- Do-it-yourself arrangement of autonomous sewage in a private house: videos and recommendations

- How much will it cost to build a sewer in a private house: turnkey price

- Tips for installing an autonomous sewer at their summer cottage

- What it is

- Self-installation of sewerage

- Methods for laying underground networks

- Design features and production standards

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- Independent sewerage device

- Purpose of underground observation chambers

- Mounting Features

- Well groups

- storage well

- Filtration Department

- manhole

- swivel well

- drop well

- Mounting sequence

- What workers will need tools and materials

- Where to go for sewerage

- Foundation preparation

Do-it-yourself arrangement of autonomous sewage in a private house: videos and recommendations

As a material for the manufacture of autonomous sewers, polypropylene is used, which is characterized by low weight, environmental friendliness, strength and high thermal conductivity.Wastewater treatment is carried out by certain types of bacteria that feed on organic waste. Access to oxygen is a prerequisite for the life of these microorganisms. The price of an autonomous sewage system in a private house is much higher than the cost of arranging a conventional septic tank.

The constituent elements of the autonomous sewage system

This is due to the numerous advantages of autonomous type systems:

- high level of wastewater treatment;

- unique aeration cleaning system;

- no maintenance costs;

- no need for additional acquisition of microorganisms;

- compact dimensions;

- no need to call a sewage truck;

- the possibility of installation at a high level of groundwater;

- lack of odors;

- long service life (up to 50 cm).

How much will it cost to build a sewer in a private house: turnkey price

The possibilities of autonomous sewers Unilos Astra 5 and Topas 5 are considered the most optimal for summer cottages. These designs are reliable, they are able to provide comfortable living and the necessary amenities for residents of a country house. These manufacturers offer other equally effective models.

The average price of autonomous sewers Topas:

| Name | price, rub. |

| Topas 4 | 77310 |

| Topas-S 5 | 80730 |

| Topas 5 | 89010 |

| Topas-S 8 | 98730 |

| Topas-S 9 | 103050 |

| Topas 8 | 107750 |

| Topas 15 | 165510 |

| Topaero 3 | 212300 |

| Topaero 6 | 341700 |

| Topaero 7 | 410300 |

The average price of autonomous sewers Unilos:

| Name | price, rub. |

| Astra 3 | 66300 |

| Astra 4 | 69700 |

| Astra 5 | 76670 |

| Astra 8 | 94350 |

| Astra 10 | 115950 |

| Scarab 3 | 190000 |

| Scarab 5 | 253000 |

| Scarab 8 | 308800 |

| Scarab 10 | 573000 |

| Scarab 30 | 771100 |

The tables show the standard cost of the system.The final price for the installation of an autonomous sewage system on a turnkey basis is formed taking into account the prices for laying an external pipeline and other points affecting earthworks and installation work in general.

The average price of autonomous tank type sewers:

| Name | price, rub. |

| Biotank 3 | 40000 |

| Biotank 4 | 48500 |

| Biotank 5 | 56000 |

| Biotank 6 | 62800 |

| Biotank 8 | 70150 |

Tips for installing an autonomous sewer at their summer cottage

As in any other system, it is recommended to install the pipeline at an angle from the house towards the purification tank. The optimal angle is between 2 and 5° per meter. If you do not adhere to this requirement, the full discharge of wastewater by an autonomous sewer for a summer residence will become impossible.

During the laying of the highway, care should be taken to securely fix its elements. To eliminate the risk of pipe deformation and displacement during soil subsidence, the soil at the bottom of the trenches must be carefully compacted. If you fill the bottom with concrete, you get a more reliable fixed base. During the installation of pipes, it is desirable to adhere to a straight path.

Be sure to check the joints for tightness. Liquid clay is usually used for docking. It is allowed to use specialized products recommended by the pipe manufacturer. If a line is being installed on the basis of elements with a diameter of 50 mm, the maximum allowable length of the straight sections of the system is 5 m. When using products with a diameter of 100 mm, this figure is 8 m maximum.

When choosing a place for a septic tank on the site, it must be taken into account that at least five meters must remain before the fence

What it is

Sewer trap in

apartment building is a kind of filter,

catching large debris and foreign objects. Its meaning is that

some careless residents of the upper floors have a habit of flushing into

sewerage various rags, napkins, paper towels, baby diapers, women's

gaskets and other items. All this garbage accumulates at the bottom

sewer riser, in the section of transition to a horizontal pipeline.

Drains stop passing, them

the level in the pipe rises and finally reaches the toilet bowl of the inhabitants of the lower floor.

They call plumbers, or try to break through the blockage on their own. Problem

is resolved for a while, but the perpetrators continue as if nothing had happened

throw garbage down the toilet. They often don't even know what the problems are.

who create their neighbors below.

In the end, the tired inhabitants of the lower floors begin to think about how to put a trap on the sewer in order to catch all the garbage and safely use the drainage system. The problem is that there are no special designs of this type on sale. Sometimes they try to solve the problem with a check valve, but it does not give the desired effect. At most, it will cut off the flow from below and protect the apartment from flooding with drains, but it will be impossible to use the sewer.

To protect against flooding by many

apartment owners install a homemade sewer trap. Most often, this is a network with

large cells, installed across the riser. There are simpler designs

two transverse bars that easily pass ordinary drains, but catch

hazardous objects that form blockages. According to the owner of the apartment, the garbage will be

stay in the pipe and blockage will no longer occur. However, the problem remains

only it is shifted onto the shoulders of the residents of the second floor (or apartments on the floor

above). Garbage will quickly clog the passage of drains, and the toilet will flow in the apartment

upstairs. At the same time, the owner who set the trap will also get it, since

drains will seep through the ceiling and flood his bathroom.

Self-installation of sewerage

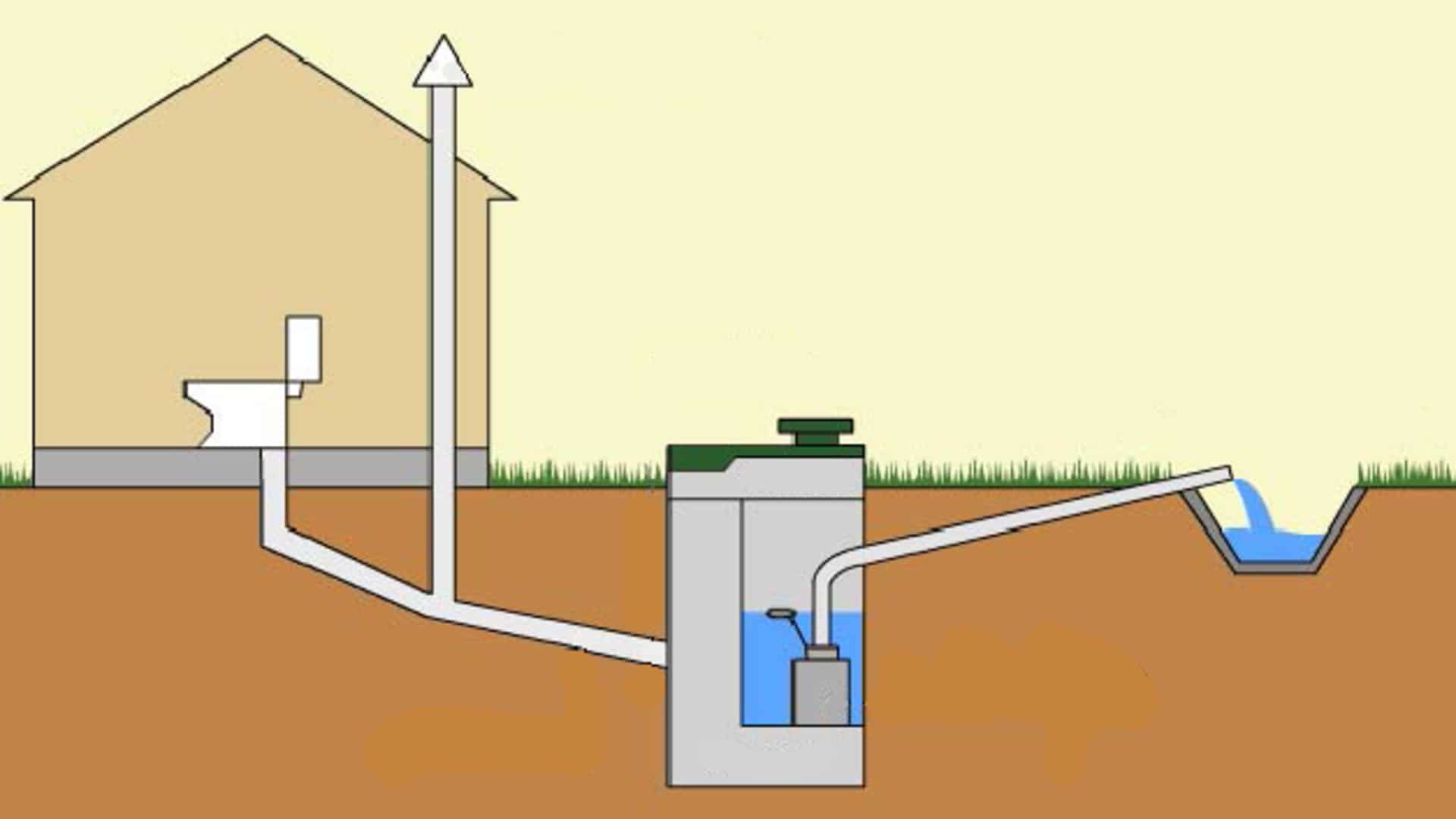

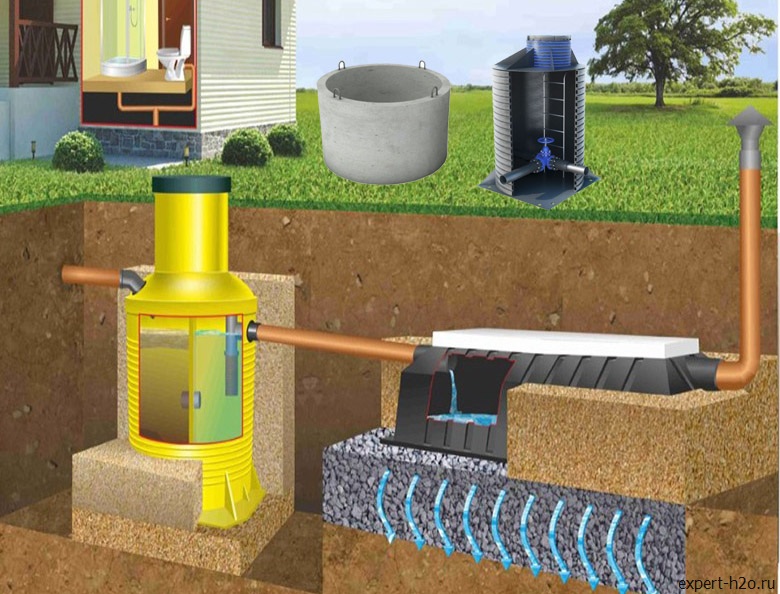

What is needed to make an autonomous sewage system in a private house? The first step is to prepare a detailed drawing of the project. It will contain both internal and external piping.

The internal highway includes:

- risers;

- sewer line;

- connection points for plumbing fixtures.

For the installation of an outdoor system, a pipeline is required. He will be responsible for the rapid withdrawal of waste liquids. The thickness of the pipe is selected in accordance with the diameter of the collector structure.

When the internal wiring of the water supply is completed, it is necessary to install the central riser. For quick removal of gases outside the premises, it is recommended to install a riser parallel to the roof level.

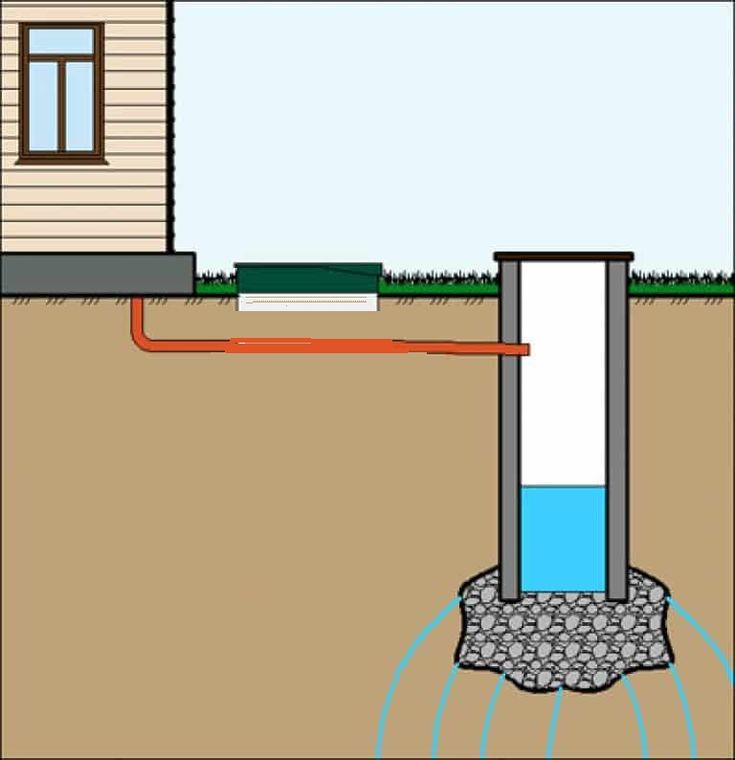

After that, proceed to the installation of the septic tank. It should be located at a distance of 3-6 m from the building. To do this, they dig a deep hole, the height of which is from 3-7 m. Next, a concrete septic tank is installed. In the side part, a hole is made for laying the main pipe.

Now we begin to connect the external pipeline. After that, we test the design. When the whole system works in the right direction, the pipes are buried.The photo of the sewerage in a private house captures the entire working process.

Methods for laying underground networks

Collectors, tunnels and canals are used to pull underground utilities in civil engineering, ditches dug in the soil are used to lay pipelines in households. If digging trenches in an open way is not possible, produce trenchless pipe laying by drilling, piercing or punching the soil with hydraulic jacks. Abroad (in Germany), an effective method of laying pipes is widely used using special equipment that cuts a trench and simultaneously immerses a polymer pipeline into it.

According to the method of arranging communications in trenches, consider:

Separate method. During installation, each highway is mounted in its own channel, the method is costly when laying a large number of adjacent communications.

joint method. According to SNiP 2.07.01-89, in common trenches it is allowed to lay heat mains from 50 to 90 cm in size, water supply up to 50 cm, more than 10 communication lines or power cables with voltage up to 10,000 volts, if there is not enough space for pulling lines in separate trenches plot.

It is allowed to lay water pipelines in tunnels with other communications (SNiP 2.04.02-84), except for pipelines with a portable combustible and flammable medium.

When laying pipe fittings in the ground, it is placed in technical wells.

If wells or wells are used on the site, from which an underground pipeline is laid to transport water to the house, the minimum depth of the water supply is taken equal to the lower freezing point of the soil in this area with the addition of 0.5 m.A layer of soil on top to avoid unwanted heating of water in pipes in summer is left at least 50 cm.

Rice. 3 Pulling underground utilities by a German pipelayer

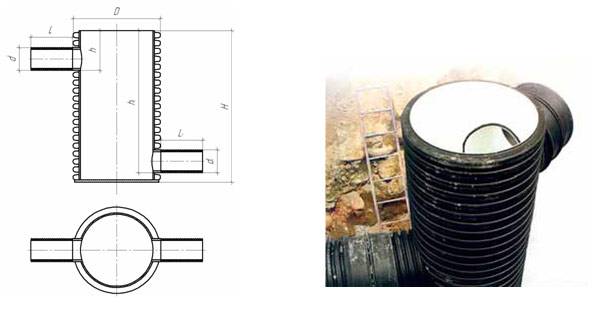

Design features and production standards

Regardless of the type of material used, the design of sewage wells is the same. The structure is a cylindrical shaft deepened into the ground, at the bottom of which there is a kinet - a tray for two or three pipes with sewage.

One of the prerequisites for the use and arrangement of plastic wells for sewage is to ensure the free movement of water

To regulate the length of the structure allows the use of extension cords and retractable shafts. To gain the required length of the structure, they are joined together, creating a strong and tight connection.

Often, sliding extension models are also used to build up the structure. Acting as connecting elements, in parallel with this they also serve as a continuation of the wall of the structure.

Depending on the operating conditions, sewer pipes can have different shapes, bends and be equipped with various branches.

The upper part of the well is equipped with an overlap with a hatch. When installing plastic wells, it is quite logical to choose hatches made of polymers, due to which it is possible to ensure equally long durability of the entire structure.

The dimensions of the plastic models correspond to the dimensions of the cast-iron counterparts. When choosing a hatch, they are guided by its functionality.

Depending on the degree of withstand load, all types of sewer manholes are divided into 4 categories:

- The "A15" standard applies to green areas and walkways.It can withstand up to one and a half tons.

- "B125" is installed on sidewalks and in park areas and parking lots, where the load weight does not exceed 12.5 tons.

- "S250" is used in the construction of sewers, the laying of which is carried out under city roads. Products withstand loads up to 25 tons.

- "D400" the most durable structures, capable of withstanding up to 40 tons, are designed for highways.

Hatches of the A15 standard can be installed directly on the well shaft, and their analogues of the B125, C250 and D400 categories can be installed on the unloading ring or a retractable telescopic pipe.

The manhole cover prevents large construction debris and other foreign objects from entering the mine, making the operation of the facility safer.

The neck is a transitional element between the shaft and the hatch. Its main purpose is to accept and compensate loads from the outside that can damage the mine and the pipes leading to it. For this reason, it is a corrugated or telescopic design.

The telescopic part of the shaft can be extended, taking the most convenient position for inspecting the condition of the wall surface and providing access during repair work. The relief ring is threaded at both ends, making the connection as tight as possible.

Holes are provided in the walls of the structure for supplying the inlet and outlet pipes.

To prevent seepage of groundwater into the cavity of the mine or seepage of sewage from it, the walls of the well are sealed

Depending on the size of the structure, wells are of two types:

- Diameter up to 1 m with unattended shaft.Compact inspection structures are installed when arranging at a shallow depth.

- With a diameter of more than 1 m. The design allows you to easily maintain the equipment and, if necessary, repair the structure.

The well itself is made of the same material that is used in the production of ordinary sewer pipes. It can be structured or two-layer polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP).

Polymers created using modern technologies are chemically resistant materials, and therefore do not pose a danger to the environment.

No less popular are models made of corrugated plastic. This solution simplifies the task of adjusting the height of the tank and allows you to partially compensate for the load on the bottom, thereby significantly extending the service life of the structure.

Both manhole options are available with single or double walls. To resist the compression of the soil from the outside, the products are equipped with stiffeners.

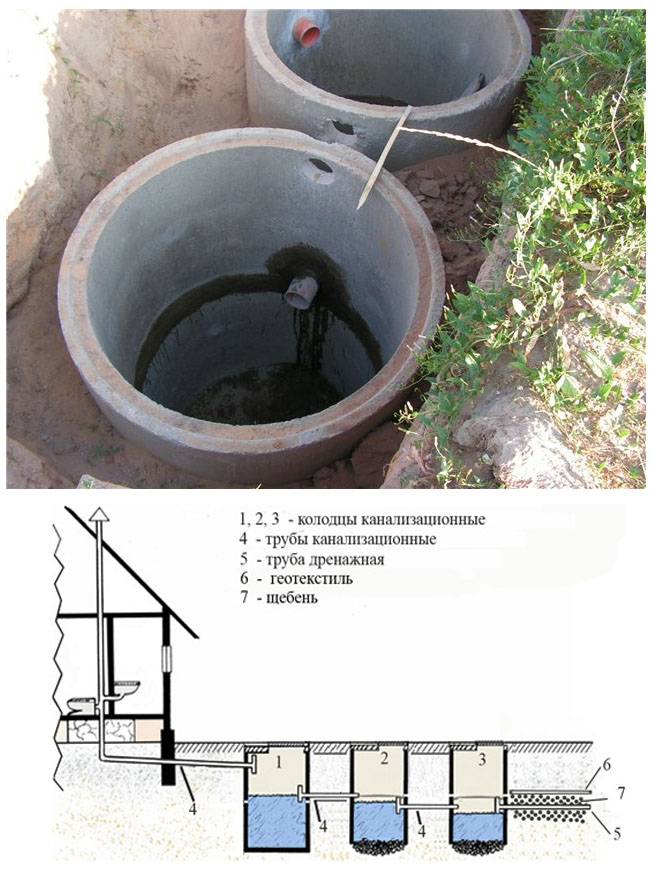

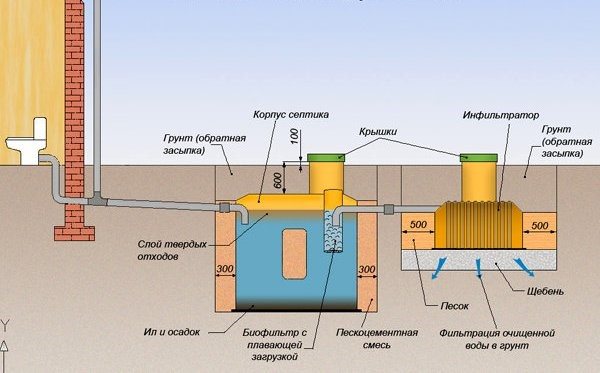

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction).It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix.To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work.Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

Independent sewerage device

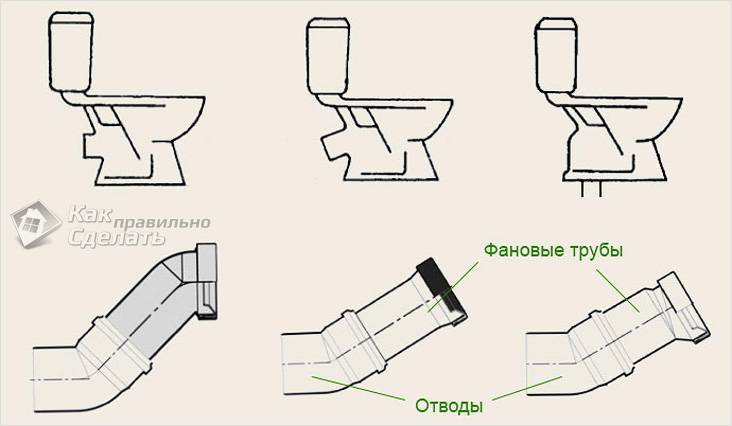

For the internal system you need:

- pipeline

- riser and fan pipe

- revisions

- locking elements

- outlet (connection to an external system).

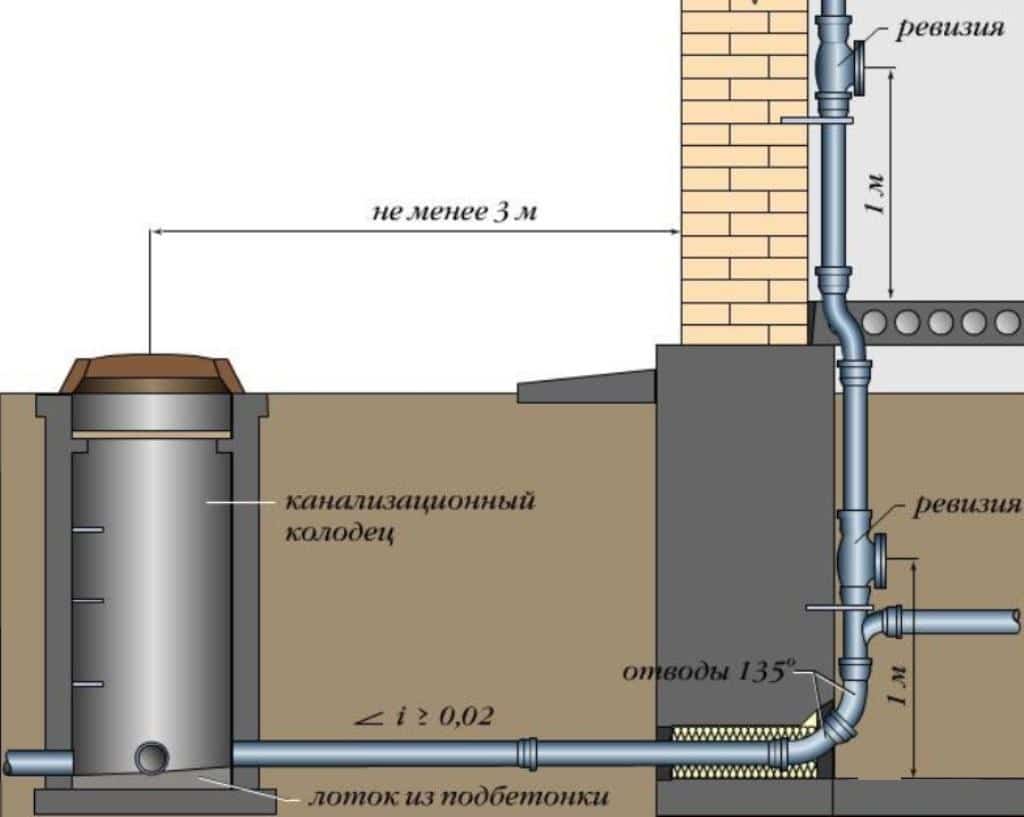

The first step is piping from each appliance to the riser. The diameter of the pipe at the bath, shower, sinks and sinks is 50 mm, at the toilet bowl - 100 mm. All plumbing fixtures have knees that prevent unpleasant “aromas” from the sewer from entering the premises. When installing and fixing the pipeline, it is necessary to take into account the slope (approximately 3 mm per meter). The riser is displayed above the ridge and covered with a grate. The opening for the outlet to the external pipeline should not be less than 30×30 cm.

The outer part of the sewer consists of:

- pipeline

- wells

- storage tank or septic tank.

A pipeline located above the freezing level is best installed from cast iron. The use of plastic materials is allowed when buried below the freezing level. In a system without a pump, the pipeline is laid with a slope

It is important that the sump or septic tank is located no closer than 5 m from a residential building and 20 m (at least) from a drinking water well. In addition, it is necessary to provide free access for the sewer truck

The size of the pit for the septic tank should be larger than the capacity (so that you can create a concrete pad at the bottom). In this case, the neck of the container at the end of the work should be located slightly above the ground level. The spaces between the septic tank and the walls of the pit are filled with a cement-sand mixture and compacted. After connecting the pipes to the septic tank and checking the tightness and functionality, all trenches are filled up.

It is more convenient to install a system for collecting melted and storm water separately. This will allow not to increase the volume of the septic tank. In addition, melt and rain water is much cleaner than domestic wastewater, so it can be used for technical needs (for example, irrigation).

First you need to make markings on the surface and dig trenches for outlets and pipes (taking into account the slope), as well as holes for storm water inlets. The trenches for the outlets are concreted, a sand cushion 10 cm thick is arranged at the bottom of the trenches for the pipes. Water collectors must be equipped with funnels that are closed with nets. All elements of the storm system are connected.

The cost of connecting the sewerage system of a private house to the public network depends on the cost of processing all the necessary documents, the amount of materials and their type, the cost of the installation contractor. Depending on the region, the total amount varies between 50-150 thousand rubles. The cost of an autonomous system can range from 500 thousand to 1.5 million rubles. To save money, you can build one system for several houses.

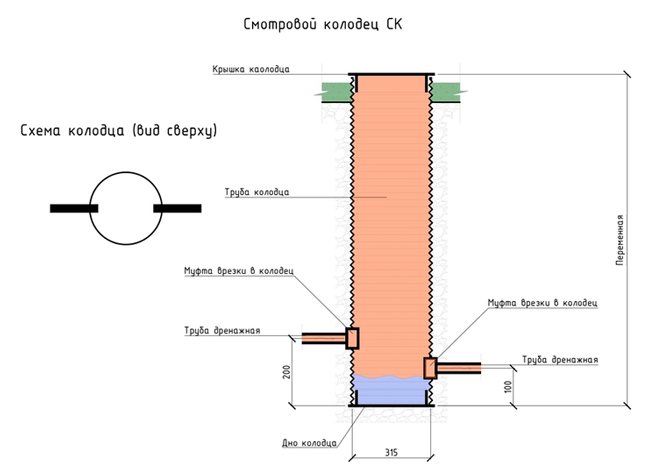

Purpose of underground observation chambers

If a breakdown occurs, it is eliminated through the inspection chamber. In the absence of such structures, it is necessary to dig out pipelines and carry out repairs.

Inspection cameras are installed in the most difficult places where blockages are most likely to occur. If the highway is located in a straight line, its length is up to 10 m, there is no need for such a design. It occurs with a large length of communications, the presence of intersections, nodes, level differences.

The device of sewerage control points is regulated by building codes. They consider the rules for the construction of manholes, the selection of sizes. The standards simplify installation work, allow you to create a single inextricable network of underground pipelines.

It's interesting: All about urban sewerage system - learn in detail

Mounting Features

Sewer rings are installed on the bottom slab, which acts as a slab foundation. The prefabricated reinforced concrete structure must have a stable and reliable foundation. Here, preparation of the bottom of the pit is also needed: leveling, tamping, backfilling with a layer of sand and gravel.

During installation, it is obligatory to seal the joints with cement mortar, followed by the treatment of the entire surface with waterproofing compounds.

The recommended height of wells is no more than three rings. If you make it higher, then the design will be "weaker".

The stage of installation of sewerage in a private house of concrete rings

The inlet to the first well is mounted at least 30 cm from the cover. And the overflow holes are made with a slight decrease. This leads to a decrease in the "working" volume of the septic tank, which must be taken into account when choosing the size of the rings.

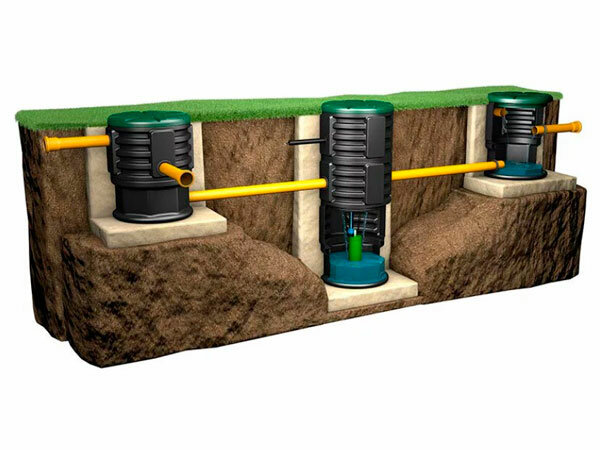

Well groups

Sewerage wells can be divided into several groups. They determine their design and features.

Everything can be easily made by hand. Here you have to make your own choice.

When building a private house, you have to deal with a lot of subtleties and nuances. One important point is the construction of a sewer well.

In order to have an idea about this system, there is a small explanation. Properly conducted sewage will work for a long time and will not cause trouble if it is cleaned in a timely manner.

There are several types.

storage well

This design is the largest in this series:

Scheme of installation of a storage well

- All slag from the house goes through pipes to this part of the sewer system.

- Dimensions are calculated based on the number of people living in the house, as well as the volume of water consumed. It is intended for separation into more liquid and dense fractions of the entire contents. In this case, the liquid part passes into the filter section, and the dense part settles to the bottom of the well.

Of course, you can use an analogue - a plastic septic tank, which is quite easy to install, has a lighter weight and can be installed without special skills. To avoid an unpleasant odor from leaks, tightness must be observed, which means that cracks and gaps must be eliminated.

Filtration Department

Designed to remove water that enters the soil from the liquid mass:

- The volume of this department is smaller than the cumulative one.Both wells do not require frequent cleaning, since the filtration of drains through the bottom (natural filtration) utilizes the liquid part.

Accordingly, it is economically beneficial, since the cost of using sewerage is reduced; - Rings (see Rings for a well: types and functional features) of the filter section are usually also made of reinforced concrete. However, the difference from the accumulative one is the smaller diameter of the rings and the absence of a bottom.

The filtering function is performed by coarse sand or crushed stone.

manhole

The name itself speaks of the purpose. With it, you can determine the need for cleaning:

- Installation is usually done at intervals of 15 meters;

- The peculiarity lies in the location of the first structure. It should be installed near the house, but not less than 3 and not more than 12 meters from it;

- Also, a check valve is installed in the first tank, which prevents the return flow of wastewater in case of blockage. If a lot of waste has accumulated, then cleaning is carried out through these wells;

- It is necessary to monitor the condition of the sewer system regularly to avoid clogging, which will be more difficult to eliminate.

Similar viewing rings can be made of reinforced concrete and plastic. As for the latter, they have found application by mounting them into the ground and thus connecting other parts of the sewer pipeline.

Sometimes pipes of larger diameter, adapted by craftsmen, perform their assigned functions perfectly.

swivel well

It is installed in the absence of a straight sewer pipeline in the places of branches.

Rotary well installation

So:

- It can be used to clean the pipe section, but the direct purpose is still to carry out a branch to the storage septic tank. The material for the manufacture of rings can also be plastic, reinforced concrete, or the use of a finished version;

- Installation is done in places where the direction of the route changes;

- The main purpose is the erosion of precipitation. They are formed as a result of a small movement of wastewater. This is quite relevant in the private sector;

- The form for manufacturing can be used both round and rectangular. Recently, polymers have become increasingly popular.

drop well

If a straight sewer pipeline with the required angle of inclination is not possible, a drop structure is used:

Diagram of a differential well

- It is intended for uneven terrain and its essence lies in the fact that the inlet pipe is placed much higher than the outlet;

- The main element - the descent - serves as a connection between the upper part (inlet pipe) and the lower outlet, which is located at an angle of 45 degrees to the vertical descent;

- Fastening to the well wall occurs by attaching with clamps. It can serve as a turning and viewing analogue and can be cleaned.

This is due to a temporarily closed tee, which is attached to the inlet pipe.

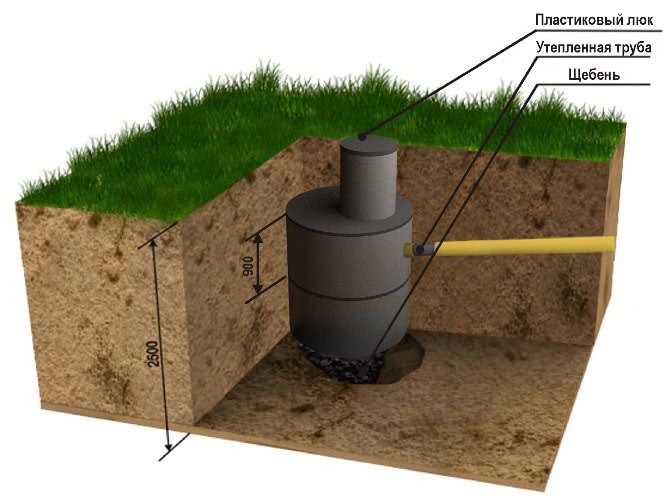

Mounting sequence

How is the installation of a drainage well:

- Pouring the concrete bottom of the well, if its tightness is required.

- Installation of a composite or solid well.

- Laying and insertion of inlet and outlet pipes.

- Arrangement of such details as a ladder, cover, hatch, pump.

- Using a level, check the vertical of the well and the horizontal slopes of the pipes.

What workers will need tools and materials

The main responsible and time-consuming work during the installation of a drainage well is making a tie-in and its subsequent sealing. In addition, it is required to dig holes and trenches, adjust pipes along the length, bring their slope to gravity, adjust the depth and height of the well.

Pipe trenches and a hole for a well can also be dug manually, but this is unlikely to be cheaper than calling an excavator

To seal the tie-ins and level the bottom, giving it the shape of pipe trays, use a cement mortar, or, if they are dealing with plastic, use glue, plaster or tape, sealant.

Where to go for sewerage

First you need to contact the local administration, from there you will have to go to the geodetic service (order a situational plan for the site), to the water utility and SES. An application is submitted to the water utility in order to obtain technical connection conditions. You need to have a copy of your passport and a document confirming the ownership of the house and land. If the pipeline has to be laid under the carriageway, a permit from the road authority will be required.

After the technical conditions are received, you can order a sewerage project. If it is created by third-party specialists, the finished document still needs to be approved by the water utility and companies whose communications take place near the house (gas service, RES, telephone service). The final approval takes place in the department of architecture of the local municipality.

For installation, you can also hire a contractor who has the appropriate approvals. But in any case, a tie-in to the general network is made by a specialist from a company servicing the municipal sewer system.

Foundation preparation

In order to properly mount the sewer shaft and connect it to the pipe system, special attention must be paid to arranging the bottom of the pit. As a rule, reinforced concrete wells are used to assemble sewage treatment plants.

Unlike plastic and other materials, they are more durable because they are not afraid of temperature changes and moisture. However, in the case of their installation, additional waterproofing will be required, which we will discuss in more detail, but a little later.

So, the device of a storage type well involves the following finishing of the bottom of the pit:

- A layer of 15-20 cm is covered with fine gravel or gravel;

- After that, the mineral pillow is poured with concrete mortar;

- In order for the water to leave the system by gravity, you need to make a slight slope of the bottom towards the outlet pipe.