- Structural elements of furnaces

- Features of brick wood stoves

- Materials for the Russian oven

- Purpose and main functions of the Russian stove

- Russian stove for space heating

- Proper kneading

- The nuances of choosing a heater

- The device of the Russian stove

- The furnace is the heart of the furnace

- Device and principle of operation of the design, diagram

- The design and principle of operation of the wood stove

- Furnaces: types of furnaces by purpose

- Pros and cons of Russian stoves

- We decorate the oven with tiles

- Principle of operation

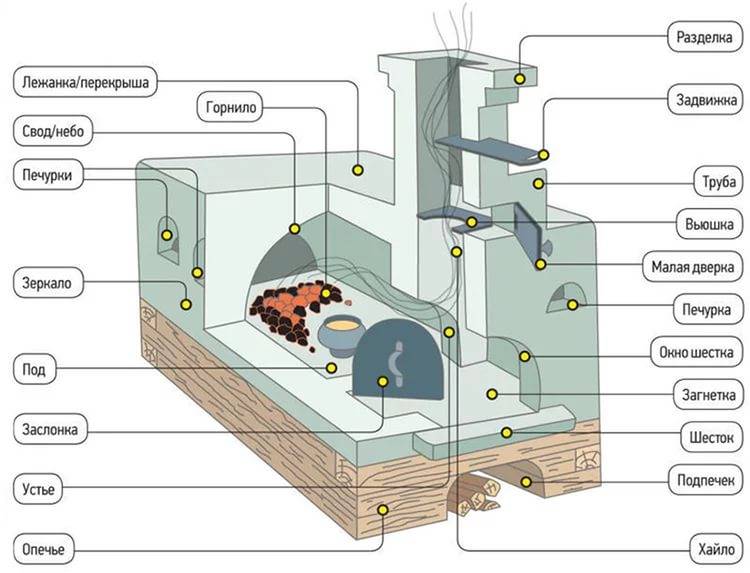

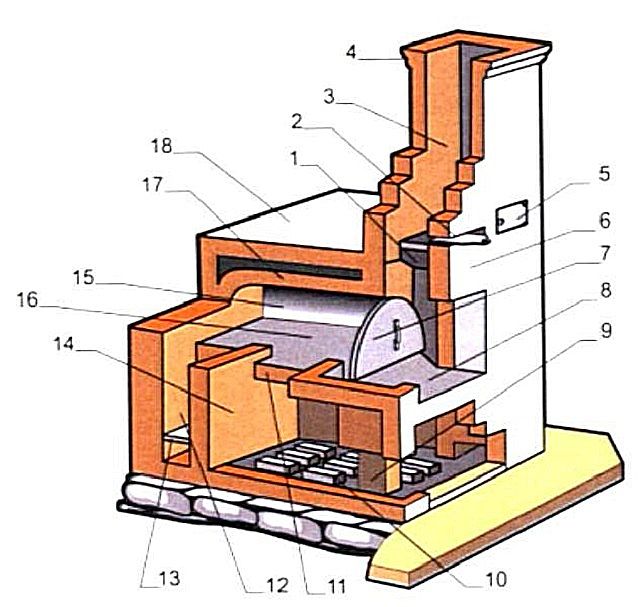

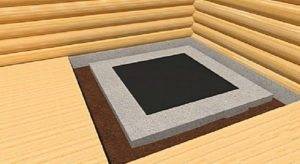

Structural elements of furnaces

| Illustrations | Description of elements |

| Foundation. This structural element takes on the load from the entire structure. That is, the foundation is the base on which the weight of the firebox, chimney and other massive and heavy parts is transferred. The foundation is laid directly on the ground and repeats the design of the foundation on which the house is built. The furnace foundation is built separately from the bearing walls, from the base of the house, etc. If the wall is located nearby, a gap of 3-5 mm is maintained during the construction of the foundation. The gap is needed so that the base under the heavy brick structure is independently movable relative to the elements in the house structure. |

| Shantsy. These are the first few rows in the design of the furnace, starting from the foundation. The use of trenches allows you to increase the heat transfer to the room. The best option is 2-3 rows of brickwork, starting from the foundation. |

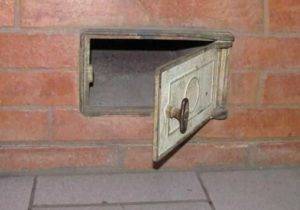

| Blower (ash chamber). This constructive element performs two functions:

In order for the blower to perform the listed tasks, a door is installed in it. By opening the door to the desired width, you can control the draft. Again, accumulated ash can be removed through this door. The instruction for using the blower is simple - after the fuel has burned out, the door must be completely closed. As a result, warm air will remain in the furnace and will not go up the chimney. |

| Firebox (firebox). A firebox is a chamber designed for burning coal, firewood or other types of solid fuels. When building a firebox, refractory fireclay bricks are used. To protect the room from sparks and hot coals, a furnace door is installed at the entrance to the furnace. The traditional Russian stove is made with an open firebox, that is, it does not have a door. At the bottom of the firebox is a grate. In the part of the furnace farthest from the door, at the top there is a hole (hailo) designed to remove smoke. So that during the operation of the furnace, ash and hot coals do not fall out through the open door of the furnace, in the lower part of the furnace, before installing the door, the level rises slightly to get a kind of step |

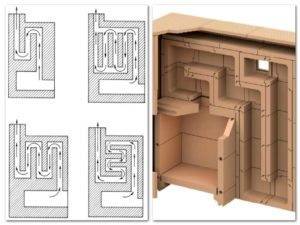

| Smoke channels (smoke rotations). These elements simultaneously remove smoke from the firebox to the chimney and take away heat. In order for the smoke to give up its heat, the smoke channels are made as long as possible.As a result, the temperature at the inlet to the channel and at the outlet can differ significantly. But the smoke circulation device is planned in such a way that these channels can be cleaned from accumulated soot from time to time. Improperly designed chimneys cause the stove to cool down quickly, as most of the heat goes up the chimney. Otherwise, the incorrect design of the smoke channels makes draft difficult, which also reduces the heating efficiency. |

| Chimney (chimney). This element is directly connected to the smoke channels and is designed to create traction.

|

Features of brick wood stoves

Heating in our homes runs on natural gas, as gasification is gradually making its way even to the most remote and deaf regions of Russia. But there are settlements in our country where there is still no gas - here people use alternative heat sources. This occurs even in gasified settlements, when people simply do not have enough money to connect to the main.

The fuel consumption of a wood burning stove is quite high. You will need to take care of its timely and voluminous replenishment.

The main alternative fuel for home heating is the most ordinary firewood. They are equipped with compact purchased stoves, home-made units of all formats and sizes, fireplaces, as well as solid fuel boilers. One truckload of firewood is enough for the whole winter, and more than enough. But some people give their preference to traditional wood-fired brick stoves - a kind of massive heating units that delight with pleasant warmth.

Wood-burning brick stoves are good because they create real comfort in households. Perhaps no other heating units are capable of this. It is not for nothing that a special spirit of comfort reigns in old Russian huts and old houses, and an impressive wood-burning stove becomes the central part of the whole dwelling. And today, some people are happy to return to heating with wood stoves.

Wood-burning brick ovens are used:

- For heating private households - this is an excellent alternative to classical heating;

- For heating temporary suburban housing - for example, you can lay out a heating brick stove for a summer residence in which there is no gas;

- For kindling baths - a stone sauna stove will become a more pleasant and cozy alternative to infrared and electric units;

- As a home decoration - lovers of antiquity will certainly like a beautifully folded Russian stove;

- For cooking - a brick oven with a wood-burning stove will allow you to try out dishes that you cannot cook in an ordinary city apartment or on a conventional gas oven.

A brick oven in the house will become a luxury item and will certainly attract the attention of guests. And on cold winter evenings, she will gather household members around her. Culinary lovers will be able to cook old Russian dishes in a massive stove using no less old cast-iron pots and soft wood-burning heat.

In other words, this is a great thing for those who understand what it is about.

Culinary lovers will be able to cook old Russian dishes in a massive stove using no less old cast-iron pots and soft wood-burning heat. In other words, this is a great thing for those who understand what its essence is.

If you build a stove in your house with your own hands, then you will have at your disposal a unique source of heat. Moreover, its heat is surprisingly soft, not like other heating units. The stove creates an incomparable comfort in the house, making you remember the good old days when it was in almost every home. Yes, it melts for a long time and requires special attention, but there is something attractive and magical in it, which modern boilers and radiators do not have.

The main features of wood-burning brick ovens:

When heated, the microporous body of the furnace emits moisture vapor into the air of the heated room, and when it cools, it absorbs them.

- They can be used not only for heating, but also for many other purposes - for example, for cooking;

- Only firewood is used as fuel - other types of fuel are not suitable;

- In order to make a stove with your own hands, you will need extreme patience - the task is quite laborious.

Making stoves with their own hands, professional stove-makers spend up to several weeks on this. But the results are worth it.

Materials for the Russian oven

Previously, the furnace was built using clay and concrete, now they use baked bricks. The roofs of houses have also changed. Straw has been replaced by safer materials. Chimneys began to be made in the form of zigzags, so that hot smoke gave off its heat to the body of the furnace, and then the cooled one went outside

When building a chimney, it is important to comply with all laws and regulations. The smoke must completely exit the chimney and not enter the room.

Otherwise, you can get carbon monoxide poisoning.

It is better to entrust the manufacture of the furnace to professionals, but with the skill of the hands, the structure can be built independently. The main condition is high-quality materials and hermetic masonry. Most often used to build:

- red oven (ceramic) brick;

- refractory fireclay - for laying out the hearth;

- heat-resistant, flexible masonry mix.

The pipe in the furnace is made of brick; asbestos pipes cannot be used. It is possible to completely construct a furnace from fireclay.

If desired, you can build a Russian stove into the desktop in the kitchen

You will also need the following items:

- cast iron hob;

- asbestos cord;

- grate made of steel or cast iron;

- blower, furnace doors;

- doors for cleaning after the firebox;

- one smoke and one ventilation damper;

- damper;

- pre-furnace sheet of roofing steel;

- you can add a hot-dip galvanized steel box to the device;

- 2 steel strips for the walls of the cooking chamber;

- corner for fastening a cast-iron plate, nuts, washers, rod, wire.

The amount of materials depends on the dimensions of the future design. The foundation of the device is made stronger than the base. You can make it out of concrete, layers from bottom to top:

- The lower level is sand (15 cm).

- Stones and bricks (20cm).

- Crushed stone (10cm).

- Concrete - 15 cm from ground level.

The service life of the Russian stove and its reliability depends on the masonry mixture. When choosing, it matters to what temperature the device heats up. You can buy a ready-made product or make a solution yourself.

Purchased mixtures for installation are divided into:

- mastic, putty, glue;

- refractory, heat-resistant, masonry mortars.

Popular representatives in stores: "Plitonit" - German quality and Russian price, "Vetonit" - a well-known French production. The lining of the structure must be carried out after a month of using the device. If white stains (efflorescence) appear on the stove, you can remove them with a damp cloth. Rags should be applied after the oven has completely cooled down.

Niches in the Russian oven help to store kitchen utensils, which will always be at hand.

Masonry mixtures are made on the basis of: cement, lime, gypsum. There are mixed solutions. How to apply mixtures:

- Foundation - lime mixture or lime-cement is used. If moisture collects in the area of \u200b\u200bthe future foundation, it is advisable to use a cement-based mixture.

- The body of the structure is a solution based on sand, clay and water.

- Chimney - lime or lime-gypsum mixture.

When burning, the main thing is to use dry firewood, otherwise the service life of the device is reduced, the amount of fuel consumed increases. You can use the stove every day, but not every hour. It is enough to warm up the device once, the heat is enough for the whole day. With frequent use, the brick heats up and may crack.

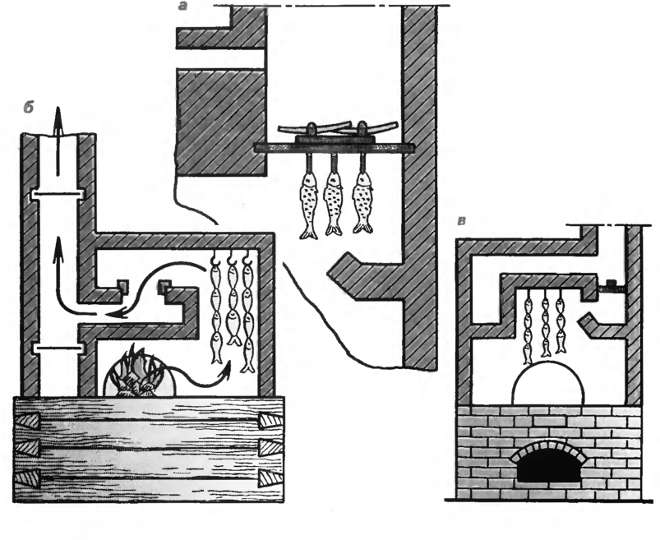

Purpose and main functions of the Russian stove

One of the advantages of Russian stoves is their versatility.

Here is a list of only the main tasks that can be solved with the help of these useful structures:

- heating the whole house or individual rooms;

- cooking on the stove and in the crucible;

- drying herbs, mushrooms, berries, fruits;

- use of a couch as a bed;

- heating water for household needs;

- drying clothes;

- warming up the samovar.

The construction of the furnace is calculated so that it heats the house.To do this, a brick structure is erected in the center of the building or positioned so that heat enters adjacent rooms. If the building is small, then there is enough heat so that the temperature in all rooms is comfortable for living.

For spacious houses, structures are built that are large or have additional heating parts - shields, boilers for heating water.

Hot water from a hot water boiler is allowed through pipes leading to heating devices - radiators. They are usually located in rooms remote from the furnace.

To save on fuel and make the house more comfortable, the owners of buildings with stove heating carefully consider thermal insulation, since a lot of heat is lost through cracks in door and window openings, cold walls and floors.

Food cooked in a Russian oven has a special taste and richness. It does not just “fit” when heated, as it would happen on a conventional stove, but languishes

Thanks to this method of cooking, soups, cereals, roasts, stews retain the beneficial properties of the products included in their composition.

The oven is also used for household purposes - for example, for drying everything that is in the house. During construction, small niches are thought out, in which hats, mittens, and pants that got wet after a winter walk were put - by morning they became dry and warm.

To dry vegetables, herbs, berries, niches were made wider so that the crop could be evenly distributed over the surface and provide good heating. Also used a stove and floor

Quite often near the stove they built tents - wooden plank sheds that continued the stove bench and performed the same functions. Since the beds were under the ceiling, they were also always warm.

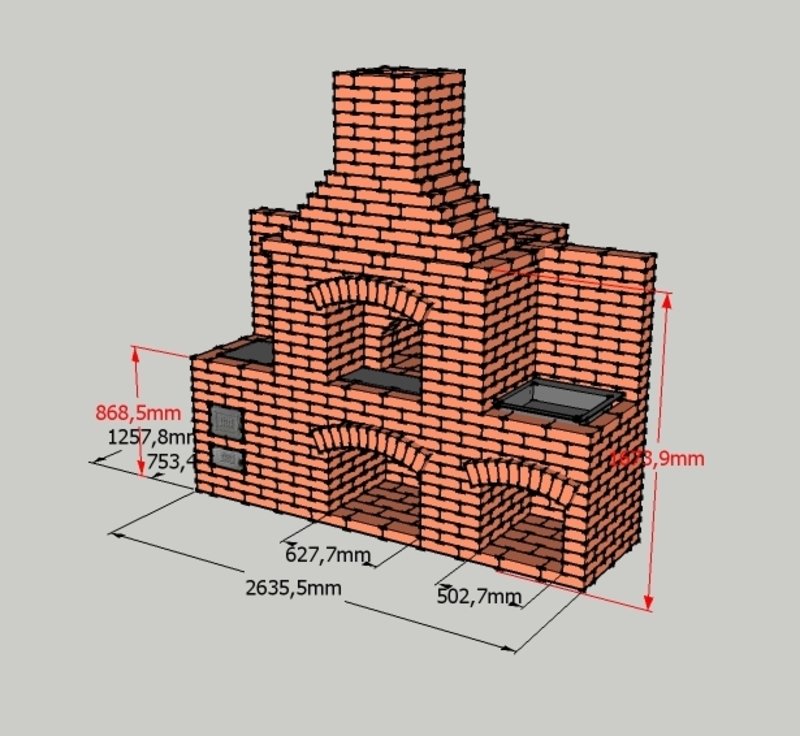

Russian stove for space heating

Familiar with fairy tales, folk art. "Little house, Russian stove."

Russian oven

Russian oven

Russian - the record holder in the number of alterations, upgrades, modifications.

"Standard" has an efficiency of 80%.

Design:

- The central part is a crucible, a cooking chamber. There is a hole - the mouth ("mouth") or forehead ("forehead"). Firewood was laid in the hole, a vessel with food was installed - a water pot, a clay pot.

- Wall ledge. Serves to separate part of the mouth, crucible, to complete the vault.

- Chimney. Through it, the gas leaving the chamber is discharged. In the cooking gas, it lingers for a short time - this allows it to cool.

Russian is arranged differently when compared with European-type stoves.

Cons of the Russian stove:

- The room heats up unevenly. The ceiling is hotter than the floor.

- The design has a high efficiency, but the heat transfer is low, 70% of the "useful" heat flies into the pipe. Modifications allow you to improve the heating capacity.

- Massiveness. The stoves occupied half the hut.

- Long warm-up time. The Dutch woman warms up quickly, the Russian stove after stagnation will take a day to return to the “working rhythm”. Designed for permanent heating.

sleeping bag

sleeping bag

The stove is universal, like a Swedish one, it runs on solid fuel. It is possible to melt with straw, dried brushwood.

Proper kneading

To lay out a Russian stove with your own hands in a hut or in a country house, you need about 3.5 m3 of the finished solution. Therefore, the necessary ingredients are taken in the ratio indicated above, and water is added to them in a ratio of 1 to 4, according to the volume of clay used.For example, 1.2 m3 of clay, 0.3 m3 of water and 2.4 m3 of sand.

As a container, you can use an iron barrel or a tin box in which the clay is pre-soaked for several days. Then sand is added and mixed with feet in high boots, until the mixture becomes homogeneous. In view of the fact that the seams of the masonry should be no more than 3 mm. (chamotte brick) and no more than 5 mm. (ordinary brick), all large parts and small stones must be removed from the finished solution.

The nuances of choosing a heater

When choosing a wood-burning stove, it is necessary to take into account working conditions, the specifics of the material, financial costs and personal preferences.

Before buying a unit, pay attention to the following points:

- Brick structures are characterized by high heat transfer, but require financial investments in construction. Cast iron warms up the room well and are installed without a foundation.

- Functional heating and cooking models are equipped with several burners and an oven.

- Pyrolysis devices provide complete combustion of fuel.

- The optimal wall thickness of the furnace with a water circuit is from 75 mm.

- A unit with automatic fuel loading is loaded with sawn timber 10-15 cm thick.

- Due to their low efficiency, cooking and heating facilities are suitable for rooms up to 25 m2.

- If you have a sauna or bath, stop at the heater.

- The safest type of firebox is closed.

- It is easier to connect an expansion tank and heat exchangers to modifications with an oven.

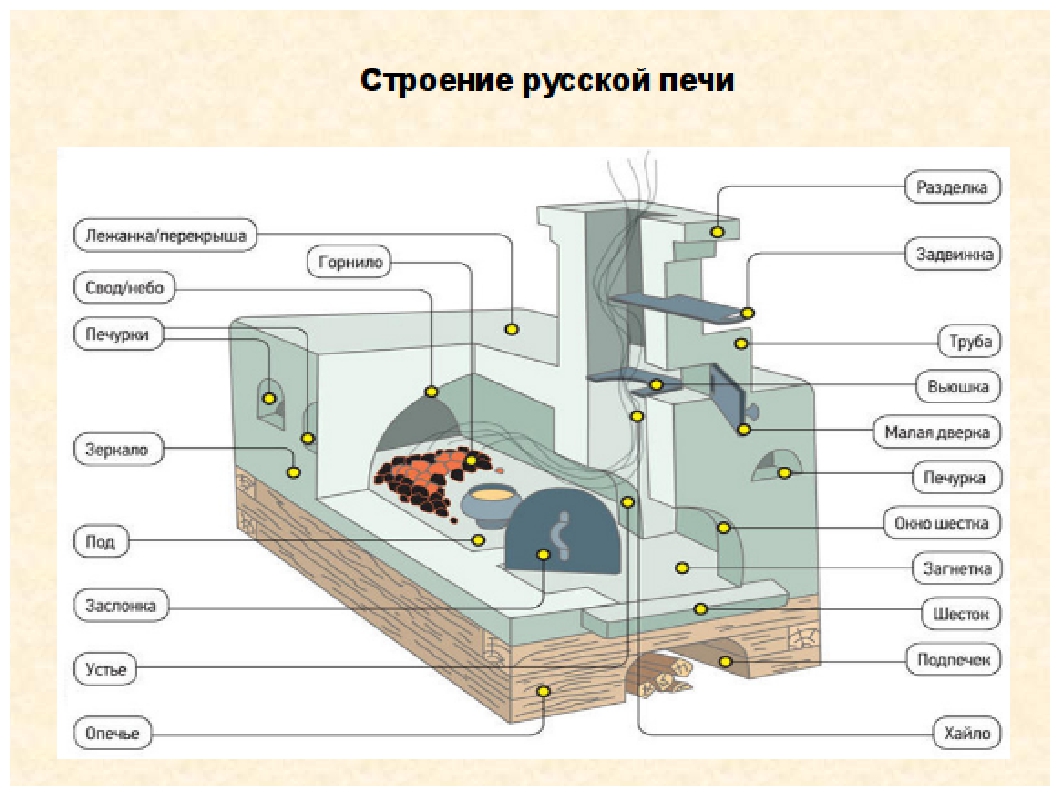

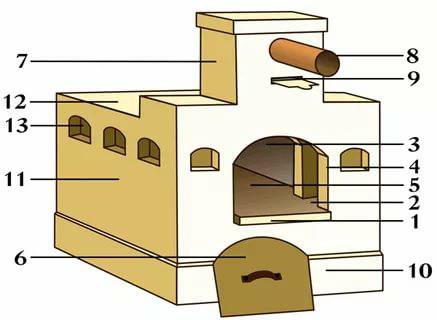

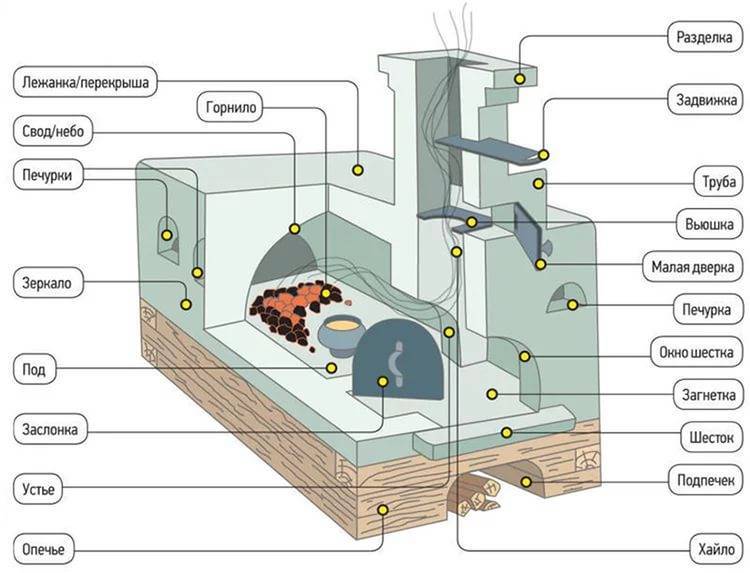

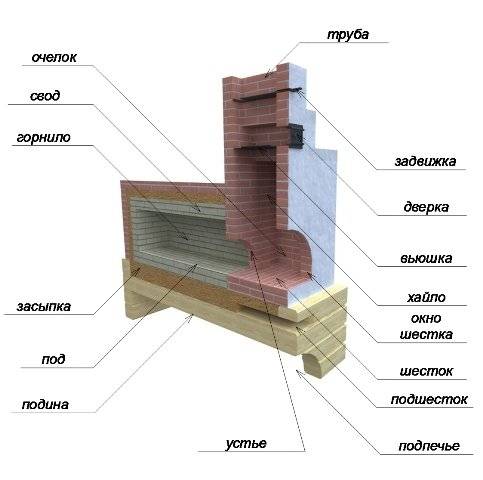

The device of the Russian stove

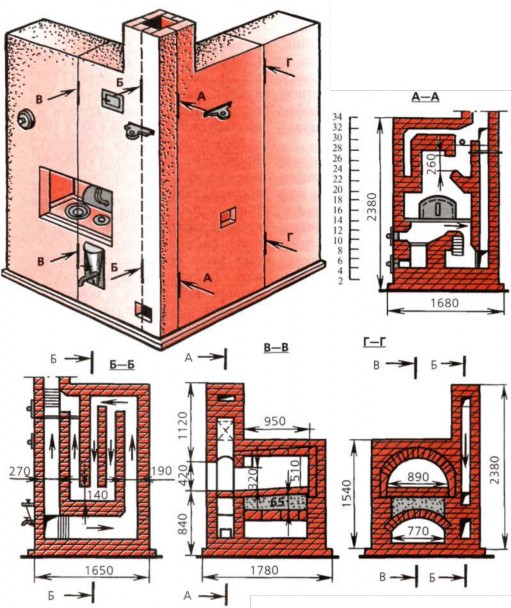

The Russian stove has a not very complicated device, but it has a lot of elements that perform different functions. The diagram below shows the components of a Russian stove:

- The overtube is the place where the flue gas is collected, and after this stage it sends them to the chimney.

- Shestok - a place located in front of the mouth of the Russian stove.

- Cutting - a place located at ceiling level, designed for fire safety.

- The damper is an iron sheet that closes the passage to the crucible.

- Epancha - a coating located on top of the furnace mouth.

- Gate valve - a metal plate that regulates draft.

- Hog - a place that leads the pipe to the end area.

- A view is a steel plate with a hole that closes with a lid and a blinker.

- A chimney is a path through which smoke can enter the street.

- The ceiling is the last brick layer.

- Bed - a place designed for sleeping and lying.

- A crucible is a place where fuel or firewood is first prepared in order to subsequently cook food.

- Vault, palate - a place located at the very top of the furnace area.

- Pechurki - recesses in the stove, helping to improve heat transfer.

- The mirror is the wall of the stove, which helps to keep the heat in the house.

- The ocholok is the outer part of the stove.

- Gornushki - a recess that preserves coals.

- Under, bream - the lowest layer of the "trough", which ensures the strength of the installation, is built from pre-hewn brick on a cylindrical surface.

- Hearth - a place located on top of the hearth area on the inside of the hearth.

- Threshold - a place that traps gases leaving the furnace.

- The cheek is the outer wall of the furnaces.

- The mouth is the place that makes up the distance between the cheeks.

- The firebox is an area where coals are collected for later use, helping to save firewood.

- Zapechek - the distance from the oven to the wall.

- Guardianship - the base of the stove.

- A stove is a recess designed for drying clothes.

- The undersheath is a place where kitchen tools are stored.

- Podpechek, podpechek - a room for storing firewood.

- Half-door - a door in order to clean up the soot at any time.

- Khailo is a well through which the gas released after the smoke exits into the pipe.

- Zev - a well located on top of the hearth.

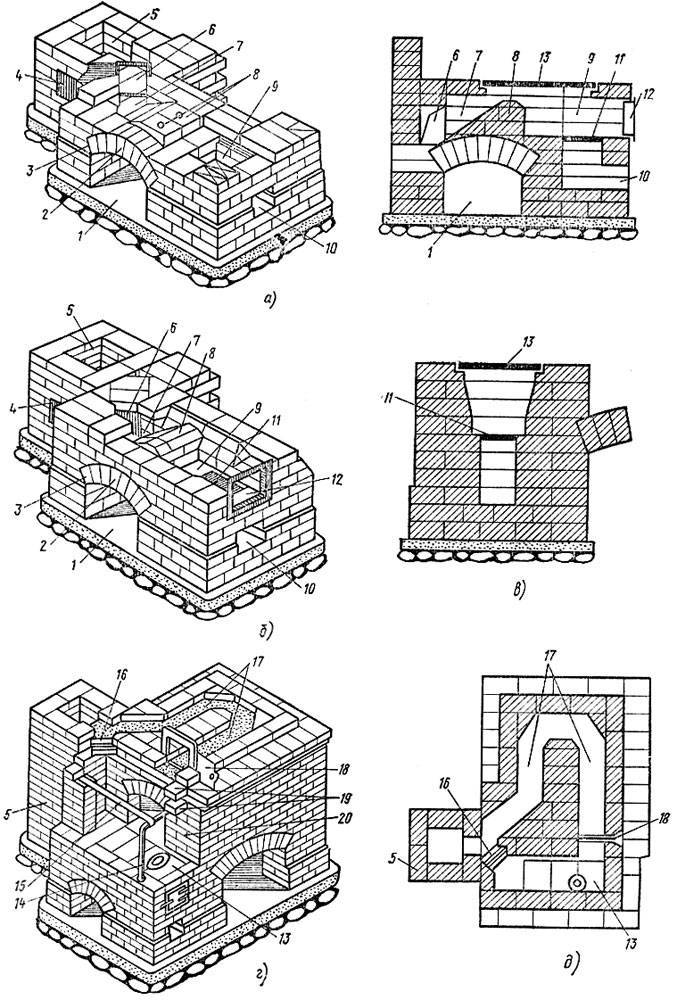

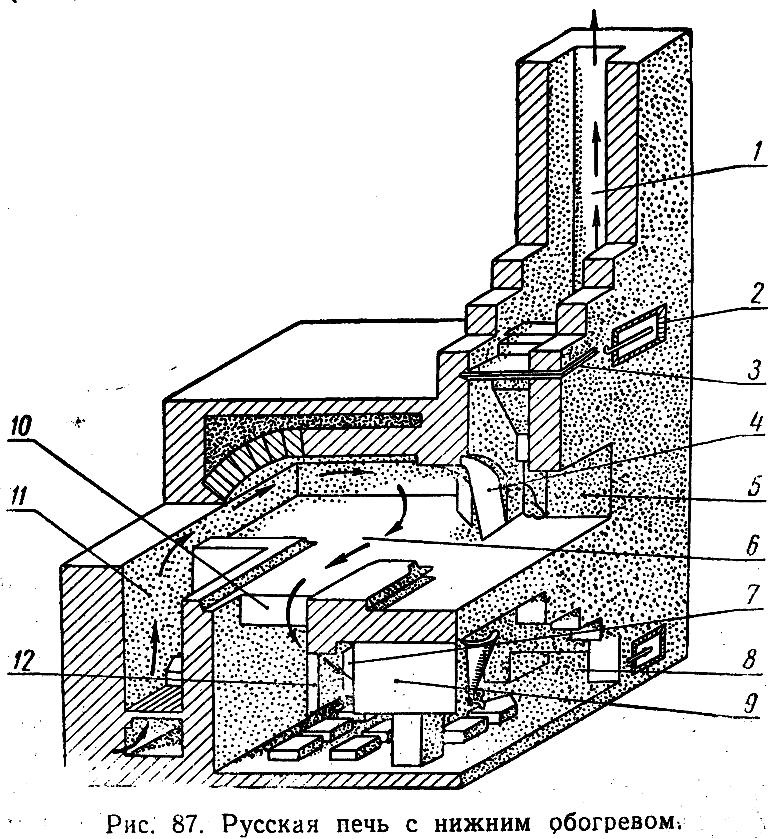

The furnace is the heart of the furnace

The firebox consists of two parts:

- firebox;

- bakery (cooking chamber).

In small stoves (124 x 178 cm), the under is laid out with a rise to the back wall of 6-9 cm evenly, and in medium (147 x 213 cm) and larger ones (160 x 231 cm) with a break in the middle or far (2 / 3) parts. This is done in order to evenly stand the dishes on the surface. At the crucible, the bottom must be with a slope. By the way, in "Domostroy" it is indicated that the height of the beds (couch) should be 142 cm.

Before you make a Russian stove, you should decide on its parameters. The dimensions may vary somewhat, depending on the size of the brick - in all dimensions (length, height, width), an even amount should be laid out, taking into account the clay mixture. Furnaces are better heated, in which the furnace from the sides also tapered 6-9 cm to the mouth.

"Aircraft" is considered to be the execution of the arch of the crucible in the form of a three-centered barrel (in the first photo, a smoothed dotted line), and not hemispherical, and the expansion of the crucible in the middle part. Then no sparks are formed, the stove does not smoke, the fuel burns out completely - 100%.

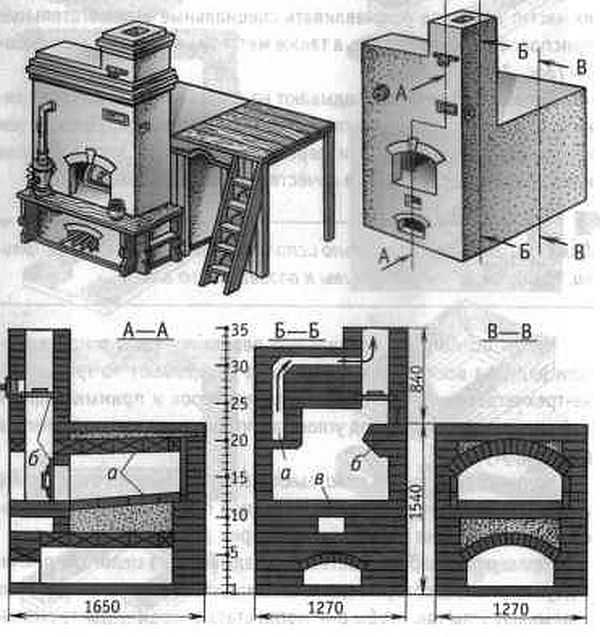

Scheme of the furnace in section on a wooden base

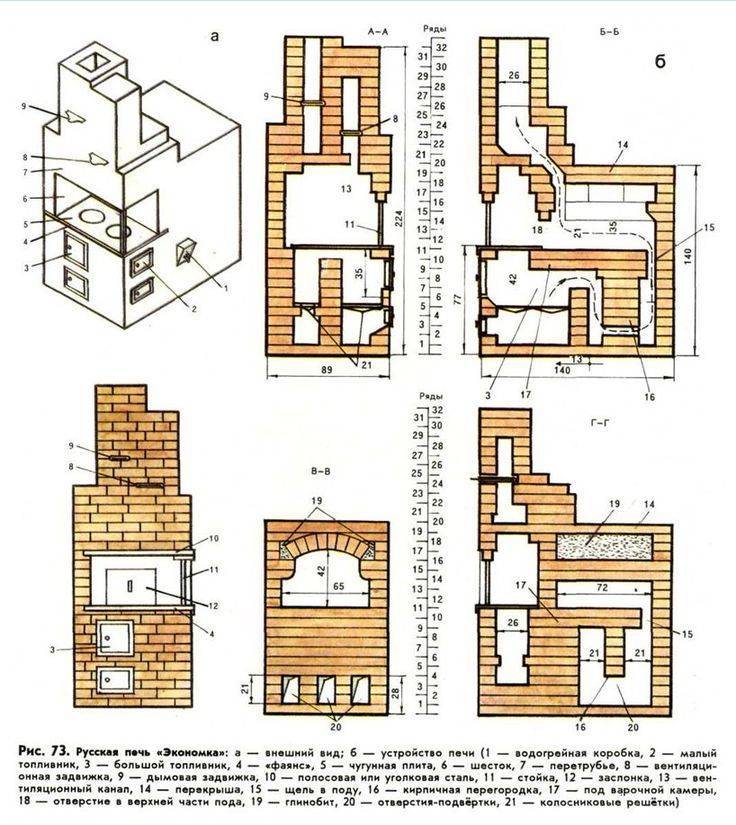

Device and principle of operation of the design, diagram

There have been a lot of modifications of the Russian stove for a long time, they differed in shape, size and device.Often in one village it was impossible to find two identical structures, each had its own unique feature. Currently, Russian stoves can be classified according to three main features:

- Sizes are small, medium and large.

- In terms of functionality - classic and improved (the stove can be equipped with a fireplace, hob, oven, bunk bed).

- The shape of the vault is domed, barrel-shaped, and three-centered.

The device of a classic Russian stove is shown schematically in the figure. Based on the purpose of the individual elements, you can understand the principle of its operation.

The diagram shows the main elements of the Russian stove

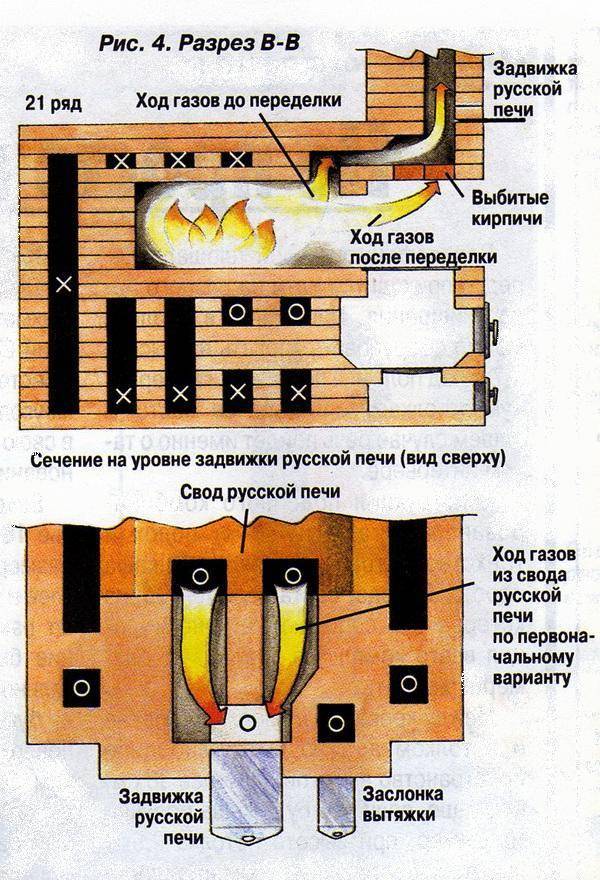

The main element of the Russian stove is the crucible, which is a firebox. The crucible consists of a vault at the top and a hearth at the bottom. Firewood is laid directly on the floor and dishes with food for cooking are placed. The opening in the crucible is called the mouth, and the opening in the front wall of the furnace is called the hearth window. These openings form a space between them, called a hearth, in which cooked hot food does not cool for a long time. First, an overtube comes out into the hearth, in which smoke is collected, above the overtube there is a hail, covered with a view. The windshield limits the ingress of cold air from the street into the oven. The valve closes the overtube, thereby regulating the draft in the chimney during the furnace, after the end of the furnace, it is completely closed so that the heat does not go into the pipe. Under the hearth is a cold stove (sub-hearth), which is used to store various kitchen utensils. And the space in the lower part of the furnace under the firebox is called the under-furnace; firewood is usually stored in it for the subsequent firebox.

The principle of operation of the stove is as follows - firewood is laid in dense horizontal rows in one or two places in the hearth. Oxygen for combustion enters through the lower part of the mouth, firewood flares up and heats the stove to high temperatures. The products of combustion first accumulate under the dome, then exit through the upper part of the mouth, first enter the hail, and then exit into the chimney.

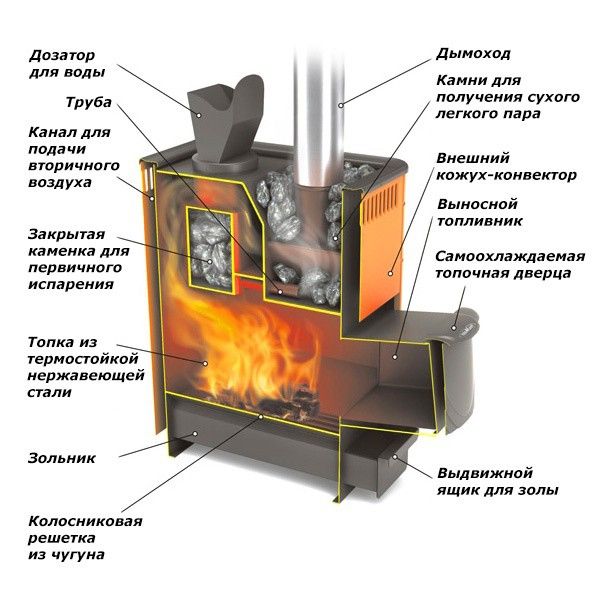

The design and principle of operation of the wood stove

Structural elements of a wood-burning stove

The modern type of wood-burning heaters consists of a chamber for laying fuel, cast-iron grates, an ash pan for collecting wood residues, a chimney for removing residual gases. Lumber is placed in the fuel compartment and ignited. The combustion reaction promotes the formation of gases with a high temperature. They, heading along the pipe, heat the walls of the device, which give off heat to the room. The heating rate depends on the body material.

To support the fire in the combustion chamber, a blower flap and a smoke damper are used. They open to a larger or smaller size. With access to excess air, the heat transfer of the structure decreases, and soot quickly appears in the chimney.

Furnaces: types of furnaces by purpose

The heat generated by these units is used either for cooking or for space heating. According to this principle, regardless of the chimney and body, there are various stoves. Types of ovens are as follows:

- Heating.

- Cooking.

- Heating and cooking.

The heating and cooking unit is a kind of universal economy stove that combines two functions. A similar design is most often found in traditional Russian variants.In addition to the hob, it has a dryer, oven and hot water box. Previously, it was equipped with a bench, located on the side of the adjacent room.

A metal stove for a summer residence can also be of a heating and cooking type. Made of modern materials, the potbelly stove with an improved design has a flat cast iron surface on its body, on which you can cook and heat food. The brewing unit, on the contrary, is a metal or brick stove with a firebox. In order to more efficiently distribute and use heat, a shield is attached to it in the form of a small wall, with which you can heat the room.

Pros and cons of Russian stoves

Pros:

- Uniform return and accumulation of heat;

- High level of efficiency;

- Safety;

- Long service life (over 30 years);

- The correct location of the stove with a stove bench allows you to save space and heat several rooms;

- Therapeutic effect;

- Good heat preservation after heating;

- Such a stove fits well into any interior.

Minuses:

- Solid fuel for the stove is the cause of garbage in the house, it takes time to harvest;

- Masonry will require professionalism and skill;

- Large consumption of firewood;

- In the classical design, only the middle and upper parts were warm, while the lower part was always cold, which required the improvement and modernization of the stove with a stove bench.

We decorate the oven with tiles

At high temperatures, tiles may burst

When choosing, you need to pay attention to heat resistance, resistance to damage. The best cladding option would be natural stone and marble, but due to their high price, materials are rarely used.

Decorating with tiles is not only beautiful, but also practical.Tiles are easy to wash and clean. The choice of tiles depends on the style of the kitchen and personal preferences. Help determine the quality of materials.

The stove with combined lining looks original: tiles and plaster with paint

Classification of tiles for the Russian stove:

- Majolica - bright, covered with painted glaze, made from baked clay. The tile is distinguished by a figured, sculptural relief. Often the elements of painting are done by hand, this factor increases the price of the material. Traditional tile colors: yellow-brown, blue-green. When lining the stove, you can combine majolica with other, more budgetary tiles. Pros: high aesthetics. Cons: fragility.

- Tiles are box-shaped (a mounting ramp), covered with transparent glaze or opaque enamel, and made of clay. Distinguish between smooth and embossed tiles. Murals can be anything: flowers, mythological drawings, ornate ornaments, figures of animals. Advantages: aesthetics, environmental friendliness, safety, high heat transfer. Cons: high price and weight.

Tiling makes the Russian stove the queen of the kitchen

- Porcelain stoneware - composition: quartz, granite dust, pieces of marble, several types of clay, mineral dyes (all this can be pressed, then fired). Tiles can be any color, with any pattern. Advantages: non-porous structure, resistance to pressure and heat. Cons: price.

- Terracotta is made from pressed and then fired clay. Appearance resembles brick, natural stone. Has a rough surface, without glaze. Advantages: fire resistance, good heat dissipation and adhesion, durability, low weight and cost. Cons: low resistance to damage.

Terracotta imitates brick, the oven approaches its original appearance

- Clinker tiles - there are several materials of manufacture, mainly shale clay and fireclay powder. Has a matte surface, not glazed. Pros: high strength, frost resistance, water resistance. Cons: not used for devices lined with oven bricks due to different coefficients of thermal expansion. Consists of a gradient of colors: yellow-brown, orange-red, white-beige.

- Fireclay tiles - made from stone flour and refractory clays. The material is made by hand. Fired at temperatures above 1300 ⁰. Advantages: resistance to temperature difference, high strength, minimum coefficient of slip. The tile does not crack and is not erased. Cons: expensive material.

A fireclay tiled stove will last for centuries

If you make a lining of tiles, then soon it will have to be replaced. Ordinary ceramic tiles are not suitable for the construction of a Russian stove. Even fire-resistant will crack from temperature changes.

Solid white tiles look good in the classic interior of a wooden house

Principle of operation

The main operation of such devices is divided into 2 stages:

- When fuel is burned, the resulting gas is collected in the main sector of the combustion chamber. A large amount of heat is released, and the smoke is gradually forced out into the cavity of the heat exchanger with convection pipes. As it cools down, it is forced out by heated air. The temperature is brought to a predetermined level.

- Cold air enters the convection pipes from below, then passing through the heated bundles of pipeline screens, it heats up to the maximum temperature and maintains the optimal and predetermined level of heating of the furnace tubular chamber. The parts undergo heat treatment in several stages and after the end of the operation of the unit they are put forward on a trolley or other type of equipment.

The temperature can gradually decrease during a break in heating, it all depends on the processing operation of the products, and when the parts cool down, they get certain properties and structure. The operation of the furnaces is monitored by automation with a system of temperature sensors.

Home-made designs will require the home master to control the processes by eye. The quality of parts after processing must comply with GOST and the main characteristics.