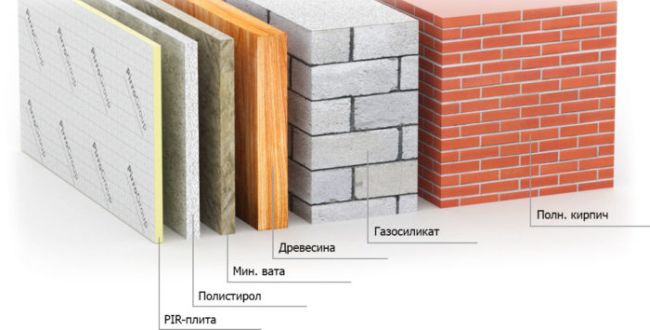

- The choice of materials for insulation and their features

- polyurethane foam

- Double wall of various materials

- Expanded polystyrene, EPPS (foam)

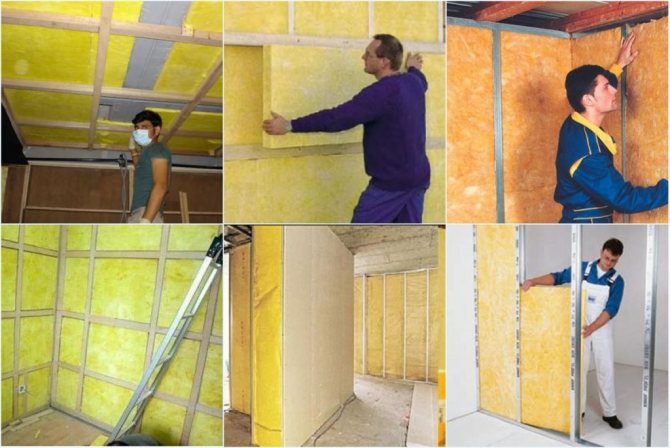

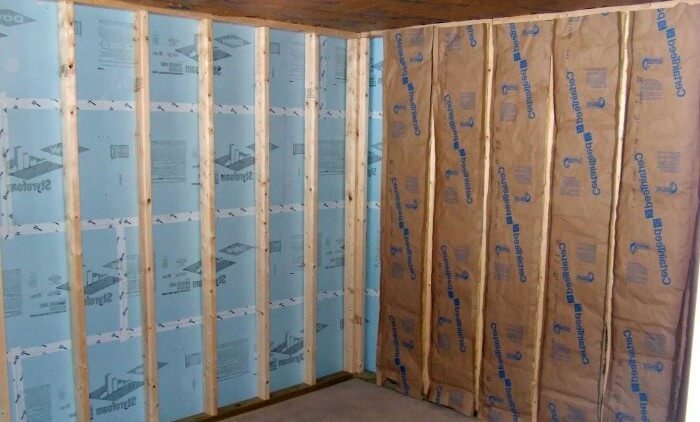

- frame

- Brief overview of other methods

- Installation of expanded polystyrene or polystyrene

- Spraying liquid-ceramic insulation

- Cork and Styrofoam Wallpaper

- List of materials for effective insulation

- We calculate the thickness of the insulation

- More ways to keep your home warm

- Is it possible to insulate with outdoor materials

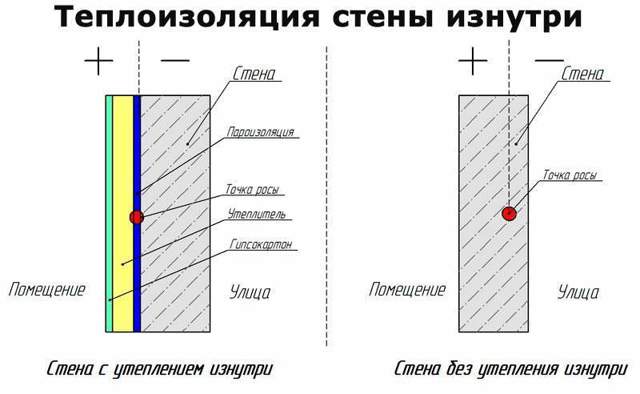

- Disadvantages of internal insulation

- The procedure for insulating the internal surfaces of the walls of the apartment with foam plastic

- Installation of insulation on brick walls

- Alternative modern heaters

- polyurethane foam

- Keramoizol

- Astratek

- Liquid thermal insulation using Mascoat as an example

- polyph

- Consumer Requirements

The choice of materials for insulation and their features

polyurethane foam

The use of polyurethane foam can create a moisture-resistant barrier with excellent thermal insulation properties. The problem with its use lies in the way it is applied. Initially, it is a foamy liquid that quickly hardens. In order for it to form a flat surface and sufficient thickness, you will have to use formwork and fill the necessary space with foam in parts.It will not work to use frames, as when insulating external walls or ceilings. At the same time, frame elements made of wood or a metal profile will become bridges of cold and dampness. When the entire surface of the insulating layer is formed, a hydro-, vapor barrier should be installed. For this, a polyethylene film is used, which is attached to adjacent walls, floors and ceilings with the help of rails and gluing with sealant or mastic.

Due to the low density and strength of polyurethane foam, it will not withstand subsequent plastering and finishing cladding. This will require the construction of an additional plasterboard wall, which should be mounted on a frame with fasteners only on adjacent walls, ceiling and floor.

In this embodiment, the dew point will be either at the junction of the wall and polyurethane foam, or in the thickness of the insulation itself. In view of the lack of air access and the practically absent vapor permeability of the material, condensate will not form there.

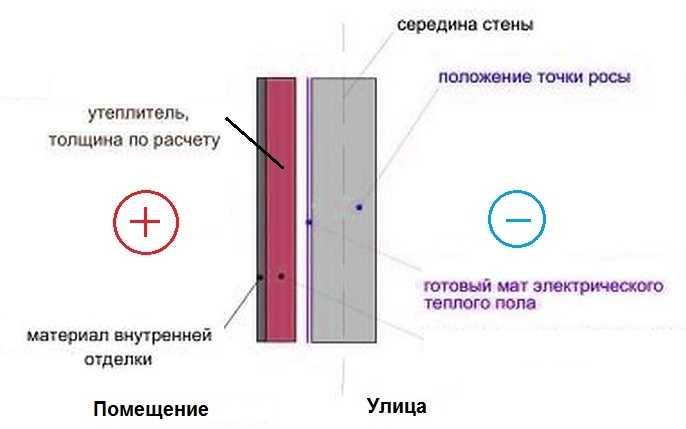

Double wall of various materials

The second option could be a double wall using underfloor heating elements as a thermal barrier. In this case, heating elements are mounted on the surface of the outer wall. It is worth turning on heating only in the most severe frosts in order to warm up the inner surface of the wall and shift the dew point to its middle.

For the possibility of normal finishing of the room, a second wall is constructed using drywall or a half-brick wall. In this case, the insulation is mounted on a false wall from the side of the opening between it and the outer wall. This option, although it will save in severe frosts and prevent the destruction and formation of dampness in the wall, however, will require huge electricity costs.After all, in fact, it will not be the volume of air in the room that will be heated, but the street.

Expanded polystyrene, EPPS (foam)

If, nevertheless, it is decided to be insulated with expanded polystyrene, which does not meet the required characteristics for internal insulation of walls not intended for this, special attention should be paid to its installation. Due to the fact that the material is flat, smooth sheets of fairly dense material of a standard size of 100x100 or 100x50, in any case, joints will form

It will not be possible to completely get rid of this, so as a solution, it is necessary to fit the sheets together as tightly as possible, and apply a layer of sealant to the ends of adjacent sheets.

As is usual with foam, the solution is applied in the form of individual cakes. This option immediately disappears when warmed from the inside. Indeed, as a result, air chambers are formed in which condensate will accumulate. Sooner or later, water will find loopholes and crevices to enter the room, spoil the appearance of the finish and lead to the development of fungus. The only option would be to apply the adhesive evenly to the entire sheet and tightly adhere to the wall over the entire area of the sheet. Before applying the mortar, a special spiked roller should be used, which perforates the surface of the material, and the mortar will eventually hold it better. This is especially true for the option with penoplex. This method of fastening will also require preliminary alignment of the wall. In this case, the usual cement-sand mortar will not work. It is best to use mixtures that form a moisture-proof layer, such as those used for finishing bathrooms.It is also impossible to use the usual anchor fasteners for foam plastic, because in the places of their installation leaky transitions are formed on the entire layer of insulation. If later mesh reinforcement and plastering over the foam will be used, then it is better to reinforce the structure with the help of "T"-shaped profiles that are inserted between the foam sheets and strengthened from above and below to the ceiling and floor.

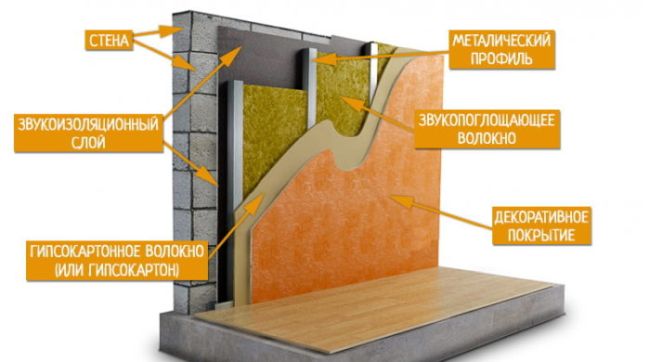

frame

The most reliable technology for insulating walls from the inside provides for the construction of a frame. For this, depending on the climate, wooden beams or aluminum profiles can be used, fixed on the inside of the building envelope in a vertical direction. The thickness of the frame is chosen depending on the selected insulation, and the horizontal distances between its elements are chosen according to the size of the sheets of material.

Frames are not made when insulating building envelopes with polystyrene.

Almost all methods of how to make wall insulation involve the installation of one layer of heat-insulating material. When installing the second one, it is also recommended to make your own frame for it. If heating radiators interfere with the installation of the selected material, non-penofol is laid behind them.

Brief overview of other methods

Other technologies are also used, among which there are both outdated, but cheaper, and modern, requiring considerable investments.

Installation of expanded polystyrene or polystyrene

With the advent of EPPS, it has become impractical to use ordinary non-pressed polystyrene foam (PSB), since it has degraded characteristics.

Namely:

- burns and melts, releasing hazardous substances;

- has brittleness, due to which the pieces break under mechanical pressure;

- not protected from rodents.

In terms of parameters, it is inferior to extruded polystyrene foam, and this can be seen from the table of physical and technical properties of expanded polystyrene plates:

For example, the compressive strength of EPPS is 0.25-0.50 MPa, and for PSB it is only from 0.05 to 0.1 MPa (at 10% linear deformation), the water absorption of EPPS is 0.2% of the volume, and for PSB - as much as 2.0

However, light and thick plates are still used when it is necessary to quickly and inexpensively insulate a room. We recommend using this material for lining garages and utility rooms, that is, non-residential premises.

Spraying liquid-ceramic insulation

Schematic representation of the composition of the liquid-ceramic mixture: vacuum microspheres of various diameters and a latex binder mixture enriched with antifungal and anti-corrosion additives

Advantages of liquid ceramic spraying:

- moisture resistance;

- mechanical stability;

- elasticity;

- ease of application;

- environmental friendliness;

- minimum load on the structure.

The main advantage is the thinness of the applied layer while maintaining important thermal insulation characteristics.

In terms of efficiency, a 1 mm layer of LCD is equal to a 50 mm thick basalt wool slab and is able to increase the temperature in the room by 3-4 degrees. The sprayer is loved by builders for its ease and high speed of application.

After applying the liquid-ceramic mixture, no additional hydro- and vapor barrier is needed. A thin layer withstands temperatures from -60 °C to +250 °C, and, subject to the application technology, serves up to 30 years.

Cork and Styrofoam Wallpaper

Of course, sticking in one layer cannot be compared with a full-fledged heat-retaining “pie”, however, wallpaper is actively used both in corner apartments and in rooms on the first floors.

Styrofoam wallpapers resemble ordinary non-woven ones, have a thickness of 0.3-1.0 mm, are sold in 10-meter rolls, and are glued according to the same principle - end-to-end. However, a special glue is intended for them.

Cork is eco-friendly, light, easy to process, and it is also a finishing decorative coating. However, its thermal insulation properties are minimal.

In terms of effectiveness, 6 mm PPS wallpaper replaces a brick wall with half-brick masonry, resists the formation of fungus and mold, and performs an additional soundproofing function.

Material disadvantages: Like PPS boards, wallpaper shifts the dew point closer to the living space and is classified as a combustible finish, like paper wallpapers.

In addition to the listed materials, eco- and glass wool, chipboard, arbolite, foamed polyvinyl chloride and polyethylene insulation, fiberboard, honeycomb boards, reflective thermal insulation with a foil layer are used - materials such as Penofol or Armofol.

Each of the listed heaters has the right to life and, in suitable conditions, perfectly performs its functions. In more detail, all the popular types of insulation that can be used for the walls of the house from the inside, we examined their pros and cons and characteristics in our other article.

When choosing a material, you need to focus on the technical properties, cost and complexity of installation - sometimes the installation technique causes difficulties for unprepared amateurs.

List of materials for effective insulation

The list of vapor-tight materials recommended for use in internal thermal insulation is small:

- extruded polystyrene foam;

- slab polyurethane foam (PPU);

- Styrofoam;

- foam glass.

When performing thermal insulation, the following rule must be observed: with each layer, the vapor permeability of the material increases. In a situation with internal insulation, it is best to let air through and water molecules should be walls.

Polyurethane foam plates have the same characteristics as the sprayed composition:

- do not support combustion;

- environmentally friendly;

- service life up to 25 years;

- thermal conductivity - 0.022;

- moisture resistance and complete vapor tightness;

- sheet thickness - 35-70 mm.

The material is an effective insulation for private and multi-storey buildings, warehouse and industrial buildings. To increase the thermal insulation properties, a layer of foil is applied to the plates, reflecting infrared radiation back into the room. At the ends of the PPU panels, grooves are made for docking without cold bridges.

Due to its strength and moisture resistance, extruded polystyrene foam is used as a heater in all areas of construction: individual, industrial and civil. It has optimal characteristics for internal thermal insulation:

- vapor permeability - 0.013;

- low water absorption allows use in damp rooms;

- plate thickness - 40 mm;

- thermal conductivity - 0.028-0.03.

The material can be used for wall insulation from concrete, wood or brick.

The thermal insulation sequence includes the following steps:

The plates are mounted directly on the wall, so it is important to check the plane of the structure. It should not have protrusions and depressions.

The old finish is carefully cleaned.The surface of the wall must be dry and even. To prevent the appearance of mold, it is primed with an antiseptic composition.

For fastening the plates, a special adhesive composition is used, applied to the entire surface with a notched trowel. Installation of insulation starts from the bottom of the corner. The joints of the panels are blown with mounting foam, which is cut off after drying.

There are two ways to finish the heat-insulating layer with your own hands: stick a reinforcing mesh on the surface of the extruded polystyrene foam and apply plaster or fix a foil film on the material, fill the crate and sew it with drywall sheets. The second option will take up more space in the room, but the effect of insulation will increase significantly.

Foam glass has many positive characteristics:

- vapor permeability - 0.005;

- excellent sound insulation;

- low water absorption;

- thermal conductivity - 0.04-0.06;

- environmental friendliness;

- strength and lack of deformation;

- does not burn, does not emit toxins;

- The material is resistant to microorganisms and rodents.

Foam glass is a universal heat insulator, it has not become popular due to the high cost and difficulties in installation. The rough surface of the material does not allow for tight joining of the plates, the joints must be sealed with liquid rubber. This takes time and requires additional costs.

Styrofoam is an affordable and popular insulation, but when choosing a material, you should pay attention to its density. Its indicator must be at least 35 kg / m3, then the material will have the necessary characteristics:

- thermal conductivity - 0.32-0.38;

- light weight and easy installation;

- vapor permeability - 0.05.

The disadvantage of polystyrene is flammability, so its use is not desirable in residential areas. The installation technology of the heat-insulating layer is similar to the installation of extruded polystyrene foam. For additional fixation, water after the glue dries, you can use dowels-umbrellas. Under them, a hole is drilled in the foam and the wall, and then plastic fasteners are clogged. 5 dowels are used on the plate - 4 at the edges and 1 in the middle.

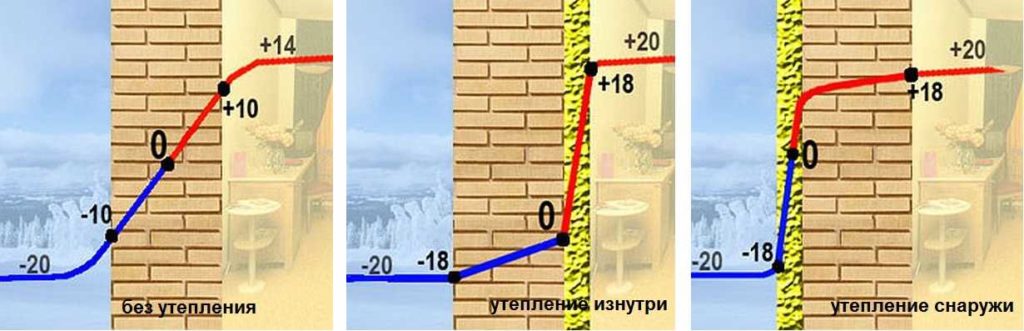

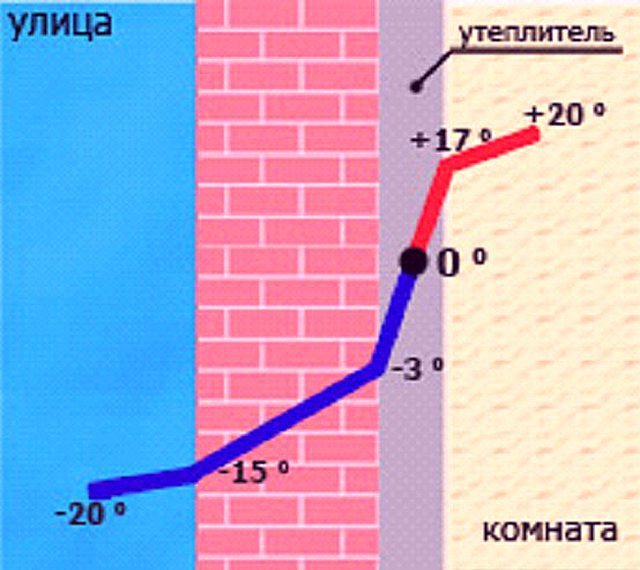

We calculate the thickness of the insulation

So, we found out whether it is possible to insulate the walls from the inside and how to do it correctly. Then we chose the material that suits us the most.

It remains an important matter - the calculation of the required thickness of the heat insulator

First, we measure the wall thickness D, and determine R - the real resistance to heat transfer. We use the formula:

R=D/L

L is the thermal conductivity of the material. For example, take a brick wall 50 centimeters thick. We get the following:

R=0.5/0.47=1.06 square meters Celsius per watt.

In Moscow and the Moscow region, the standard value of this indicator is 3.15 or more. We calculate the difference, which amounted to 2.09 square meters-degrees Celsius per watt. This difference must be compensated with the help of wall insulation.

To determine the thickness of the insulation, the inverse formula is needed:

D=L∗R

For expanded polystyrene, for example (L = 0.042), the following value comes out:

D \u003d 0.042 ∗ 2.09 \u003d 0.087 meters, otherwise, 8.7 centimeters. It is better to take with a margin - 10 centimeters, then the dew point will definitely be inside the heat insulator.

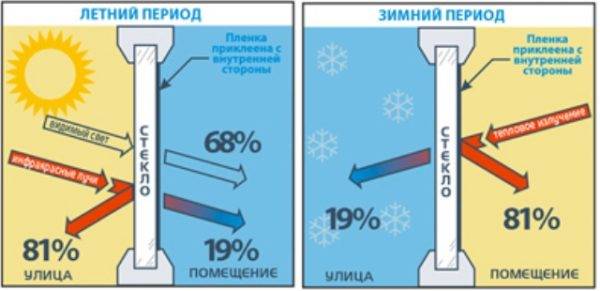

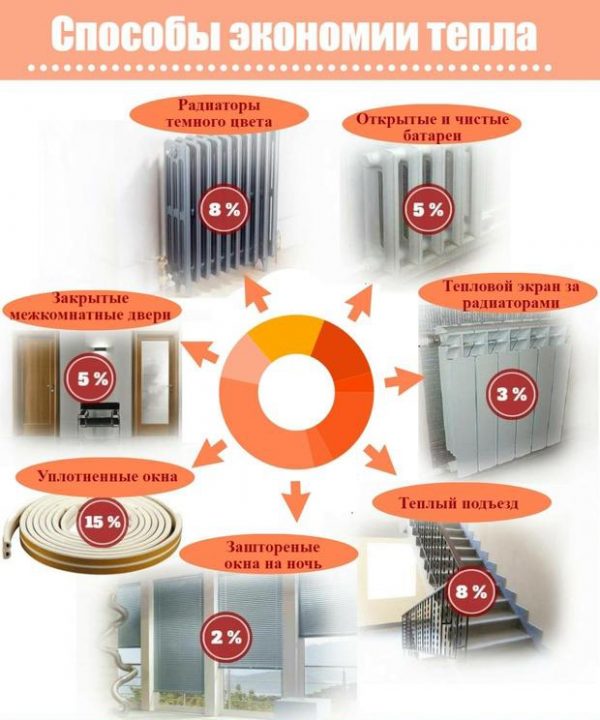

More ways to keep your home warm

There are several other options to keep the heat in the room. Experts recommend doing the following:

- If the apartment is located on the south side, then on a sunny day, try to open the curtains as much as possible. Even the seemingly cold winter sun gives a sufficient level of heat through the prism of glass.

- You can additionally stick a thermal protective film on the windows. It does not reduce visibility. But it retains heat well in the room.

Filmed windows

Filmed windows

If the house has a fireplace or stove that you do not use, be sure to block the chimney. 30% of heat escapes through it.

But do not forget to open the chimney at the time of using the hearth. Otherwise, carbon monoxide will go into the room.

If it is possible to install heating in the house in addition to central heating, use oil-filled radiators or ceramic panels. They are the safest and give a large percentage of heat. If possible, give up central heating in favor of individual. So you can independently control the temperature in the house.

And of course, just dress warmly in winter. Warm socks, tied by the hands of a caring grandmother, will give not only warmth, but also spiritual comfort.

Having figured out how to insulate an apartment from the inside with your own hands without repair, do everything necessary to keep warm. And in the spring and summer, if possible, do major work to replace windows, doors and floor insulation.

How do you warm up for the winter?

Is it possible to insulate with outdoor materials

Materials that are intended for external work cannot be used for internal thermal insulation, they can be hazardous to human and animal health.

In addition, some outdoor materials are flammable.

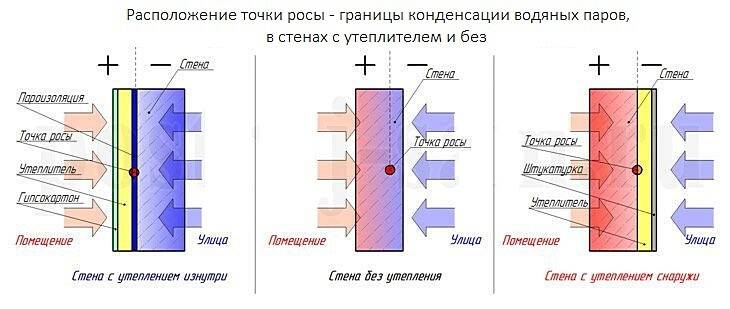

Disadvantages of internal insulation

Compared with the external thermal insulation of the walls, the internal insulation of the apartment has its rather significant drawbacks:

An insulated wall does not accumulate or retain heat, and heat losses range from 8 to 15%.

With internal insulation, the “dew point” may be inside the insulation, which leads to dampness

- The “dew point” for internal thermal insulation is between the insulation and the wall, sometimes inside the insulation layer. This leads to the formation of condensation and the appearance of mold colonies.

- An improperly insulated wall from the inside will freeze all the time, and this inevitably causes irreversible destructive processes in the thickness of the material over time.

The procedure for insulating the internal surfaces of the walls of the apartment with foam plastic

- Wall surface preparation. The walls need to be level. If the new building and the wall are brick, it is necessary to plaster and putty it, if it is concrete, it is enough to level it with putty. If we decide to insulate the walls of the apartment in which we live, it is necessary to clean them of wallpaper, paint, remove nails, dowels from the surface, and cover the chips and recesses with alabaster, if there are protruding irregularities, beat them off. In the presence of fungus or mold, we clean with an emery cloth, and wash and dry the walls, putty the surface, if there are significant irregularities, we plaster.

- Preparing the work site. When preparing the wall, we remove the plinth and flooring, baguette, so that nothing prevents the installation of foam boards. We prime a dry wall with a brush or spray, you can use an antifungal primer.Experts recommend laying waterproofing material between the PPS boards and the wall, then moisture will not get on the insulation.

- Foam padding. After complete leveling and drying of the wall surface, we begin to lay the foam, starting from the corner, from the floor. We press the insulation tightly against the surface and drill a hole exactly in the center with a 5 cm recess into the wall, drive in the fasteners - an umbrella, and then a dowel so that the hat does not protrude on the surface of the sheet. Carefully fix the foam plate in 5-6 places. And so each sheet is carefully pressed against the wall and against each other, we provide a tight and monolithic fastening. If gaps have formed, they can be removed with mounting foam. Now more and more often glue is used to fix the foam, which is applied to the wall with a comb.

- We seal the seams between the foam sheets. We apply glue to all the seams, and put a reinforced tape on top, so that it becomes one with the foam surface and does not act as bumps and folds. To obtain the desired effect, we stretch it and press it against the foam with a spatula and press it into the adhesive mixture. We also coat the caps of the fastening elements with glue. It is impossible for gaps to remain, they become “cold bridges” and nullify all the work.

- We lay the vapor barrier material. After the surface at the seams becomes dry, it is necessary to cover the insulation with a special material. To do this, we apply a mesh (film) over the foam plastic, which protects it from moisture coming from inside the room.On top of the seams covered with a reinforced mesh, we apply glue along its width and apply a vapor barrier material, with a spatula we sink it into the glue, and so on, each row with a slight overlap. After the wall is covered with a grid, we smooth out the bumps with sandpaper or a special grinding tool.

- Outcome. Before us is a flat wall that can be decorated at your discretion.

Installation of insulation on brick walls

How to insulate brick walls inside an apartment with your own hands? Corner walls in a brick house can be insulated using the same method as in a panel house. Therefore, we will analyze the work of installing a material made of polystyrene.

Warming walls in the apartment from the inside:

- clean the walls down to the plaster. If it is missing, then it should be applied. After that, the walls must be leveled, cracks repaired and then treated with a primer;

- you need to prepare the glue according to the manufacturer's recommendations and apply it to the walls that you will insulate. In the beginning, you can use a regular spatula. It is necessary to apply glue to them on the walls, then take a notched trowel and re-walk around the entire perimeter. This is done in order to create an uneven surface of the glue. This contributes to better bonding of the insulation;

- how to insulate a wall in a corner apartment from the inside? Next, we take sheets of heat insulator and begin to install them on the walls. First of all, the bottom row is laid. We tightly apply the polystyrene sheet and push it through, you can not use dowels or other fastening materials.When installing, we use the level and carefully join the edges so that no gaps form, if necessary, cut the sheets. The next row is set so that the junction of the two sheets falls in the middle of the bottom sheet. This will give great durability to the entire structure.

By following these steps, you can insulate a corner room from the inside.

Alternative modern heaters

There are many non-standard alternative ways to insulate corner apartments. They are distinguished by the use of modern innovative materials.

polyurethane foam

PPU insulation satisfies all the requirements for vapor barrier, water absorption and the absence of seams. Therefore, even if there is a dew point inside the layer, it will remain “conditional”, since there is no condensation in vapor-tight materials. It turns out from the side of the room a completely sealed heat-insulating layer.

Wall insulated with polyurethane foam

Keramoizol

Keramoizol

Modern building material, which is characterized by increased thermal insulation. Sold in liquid form. For the most effective insulation, 6 layers are laid on the wall in a direction perpendicular to each other.

Astratek

Astratek

Astratek is a liquid insulation material. It can be applied to the surface with a sprayer or a brush, and after drying it forms a strong and elastic substance with a porous structure. Such a heater perfectly passes air, but effectively retains heat inside the building.

Liquid thermal insulation using Mascoat as an example

mask

The paint of a well-known American manufacturer has increased thermal insulation properties, and also repels moisture very effectively. Its efficiency is 5 times higher than mineral wool. 1 mm.In terms of efficiency, paints will not yield to a layer of mineral wool half a centimeter thick. It is applied to the surface of the wall in the same way as ordinary paint. It can be used simultaneously for decorative finishing.

polyph

This material is made from a polyethylene base. Its thermal insulation properties are slightly lower than those of the previous options, but the material also has its advantages. A durable polyethylene film made by foaming is covered on the inside with a thin layer of foil. Sheets of paper are glued on top on both sides. Outwardly, the material resembles wallpaper, often used as a preparatory finish before gluing them. The main disadvantage is the possibility of using only for dry walls. It may not be suitable for a corner apartment, since such rooms are characterized by high humidity.

Mounting polyform

Consumer Requirements

Insulation from the inside requires a particularly reverent attitude to the choice of insulation material. Placing it inside, in close proximity to a person, in a limited space, requires him to comply with safety standards.

What is the best way to insulate a house? It is necessary to determine what is an important and necessary condition for the choice. Wall insulation inside the house must meet the following requirements:

- have a high degree of environmental cleanliness;

- during operation, do not emit substances harmful to breathing into the environment;

- do not collapse for a long time;

- have a certain resistance to biological, chemical, mechanical stress;

- ensure the required level of fire safety.

What is used to insulate a private house from the inside? Fibrous and polystyrene foam insulators.