- Difficulties when drilling tiles

- How to drill a hole in metal

- How to drill metal with a drill

- Features of deep hole drilling

- Tile drilling rules

- Features of drilling holes in tiles

- How to drill tile correctly

- List of required equipment

- drilling algorithm. Step-by-step instruction

- Common Newbie Mistakes

- Application of core drills with diamond coating

- Application of core drills with diamond coating

- Working with a drill and crown

- drilling algorithm. Step-by-step instruction

- The most suitable way

- Perforator

- Household drill VS screwdriver

- Diamond drilling

- How to make a large hole for a socket or pipe

- Which is better: crown or ballerina

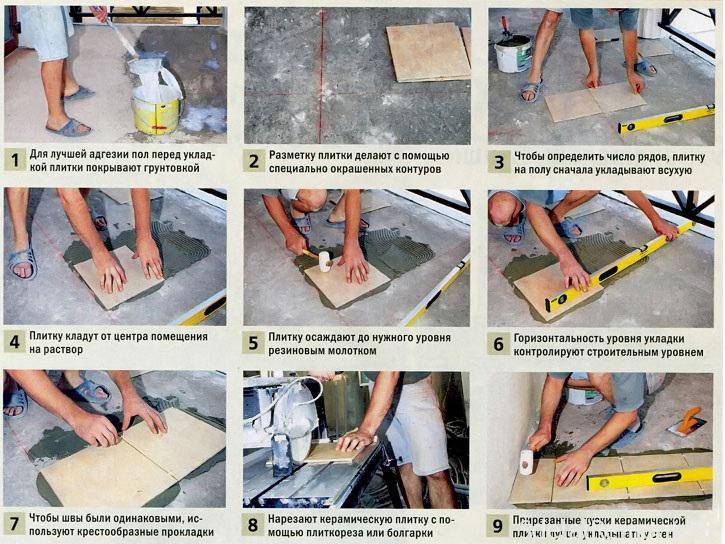

- We drill tiles according to the rules

Difficulties when drilling tiles

The complexity of drilling ceramic tiles is due to the following nuances:

- Risk of splitting under shock loading and vibration. Efficient drilling tools operate through rotation and shock loading. Hard tip impacts and rotation at over 1000 rpm result in the formation of fine and major cracks in the tiles.

- Slippage of the drill from the surface.The surface of each cladding element is coated with glaze, which provides protection against moisture and abrasion during cleaning. At a low rotation speed, the tool may slide off the coating.

- The formation of chips on the edges of the tiles. The edges of the tiles are characterized by increased fragility, because. do not have a protective coating. Breaking off the surface of the glaze, the drill jumps into the seam and forms a crack on the edge. If the required recess is near the corner, then there is a high risk of breaking off the segment.

- High labor intensity of the process. Despite the increased fragility, ceramics is a fairly strong and hard material. The speed limit causes increased demands on physical strength, the professionalism of the master and the quality of the drills.

- The need to use multiple tools. To make a hole, you will need a tap or hammer, a drill with a carbide drill, and a drill for concrete under the tiles. Holes of large diameter are made with a grinder, a drill in combination with glass pliers, a “ballerina” and other devices.

How to drill a hole in metal

Metal products, in comparison with parts made of other materials, have increased hardness and strength, therefore, for successful work with them, it is necessary to follow the technological process and use high-quality cutting tools.

Metal drilling tools:

- Electric or hand drill;

- twist drill;

- Kerner;

- A hammer;

- Protective glasses.

Drills for metal are selected based on the diameters of the holes and the properties of the material being processed. As a rule, they are made of high-speed steels, such as R6M5K5, R6M5, R4M2.Carbide drills are used to work with cast iron, carbon and alloy hardened steels, stainless steel, and other difficult-to-cut materials.

The power of the electric drill must be designed to drill a hole of the required diameter. Power tool manufacturers indicate the relevant technical data on the product. For example, for drills with a power of 500 ... 700 W, the maximum drilling diameter for metal is 10 ... 13 mm.

There are blind, incomplete, and through holes. They can be used to connect parts to each other by means of bolts, studs, pins and rivets.

If the hole is drilled for the purpose of threading, it is worth paying special attention to the choice of drill diameter. Due to its beating in the cartridge, a breakdown of the hole occurs, which must be taken into account. Indicative data are presented in the table

Indicative data are presented in the table.

| Drill diameter | 5 | 10 | 15 | 20 |

|---|---|---|---|---|

| Hole breakdown | 0,08 | 0,12 | 0,20 | 0,28 |

| Result | 5,08 | 10,12 | 15,20 | 20,28 |

To reduce breakdown, drilling is performed in two stages: first with a smaller diameter drill, and then with the main one. The same method of sequential reaming is used when it is necessary to make a hole of a large diameter.

How to drill metal with a drill

After marking the workpiece, the center of the future hole should be punched. This will prevent the drill from moving away from the set point. For the convenience of work, the workpiece should be clamped in a bench vise or placed on a stand so that it takes a stable position. The drill is set strictly perpendicular to the surface to be drilled.

This is important to avoid breakage.

When drilling metal, the drill does not need to exert much pressure.On the contrary, it should decrease as you go. This will prevent breakage of the drill and also reduce burr formation on the trailing edge of the through hole. Chip removal should be monitored. If the cutting tool jams, it is released by reverse rotation.

Cutting mode selection

When using a tool made of high speed steel, you can refer to the speed according to the data in the table. When working with carbide drills, the allowable values are 1.5 ... 2 times higher.

| Drill diameter, mm | up to 5 | 6…10 | 11…15 | 16…20 |

|---|---|---|---|---|

| Rotation frequency, rpm | 1300…2000 | 700…1300 | 400…700 | 300…400 |

Drilling of metal products must be carried out with cooling. If it is not used, there is a high probability that the tool will lose its cutting properties due to overheating. The cleanliness of the surface of the hole in this case will be quite low. An emulsion is usually used as a coolant for hard steels. At home, machine oil is suitable. Cast iron and non-ferrous metals can be drilled without coolant.

Features of deep hole drilling

Holes are considered deep if their size is greater than five drill diameters. The peculiarity of the work here lies in the difficulties associated with cooling and chip removal. The length of the cutting part of the tool must be greater than the depth of the hole. Otherwise, the body of the part will block the helical grooves, through which chips are removed, and liquid is also supplied for cooling and lubrication.

First, the hole is drilled with a rigid short drill to a shallow depth. This operation is necessary to set the direction and centering of the main tool. After that, a hole of the required length is made. As you progress, you need to remove metal shavings from time to time.For this purpose, use coolant, hooks, magnets, or turn the part over.

Tile drilling rules

Before drilling, the tile is marked out and paper tape or plaster is glued to the area where the hole is provided. Also, to facilitate reaming a smooth surface, you can use a plywood stencil. Pressing it against the surface of the tile, you can start drilling a hole. To make a hole in a tile that has not yet been placed on the wall, work should be done on a flat surface.

Drilling starts with small revolutions, without much pressure. The crown should be located parallel to the tile so that when the drill is sunk, it can go deep into the surface evenly along the entire diameter. No sudden movements are allowed.

When working with diamond crowns, it is allowed to make holes with high speeds. But as a result of this, a strong heating of the tool is observed, which will entail burning (combustion) of the diamond coating, because of this, the tool itself will deteriorate. Thus, for fast work, it is necessary to provide for the presence of water to water or wet the drill. Dry drilling is allowed, but at low speeds.

If there is no diamond coating on the crown, then it is necessary to adhere to the “wet” method of drilling. In particular, if this applies to tiles on which there is a coating in the form of glass glaze. But for ordinary tiles, the use of this method is more preferable. In addition, wetting tools with coolant allows you to complete the job many times faster.

Using a ballerina, it is important to choose the right size on it. The distance between the central and side tools is set 2 times less than the size of the holes we need

Then, in the designated places, drilling is performed at low speeds. The tile must adhere in such a way that the scattering of fragments does not injure anyone. It is important to use goggles as eye protection. The power tool should be positioned as evenly as possible when drilling, without tilting or distortion.

Now you know how to drill tiles correctly, taking into account the use of various tools. This process is not particularly difficult, but requires some training and knowledge.

When doing such delicate work, take your time, be calm and careful, and do not forget to wet the tool with coolant

Features of drilling holes in tiles

Due to the fact that clay is the main component of the tile, and the glass that is part of the coating, you will need cutting tools that can cut or drill both of these materials without any problems. This requires one of the following tools:

- a drill with various nozzles (a special crown and a drill with a spear-shaped tip);

- perforator with the option of non-impact mode;

- screwdriver.

Accessories for drilling holes in tiles with your own hands:

- masking tape;

- a vacuum cleaner.

Spear bits for drilling tiles

Drills with a spear-shaped tip are useful for drilling holes with your own hands, having a diameter of up to 12 mm, crowns will be more appropriate for all other holes in the tile.It is not recommended to carry out work without them, since it is better to immediately spend money on the purchase of nozzles than to lose damaged tiles.

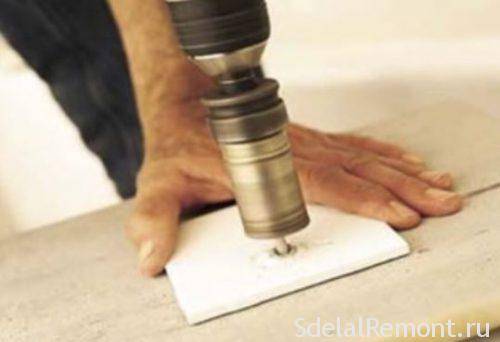

How to drill tile correctly

We prepare the power tool for work - we insert a drill for tiles, turn off the impact mode and set the minimum rotation speed. At this minimum speed, we start drilling in the marked place

We do this with the utmost care, without strong pressure. Thanks to the glued masking tape, the drill will not slip off the drilling point, and will gradually go deeper into the thickness of the tile

As the drill advances, we increase the number of revolutions, and when the tile is drilled through, turn off the electric drill to replace the first drill with the second one - the one that we prepared for the wall material.

In order to prevent the drill from overheating while drilling the tile, it is necessary to moisten the tile with water in the place where the hole is made.

Further drilling is carried out as usual, nevertheless, being careful not to damage the drilled tile. When the hole of the required depth is drilled, we remove the glued piece of self-adhesive material, remove the envelope with garbage, and that's it - you can hammer the dowel into the hole, screw in the screw and hang what you planned on it

List of required equipment

First of all, you need to prepare a tape measure and a pencil for marking. If there are two or more holes, then most likely a level will come in handy.

This is especially important when work is carried out to place shelves, cabinets, hangers, heated towel rails, toilets, mirrors. When marking on a dark or bright glossy tile, it is better to take a marker instead of a pencil

It is easier for them to draw, and you can see it much better.

When marking on a dark or bright glossy tile, it is better to take a marker instead of a pencil. It is easier for them to draw, and you can see it much better.

When marking on a dark or bright glossy tile, it is better to take a marker instead of a pencil. It is easier for them to draw, and you can see it much better.

As the main tool, a hammer drill with a disabled percussion mechanism, an electric drill or a screwdriver is suitable. The declared speed of rotation in this case should be from 300 to 1000 revolutions per minute.

The next item is drills. You can give preference to diamond-coated products, as well as tungsten carbide-coated blade and core drills. As practice shows, they do an excellent job with all types of tiles.

When drilling holes of large diameter (up to 9 cm), you need to stock up on a "ballerina". This is the name of a circular drill with adjustable teeth: by fixing the teeth at the right distance from the center, you can get a hole with the desired radius.

Very often, the glossy surface of the tile provokes slippage of the drill. To avoid such incidents, experienced tilers advise to paste over the drilling area with tape. And put the markup on top of the tape

Very often, the glossy surface of the tile provokes slippage of the drill. To avoid such incidents, experienced tilers advise to paste over the drilling area with tape. And put the markup on top of the tape

A glass of cold water will also come in handy. It must be prepared to cool the drill during operation.

This will be especially true if diamond-coated products have been chosen. They demonstrate rapid heating and a significant decrease in cutting properties.

drilling algorithm. Step-by-step instruction

Consider the algorithm for drilling ceramic tiles using the example of making a hole in the wall for a dowel.

Before starting work, it is necessary to study the parameters and condition of the tile, as well as the base under it

It is important to clarify the thickness of the cladding, tap the tile, find out if there are voids under it, and in what place.A void may occur if a marriage was made when laying the tiles

In a place where there is a void under the tile, making a hole is risky.

Make a hole marking with a ruler. To avoid cracks in the tile, the hole is placed at least 15 mm from the edge of the tile.

The drill is switched to the drilling mode, the selected drill is inserted into its cartridge, the lowest speed is set with the switch, it is set strictly perpendicular to the tile and drilling is carried out in the intended place.

After passing through the glazed layer, the speed and pressure are gradually and carefully increased, avoiding overheating of the instrument. If necessary, the drill is moistened with water, while turning off the tool.

When the tile is drilled through, the drill is replaced with a puncher. An appropriate drill is inserted into it, the puncher is switched to shock mode. Carefully, trying not to damage the tile, continue to drill the base under the tiled lining. To drill a hole in the wall of the required depth, a marker is made on the drill.

In the absence of a puncher, continue to work with a drill

The drill is switched to shock mode, the drill is fixed in the chuck for concrete and carefully, maintaining the perpendicular position of the drill with respect to the wall, drill a hole to the proper depth. It should be noted that the concrete drill should not exceed the previous equipment, otherwise the tile will be damaged.

At the end of the operation, the opening is cleaned of dust and small waste, and only then the dowel is inserted.

Common Newbie Mistakes

Surprisingly, many chips and cracks appear even at the marking stage.This happens when a hammer and a sharp nail are used for these purposes: trying to make a mark on the surface of the tile, inexperienced users do not calculate the impact force well. The result is a chip, break or deep crack.

Other common bugs include:

- illiterate choice of the operating mode of the power tool - too high speed, use of shock mode;

- incorrect selection of drill;

- poor fixation - slipping of the drill at the beginning of drilling.

Another common omission is ignoring the search for voids. Experts look for hollow spaces by tapping on tiles.

If the void is located near the edge of the tile, you can try filling it with glue. To do this, make a liquid adhesive solution and use a gun or syringe to drive it through the seam into the hollow space.

If the void is located near the edge of the tile, you can try filling it with glue. To do this, make a liquid adhesive solution and use a gun or syringe to drive it through the seam into the hollow space.

A dull sound heard indicates that the tile is firmly attached to the surface of the wall or floor, and a sonorous one indicates the presence of voids.

Areas with emptiness should be avoided, since when drilling, it is on them that cracks often form.

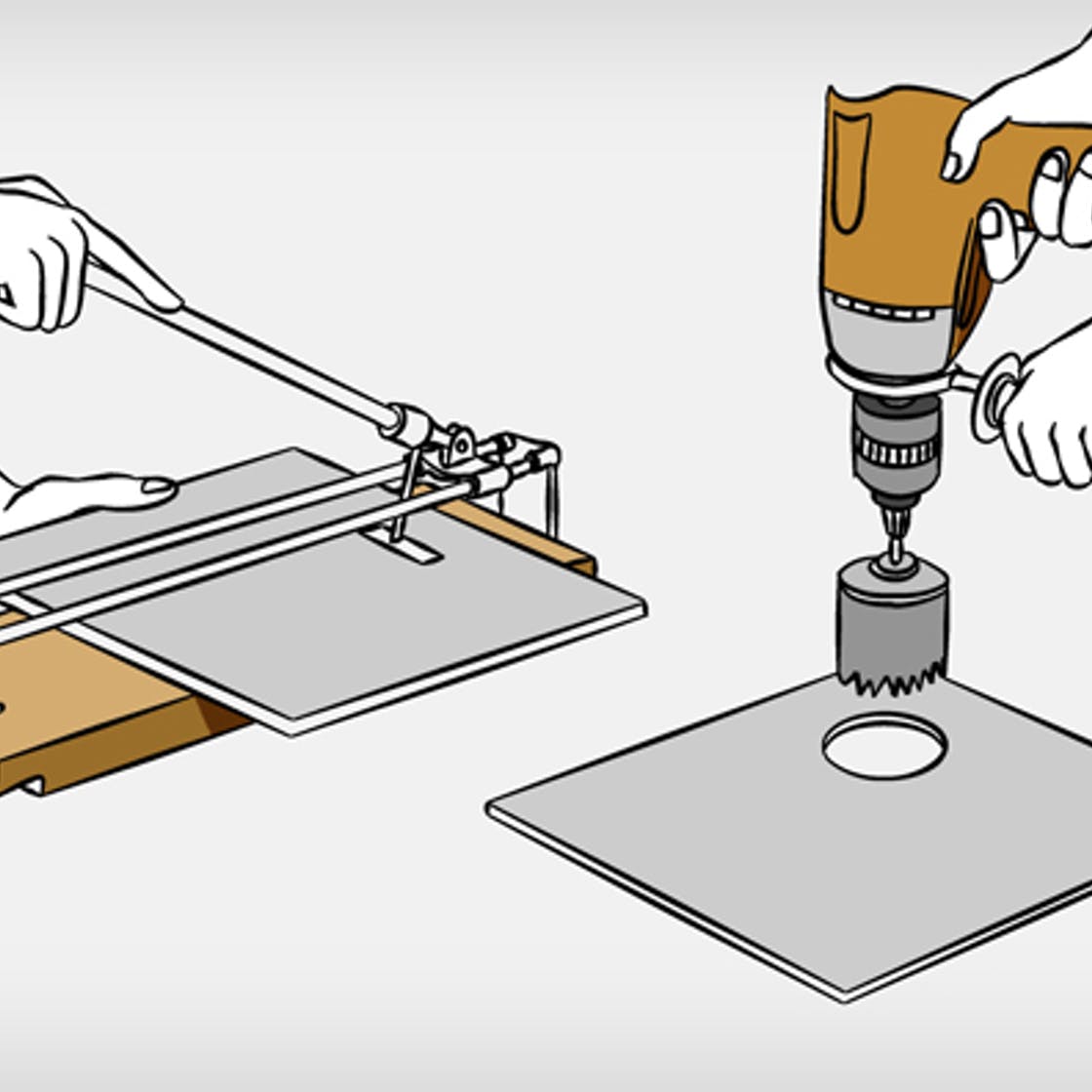

Application of core drills with diamond coating

This type of drill is used when it is necessary to drill tiles in the wall in order to obtain holes for mounting pipes or sockets.

Select a crown of the required size, fix it in a drill.

The drill is set in the mode up to 500 rpm. Drilled with a diamond crown with mandatory water cooling. Proper use of the crown allows you to drill up to 50 holes.

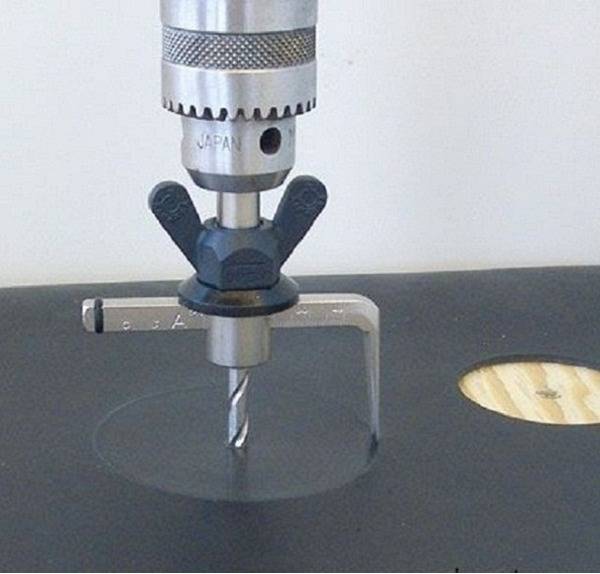

drillingballerina

A big plus of this type of drill is that with it you can perform a significant amount of work on the manufacture of holes of any size.

- The ballerina is fixed into the drill chuck with a rod.

- Set the desired drill size. Here it is necessary not to be mistaken. First, the radius of the future opening is calculated, and then the result is set between the core and side drills.

- The locking screw is firmly tightened with force so that the movable cutter does not move under the influence of vibration.

- Marking on the tile is done by determining the center of the hole.

Drilling is carried out at low speeds, firmly holding the drill in your hands.

Pay attention that the depth of cut is the same around the entire perimeter of the circle.

The edges of the hole after drilling may require a little rework. It is made with pliers and then sanding paper.

The process of drilling with a ballerina is often accompanied by increased vibration, and therefore it is not popular with users.

To increase safety, the “ballerina” can be used with a special plastic cover that protects against ceramic fragments.

Application of core drills with diamond coating

This type of drill is used when it is necessary to drill tiles in the wall in order to obtain holes for mounting pipes or sockets.

Select a crown of the required size, fix it in a drill.

The drill is set in the mode up to 500 rpm. Drilled with a diamond crown with mandatory water cooling. Proper use of the crown allows you to drill up to 50 holes.

Drilling a ballerina

A big plus of this type of drill is that with it you can perform a significant amount of work on the manufacture of holes of any size.

- The ballerina is fixed into the drill chuck with a rod.

- Set the desired drill size. Here it is necessary not to be mistaken. First, the radius of the future opening is calculated, and then the result is set between the core and side drills.

- The locking screw is firmly tightened with force so that the movable cutter does not move under the influence of vibration.

- Marking on the tile is done by determining the center of the hole.

Drilling is carried out at low speeds, firmly holding the drill in your hands.

Pay attention that the depth of cut is the same around the entire perimeter of the circle.

The edges of the hole after drilling may require a little rework. It is made with pliers and then sanding paper.

The process of drilling with a ballerina is often accompanied by increased vibration, and therefore it is not popular with users.

To increase safety, the “ballerina” can be used with a special plastic cover that protects against ceramic fragments.

Working with a drill and crown

Fix the cutting tool in the chuck, reduce the speed on the drill to 600 per minute. Kernel center is not required, it is a relic of a bygone era. The contact of the cutting edge with the surface of the part must be carried out when the drill picks up the set number of revolutions. If you first press the drill against the tile, and then turn on the rotation, then there will certainly be slippage.

You don't have to push right away. Lightly touch the tile, and with light pressure, mark the center of the hole. Only then, the pressure is increased

IMPORTANT: tiles must be fixed on a flat and level surface

To make the job easier and prolong the life of the cutting tool, water the drilling site with a thin stream of water.

While this is a recommendation for spear and twist drills, it is a must for crowns and tubular drills.

With a thin drill, if desired, you can make a cutout of any shape and size. To do this, drill frequent holes along the contour, and then squeeze out unnecessary elements. The edges are processed with a file.

drilling algorithm. Step-by-step instruction

Consider the algorithm for drilling ceramic tiles using the example of making a hole in the wall for a dowel.

Before starting work, it is necessary to study the parameters and condition of the tile, as well as the base under it

It is important to clarify the thickness of the cladding, tap the tile, find out if there are voids under it, and in what place. A void may occur if a marriage was made when laying the tiles

In a place where there is a void under the tile, making a hole is risky.

Make a hole marking with a ruler. To avoid cracks in the tile, the hole is placed at least 15 mm from the edge of the tile.

The drill is switched to the drilling mode, the selected drill is inserted into its cartridge, the lowest speed is set with the switch, it is set strictly perpendicular to the tile and drilling is carried out in the intended place.

After passing through the glazed layer, the speed and pressure are gradually and carefully increased, avoiding overheating of the instrument. If necessary, the drill is moistened with water, while turning off the tool.

When the tile is drilled through, the drill is replaced with a puncher. An appropriate drill is inserted into it, the puncher is switched to shock mode. Carefully, trying not to damage the tile, continue to drill the base under the tiled lining.To drill a hole in the wall of the required depth, a marker is made on the drill.

In the absence of a puncher, continue to work with a drill

The drill is switched to shock mode, the drill is fixed in the chuck for concrete and carefully, maintaining the perpendicular position of the drill with respect to the wall, drill a hole to the proper depth. It should be noted that the concrete drill should not exceed the previous equipment, otherwise the tile will be damaged.

At the end of the operation, the opening is cleaned of dust and small waste, and only then the dowel is inserted.

The most suitable way

You must decide what is the best way to drill concrete walls. Often a regular drill is used. It is convenient if it is two-handed, which will facilitate the process, because the master will need to make a lot of effort.

If large-scale work is planned in the apartment, then you can drill the wall with a puncher. To make holes of an impressive diameter, it is worth taking a motor drill. Its power should start from 5 kW. There are no such household models, therefore, such a device cannot be powered by a single-phase network.

Perforator

The efficiency of this tool is quite high due to the chiseling option, but this equipment is more expensive than an impact drill. When thinking about how to drill a concrete wall, it is recommended to consider a hammer drill that uses the principle of rotation and reciprocating movements of the working part, which speeds up the task. It is better not to drill cellular concrete like this, because it is completely destroyed under such influence due to its fragility.

When there is a stucco finish on the surface of ordinary concrete, care must be taken when making holes so that the cladding does not crumble. In order to drill holes in concrete, in addition to the tool, you need to use special drills with a diameter of 4 to 8 cm. In order to eliminate unnecessary expenses, you need to select the diameter of the drill according to the corresponding parameter of the dowel.

Household drill VS screwdriver

Thinking about the question of how to drill a concrete wall in an apartment, you can choose a drill. The result and safety of the equipment depends on how correctly the drill is chosen. Recommended consumables with triangular tips. It is better if they are made of carbide metal. The drill may get stuck and no longer advance. In this case, you need to temporarily work with a punch.

When thinking about how to drill concrete with a screwdriver, you should take care not to disable the tool. More powerful technology may be the solution. But when the right equipment is not available, you can try to carry out the work with the tool that is at hand. In addition to it, a hammer and a punch are used.

The drill must be designed for metal work. But you should be prepared for the fact that after such manipulations it will no longer be suitable. When it is necessary to drill concrete without a hammer drill and only using a screwdriver, it is good if the equipment has an impact function. In addition to the model, you need to use equipment with a hard-alloy working part for bricks.

Diamond drilling

The most effective way to drill holes in a concrete wall is through diamond drilling.The peculiarity of these works is that you can move even at an angle. You can immediately start installing socket boxes or other devices. Very little dust is generated. The main disadvantage of such drilling is the sometimes prohibitive price of equipment and the impressive cost of the work itself.

How to make a large hole for a socket or pipe

When a mixer is changed, an electrical outlet is installed, or a new pipe is connected, it becomes necessary to make a neat large hole of the appropriate diameter. Now consider which drill to drill ceramic tiles.

There are two options:

- Carbide crown.

- Circular drill type ballerina.

Which is better: crown or ballerina

1. There are special diamond-coated cutting crowns. It is quite expensive, and it does not always make sense to purchase it. When working with this tool, do not forget to moisten it with water. Do not make the drill speed high - the crowns are afraid of overheating.

Varieties of crowns with diamond coating.

2. However, a cheaper option can be used for one-time work. This is a crown with teeth from Pobeda. Its disadvantage is that after 20 holes the crown can be safely thrown away - its resource will be exhausted. Crown diameters are up to 15 centimeters, which is enough even for a hole for a sewer pipe. But you need to work with a crown with teeth very carefully, without making sudden movements, while the edges of the hole will still be chipped and uneven.

Crown with victorious teeth for drilling in concrete.

3. Ballerina is a drill in the form of a spear or a cylinder, in which a bracket is fixed on the tail.In it, in turn, there is another spear-shaped drill. By moving it along the bracket, you can vary the diameter of the resulting hole. It is better if the middle center drill is not cylindrical - this is an unfortunate option, but hexagonal. The ballerina is inexpensive, no more than 300 rubles, so every home master can buy it.

And this is what the same ballerina looks like

We drill tiles according to the rules

Before drilling, the tile is marked out and, if necessary, a piece of paper tape or plaster is glued to the drilling site. In addition, to make it easier to start, you can cut a stencil from fiberboard or plywood, then pressing it firmly against the tile to start drilling. If you need to drill a tile that has not yet been glued to the wall, then it must be laid on a flat surface.

We start drilling at low speeds without pressing hard on the snap. Try to keep the crown itself parallel to the tile, so that when the drill sinks into the tile, it even starts to bite into the tile around the entire circumference. Sudden movements from side to side are not allowed.

The beginning of drilling with a crown and diamond coating.

If you have to work with a diamond crown, then you can quickly make a hole by working at high speeds. Only heating in this case, alas, cannot be avoided. And it is fraught with burning (burning) of the diamond grains on the coating, which degrades the quality of the tool. Therefore, if you want to work quickly, be sure to put water next to you to wet the tool. Or you can drill dry, but at low speeds.

However, if the crown does not have a diamond coating, it is better to use the “wet” drilling method. This is especially true for tiles covered with glass glaze.Yes, and for ordinary tiles, this option is preferable - and the drill lasts longer, and dust does not form. In addition, when moistening the tool with water, the hole can be made much faster.

After being drilled a little, we moisten with water.

We continue to drill, periodically wetting the surface of the tile with water.

After the hole is ready, you will have such a washer.

If you have to work as a ballerina, first set the desired diameter on it. The distance between the central and side drills is set two times less than the desired hole diameter. Then, in the intended place, we drill at low speeds. We hold the tile firmly so that flying fragments of drilling products do not injure anyone

Safety glasses are a necessary precaution. Hold the drill straight, do not tilt it

A tripod will not hurt to secure it.

As you can see, drilling ceramic tiles is not particularly difficult.

The main thing is not to rush, work carefully and carefully, using a special tool. And save water for wetting