- Connection of wires by crimping sleeves

- Still, welding is preferable.

- Welding and soldering

- What is wire twisting and why is it dangerous

- Terminal blocks and terminal blocks: how to distinguish between durable and unreliable designs

- Terminal blocks

- How to connect wires of different sizes?

- How to connect wires of different sizes?

- Wiring arrangement rules

- Wire and its parameters

- Solder paste for soldering without a soldering iron

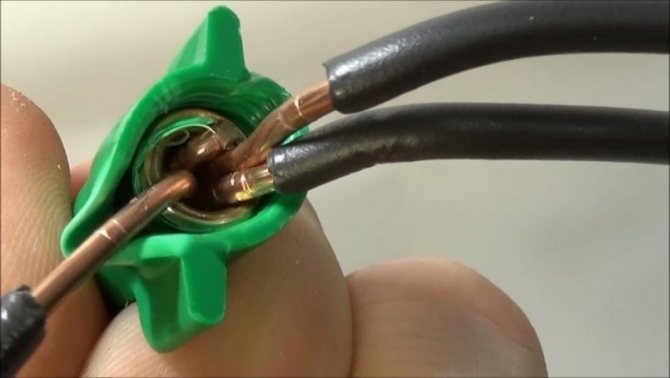

- Installing PPE caps

- Wago

- ZVI

- The sequence of soldering wires

- Connect wires with ease

- Types of terminal blocks

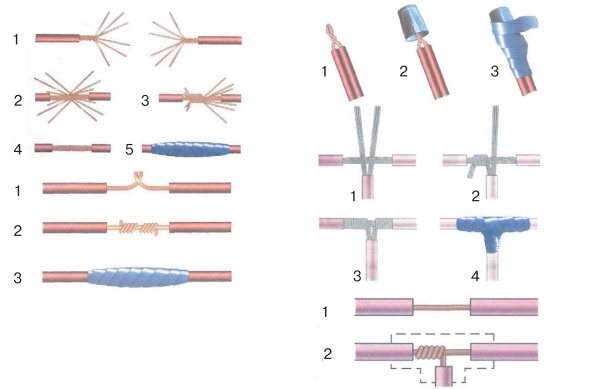

- Various twist options

- Disadvantages of soldering

- Why is it better to crimp (crimp) the wires

- Sleeves

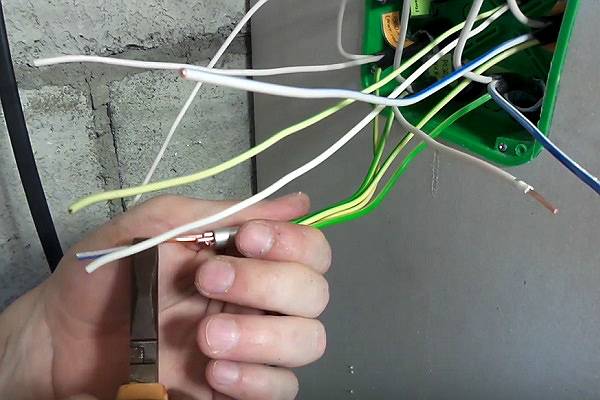

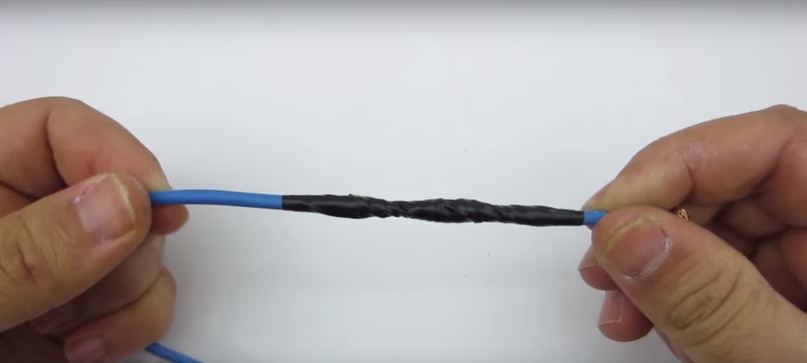

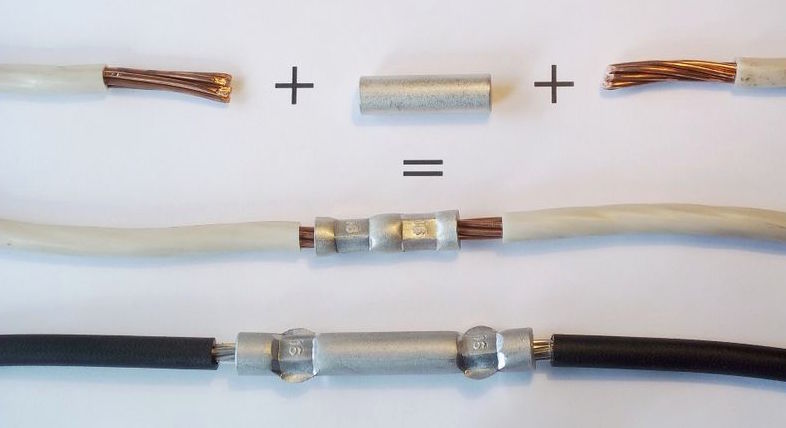

Connection of wires by crimping sleeves

Connecting wires using a sleeve with subsequent crimping is the most reliable way and has good electrical contact.

How to connect wires:

electrical wires of a certain length are stripped of insulation;

take a sleeve of the appropriate length and diameter;

- lead bare wires into the sleeve;

- crimp (press) the sleeve in two, three places with a special power tool (press - tongs);

apply an insulating material (heat shrink tube) to the sleeve.

If heat shrink tubing is not available, electrical tape can be used.

You should note that the sleeves are selected in such a way that the diameter of the stranded wires corresponds to the internal diameter of the sleeve. It is not worth using a sleeve that is not the right size.

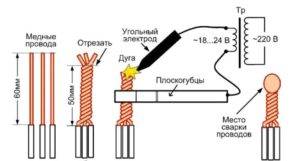

Still, welding is preferable.

In terms of connection strength and contact quality, welding surpasses all other technologies. Recently, portable welding inverters have appeared that can be carried to the most inaccessible places. Such devices are easily held on the welder's shoulder with a belt. This allows you to work in hard-to-reach places, for example, to weld from a ladder in a junction box. To weld metal wires, carbon pencils or copper-plated electrodes are inserted into the holder of the welding machine.

The main drawback of welding technology - overheating of the parts to be welded and melting of the insulation is eliminated by:

- Correct adjustment of the welding current 70–120 A without overheating (depending on the number of wires to be welded with a cross section of 1.5 to 2.0 mm).

- The short duration of the welding process is no more than 1–2 seconds.

- Tight pre-twisting of wires and installation of a copper heat-dissipating clamp.

When connecting wires by welding, the twisted cores should be bent and be sure to turn up with a cut. An electrode is brought to the end of the wires connected to the ground and an electric arc is ignited. The molten copper flows down in a ball and covers the wire strand with a sheath. In the process of cooling, an insulating belt made of a piece of cambric or other insulating material is put on the warm structure. Lakotkan is also suitable as an insulating material.

Welding and soldering

electric welding

soldering wires

However, this type of docking cannot be attributed to simple ones.It requires special equipment, which even 90% of electricians often do not have.

Yes, and it is not always possible even with its help. connect aluminum stranded wire with flexible copper stranded. In addition, you are forever tied to an outlet or extension cord.

And if there is no voltage or generator nearby at all?

At the same time, elementary press tongs, on the contrary, are present in 90% of electrical installers. It is not necessary to purchase the most expensive and fancy ones for this.

For example, batteries. Convenient of course, go and just press the button.

The Chinese counterparts also cope well with their task of crimping. Moreover, the whole process takes no more than 1 minute.

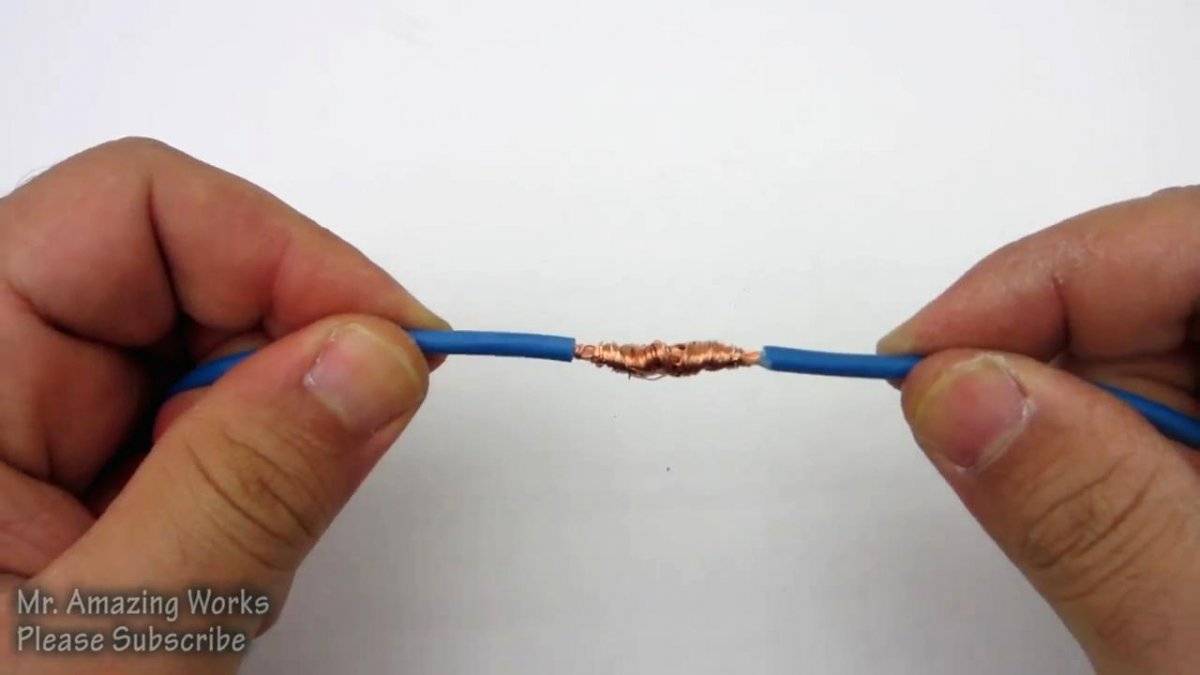

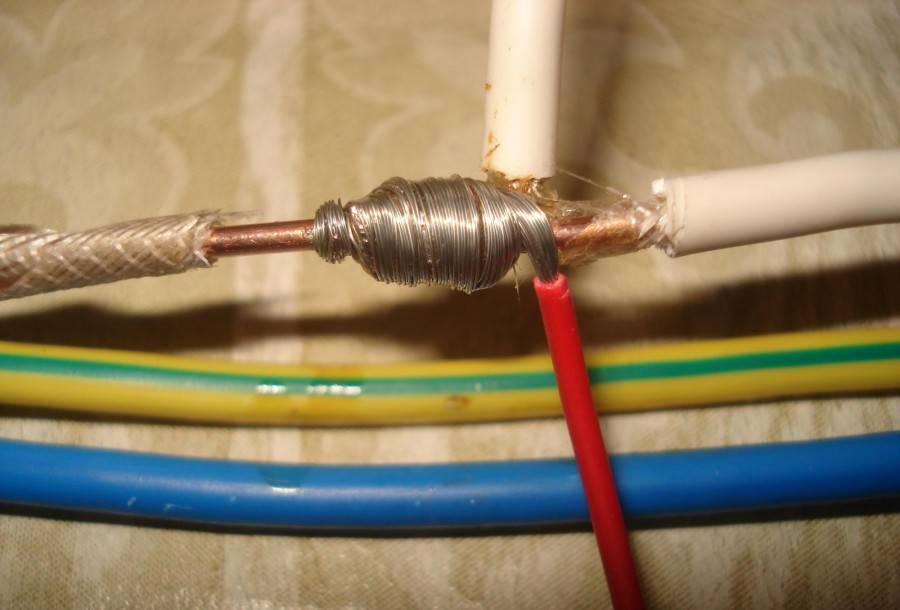

What is wire twisting and why is it dangerous

A few decades ago, when the loads on electrical wiring were not so large, such a connection was popular. Moreover, experienced craftsmen taught me, then still a young electrician, to preliminarily clean the metal of the core well, twist them tightly, and crimp them with pliers.

The length of such a twist had to be created with a length of the order of 10 cm to ensure good electrical contact, as shown in the lowest example. And all that is higher - they would have rejected, despite the beauty.

Inside closed dry rooms, such twists worked for years and decades. However, many electricians violated the technology and created poor-quality contact.

In addition, in a humid environment, the metal oxidizes. The electrical resistance of its transitional surface layer deteriorates. This leads to increased heating of the wires, premature damage to the insulation.

Therefore, modern rules, in particular the PUE (clause 2.1.21.), Simple twisting of wires is prohibited, no matter how beautifully and reliably it is done.

Of particular danger are the twisting of aluminum wires, as well as cores made of different metals - copper and aluminum.

This is due to the high ductility of soft aluminum and its high ability to create, under the influence of atmospheric oxygen, an outer layer of oxides that protects the internal structure of the metal. This film reduces conductivity.

When currents flow with increased loads, aluminum, which has a high coefficient of linear expansion, heats up, increasing its volume. After cooling, it shrinks, breaking the tightness of the connection.

Each cycle of heating and cooling degrades the electrical characteristics of the strand. In addition, copper and aluminum work as a galvanic couple, and these are additional chemical reactions with the formation of surface oxides.

My recommendation: wherever you see a simple twist, get rid of it. Reinforce it by soldering, welding, crimping, or any other approved method.

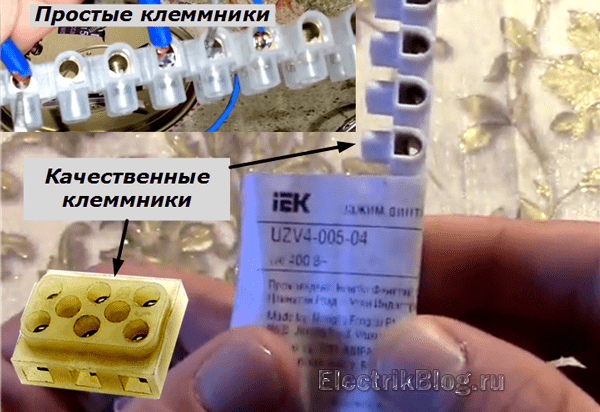

Terminal blocks and terminal blocks: how to distinguish between durable and unreliable designs

Most often, terminal blocks are used in lighting circuits with relatively small loads. They are made from different materials and different shapes.

In the case closed with plastic, there are holes for installing a stripped wire and a slot for the head of the clamping screw.

All simple terminal blocks are made of cheap transparent polyethylene with inserts of thin brass sockets with screw clamps, as shown at the very top of the picture.

Their disadvantages:

- thin-walled brass easily bursts when the metal core is normally clamped with a screw;

- weak thread on the nut does not withstand loads when tightening the wire;

- the lower edge of the screw is made with sharp edges, which strongly deform the wire, even crimped in the NSHVI tips.

It is difficult to work with such structures. They are not reliable, break, create excessive heating of the wiring.

After connecting each core to the screw connection, it is necessary to check the quality of the connection: the terminal block is taken in one hand, and the wire in the other. A sharp pull should not destroy the contact created.

Higher-quality terminal blocks are made of strong, smooth plastic with thick metal tubes and clamping plates that do not crush the metal of the core. They have strong screws and nuts.

With their help, it is convenient to connect wires from different metals, for example, to connect aluminum apartment wiring with flexible copper wires of an LED chandelier or lamp. But you should not neglect the NShVI tips.

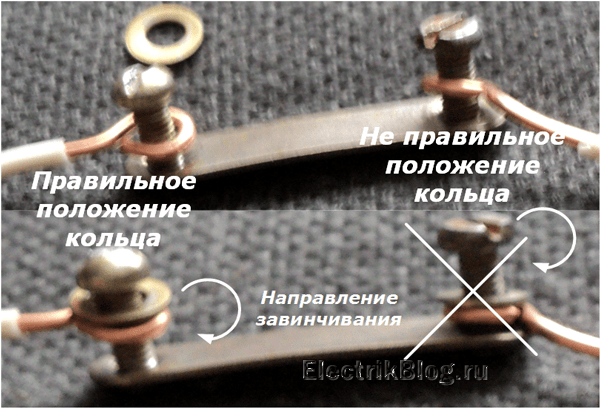

Previously, terminals with a screw clamp for a ring were common, which provides tighter contact between the core and the terminal.

When mounting, pay attention to its correct installation in the direction of screw tightening.

The squeezing force of the ring should be compressed inward, and not unbent outward, weakening the contact.

When connecting without a ring in a straight section, the metal of the cores is placed closer to the thread, and its position is monitored during clamping. In the tightened position, it should be well fixed, not fall out. Check by pulling.

In all terminal blocks, without exception, the condition of the wire insulation is monitored. It should not fall under the thread anywhere, interfere with the creation of electrical contact.

Terminal connections are permitted by all electrical installation regulations.But, they require periodic inspection and tightening of screw terminals approximately once every two years in circuits with permissible loads. After overloads and short circuits, they should be inspected immediately.

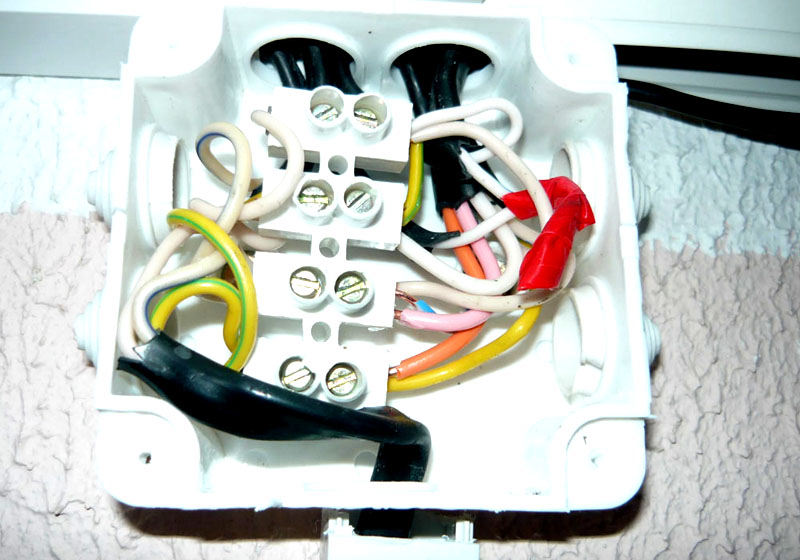

Terminal blocks

Connecting wires using terminal mounting blocks is the most convenient and aesthetic option. It does not require much time and effort. The blocks have tubular brass sleeves with screw clamps. The stripped wires are inserted into certain sockets and fixed with screws. The advantages of using terminal blocks are ease of use and the ability to connect strands of different metals. However, to connect stranded wires, their preliminary crimping is required. Also, the disadvantages include the need to regularly check the connection.

Screw terminal block - a convenient and fast way to connect wires

Screw terminal block - a convenient and fast way to connect wires

How to connect wires of different sizes?

It often happens that wires of different sections come to the junction box and they need to be connected. Everything seems to be simple here, as with connecting wires of the same section, but there are some peculiarities here. There are several ways to connect cables of different thicknesses.

Remember that it is impossible to connect two wires of different sections to one contact in the socket, since the thin one will not be strongly pressed by the bolt. This will lead to poor contact, high contact resistance, overheating and melting of the cable insulation.

How to connect wires of different sizes?

1. Using twisting with soldering or welding

This is the most common way.You can twist wires of adjacent sections, for example 4 mm2 and 2.5 mm2. Now, if the diameters of the wires are very different, then a good twist will no longer work.

During twisting, you need to make sure that both cores wrap around each other. Do not allow thin wire to wrap around thick wire. This may result in poor electrical contact. Do not forget about further soldering or welding.

Only after that your connection will work for many years without any complaints.

2. With ZVI screw terminals

I already wrote about them in detail in the article: Methods for connecting wires. Such terminal blocks allow you to start a wire of one section on the one hand, and on the other side of a different section. Here, each core is clamped with a separate screw. Below is a table on which you can choose the right screw terminal for your wires.

| Screw terminal type | Cross-section of connected conductors, mm2 | Permissible continuous current, A |

| ZVI-3 | 1 – 2,5 | 3 |

| ZVI-5 | 1,5 – 4 | 5 |

| ZVI-10 | 2,5 – 6 | 10 |

| ZVI-15 | 4 – 10 | 15 |

| ZVI-20 | 4 – 10 | 20 |

| ZVI-30 | 6 – 16 | 30 |

| ZVI-60 | 6 – 16 | 60 |

| ZVI-80 | 10 – 25 | 80 |

| ZVI-100 | 10 – 25 | 100 |

| ZVI-150 | 16 – 35 | 150 |

As you can see, with the help of ZVI, you can connect wires of adjacent sections. Also do not forget to look at their current load. The last digit in the screw terminal type indicates the amount of continuous current that can flow through this terminal.

We clean the cores to the middle of the terminal ...

We insert them and tighten the screws ...

3. Using Wago universal self-clamping terminals.

Wago terminal blocks have the ability to connect wires of different sections. They have special nests where each vein is “stuck”. For example, a 1.5 mm2 wire can be connected to one clamp hole, and 4 mm2 to another, and everything will work properly.

According to the manufacturer's marking, terminals of different series can connect wires of different sections.See the table below:

| Wago terminal series | Cross-section of connected conductors, mm2 | Permissible continuous current, A |

| 243 | 0.6 to 0.8 | 6 |

| 222 | 0,8 – 4,0 | 32 |

| 773-3 | 0.75 to 2.5 mm2 | 24 |

| 273 | 1.5 to 4.0 | 24 |

| 773-173 | 2.5 to 6.0 mm2 | 32 |

Here is an example with series 222 below...

4. With bolted connection.

A bolted wire connection is a composite connection consisting of 2 or more wires, a bolt, a nut and several washers. It is considered reliable and durable.

Here it goes like this:

- we clean the core by 2-3 centimeters, so that it is enough for one full turn around the bolt;

- we make a ring from the core according to the diameter of the bolt;

- we take a bolt and put it on a washer;

- on the bolt we put on a ring from a conductor of one section;

- then put on the intermediate washer;

- we put on a ring from a conductor of a different section;

- put the last washer and tighten the whole economy with a nut.

In this way, several wires of different sections can be connected at the same time. Their number is limited by the length of the bolt.

5. With the help of a squeezing branch “nut”.

About this connection, I wrote in detail with photographs and relevant comments in the article: Connecting wires using “nut” type clamps. Let me not repeat myself here.

6. Using tinned copper tips through a bolt with a nut.

This method is well suited for connecting large cables. For this connection, it is necessary to have not only TML tips, but also crimping press tongs or a hydraulic press. This connection will be a little bulky (long), may not fit in any small junction box, but still has the right to life.

Unfortunately, I didn’t have a thick wire and the necessary tips at hand, so I took a photo from what I had.I think it is still possible to understand the essence of the connection.

Let's smile:

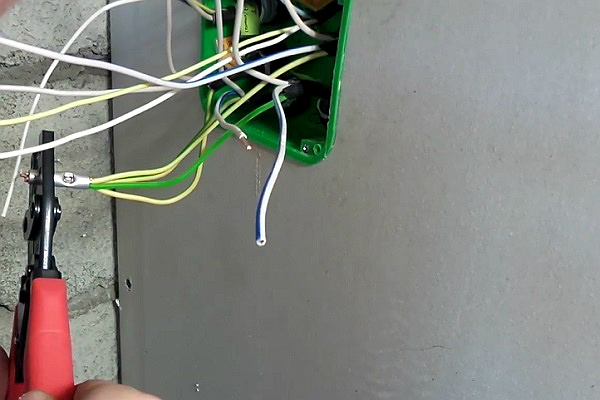

Wiring arrangement rules

In order to understand which wire connections it is advisable to make in a particular case, it is necessary to consider the rules for the arrangement of electrical installations. They clearly indicate which methods are acceptable in the arrangement of modern communication systems. Considering the rules for connecting wires, we can draw conclusions about the unacceptability of the use of twists. The regulatory documentation clearly states that all cores must be connected by welding, crimping, clamping or soldering.

The wiring must be made from a cable with a copper core. In order for such a network to have high reliability indicators, the connections must be as strong as possible. The cross section of the cores is selected in accordance with the total expected load. The more equipment connected to the network, the thicker the conductor needs to be connected to the system.

Considering how to connect the wires to each other. some non-professional craftsmen still decide to give preference to twisting the wires. This is acceptable if local wiring is being repaired or a low-power appliance is being connected to the home network. The master can in this case somewhat improve such a junction of veins.

To ensure greater reliability, special caps are used. They are used instead of electrical tape. They are also called connecting insulating clips (PPE).

Connecting wires with clamps is safer than the duct tape option. The connector looks like a plastic cup. It has a steel spring built into it. It clamps the contacts and ensures reliable contact. High-quality clamps have a special lubricant that prevents oxidation processes.When choosing, it is necessary to take into account for which wires the product is intended (stranded or solid). You should also evaluate the cross section of the conductor for which the clamp is intended. PPE is not used to connect conductors of different materials.

Most often, the cable connector today has the form of terminals. They are made from brass. In this case, the connected ends of the cable do not contact each other directly. Therefore, with the help of such structures, it is possible to switch the same conductors, conductors of various cross-sectional sizes, made of different materials.

To be able to create the correct joint, you need to select the appropriate types of terminals. They differ in the nominal current indicator, as well as the permissible diameter for the wire. All characteristics of the terminals are indicated on their body.

Some commercially available terminals may contain a special filler. The gel prevents oxidation processes, increasing the reliability of the connection. Terminals are knife, spring, screw.

Wire and its parameters

In recent years, when laying electrical wiring and connecting household appliances, copper conductors are most often used. Although they cost much more, it is more convenient to work with them, besides, copper requires a much smaller core diameter than when using aluminum conductors.

The cross-section of conductors is selected depending on the type of network - 220 V or 380 V, the type of wiring (open / closed), as well as the current consumption or power of the equipment. Typically, copper conductors with a core of 4 mm (with a line length of up to 12 m) or 6 mm are used.

Conductor cross-section selection table

When choosing the type of cable for laying from the shield to the outlet, it is better to stop at single-core conductors. They are tougher, but more reliable. To connect the stove itself (to which it will be necessary to connect the power plug), you can choose a flexible stranded wire: a single-core one in this case will be too inconvenient.

Connecting the hob is described here.

Solder paste for soldering without a soldering iron

Solder paste includes flux and solder. This is very convenient when soldering without a soldering iron. No need to mess around with these two components separately. It is enough to apply one paste to the junction of the wires and then heat it up to the melting temperature of the solder.

Solder paste consists of metal powder, flux, and a fixative (a sticky substance to keep the alloy in a liquid state within the solder area). The paste contains a powder of tin and lead with the addition of silver. The proportions of the composition vary depending on the purpose of the product.

Soldering with a lighter

Soldering with a lighter

When heated, the flux instantly evaporates, the solder firmly and tightly covers the entire twist of wires. As a result, soldering is of high quality. The applicable composition allows you to do without soldering irons and soldering stations.

For food soldering, it is recommended to use pastes of the following brands: POS 63, POM 3 and others. Paste soldering is used to work with microcircuits, where instead of soldering irons they take thin metal rods heated by external heat sources.

solder paste

solder paste

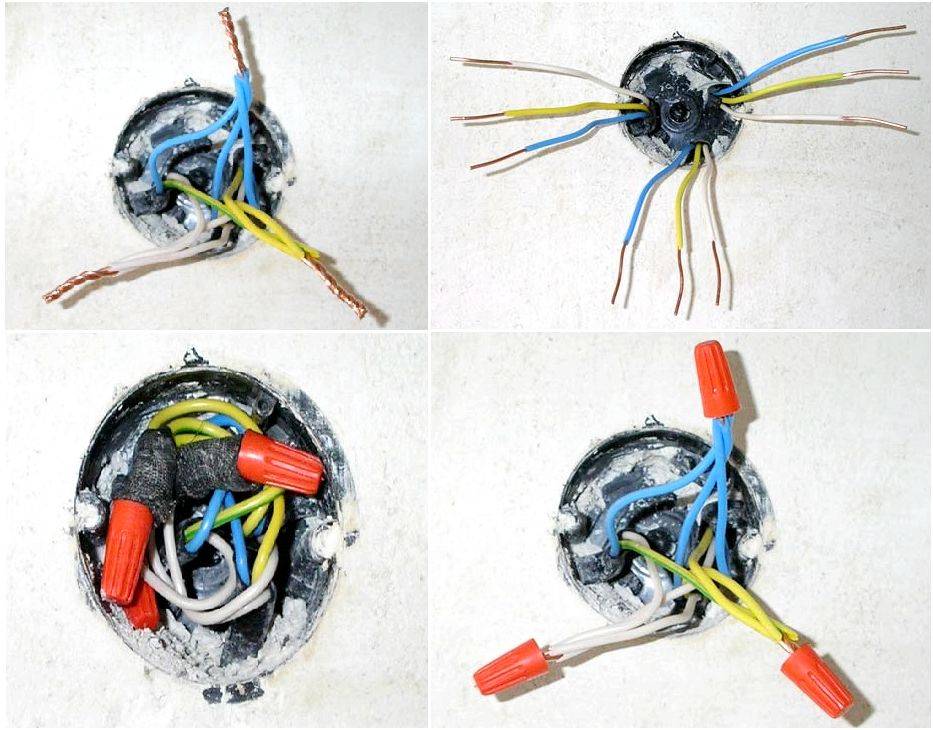

Installing PPE caps

PPE caps are used to connect cables. For the manufacture of this product, polymeric materials are used that, when ignited, do not support combustion and at the same time have electrical insulating properties.These devices work quietly under a voltage of 600 V.

A steel spring is mounted in the body of the cap, compressing the conductor.

The case, made of polymers, performs the function of protecting the connection, in addition, it isolates the junction of the wires. When cutting the insulation, the installer must ensure that the bare metal does not extend beyond the cap, and at the same time falls into the zone of action of the spring. When using PPE caps, there is no need to use additional insulating materials.

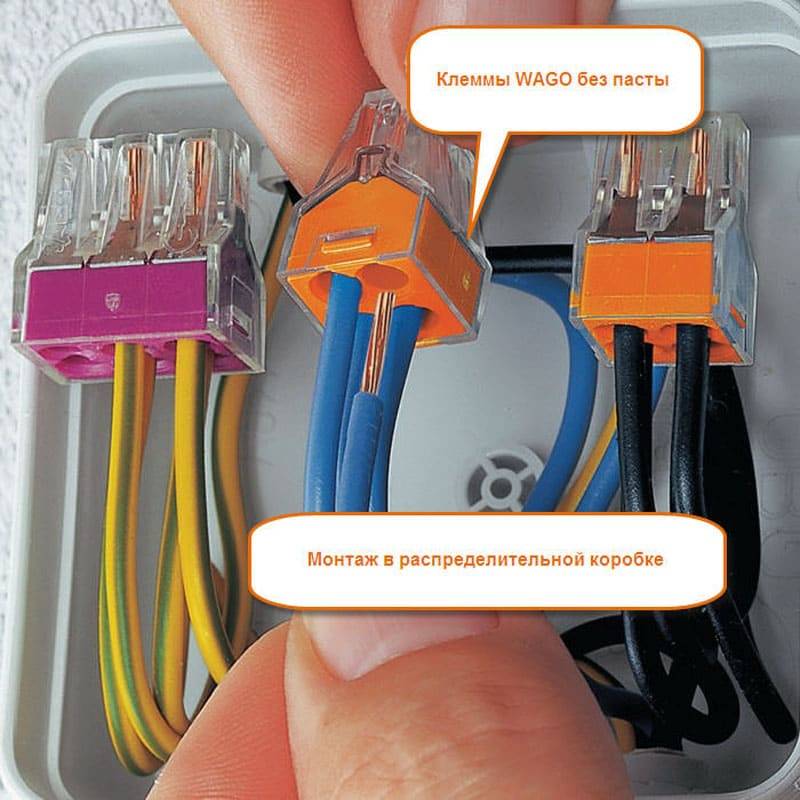

Wago

The next view is the Wago terminal blocks. They also come in different sizes, and for a different number of connected wires - two, three, five, eight.

They can join together both monocores and stranded wires.

For multi-wire, the clamp should have a latch-flag, which, when open, allows you to easily insert the wire and clamp it inside after snapping.

These terminal blocks in home wiring, according to the manufacturer, can easily withstand loads up to 24A (light, sockets).

There are separate compact specimens on 32A-41A.

Here are the most popular types of Wago clamps, their markings, characteristics and for what section they are designed:

There is also an industrial series for cable sections up to 95mm2. Their terminals are really large, but the principle of operation is almost the same as that of the small ones.

When you measure the load on such clamps, with a current value of more than 200A, and at the same time you see that nothing is burning or heating, many doubts about Wago products disappear.

If your Vago clamps are original, and not a Chinese fake, and at the same time the line is protected by a circuit breaker with a correctly selected setting, then this type of connection can rightfully be called the simplest, most modern and easy to install.

Violate any of the above conditions and the result will be quite natural.

Therefore, you do not need to set wago to 24A and at the same time protect such wiring with an automatic 25A. The contact in this case will burn out during overload.

Always choose the right vago terminal blocks.

Automatic machines, as a rule, you already have, and they protect primarily the electrical wiring, and not the load and the end user.

ZVI

There is also a fairly old type of connection, such as terminal blocks. ZVI - insulated screw clamp.

In appearance, this is a very simple screw connection of wires to each other. Again, it happens under different sections and various shapes.

Here are their technical characteristics (current, cross section, dimensions, screw torque):

However, ZVI has a number of significant drawbacks, due to which it cannot be called the most successful and reliable connection.

Basically, only two wires can be connected to each other in this way. Unless, of course, you don’t specifically choose large pads and shove several wires there. What to do is not recommended.

Such a screw connection is well suited for solid conductors, but not for stranded flexible wires.

For flexible wires, you will have to press them with NShVI lugs and incur additional costs.

You can find videos on the network where, as an experiment, the transient resistances on different types of connections are measured with a microohmmeter.

Surprisingly, the smallest value is obtained for screw terminals.

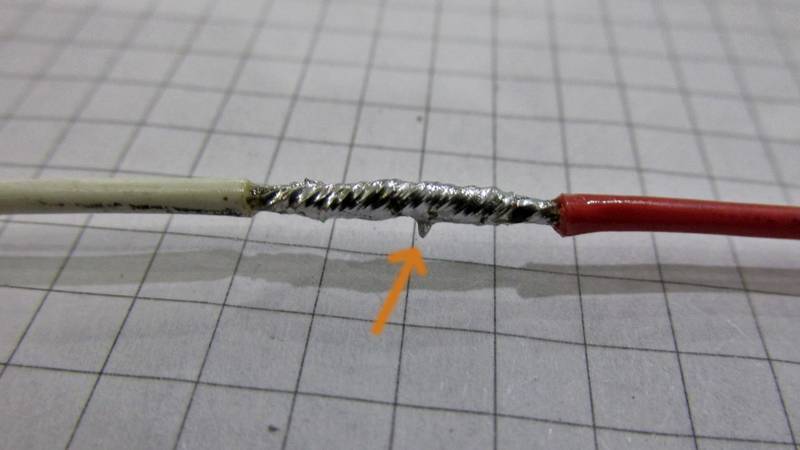

The sequence of soldering wires

The technological process of soldering two metal thin conductors consists of the following steps.

1. Cleaning the surfaces of conductors, removing corrosion and other contaminants. The process is carried out carefully to the shine of the metal. Any third-party raid will make the connection unreliable.

2. The stripped ends of the conductors are covered with flux. This is a special substance that removes oxide fragments well, and also prevents the wires from oxidizing during operation. When choosing a flux, preference should be given to solid and pasty substances; a liquid is of little use in this matter.

3. Using a soldering iron, the solder is melted and applied to the ends of the conductors in an even thin layer. The solder should bond well to the metal.

4. Connect the wires with a temporary twist or with tweezers. Alternatively, a vise can be used.

5. Apply flux to the joint to prevent rust formation under the solder.

6. Melt the solder with a soldering iron and distribute the substance around the joined ends of the conductors. If the fixation turned out to be weak, it is recommended to choose a different type of solder.

The work is completed by cleaning the soldering iron tip and treating it with an inactive flux (if it is tinned). A fluxed tool will help you to perform high-quality soldering in the future. It is recommended to store the soldering iron in a closed box.

Connect wires with ease

You can put the duty tape in the far drawer: you won't need it anymore. Instead of this:

- We go to the nearest store and buy terminals (clamps). The issue price is 8-50 rubles. It is advisable to take WAGO 222 terminals with levers. As the electrician explained, they are the most reliable and easy to use.

- We clean both wires to the depth of the terminal block, about 1 cm.

- We collect the cores of the stranded wire into a tight bundle and twist it slightly.

- Both conductors must be straight and clean.

- Raise the levers and put both wires into the holes. We clamp, lowering the levers down.

Ready. With this method of connection, you do not need to think about the quality of twisting and insulation. The wire length remains the same. If necessary, the lever can be lifted and the wire removed - that is, the clip is reusable.

Clamp WAGO 222 is 2 holes and more. It is designed for connecting copper single- and stranded wires with a cross-sectional area of 0.08–4 mm, used in household electrical networks with voltages up to 380 V. Lamps, electricity meters, garlands and much more are connected using the terminal block.

Types of terminal blocks

It is worth saying that the terminal blocks are different:

- Screw terminals in polyethylene sheath. The most common, inexpensive and structurally simple. Inside the insulating shell there is a brass sleeve with two screws - they are used to screw the wires inserted into the holes on both sides. The downside is that screw terminals are not well suited for aluminum conductors and stranded wires. Under the constant pressure of the screw, aluminum becomes fluid, and thin veins are destroyed.

-

Screw terminals with metal plates. More reliable design. The wires are clamped not with screws, but with two plates with characteristic notches. Due to the increased pressure surface, these terminals are suitable for stranded wires and aluminium.

- Self-clamping express terminal blocks. No less simple design, but much more convenient. It is enough to put the wire into the hole until it stops, and it will be securely clamped.Inside are a miniature tinned copper shank and a fixing plate. Also, manufacturers often put a paste inside - a mixture of technical petroleum jelly and quartz sand. It removes the oxide film from the aluminum surface and subsequently prevents it from forming again.

To connect an aluminum wire to a copper wire (no matter how many lived they have), a special terminal block with paste is required. The fact is that copper and aluminum form a galvanic couple

When metals interact, the destruction process starts. The resistance at the connection point increases, as a result of which the structure begins to heat up. Often this leads to melting of the insulation or, even worse, sparks. The greater the current, the faster the destruction occurs.

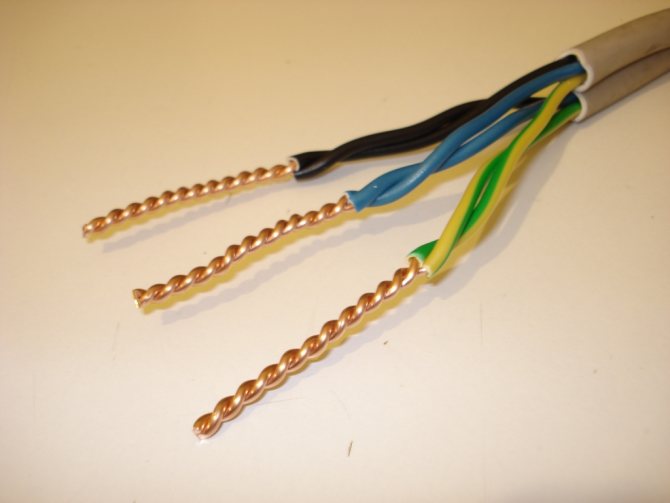

Various twist options

Unprofessional connection. This is a twisting of a stranded wire with a single-core. This type of connection is not provided for by the rules, and if such a connection of wires is discovered by the selection committee, then the facility will simply not be accepted for operation.

However, twisting is still used, and here you need to know how the correct twisting of stranded wires is performed. It is often used in emergency cases when it is not possible to professionally make a connection, and the service life of such a connection will be short. And yet, twisting can temporarily be used only for open wiring, so that you can always inspect the junction.

Bad wire connection

Why is it impossible to connect the wires with a twist? The fact is that when twisting, an unreliable contact is created.When the load currents pass through the twist, the place of the twist heats up, and this increases the contact resistance at the junction. This, in turn, contributes to even more heating. Thus, at the junction, the temperature rises to dangerous values, which can cause a fire. In addition, a broken contact leads to the appearance of a spark at the place of twisting, which can also cause a fire. Therefore, in order to achieve good contact, it is recommended to connect wires with a cross section of up to 4 mm2 by twisting. Details about the color marking of wires.

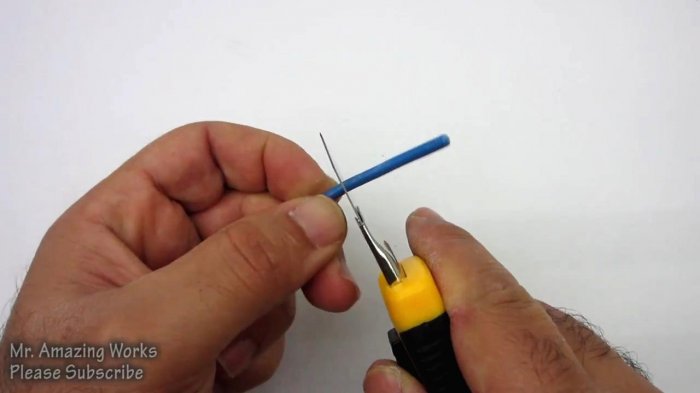

There are several types of twists. When twisting, it is necessary to achieve good electrical contact, as well as the creation of mechanical tensile strength. Before proceeding with the connection of wires, they should be prepared. Wire preparation is carried out in the following sequence:

- from the wire, the insulation is removed at the junction. The insulation is removed in such a way as not to damage the wire core. If a notch appears on the wire core, then it may break in this place;

- the exposed area of the wire is degreased. To do this, it is wiped with a cloth dipped in acetone;

- to create a good contact, the fat-free section of the wire is cleaned with sandpaper to a metallic sheen;

- after connection, the insulation of the wire must be restored. For this, insulating tape or heat shrink tubing can be used.

In practice, several types of twists are used:

-

simple parallel twist. This is the simplest and most common type of connection. With a good parallel twist at the junction, a good quality of contact can be achieved, but the mechanical forces to break will be minimal.Such twisting can be weakened in the event of vibration. To properly perform such a twist, it is necessary that each wire wrap around each other. In this case, there must be at least three turns;

- winding method. This method is used if it is necessary to branch the wire from the main line. To do this, the insulation of the wire is removed at the branch section, and the branch wire is connected to the bare place by winding;

Connecting the wire to the main

- bandage twist. This type of twist is often used when connecting two or more solid wires. With bandage twisting, an additional conductor is used from the same material as the wire cores. First, a simple parallel twist is performed, and then a bandage from an additional conductor is applied to this place. The bandage increases the mechanical tensile strength at the junction;

- connection of stranded and solid wires. This type is the most common and simple, first a simple winding is performed, and then clamped;

Connection of stranded and solid copper wire

other various connection options.

In detail, about the methods of connecting single-core wires

Disadvantages of soldering

Despite significant advantages, the method also has negative features:

- Lack of technology. There are many preparatory operations that need to be done before soldering itself.

- High labor intensity, as a result of which the method is not suitable for use on an industrial scale. A high-quality electrical installation takes a lot of time, therefore, with large amounts of work, it is much easier to perform pressure testing.

- Requirements for the skills and knowledge of a specialist.It is necessary to understand how and with what consumables it is optimal to connect one or another type of wire.

- The need to use a soldering iron of sufficient power. It is usually impossible to connect thick wires with a low-power soldering iron. High-power ones are sold in radio parts stores, but their cost is slightly higher than ordinary household models.

- Only neutral fluxes can be used. Sometimes it is more difficult to work with them, which again requires high qualifications.

In order to perform the installation with high quality, the performer must be well versed in the technology itself, understand the physical and chemical characteristics of different metals

For example, when attaching stranded wires, it is important to treat with flux and tin each core

Special care is required when working with aluminium. Such wires are much more difficult to connect due to the oxide film. The latter must be removed from the conductor before tinning. To do this, you need to use special fluxes that do not contain acids.

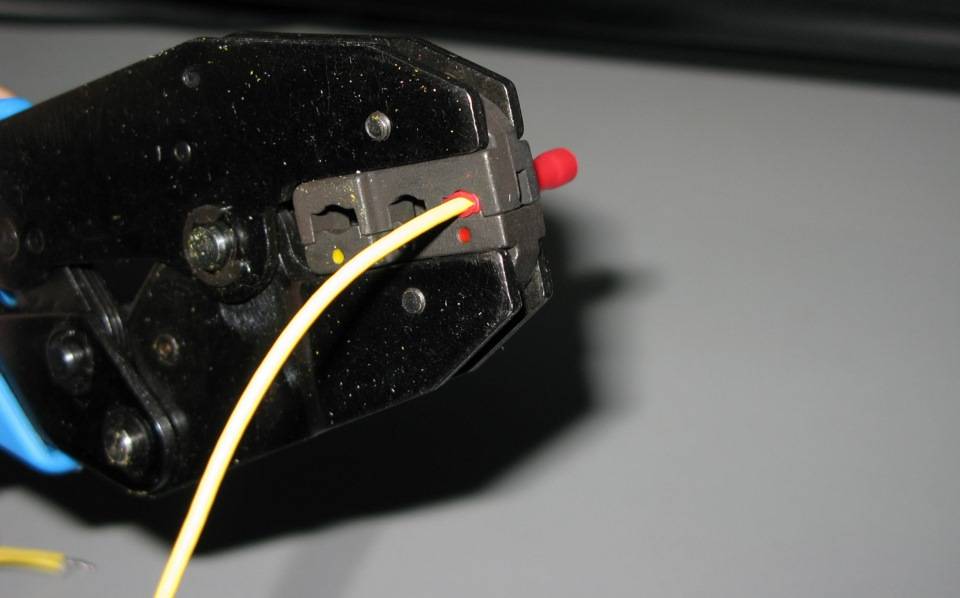

Why is it better to crimp (crimp) the wires

Crimping of wires is one of the most reliable and high-quality methods of mechanical connections currently used. With this technology, the loops of wires and cables are crimped in the connecting sleeve using press tongs, ensuring tight contact along the entire length.

The sleeve is a hollow tube and can be made independently. For sleeve sizes up to 120 mm², mechanical tongs are used. For large sections, products with a hydraulic punch are used.

During compression, the sleeve usually takes the form of a hexagon, sometimes local indentation is made in certain parts of the tube.In crimping, sleeves made of electrical copper GM and aluminum tubes GA are used. This method allows the crimping of conductors of different metals. This is largely facilitated by the treatment of the constituent components with quartz-vaseline lubricant, which prevents subsequent oxidation. For joint use, there are combined aluminum-copper sleeves or tinned copper sleeves GAM and GML. The crimp connection is used for conductor bundles with a total cross-sectional diameter between 10 mm² and 3 cm².

Sleeves

When powerful clamps are needed for several wires, sleeves are used. They are a tinned copper tube, or a flat tip with a hole made for fastening.

It is necessary to insert all the wires to be connected into the sleeve and crimp using a special crimper tool (crimping pliers). This wire clamp has a number of positive aspects:

- It is very convenient to use lugs with holes when there is a need to fix the wire knots on the housings with screws.

- Crimping at the junction does not contribute to increased resistance.

As you can see, there are a lot of wire clamps, each with its own advantages and disadvantages. Choose based on which wires you need to connect, where the junction will be located. But do not forget that the most important thing in electricity is reliability and safety.

![How to connect wires without soldering | [instruction]](https://fix.housecope.com/wp-content/uploads/1/9/1/1914a68d79c28d79452ec1af26675c62.jpg)