- Using a manual profile bender

- How to bend rebar, sheet metal, etc. without a special tool

- How to bend a sheet of metal, galvanizing, profile

- Why do you need to know the characteristics of the profile?

- Varieties of bending. We use a pipe bender

- Spring for bending

- Alternative ways to bend profile pipes

- Method #1 - grinder + welding machine

- Method # 2 - blank and sand

- Method #3 - Bending a Pipe with a Square Spring

- Arch (canopy) without pipe bender

- Pipe bending features

- Varieties of domestic products

- Pipe benders for profile and round products

- Manual devices

- Mechanical apparatus

- Features of different methods of profile bending

- Simple ways to bend pipes

- Profile

- Stainless or steel

- Copper and aluminum

- metal-plastic

- Polypropylene

- Tips

- About the intricacies of the hot method

- About the intricacies of the cold method

- What is the problem of profile bending

- What is the complexity of profile bending

- Drawing conclusions

Using a manual profile bender

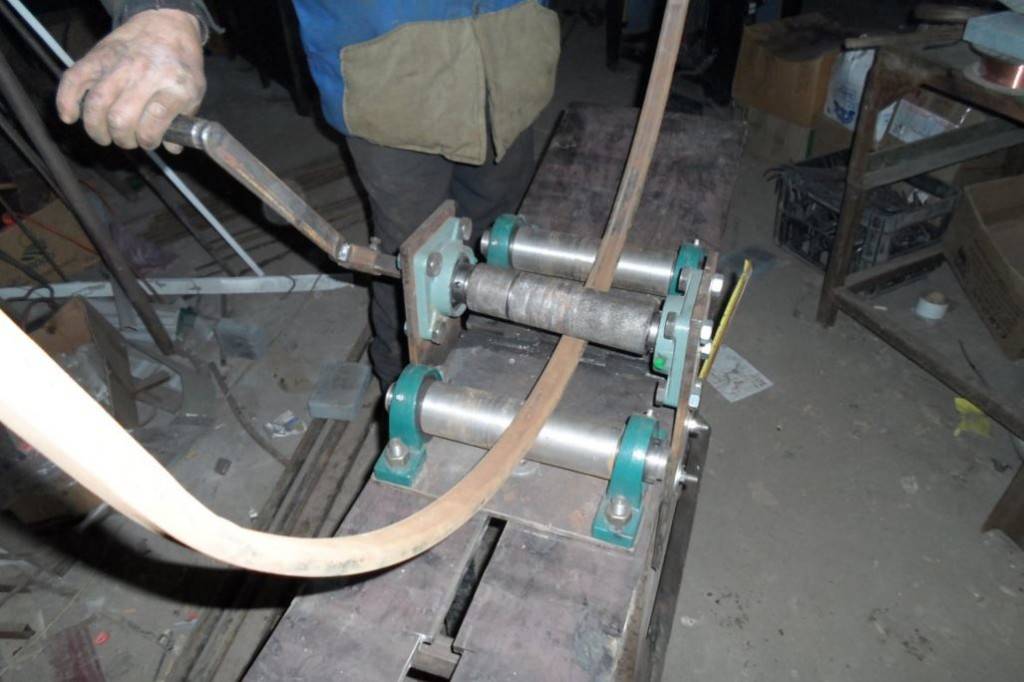

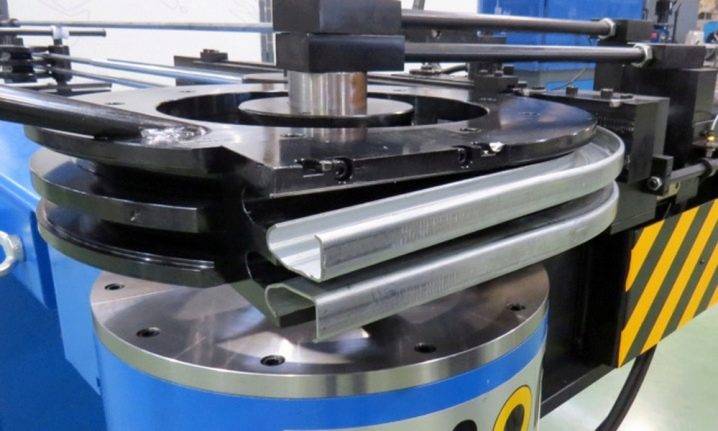

Significant amounts of deformation work require mechanization. Mass production of curved parts will take too much health from the performer. To facilitate bending, it is advisable to make a machine according to a drawing. They are mainly used for work with large-sized workpieces.The main working bodies of the manual unit are three rolls, two of which are fixed. Changing the position of the third movable roll determines the angle of bending.

If the methods described above are not acceptable, then the future owner of the greenhouse has two options - renting a manual installation or ordering the manufacture of rounded parts. The process of deformation of the workpiece was demonstrated by the video: it is up to the performer to decide how easier it is to bend the profile pipe - by repeated rolling or physical impact.

When working manually, it is important to follow the rules for bending profile pipes and not to make sudden movements. It is necessary to monitor the uniformity of deformation on the outer and inner sides of the rolled product.

However, you should not be too upset about small wrinkles on the inside of the fold: they can be corrected with hammer blows. Before starting work, it is necessary to make templates from wire, chipboard or drywall for verification and obtaining a result corresponding to the project.

How to bend rebar, sheet metal, etc. without a special tool

If you have already started a major overhaul with your own hands, regardless of where it is carried out: at home or in an apartment, then you need to be prepared for many tests.

In particular, a number of issues may arise that are very difficult to solve without proper experience and special equipment. For example, not everyone knows how to bend a sheet of metal, rebar, profile, corner, etc. while getting good results. In this article, we will try to answer the "inflexible" questions, while getting by with a minimum amount of tools.

How to bend a sheet of metal, galvanizing, profile

Very often, when mounting metal structures, it is necessary not only to cut steel sheets, but also to give them a curved shape.

You can do this at home without spending money on third-party services. For example, how to bend a sheet of metal? To do this, we need a wooden or rubber hammer, tongs, a table.

If a 90 degree curvature is expected, then this set of tools should be enough. The sheet simply hangs from the edge of the table, after which the desired curvature is achieved by uniform tapping in the bend area.

Why do you need to know the characteristics of the profile?

Profile pipe rolling differs from the standard round version in the cross-sectional shape, which can be square, oval, rectangular or flat-oval. According to the GOST R regulation No. 54157-2010, a round product is also included in the list of profile products. However, in greenhouse construction, products with a square and rectangular section are most often used, for example, profile pipes 40x20 mm, because it is easier to attach a coating to their even flat walls.

For a variety of national economic needs, products are produced in a wide range of sizes. It differs in configuration and cross-sectional area and, of course, in wall thickness. The set of dimensions determines the plastic possibilities. In professional language, they are called the minimum permissible radius of curvature. So, before you learn how to make a blank for the frame, you need to find out what is the smallest radius of flat rounded deformation that the blank can “survive” without damage.

To determine the minimum allowable bend radius of a square or rectangular profile, we need the height h, because:

- products with a profile height of up to 20 mm will bend without going into the category of unusable marriage if bending is carried out in a section with a length of 2.5 × h or more;

- pipe with a profile height of more than 20 mm without loss will withstand deformation in a section with a length of 3.5 × h or more.

The indicated limits are necessary for those who are planning to make shelving, shelves and frames for vents or doors. The wall thickness also introduces its own adjustments to the limitation area. Wide pipes with thin walls up to 2 mm thick are generally not recommended for bending. It is better to use welding.

Home craftsmen who decide to make arcs for an arched greenhouse need to take into account that household products made of ordinary carbon or low-alloy steel alloys, after applying effort to them, tend to “spring” slightly. They seem to be trying to return to their previous state. Therefore, after the novice locksmith completes the bending of all the arcs with his own hands, he will have to repeat the processing and re-fit the arches according to the template. It is desirable to initially take into account the value of the plastic modulus Wp. It is usually indicated in the documents of the building material being sold. The smaller the moment, the less fuss there will be with the fit.

Varieties of bending. We use a pipe bender

There are few options - either bend a profile pipe without a pipe bender, or use a machine of our own or factory production.

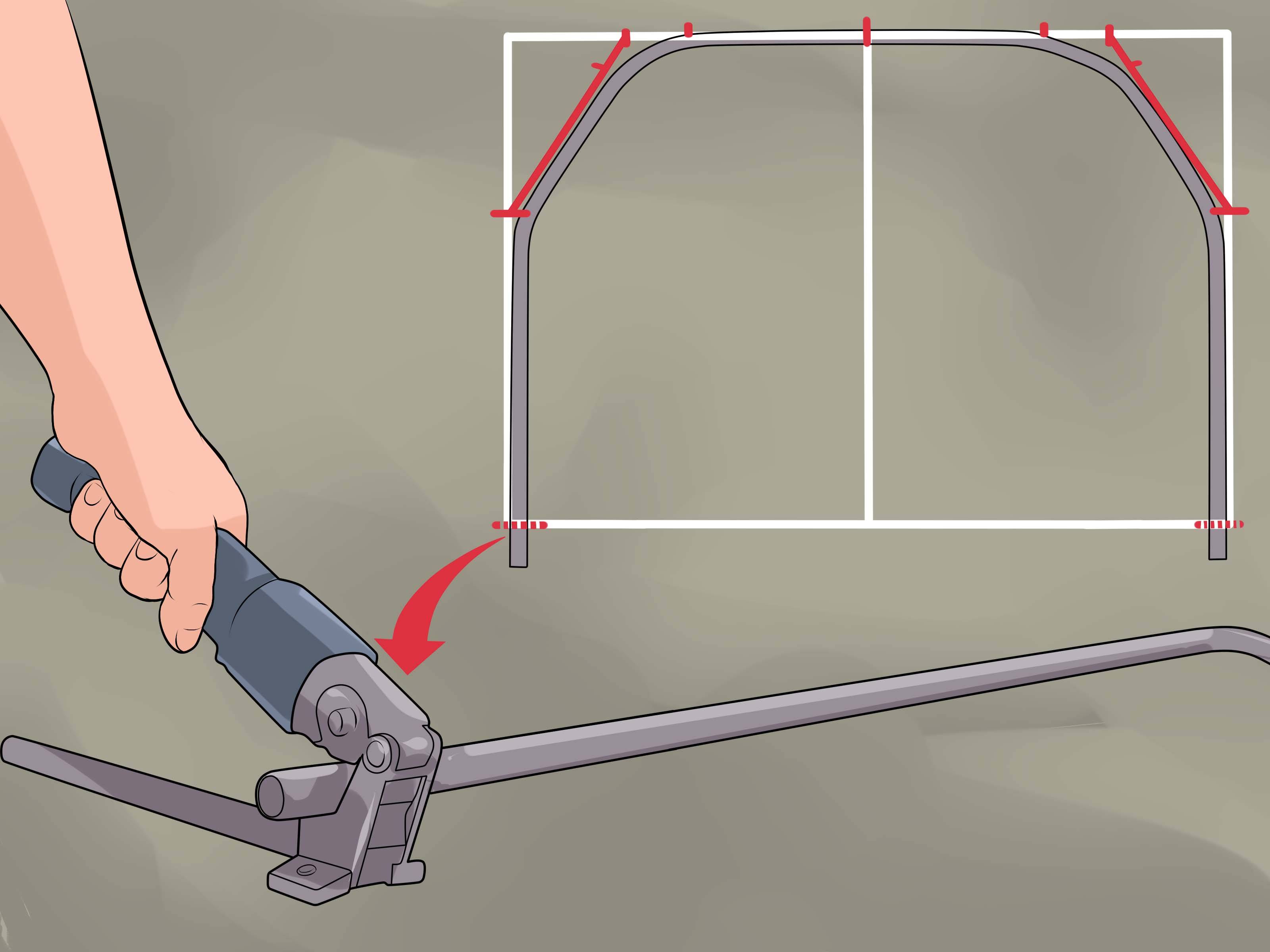

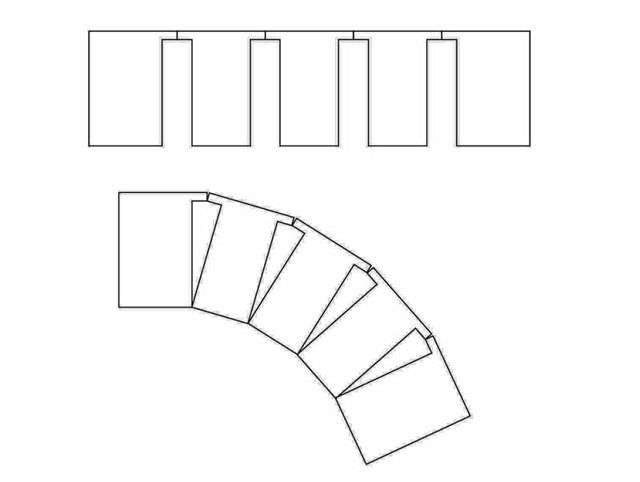

A general view of a manual pipe bender is shown in the figure. Recall that the corresponding devices are also produced with an electric, hydraulic drive, and even with numerical control.

Compact machine for bending hollow profiles

How to bend a profile pipe on a pipe bender is always indicated in the manufacturer's instructions.The trick is different: this technique pays for itself only with very frequent use. Therefore, we turn to more real problems.

Spring for bending

All masters know about this method. Its essence is as follows: a special square-section spring made of steel wire is placed inside the pipe in the place where it is necessary to obtain a bend. The spring will serve as a mandrel, its cross section should be 1-2 mm less than the internal section. Using a blowtorch, the place of further bending is heated, applied to a blank with a suitable bending radius and, using force, is not sharply pressed until the desired curvature is obtained. This method is quite simple, but when using it during work, it is recommended to carefully observe safety precautions: work in special gloves and use pliers.

Alternative ways to bend profile pipes

Method #1 - grinder + welding machine

How to bend a profile pipe at the right angle with your own hands without using factory machines? If you have a grinder and a welding machine, then you can bend according to the following algorithm:

-

- calculate the radius of curvature according to a previously drawn scheme;

- in the place of the intended bend of the pipe with a circular saw (grinder), several transverse cuts are made;

- holding the pipe in a vice, they begin to bend it in the right direction, applying a little physical effort for this;

- then the cuts are welded with a welding machine, not forgetting to comply with safety requirements;

welding seams are polished.

A circular saw or grinder, mounted on a special sole, is necessary to make several cuts at the bend of the profile pipe

Method # 2 - blank and sand

You can bend the profile pipe along the required radius using another simple method. For this, sand is prepared, which must be sieved and dried, if necessary. Then one end of the profile pipe is closed by hammering a wooden wedge into it. Sifted sand is poured into the profile, clogging the entrance to the pipe on the other side. After that, the product begins to be bent around a metal blank having a suitable diameter. One end of the profile is fixed securely between the pins, and the other is pulled.

Having finished the bending process, they begin to remove the clogged wedges by burning them out or knocking them out. Sand is also completely removed from the pipe cavity. As you can see, artisanal methods are more troublesome, so they can be put into practice for one-time bending of pipes.

In winter, sand can be replaced with water, which is poured into a profile pipe and the product is exposed to frost. It is clear that the ends of the profile are plugged with plugs. After freezing of the liquid in the pipe, they begin to bend it according to a pre-prepared blank-template.

A metal blank used by craftsmen for bending shaped pipes with their own hands without the use of special equipment in the form of pipe benders

Method #3 - Bending a Pipe with a Square Spring

The spring, which has a section of the same shape, but smaller, does not allow the walls of the profile pipe to deform when bent. The spring is made of steel wire, the diameter of which is selected based on the wall thickness.The spring should easily go inside the pipe. The planned bending point is heated with a blowtorch or gas burner. The heated profile walls are easier to bend. To prevent burns, it is necessary to work in special protective gloves, and hold the product with ticks. A blank or metal pins hammered into the ground around the circumference helps to achieve the desired bending radius.

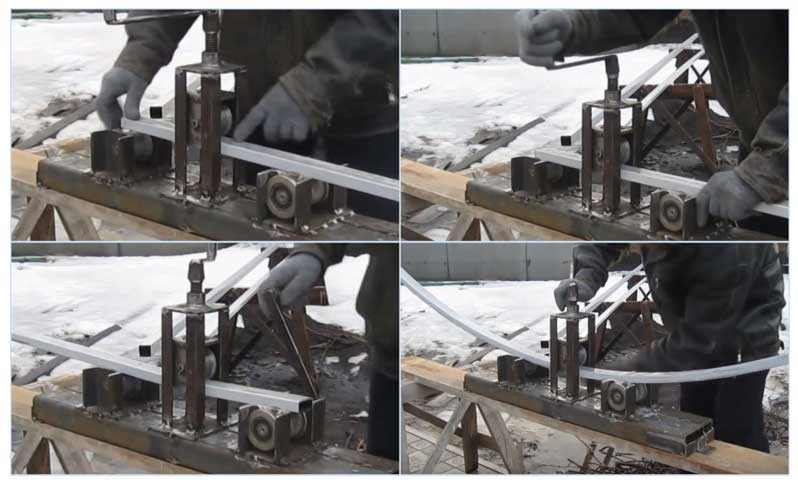

Arch (canopy) without pipe bender

As you know, for a canopy, for example, in the form of an arch, you need a curved profile pipe

It is important to make sure that the arcs are equally curved, otherwise the canopy will not work. Now we will look at how to do this without using a machine, a pipe bender and other auxiliary tools of this kind.

We will need:

The support on which we will work, for example, a metal table;

As a beam, you can take a pipe 80 by 60 or 50 by 50 mm 3 meters long

But this method is universal - so what kind of support beam you end up with is not important;

Profile pipe 20 by 20 or 20 by 40 mm, which we will bend .. Procedure (step by step instructions):

Procedure (step by step instructions):

We divide the support into 6 equal parts

It is very important here - exactly into 6 parts, no matter how long it is;

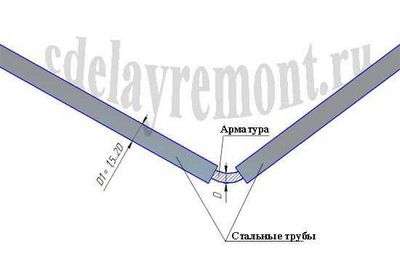

On the dividing lines, it is necessary to weld the racks strictly at 90 degrees to the beam. The middle stand is 250 mm, the closest to the middle stand is 250 mm * 0.8888 = 222.22 mm, and the extreme (smallest stand) is 250 mm * 0.5556 = 138.9 mm;

- We fix the beam itself to a metal table;

- We take the pipe that we will bend, put it on the racks and move it relative to the beam with an allowance of 10-15 cm, so that there is a lever for which we could take it and bend it around the racks;,

-

We tie it to the beam with a rope (fix it);

profile pipe on the racks and tied it with a rope to the beam. Next, carefully bend the pipe around the racks and weld it to the ends of the beam with a welding machine.

we get a bent pipe for a canopy

- Then you make the required number of such structures (arcs), use polycarbonate sheets and your arched canopy is ready!

Pipe bending features

All methods of bending workpieces can be divided into manual and mechanical, as well as hot and cold. Sometimes the bending process is accompanied by undesirable consequences for the tubular product, which have a significant impact on the subsequent operation of the element. The degree of manifestation of these consequences depends on the material from which the pipe is made, its diameter, bending radius, as well as the method by which the bending procedure was performed.

The negative consequences of bending include the following points:

- Reducing the wall thickness of the workpiece located along the outer radius of the bend.

- The formation of creases and folds on the wall, which is located along the inner radius of the bend.

- Changing the configuration of the section (reducing the size of the lumen and its shape - ovalization).

- Change in the bending radius due to the spring effect of the material.

The most common drawback of bending is a change in the configuration of the section and wall thickness. Due to the stresses of the metal, the outer wall becomes thinner at the bend, while the inner wall, on the contrary, thickens. This results in a noticeable weakening of the tubular element. This phenomenon is dangerous by rupture of the outer wall of the pipe, since it is it that is subjected to greater pressure of the transported medium.

Ovalization also significantly weakens the workpiece.This phenomenon is especially dangerous when bending a pipeline designed to transport a substance under conditions of a pulsating load. If such elements are used as building structures, then ovalization will affect the appearance of the element. That is why in the process of bending, they strive to minimize such phenomena as much as possible.

If folds form on the inner wall due to thickening of the material, then they will entail not only a decrease in the cross section, but will also create resistance to the moving flow. This in turn increases the likelihood of corrosion. In addition, the bearing capacity of the structural tubular element will decrease.

Varieties of domestic products

Bending a profile pipe is an operation that depends on the material of the rolled product, the dimensions of its cross section, the length of the workpiece and the bending radius. In the domestic pipe-rolling industry, the most popular are square and rectangular sections (see Fig.). Oval ones are much less common, noticeably lose in price, and they have no practical advantages.

We list the relevant standards:

- GOST 8645-68. Applies to steel products of rectangular cross section. Size range, mm - from 15×10 to 180×150, with wall thickness from 1 to 7 mm. Length - a multiple of 1250 mm, and up to 6000 mm;

- GOST 8639-82. Refers to steel pipe rolling of square sections. Dimensional range, mm – from 10×10 to 180×180 mm. Wall thickness, mm - from 0.8 to 14.0 mm. The length is a multiple of 1250 mm, with a maximum size of 6000 mm;

- GOST 32931-2015.Designed for the production of metal structures, which, in addition to the actual round profiles, also includes rolled products of rectangular, square, oval and flat-oval cross sections. Length - from 3.5 to 12.5 m.

It is on the last GOST, as the most detailed, that users should be guided.

Assortment of non-circular cross-section

Sometimes you have to face the need to bend a profile pipe made of non-ferrous metal or alloy, such as aluminum or copper. But these materials are known to be more ductile than steel, so the recommendations below are also valid for blanks of this type.

Pipe benders for profile and round products

Pipe benders for steel and copper pipes are:

- manual,

- mechanical.

Moreover, belonging to a manual or mechanical type determines both the design features of the pipe bender and its performance.

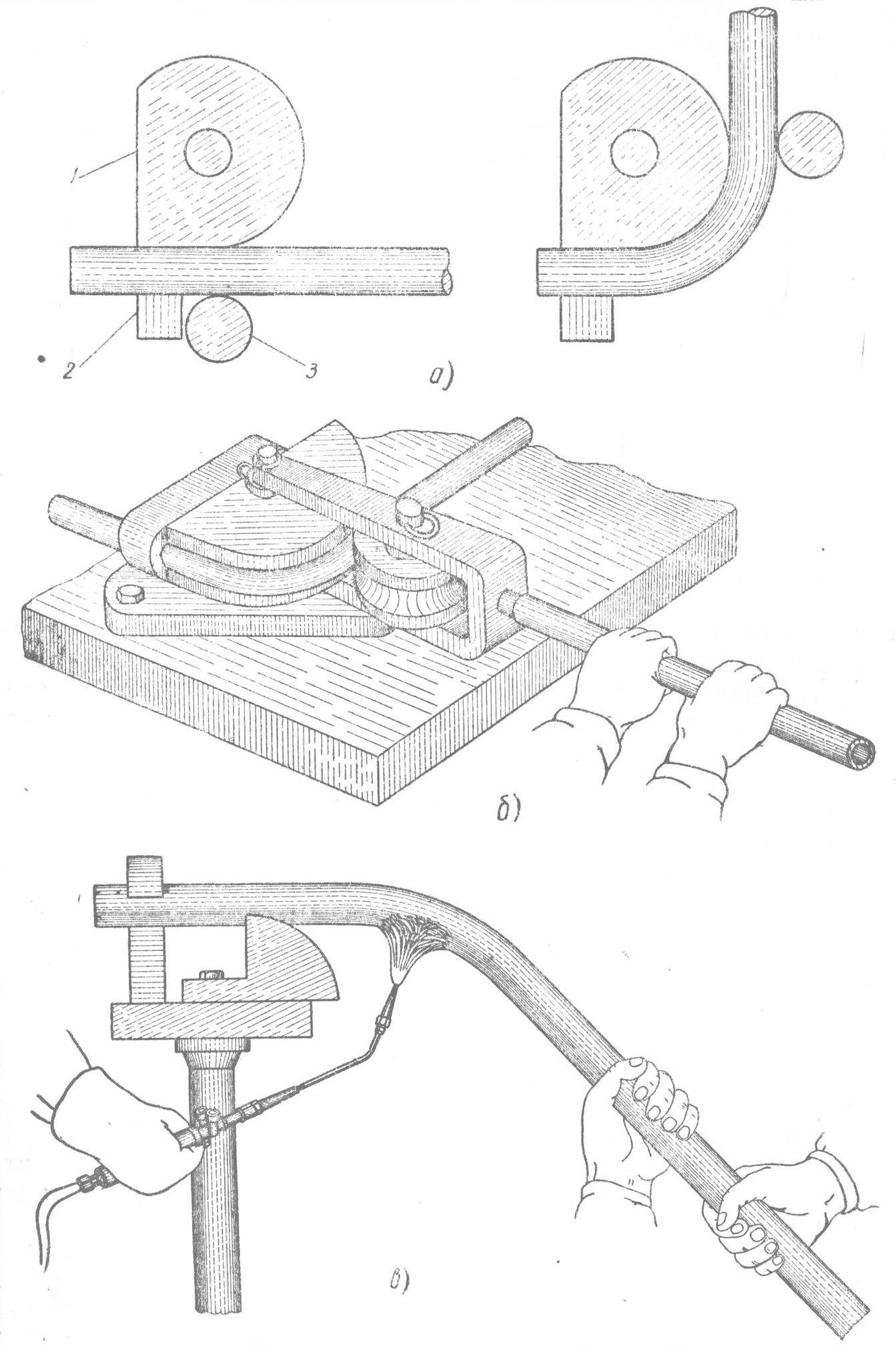

Manual devices

Manual pipe bender consists of:

- bed,

- conveyor,

- clamping element.

The pipe is loaded into a conveyor, consisting of rollers connected by a chain transmission, and is pressed by the upper (or lower) roller, which presses on the corresponding face of the product. By rotating the handle of the feed rollers, it is possible to advance the measured segment through the pressure zone, and as a result, to bend the profile pipe or a similar round product.

However, the manual process has its own nuances. Firstly, you can still bend the profile pipe with your own hands, but to achieve the result, you need to make a significant effort. Secondly, manual pipe benders are suitable for processing only small batches of products.

Mechanical apparatus

The mechanical apparatus saves us from the need to spend our strength on bending the profile pipe to the desired radius. Indeed, in a mechanical pipe bender, both the conveyor and the clamping element work not from the muscular strength of the operator, but from an electric motor and a hydraulic drive.

In this case, the scheme of operation of the device remains unchanged. That is, as in the first case, we fill the conveyor with a pipe, create a clamping force on the plane of the product to be bent (where it is necessary to bend the profile pipe even before the measuring section begins to move along the conveyor) and turn on the device in the network. As a result, the pipe passes through the pressure roller zone and changes its curvature. The process of manual and mechanical bending will be discussed in more detail below.

Features of different methods of profile bending

There are two main methods for bending a profile pipe: cold and hot. The first assumes that the bending process is performed without preliminary temperature exposure to the part.

Whereas the second is carried out only with a preheated pipe. It must be admitted that heating the part significantly increases its plasticity and facilitates the bending process.

There are no standards strictly regulating the use of cold and hot bending methods for profile products. They are only for pipes with a round cross section. According to these standards, hot bending is used for parts with a diameter of 100 mm or more. For rectangular and square pipes, slightly different rules apply.

If you have one-time pipe bending work to do, you can buy, but it’s better to rent a manual hydraulic pipe bender:

Plumbers recommend cold bending all pipes with a profile height of less than 10 mm.Products with a profile height of 40 mm or more are hot-bent.

How to bend parts, with a profile height of 10 to 40 mm, is up to the performer. In order not to be mistaken, you can make a trial bend. In general, if a pipe bender is available, it can be used to bend the pipe without any heat.

If there is no special tool, it is worth performing a test bending of the profile pipe. To do this, one edge of the part is firmly clamped in a vice. At the other end, a pipe is put on that is larger than the diameter of the product to be bent.

The resulting "shoulder" should be strongly pulled, bending the product. If the part is bent, the cold bending method can be used. Otherwise, preheat bending is applied.

Simple ways to bend pipes

The method of deflection with heating is inappropriate for workpieces made of stainless steel, copper, metal-plastic and polypropylene.

Profile

Profile metal-roll - products with a square, oval or rectangular configuration. They are very difficult to bend without violating the technical parameters. The best option is welding with preliminary cutting of the walls with a grinder in several places on the bend. First, cuts are made, the part is bent to the desired radius, then the seams are welded. Parts of small diameter can be soldered with a special soldering iron.

Stainless or steel

Stainless steel products cannot be bent by heating. To reduce the likelihood of deformation, various fillers are used: fine-grained sand, frozen water, or a sizing plug. Rigid fillers allow you to save the shape of the workpiece, elastic - less stretch the outer wall. To obtain a uniform bend, limiters are installed both inside and outside the part.

Important! To avoid notches and flaws from the calibration plug, apply lubricant: engine oil or soapy anti-corrosion emulsion

Copper and aluminum

Aluminum and copper are quite soft. Bending can be done with cold methods and with heating. Sand, water, spring or rosin is suitable as a filler. The hot method is best suited for workpieces with a small diameter.

metal-plastic

Metal-plastic blanks are bent without heating by hands, it is enough to make an effort. Care must be taken not to form a kink. The allowable value is 15⁰ for every 2 cm.

Products are easily bent with the help of wire, which is introduced into both cavities, evenly filling the cavity. The hot method is allowed. The workpiece is heated with a gas burner or a building hair dryer, gradually bending. The heating temperature is controlled by a paper sheet. Warming up should be continued until the sheet smokes.

Polypropylene

Bending polypropylene parts is recommended only in case of emergency. The surface is heated with a building hair dryer to a temperature of 150 ° C, bent with gloves manually without improvised means. Using this method, it is possible to bend workpieces with a radius equal to 8 diameters of the part.

Video: Tips for bending different pipes

Important! When bending, a thick wall should be located on the outside, a thinner one - at a break

When choosing a bending method, you should pay attention to the material of the part, its diameter and the required bending radius. Not all materials allow the procedure to be performed by heating

Preliminary it is recommended to practice on unnecessary residues. It should be remembered that with the help of improvised means it is impossible to obtain a perfect bend.For thick-walled products, it is better to take a pipe bender.

Tips

About the intricacies of the hot method

To successfully bend the pipe in a hot way, you should use a sand filler. The ideal option is medium-grained sand - building or river. If it is not possible to use just this one, in extreme cases, material from the children's sandbox is also suitable, but previously cleared of unnecessary contents. To remove unwanted impurities, it must be sifted through a sieve with holes of about 2 millimeters. After the first sifting, large elements will remain on the sieve - twigs and pebbles. Their presence in the filler is highly undesirable, because when heated, they can affect the relief and form bulges. Next, you need to sift the future filler a second time, already through a fine sieve to get rid of too fine sand. After sifting, the sand is subjected to calcination.

The pipe, at the place where the bending will take place, is annealed. Before filling the filler, you should take care of the plugs that will prevent it from getting enough sleep. It is recommended to make them from wood, so that they fit snugly against the walls. In one of the plugs, it is necessary to make grooves through which hot air will have to escape. Such holes are located on each side, that is, with a square section, there should be four of them. After installing a plug without holes through the funnel, you can start filling the filler. At the same time, the part to compact the sand should be tapped periodically.After fixing the second plug, you can mark the place of bending, fix the part and produce uniform heating. If the part is welded, then the seam must be located outside the bend in order to avoid its divergence. The color of the part ready for bending should be cherry red, and scale should fly off the pipe.

About the intricacies of the cold method

The subtleties of the cold method:

- Without the use of special tools and heating during the cold season, the bending process can be greatly facilitated. For this, as an alternative to the sand method, water is used as a filler. After filling and installing the plugs, the product is exposed to frost for the time required for the liquid to completely freeze. In light of the physical properties of frozen water, bending will be easier.

- In order to avoid injuries to the hands and to reduce the applied efforts, it is proposed to use a profile pipe with a section slightly larger than the bending one. To do this, a larger profile is put on at the edges of a smaller one, thus increasing the arm of the force.

- Masters are advised to make a test bend on an unnecessary part of the product, this will give an idea of its physical properties and prevent errors in subsequent attempts.

Summing up the above, we can draw conclusions about how effective this or that method will be. It is more expedient to obtain a better result and save time to turn to professionals who have equipment specially designed for this purpose. If the work involves multiple bending of products, then why not think about purchasing special equipment, and also, possibly, providing bending services to other people. In this case, it will be possible to quickly recoup the device.

How to bend a pipe without a pipe bender for a canopy, see the following video.

What is the problem of profile bending

Rolled metal with a rectangular cross section is easy to use, blanks can be joined at different angles. Difficulties arise when there is a need to give the design details a curvilinear shape. This is due to the fact that a tensile force acts on the outer wall of the product, and the inner side is subjected to compression.

Attempts to bend a profile pipe without a pipe bender are associated with such problems:

- The appearance of cracks in the material. If the wall thickness is small, then metal rupture is possible.

- Crease of the sides. A similar effect occurs when excessive pressure is applied while passing workpieces through bending fixtures.

- The appearance of internal folds. The greater the height of the product profile and the smaller the dressing radius, the greater the likelihood of such a defect.

- Section break. Occurs when a sharp force is applied to the workpiece.

- Changing the section configuration. If the technology is violated, there is a displacement of the planes, the longitudinal axis, the curvature of the part in the form of a spiral.

- Reducing the strength of the metal. Such a flaw is a consequence of overheating and a violation of the crystalline structure of iron because of this.

It is not difficult to avoid such complications. It is enough to approach the matter competently and thoughtfully.

What is the complexity of profile bending

The process of bending linear tubular elements of rectangular section allows you to give the bent element a round or arched shape. This technological operation is associated with external pressure on the segment simultaneously with the heating of the bent section.

The workpiece is affected by physical forces of multidirectional action.

- Tensile forces directed to the outside of the bend.

- Tensile forces acting on the inner surface.

The vectors of these efforts are directed in opposite directions, which creates a certain complexity in the process of bending square or rectangular tubes:

- Under the action of external forces in the segments of the product, an uneven change in the linear shape of the section occurs, which causes a displacement of the central axes of the cross section. In this case, the strength indicators are reduced, which negatively affect the bearing capacity of the structure as a whole.

- In the process of strong tensile stress, significant bending forces and torques are applied to the outer part of the pipe walls, which can cause irreversible deformations, the pipe may crack or break.

- During compression of a linear segment, the inner surface can be covered with folds and waves.

Only knowledge of the totality of technical characteristics, numerous geometric parameters, wall thickness, bending radius will help you choose the right bending method. And then instead of a workpiece with a deformed surface, a uniformly curved pipe will be obtained.

All the ways to bend a HDPE pipe at work and at home Sometimes the installation of sections of communication systems (sewer, water, gas supply) is required to be performed at a certain angle to each other. For these purposes, a HDPE pipe is suitable, which without ...

Based on practical experience, many experts do not recommend bending profile pipes with a wall thickness of up to 2 mm. Even the correct bending technology does not guarantee the strength of the bends.

Drawing conclusions

The main assistants in bending thin-walled pipes from any materials in the household are external and internal springs, or sand fillers, which allow you to evenly distribute the applied force. If we bend steel pipes of pipelines with thick walls, with a large radius it is practical to use three-roll home-made structures, and for a small radius, heat the profile with gas burners.

Rice. 11 How to bend a pipe at home

In everyday life, if desired, each homeowner can bend pipes from various materials without the use of factory pipe benders - for this, simple spring parts or simple home-made devices are used. To make a manual pipe bender, you will need a welding machine and some welder skills; in many cases, a blowtorch is an indispensable assistant in carrying out the work.

This is interesting: Do-it-yourself cinder blocks at home - we disassemble together