- Materials and methods for warming a water well for the winter

- How to insulate a well with natural materials?

- What is caisson insulation?

- How to insulate a pipe with an electronic heater?

- How to make a casing pipe with your own hands?

- We install passive winter insulation on the well

- Building a caisson for a well

- We warm the well with a casing pipe

- We warm the well with improvised materials

- Requirements for the location of the well

- How to insulate a well for the winter

- What is a caisson and does it need to be insulated

- Do-it-yourself thermal insulation stages

- Caisson

- Casing pipe and head

- street plumbing

- Lead to the house

- Briefly about the main

- Resources involved in warming

- Varieties of thermal insulation materials

- The specifics of the operation of the heating cable

- Insulation of the water pipe from the well to the house

- Ways to insulate a water pipe:

- Conclusion

- A group of well insulation methods

- Insulation of a well with a caisson

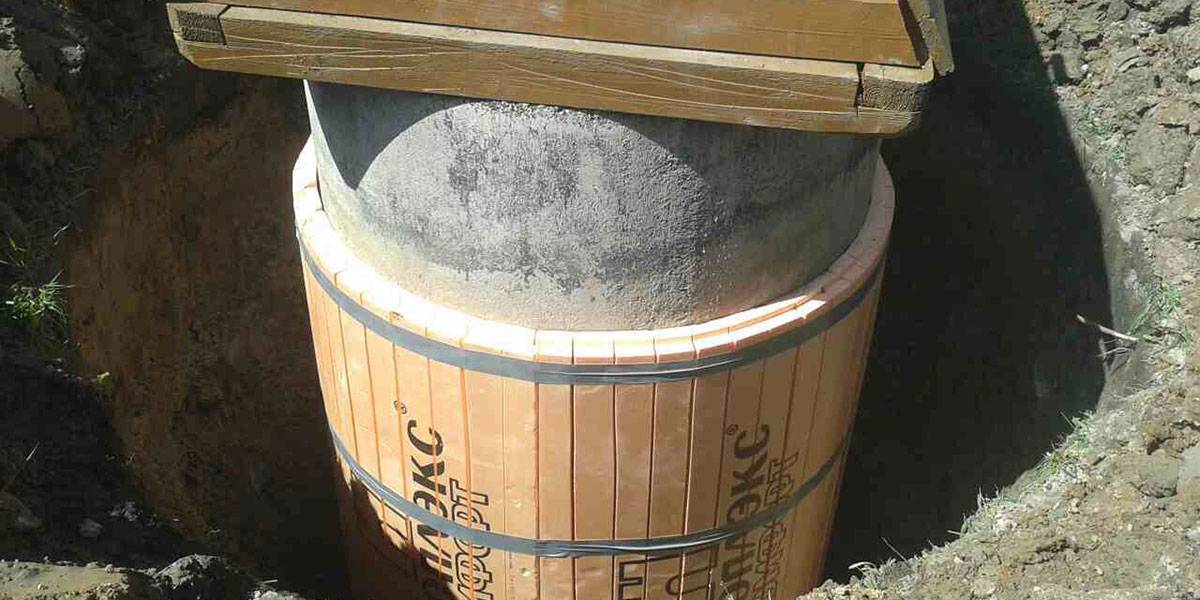

- How to make / install a caisson for a well

- Well insulation without a caisson

- Casing pipe insulation

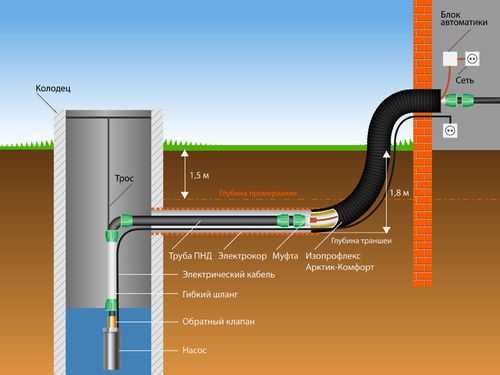

- Well insulation with heating cable

- How to insulate a well for the winter with your own hands?

- What material to choose

- How to insulate

- Box installation

- Warming of the supply to the house

- Caisson - the number one choice

Materials and methods for warming a water well for the winter

Work on the insulation of the well does not belong to the category of increased complexity and each homeowner can carry it out independently

It is only important to choose the right material and method of thermal insulation

The amount of insulation depends on several factors:

- the climate of the region and the depth of soil freezing;

- the level of location of ground water heating;

- the quality of the insulating material.

How to insulate a well with natural materials?

readily available and practically free material

Work order.

Dig a pit around the device and fill the resulting hole with sawdust. If you fill up not just sawdust, but mix them with liquid clay, then when the solution hardens, you will get not only a heat-insulating layer, but also a strengthening one.

It is even easier to insulate the water well with a layer of dry leaves and straw. When rotting, such material will release some heat. But such a heat insulator is very short-lived and after 2-3 years the insulation layer will have to be updated.

The whole process of well insulation for the winter is divided into several stages. First of all, the casing pipe protruding from the well is insulated. To begin with, it is recommended to wrap it with a metal or plastic mesh, leaving a small gap, which is subsequently filled with sawdust or leaves. In order to protect the structure from moisture ingress, it is necessary to lay a layer of waterproofing material (you can use ordinary roofing felt).

What is caisson insulation?

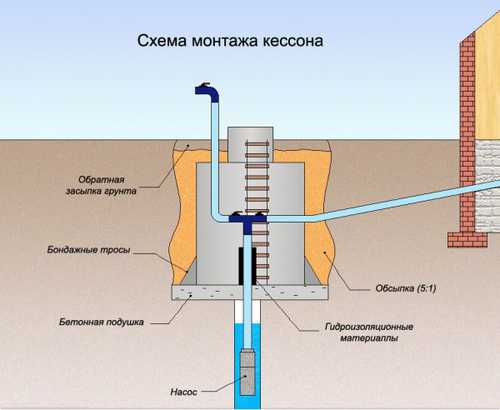

A caisson is a heat-insulating structure built around a well. The material for its construction can be reinforced concrete, wood, plastic.To insulate a well that does not involve the installation of additional hydraulic equipment, an ordinary plastic barrel of 200 liters is quite suitable.

Work order.

- A pit is dug around the head of the well, the bottom of which should be 30-40 cm below the freezing level of the soil in your area.

- At the bottom of the pit, a pillow is poured from a mixture of gravel and sand, 10 cm thick.

- Holes are cut in the barrel: in the side wall under the water pipe, at the bottom under the head of the well.

- The barrel put on the head of the well is lowered to the bottom of the pit.

- Inside the tank, a connection is mounted between the head of the well and the inlet water pipe.

- In principle, automatic water distribution equipment or a surface pump can also be placed in such a barrel. Also, a drainage tube can be installed at the bottom of the caisson to drain the accumulated condensate deep into the ground.

- Work is underway to insulate the caisson. To do this, a layer of any material that is not subject to the aggressive effects of the soil, for example, foamed polystyrene, is laid around the barrel. You can also use mineral wool, on top of which a layer of waterproofing is applied.

- The container is closed with a lid equipped with a ventilation pipe. A layer of thermal insulation is also laid on top.

- The pit is filled with earth. The device is ready for use.

For the construction of a heat-insulating box, galvanized iron is also used, which is wrapped around concrete rings. Then the device is securely fixed and covered with insulation.

How to insulate a pipe with an electronic heater?

considered the most effective

The heater can also be mounted inside the casing pipe.In this case, it is necessary to select the desired power and lay the cable in accordance with the installation rules for such devices.

Installation of this design requires special knowledge and skills, so it is better to entrust this work to professionals.

How to make a casing pipe with your own hands?

Work order.

- A pit is dug around the casing pipe with a depth of at least 2 m.

- The pipe is wrapped in a heat-insulating material, such as mineral wool.

- A pipe of a larger diameter is put on top of the resulting structure.

- Backfilling of the excavation is in progress.

We install passive winter insulation on the well

Depending on the volume of water consumed and the design of the well, you can choose the following technologies for its winter insulation with constant use.

Building a caisson for a well

The classic method of winter insulation of a permanent well is the construction of a caisson.

Finished steel caissons for well insulation

The caisson is a kind of structure around that part of the well column, which is located in the frozen soil layer. Caisson construction materials can be very different: from monolithic concrete to a finished product made of durable plastic or iron. Also, the forms of the caisson can be very different, but the most common is the barrel.

Caisson construction technology

-

Choose a suitable plastic or metal container. You can use 200 liter drums. If you do not intend to place additional hydraulic equipment in the caisson, then these dimensions will be quite enough.

- Dig a pit around the head of the well.The bottom of the pit should be below the level of soil freezing in your area by about 30-40 centimeters, based on particularly severe winters. The horizontal dimensions of the pit should exceed the dimensions of the barrel by about half a meter.

- At the bottom of the pit, pour a pillow of sand and gravel. 10 centimeters of embankment will be enough.

- Cut holes in the barrel - at the bottom under the head of the well and in the side wall under the supply pipe.

- Lower the barrel to the bottom of the pit, putting its bottom on the head of the well.

-

Mount the connection of the supply pipe of the water supply and the head of the well inside the barrel. In principle, even a surface pump or automatic water distribution equipment can be accommodated in a 200 liter drum. At the bottom of the caisson barrel, it is also possible to insert a drainage tube, which will drain the accumulated water condensate deep into the ground.

-

A layer of thermal insulation is laid around the barrel in the pit. To create it, you can use a material that is not subject to the aggressive influence of the soil, for example, expanded polystyrene. It is possible to wrap the barrel from the sides with a layer of mineral wool with a mandatory subsequent wrapping with a layer of waterproofing.

- The caisson barrel is closed with a lid with a ventilation pipe. The upper part of the barrel is also insulated with a layer of thermal insulation.

- Backfilling of the excavation is in progress. The mini-caisson is ready for winter use.

Such a caisson may well serve a small water intake well for a private house.

We warm the well with a casing pipe

It is also possible to insulate the well by creating an additional casing pipe.When choosing this option, you will not be able to place hydraulic equipment in the immediate vicinity of the head, but if there is, for example, a surface pump that pumps water from a well, this is not required directly in the house or in a heated room. We operate on the following technology:

- we dig a pit around the casing pipe of the well to the level of soil freezing in your area;

- we wrap the well casing with a heat-insulating material, for example, mineral wool;

- we put a larger diameter pipe on top of the resulting structure;

- we backfill the previously excavated pit.

Insulated well pipe

We warm the well with improvised materials

You can insulate a water well with any improvised materials. This method can be used in regions with a mild climate, where the temperature in winter does not fall below 15 degrees. Consider possible materials for insulation.

- Sawdust. This material can be found on almost every personal plot or borrowed from neighbors. Sawdust is suitable for various insulation works, including for the equipment of water wells.

Dig a pit around the well with a cross section of 0.5-0.6 meters just below the freezing line of the soil and fill the sawdust into the resulting cavity. In the pit, you can fill up not just a layer of sawdust, but mix it with liquid clay. When solidified, you will get both an insulating and strengthening layer at the same time. - It is even easier to insulate the space around the water well with a layer of straw and dry leaves with a similar cross-section. During the natural decomposition of this material, a certain amount of heat will be released.However, such a mixture is short-lived and after a couple of years the insulation layer around the water well will have to be renewed.

Requirements for the location of the well

When choosing a drilling site, many factors are taken into account: the geological features of the site, its topography, the influence of hydrological factors, and the location of other economic activities.

In addition, the convenience of the location of the future source of water supply is important, which will allow it to be operated without problems in the future. The selected location for the well must meet the following requirements: The selected location for the well must meet the following requirements:

The selected location for the well must meet the following requirements:

- the presence of an aquifer;

- convenient location for water intake;

- the possibility of plumbing;

- providing access to the drilling machine and other equipment for servicing the well;

- compliance with sanitary standards;

- lack of power lines, underground utilities.

Also, at the stage of choosing a place for a well, it is worth considering how the pumping equipment will be connected, i.e. take into account the presence of power lines.

If in the future you plan to lay a surface water supply from the well, then it is desirable that the slope of the site does not exceed 35º.

When choosing a location for a well, not only the characteristics of its own site are taken into account, but also the surrounding areas for compliance with the specified requirements

How to insulate a well for the winter

There are several methods of thermal insulation, the choice of the optimal method will depend on the frequency of well operation.

- Seasonal use.This mode of operation is typical for summer cottages, when the well does not function during the cold season. There is no need to insulate the well in the country, since proper conservation of the well for the winter eliminates the possibility of water freezing.

Preservation involves draining water from the pipeline system. To completely drain the water, turn off the water supply pump and open the tap. It will not be superfluous to make sure that there is no water in the mixers at home and storage tanks.

Periodic use. It provides for the operation of a well with a certain period. For example, a country house is used only on weekends. Or, on the contrary, they do not use it only on weekends. In this case, passive insulation will not help, because. insulation only slows down the rate of cooling of water. The way out of the situation can be cable heating of pipes. This option will be described below.

Constant use. Daily use of water ensures its movement, which means it eliminates the possibility of water freezing in the pipe. But, there is a catch here too. After all, at night the water supply is idle, and in severe frosts (if the pipes are laid above the freezing level of the soil), it is highly likely that the water in them will freeze. In addition, water supply equipment (pumps, pumping stations) is also sensitive to temperature fluctuations.

We recommend a detailed description of the technology of water supply from a well

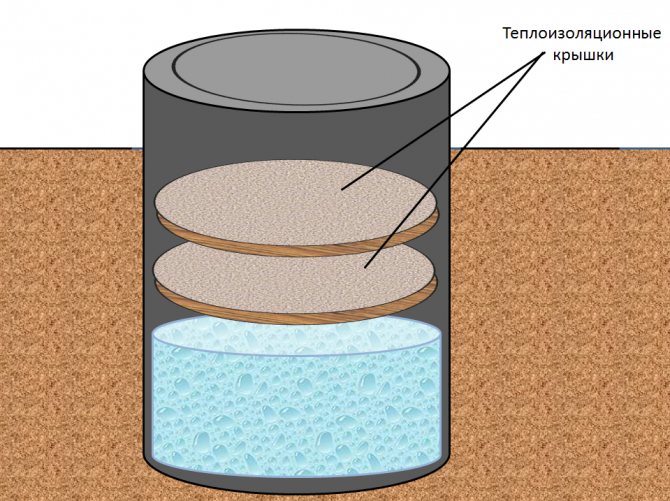

What is a caisson and does it need to be insulated

The caisson for the well is a reservoir located at the mouth of the installation of an autonomous source of water supply.Inside the caisson, which is also called a reservoir or wellhead, there are such component devices of an autonomous source of water supply as a hydraulic accumulator, filters, and a pipeline. The caisson is mounted in order to be able to take the accumulator out of the house.

The caisson is not mounted only if the accumulator is located in the house, which is also acceptable. In any case, well insulation with and without a caisson is mandatory. Caissons can be made of various materials: concrete, metal or plastic.

The caisson can be insulated both from the outside and from the inside. However, as practice shows, the space inside the caisson is small, so it is more convenient to carry out insulation from the outside. Styrofoam or expanded polystyrene is used for internal insulation.

Do-it-yourself thermal insulation stages

The further fate of the entire water supply system will depend on how well the thermal insulation will be carried out. Therefore, it is better to entrust it to professional companies with extensive experience. Nevertheless, every private homeowner has the right to know how to insulate a well and water supply for the winter on the surface - a well for his own home for the entire period of turnkey cold weather with his own hands.

Visually about the insulation of the well, see this video:

In the standard case, the procedure consists of sequential thermal insulation of the following main elements:

Caisson

Stages of work:

- The required amount of foam or other heat insulator is prepared.

- Further, the material is cut into the necessary fragments, based on the shape and size of the caisson.

- The outer part of the caisson is waterproofed with bitumen, except when it is made of plastic or iron.

- The prepared fragments are applied to the outer walls and fastened with wire, stops, mesh or tape.

- The joints between the sheets are filled with mounting foam - for sealing.

- Upon completion of the fastening, the structure is covered with a layer of expanded clay.

Casing pipe and head

Subsequence:

- From pieces of chipboard, boards, plywood, sheets of metal or rigid insulation, a box is made for external closing of the casing and head.

- The box is installed over the casing pipe and the head.

- Its internal space is filled with parts of mineral wool, glass wool or natural components (hay, straw, paper).

Alternatively, instead of a box, a cylinder is formed from a chain-link mesh with a diameter exceeding the head by 0.3 m.

Do-it-yourself well insulation

street plumbing

Sequence of work:

- At the outlet of the pressure pipe of the well, at the point of connection to the domestic water supply, a piece of heating cable is wound or a special tee with a gland is installed.

- Next, the water pipe is placed in a PPS shell or in a sewer pipe of a larger diameter, which creates an air gap.

- The structure is laid in a previously dug trench and then filled with expanded clay, then with a layer of sand and previously removed soil.

Lead to the house

In view of the fact that the wellhead is already heated by a heating cable, and the supply water supply is insulated with shells, it is not necessary to make special heating of the liner. As a standard, it is thermally insulated along with the supply pipe.

See in this video how to mount the heating wire inside the pipe

Briefly about the main

Depending on the frequency of operation, there are the following ways to insulate a well on the street:

- Seasonal, when the well is not in operation, but simply drained and turned off for the winter.

- Periodic, when water is taken on weekends or every few days. To maintain efficiency, heat-insulating materials and heaters are used.

- Constant, when the well is practically not idle, so the flow never stops for a long time. However, in cold weather, icing can begin. Therefore, professional insulation is required.

At the same time, 4 technologies are used for thermal insulation - by means of a heater, with a coffered structure, without it, and with the installation of a heating cable. In most cases, combined methods are used. The heat-insulating materials are polystyrene foam, foam plastic, foamed polyethylene, mineral or glass wool, as well as penoizol, foamed polyurethane foam and expanded clay. You can do the thermal insulation yourself, but it is better to entrust the matter to a professional team.

Resources involved in warming

When deciding how to insulate a well for the winter, craftsmen choose between three methods - the introduction of specific materials, heating elements, or the use of caissons. Conventional heaters are based on synthetic porous substances with low thermal conductivity due to the fibrous structure, the presence of air cells.

Heating elements - cables - vary in power and functionality, the advantage of their use is the ability to control temperature parameters. Caisson chambers are produced in a factory way, plastic variations are the most common.

Varieties of thermal insulation materials

In a separate form, they are used in areas with a mild climate and in relation to wells operated without downtime. In more severe weather conditions, a tandem with a heating cable is appropriate. Useful categories of raw materials:

- regular and extruded polystyrene foam. A synthetic resource with an abundance of air cells is characterized by low thermal conductivity; it is used to strengthen underground and external pipelines, caisson chambers;

- penofol is sold in the form of cylindrical shells and flat panels, it is used for structures without external loads, as it is vulnerable to compression;

- glass and mineral wool is highly hygroscopic, therefore not suitable for installation in a humid environment. Cotton wool can be used to close the head - winter preservation of the mouth of the well.

Expanded polystyrene - material for well insulation

Expanded polystyrene - material for well insulation

Foamed polyurethane foam and penoizol are also used; specialized equipment is required for their application. Budget expanded clay is useful for sprinkling caisson pits and water ditches.

The specifics of the operation of the heating cable

The advantage of this method is the possibility of preheating the liquid supplied to the system. In this case, in case of a strong drop in temperature or downtime, freezing of water is prevented. The cable can be mounted outside or placed inside the pipeline, in the first case insulation is used according to the shell principle.

Water intake is usually provided by HDPE pipes characterized by low thermal conductivity, here the assembly of the cable inside is more efficient.When choosing between self-regulating and resistive cables, it is better to give preference to the former, as they develop a high efficiency due to the fact that their sheath heats up under the influence of the environment.

Despite the fact that self-regulating products are significantly more expensive than resistive ones, even when laying a short section, there is a fair amount of energy savings.

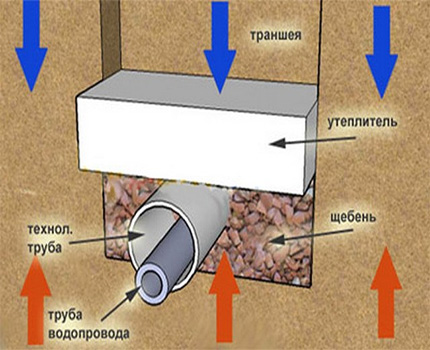

Insulation of the water pipe from the well to the house

The purpose of the transmission water pipe is to transport water from the well to the house. It is worth noting that the pipe is the most vulnerable point of the entire water supply system, since, one way or another, it passes through the freezing point of the soil. The exception is the organization of water supply through a full-fledged, insulated basement.

It is recommended to insulate the pipe even at the stage of laying the water pipe. But you can perform it as needed, you just need to be prepared for a large amount of earthwork.

Ways to insulate a water pipe:

- use of polyurethane foam shell;

- wrapping the pipe with soft insulation, followed by waterproofing;

- installation of a heating cable of low power, due to the small diameter of the pipe;

Conclusion

Insulation of the well for the winter will ensure a constant supply of water for a residential building and ensure the safety of the water supply for summer cottages and country cottages.

Low temperatures are a danger to the external water supply system of a private house. Even if the water pipe is located below the freezing point of the soil, this does not mean that the system will not freeze. In private houses, where a well serves as a source of water supply, it is necessary to insulate it.Previously, the well was insulated with the help of improvised means, which were leaves, sawdust and straw. The use of this method is irrelevant, especially since more rational methods have long been available.

A group of well insulation methods

Thermal insulation can be passive (insulated caisson) and active (heating cable).

Insulation of a well with a caisson

The construction and insulation of the caisson is considered a classic way of thermal insulation of a well. The caisson can be purchased as a finished structure or built independently.

The acquired caisson has an undoubted advantage, which is tightness. Homemade will be cheaper.

How to make / install a caisson for a well

dig a pit. The lowest point of the pit should be below the freezing level. Therefore, the depth of the pit often reaches 2.5-3 m. To determine the exact required depth, you need to find out the freezing depth and add half a meter to be sure. The width of the pit should exceed the dimensions of the future caisson by 0.5 m;

equip a sand and gravel cushion at the bottom of the pit (height 0.1 m);

cut a hole for the supply and distribution pipes (for a purchased caisson), install the caisson;

Advice. An additional hole can be made at the bottom of the pipe through which condensate will be discharged.

lay out a brick caisson or lay a concrete circle (concrete rings), the amount will vary depending on the depth of the pit;

mount the necessary equipment in the caisson;

perform insulation of the caisson from the outside (insulation layer - 50 mm)

Please note that a self-built caisson can be insulated from the inside if reliable waterproofing of the structure is provided; close the caisson with an insulated lid

It is advisable to make a ventilation pipe in the lid;

close the caisson with an insulated lid. It is advisable to make a ventilation pipe in the lid;

backfill the pit. For additional insulation, you can mix the earth with expanded clay.

In such a caisson, it is already possible to leave all the equipment for the winter without consequences.

Note that the arrangement of the caisson is also required by the Abyssinian well.

Well insulation without a caisson

In regions with slight sub-zero temperatures, the construction of a caisson can be avoided, and insulation will consist in arranging an insulated box located at soil level. The presence of an insulated cover on the box is a mandatory element.

The device of a protective house above the well

Casing pipe insulation

Such insulation allows you to do without the construction of a caisson.

How to insulate a well casing

dig the casing pipe to the estimated depth. The sufficient width of the trench (0.7-0.8 m.) will simplify further work;

insulate the pipe with heat-insulating material. PPU shell is ideal for well insulation. This material is hygroscopic, durable, resistant to rotting, thanks to a wide range of diameters it provides reliable sealing, and besides, it is easy to install. If the insulation is made with mineral wool, it is advisable to protect it by wrapping it in a film or putting another pipe of a larger diameter on the insulated casing pipe;

fill up the trench;

equip a clay castle near the head, which will prevent water from flowing along the pipe.

Well insulation with heating cable

The heating cable is considered an active method of insulation and the most effective. However, it is also the most expensive of the listed.

How to insulate a well with a heating cable

Heating cable installation technology involves:

a trench is being dug (depth is below the freezing point);

installation of the heating cable around the casing pipe. For a low-power cable, a small pitch of turns is selected, a powerful cable is laid in a straight line;

the pipe is additionally insulated with heat-insulating casings;

if necessary, waterproofing of the insulation is carried out;

the soil removed from the trench is backfilled.

The electric heating system is good because you can use it all the time and not guess if the well will freeze in winter, but you can operate it from time to time. For example, installing a sensor will regulate the period of operation and downtime of the system. Also, this approach will allow you to defrost the system after winter or freezing. Of course, installing a sensor involves extra costs, but they will pay off with savings on electricity.

How to insulate a well for the winter with your own hands?

There are several ways to insulate a well for the winter. Choose one of them or combine several - the choice that needs to be made. Since the risk of well freezing in a cold winter is significantly high (although it depends on the region), it is necessary to take care of warming in advance.

What material to choose

The choice of material that will not allow frost to make its detrimental effect on the well depends on the climatic characteristics of the region. If winters in the region do not bring severe frosts, then it is quite possible to get by with simple, cheap, but still effective materials - peat, straw, sawdust and even dry leaves.However, such materials have one feature - hygroscopicity.

Source insulation is more efficient when using industrial materials. Their choice is huge: expanded polystyrene, polystyrene, mineral wool, penoizol, glass wool. Such materials are more thermally insulating than straw or peat.

Sometimes it is recommended to use them in combination with an air cushion in order to enhance the effect. But practice has shown that this is an unnecessary move - modern materials have excellent thermal insulation properties, since they themselves have a porous structure. Even if frosts drop to critical levels, they are able to withstand such temperatures.

How to insulate

It should be understood that the insulation of the well should not have a continuous view, but a partial one, from the top. The water in the well will not freeze under any frost, because it is at a depth where, in any case, there will be a positive temperature. Condensation freezes on the walls - water evaporation or water in the pipe leading to the house. Therefore, only the initial level of the well, approximately the first 40 centimeters, will have to be insulated. To do this, the earth is removed around the casing.

It will be better if the walls are reinforced with boards, plastic or other material to prevent moisture from transferring from the ground to the insulating material. Further, a heat-insulating material is laid in the void between the soil and the casing.

If it is polystyrene or polystyrene foam, it is advisable to use their crumbs, and not whole pieces. You can use mounting foam, just keep in mind that the consumption will be considerable - 2-3 cans.The top of the shaft must be closed with a lid, but not insulated with a material similar to mounting foam - access to the inside of the shaft may be necessary at any time.

Box installation

Any insulation work will be more effective if you additionally install a decorative box over the well. Shape, size, material - it does not play a fundamental role

It is important that access to the well is not limited and decorative so that the box matters. That is, it is advisable to try to maximize its aesthetics.

Combined boxes should be considered as options: brick bottom / wooden top. Brickwork will certainly protect against drafts, and a wooden frame is easy to make at home. Moreover, this type of insulation will visually resemble a traditional well log house, which, of course, looks quite beautiful and aesthetically pleasing.

Warming of the supply to the house

The pipeline from the well to the house must be insulated at the time of manufacture. To do this, you can use the same production heaters - mineral wool or polystyrene. Given that the depth of the pipeline is usually rather big, you should take care of the integrity of the pipe and / or cable. Then the insulation can be done and forgotten about it.

For insulation of plastic pipes of any diameter, you can also use ready-made insulation in the form of cut pipes made of expanded polystyrene.

Caisson - the number one choice

So far, we have been talking about inexpensive or completely free materials. But their quality is not always happy. The use of a caisson makes it possible to achieve much greater efficiency in the fight against frost and its influence.

Installing a caisson will cost more than using sawdust or straw, but it's worth it.If you carefully study the forums and other user resources on the Internet, you can come to the bold conclusion that the caisson has no drawbacks.

A caisson is one of the answers to the question of how to insulate a well so that it is beautiful, convenient, and reliable.