- Blitz Tips

- Where to buy a ball valve

- Selection of gas valves

- Kinds

- Basic selection parameters

- Opening and closing valves

- Determining the position of the ball valve

- Determining the position of a plug valve

- Polypropylene heating systems

- PVC pipeline

- Production material

- Brass

- Plastic

- Gas valve installation

- Preparatory stage

- Replacement process

- Leak test

- Types of cranes

- Ball valve

- balancing valve

- Valve with thermostat

- Flush tap

- Mayevsky Air Crane

- Installation of taps on radiators

- Other types

- screw valve

- Mayevsky crane

- Flushing

- Throttle

- thermostatic head

- Which ball valve is better to choose so that it works for a long time and reliably

- The need for shutdown

- Conclusion

Blitz Tips

Before starting the heating system, it is necessary to check the serviceability and condition of the three-way valve and the entire heating system.

Do not mount the valve on pipes with diameter above 40 mm.

In a hot environment, the valve must be opened very carefully to avoid failure of the hydraulic valve.

It is important that the stem, together with the regulating device or the turning handle, go in the direction of free access to them.

It is better to buy a faucet made of brass. It will last a little longer than other materials.

The best option is a crane with pneumatic control of work.

To avoid mistakes, consult with a specialist first.

Where to buy a ball valve

If we talk about the Bugatti brand, you will definitely not find these products in the market near the house. Real ball valves from an Italian manufacturer are sold only in specialized stores.

There is nothing worse than paying a lot of money for a supposedly real Bugatti crane, bought at a local market or in a nearby shop. The chance of buying a counterfeit there is very high. After a breakdown, you are unlikely to be able to return the money back - as a rule, neither checks nor certificates are provided on the market.

We conclude: regardless of the brand chosen, it is better to buy valves in a certified store or at least in construction hypermarkets. To dispel all doubts, do not be too lazy to ask for a certificate confirming the quality of the chosen model.

Selection tips: what to look for when buying?

In addition to certificates, you can simply pick up the crane and inspect it visually. If you have a genuine Bugatti or an original ball valve from any other well-known company, it definitely should not have incomprehensible sags and bumps. The applied marking should have even letters that are easy to read and distinguish.

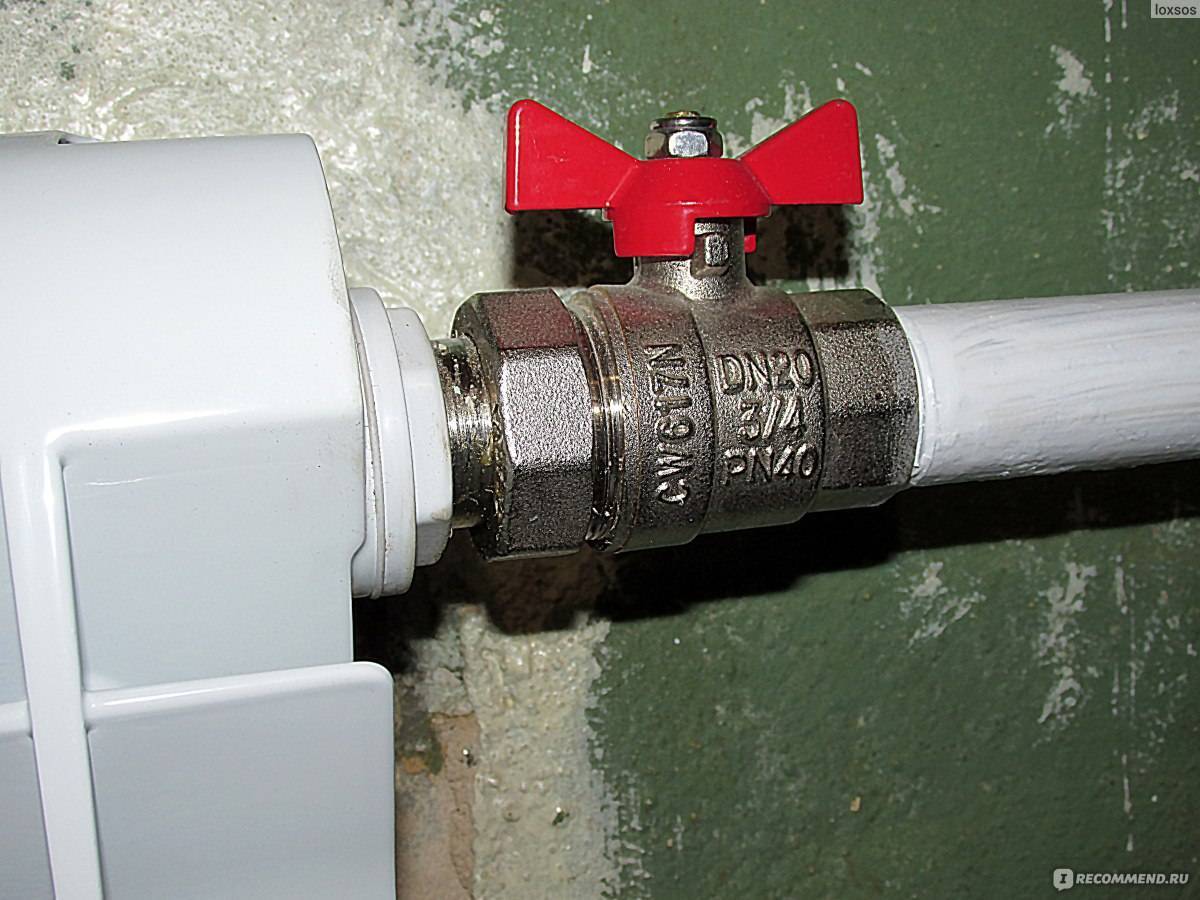

Brass marking is another point that you should pay attention to at the time of purchase. For example, Bugatti make their products from brass material marking CW617N. Be sure to look inside and find a ball there

If it is mirror-like and polished to a shine, this is a good sign of quality. Feel free to scratch the case a little - the yellow metal will indicate brass.Fakes are most often made from silumin or steel.

Be sure to look inside and find a ball there. If it is mirror-like and polished to a shine, this is a good sign of quality. Feel free to scratch the case a little - the yellow metal will indicate brass. Fakes are most often made from silumin or steel.

Finally, a few more tips:

Take Bugatti "reinforced" type cranes. They have a 6xx serial number and a PN 40 stamp. This figure indicates a valve operating pressure of 40 atm (a very good indicator).

Reliable faucets have higher cleanliness, thicker walls at the threads, and more weight.

Try to avoid buying faucets that have plastic handles. The slightest effort will break the spitz, the handle will begin to scroll. Most often, such "pseudo-faucets" are placed on a washing machine, a toilet bowl and an eyeliner to a mixer.

The crane, even when buying, should spin freely enough (with minimal effort). If you managed to scroll only with a gas key, and at the same time you also rested your feet against the wall, it is better to refuse to buy

The thing is that the ball valve is never lubricated.

Pay attention to the size of the ball itself. The size of the "hole" in it must match the size of the attached pipe.

Selection of gas valves

If a malfunction is detected in the operation of the gas valve, it is recommended to replace the device as soon as possible. First of all, you need to choose a new valve. When choosing, experts recommend considering:

- valve type;

- basic device settings.

Kinds

The gas pipe valve can be:

cork. A conical element driven by a flywheel is placed in the cork faucet body.In the conical element (plug) there is a hole, which, when aligned with the hole in the pipe, passes gas to the equipment. The stuffing box acts as a sealing material sealing the connection of the faucet with pipes;

Cross sectional valve

ball. The device of a ball-type gas valve differs from a cork one in that the locking mechanism is based on a ball made of durable metal. The ball has a hole, which, when the flywheel is turned, is located along the gas pipeline and in this way passes gas to the consumer.

Valve for gas pipeline with ball locking mechanism

Experts recommend using ball valves for a domestic gas pipeline, as they are more reliable.

According to the method of connection with pipes, a household ball valve can be:

threaded. The valve is connected to the gas pipeline pipes with a threaded connection;

Threaded valve

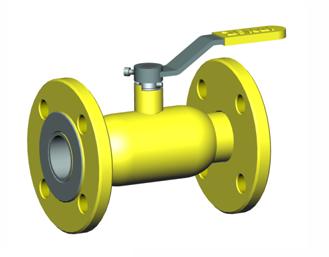

flanged. Connection with pipes is carried out using flanges, which in turn are fixed with bolts;

Gas valve fixed with flanges

welded, that is, installed using a welding machine.

Welded gas cock

Threaded and flanged valves are reusable, that is, if necessary, you can remove the device from the gas pipe, check its performance, carry out repairs and install it in its original place. The weld valve can only be installed once.

Basic selection parameters

To select a shut-off valve for gas, it is recommended to pay attention to the following factors:

- pipeline diameter. The shut-off element of the valve must completely cover the pipe in the apartment.If the valve is larger or smaller, then the tightness of the tap will not be complete;

- pitch and diameter of the thread on the pipeline. To quickly replace the device, a complete match of the specified parameters is necessary. Otherwise, you will need to purchase and install additional adapters;

- the material from which the gas pipeline valve is made. It is more expedient to purchase brass taps, as they have a longer service life. On sale you can also find silumin, zinc and plastic taps. It is possible to distinguish the material used for the manufacture of the valve by weight. Brass faucets are heavier than faucets made from other materials. In addition, you can inspect the place where the thread is cut. Brass has a yellow tint, and all other materials (except plastic) are gray;

Gas valve made of nickel-plated brass

- The valve body must be free of chips, bulges, cracks and other defects. The presence of these factors indicates non-compliance with the rules for manufacturing the product, which will lead to a reduction in service life;

- it is more expedient to purchase valves from well-known manufacturers. For example, you can choose cranes manufactured by Bugatti (Italy), Dungs (Germany), Broen Ballomax (Poland).

Compliance with simple rules when choosing a gas valve will allow you to choose a reliable device with a long service life.

Opening and closing valves

It is possible to determine whether the valve is open or closed by several signs, depending on the type of device installed.

Determining the position of the ball valve

To determine the status of a ball valve, you can use:

- control knob;

- recess located on the stem.

The ball valve can be equipped with two types of handles:

- a handle, which is an elongated element attached to the body of the device;

- a butterfly handle consisting of two similar parts arranged symmetrically with respect to the attachment point.

The valve closes if the handle is turned perpendicular to the device and the direction of the pipeline, and opens if the handle is turned in the direction of the axis of the device and, accordingly, the pipeline.

Determination of the state of the valve by the handle installed on the device

The following video will help determine the state of the valve by the handle.

If the handles are broken or completely missing for some reason, is it possible to find out the position of the valve? For device state detection under the circumstances under consideration, you can use the recess located on the stem.

Element by which the position of the valve can be determined

If the groove is parallel to the pipeline, then the valve is open and passes liquid (gas). If the recess is located perpendicular to the direction of the pipes, then the valve is closed and the movement of fluid through the system is impossible.

Determining the position of the valve by recess

For ease of use of the ball valve, special protrusions are located on the body of the device, which are designed to limit the rotation of the handle and, as a result, extend the period of use of the device.

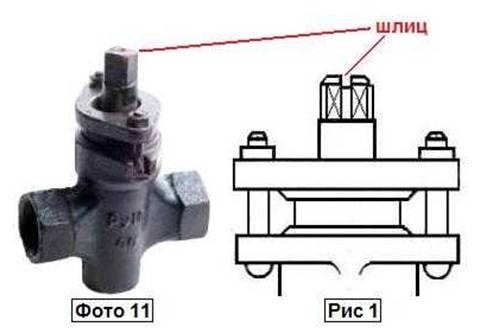

Determining the position of a plug valve

In which direction should the plug valve be unscrewed if there is no handle on the device, and how to find out the position of the valve in this case?

To determine the position of a valve that does not have a handle, you must:

- find a slot on the top of the stem (risk);

- visually check the status of the device.

Determination of the state of the plug valve in the absence of a handle

To close a valve of any type, it is necessary to turn the control handle or the mounting stem in a clockwise direction. To open the valve, the handle rotates in the opposite direction, that is, counterclockwise.

Polypropylene heating systems

Polypropylene is much more rigid and hard than polyethylene. The PP pipeline is assembled by welding and the installation of valves is no exception. A fitting of this kind has the form of a coupling; a welding machine is required for installation.

How to put a tap on a PP plastic pipe?

- Nozzles of the required diameter are fixed on the soldering device, the device is turned on and heated to the desired temperature.

- The ends of the connected fragments are cleaned.

- The coupling and the plastic pipe are inserted into the heated nozzle and wait until the sections of the product become soft. The time required for this is indicated in the instructions for the device.

- The ends are removed from the nozzle and connected to each other so that the plastic is fused into one. In no case should you unscrew and change the position of the product at this moment. The retention time depends on the material and wall thickness of the product.

- In the same way, the element is fixed on the other side.

PVC pipeline

Ball valves for PVC plastic pipes are a special type of fittings. They are connected by a threaded method. But in order to put the part, you need to glue special tips to the conduits. The latter are included with the product.

Without exception, all pipelines, whether it be plumbing or heating, are mounted with the installation of shutoff valves. A crane is required to disconnect a separate section of the pipeline from the common line.

There are many varieties of cranes, differing in their device and principle of operation. Many models are designed for specific pipes. In this article, we will look at the types of valves, learn how to connect a HDPE pipe to a faucet, and what types of faucets are used when installing a pipeline.

Production material

As for the material, you should pay attention to the two most commonly used options:

Brass

High resistance to mechanical stress

. Withstands any inaccurate treatment of himself, survives the most extreme situations.

- High resistance to temperature changes. Calmly withstands the pressure of hot water and does not deteriorate in the cold.

- Ease of installation. easy to assemble and dismantle.

- No corrosive processes. Most other metals cannot boast of this property.

Plastic

Polypropylene is a relatively new material, which, despite this, has already managed to take a strong position in the field of plumbing.

Plastic faucets boast the following advantages:

- Low cost. Plastic products are always cheap, especially when compared with metal counterparts.

- Small mass. Due to this, there is no pressure on the pipeline.

- Reliability of joints. The installation of a plastic pipeline takes place using a special soldering iron, which guarantees complete tightness. Although it should be noted that there are also classic models with threaded connections.

- Neutrality to the aquatic environment - does not rust and does not change the taste of water.

- Durability. Polypropylene decomposes no earlier than after 200 years.

But there are some difficulties that you need to be aware of when choosing valves from this material:

- Weak resistance to mechanical stress. Plastic can crack under strong physical exertion.

- Fear of high temperatures. Polypropylene begins to deform already at +95 degrees Celsius.

Therefore, depending on the conditions in which your plumbing will serve, choose which of the materials is more suitable.

Gas valve installation

Preparatory stage

To change the gas valve in the kitchen yourself, you need to prepare:

- new faucet;

- two gas keys. One wrench is required to unscrew the threads, and the second to hold the down tube stationary. Otherwise, you can damage the pipeline leading directly to the gas stove;

- means for sealing threaded connections. FUM tape, Tangit Unilok thread or regular linen thread will do. When using linen thread, additional processing of the sealing material with paint is necessary;

Special thread for sealing threaded connections

graphite grease designed for gas valves;

Special composition for gas appliances

pipe cap. If you replace the valve with two people, then you can do without the use of a plug.

Replacement process

The replacement of the gas valve is carried out according to the following scheme:

- the gas supply to the dwelling is shut off. To do this, the handle of the gas valve is turned to a position perpendicular to the pipe;

Gas valve in closed position

- the valve is unscrewed from the pipe.If the thread cannot be unscrewed, then it is recommended to treat the threaded connection with WD-40, which will ensure smooth running. If a welded valve is installed in the apartment, then it is cut off with a grinder, and threads are cut on the pipes;

- a temporary plug is installed in place of the valve. If the work of replacing the gas valve is done by two people, then instead of a plug, you can use a partner's finger. This procedure will facilitate the installation of a new crane;

- a sealing thread is wound onto the thread;

Winding linen thread to make a threaded connection tight

- a layer of graphite lubricant is applied over the thread;

Final thread preparation for valve installation

- a new faucet is installed.

When carrying out work, it is recommended to open the windows in the room and turn off all electrical appliances. These actions will lead to maximum security.

The process of self-replacing the gas valve is presented in the video.

Leak test

After installing the gas valve, it is recommended to check the tightness of the device and the resulting connections. For this:

- open the tap and start the gas supply to the stove;

- prepare a saturated soapy solution, which is applied to the faucet and joints.

Finding gas leaks with soapy water

If the device and thread pass gas, then small soap bubbles will form at the pass point. When a leak is detected problem needs to be fixed quickly.

It is risky to carry out the work of replacing the gas valve on your own

Any careless action or violation of safety rules can lead to an explosion. Therefore, it is recommended that the replacement be carried out by qualified personnel.

Types of cranes

Conventionally, reinforcement can be divided as follows:

- ball half-turn valve;

- balancing valve;

- thermostatic valve;

- flushing tap;

- Mayevsky bleed valve.

Cranes differ in price, design and application features, which determine where and for what purpose the device is installed.

There are valves with manual and automatic adjustment, here the difference is also noticeable in the price of the crane. The system with automatic temperature control works as follows: the controller receives a signal from the temperature sensor and gives a command to the servo drives, as a result of which the size of the flow hole in the tap is regulated depending on the set mode.

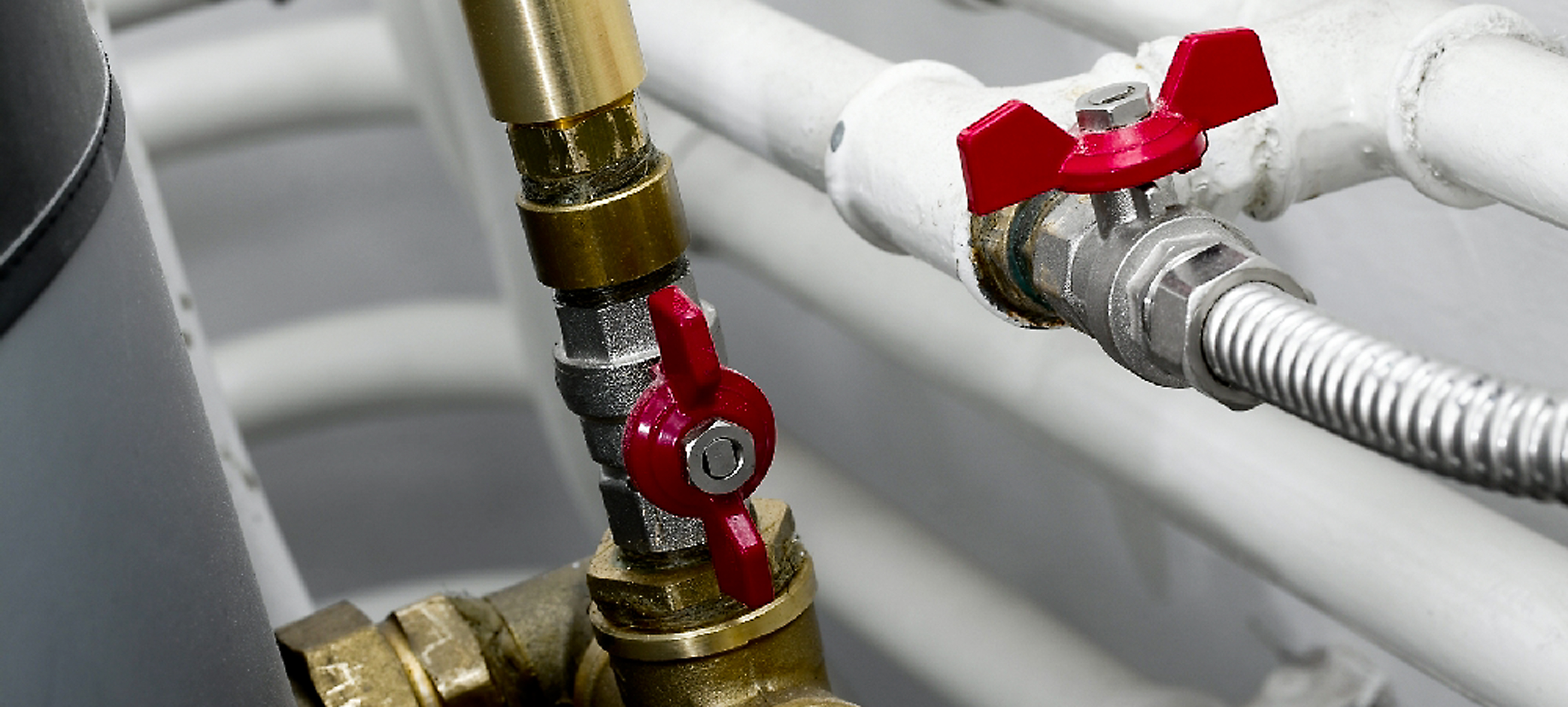

Ball valve

The name of the valve is due to the spherical shape of the valve, which has a through hole. The valve is designed for only two positions - open or closed, it is not intended for quarter-turn operation. When the valve handle is turned, the valve also rotates, and the hole in it is located either parallel or perpendicular to the pipeline.

The body of the device is made of steel, brass, bronze or silumin. Steel is the leader in strength, but it is subject to corrosion, therefore bronze and brass products are most preferable as they are more durable.

A good choice would be a brass half-turn with thick walls and an American - this is the name of the union nut, which allows you to connect pipes and a radiator without rotating them and quickly.

balancing valve

The difference between a balancing valve and a ball valve is the ability to smoothly adjust the position of the valve, by several turns of the lamb. So that the valve settings do not go astray, or someone accidentally knocks them down, it can be fixed in its current position. It is placed on the outlet pipe of the battery, and makes it possible to smoothly regulate the flow of coolant.

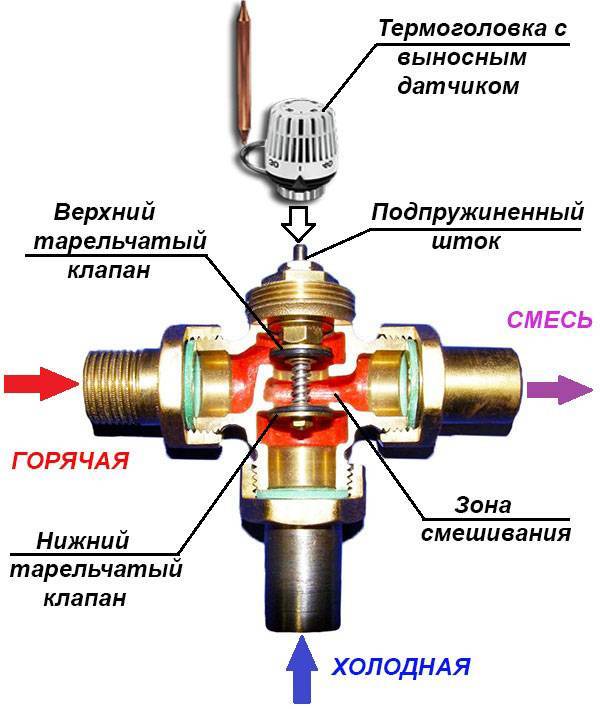

Valve with thermostat

The most expensive, but also the highest quality, are thermostatic valves. The thermal head adjusts to a certain temperature in the room and acts on the valve stem.

Under its influence, the valve increases or decreases the cross section of the hole for the passage of the coolant, due to which the temperature of the radiator is regulated. A valve with a thermal head is installed on the inlet pipe, and a balancing valve is placed on the outlet pipe.

Flush tap

As the name implies, it is designed to drain water or other coolant from the radiator in order to flush it. It consists of a metal body and a long stem, equipped with a rubber gasket. Opens with pliers or wrench. The disadvantage of the design is the rapid wear of the rubber gasket and the need to replace it.

Mayevsky Air Crane

Modern radiators provide for the installation of Mayevsky taps, some models come with already built-in valves. The Mayevsky crane is mounted in the upper part of the battery, since it is at the top that compressed air accumulates.

The valve is actuated, as a rule, with a flat screwdriver or a wrench. The air is bled until the hissing stops and water begins to ooze from the faucet.

Installation of taps on radiators

The next step in the installation of the heating system is the installation of shut-off and control valves in the plugs. Radiators are equipped with "full-bore" ball valves or valves in which manual adjustment of the movement of the coolant works. Thermal heads are now being produced that have automatic flow control.

Taps for heating systems can have a different design, but taps with an American connection with union nuts are considered the most practical. The advantage of taps with an "American" connection lies in their design, which allows you to remove any type of radiator without turning off the heating system. The flow of coolant with the help of such a tap is quickly blocked, and to remove the battery, you only need to unscrew the threaded connection.

The use of "American" taps is especially in demand when the heating system is forced to start, when the heaters are installed on the draft wall. Their use allows you to easily remove the radiator and finish the finishing work of the wall section without turning off the heating system (make strobes, putty or plaster walls, glue wallpaper, and so on). Most importantly, taps with a detachable "American" connection can be used repeatedly, regardless of the type of gaskets (rubber or paranitic) or the option when sealing is carried out only with stainless alloy cones.

Valves with union nuts can be straight or angled. They are selected depending on the pipeline supply system to the radiator (from the wall or niche slopes).

The tap is screwed into a plug with an “American” connection using a special key that is inserted inside the pipe.The cross section of the key can be of various shapes. It is easier if a hexagon is used, it is enough to choose the right size for work. It is more difficult when two protrusions are made in the “American” connection, you have to look for a suitable profile for a reliable hook.

Sponges of an adjustable wrench or pliers are sometimes used in work, but more often craftsmen make an L-shaped key with a square section. Its ends are slightly tapered. This allows you to work with different manufacturers of taps with an American connection.

The connection of the through plug is sealed with the “American” branch pipe using winding. Plumbers use imported flax and packing paste (like UNIPAK) for this purpose. FUM tape is used when the thread profile does not have sharp corners. Also, the thread must have a special notch that prevents the sealing material from scrolling.

Two parts must be checked for thread compatibility by connecting them without tow. The degree of density of the assembled connection shows how much tow must be used. With a large layer of winding, cracks may form or thin-walled parts may be deformed. And an insufficient layer often causes a connection to leak.

The winding must be assembled into a thin bundle and wound in the direction opposite to the direction of the pipe thread. It is necessary to start from the edge of the thread that comes out. It is necessary to fill the entire depth of the thread with flax fibers, pressing the previous one with each new turn and preventing the winding from scrolling. Next, the part is lubricated with UNIPAK paste, which is then screwed into place.

If the heating system is mounted using metal ball valves, threaded couplings are screwed onto them using winding, which are necessary for switching to polypropylene pipes. The Mayevsky crane included in the radiator fittings kit comes with a rubber gasket, so it does not need winding.

The radiators prepared for work are installed in their place, after which the installation of pipes can begin.

After completing the installation of the heating system, you need to start it, after filling the riser from the bottom up with coolant and bleed the air. It is necessary to open the supply valve and check the connections for leaks.

Proper replacement of radiators is a good way to increase the efficiency of heating in your home or apartment and reduce the cost of paying bills. This work can be done quickly and easily with your own hands, but if you are not familiar with the intricacies of the process, it is better to turn to professionals.

Other types

Consider screw valves, Mayevsky's tap, flushing tap, throttle and thermostatic head in more detail.

screw valve

The working body of such a valve is a stem with a valve fixed at its end. The stem is threaded, so when the lamb with the nut is rotated, it can move up and down. At the extreme lower position of the stem, the valve located at its end closes the hole - the saddle, thus preventing the movement of the water flow.

Experienced plumbers do not recommend the use of this type of faucet on radiators. Over time, the gland installed to seal the stem hole begins to leak.The valve will also leak sooner or later: brass - due to salt deposits, having a rubber gasket - due to the destruction of rubber in hot water. Wedge-shaped brass valves are more reliable, but they are not perfect: with excessive force, such a valve can jam in the seat.

Unlike ball valves, a screw valve should only be installed in the direction indicated by the arrow on its body. If the part is installed in the opposite direction, the water pressure will quickly break the valve.

If the valve is not completely closed, then the valve, which loosely covers the seat, begins to vibrate. This causes a series of hydraulic shocks, accompanied by a characteristic sound. As you know, water hammer is an undesirable phenomenon, since it can lead to the destruction of equipment and pipeline parts.

Mayevsky crane

This type of fitting is used to bleed air that forms a plug in radiators. The Mayevsky crane is a fairly reliable device; its replacement or repair is extremely rare. The valve is equipped with a thread, through which it is installed in the radiator cap. In the vast majority of modern models, the stem is turned with a screwdriver, but there are instances that open / close only with a special key. Their installation is not recommended, since the key, which is needed only once a year, is quickly lost.

When buying a Mayevsky crane, you should carefully check it, since in some models the stem can be completely unscrewed. If this happens accidentally during the flushing of the heating battery, it will no longer be possible to return it to its place due to the pressure of hot water.In this case, you will have to turn off the entire riser.

Flushing

On sale, these taps with a welded steel body are quite common, but experts consider them unreliable due to the rubber gasket, which can collapse during flushing of the radiator. The rotation of the rod is made wrench or pliers.

Throttle

With this tap, you can change the volume of coolant entering the radiator. Adjustment is carried out manually.

thermostatic head

In its function, this device is absolutely similar to the previous one, only here the throughput is automatically adjusted using a thermostat, which thus maintains the required temperature in the room. According to the principle of the device, thermostatic heads are divided into mechanical and electronic.

Which ball valve is better to choose so that it works for a long time and reliably

Ball valves have long been widely used in pipeline systems, due to the simplicity of the device and ease of use. However, they must have another valuable quality: reliability. After all, if the crane is made of insufficient quality materials, it can fail prematurely, or even cause an accident. It is not uncommon for buyers, when deciding the question: “which valve to choose?”, In pursuit of savings, purchase ball valves made of cheap aluminum-based alloys, made by some unknown company. And this can turn into big troubles and losses - for example, if the tap breaks under the pressure of water, and the apartment of the neighbors below is flooded.

The need for shutdown

Before moving on to the scheme for disconnecting the battery from the riser in an apartment building, we suggest considering the basic reasons that can cause a malfunction in the heating system.

Here is a list of the most likely causes of battery failure:

- an emergency that threatens to flood your and your neighbor's apartment with a hot coolant;

- painting radiators in the cold season, when the heating is already on;

- if there is a need to change the radiator, or flush it;

- in winter the batteries are too hot and you want to lower the room temperature.

In some apartments, residents practice shutting off batteries in the summer without draining the coolant in order to protect radiators from blockages during the autumn heating system. At this time, the water through the pipes often comes with fragments of rust. How to do it correctly, we will tell in one of the sections of this article.

Conclusion

The main requirement for any pipeline, and especially for hot water, is its reliability. Of course, the pipeline must fulfill its main function - to pass water. Also, it must be repairable. Any malfunction should be eliminated with minimal labor costs. To do this, it must initially be done according to the rules, observing all the requirements of the technology and taking into account the experience of skilled professionals.

Previous EngineeringWinter is coming: how to defrost and thaw plastic pipes underground without digging

Next EngineeringHow to properly drain under the foundation