- Design features of the garage that affect the process of insulation

- How to insulate the entrance wooden door in a private house with your own hands

- How to warm up a gas cylinder?

- Elimination of emergency freezing

- Floor insulation

- Do dogs' paws get cold in winter?

- How to calculate how many bottles of gas you need per month

- How to act if the rules are violated

- Mineral wool

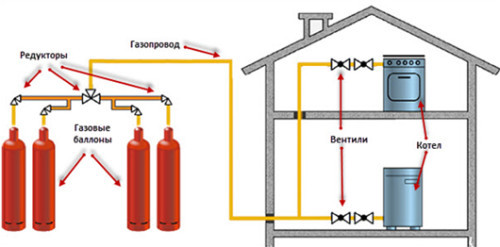

- The specifics of the arrangement of balloon heating

- Materials and methods for warming a water well for the winter

- How to insulate a well with natural materials?

- What is caisson insulation?

- How to insulate a pipe with an electronic heater?

- How to make a casing pipe with your own hands?

- What to do if the water in the well is frozen?

- Market overview of thermal insulation materials

- Mineral wool

- Styrofoam boards

- polyurethane foam

- Warm plaster

- Insulation of heating pipes in the basement

- - advice on insulating pipes in the basement

- Thermal insulation of external pipelines: choice of material

- Types of materials for thermal insulation

- Foamed polyethylene

Design features of the garage that affect the process of insulation

The main feature of the garage, which directly affects the insulation technology, is thin walls and a roof. Even garages built of brick or cinder blocks rarely have walls more than 25 cm thick.And the thickness of metal garages is measured in millimeters. Such walls are not able to provide the necessary thermal insulation and require proper insulation.

For comparison, in residential premises, the thickness of external brick walls ranges from 51 cm (two bricks) to 64 cm (two and a half bricks).

When choosing a future insulation and calculating the thickness of its layer, it is necessary to strive to ensure that the temperature inside the garage is maintained slightly above zero.

Moreover, with proper installation, the insulating layer will work for the desired result at any time of the year: in winter, it will keep heat inside the garage, and in summer it will prevent heat from outside. This is achieved due to the so-called thermal inertia, which occurs due to a decrease in the thermal conductivity of the surfaces in the direction from the outside to the inside.

You can create the desired direction of thermal inertia by insulating the garage from the inside. Then outside in relation to the external atmosphere there will be a material with a higher thermal conductivity - cinder blocks, brickwork or metal, and inside - thermal insulation with low thermal conductivity.

How to insulate the entrance wooden door in a private house with your own hands

It is very important to seal the windows for the winter, but it often happens that a large amount of heat is also lost through the doors. This is especially true when it comes to old wooden doors.

There are several ways to insulate the front door:

- using a sealant;

- providing sealing due to rollers;

- making upholstery from a sealant.

The latter option is usually used if the door leaf does not fit snugly enough to the frame, which leads to the penetration of cold air through the cracks, even if the door itself holds heat well.The rollers are used rather as an auxiliary element that allows you to increase the efficiency of the upholstery.

To insulate doors, a special sealing rubber with an adhesive strip on the base is used.

For upholstery on the outside of the door, one of the following materials is usually used:

- foam rubber;

- mineral wool;

- expanded polystyrene;

- Styrofoam;

- isolon.

Foam rubber is the most popular, as this material is inexpensive, and it is easy to work with it. But it absorbs moisture, which is a significant drawback, and also begins to crumble over time. A better, but at the same time more expensive material is isolon. Its thermal insulation performance is very good.

Mineral wool is not used too often, as it tends to go astray over time, which deprives the design of visual appeal. Well, polystyrene and expanded polystyrene not only perfectly hold the necessary shape, but also perfectly cope with the task.

Entrance doors can be insulated with foam or foam

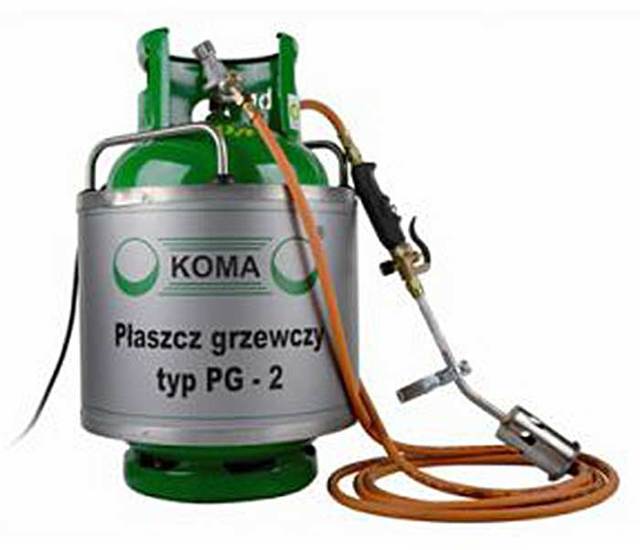

How to warm up a gas cylinder?

And now let's look at how to ensure the correct operation of gas equipment at low air temperatures, and what can be done so that the gas does not freeze. To resolve this issue, there are several options.

First of all, try to transfer the gas cylinder to a warm room, after a while the frost from the surface will gradually evaporate, and the conditions necessary for converting liquefied gas into a vapor state are formed inside the cylinder. After that, the gas supply will be restored, and the gas appliance can be used for its intended purpose.

But, if it is not possible to transfer the equipment, then it is necessary to heat the tank on site so that the gas inside does not cool. Very often, owners of gas appliances resort to heating the cylinder by direct exposure to fire. It is strictly forbidden to perform such actions, as this contributes to the rapid conversion of gas into a vapor state, respectively, the pressure in the container is growing rapidly and can cause an explosion.

To reduce the likelihood of fuel cooling, you can insulate the cylinder with special materials that prevent the penetration of cold. But this method is suitable for small temperature changes in the environment.

In order to prevent freezing of the gas cylinder, it is possible to insulate the container with a special material with a thermo-regulating base, but this does not create the effect of a thermos

In order to prevent freezing of the gas cylinder, it is possible to insulate the container with a special material with a thermo-regulating base, but this does not create the effect of a thermos

If the temperature is colder outside, then you can use special heating equipment. An electric heater is able not only to warm the gas cylinder, but also to provide a constant temperature at which the device will perform its functions with the greatest efficiency.

Thus, fuel consumption is reduced by up to 30 percent.

Elimination of emergency freezing

If it was not possible to prevent the freezing of the well, it is quite simple to solve the problem, given the small diameter of this hydraulic structure.

It is necessary to melt the ice plug in the well using the simplest device:

well freezing

- To do this, you need a steel tube with a diameter of at least 10 mm.

- Using a hose, this tube is connected to a conventional watering funnel.

- The pipe descends to the level of cork formation (usually this depth does not exceed 1 meter) and boiling water begins to flow through it to the freezing point.

- Gradually, the tube begins to sink into the layer of ice, and it will take no more than 10 minutes to completely remove the plug.

Moreover, if there is no experience in performing construction work, then it is better to entrust the installation of equipment and insulation to professionals who can choose the most effective option.

Floor insulation

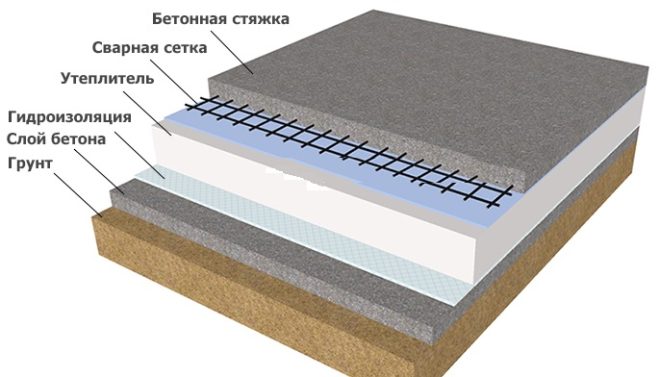

If the garage has a cellar for storing conservation, vegetables and fruits, there is no need to insulate the floor. In the absence of such an underground room, insulation is carried out without fail. The easiest way to insulate the floor is with foam boards. The whole workflow is as follows:

- vacuum the base, clean it from dirt;

- we lay roofing material or plastic film on the base;

- we fix sheets of foam of maximum density (the thickness of the cake is not less than 10 centimeters);

- we lay waterproofing material and reinforcing mesh;

- we install beacons and fill in the leveling screed.

Following the above recommendations, you can quickly insulate all the structural elements of the garage. At the final stage of work, surfaces are painted or finished with the selected material.

Do dogs' paws get cold in winter?

Fanatical dog breeders humanize their pets, sometimes completely forgetting about their true nature and the fact that Mother Nature took care of everything. The logic of people is that if their feet are cold, then the poor dog suffers from the same.

The blood in the limbs of a dog has a different circulation than that of a human. Therefore, they do not need shoes at all, and, according to scientists from Japan, this accessory is superfluous even for domestic “quivering” breeds. In many tetrapods, the circulatory system circulates so that heat stays in the paws rather than escaping. Cold blood from the paws simply does not have time to return to the chilled body, since the veins are close to the arteries and heat up quickly. Even at -35, paws in dogs do not freeze.

Penguins and arctic foxes have a similar system of blood circulation in the body, conceived for the same purpose. Some scientists suggest that the structure of the circulatory system is just that, because the distant ancestors of today's dogs come from cold lands.

But this does not mean at all that all dogs will not freeze in the winter on the street.

Factors Affecting Cold Tolerance in Dogs

It is natural to assume that a healthy and young individual can easily endure the winter cold, compared with an old or sick one.

Most vulnerable:

- puppies;

- dogs with arthritis

- exhausted.

Everyone knows that energy is needed to keep the body warm, and dogs, like people, get it from food. Therefore, dogs, forced for various reasons to stay in the cold for a long time, must eat intensively. A properly balanced diet, which will include high-calorie foods, will help your pet to live outdoors in winter with minimal or no health damage. If the dog is not eating well, frostbite will overtake quickly enough.

If the weather conditions are very severe, provide the animal with a sheltered place. It is not at all necessary to be overly insulated, even a simple kennel will help to escape from rain, snowfall or strong wind.The less space in the place where the dog can hide, the faster it will warm up.

How to calculate how many bottles of gas you need per month

On average, a cylinder is enough for 3-4 days of work, subject to heating of 100 m². It turns out that for continuous operation of the boiler during the week, it is necessary to empty two containers of 50 liters each. each. Further calculation of gas consumption for heating when using bottled gas is carried out in the following way:

- With the help of two 50l. cylinders can heat a house of 100 m² for a week.

For a month, respectively, about 10 cylinders are needed.

In order to accurately calculate heating using cylinders, it will be necessary to determine the possible heat losses, as well as the additional number of parsing points that will be used in addition to the heating boiler. The approximate consumption of liters of bottled gas per month will be about 500 liters.

The exact number of cylinders required to maintain a comfortable temperature is calculated only after the thermal engineering examination of the building.

How to act if the rules are violated

If it was found that batteries in the apartment are cold, you should find out whether this is a problem exclusively for this room or all residents of the house have encountered it. A collective appeal always attracts more attention than an individual one.

In case of unsatisfactory quality of heating, which does not comply with SNiP, a complaint can be filed:

- to a service organization: a homeowners association, a management company, a housing construction cooperative;

- resource supply company;

- emergency dispatch service;

- housing inspection. It usually has a special hotline for such requests.

Organizations will take the complaint over the phone and then register it. After that, specialists will establish and eliminate the cause of the lack of heating, fixing the violation.

Later, on the basis of the act of inspection of heating networks, a recalculation for the period of lack of heat takes place.

If the above organizations do not take any measures to restore heating, you should file a complaint with Rospotrebnadzor and the prosecutor's office.

Mineral wool

The preparation of the base for insulation is carried out similarly to the previous option, but the insulation of the walls of the garage from the inside in this case will differ in technology. First, it is worth assembling a crate made of wood or metal parts. Usually, these are all familiar profiles intended for the installation of structures from gypsum boards. The installation step of the elements almost corresponds to the width of a mineral wool roll or a rigid mat made of the same material, but slightly less. So the insulation will be securely fixed in the cells of the frame.

Next, you should take care of protecting the insulator from moisture and lay a layer of waterproofing. Rigid mats of a cotton heat insulator are laid inside the cells or parts of rolled wool cut to size are inserted. On top of the resulting design is closed with a layer of vapor barrier and decorated to your liking. It should be noted that mineral wool will completely lose its properties when it gets wet and protect it as well as possible from water ingress.

The specifics of the arrangement of balloon heating

To heat the house with bottled liquefied gas, choose the right boiler. Not every heating equipment can operate on this type of fuel. A burner must be installed in the device

Buy equipment with a capacity of 10-20 kW, pay attention to the heated area

Follow safety precautions, choose proven high-quality gas cylinders. Post them outside. In winter, when the air temperature drops, the vessel may freeze, which will lead to a decrease in pressure in it, the gas will not evaporate. The supply to the boiler is stopped. Therefore, the gas cabinet where the equipment is located must be insulated and installed on the north side of the house. The gas cabinet should be as dark as possible.

To insulate the gas cabinet, run a special sleeve from the boiler room, through which heated air is supplied with the help of fans. Heating the gas shield with heating cables is prohibited. For gas heating, use at least four vessels.

In order for the heat to be evenly distributed throughout the building, correctly calculate the required number of radiator sections. On average, for one section of a standard aluminum radiator, it can emit from 200 watts of heat. If we take the area of \u200b\u200bthe house 100 square meters. m. and a ceiling height of 2.5 m., then a boiler with a capacity of 10 kilowatts or more is required. Therefore, 50 radiator sections will be required. An accurate calculation can be carried out taking into account heat losses through windows, walls and roofs. If in doubt about the correctness of the calculations, contact the experts.

Materials and methods for warming a water well for the winter

Work on the insulation of the well does not belong to the category of increased complexity and each homeowner can carry it out independently

It is only important to choose the right material and method of thermal insulation

The amount of insulation depends on several factors:

- the climate of the region and the depth of soil freezing;

- the level of location of ground water heating;

- the quality of the insulating material.

How to insulate a well with natural materials?

readily available and practically free material

Work order.

Dig a pit around the device and fill the resulting hole with sawdust. If you fill up not just sawdust, but mix them with liquid clay, then when the solution hardens, you will get not only a heat-insulating layer, but also a strengthening one.

It is even easier to insulate the water well with a layer of dry leaves and straw. When rotting, such material will release some heat. But such a heat insulator is very short-lived and after 2-3 years the insulation layer will have to be updated.

The whole process of well insulation for the winter is divided into several stages. First of all, the casing pipe protruding from the well is insulated. To begin with, it is recommended to wrap it with a metal or plastic mesh, leaving a small gap, which is subsequently filled with sawdust or leaves. In order to protect the structure from moisture ingress, it is necessary to lay a layer of waterproofing material (you can use ordinary roofing felt).

What is caisson insulation?

A caisson is a heat-insulating structure built around a well. The material for its construction can be reinforced concrete, wood, plastic. To insulate a well that does not involve the installation of additional hydraulic equipment, an ordinary plastic barrel of 200 liters is quite suitable.

Work order.

- A pit is dug around the head of the well, the bottom of which should be 30-40 cm below the freezing level of the soil in your area.

- At the bottom of the pit, a pillow is poured from a mixture of gravel and sand, 10 cm thick.

- Holes are cut in the barrel: in the side wall under the water pipe, at the bottom under the head of the well.

- The barrel put on the head of the well is lowered to the bottom of the pit.

- Inside the tank, a connection is mounted between the head of the well and the inlet water pipe.

- In principle, automatic water distribution equipment or a surface pump can also be placed in such a barrel. Also, a drainage tube can be installed at the bottom of the caisson to drain the accumulated condensate deep into the ground.

- Work is underway to insulate the caisson. To do this, a layer of any material that is not subject to the aggressive effects of the soil, for example, foamed polystyrene, is laid around the barrel. You can also use mineral wool, on top of which a layer of waterproofing is applied.

- The container is closed with a lid equipped with a ventilation pipe. A layer of thermal insulation is also laid on top.

- The pit is filled with earth. The device is ready for use.

For the construction of a heat-insulating box, galvanized iron is also used, which is wrapped around concrete rings. Then the device is securely fixed and covered with insulation.

How to insulate a pipe with an electronic heater?

considered the most effective

The heater can also be mounted inside the casing pipe. In this case, it is necessary to select the desired power and lay the cable in accordance with the installation rules for such devices.

Installation of this design requires special knowledge and skills, so it is better to entrust this work to professionals.

How to make a casing pipe with your own hands?

Work order.

- A pit is dug around the casing pipe with a depth of at least 2 m.

- The pipe is wrapped in a heat-insulating material, such as mineral wool.

- A pipe of a larger diameter is put on top of the resulting structure.

- Backfilling of the excavation is in progress.

What to do if the water in the well is frozen?

Wrap the plinth of the structure with Styrofoam

If the winter turned out to be really very cold, but you didn’t have time to insulate your source, you will have to familiarize yourself with the features of its “defrosting”. What will be required for this?

- Assess the degree of freezing of water in the source;

- If the layer of ice is not too thick, break it with a crowbar;

- After that, remove large pieces of ice from the water;

- Cover the source with an insulated lid;

- Wrap the plinth of the structure with styrofoam.

In fact, thermal insulation of a well is a way to extend the “life” of the entire structure. When the water freezes, the walls of the source begin to quickly collapse, as a result of which it is no longer possible to operate it. To insulate the structure, you can use materials such as foam, polystyrene foam, isolon and others. They will protect the well from freezing water, and the structure itself from deformation and complete destruction.

Market overview of thermal insulation materials

Before moving on to the process of insulating a garage structure itself, let's talk about heaters. About those that are used today for this purpose. There is a fairly large layer of building materials of this type, which builders use today. There are traditional materials here, there are those that have appeared recently, but have already gained popularity.

Mineral wool

This insulation has been used in construction for a long time. At the very beginning of its appearance, it was a roll-type material.Today it is still produced in this design, but the modern form of mineral wool is slabs. They are called mineral wool boards.

Mineral wool boards - popular insulation

The only drawback of mineral wool is hygroscopicity. That is, this material absorbs moisture well, while losing its thermal characteristics. To prevent this from happening, the heat-insulating layer is covered on both sides with waterproofing films. Today, manufacturers offer moisture-resistant mineral wool boards, in which hygroscopicity is reduced to the maximum. This makes it possible to refuse waterproofing.

So, for mineral wool, this characteristic is 0.035-0.04 W / m K.

Styrofoam boards

Many people call this material foam, which is fundamentally wrong, although both materials are included in the group of foamed plastics made from polystyrene. Styrofoam is simply a material originally created for packaging. It has a low density and low thermal insulation qualities. What can not be said about polystyrene foam, which was originally developed as a heat-insulating material.

Moisture resistant polystyrene boards

This foam insulation has serious advantages:

- thermal conductivity - 0.028-0.034 W / m K;

- extruded version does not absorb moisture;

- passes air through itself;

- strength - 1 kg / cm²;

- inert to many chemicals;

- mold and fungi do not live on the surface of the insulation;

- it is a good sound insulator;

- service life - 30 years.

But polystyrene boards also have their drawbacks. And the most important of them is fire hazard.The insulation burns well and supports combustion, while emitting acrid smoke. Today, manufacturers are trying to change the situation with this indicator. Fire-resistant boards have already appeared on the market, but there are not so many of them.

Expanded polystyrene plates of the brand PSB-S-35

polyurethane foam

This is a two-component material, the ingredients of which are mixed before application. According to its physical state, it is a foamed semi-liquid mass, which hardens in air, forming a hydrophobic layer on the insulated surface. That is, not afraid of moisture.

This is a non-flammable heater. Service life - 50 years. Thermal conductivity - 0.019-0.028 W / m K. Minimum moisture absorption - 1.2%.

Layer of applied polyurethane foam

Warm plaster

This plaster mortar got its name because manufacturers add particles of heat-insulating material to its composition. These can be expanded polystyrene granules, the so-called crumb, vermiculite (foamed rock of volcanic origin), sawdust and other ingredients.

Warm plaster is applied to the wall in a thick layer

So, we examined the main heat-insulating materials that are most often used today when insulating a garage building. Of course, this is not the whole list of proposed options. They just use it more often.

| insulation | Mineral wool boards | Styrofoam boards | polyurethane foam | Warm plaster |

| Price | 13-20 rub. per 1 m² | 15-50 rub. per 1 m² | 1200-1500 rub. per 1 m² | 350-750 rub. per 1 m² |

The price fork for each material is quite wide. This is due to the fact that the basis of pricing is the thickness of the insulation, its density. The table shows that the most inexpensive option is mineral wool and polystyrene foam boards.

The most economical thermal insulation materials

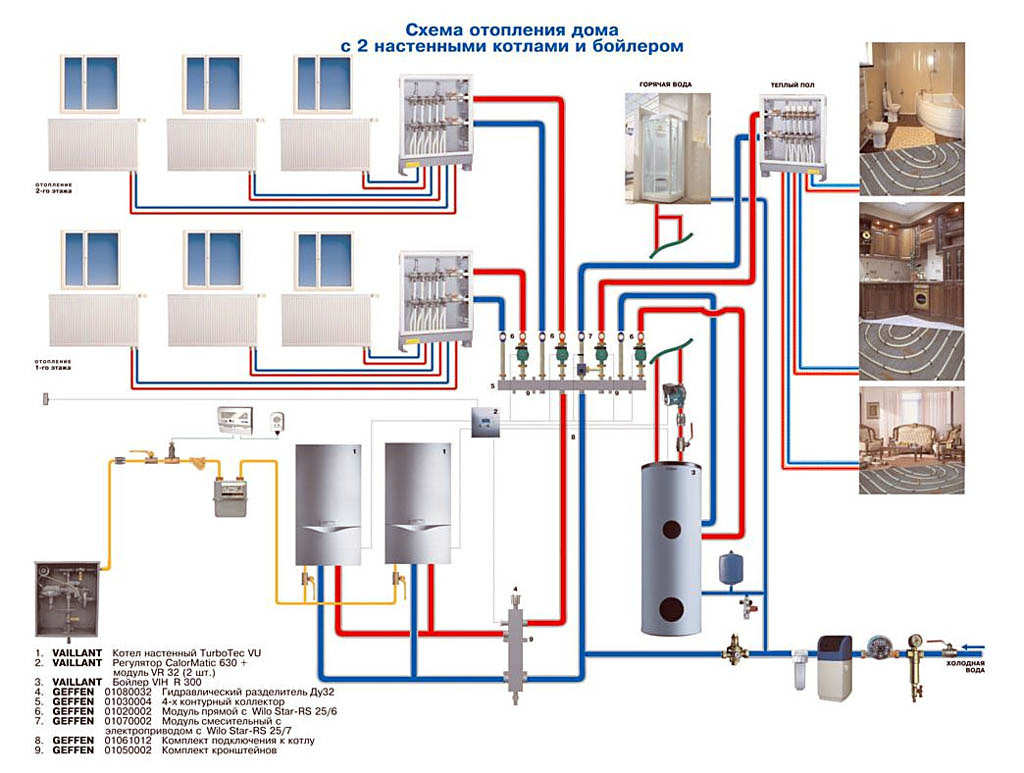

Insulation of heating pipes in the basement

The cost of heating a house increases every year. Each owner is looking for ways to save money: the boiler turns on periodically, or it constantly works only at a minimum, and so on.

The use of such methods leads to a significant decrease in the temperature in the house.

But few people think about how efficiently the residential area is heated, because most of the heat is lost on the way to it.

If heat loss can be minimized, then the rooms will warm up better and faster, so the boiler will not need to work continuously, and it will be possible to resort to savings without compromising the temperature. Since boilers are often located in basements and other utility rooms, we will consider how to insulate heating pipes in the basement and other possible places for the system to pass through.

- advice on insulating pipes in the basement

Only the purchase of materials that will pay off in the first heating season will be costly.

And changes in the quality of heating residential premises will be noticeable immediately, since the heat will not be wasted.

Thermal insulation of external pipelines: choice of material

For central and autonomous heating systems, a common problem is the decrease in the temperature of the coolant during its movement through the pipeline.

First of all, this concerns the external sections of the heating network, but also inside the building, in some areas, thermal insulation of heating pipes and hot water supply is required to avoid heat loss.

Variety of materials

Communications inside the house, as well as within your land plot, can be insulated on your own by choosing the right materials.By performing the insulation of the heating main and the DHW pipeline, you will achieve:

- reduction of heat losses in areas where the heat supply pipeline is laid on the ground or passes through unheated (including basement) premises;

- reducing the risk of corrosion from the outside of metal pipes;

- prevention of freezing of the coolant when the boiler is stopped (freezing of the system leads to its failure due to pipe breaks);

- saving money on heating the house and preparing water for hot water supply.

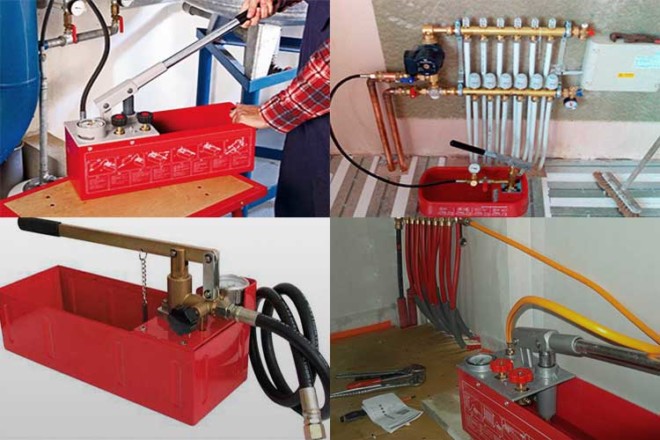

Types of materials for thermal insulation

Insulation of pipelines of heating networks increases the efficiency of the system, reduces the load on the heating boiler, and contributes to fuel savings.

For these purposes, thermal insulation is used for pipes of various types; when choosing, one should take into account the functional features of insulating materials and the principles of their installation.

The following types of thermal insulation are distinguished:

- roll;

- piece;

- casing;

- sprayed;

- combined.

Types of thermal materials

Thermal insulation materials allow you to insulate building structures, chimneys, ventilation ducts, pipelines for various purposes.

When choosing a material for insulating pipes with a heat carrier or hot water, which are laid outside the building by land or air, you should use a moisture-resistant insulation.

The universal properties of heat insulators, with which you can insulate heating pipes on the street and in the house, include:

- low thermal conductivity;

- resistance to chemically active substances;

- does not corrode;

- fire resistance;

- safety for human health;

- simple installation;

- durability.

When choosing an insulating material for pipelines, the diameter of the pipe, the location and operating conditions, and the operating temperature of the transported medium are also taken into account.

Foamed polyethylene

Thermal insulation for heating pipes made of polyethylene foam is in high demand due to its affordable cost and functionality.

The thermal conductivity coefficient of the material is about 0.035 W/m•K, while the material due to its cellular structure has a low weight and does not exert a significant load on the pipes.