- Design nuances

- Location features

- Installation of natural ventilation

- Forced ventilation installation

- Installation of vacuum valves. Siphon and odors

- How to eliminate the smell of sewage, which arose for other reasons

- Materials and installation of sewer ventilation. Vacuum ventilation valves

- Chimney Ventilation

- Principle of operation

- Mounting Tips

- Ventilation with vacuum valves

- Operating principle

- Valve mounting

- How to make a valve with your own hands?

- Function test

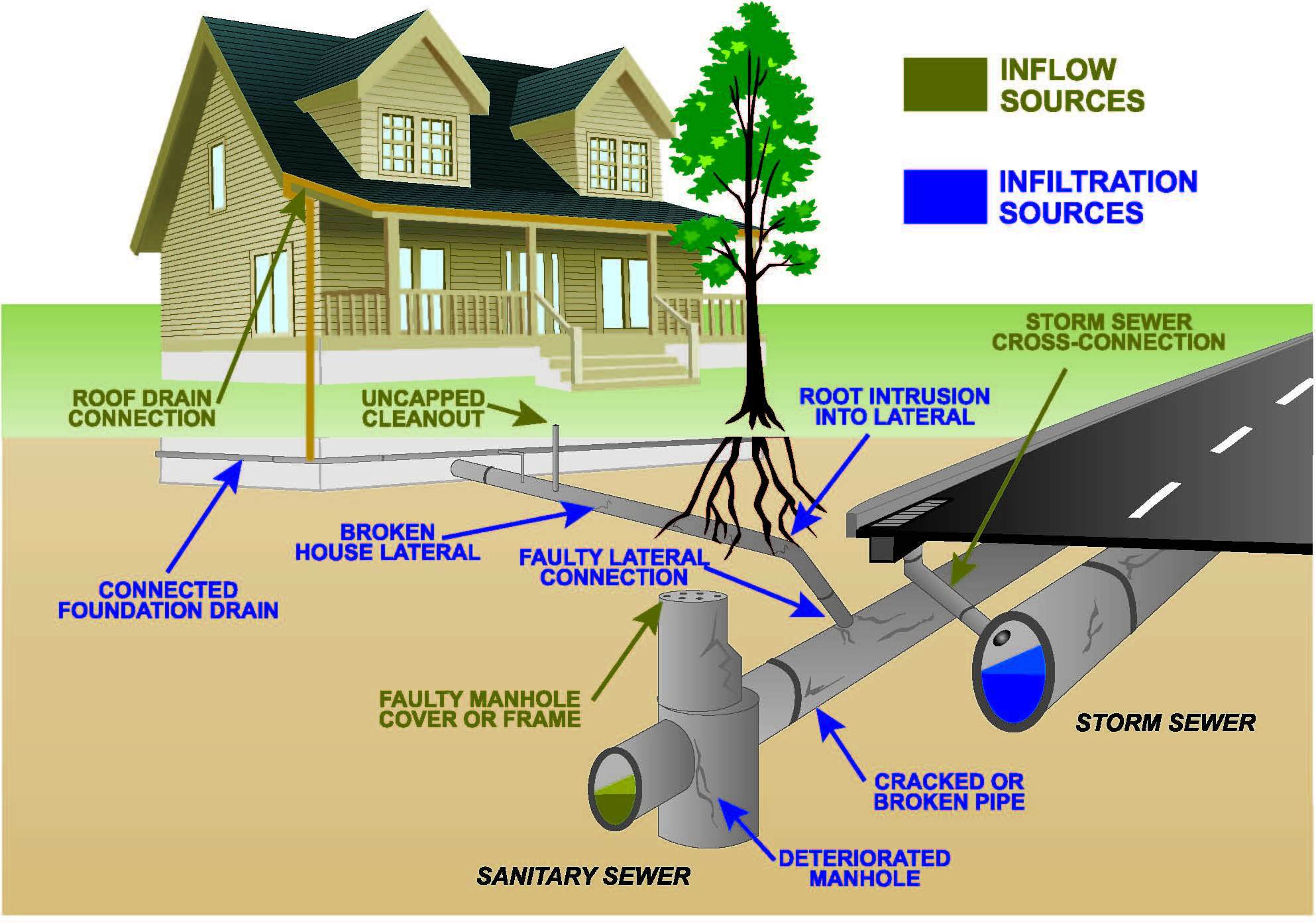

Design nuances

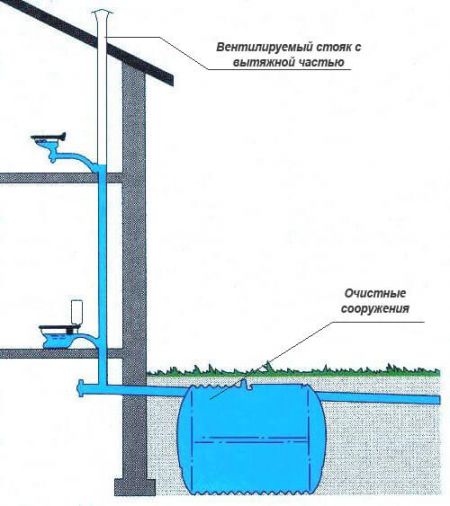

When designing sewer ventilation, special attention must be paid to the height of its outlet element. It should be located as high as possible from the ground level, and only then it will be possible to prevent water leakage from hydraulic valves, avoid the formation of air locks in the system, and also eliminate the possible spread of unpleasant odors in the interior of the house.

It should be located as high as possible from the ground level, and only then it will be possible to prevent water leakage from hydraulic valves, avoid the formation of air locks in the system, and also eliminate the possible spread of unpleasant odors in the interior of the house.

The sewerage device in a private house is best done using plastic pipes.

Video:

This is due to the fact that these pipes have a relatively low weight, their installation is simple and fast, in addition, they are equipped with all the necessary connecting elements.

Even at the design stage of the house, it is imperative to provide for a special ventilation duct in its design, through which pipes will be brought out in the sewer system.

In the event that in the sewer system of a private house, for some reason, the design did not provide for the installation of a ventilation pipe, then it can be removed along the outer wall, while covering it with a special decorative rosette.

If the construction of a house is carried out in areas with fairly severe climatic conditions, then the sewer ventilation scheme must necessarily provide for the possibility of insulating the pipe in order to avoid icing.

It often happens that it is not possible to equip high-quality ventilation of sewerage, heating, and water supply systems for some reason, in which case the installation of a special vacuum-type valve can be a way out.

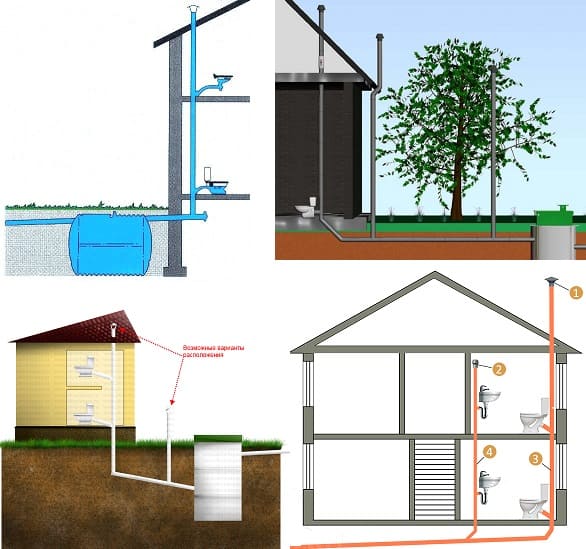

Location features

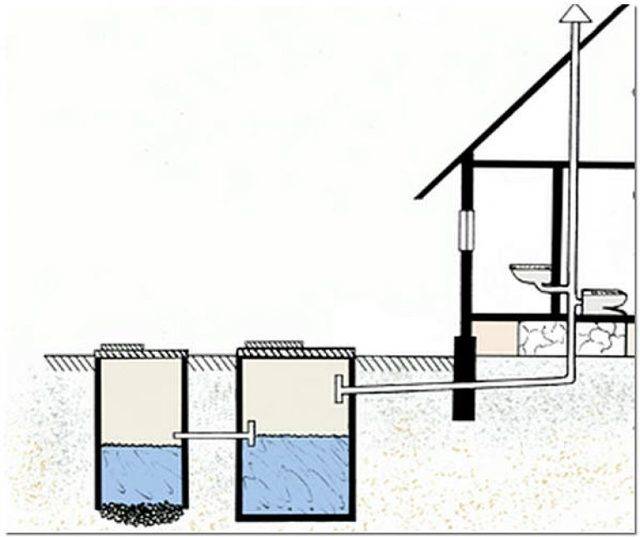

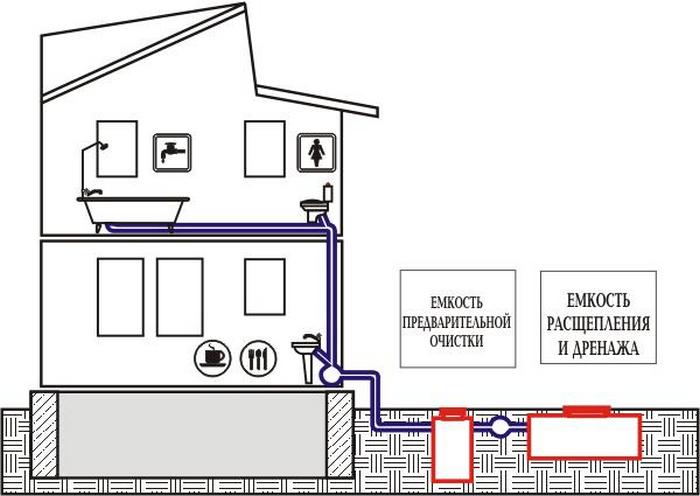

The pit should not be placed too close to the house

To prevent the unpleasant smell from disturbing the inhabitants of the house, it is necessary to pay attention to the fit of the collection hatch. Outdoor toilet must be attached without gaps

Ventilation in a pit latrine can be arranged by installing a regular PVC sewer pipe, ten centimeters in diameter. It is attached to the wall at the back.A hole is drilled on the floor for the pipe and lowered by about ten centimeters. The upper end extends beyond the roof by more than twenty centimeters. From below, the pipe must be insulated with tow moistened in advance with a bitumen primer. The exit is covered with a tin sheet, treated with foam or cemented.

When ventilation is installed in a cesspool without a toilet, installation is carried out in the same way. A pipe is inserted not far from the hatch, the length of which is calculated depending on the height of the outlet. If you attach an exhaust motor to the upper end, then the stench will not spread to the area, even in the summer heat.

By constructing a ventilation system in this way, it will be possible to avoid the accumulation of harmful gases and, as a result, the occurrence of an unpleasant odor in the toilet itself.

In addition, ventilation of the cesspool will prevent the harmful effects of fumes from feces on the wooden structure. Thanks to this, the term of the country toilet will increase markedly.

When building a pit latrine, it is best to make sure that the pit latrine is separate from the pit latrine. It is not difficult to connect them using a conventional sewer pipe with a large cross section. In this case, a branch for ventilation is connected to the pipe itself through a tee. Then excellent ventilation will be guaranteed, but on condition that a drain system is additionally provided for the toilet.

One way or another, the ventilation system here can be built in two ways:

- natural ventilation involves ventilation through increased pressure in the pit;

- with forced ventilation, air exchange will be carried out through fans that are powered by electricity.

Installation of natural ventilation

Above, we briefly mentioned the installation of natural ventilation of the toilet. Let's consider this process in more detail.

The air from the cesspool will be vented to the atmosphere through a vertical vent pipe installed on the back wall of the toilet. The outlet end at the top must extend beyond the roof.

Air will move due to the difference in pressure in the toilet and the atmosphere. Then the smell will not get into the room itself and the gases will be effectively removed to the outside.

The entrance of the sewer pipe must not be lower than the level of filling with sewage. Then it will never be closed by waste products.

To ensure sufficient air movement, the outlet section is made more than ten centimeters, and the upper end is raised more than seventy centimeters above the roof.

For a tighter fixation of the pipe to the toilet wall at the back, plastic clamps are sometimes used. Then you can be calm for her even during a strong wind.

In addition, the junction of the inlet pipe of the ventilation pipe and the cesspool must be carefully sealed.

Forced ventilation installation

The most effective method of ventilation is forced. It can only be implemented if there is electrical power on plot. But when used, you don’t have to worry: all gases from organic decay will be completely removed. The device is mounted as follows:

- Even when the toilet is being built, you need to think about the location of the ventilation system and build a window for ventilation. It will be a source of illumination on the one hand, and an opening for air flow, on the other.

- The toilet is supplied with electricity.A suspended structure for this will be the easiest way. When laying the power line, a cable is used that has special protection against external influences.

- The fan is selected. In order for the air circulation here to occur normally, a model with a power of up to 300 watts will be sufficient.

- It is best to first select a fan, and only then form the necessary hole under it. It only moves air in one direction. Usually this is air distillation to the outside.

- To prevent vacuum from forming in the toilet, holes must be provided for air to enter. Their role may well be played by a gap located between the end of the door from below and the threshold.

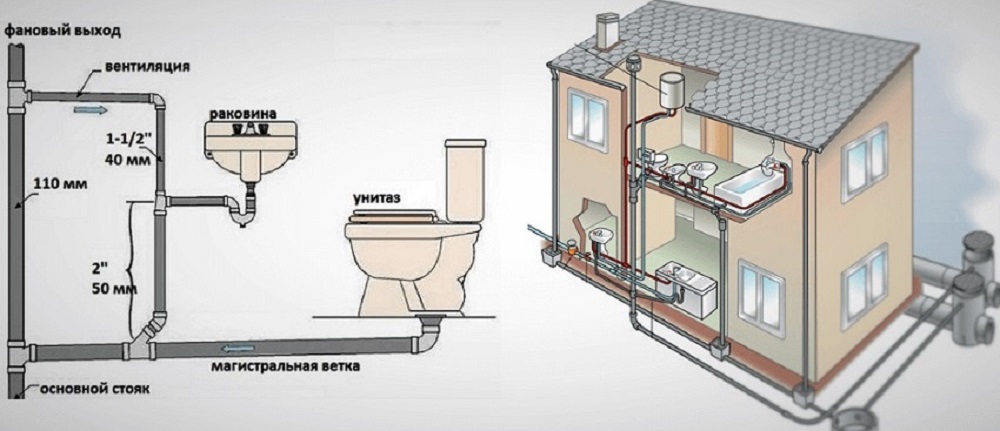

Installation of vacuum valves. Siphon and odors

Let's consider in more detail installation of vacuum valves.

Installation of vacuum valves is carried out inside the house at the end of the sewer riser.

<-

The vacuum valve installed at the top of the riser is activated when it is discharged and does not allow unpleasant odors to leave the riser. Their device and principle of operation:

- the spring works, closing the valve opening and thereby preventing the ingress of a fetid odor from the sewer riser into the house, in the future, after the pressure in the room and the sewer system is equalized.

- the valve has a spring with little resistance, as well as a rubber tight seal;

- passing air from the room into the system sewers, when discharged in the sewer from drains moving along the riser, the valve immediately works - it opens. As a result, the vacuum is extinguished;

Vacuum valves cannot, however, be a complete replacement of ventilation pipes.

Over time, they become clogged and fail. If the water has dried up in the siphons installed to the plumbing fixtures, in addition, the vacuum valves will not be able to eliminate odors sewers.

The layer of water in the water seal is a reliable barrier to the entry of sewer odors into the apartment

This is important! Even the best sewer, in its absence, cannot fully guarantee the removal of an unpleasant odor. A water seal is a mandatory attribute of all wastewater receivers mounted in the sewer system

<-

With these materials at hand, you can make a vacuum valve on your own. If it is impossible to place a check valve on the riser, it is installed on any section of the horizontal pipe leading to the sewer riser.

Now let's look in detail siphon and foreign odors

septic tank

.

<-

Is it necessary in sewers private house, certain owners doubt. When the stench spreads from the bathrooms and kitchen throughout the house, they are convinced of its necessity.

The composition of sewage is heterogeneous, as a result, fermentation processes are constantly going on in the pipes, accompanied by gas formation. To avoid the release of odors sewers from ventilation, plumbing drain holes are equipped with a siphon (water seal).

When working perfectly sewers the siphon is filled with water to a specific level. The water level drops, organic vapors spread throughout the room if the plumbing is not used for a certain time.

_

Water level — the height of the water surface in the water body above the conditional horizontal comparison plane.(GOST 26775-97)

Ventilation needed to balance the pressure in the drain system.

Disgusting smells and gurgling are also explained by the fact that when flushing feces, pressure drops in the pipes. The liquid from full siphons is drawn into the pipes and nothing prevents the stench.

There is only one way to prevent the appearance of vacuum plugs - a ventilation device for the sewer system.

How to eliminate the smell of sewage, which arose for other reasons

Even if the plumbing fixtures were installed in accordance with the rules, and the owners still noticed the stench, there is an explanation for this:

- Accumulated dirt, debris at the bottom of the siphon. To eliminate the smell of sewage, you need to substitute the container under the sink, remove the siphon and rinse it. To be sure, after cleaning, you can fill in chemicals so that the remaining parts of the dirt do not form a new plug. Before deciding to take this step, you need to understand that the aroma from the siphon will be “stunning”.

- The sewer pipe was damaged, on which cracks and chips appeared. Residents may not notice how fluid seeps through these areas. This leads to the fact that stains, mold, fungus begin to appear. From these "buddies" an unfavorable odor emanates, which can be mistaken for the smell that the sewer "publishes". Residents will think it comes from a shell. Although in fact you need to look much lower - at the siphon itself.

- The tightness of the connection between the sewer and the drain has disappeared. It will take 15 minutes to fix the problem and a new sealant. You need to remove the old one, clean the surface a little and put a new layer.

- Difficulties with the sewer riser.The plumbing may be excessively clogged or have damage that neighbors upstairs or downstairs brought to it when they repaired the toilet or kitchen. These cracks lead to airing of the system. That is, air enters the riser, which disrupts the proper functioning of the system. To solve it, you need to call a plumber who services a house or apartment, since it is difficult to solve this problem on your own.

In addition to the above reasons for the appearance of a disgusting aroma, you need to remember the simple rules of hygiene. No need to try to "wash away" the remnants of food. The sewer is not a trash can. There is a special device - silicone, plastic mesh for catching food residues, hair, wool, debris, and so on. The device costs around 100 rubles. The sink will be in order and communications will be protected from blockages.

Do not leave wet rags near the sink. It is better to leave a rag on the battery. Wait until completely dry and remove.

Finding a way to make sure that the sewer does not “fonil” can be much faster than finding the true reason for its appearance. To find and eliminate the cause of the stench, people resort to the help of plumbers who have the necessary equipment and tools to quickly and permanently eliminate the irritant.

Read:

Materials and installation of sewer ventilation. Vacuum ventilation valves

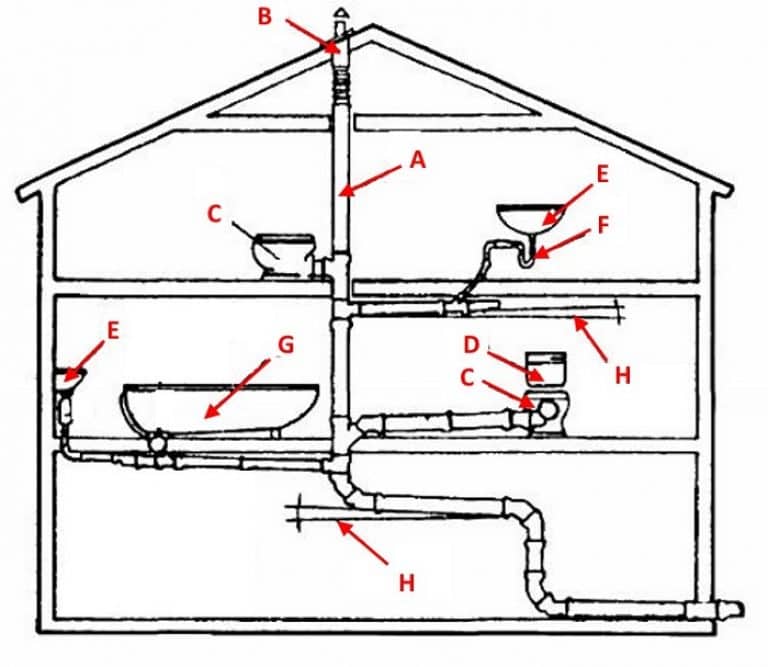

Let's move on to the section: materials and installation of sewer ventilation.

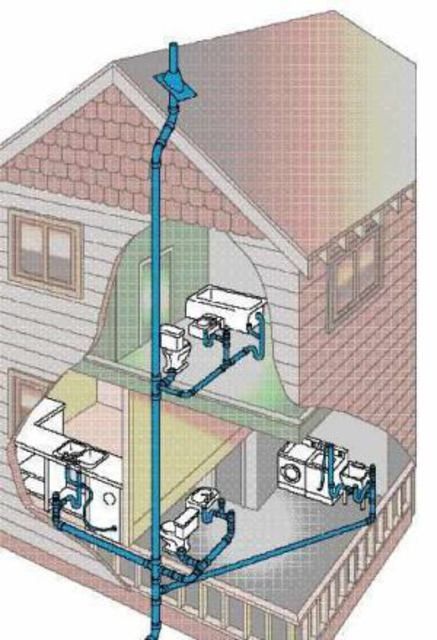

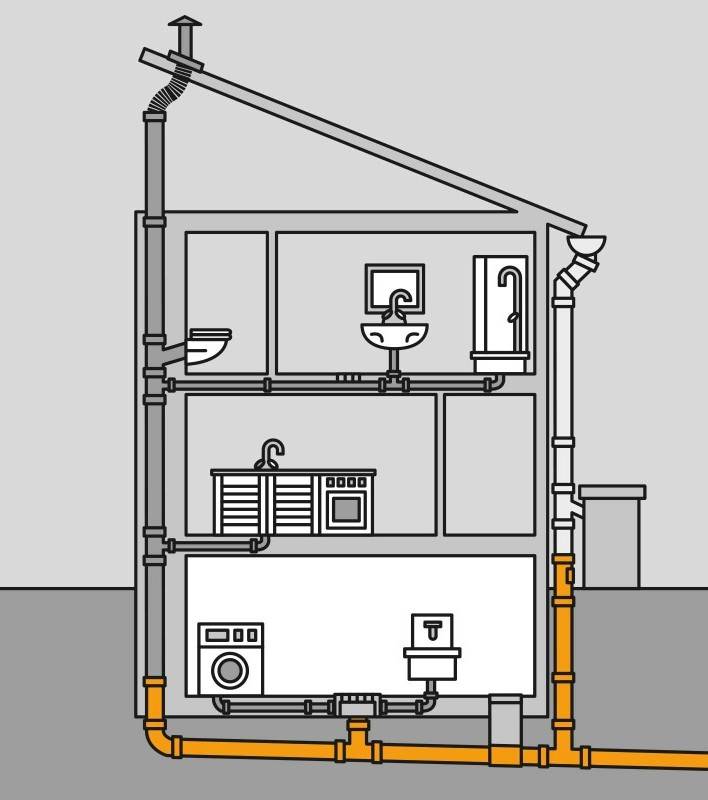

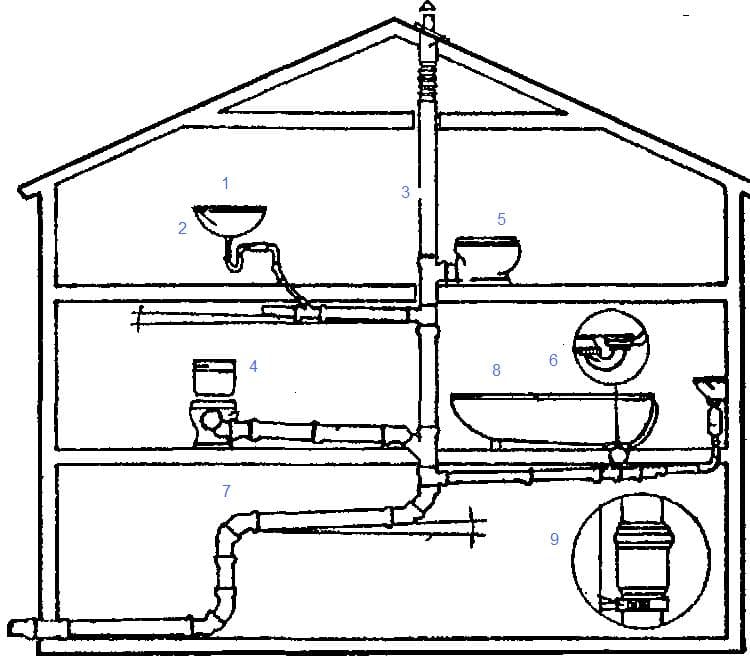

Considering the outlets, two ventilation schemes are possible sewers private house:

- Non-isolated.

- insulated or insulated;

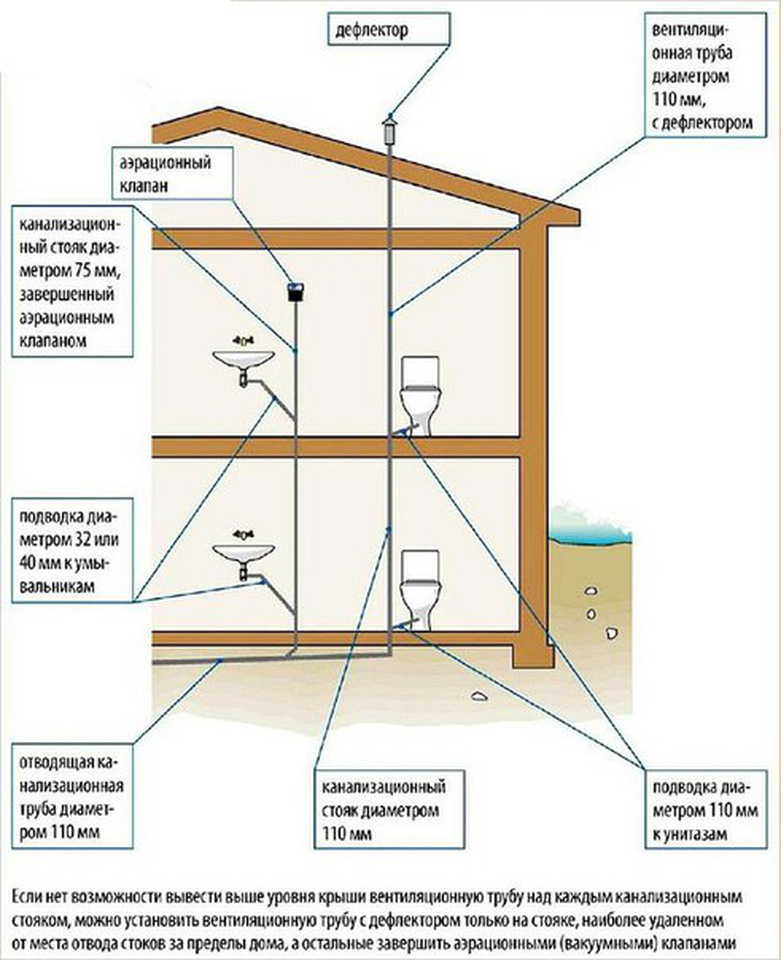

The first option is widely used in areas with a harsh climate.Hermetically interconnected, easy to mount, in private houses for ventilation sewers use PVC pipes, which are inexpensive. From 5 cm in a 1-storey house and from 11 cm in 2 or more, the diameter of the cross-section of the fan pipe should be selected greater than or equal to the cross-section of the riser.

<-

The diameter of the insulated riser at the outlet is about 16 cm. The diameter of the pipes for ventilation sewers in an apartment building and a cottage for:

- kitchen sinks, showers, bathtubs - 5 cm;

- risers 6.5 - 7.5 cm.

- connections to sinks or bidets 3 - 4.5 cm;

- toilets 11 cm;

Ventilation sewerage in apartment buildings, connecting 2 or more risers, is made of PVC pipes up to 20 cm in diameter. To connect collectors and wells, pipes of even larger sections are used.

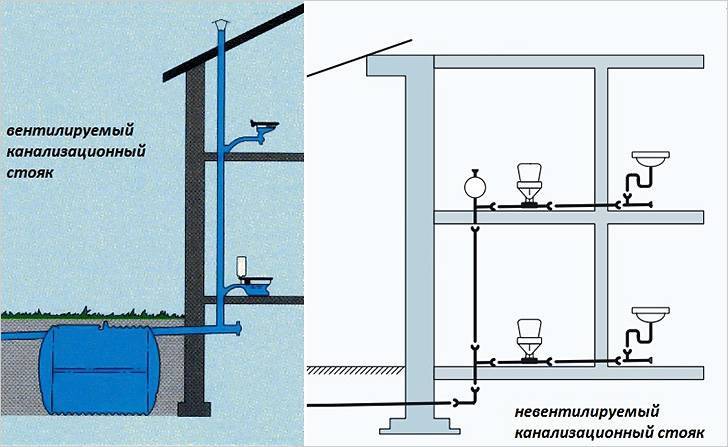

Now let's take a closer look vacuum ventilation valves.

<-

internal sewer valve

Valves are used as an alternative or addition to a fan pipe. This is the way out, if the house has already been built, but it is provided.

_

Alternative - a situation in which it is necessary to make a choice of one of two mutually exclusive possibilities (these possibilities are also often called A.). In the logic of A., a statement of the form "A" or "B" is sometimes called.

Ventilation valves should not freeze, as a rule they are installed in the attic. Air is discharged in the riser, the membrane moves back and lets air into the sewer system when the water is drained. Mechanism of operation of the ventilation valve for sewers very simple. Its clearance is hermetically covered by a membrane held by a weak spring. The valve closes automatically, the pressure in the pipe equalizes. Thus, as you can see, the valve is open only when you need to start air from the room into pipes.

Certain owners prefer to install a vacuum valve for sewer ventilation directly in the bathroom or toilet

Under these circumstances, it is important to provide access to it for control

The valve should be 30 - 35 cm above the floor. Valve for system ventilation sewers can be assembled on your own. Materials and tools:

- self-tapping screw 45 mm;

- polyethylene lid for a glass jar;

- a small sheet of thin foam rubber;

- spring from a fountain pen;

- glue;

- end tee;

- awl.

_

materials - a collective term denoting a variety of material elements of production, used mainly as objects of labor - raw materials, basic and auxiliary materials, fuel, energy, purchased products and semi-finished products, overalls, spare parts for repairs, tools and low-value and quickly wearing out items.

- We cut out a circle of a slightly larger diameter from foam rubber and glue it to a plastic mug by pulling out a self-tapping screw;

- Now we unscrew the screw and assemble the finished valve.

- We screw a self-tapping screw into the center, cut a circle with a diameter of 50 mm from the cover;

- We punch a hole with an awl and insert a self-tapping screw, in the end tee we make holes with a diameter of 5 mm at intervals of 25 mm;

If the valve is assembled correctly, the air blown into the holes will pass freely. The slot width is adjustable with a self-tapping screw.

Unfortunately, a vacuum valve can only to some extent replace a full-fledged ventilation system.

After a certain time, it can become clogged or break. And the valves are absolutely useless when the water seals dry out.

The drain pipe prevents the suction of water traps from the siphons into the pipes and is very effective in preventing odors. sewers.Characteristic for showers and drains, reduces stench even when water seals dry out.

Drain plumbing equipment must contain a water seal. Even with a competent ventilation device in a private house, some of the unpleasant odors can penetrate through drains without a water seal.

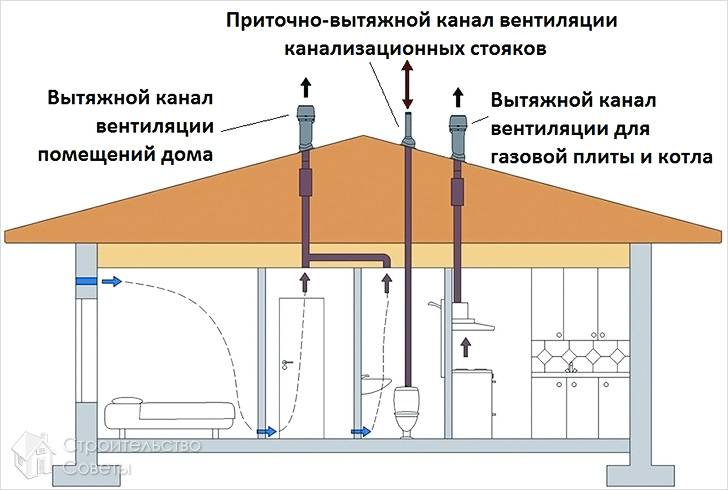

Chimney Ventilation

Fan pipe indoors with a conclusion through overlappings

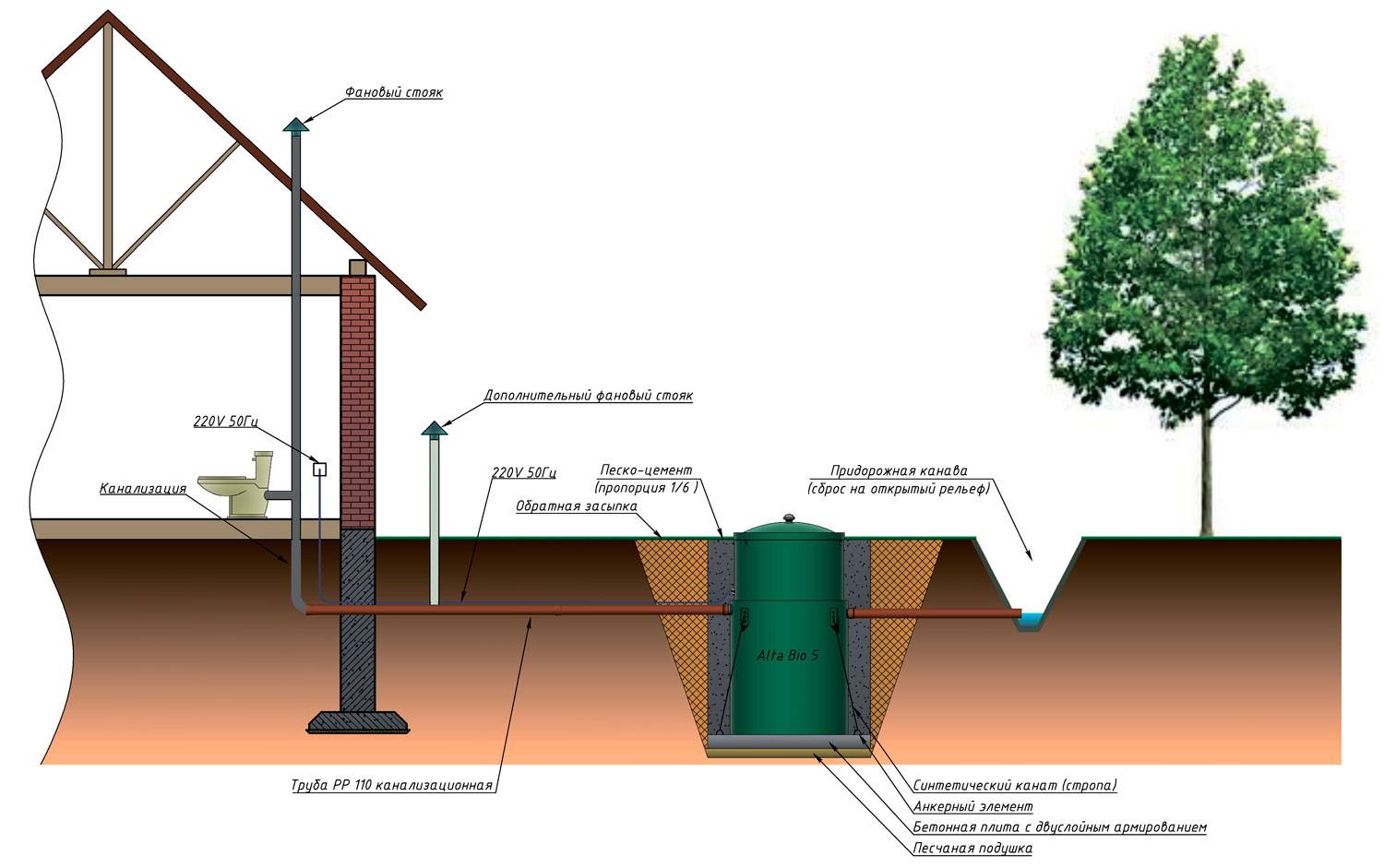

The fan pipe is used to connect the pipeline to the exhaust pipe (ventilation duct). Fan pipes are divided by shape and material. The choice of one or another product depends on the configuration of sewer communications and the place of their withdrawal from the building.

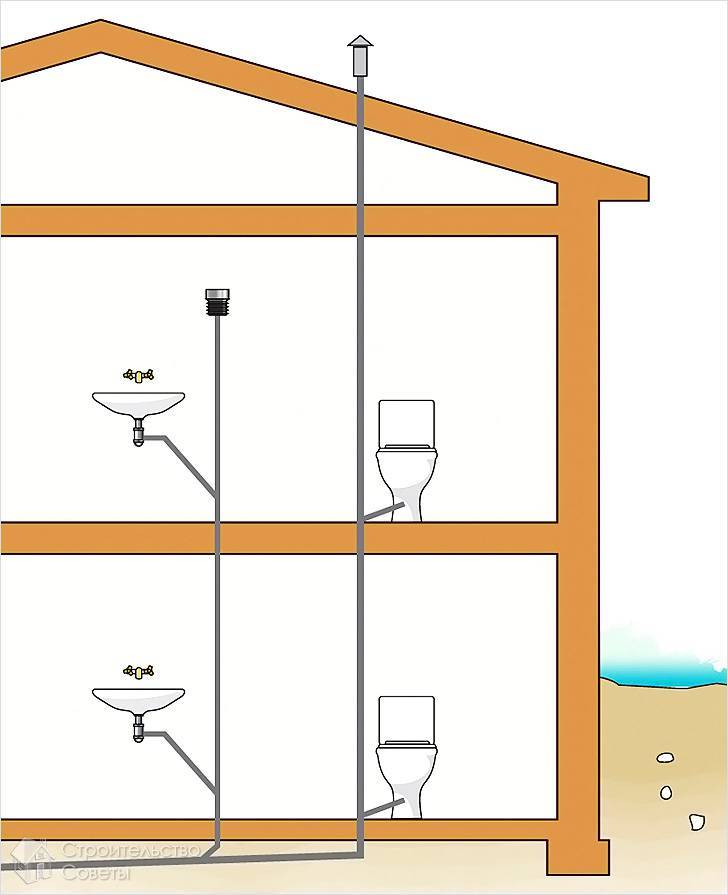

Principle of operation

If the drainage system is not equipped with a ventilation duct, then the sewage entering the sewer riser creates a "rarefaction" of the air. The lack of air is partially replaced by water in the siphons of sinks, bathtubs and other equipment.

With simultaneous draining, especially in multi-apartment and multi-storey private houses, a vacuum is created in the sewer pipe, which “breaks” the water seal. Therefore, unpleasant odors and harmful gases freely enter the room.

In sewer communications, where the installation of a fan pipe was carried out, the process is different. The air entering through the ventilation duct during the "discharge" in the riser protects the integrity of the water seal and normalizes the pressure inside the pipeline.

Mounting Tips

Accessories for assembling a ventilation pipe

When installing the exhaust pipe and sewage, it is recommended to use products from similar materials. This will allow for reliable sealing of joints due to the same fasteners and fittings. It is not recommended to use pipes made of various materials (plastic, cast iron), as the connection will not have sufficient strength.

Ideally, if design work has been carried out earlier and a place is provided for the installation of an exhaust pipe. Before starting work, it is advisable to prepare all the necessary materials and tools.

If installation work is carried out in old houses where a sewer system based on cast-iron pipes already exists, then you will need to purchase a fan pipeline from a similar material. When using plastic products, the existing system is completely dismantled and new communications are laid.

Exhaust pipe outlet through interfloor ceilings and roof

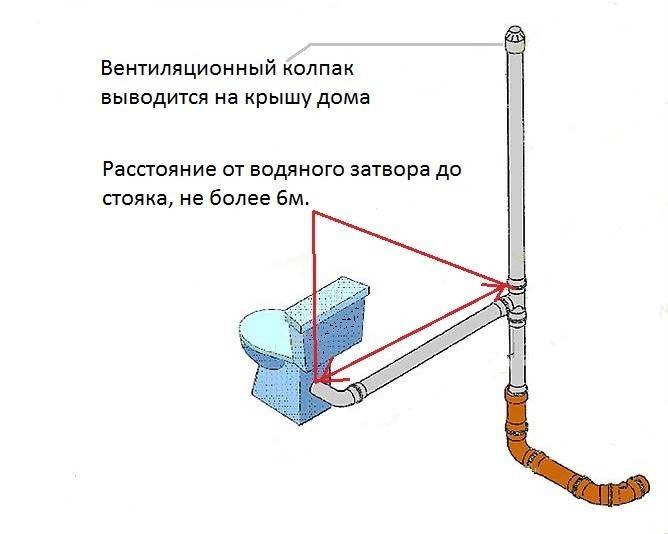

With independent installation of ventilation based on fan pipes should follow certain rules:

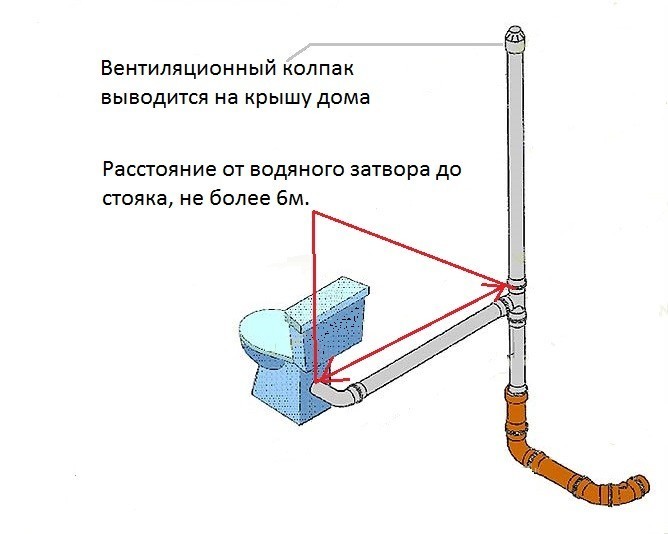

- According to the project, the end of the exhaust fan pipe is led to the roof of the house through interfloor and attic floors. The height above the roof level is at least 50 cm. When passing through the attic, the height from the ceiling to the end of the vent pipe is at least 300 cm.

- When the exhaust pipe is led through the ceiling, the interface is insulated with sound-absorbing material. If necessary, a steel box is mounted, the space inside of which is filled with heat-insulating material.

- When constructing ventilation for sewerage at an already operated facility, the outlet of the vent pipe is carried out through the bearing wall.Laying through the floors is undesirable, as this can lead to a decrease in their strength.

- The cross section of the exhaust pipe must be equal to the cross section of the riser pipe. As a rule, in multi-storey private houses, a pipe with a cross section of 110 mm is selected.

- If there are several risers, they can be connected to one exhaust pipe at the top. The connection of sewer ventilation with a stove chimney and an exhaust hood is not allowed.

- The length of the pipe from the plumbing equipment to the exhaust pipe should not exceed 6 m. The connection is made by connecting the siphon of the equipment to the socket adapter.

- For laying and exiting the pipe, special couplings and bends with the desired angle of rotation are used. The connection of various elements of the exhaust pipe is carried out using crimping metal clamps, seals and silicone-based sealant.

If during the process of output through the roof the fan pipe hits the floor beams, then a bend with the required angle of rotation (30–45) is installed for displacement. In multi-storey private houses, it is recommended to install an element with a plug (revision) on each floor. In the event of blockages, this will fix the problem quickly without dismantling the ventilation duct.

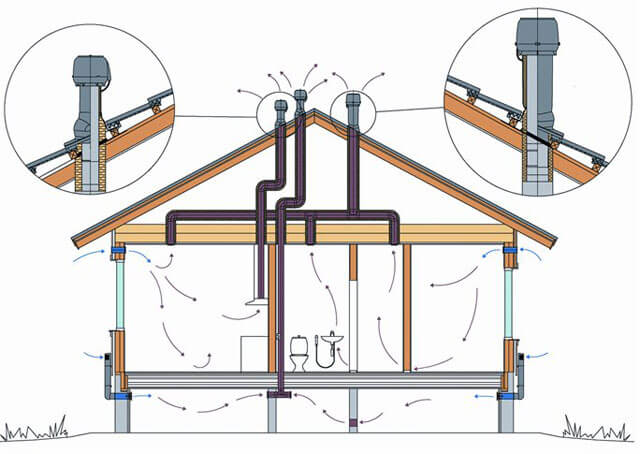

Ventilation with vacuum valves

Vacuum valve with rubber cuff for ventilation

A non-return (vacuum) valve is equipment for ventilation of the sewer system, used in cases where the installation and removal of the ventilation riser through the roof of the building is impossible for a number of reasons.

Operating principle

The principle of operation of the vacuum valve is quite simple - at the moment of "discharge" of air inside the riser, the valve valve moves away and lets air into the sewer system.Due to the influx of air, the pressure inside the pipe normalizes. After that, the valve closes, thereby blocking the flow of an untidy odor.

Valve mounting

Installing a ventilation valve at the top of the riser

The vacuum valve is mounted at the top of the sewer system. It is optimal if the distance from the riser to the valve is less than the distance from the riser to the sink, bathroom or any equipment with an installed water seal.

Usually the valve is installed near the extreme plumbing equipment. For example, on a horizontal branch in the bathroom near the toilet at a low height in the socket of the outlet or tee.

During installation, it is important to observe the following rules:

- The connection between the valve and the socket must be completely tight. When installed in a socket of a plastic pipe, the valve is mounted without additional accessories. To ensure tightness, the included seal in the form of a ring is used.

- When used with a cast iron riser, you will need to purchase a rubber cuff. Before installation, the pipe socket is thoroughly cleaned of rust and debris. Next, the pipe is dried with a building or conventional hair dryer. Then the cuff and valve are attached to the silicone sealant.

How to make a valve with your own hands?

Valve for sewerage ventilation from improvised means

The assembly of the valve can be done by hand using simple improvised means. To do this, you will need: a spring from a fountain pen, a self-tapping screw 45 mm long, foam rubber, a polyethylene cover, an end tee, universal glue, an awl.

The assembly process consists of the following steps:

- The spring is removed from the fountain pen and screwed onto a 45 mm self-tapping screw.The diameter of the self-tapping screw should fit the spring and not stretch it.

- A circle with a diameter of 50 mm is cut out of the plastic cover. Further, a self-tapping screw with a spring is screwed in the center of the workpiece so that the spring is located between the plastic washer and the screw head.

- A circle with a diameter of 60 mm is cut out of foam rubber. The blanks are glued together with universal glue. Before gluing, the self-tapping screw is unscrewed.

- Several holes are pierced in the plug of the end tee with an awl. If necessary, use a drill or screwdriver.

- Glued washers with a self-tapping screw in the center are screwed to the inside of the plug.

- The resulting design is installed in a plastic tee, which is mounted on a selected section of the pipeline at a height of 30–35 cm from the extreme plumbing equipment.

When the air is "discharged" in the riser, the pressure from the outside will act on the spring through the holes made. The spring, in turn, will move the valve, thereby passing air and normalizing the pressure inside the sewer system.

Function test

Before installing the assembled valve, it is recommended to check its operation. To do this, blow into each of the drilled holes. If everything is assembled correctly, then the air will pass unhindered. Otherwise, slightly unscrew the self-tapping screw to weaken the spring force.

After that, you will need to carry out the opposite actions - you will need to draw air into yourself. In this case, air should not enter, since the spring will firmly press the workpieces to the base of the plug.