- How to insulate a well for the winter with your own hands: ways

- How to insulate a well for the winter

- Do-it-yourself thermal insulation stages

- Caisson

- Casing pipe and head

- street plumbing

- Lead to the house

- Briefly about the main

- Tools and materials

- Making passive insulation

- How to insulate a well on the street in a private. Well insulation for the winter: practical advice for summer residents

- What structures need insulation and why

- How to insulate a well for the winter with your own hands

- We install passive winter insulation on the well

- Building a caisson for a well

- We warm the well with a casing pipe

- We warm the well with improvised materials

- How to close the well for the winter?

- Conventional Source Conservation

- Abyssinian well conservation

- If well with adapter

- Casing pipe and improvised materials

How to insulate a well for the winter with your own hands: ways

To insulate the well, you need to choose the best option for insulation. To do this, the materials must meet the following requirements:

- do not absorb moisture, since when moisture is absorbed, the insulation will lose its properties, and the system will freeze;

- do not change their original properties when exposed to soil pressure, which reduces the temperature index;

- do not attract the attention of rodents, as small animals can spoil the material even before the arrival of cold weather.

Based on the above requirements, it can be noted that the best option for the construction of well insulation is the use of expanded polystyrene. Styrofoam differs from expanded polystyrene not only in shape, but also in porous consistency. Due to this consistency, the attention of rodents and other pests that can violate the integrity of the structure is attracted. You can insulate the well in the following ways:

- installation of a heater;

- installation of a finished insulated box;

- the use of a caisson made of plastic materials;

- laying a heating cable on the surface of the caisson;

- casing pipe installation.

To get acquainted with the principles of insulation of each method, we will consider them separately.

How to insulate a well for the winter

There are several methods of thermal insulation, the choice of the optimal method will depend on the frequency of well operation.

- Seasonal use. This mode of operation is typical for summer cottages, when the well does not function during the cold season. There is no need to insulate the well in the country, since proper conservation of the well for the winter eliminates the possibility of water freezing.

Preservation involves draining water from the pipeline system. To completely drain the water, turn off the water supply pump and open the tap. It will not be superfluous to make sure that there is no water in the mixers at home and storage tanks.

Periodic use. It provides for the operation of a well with a certain period. For example, a country house is used only on weekends. Or, on the contrary, they do not use it only on weekends.In this case, passive insulation will not help, because. insulation only slows down the rate of cooling of water. The way out of the situation can be cable heating of pipes. This option will be described below.

Constant use. Daily use of water ensures its movement, which means it eliminates the possibility of water freezing in the pipe. But, there is a catch here too. After all, at night the water supply is idle, and in severe frosts (if the pipes are laid above the freezing level of the soil), it is highly likely that the water in them will freeze. In addition, water supply equipment (pumps, pumping stations) is also sensitive to temperature fluctuations.

Recommend detailed description well water supply technology

Note. Even drilling wells in winter requires constant pumping of water through pipes, to say nothing of domestic use.

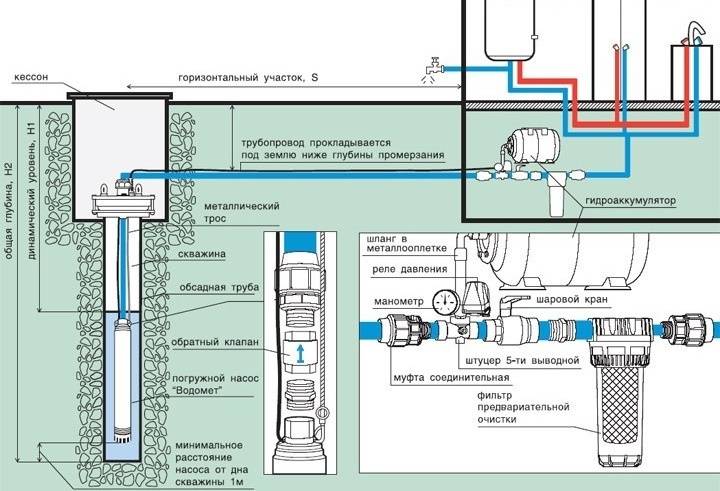

Do-it-yourself thermal insulation stages

The further fate of the entire water supply system will depend on how well the thermal insulation will be carried out. Therefore, it is better to entrust it to professional companies with extensive experience. Nevertheless, every private homeowner has the right to know how to insulate a well and water supply for the winter on the surface - a well for his own home for the entire period of turnkey cold weather with his own hands.

Visually about the insulation of the well, see this video:

In the standard case, the procedure consists of sequential thermal insulation of the following main elements:

Caisson

Stages of work:

- The required amount of foam or other heat insulator is prepared.

- Further, the material is cut into the necessary fragments, based on the shape and size of the caisson.

- The outer part of the caisson is waterproofed with bitumen, except when it is made of plastic or iron.

- The prepared fragments are applied to the outer walls and fastened with wire, stops, mesh or tape.

- The joints between the sheets are filled with mounting foam - for sealing.

- Upon completion of the fastening, the structure is covered with a layer of expanded clay.

Casing pipe and head

Subsequence:

- From pieces of chipboard, boards, plywood, sheets of metal or rigid insulation, a box is made for external closing of the casing and head.

- The box is installed over the casing pipe and the head.

- Its internal space is filled with parts of mineral wool, glass wool or natural components (hay, straw, paper).

Alternatively, instead of a box, a cylinder is formed from a chain-link mesh with a diameter exceeding the head by 0.3 m.

Do-it-yourself well insulation

street plumbing

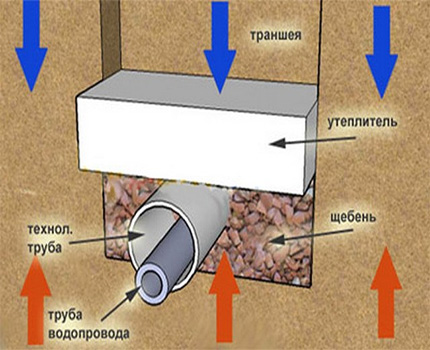

Sequence of work:

- At the outlet of the pressure pipe of the well, at the point of connection to the domestic water supply, a piece of heating cable is wound or a special tee with a gland is installed.

- Next, the water pipe is placed in a PPS shell or in a sewer pipe of a larger diameter, which creates an air gap.

- The structure is laid in a previously dug trench and then filled with expanded clay, then with a layer of sand and previously removed soil.

Lead to the house

In view of the fact that the wellhead is already heated by a heating cable, and the supply water supply is insulated with shells, it is not necessary to make special heating of the liner. As a standard, it is thermally insulated along with the supply pipe.

See in this video how to mount the heating wire inside the pipe

Briefly about the main

Depending on the frequency of operation, there are the following ways to insulate a well on the street:

- Seasonal, when the well is not in operation, but simply drained and turned off for the winter.

- Periodic, when water is taken on weekends or every few days. To maintain efficiency, heat-insulating materials and heaters are used.

- Constant, when the well is practically not idle, so the flow never stops for a long time. However, in cold weather, icing can begin. Therefore, professional insulation is required.

At the same time, 4 technologies are used for thermal insulation - by means of a heater, with a coffered structure, without it, and with the installation of a heating cable. In most cases, combined methods are used. The heat-insulating materials are polystyrene foam, foam plastic, foamed polyethylene, mineral or glass wool, as well as penoizol, foamed polyurethane foam and expanded clay. You can do the thermal insulation yourself, but it is better to entrust the matter to a professional team.

Tools and materials

Ready-made heat-insulated pipes are on sale

Ready-made heat-insulated pipes are on sale

To properly insulate the well from the street, it is necessary to prepare the following tools:

- roulette;

- construction tape and pencil;

- hacksaw for cutting insulation;

- liquid nails, self-tapping screws for attaching sheets of material to the frame of the caisson;

- shovel.

Additionally, you should prepare the heater itself. The most commonly used materials are:

- Glass wool or mineral wool. The cheapest options. Prone to deformation and drink moisture.To use such heaters, you will have to create an additional protective durable casing on top of the materials. It is necessary to use cotton wool only in those places where condensation or leakage is excluded. It is forbidden to use these types of heaters, subject to the high location of groundwater on the site.

- Basalt fibre. Thanks to the foil coating, the material is considered convenient to use, having good thermal insulation characteristics.

- Expanded polystyrene or polystyrene. Can be used as sheets or special cylinders. Both types of material are easy to cut, retain heat well, but are of interest to rodents. When using foam insulation, you need to make a special protective coating of cement and broken glass.

- Sprayed polyurethane foam. Easy to use. When using it, the water pipes must be laid on expanded clay bedding.

- Thermal paint. A liquid heat insulator is expensive, but it can be used to process the most inaccessible sections of the highway and equipment. If the paint is used on metal parts, it additionally acts as a corrosion protection.

Making passive insulation

Passive well insulation is provided if the water supply is used all year round. Three technologies can be used for this purpose:

- insulation by installing a caisson;

- use improvised materials;

- insulated with a casing pipe.

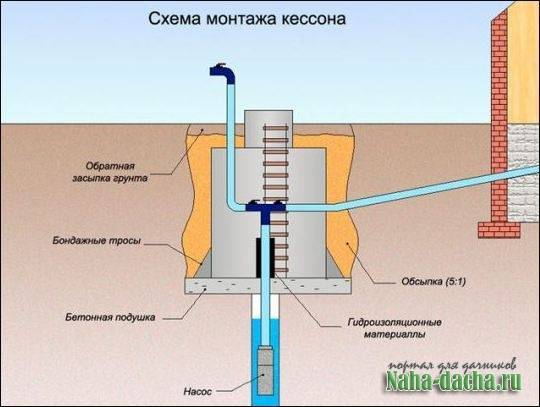

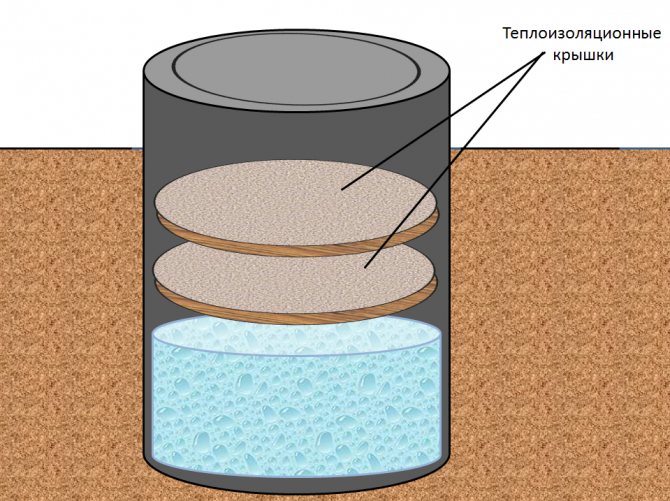

A caisson is a structure that is installed at the top of the well. It is a hollow container that surrounds the pipe to the depth of soil freezing. To create a caisson, you can use different materials: concrete rings, brickwork, a metal barrel or finished plastic products.

The caisson installation will look like this:

- a pit is dug around the well, its depth should exceed the level of soil freezing by at least half a meter;

- at the bottom of the pit, a sand cushion is made, 10-15 centimeters thick. Walls are erected on it (around the well) or a ready-made container is installed. At its bottom, it is desirable to make a hole and connect a drainage pipe. This is necessary to remove the accumulated condensate from the caisson;

- further, a layer of heat insulator is laid around the container. To do this, you need to use a material that is not susceptible to the harmful effects of moisture;

- installs an inspection hatch in the upper part of the tank and you can fill up the pit.

The caisson does an excellent job of protecting the well from freezing in winter. In addition, all the work can be completely done with your own hands and for little money.

Another way to insulate a well is to use a casing pipe. The principle of operation is similar to the installation of a caisson. With his own hands, he digs a pit to a depth below the level of soil freezing. Then the main pipe of the well is wrapped with a heat-insulating material that tolerates moisture well. After that, a pipe of a larger diameter is put on top of the entire structure. Such a structure also reliably protects the well in winter, and besides, it is much easier to make it than to install a caisson.

To insulate the well do-it-yourself winter you can use improvised materials. If in your area the temperature rarely drops below 15 degrees, then sawdust can be used as a heat-insulating layer. It is even easier to make insulation with your own hands using straw or dry leaves. It is enough to pour a bunch of this material around the well.Leaves and grass will rot, causing heat to develop.

How to insulate a well on the street in a private. Well insulation for the winter: practical advice for summer residents

During the construction of a private house, autonomous water supply is equipped. A well or well serves as a source for it. The system should work smoothly, but in winter, problems may arise due to freezing of hydraulic structures. They need thermal insulation. Consider how to properly organize the insulation of a well or well in order to save energy, time and money as much as possible.

What structures need insulation and why

Some wells do without additional thermal insulation; it is enough to cover them with an airtight lid. These are buildings built according to the old technology - with wooden walls and a log house. Wood holds heat very well. If the shaft is covered with an insulated wooden cover and a house is built, the problem is solved automatically. Water in such a well will not freeze even in the most severe frosts.

Things are quite different with structures made of metal and concrete. These materials are durable and cope with any mechanical stress, but do not differ in special heat-insulating properties. It is necessary to consider how to insulate a well from concrete rings. If the aquifer lies relatively deep, a decrease in temperature will not affect the operation of the water supply system, but in shallow wells, the water is covered with an ice crust.

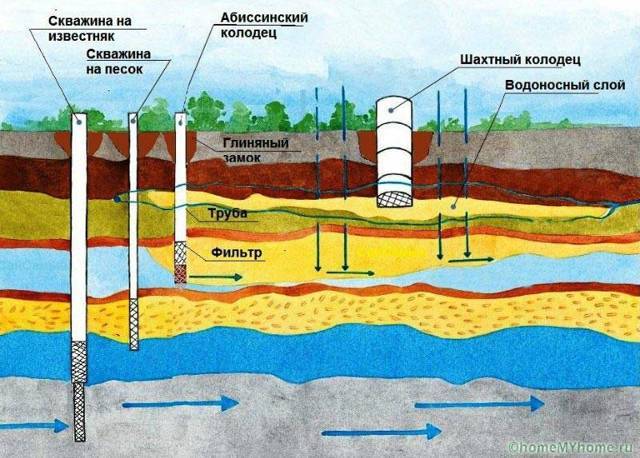

Scheme of autonomous water supply from a well

Low temperatures and fluctuations adversely affect the performance of the well: in cold weather, pumping equipment fails, casing and supply pipes freeze and perform their functions worse.To prevent interruptions in the water supply, it is necessary to select effective insulating materials and install them correctly.

Scheme: water supply of a private house from a well

How to insulate a well for the winter with your own hands

Ground parts of hydraulic structures, as well as those located at ground level, need thermal insulation.

When warming the well for the winter, special attention is paid to the upper ring and the cover. In most cases, it makes sense to build a house

It is necessary to take into account such nuances:

Top ring. This part of the structure must be insulated, because. temperature changes over time can lead to cracks. Through them, surface water enters the mine and pollutes the drinking well. Foam polystyrene, polyurethane foam, isolon, mineral wool are usually chosen as heaters.

Well cover. In addition to the top cover, they make a special cover for the well at ground level. It protects the mine from debris, atmospheric water, temperature changes, so it must be durable, without cracks and cracks. For better thermal insulation, this cover can be additionally trimmed with any available insulation. Foam is often used.

House. In regions with a harsh climate, the house must protect the entire above-ground part of the well. Ideal if it is made of wood and additionally insulated from the inside. In areas where winters are mild, you can build a light roof or do without a house at all.

We install passive winter insulation on the well

Depending on the volume of water consumed and the design of the well, you can choose the following technologies for its winter insulation with constant use.

Building a caisson for a well

The classic method of winter insulation of a permanent well is the construction of a caisson.

Finished steel caissons for well insulation

The caisson is a kind of structure around that part of the well column, which is located in the frozen soil layer. Caisson construction materials can be very different: from monolithic concrete to a finished product made of durable plastic or iron. Also, the forms of the caisson can be very different, but the most common is the barrel.

Caisson construction technology

-

Choose a suitable plastic or metal container. You can use 200 liter drums. If you do not intend to place additional hydraulic equipment in the caisson, then these dimensions will be quite enough.

- Dig a pit around the head of the well. The bottom of the pit should be below the level of soil freezing in your area by about 30-40 centimeters, based on particularly severe winters. The horizontal dimensions of the pit should exceed the dimensions of the barrel by about half a meter.

- At the bottom of the pit, pour a pillow of sand and gravel. 10 centimeters of embankment will be enough.

- Cut holes in the barrel - at the bottom under the head of the well and in the side wall under the supply pipe.

- Lower the barrel to the bottom of the pit, putting its bottom on the head of the well.

-

Mount the connection of the supply pipe of the water supply and the head of the well inside the barrel.In principle, even a surface pump or automatic water distribution equipment can be accommodated in a 200 liter drum. At the bottom of the caisson barrel, it is also possible to insert a drainage tube, which will drain the accumulated water condensate deep into the ground.

-

A layer of thermal insulation is laid around the barrel in the pit. To create it, you can use a material that is not subject to the aggressive influence of the soil, for example, expanded polystyrene. It is possible to wrap the barrel from the sides with a layer of mineral wool with a mandatory subsequent wrapping with a layer of waterproofing.

- The caisson barrel is closed with a lid with a ventilation pipe. The upper part of the barrel is also insulated with a layer of thermal insulation.

- Backfilling of the excavation is in progress. The mini-caisson is ready for winter use.

Such a caisson may well serve a small water intake well for a private house.

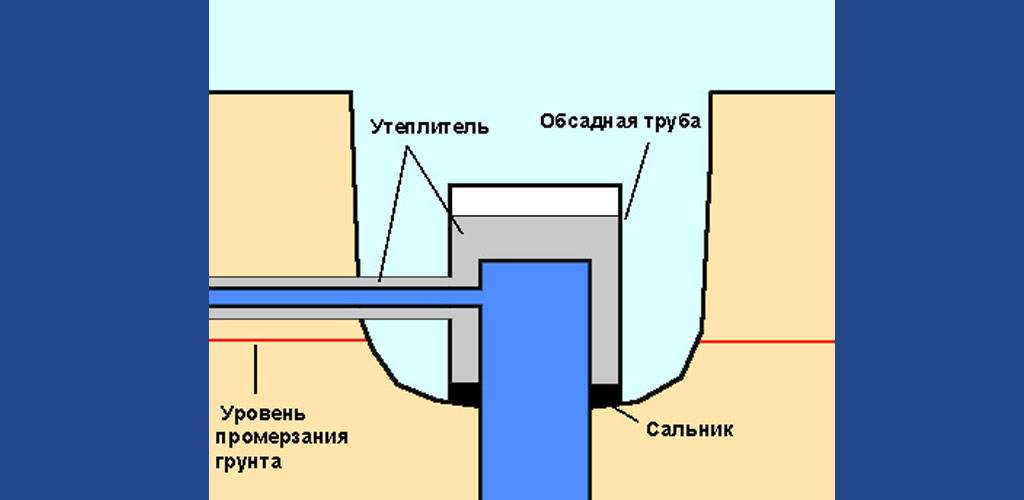

We warm the well with a casing pipe

It is also possible to insulate the well by creating an additional casing pipe. When choosing this option, you will not be able to place hydraulic equipment in the immediate vicinity of the head, but if there is, for example, a surface pump that pumps water from a well, this is not required directly in the house or in a heated room. We operate on the following technology:

- we dig a pit around the casing pipe of the well to the level of soil freezing in your area;

- we wrap the well casing with a heat-insulating material, for example, mineral wool;

- we put a larger diameter pipe on top of the resulting structure;

- we backfill the previously excavated pit.

Insulated well pipe

We warm the well with improvised materials

You can insulate a water well with any improvised materials. This method can be used in regions with a mild climate, where the temperature in winter does not fall below 15 degrees. Consider possible materials for insulation.

- Sawdust. This material can be found on almost every personal plot or borrowed from neighbors. Sawdust is suitable for various insulation works, including for the equipment of water wells.

Dig a pit around the well with a cross section of 0.5-0.6 meters just below the freezing line of the soil and fill the sawdust into the resulting cavity. In the pit, you can fill up not just a layer of sawdust, but mix it with liquid clay. When solidified, you will get both an insulating and strengthening layer at the same time. - It is even easier to insulate the space around the water well with a layer of straw and dry leaves with a similar cross-section. During the natural decomposition of this material, a certain amount of heat will be released. However, such a mixture is short-lived and after a couple of years the insulation layer around the water well will have to be renewed.

How to close the well for the winter?

This procedure depends on the type of structure. The preparation is somewhat different for a conventional well, an adapter design, and an Abyssinian needle.

Conventional Source Conservation

Before closing the well for the winter, the water supply is turned off, then it is drained from the water supply, all plumbing fixtures, including water heaters (boiler). The liquid is removed with the help of valves that are embedded in the lower sections of the water supply, at turns, rises. During this operation, do not forget to get rid of the water remaining in the shower hoses and watering cans, in the siphons of the sink, sink and bathtub.

Water is poured out of the tank. All liquid is also pumped out of the toilet siphon, then antifreeze is poured into it to get rid of the sewer smell. Just like plumbing, pumping and preparation requires a septic tank. The pumping station is transferred to a place intended for its storage. Then it is blown with air using a pump or a hand pump to completely get rid of residual moisture.

As for the submersible pump, it can not be removed. Since the unit is located at a considerable depth, freezing does not threaten it. The last stage of the operation is the discharge of water into the well. To do this, open the check valve located after the pump. There are models of borehole pumps in which this element is already built in.

Abyssinian well conservation

The water in the Abyssinian needle is also below the level of soil freezing. In this case, the main tasks are two stages - draining water from the system and organizing reliable protection of the mouth.

First, the pump is removed, then the hose is disconnected, both elements are removed in a warm and dry room. Water is drained from the pipeline, if necessary, it is blown with air. A head is screwed onto the thread, then it is waterproofed with a plastic cap or a dense plastic film.

If well with adapter

Downhole adapter is a device that ensures the tightness of the connection between the pipe and the source. This design is already more complicated, but well preparation in this case is reduced to a minimum of actions. First, the power is turned off from the installed pump. Then one of the taps in the building is opened. When the pressure in the system drops to 0.5 bar, the drain valve will open, and the liquid will begin to leave the system to the source.

In any case, it is advised to disinfect the well before wintering. For this purpose, a solution is prepared from bleach powder and water (30 g per 10 l per meter of well). This drug will disinfect the liquid, rid it of organic debris, and prevent the reproduction of pathogenic microorganisms. Before starting the operation of the source, such water is pumped out.

Casing pipe and improvised materials

The construction of the casing pipe consists of the following steps:

- Dig a pit around the head. The depth of the pit should reach the level of soil freezing.

- Wrap the well pipe with a heater, for example, mineral wool. After the material is fixed, put a larger pipe on top

- Fill in the hole.

The next method of well insulation is based on the use of materials at hand. If the house is located in a region with a warm climate, sawdust can be used for thermal insulation. Please note that the temperature must not fall below -15 °C. Sawdust is cheap, you can buy it anywhere.

What to do if there is no well on the site? It is not worth drilling it on your own - it is better to contact a specialized company.

When insulating the well with sawdust, dig a hole with a diameter of 60 cm around the well, it should be slightly deeper than the freezing of the soil. If you do not want to do this yourself, use the services of teams. Pour sawdust into the pit, it is recommended to mix them with liquid clay. The solution will not only insulate the well, but also further strengthen the structure.

Straw and leaves are another option. They are laid in a pit and covered with earth. As it decomposes, the straw will release heat. But it must be remembered that this type of insulation is not durable.After 2-3 years, it will have to be replaced with a new one.

Laying a heating cable is the most efficient option for a well heating device. You will have to buy a special heating cable, it is highly resistant to external mechanical stress. If you are just thinking of making a well, contact the services of a drilling service.

For greater efficiency, the design can be additionally equipped with an automatic system. This will reduce the cost of electricity, but the estimate will change. You will have to increase the cost of insulation.

Cable laying consists of the following steps:

- Make a ditch around the well. its depth should exceed the freezing mark of the soil.

- Take the cable and wrap it around the casing. It is necessary to wind the pipeline. which is adjacent to the well. The cable can be laid not only in coils, but also in a straight line.

- on the pipe frame. around which the heating cable is wrapped, lay insulation. Mineral wool is excellent for this purpose, with it the insulation of the well will be done with high quality.

- When choosing an insulating material, consider the maximum allowable temperature of its heating, otherwise the insulation layer will melt. Put a waterproofing material on top of the heat-insulating layer, so you protect the frame from groundwater.

- Fill in the pit.

Which of the four options to choose? The issue is quite complicated, since the choice of a specific method for heating a well in winter is determined by the following key points:

- You must decide how often you are going to use the well in winter.

- Find out how severe frosts are in your area.If you are not going to come to the dacha in winter, then preserve it before frost. Lubricate the parts of the system, wrap the head with a cloth, and then wrap it with polyethylene.

The most effective method of insulation is the installation of a caisson. Warming will require financial investments, but in this case, you can use the well even at the lowest temperatures. In addition, the construction of the box will allow you to install devices outside the building, but high-quality insulation of the caisson will be required.

But you must understand that building a reliable caisson is expensive. It is best to entrust its construction to specialists who offer well drilling services.

If you plan to use the well only occasionally, then heating cable is the best option. By turning it on, you can raise water in 10 minutes. If your area is relatively warm, then to protect against frost, you can install a 2 casing pipe by placing a heater between the parts of the structure.