- Types and arrangement of the valve

- Step-by-step instructions for draining gas condensate

- Arrangement of a summer residence

- Draining the condensate from the compressor

- Related posts:

- Step-by-step instructions for draining gas condensate

- Recommended to see:

- What you need to know about gas cylinders?

- Soviet-style cylinders

- Steel modern containers

- Composite gas tanks

- What condenses in a gas cylinder?

- Transport rules

- Terms of service

- Cylinder safety rules

- Refueling of gas cylinders

- Gas cylinder filling methods

- Technical gases

- food

- Leg welding

- What are

- Conclusions and useful video on the topic

Types and arrangement of the valve

Before moving on to practice, you have to get a little acquainted with the theory and figure out which way the valve on the household gas cylinder should be unscrewed. And also briefly consider the device of the cylinder and the valve itself. This knowledge will help you get the job done faster.

So, the main structural elements can be considered in detail in the following image.

The design of the cylinder and valve is extremely simple. Depending on the chosen method of unscrewing the valve, a shoe, lining rings of the cylinder will be used to ensure reliable fixation of its body

Most often on propane-butane cylinders you can find valves of the VB-2 and VB-1 brands. The body of such a crane is extremely simple and equipped with a handwheel that can be easily rotated by hand. Such valves are installed on gas cylinders for pressures up to 1.6 MPa. It is possible to attach a balloon reducer and a pressure regulator to them, for which the valve design has a union nut with a left-hand thread.

Connecting dimensions of the valve brand VB-2:

- at the outlet for gas sampling SP 21.8 - 14 threads per 1 ″ left;

- for installation on a cylinder - a conical thread with a diameter of W19.2, W27.8, W30.3.

The side fitting of a cylinder valve used to store combustible gases is always made with a left-hand thread. But for non-combustible - on the right. This measure is designed to protect the average user who decides to independently attach the cylinder to gas-using equipment.

As for the material of manufacture, the valves are made of steel or brass. The body of the product must contain information about the allowable pressure.

Step-by-step instructions for draining gas condensate

First you need to prepare a container of a suitable size (a cut plastic bottle will do) and rags that you don’t mind recycling. Before removing the liquid, it is necessary that the car's engine run on gas to warm up the evaporator. It is best to do this in warm weather or in a closed box.

If we drain Tomasetto AT 07 (Tomasetto) aka Digitronic (Digitronic) from the gearbox, it would be more correct to prepare, for replacement, a propane-butane mixture coarse filter and o-rings to it. Then you need to shut off the fuel supply valve from the cylinder and work out the remaining gas from the system.

- replace element;

- place a container under the drain plug (the drain is located at the bottom of the evaporator);

- unscrew the plug (with a 6 mm hexagon);

- decant liquid (often the amount does not exceed 30-50 grams);

- screw the cap back;

- wipe the stains with a rag.

After switching from gasoline to gas, many motorists mistakenly believe that installing LPG is all that is required of them in order to forget about gasoline prices and start saving. However, it is not. In fact, in order for everything to work properly, it is necessary to regularly monitor the condition of the gas-balloon equipment and timely replace certain elements.

One of the most important "commandments" in the operation of HBO is the timely replacement of filters and, of course, the timely draining of condensate from the gas reducer. Unfortunately, not everyone knows about this, and some know, but simply ignore this rule.

In this article, I will talk about what to drain the condensate for, when it is necessary to do this work, and also how to do it correctly.

In fact, this important procedure should be performed regularly or after a certain mileage. If you ignore it, then very soon you may have trouble in the form of a decrease in engine power, tripling, or other unpleasant phenomena associated with the unstable operation of the power unit.

Arrangement of a summer residence

Draining the condensate from the compressor

Category: Arrangement of a summer residence

When the air compressor is running, condensate regularly accumulates inside the receiver or oil separation tank. This is a completely normal process, because the air around us always has a certain humidity.When the air is compressed, it heats up, the moisture content in the compressed volume increases, and later, when the air cools down and the temperature drops, when the dew point is reached, it condenses from the air inside the receiver.

To increase the life of the compressor and ensure its normal operation, it is necessary to regularly drain the condensate from the receiver or compressor tank. It is best to drain the accumulated fluid after each use of the compressor. However, if it works constantly, then it should be done at least once a week.

To do this, manufacturers install a so-called condensate drain valve in the compressor. This valve is usually located at the bottom of the tank for easy draining.

It is important that before draining the condensate, all compressed air from the receiver is released and completely depressurized. Always read the instruction manual for compressor equipment, which tells you how to properly drain condensate and everything you need to know about compressor operation.

Always read the instruction manual for compressor equipment, which tells you how to properly drain condensate and everything you need to know about compressor operation.

Keep in mind that water can cause corrosion and rust in the receiver or compressor tank, so it is recommended to regularly drain the condensate from them. In this way, you extend the life of the equipment and achieve its most efficient operation.

In addition to pure water, condensate may also contain harmful impurities. Environmental regulations prescribe the disposal of the drained fluid.Therefore, with a large volume of condensate, it is necessary to use special devices - separators for separating condensate into oil and clean water. When using them, it is possible to drain condensate in the form of purified water directly into the sewer.

| ← What volume should the compressor receiver have? | Compressor oil change: instructions and tips → |

|---|

Related posts:

Compressor applications

The compressed air compressor can be used to solve many different tasks in the country house and garden. In our article, you will find out for which tasks and with what tools a household air compressor is used.

…

What volume should the compressor receiver have?

When buying a compressor, the volume of the receiver or air collector is an important criterion.

In our article, we have prepared for you information on what to look for when choosing a compressor that works in conjunction with the receiver.

..

Compressor oil change: instructions and tips

The manufacturer's manual for any compressor indicates that it is necessary to change the oil regularly and fill in fresh. According to the manufacturer, it is recommended to change the compressor oil once a year, but whether this interval is sufficient depends on various factors. The more often you use the compressor, the more often you need to change the oil, ensuring the functionality and smooth operation of the equipment.

Compressed air compressor selection

Most modern compressors are not only designed for use with a wide range of pneumatic tools, but are also equipped with many convenient features and are suitable for use on manufacturing and construction sites. To make sure you choose the right compressor for solve your problems, answer the main questions presented in this article.

…

The electricity was cut off ... What to do?

Modern man tries to surround himself with familiar comfort, wherever he is. Home theater, washing machine, dishwasher, microwave oven and other attributes of civilization allow us to organize our life and leisure in the best possible way.

Household appliances and electronics help to cook, wash, clean, listen to your favorite music. But as soon as electricity disappears, as well-being and to ...

Share link:

Step-by-step instructions for draining gas condensate

First you need to prepare a container of a suitable size (a cut plastic bottle will do) and rags that you don’t mind recycling. Before removing the liquid, it is necessary that the car's engine run on gas to warm up the evaporator. It is best to do this in warm weather or in a closed box.

If we drain Tomasetto AT 07 (Tomasetto) aka Digitronic (Digitronic) from the gearbox, it would be more correct to prepare, for replacement, a propane-butane mixture coarse filter and o-rings to it. Then you need to shut off the fuel supply valve from the cylinder and work out the remaining gas from the system.

- replace element;

- place a container under the drain plug (the drain is located at the bottom of the evaporator);

- unscrew the plug (with a 6 mm hexagon);

- decant liquid (often the amount does not exceed 30-50 grams);

- screw the cap back;

- wipe the stains with a rag.

Recommended to see:

-

Draining condensate from the gearbox

- Engine decarbonizer

-

I can not unscrew the spark plugs what to do

- Replacing fluid in the gearbox

- Do-it-yourself diagnostics of gas equipment of a car

- Setting up the HBO Digitronic 4th generation with your own hands

What you need to know about gas cylinders?

The use of gas cylinders in houses and cottages where there is no centralized gasification is a common practice. In this case, propane (or rather, a propane-butane mixture) more often becomes a fuel for gas stoves, less often for water heating systems. In order to protect yourself and your loved ones from unpleasant, often extremely dangerous consequences, before work you need to find out what rules for installing a gas cylinder in a private house must be observed.

But before moving on to them, you need to dwell on the mini-storages of this fuel themselves. First you need to give information about the volume and mass of the tanks. It is better to bring household containers immediately with their approximate weight:

- 5 l - 6 kg;

- 12 l - 11 kg;

- 27 l - 26 kg;

- 50 l - about 43 kg.

There are also the smallest cylinders - 220 and 400 ml, but their use is limited to blowtorches and portable stoves. Connect the elements with thin hoses, or directly.

Soviet-style cylinders

Until now, some economical owners use old metal tanks, which should be in the trash. It is not recommended to keep such products in the house, and not only because of their unsympathetic appearance. The metal is subject to corrosion, so no one can vouch for the reliability of the old cylinder: in the house it becomes almost a real powder keg.

In some CIS countries, the use of such "rarities" is either completely prohibited or allowed, but only after verification and issuance of a certificate confirming the satisfactory condition of the products.However, it is better to abandon these vessels in time, replacing them with safer, modern counterparts.

Steel modern containers

This option is slightly better due to the not so “respectable” age, however, the new tanks are not without the same drawbacks as the old vessels. Welded steel cylinders are similarly susceptible to corrosion. They are sensitive to temperature changes and explosive. Large containers (50 l) are strictly forbidden to be installed in the house.

They are stored outside, in special cabinets near the walls of the building in a place that is protected from sunlight. The installation of small tanks in housing is allowed, but in this case it is necessary to follow the rule: the minimum distance from the stove to the cylinder should be 1.5 m, but further is better. Other recommendations:

- containers should be stored in a room with a stable temperature, ventilation, away from heating appliances and sunlight;

- regular checking of the cylinder and gas pipeline for tightness is mandatory.

To ensure safety, the gasket on the neck of the container is recommended to be changed periodically. Gas leakage due to a malfunction of this element is already a great danger, especially indoors. In addition, gas consumption increases.

Composite gas tanks

These are the latest models that can be placed in residential premises: both a private house and a summer cottage. Their main advantage is absolute security. Composite tanks are made from epoxy resin and fiberglass. First, the threads of the material are tightly wound around the mold, then they are impregnated with resin and treated with a hardener. A plastic casing with handles is put on top of the container.This element is removable, so after accidental damage it is easy to replace.

Composite, or eurocylinders, have quite a few advantages when compared with metal products. The list includes:

- a wide range of;

- maximum strength;

- the possibility of stacking;

- maximum safety: the container will protect the gas even at a temperature of 100 °;

- low weight of the tanks: it is almost half as much (together with the casing) as compared to metal tanks;

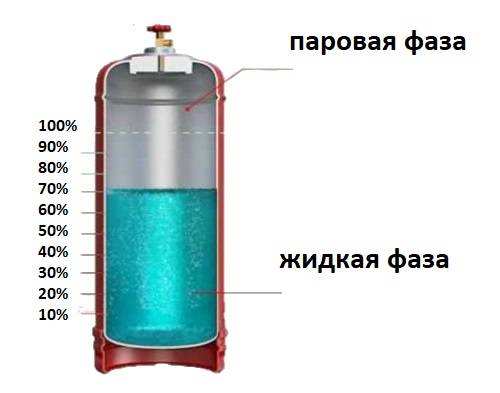

- convenience: it is guaranteed by transparent walls that allow owners to monitor the level of liquid in the cylinder;

- the presence of a bypass valve, which gives a chance to dump excess gas with a sudden increase in pressure.

These are the reasons why eurocylinders can be considered optimal containers for domestic use: they are convenient, practical, light and safe. If you look for shortcomings, then they include the high price of products. But it is explained by the fact that composite tanks are produced so far only in European countries.

What condenses in a gas cylinder?

You can often notice that the gas in the cylinder is over, and at the bottom something continues to splash. Some people think that there is still some liquefied gas left, just for some reason it does not come out and does not light up, but this is not so. In fact, after using all the gas in the cylinder, condensate remains - a residue that does not go into a gaseous state at room temperature, and therefore does not go out under pressure and does not provide combustion.

To understand why condensation forms in your gas cylinder, let's look at what it consists of.

The liquid that remains at the bottom of the cylinder after all the gas has been used up usually consists of several components.

Among them may be:

- Gasoline is a non-volatile refined product, a cross between butane and gasoline.

- An odorant is a flavoring gas.

- Non-combustible impurities are not uncommon when using insufficiently purified gas or refueling from an almost empty tank.

- Water is the rarest, but also the most dangerous component in this case.

- Butane - if the cylinder was used in the cold.

The amount of such impurities present in the propane-butane mixture and forming condensate directly depends on the quality of the cylinder filling, as well as on the season.

Propane at normal pressure turns into a gas already at a temperature of -30 degrees, and butane - at 1 degree below zero.

However, there are other products of oil refining, the boiling point of which is much higher: +30 - +90 degrees and above. That is, when heated to a sufficient temperature, they will behave in the same way as propane and butane - only heating a gas cylinder is very dangerous. And at room temperature, and even at elevated pressure inside the cylinder, they remain in a liquid state, forming condensate.

These non-volatile fractions under normal conditions are called gasoline, and the better the gas at the gas station, the lower the percentage of their content.

In addition to gasoline, propane-butane technical mixture, which is filled with household gas cylinders, always contains an odorant. This is a special substance, ethyl mercoptan, with an extremely strong pungent odor: it is added in order to notice the leak in time and to have time to prevent the accumulation of gas in the room. In addition to the smell of an odorant, it is possible to detect a gas leak in a timely manner and analyze the composition of the gas mixture using special equipment - a gas analyzer.

Without the addition of an odorant, the gas mixture would have no odor - just like purified propane, pure butane, and natural gas do not. The odorant is also non-flammable, so it remains in the condensate. Its volume is negligible, because according to the norms, 6-9 ml of flavoring per 100 kg of liquefied gas are added. However, after using the cylinder, it almost completely remains in the condensate, due to a decrease in the total mass of substances, its concentration increases.

Water and non-combustible impurities should normally not be in the gas. However, when refueling at unverified stations, anything happens, so we named these components of the condensate. Water in a gas cylinder is dangerous because it provokes corrosion of the inner surface of the metal. The cylinder is not painted from the inside, and therefore easily rusts, and it is impossible to control this process. Such rust is detected only when it eats through the metal - and this is already too late and extremely dangerous.

Butane is added to household gas cylinders in a smaller amount than propane: in summer their ratio is about 2:3, and in winter - at least 2:8. This is only subject to refueling at a specialized station, and not with automobile gas. As we already mentioned, butane, unlike propane, does not turn into a gas at negative temperatures, so a cylinder installed outdoors may run out earlier than expected.

If you used bottled gas in late autumn or winter, especially if it was filled in summer, try bringing the bottle indoors after the gas stops flowing. Most likely, after its contents warm up to room temperature, you can use it for some more time.

Nothing needs to be done with condensate or frost on the outside of the cylinder, this moisture can only harm the container on which the paint layer is damaged: with prolonged and regular exposure, the steel of the cylinder may begin to rust, and corrosion can lead to leakage, fire and even explosion of the gas cylinder .

However, this will take quite a long time, so the task of the user is limited to maintaining a uniform and high-quality color.

Transport rules

- Transportation is carried out by specially equipped vehicles marked with warning signs.

- For the transportation of cylinders with LPG, technical gases, a special permit is issued.

- Each gas cylinder is marked with its own color: propane-butane domestic mixture - red, oxygen - blue, acetylene - white, carbon dioxide / nitrogen - black with the designation of a chemical element / compound, argon - gray, helium - brown.

- The joint transportation of tanks with different gases, as well as empty / used up together with full ones, is strictly prohibited.

- When transported in a car, they are laid horizontally no higher than the sides, no more than three rows; in a container - standing, and it is permissible to transport tanks with oxygen, acetylene together.

- Tanks with propane-butane can be transported standing up without containers, with a gasket between them and a reliable fence.

When loading / unloading gas cylinders, it is prohibited:

- To work alone, there must be at least two loaders.

- Work in overalls, gloves contaminated with fuels and lubricants, vegetable oils.

- Load oxygen tanks into a car body that has fuel spills / stains, as well as garbage, foreign objects.

- It is categorically unacceptable to carry tanks with gases on the arms/shoulders, to roll cylinders, and also to move them, dropping them, hitting them against each other.

- Hold, feed the container with the stop valves down.

- Load/unload tanks without protective caps.

Inside buildings, steel containers with any gases must be transported on a stretcher with a secure fastening or a special cart with wheels with rubber tires; at the same time, the joint transportation of two cylinders is permissible - with oxygen, acetylene for gas welding.

Terms of service

Normal and stable operation of gas equipment on a car is possible only with its timely maintenance (TO). HBO manufacturers of the 1st, 2nd and 3rd generations announce routine maintenance within 10-15 thousand km. car mileage. Which includes operations such as:

But in reality, it is often necessary to reduce the service interval by mileage, there are several reasons:

- low-quality gas fuel at gas stations (propane-butane mixture);

- low quality of spare parts, as well as their fakes;

- long engine operation on gas, when the car is parked (as is the case with engine oil).

If there is no certainty in the absence of these reasons, it is recommended to monitor the presence and pour out the oily liquid from the evaporator every 2-3 thousand km. mileage

In addition, it is important not to forget to remove condensate from the gearbox before preparing the car for winter operation.

Cylinder safety rules

Gas cylinders are extremely dangerous. Every year, dozens and hundreds of household gas cylinders explode, destroying housing and killing people, and in most cases the reason for this is a violation of the rules for their operation.

Refueling gas legally at a specialized substation, together with a full cylinder you will receive a memo on its safe transportation, storage and use. Among other things, it is forbidden to install cylinders closer than half a meter from a gas stove or a meter from a stove, heater or battery.

Do not allow the cylinders to heat up - from any devices or in the sun - this is fraught with their rupture. Also, you can not store them in a tightly closed cabinet without ventilation at the bottom of the doors: in the event of a leak, the gas will fill the cabinet, and in combination with oxygen from the air, the mixture becomes extremely explosive. The slightest spark or electric discharge is enough, and there will be an explosion.

You should not use a winter gas mixture with a high propane content in the summer: it will evaporate too actively, and the cylinder may swell or even burst from excessive pressure - and this is with 3 mm thick steel walls.

It is also forbidden to use swollen, dented or damaged cylinders: there is no guarantee that they are airtight and can withstand gas pressures up to 8 bar.

Refueling of gas cylinders

It is not necessary to buy a new cylinder every time when the gas from the previous one is used up. These containers are great for repeated use and thus save money to their owners.

Refueling household gas cylinders is a simple and ordinary procedure, the main attention of which should be given to safety

There are 4 options for filling up gas:

- specialized filling station;

- car filling stations (if special equipment is available);

- mobile modular station;

- home gas station.

It is better to focus on the first option - it is safer, employees have experience and equipment, they know how to assess the strength of vessels and use several methods of gas injection. At filling stations, employees often do not know how to work with gas and check containers, they do not have the necessary equipment, including scales to control the mass of a container. A specialized gas station would be a safer choice.

As for mobile modular stations, as a rule, they are used for filling oxygen cylinders. This is true for medical institutions and industrial enterprises that use oxygen daily in their work. The cost of such a station starts from 4 million rubles.

Gas cylinder filling methods

Proper filling of cylinders, domestic or travel, begins with checking the vessel. The manager evaluates:

- is there any damage and dents to the body (if there is, you should refuse to use the container and replace it with a new one);

- whether the valve and valve are in order;

- residual pressure in the empty container (there must be no pressure).

If the container is in order, you can start refueling. The design is quite simple. The cylinder is connected to the source of the substance by a special hose through which the gas enters the container. All necessary elements - valves, hoses, adapter, adapter - must be included. However, specialized stations usually have the necessary equipment.

There are 3 charging methods:

- Pumping. The simplest, the substance is pumped into the tank by a pump.

- Pump-evaporative. Simultaneously with the pumping of the substance into the cylinder, heating and an increase in pressure in the system occur.

- Pump and compressor. Differs in the increased pumping speed which compressors set to the pump.

The cost of refueling depends on the volume of the cylinder, but usually it is 200-300 rubles.

The color of the cylinder indicates the gas contained inside, blue for oxygen

Technical gases

Technical gases are substances that are used in industry, agriculture, medicine, and the service sector. Gas vessels are used not only in dachas and when traveling for space heating, cooking and refilling lighters, but also at various enterprises. Selling and refueling cylinders to a business can even become a separate line of income.

The most common technical gases include:

- helium - for melting, welding and cutting metals, as well as for inflating balloons;

- oxygen - in hospitals, as well as in metallurgy for fuel combustion;

- nitrogen - for the chemical and oil and gas industries, as well as in medicine for transporting internal organs.

food

Food or shielding gases are gas mixtures that are used to process food in order to protect it from the environment and extend its shelf life. They are not used at home, only in the food industry. They protect the product from interaction with oxygen, therefore they prevent oxidation and reproduction of microorganisms. As a rule, these are carbon dioxide and nitrogen. Harmless, legally allowed to use E290, E941, E938, E939, E942.

Also available in refillable bottles.

Leg welding

The legs or stand can be welded from improvised material, can be made collapsible or stationary, with or without tables. You can even use a stand from an old sewing machine, but I got by with the most economical option.

We take a corner and cut off two blanks of 14 cm each, we find a longitudinal welding seam on the cylinder, which we took as a reference line. We put the cylinder on a horizontal platform or on a table, so that the seam is at the bottom and, placing a corner parallel to the platform, weld it at a conventional distance from the edge of the cylinder so that the center of the corner shelf coincides with the welding seam of the cylinder.

We do the same on the other side. So we got the base for attaching the legs. And now we look if we need to make the legs not separate from the brazier, then we simply cut a 30x30 pipe or a corner in length, which will be convenient for us for the height of the brazier - about 50 to 70 centimeters. Next, weld it to the corner, which is on the cylinder.

And if we plan to make a collapsible structure, then we also cut the blanks into legs, but do not weld them to the corner, but drill holes of about 8 millimeters in the upper part of the leg and in the corner welded to the cylinder. Thus, we get a collapsible design: the cylinder is separated from the legs and can easily fit in the trunk of a car for going to a barbecue in nature.

It should be noted that the legs must also be mounted observing the identity of the dimensions and diagonal of the structure. In the lower part of the legs, it is desirable to weld the support patches, after cutting them out of sheet metal and placing the brazier on the legs on a flat area. This is necessary so that the brazier does not fall into the ground under its own weight and has good resistance to tipping over. For more convenient transportability, small wheels can be mounted on two legs.

What are

There are several standard container sizes for gas delivery.For frequent use, it is better to choose a large tank. Whereas a gas cylinder to the country house can be taken in a smaller size. It is more convenient to transport and it is easier for him to find a place in a limited space. Cylinders have the following characteristics:

| Volume (l) | Empty weight (kg) | Full container weight (kg) | Amount of gas in cubic meters | Permissible filling volume (l) |

| 5 | 4 | 6 | 0,95 | 4,3 |

| 12 | 5,5 | 11 | 2,59 | 10,2 |

| 27 | 14 | 26 | 5,38 | 13 |

| 50 | 22 | 43,2 | 10,01 | 42,5 |

It should be noted that the volume of propane being poured is less than the volume of the tank itself. This is due to the safety of the gas cylinder

Gas filled in winter expands significantly in a warm room and can burst the bottle if filled in excess.

Conclusions and useful video on the topic

Summing up, it can be argued that it is forbidden to store gas cylinders in an ordinary apartment. It is allowed to use 5-liter tanks connected to a stove of factory origin

At the same time, it is important to observe the distances specified in the requirements and always monitor the operation of the equipment.

Using the example of a hob, the procedure for connecting a gas bottle is shown.

Please note - at the end of the work, the tightness of the connections is checked:

You can provide interesting information on the topic, ask questions to experts, share your experience or participate in the discussion of this material - the contact block is located under the article.