m3, then the material will have the necessary characteristics:

- thermal conductivity - 0.32-0.38;

- light weight and easy installation;

- vapor permeability - 0.05.

The disadvantage of polystyrene is flammability, so its use is not desirable in residential areas. The installation technology of the heat-insulating layer is similar to the installation of extruded polystyrene foam. For additional fixation, water after the glue dries, you can use dowels-umbrellas. Under them, a hole is drilled in the foam and the wall, and then plastic fasteners are clogged. 5 dowels are used on the plate - 4 at the edges and 1 in the middle.

What does "corner apartment" mean?

Corner apartments are located in the end sections of residential buildings. One or two rooms in such apartments have two adjacent walls bordering the street. The layout of such apartments is no different from the configuration of all the others in the house, only an additional window and a heating radiator appear, moreover, such an addition is not found in all corner rooms. To compensate for heat losses through enclosing structures resulting from an increase in the area of external walls, an increase in the internal temperature by 2 ° is provided, which is ensured by an increase in the standard number of radiator battery sections.In practice, this is achieved either by having a battery installed under an additional room window, or by installing a larger radiator (number of sections).

These measures rarely work as intended, as they are designed to solve the problems of the conventional premises and do not take into account many of the impacts that exist in reality:

- The outer wall is located on the windward side of the house;

- Worn-out heating networks, non-compliance of the heating regime with regulatory requirements;

- Mistakes and shortcomings made during the construction of the house.

These factors are often present all together, significantly changing the temperature in the apartment for the worse. The cold surface of the walls begins to get wet due to the active formation of condensate, the apartment becomes cold and uncomfortable. Such situations are quite common and require appropriate measures.

Wall freezing is a common occurrence in corner apartments.

External insulation

Insulation of the facade of a panel house is carried out in the following steps:

Preparatory stage

Surface preparation of the facade is necessary - the end walls of the panel house are leveled, the plates are cleaned of plaque

It is also important to seal voids, cracks, and panel joints are sealed. If necessary, it is worth laying a sealant between the joints, while a special mastic is used to seal the cracks. Roughness of the surface of the walls within two centimeters is allowed - such a deviation can not be closed

When all materials are dry, the wall is impregnated with a universal primer, which is applied using a sprayer or roller.

Roughness of the surface of the walls within two centimeters is allowed - such a deviation can not be closed.When all materials are dry, the wall is impregnated with a universal primer, which is applied using a sprayer or roller.

Insulation installation

Since in the vast majority of cases it is foam plastic that is used for thermal insulation of panel houses, it is worth considering the installation technology of this insulation. You can fix the foam by the following methods: put the plates on glue, fasten with dowels, or connect these two options, this is the most reliable choice. The direction of gluing is from bottom to top. In this case, pasting begins with the installation of the starting bar.

After that, we begin to apply glue to the surface of the panel house - the technologies used directly depend on the quality of the walls. If they are even, then you can apply glue with a comb. If, as is often the case, the walls are uneven, then the glue simply pounces onto the surface.

It is important to carefully fill the seams with glue. All this allows you to get rid of voids under the heat insulator. No need to apply glue to the foam

It is not necessary to apply glue to the foam.

The option when the glue is applied to the foam, and not to the house, is not suitable in this case, since the voids under the insulation will become natural cold bridges, which will reduce the effectiveness of the entire event as a whole.

Styrofoam is applied to the glue layer and pressed well. After gluing all the plates, you need to leave them alone for a few days. During this period, the adhesive solution will dry and shrink, after which it will be possible to perform the next stage of work. As for fixing the plates with dowels, you can choose plastic fungi. This is due to the lightness and low strength of the foam - such fasteners will save the facade from unnecessary heat loss.

As for the dowel caps, they must be covered with an adhesive mixture. All the irregularities remaining after the glue has dried can be removed with ordinary sandpaper.

Reinforcement preparation

The fragility of the foam is a serious drawback, so the insulation needs to be reinforced - it is enough to glue a thin mesh. Such protection should prevent the destruction of the foam due to atmospheric phenomena and other adverse factors.

Preparation for reinforcement is as follows: first, the corners are pasted over, after which you can proceed to pasting the walls themselves. To simplify the process, grids with ready-made corners are used, which minimizes time. If there are no such grids, then you will have to make corners from a regular grid. It is enough to cut off a long strip 30 centimeters wide and bend it at an angle - this design is pressed against the corner of the house smeared with glue. In general, cutting the mesh into fragments greatly simplifies the installation itself, which makes it possible to sequentially cover the areas smeared with glue with fragments. At the same time, the mesh should overlap at the junction.

After gluing the mesh, it is necessary to wait for the glue to dry, after which it remains to clean the excess mortar with a plastic grater and remove irregularities.

Finishing

Before finishing, a leveling layer is applied to the entire treated facade. After that, it is necessary to apply a primer and a layer of plaster. The final step is to paint the wall, preferably in a color that will not stand out too much against the background of the main color of a multi-storey panel house.

New generation thermal insulation

Keramoizol

A heat insulator of a liquid consistency in the form of a paste (it looks like acrylic paint) with excellent heat-saving qualities, operation is designed for several decades. Keramoizol eliminates the cold in the house, rids the walls of fungi, mold, eliminates the formation of condensate (often used to cover water pipes). It is used for thermal insulation of the entire room or part of it. Applied to walls up to six layers, it is distinguished by quality, strength and durability. The disadvantage is the high price.

Penoizol

A building energy-saving material, penoizol is a polyurethane (polystyrene) in the form of a liquid state of aggregation (foam). The material easily and quickly covers the surface of the wall (up to 3 m² in 1 hour) of a certain thickness, instantly hardens without leaving seams, reduces the time of construction and installation work, and has high heat and sound insulation performance. The surface is monolithic, the appearance of "cold bridges" is excluded. Wall insulation with penoizol is 1.8 times cheaper than with a similar insulation.

Astratek

Material - polymer suspension (liquid with small solid inclusions), outwardly resembles mastic. It is applied to the wall with a spray gun or brush in a thin layer, and the effect exceeds all expectations - a coating of 1 mm corresponds to a mineral wool slab 5 cm thick. It saves room space, has excellent thermal properties. After drying, a homogeneous coating with a microporous structure is formed. Application is limited due to the high cost of the material.

To insulate your apartment from the inside, you must be guided by its individual characteristics.When purchasing a heater, you can get professional advice from the seller or find out the answers to questions from the manual in the attached instructions for the product. As an example of work on the insulation of apartments, we will choose a material - expanded polystyrene (PPS), the more common name is polystyrene. To date, it is most often used for insulation of apartments, has excellent insulating properties, is cheap and easy to install.

One-Stop Solution

If you need to quickly insulate and decorate the house, then it makes sense to use effective and aesthetically attractive thermal panels.

At the heart of these products is a plate of dense polystyrene foam 40-100 mm thick or polyurethane foam 25-40 mm thick. Some models also have a rigid OSB substrate, which provides the facade insulation with additional strength and geometric stability.

From the outside, the thermal panels are lined with thin-walled clinker bricks, porcelain stoneware, glazed or engobed ceramic tiles, and artificial stone.

Installation begins with marking the base surface (smooth and clean) and fixing the starting aluminum profile, on which corner and then ordinary thermal panels are installed first. Panel insulation is attached to the wall with self-tapping screws. The joints are filled with mounting foam, and at the final stage - with colored mineral grout.

Unity and struggle of heaters

The mineral heat insulator is durable, vapor permeable (that is, it does not prevent the walls from "breathing"), resistant to biological damage and fire resistant (prevents the spread of fire and thereby increases the fire safety of the building).

An alternative option - facade expanded polystyrene - is cheaper and at the same time noticeably surpasses stone and glass wool in terms of thermal performance.

However, the polymer heat insulator burns (although it belongs to slow-burning and self-extinguishing materials) and almost does not let steam through.

For reasons of fire safety, cuts are made from mineral wool on the polystyrene foam "field".

In addition, windows and doors are framed with “stone” insulation.

Almost half of the heat we lose in our homes is not blown through windows and doors. Up to 40% of the heat literally escapes through the cold walls. Realizing and feeling this fact, have you decided to insulate the walls outside your house? Well, the costs of these works will more than pay off in the near future - your loved ones will be warm and comfortable, and gas or electricity bills will become much smaller due to the insulation of the walls outside the house.

It is the insulation of the walls private house outside, and not from the inside, is the most effective way to make your home really warm and at the same time prevent excessive moisture condensation on the walls: an incorrectly calculated “dew point” often increases the accumulation of moisture on the walls of a house insulated from the inside.

In addition, the loss of 5 centimeters of area from each wall, as well as the complete release and thorough preliminary preparation of internal vertical surfaces, are pushing to make a choice in favor of insulating the walls of a private house from the outside.

The insulation layer becomes a barrier between the cold outside air and the internal microclimate of the house. Another plus is that the insulated walls of the house from the outside will be additionally protected from moisture and sunlight, which means they will last longer and will not require updating.

So, the insulation of the walls of the house from the outside has the following advantages compared to the internal insulation:

- the entire interior space of the house is preserved to the millimeter;

- the walls are not subject to a sharp temperature drop, the humidity level remains approximately at the same level.

When insulating the walls of the house from the outside, some features should be taken into account:

- it is necessary to install scaffolding and dismantle it after work - this is additional time and money;

- in rain and strong wind, as well as in the cold season, work cannot be carried out;

- the appearance of the building will change.