- Making a spark arrester with your own hands

- Popular models

- Common Mounting Mistakes

- What is a deflector for? Functional features

- Mounting the deflector-weather vane

- Classification of deflectors for chimneys

- Mounting

- Characteristics of popular deflector models

- Grigorovich deflector

- How to make a TsAGI deflector on a chimney pipe with your own hands

- Required Tools

- Development of a drawing of the TsAGI deflector model

- Step-by-step instruction

- Drawings how to make a deflector on a chimney with your own hands

- Types of chimneys

- Brick

- galvanized pipe

- coaxial chimney

- Ceramic

- Stainless steel

Making a spark arrester with your own hands

We have already figured out that the design of the spark arrester is simple, the device often looks like a cover that is put on the chimney.

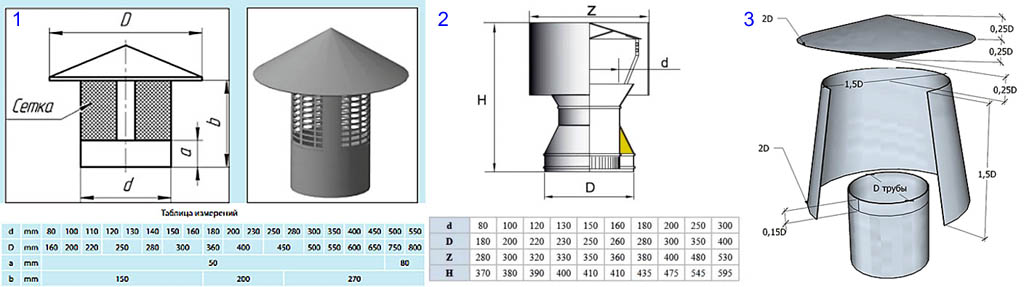

Spark arrester in the form of a chimney cap

It is not difficult to buy a product, but it will be even easier and cheaper to make a spark arrester for a chimney with your own hands. This option is recommended for a short time, because it is not very convenient to use and has the following disadvantages:

- Dirt and soot quickly settle on the grid. This will eventually affect good draft and the removal of gases from the chimney.

- Incorrectly calculated distance between cells. This design does not hold sparks well, which can easily fly out of the pipe.At the same time, a mesh that is too small will cause clogging.

Spark arrester in the form of a pipe with holes

Another option that is not difficult to do yourself (in the image).

It looks like a pipe with drilled holes. You can buy it or make it yourself. Choose a pipe slightly larger than the chimney. Holes are drilled in it, an umbrella is fixed with reconciliation. Then all this product is attached to the chimney with rivets. This option looks pretty simple, but the problem lies in the number and size of holes. Incorrectly drilled holes can reduce traction. Therefore, if you make the design yourself, then carry out the necessary calculations or go empirically. Remember that the latter will require more time and effort.

Here is another photo of this product.

Mesh chimney spark arrestor

In this case, it is necessary to responsibly approach the choice of grid size to eliminate problems similar to those in the model above. This product will also have to be removed and cleaned more than once, because the holes will become clogged with dirt.

If you don't want to bother with cleaning all the time, you can put a dome-shaped spark arrester. In it, the size of the grid cells is changed.

However, it does not exclude the problems associated with the ingress of dirt into the oven, because this model does not have an umbrella.

Popular models

Now consider more durable options. In the image - the best option in terms of functionality. It is inexpensive, and it is not difficult to do it yourself if you have the skills of a locksmith.

Chimney spark arrester with mesh and umbrella

The base is made of galvanized steel with a thickness of 0.6 to 1 mm. It is not necessary to choose a very thin one, although it is easier to work with it.We need reliability. The mesh can be welded from bars, but it is better to buy ready-made, made of stainless steel. The cost will not be much more expensive, but it will be much easier to work compared to bars. Take cells ranging in size from 3 to 5 mm. Carry a grinder, metal shears and a drill to make holes for fasteners. Due to the fact that the metal will have to be bent, you will have to prepare a workbench with a metal corner or part of a flat channel / corner.

For those who have little experience, it is recommended to try to make a cardboard blank. You can learn the intricacies of this process: where to make a hole, where to bend. Review the calculation chart.

Spark Arrestor Dimensions

Remember the need to comply with fire safety, especially if you have a wooden building that is heated with wood. The spark arrester is an important part of the smoke exhaust system, which will allow you not to worry about the occurrence of a fire when heating the stove.

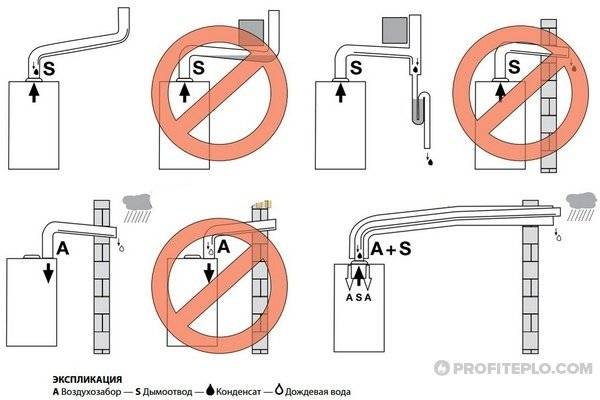

Common Mounting Mistakes

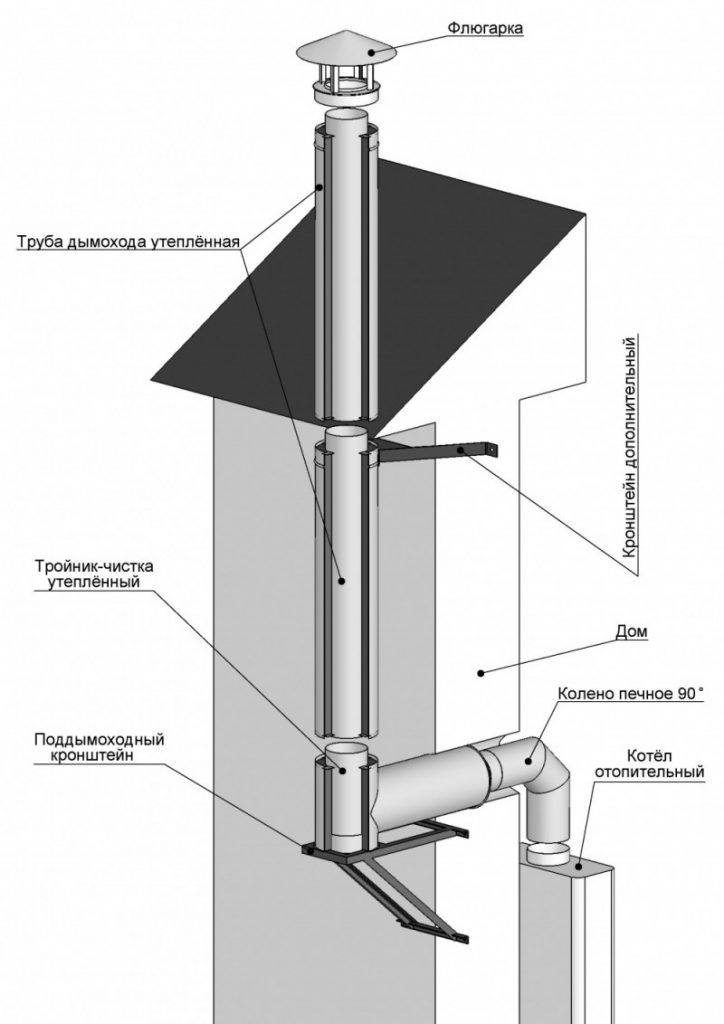

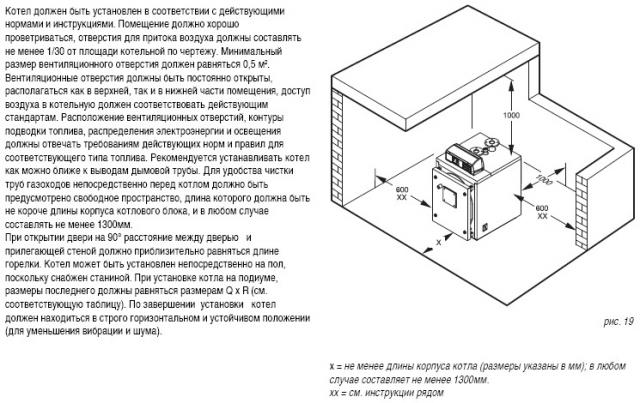

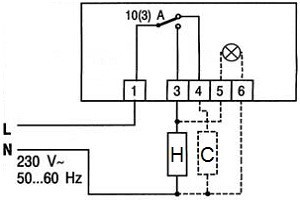

If the coaxial chimney pipe is installed by a non-professional, there is a risk of violating the technology, and improper installation leads to problems in the operation of the boiler and chimney. It is recommended to entrust the whole complex of works to licensed specialists.

The most common mistakes include:

Incorrect calculations of the allowable pipe length. The longer the channel through which the flue gases move, the more they cool down and at the exit already cannot heat the incoming air. At the same time, the amount of condensate increases and on frosty days it freezes on the walls of the head, forming icicles. This results in a decrease in thrust, a deterioration in the operation of the boiler and can lead to carbon monoxide in the roomif the outlet of the pipe is completely clogged.

Insufficient slope of a long horizontal pipe. If the slope towards the condensate collector on a long pipe is insufficient, the risk of freezing on the head is higher.

Absence of a condensate collector on a long horizontal or vertical pipe

If the chimney passing through the wall is short, the flue gases do not have time to cool down enough to condense moisture, and if the pipe is long, it is important to provide for the installation of a tee with a moisture collector, otherwise it will enter the boiler combustion chamber, reducing the efficiency of the unit.

Failure to comply with fire safety standards when installing a chimney through wooden structures. The pipe head must be located no closer than 60 cm from wooden wall.

Lack of anti-icer, wind protection diaphragm at the horizontal chimney.

A coaxial chimney for wall-mounted gas boilers will ensure optimal operation of the heating unit and will last a long time only if installed correctly, using only standard system elements and special protective equipment.

Related video:

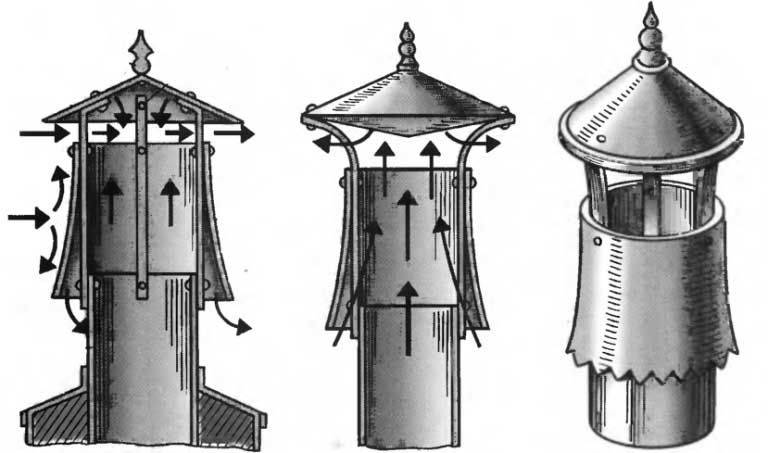

What is a deflector for? Functional features

If the wind blows from under at the bottom, under the hood of the structure, some turbulences form, which cause the slowdown in the release of smoke (this is an insignificant, but still, drawback of the products in question).But there is a way out here too, namely the solution to such a problem - the establishment of an inverted cone under the umbrella of the device itself.

Chimney deflectors are quite simple in design and their principle of operation of the device, but at the same time, their efficiency, no doubt, can be called high. Each device, and deflectors are no exception, have some drawbacks, but if you conduct a general analysis of all the available characteristics and capabilities of this device, then the pros and positives clearly have advantages over the minuses and disadvantages.

Deflector (translated from English. "Reflector") - a pipe structure installed on the head to protect the upper part of the chimney.

The presence of such a device helps to increase the efficiency of heating equipment up to 20%.

In addition to the main purpose - smoke removal, the device is used to perform a number of important functions:

- Traction alignment. Good traction ensures the supply of oxygen, which leads to savings in fuel material - it burns faster and completely in the heat generator.

- Spark extinguishing. The formation of sparks occurs as a result of an increase in the combustion temperature of the fuel and draft in the chimney structure, which can cause a fire. The device provides safe burning out of sparks.

- Protection from the negative effects of precipitation. Such a device provides reliable protection of the smoke channel from rain, snow, hail and strong winds. This contributes to the efficient and uninterrupted operation of heating equipment, even in bad weather.

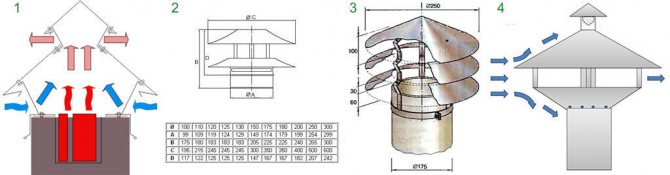

Now let's see what is possible and how to make a deflector on the chimney yourself.The easiest way to start is with an imperfect umbrella deflector; its possibilities are much wider than it might seem, and it takes a little material and not very complicated work.

In the climatic conditions of the Russian Federation, a deflector-umbrella on a chimney most often turns out to be enough, especially since no waste was also noted through his fault. But - if the chimney-umbrella is made correctly. The most common mistake is to raise the cap too high on the racks. This will not help to return 100% of the original thrust, but the likelihood of blowing into the pipe increases dramatically.

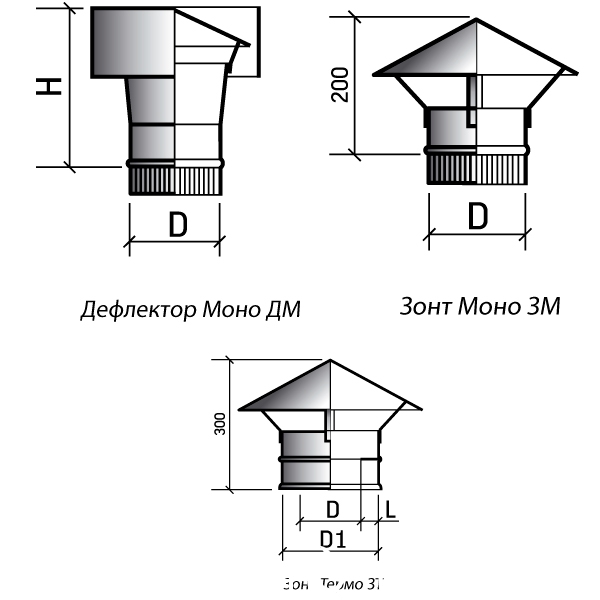

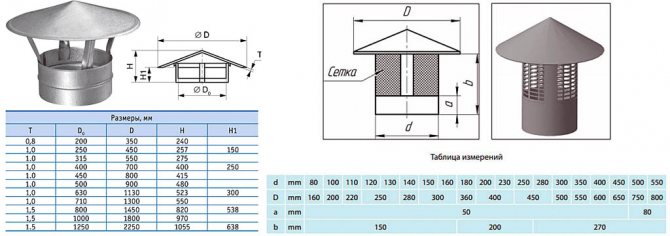

The correct dimensions of the deflector-umbrella on the chimney are given on the left in fig. For pipes with a clearance of 100-200 mm, they decrease proportionally, and then the value of H1 increases 1.3 times for pipes 150-200 mm and 1.6 times for pipes 100-150 mm.

Dimensions of deflectors-umbrellas for chimney and ventilation.

On the right in fig. the dimensions of the non-blown deflector-umbrella are given, but in the conditions of the Russian Federation it is better to put this one on the ventilation pipe of natural ventilation, because the grid is quickly overgrown with soot or flue gas condensate, and then dust adheres very well to it.

Modifications of the deflector-umbrella on the chimney and ventilation pipe

A 3-story umbrella for a ventilation pipe (pos. 3) is less likely to freeze over and clog less than an umbrella with a net. For pipes 130-200 mm, the dimensions change proportionally. And, finally, the Kiryushkin deflector (pos. 3; all cones - Grigorovich) is used mainly as an active-passive one - a low-power smoke exhauster for 12 V 100-200 mA is placed under a small cone.

Before taking on an aerodynamically open deflector, let's see how the most advanced TsAGI deflector is modified for a private house. Its original design was designed primarily for industrial facilities and then for apartment buildings.

TsAGI deflector modifications for chimneys and ventilation pipes

And on the right in Fig. - dimensions of the TsAGI ventilation deflector. It can be turned from passive into passive-active by painting the shell with black blacksmith's stalemate or other paint that absorbs well the thermal radiation of the earth and the objects surrounding the house. Fans in the vents of the house ventilation system must, of course, be left, but they will have to be turned on occasionally. How to make a TsAGI deflector with your own hands, see video

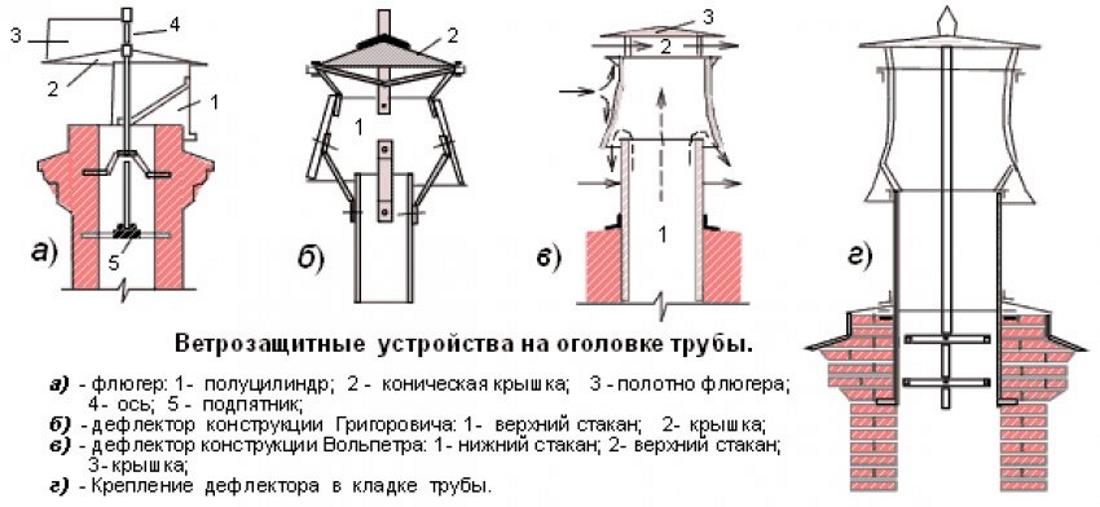

Mounting the deflector-weather vane

Installation of a probe with a windproof element is carried out according to a certain algorithm.

The operation is performed as follows:

- Inside the smoke channel, the upper and lower bearings are strengthened at two levels. In addition, you need to fix the vertical axis.

- A semi-cylindrical screen, a roof and a weather vane canvas are placed on a vertical axis.

The principle of operation of the deflector-weather vane is quite peculiar. After changing the direction of the wind, the weather vane begins to rotate. A curtain moves along with it, closing the channel from the effects of the wind. Therefore, the smoke begins to exit from the leeward side of the chimney.

Reception wind currents slide on a semi-cylindrical screen, increasing traction. In order for the wind vane to rotate easily with the canvas, it is necessary to lubricate the head bearings. In the cold season, it is also necessary to knock down the ice arising from the appearance of condensate.

This type of device is best used in regions with a mild climate and not too severe winters. Since it is quite difficult to maintain this device in conditions of very low temperatures.

Classification of deflectors for chimneys

All devices are divided into three large groups according to several criteria.

Before making a final decision, it is recommended that you familiarize yourself with the most famous deflector designs.

The comparative table will list only those models that are popular with private developers.

Table. Types of deflectors for the chimney

| Grigorovich's cap | A classic and very common option, the speed of movement of combustion products increases by about 20–25%. The device consists of two almost identical umbrellas connected into one structure at a small distance between them. Can be installed on both round and square chimneys. Due to the design features, there is a double acceleration air movement: in the direction of the constriction of the diffuser and towards the upper return hood. |

| TsAGI nozzle | The model was developed by employees of the Central Aerohydrodynamic Institute, in the recent past the most famous specialized scientific institution. Thrust is enhanced by attracting wind pressure and pressure difference in height. The nozzle inside has an additional screen, inside of which a traditional deflector is installed. The TsAGI nozzle eliminates the effect of reverse thrust. The disadvantage is that under certain climatic conditions in the winter period, frost may appear on the walls, which worsens the parameters of the chimney draft. |

| Cap Astato | The product was developed by specialists of the French company Astato.It consists of a static and dynamic part, it is rarely used on chimneys. The reason is that the extremely difficult operating conditions of the fan put forward strict requirements for reliability and security. Such fans significantly increase the overall cost of installing chimney pipes. |

| Turbo deflectors | Quite complex devices, consisting of a rotating turbine head and a fixed body. Due to the rotation of the blades under the hood of the device, the pressure decreases, the smoke from the chimney is sucked out more efficiently. Modern bearings allow the turbine to rotate at a wind speed of only 0.5 m/s, which significantly improves the performance of the chimneys. Turbo deflectors are 2–4 times more efficient than static models and have an attractive appearance. |

| Rotatable hoods | The protective visors are connected to the chimney pipe by a small bearing closed on both sides. The canopy has a curved geometry and in terms of projection completely covers the cross section of the chimney. A weather vane is installed on top of the hood, which rotates the structure depending on the direction of the wind. Air flows pass through special slots and go up. Such movement causes a decrease in pressure and an increase in the natural draft of the exhaust gases from the chimney. |

| H-shaped module | It is most often mounted on industrial chimneys. The main feature is the ability to work with strong gusts of wind. In addition, the possibility of reverse thrust is completely eliminated. |

The master should choose a suitable deflector after a careful analysis of all factors. But it must be borne in mind that very strong traction has not only positive, but also negative sides. What exactly?

- The air movement is so fast that the wick is extinguished. This problem often occurs on gas heating boilers. Modern models have automatic ignition with an electric spark. It constantly works, which causes inconvenience to users. Boilers of an outdated design are not equipped with such devices; they have to be started manually.

If the draft is too strong, the flame in the boiler will constantly blow out

- Strong draft reduces the efficiency of the heating boiler. Hot combustion products for a short period of contact with the heat exchanger do not have time to give it the maximum amount of thermal energy. A significant part of it is removed through the chimney, which increases the cost of financial resources for the maintenance of the building in the winter.

Strong draft significantly reduces the efficiency of the boiler, as a result of which heating costs increase

- The strong draft of the chimney causes an increased influx of cold outside air. As a result, the comfort of staying in the premises worsens, the temperature drops, it is necessary to increase the power of the boilers. And this, taking into account the current cost of energy carriers, is reflected in the financial situation of users.

Method for checking the presence and strength of draft in the chimney

Mounting

To install a rotary turbine, there is no need to have any serious knowledge or skills. The product is small in size and weight. It can only be installed by one person. On average, it will take you two hours to mount a turbo deflector. Installation of the product is carried out at the highest point of the roof and along the ridge. The distance to other deflectors must be at least four meters.

Remember that the temperature level inside the channel should not be more than one hundred degrees. To remove gases with high temperatures, you need to use special nozzles.

An example of installing a deflector on a part of the vent. channels with transition

Rotary turbines can be created by hand. To do this, you need a drawing of the device. To create a device, you do not need to have serious skills and knowledge. The device is also available for purchase. There are a lot of companies offering their products on the market. Study the market in detail before buying. Remember that every manufacturer claims that their products are the best. This is far from always the case.

Video

Characteristics of popular deflector models

Today, for a heater, you can choose different types of deflectors, so I would like to consider the classification and features of each type of such a device. Deflectors come in different shapes, namely, flat, semicircular, with a lid, with a gable gable roof.

Installation of the first option, as a rule, is carried out on buildings that are built in the Art Nouveau style. If we are talking about typical modern houses, then semicircular deflector models are most often used.

In the case where a person lives in such an area and under such conditions that heavy precipitation is observed on throughout the year, and especially a lot of snow in winter, it is best to use a gabled roof deflector.

Now you can consider the question about that. What materials are chimney deflectors most often made of? As a rule, most of these devices are made from galvanized iron or copper.

Although at the present time there is a tendency when more and more often you can see samples created from a heat-resistant polymer and covered with high-quality, resistant to many possible harmful factors, enamel. If the exhaust duct for the boiler is designed in such a way that there is no direct contact with hot air, then it is quite possible to use even a cap made of ordinary plastic.

In the domestic market, the most popular and common are:

- "Smoke tooth";

- "Star Shenard";

- Deflector steps, having a rotating mechanism;

- "Grigorovich's device".

First of all, you need to decide on the material that you plan to use. Stainless steel or iron is best, as well as copper. These metals are quite resistant to all kinds of weather conditions, in particular to precipitation and sudden changes in temperature.

This is what the chimney deflector looks like

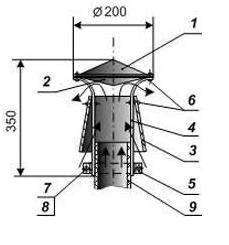

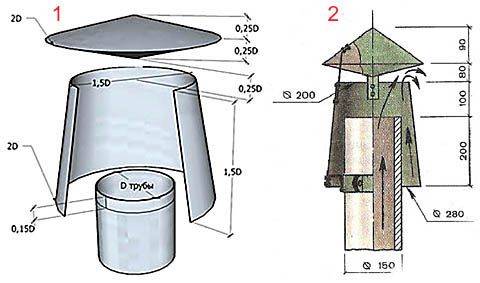

When calculating, it must be remembered that the height of such a device should be approximately 1.5 - 1.8 of the total internal diameter of the pipe, and the width, respectively, about 1.9.

After the calculation has been carried out, you can proceed directly to the installation, which consists of the following steps:

- A scan of the main elements is drawn on ordinary cardboard using a marker or felt-tip pen;

- The pattern is moved to the metal, after which the necessary details are cut out;

- All elements are interconnected. For this purpose, you can use either welding or some fasteners;

- A special bracket is made of metal, which is necessary in order to install the cap itself directly on the surface of the duct;

- At the end, a cap is assembled.

Deflector models differ in both size and wind sensitivity.The most popular models are TsAGI, Khanzhenkov, Volpert-Grigorovich, "Smoke tooth", "Hood" aka "Net", "Shenard". The first of these models was developed at the Aerodynamic Institute. Zhukovsky.

More often, TsAGI is used in ventilation systems due to the difficulties that arise when cleaning the device from soot. The second model is essentially the same TsAGI, but somewhat improved by the inventor. In fact, this is an additional cylinder around a pipe with an umbrella cover, immersed inside the cylinder for a certain distance.

The Volpert-Grigorovich deflector has proven itself well as a chimney draft booster. It works effectively in areas with prevailing low winds. The design includes 2 cylinders - the lower one with two outlet pipes and the upper one with a cover. "Smoke tooth" is mounted in a door specially provided in the chimney. Due to the fact that the design includes 2 handles, you can adjust the air flow.

Covers for chimneys are made in a variety of shapes. Sometimes they are covered with heat-resistant enamel. Individual specimens look very decorative

The deflector "Hood" has a rotary design. It consists of a semicircular trough-shaped air trap mounted on a rotary rod mounted inside the pipe. The increase in traction power by installing a deflector-weather vane occurs due to turbulence that occurs during wind load.

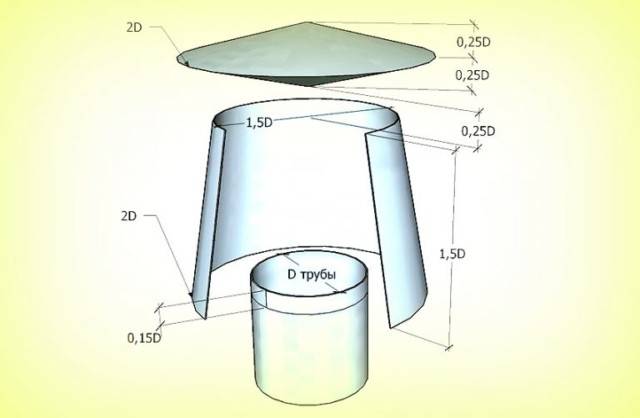

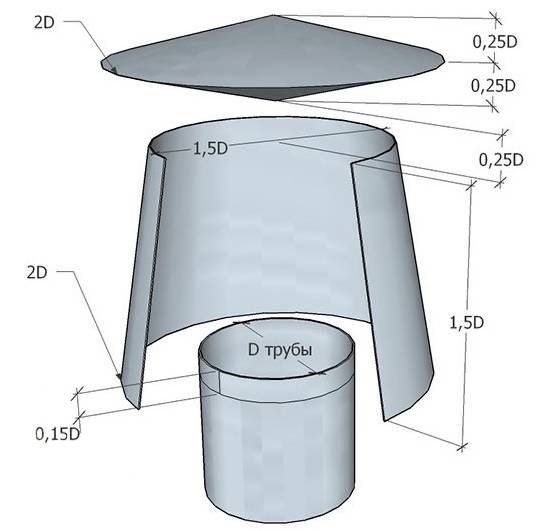

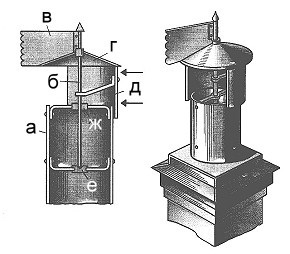

Grigorovich deflector

Another time-tested design is the Grigorovich deflector, which is installed on round chimneys to stabilize draft. The Grigorovich deflector consists of several parts:

- deflector in the form of a truncated cone;

- a cap that protects the pipe from precipitation;

- reverse cone, which creates an area of reduced pressure under the cap and improves traction.

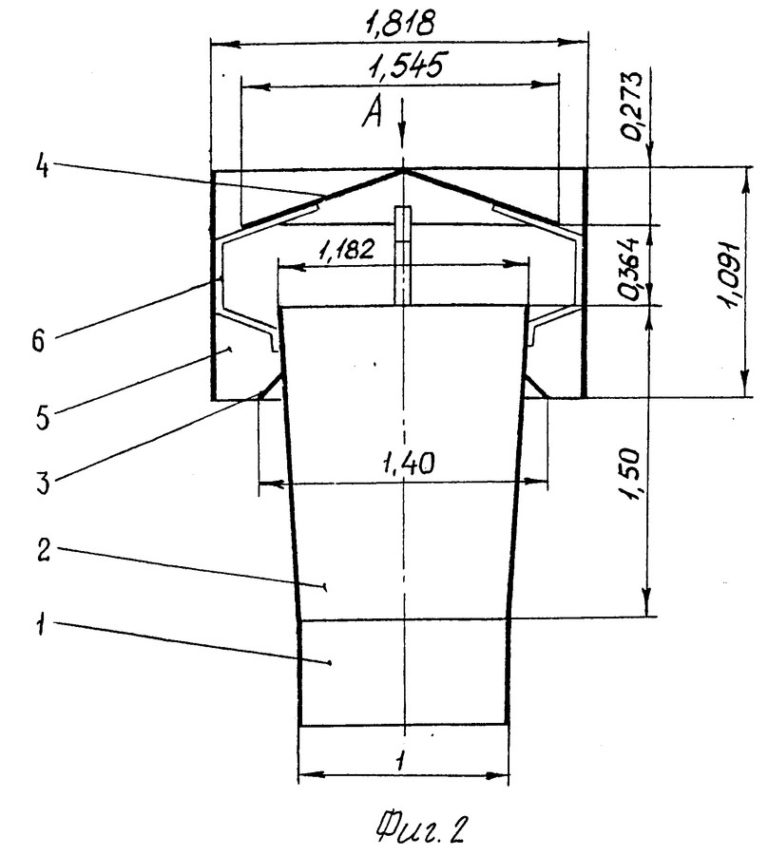

You can make a Grigorovich deflector from the same materials as the above models, the technology for their manufacture is generally similar. Dimensions are determined based on the diameter of the pipe. It is taken as a basis and, using the coefficients, the remaining dimensions are calculated:

- The diameter of the cone-shaped diffuser in the lower part is taken as 2d, in the upper part - 1.5d, the height of the truncated cone - 1.5d.

- The cone-shaped umbrella cap and return cap have a diameter of 2d and a height of 0.25d.

- The distance from the top of the return cap to the top edge of the diffuser is also 0.25d.

- The distance from the upper edge of the pipe to the lower edge of the diffuser is 0.15-0.2d.

The last two sizes are provided with brackets of the required height, which are made from tin scraps and fastened with rivets, bolts or by welding.

Manufacturing and installation technology:

- According to the calculated dimensions, a sketch is made, transferred to sheet metal and the elements are cut with scissors for metal.

- The cones are bent on a mandrel and fasten the edges with rivets or by bending. Connect the umbrella and the reverse cone in the same way.

- With the help of brackets, the parts are fastened together, maintaining the calculated distances.

- Attach the deflector to the pipe. To facilitate its installation, the deflector can be equipped with a lower cylinder, the diameter of which allows it to be pushed onto the pipe.

The service life of a cap or deflector made of stainless steel is 25 years, of galvanized steel - at least 10 years. To extend it and give the galvanization an attractive look, you can cover it with black heat-resistant paint from a can. In this case, soot and soot will not be visible on the cap.

Install cap for chimney quite simple, and the benefits of it are obvious - you no longer have to spend time at the beginning of the heating season cleaning the pipes from leaves, fluff, dust. Precipitation will not get into the pipe, which will allow it to be operated without corrosion and brick destruction. Installing a deflector, in addition, will make the draft stable even with a small pipe height, regardless of weather conditions.

How to make a TsAGI deflector on a chimney pipe with your own hands

The process of developing and assembling the deflector to exhaust pipe consists of four stages: drawing, creating blanks, assembling, installing the structure and fixing it directly on the chimney.

Required Tools

You will definitely need:

- a sheet of thick paper for drawing and layout;

- marker for marking;

- riveter for connecting structural elements;

- scissors for metal for cutting parts;

- drill;

- a hammer.

Do not forget about the right tool before installing the deflector

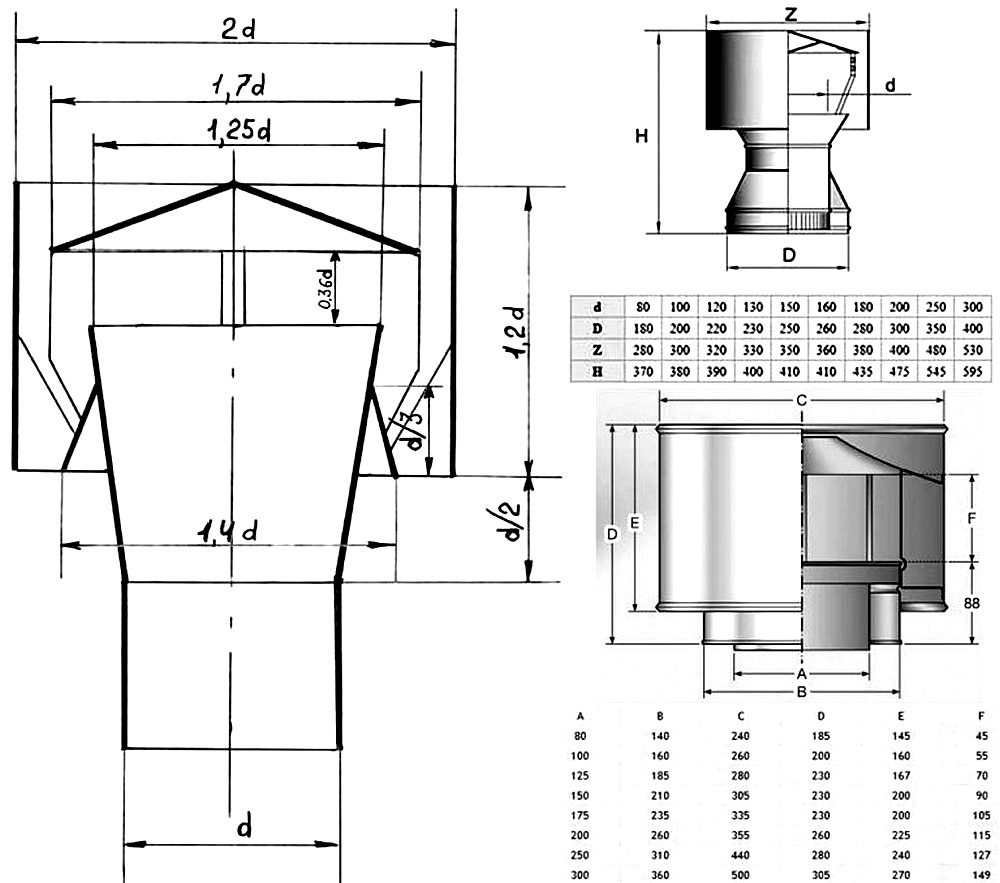

Development of a drawing of the TsAGI deflector model

There is an algorithm for how to make a deflector on the flue pipe with your own hands. The first step is recommended to be done on paper. First you need to calculate the dimensions of the diameter of the nozzle and the upper cap of the structure, as well as calculate the height of the reflector.

For this, special formulas are used:

- diameter of the upper part of the deflector - 1.25d;

- diameter of the outer ring - 2d;

- construction height - 2d + d / 2;

- ring height - 1.2d;

- cap diameter - 1.7d;

- the distance from the base to the edge of the outer casing is d/2.

Where d is the diameter of the chimney.

A table will help to facilitate the task, which contains ready-made calculations for standard sizes of metal pipes.

| Chimney diameter, cm | Outer casing diameter, cm | Height of the outer casing, cm | Diffuser outlet diameter, cm | Cap diameter, cm | Installation height of the outer casing, cm |

| 100 | 20.0 | 12.0 | 12.5 | 17.0…19.0 | 5.0 |

| 125 | 25.0 | 15.0 | 15.7 | 21.2…23.8 | 6.3 |

| 160 | 32.0 | 19.2 | 20.0 | 27.2…30.4 | 8.0 |

| 20.0 | 40.0 | 24.0 | 25.0 | 34.0…38.0 | 10.0 |

| 25.0 | 50.0 | 30.0 | 31.3 | 42.5…47.5 | 12.5 |

| 31.5 | 63.0 | 37.8 | 39.4 | 53.6–59.9 | 15.8 |

If the chimney has a non-standard width, then all calculations will have to be done independently. But, knowing the formulas, it is easy to measure the diameter of the pipe and determine all the necessary indicators to use them when drawing up drawings.

When the patterns are made, it is recommended to first assemble a paper prototype of the future reflector. Even if you are an experienced craftsman and are sure that you will construct a deflector for a stove chimney with your own hands without problems, you should not skip this step, since it will help you identify possible errors and flaws, and correct calculations or a drawing. Only after creating the correct paper layout, which confirms that the deflector scheme is accurate, you can proceed to the next step.

Step-by-step instruction

There is a work order that must be followed, otherwise you will not be able to connect the individual parts of the chimney deflector yourself with your own hands.

The procedure is as follows:

- Using paper blanks, transfer the template to the surface of the metal from which you plan to make a reflector. Carefully trace the outlines of the paper details. You can use a permanent marker, special chalk and even a simple pencil for this purpose.

- Using scissors for metal, cut out the blanks of the necessary structural details.

- Along the entire contour on the sections, the metal must be bent by 5 mm and carefully walked with a hammer.

- Roll the workpiece into a cylinder shape, drill holes for fasteners so that you can connect the structure with rivets. Welding is allowed, but not arc welding.Care must be taken not to burn through the metal. The distance between the main attachment points, choose from 2 to 6 cm, it varies according to the size of the finished structure. The outer cylinder is folded and fastened in the same way.

- Bending and connecting the edges, make the rest of the details: an umbrella and a protective cap in the form of a cone.

- Fasteners must be cut out of the galvanized sheet - 3-4 strips: width 6 cm, length - up to 20 cm. Bend around the entire perimeter on both sides and walk along them with a hammer. From the inside of the umbrella, it is necessary to drill mounting holes, departing from the edge by 5 cm. 3 points will be enough. After that, fasten the metal strips to the cap with rivets. Then they need to be bent at an angle of 90 degrees.

- Connect the diffuser and cone using rivets to the inlet pipe. Having made a deflector for a round pipe with your own hands, you can proceed with its installation.

A Volper chimney deflector can also be created using a similar method. Its design is very similar to the TsAGI model, but at the top there are some differences. They are also made of stainless steel, galvanized or copper.

Drawings how to make a deflector on a chimney with your own hands

The sequence of actions in the manufacture of the device will be as follows:

- We make a drawing of all the details on paper (moreover, their hollow size), cut them out and connect them together.

- If all the parameters on the paper layout match, we do the same on the metal sheet.

- A diffuser shape is cut out on a piece of metal and twisted into a cylinder.

- To connect all the parts of the deflector, you need to carefully drill holes in the elements and use bolts or special rivets to create a single structure.

- Then a cap, strips are made, all separately made parts are connected together.

What is a chimney deflector video review

There is nothing complicated in the process of making a deflector for a pipe with your own hands, the main thing is to follow the assembly rules and do not forget about the correct selection of all design parameters.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance. At the same time, they comply with sanitary standards and rules, which state:

-

The pipe is made of fireclay bricks.

-

For the construction of walls, a solution of clay or special glue is used.

-

To improve draft, the chimney rises above the level of the roof ridge.

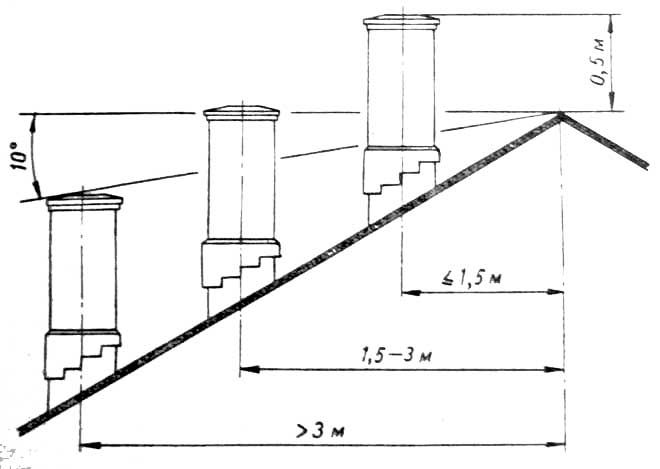

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

-

The masonry provides tightness.

-

At the inner hole, the deviation is no more than 3 mm per 1 m.

-

To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

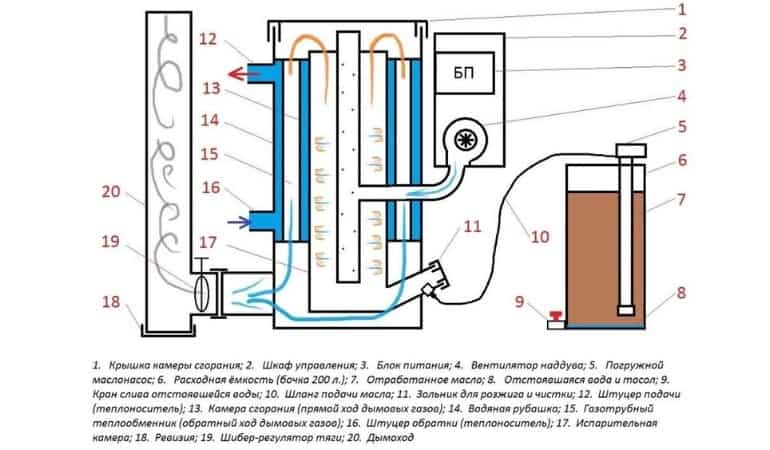

coaxial chimney

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element. The inner pipe serves as a chimney, and the outer pipe serves as a fresh air intake.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion. The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure, including:

-

Smoke duct made of ceramic material.

-

Insulation layer or air space.

-

Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation.The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney become

In addition, such stainless steel pipes have a number of advantages:

-

Long period of operation.

-

Multifunctionality.

-

Relatively low cost.

-

Great strength.

-

Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.