- Grounding of individual household appliances and equipment

- How to make grounding for a gas boiler All about electricity

- What is it for?

- Scheme for heating a private house with a gas boiler: scheme for installing and piping a gas boiler

- Which heating scheme with a gas boiler is best suited for a cottage or a private house

- Rules and requirements of the PUE

- Best Answers

- Why are gas boilers grounded?

- Why is this a mandatory measure?

- Installation of protective circuit earthing switches

- How to choose the right grounding conductor?

- Requirements for the quality of grounding

- Ground loop resistance

- Do I need to ground a gas boiler

- Typical mistakes of home masters

- Types of grounding conductors and grounding methods

- DIY grounding device: step-by-step instructions

- Choosing a place for mounting the ground loop

- Excavation work

- Clogging of ground electrodes

- Welding

- backfilling

- Checking the ground loop

- Conclusions and useful video on the topic

Grounding of individual household appliances and equipment

It often happens that the owners of private houses (especially country houses) do not see the point of installing a full-fledged grounding. We cannot justify or condemn anyone, which means that this option is also worth considering. We will figure out how to ground a water heater in a private house without installing the entire protection system.

Grounding sign GOST-21130

This is quite simple to do using a natural ground electrode. From it you need to lay the cable directly to the device or to the outlet from which the device is powered. Often, in this way, a gas boiler is grounded in a private house, but any other household appliance can be protected in this way.

There are "electricians" who, when asked how to ground an outlet in a private house, advise throwing a jumper from the zero contact to the ground. It is clearly not worth listening to such advice - this is fraught with problems. We will definitely talk about such errors today. And now it is worth dwelling in more detail on how to check the finished ground loop, whether it meets the necessary requirements.

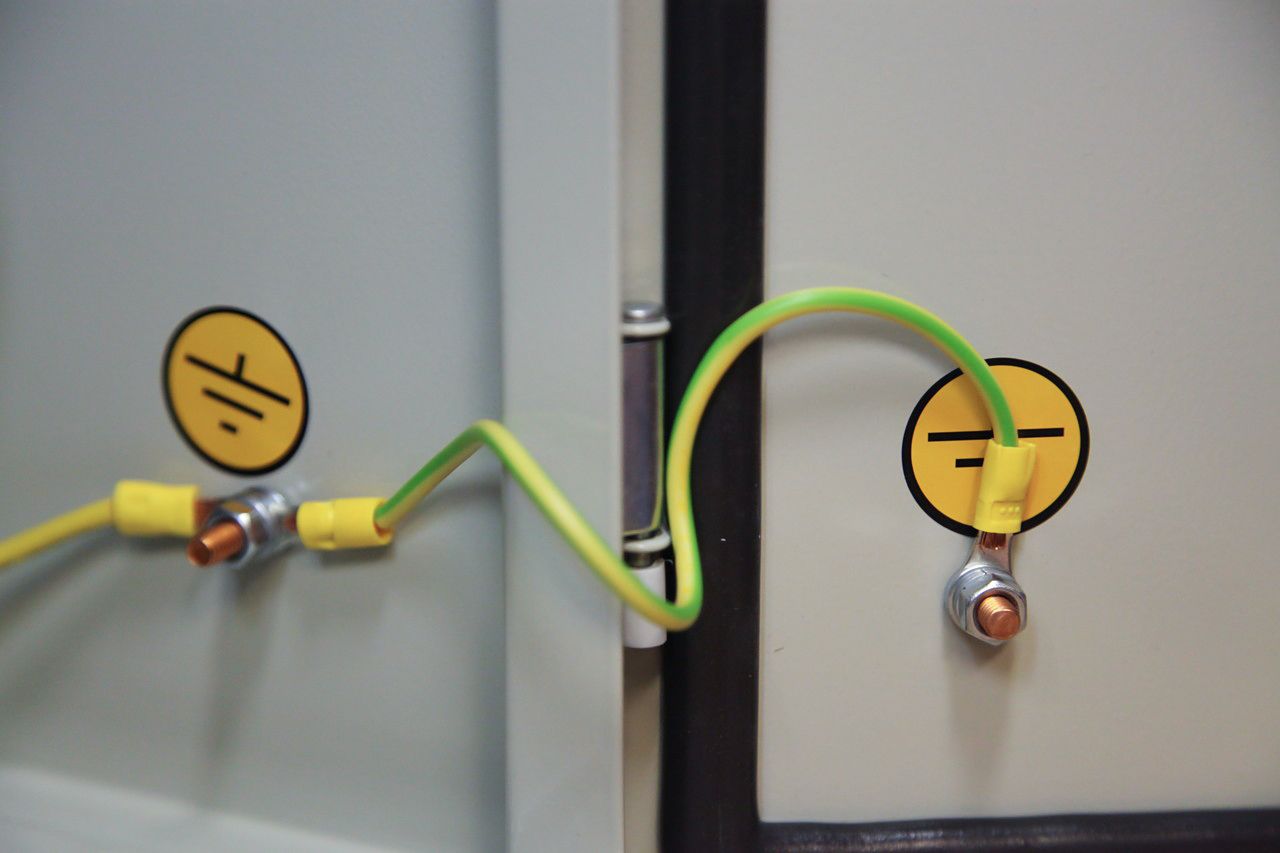

The seams of the connection on the tires must be well welded

How to make grounding for a gas boiler All about electricity

You are here: In order to enter into working condition and safe use of a gas boiler in an apartment or in a private house, it must be grounded, guided by certain papers, which indicate the rules and regulations.

As soon as the grounding is completed, acceptance documents must be drawn up. They contain information about various indicators that the grounding circuit has.

In this article, we will tell readers of the Sam Electrician website how to make a grounding of a gas boiler in a private house with our own hands.

What is it for?

Regardless of the principle of operation of the gas boiler, surface stress is formed on the body during operation. Grounding will avoid the following problems when contacting such equipment:

- Depreciation of electronics - boilers installed in a private house or apartment, as well as equipped with computer control, can fail under the influence of a harmful current of surface currents. The same can happen from static electricity. In this regard, from gas equipment for which a ground loop is not equipped, one should not expect long-term uninterrupted operation, and correcting the situation by replacing the processor will be extremely expensive.

- Explosiveness - electricity of a static nature very often causes the subsequent explosion of devices operating on gas under pressure. If you make grounding, the possibility of an arc will be excluded.

Scheme for heating a private house with a gas boiler: scheme for installing and piping a gas boiler

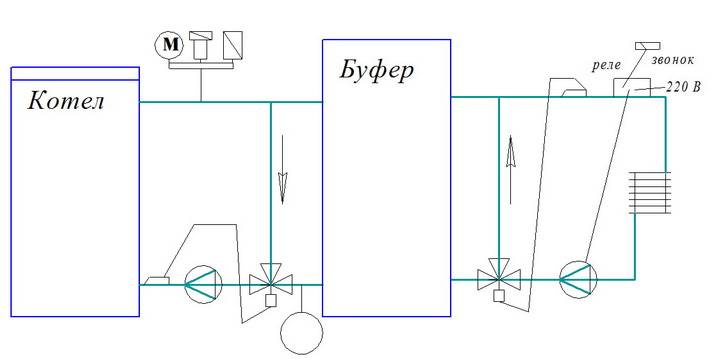

A comfortable private house should have comfortable heating. Even during the design it is necessary to lay, think over the scheme of heating systems. Gas heating is more often chosen as heating. Since this heating system reliably, effectively heats the entire room.

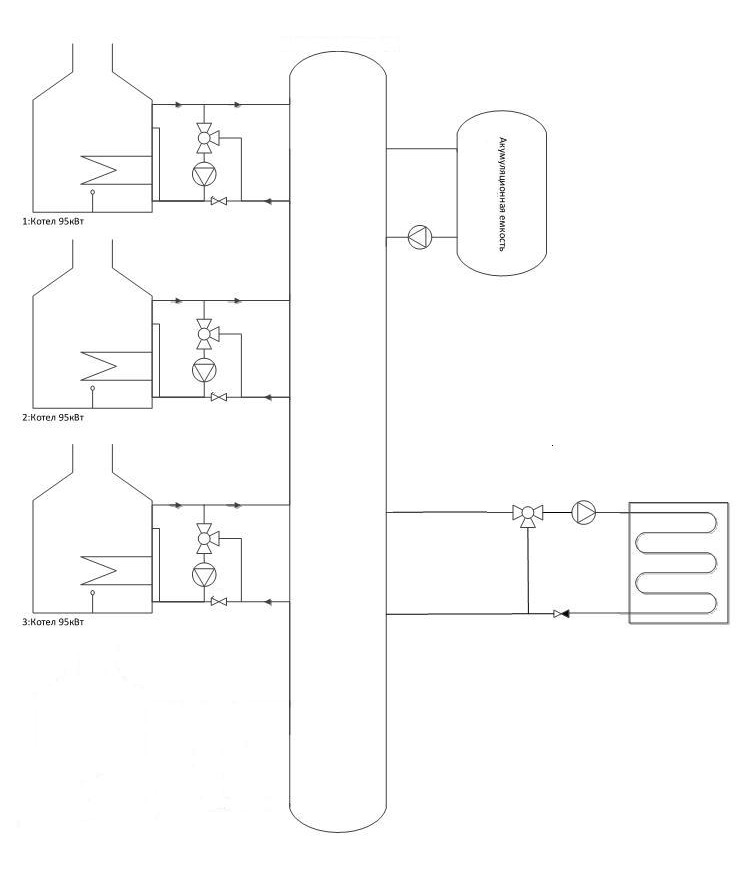

Which heating scheme with a gas boiler is best suited for a cottage or a private house

When it is planned to equip the entire system without the help of professionals, then you need to calculate the heating scheme.

There are two types of gas heating circulation:

- forced circulation is carried out thanks to pumps;

- natural produces movement, due to the difference in the densities of hot and cold water.

IMPORTANT. The natural one works better when the equipment is installed lower in level relative to the radiators. For stable movement of the coolant, it is necessary to make a natural slope of the pipelines

For stable movement of the coolant, it is necessary to make a natural slope of the pipelines.

At artificial it is possible to install a pump. The installation is simple, but the pump with artificial circulation has disadvantages: uneven heating, dependence on electricity and the possible occurrence of air pockets.

Heating wiring happens:

- Single pipe. Suitable for a not too large area with a small number of rooms, when using this wiring, the temperature in the pipes varies.

- Two-pipe. Difficult to implement, suitable for adjusting the temperature in different rooms.

ATTENTION. When using single-pipe wiring, a big minus is revealed: the lower part of the radiator does not heat up well. Radiators will warm up differently on different floors in the house

This problem can be solved by installing jumpers to the batteries, increasing the volume of the batteries. Also, for sufficient movement of the coolant, it is recommended to install pumps

Radiators will heat up differently on different floors in the house. This problem can be solved by installing jumpers to the batteries, increasing the volume of the batteries. It is also recommended to install pumps for sufficient movement of the coolant.

The advantage is the easy installation of the wiring, which you can do yourself. During installation, a small amount of materials is spent, which is also a plus.

Two-pipe wiring heats the pipes evenly. However, it requires a large amount of material for installation, pipe laying. The advantage of two-pipe wiring is the ability to regulate pipes with shut-off valves.

REFERENCE. There is also a Leningrad wiring. A pipe is attached to it, which circulates the liquid in parallel.This system is suitable for arranging a cottage or a private house.

Rules and requirements of the PUE

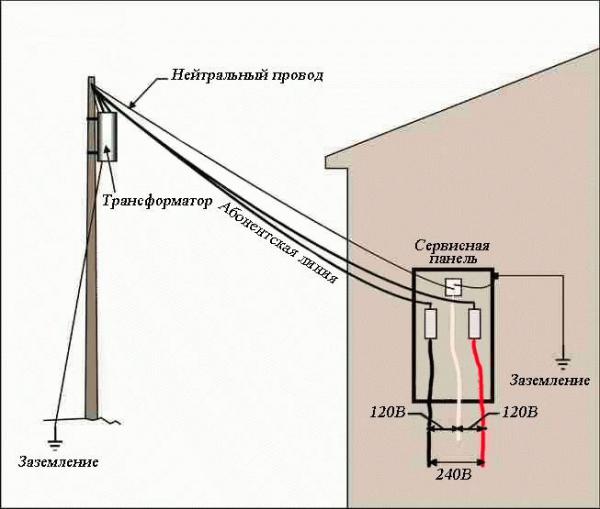

At any residential facility located within the city limits and beyond, in accordance with the requirements of the PUE, special protection against dangerous voltages of 220/380 Volts is organized. For this purpose, special steel structures called grounding devices (GD) are arranged on their territory. Their main purpose is to create conditions that guarantee the protection of people living in the house from electric shock.

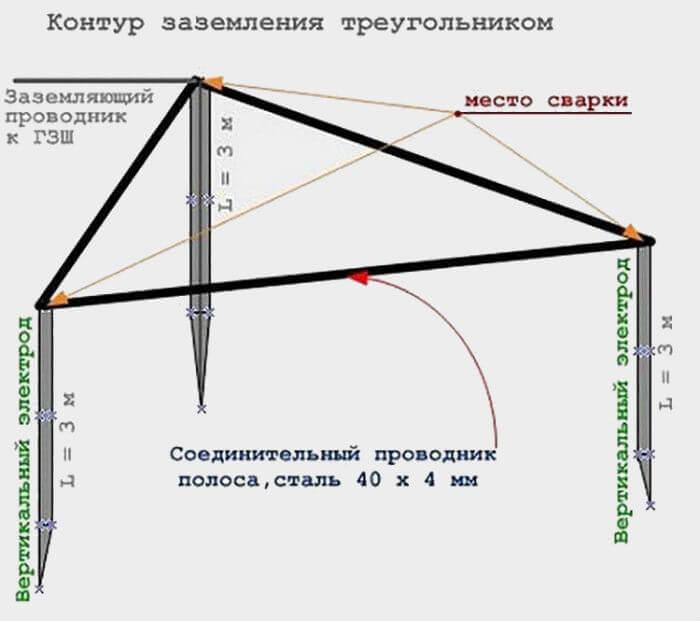

In accordance with the PUE, chapter 1.7., Part 1, clause 1.7.72, the dimensions of the metal blanks are selected taking into account the need to obtain the required resistance to the spreading of current into the ground. For various structural elements, these indicators may vary from sample to sample. However, their minimum dimensions must comply with the following standards:

- the connecting strip between the pins cannot be smaller than 12x4 mm (section 48 mm2);

- the pins themselves based on the corners are selected with sides of 4x4 mm;

- when using a round reinforcing bar, the cross section should not be less than 10 mm2;

- the metal pipe should have a wall thickness of about 3.5 mm.

During its arrangement, it is necessary to act in accordance with the provisions of industry standards regarding the operation of the equipment available at the facility.

Best Answers

Milana Sokolova:

Take a copper wire with a cross section of 4 squares and connect it to the boiler and the ground loop of the house (buildings, structures).

Uvarov Sergey:

In new houses, grounding is already provided. In the old ones, a wire is taken, soldered to an old bucket, and the bucket is buried in the ground to a depth of about 1 meter.

Egor Shilov:

in general it is necessary to weld the contour

Cloths:

it is not clear where the name of the boiler has to do with it))) 0 And what kind of scheme is needed? How to drive in reinforcement with a triangle to a depth of three meters? )))0 Well, or how then to weld these three fittings together and throw a wire from the circuit to the boiler? )))0

Why are gas boilers grounded?

There are two main reasons why you should pay attention to connecting the heater's steel body to the neutral bus:

- The electronic control systems of the installation are sensitive to various surface currents or statics that accumulate on metal parts during operation. The result of exposure to such undesirable factors may be a malfunction of the processor or its failure.

- With possible gas leaks, the appearance of a spark in most cases leads to an explosion. Grounding neutralizes any potentials or leaks, eliminating the possibility of an accident.

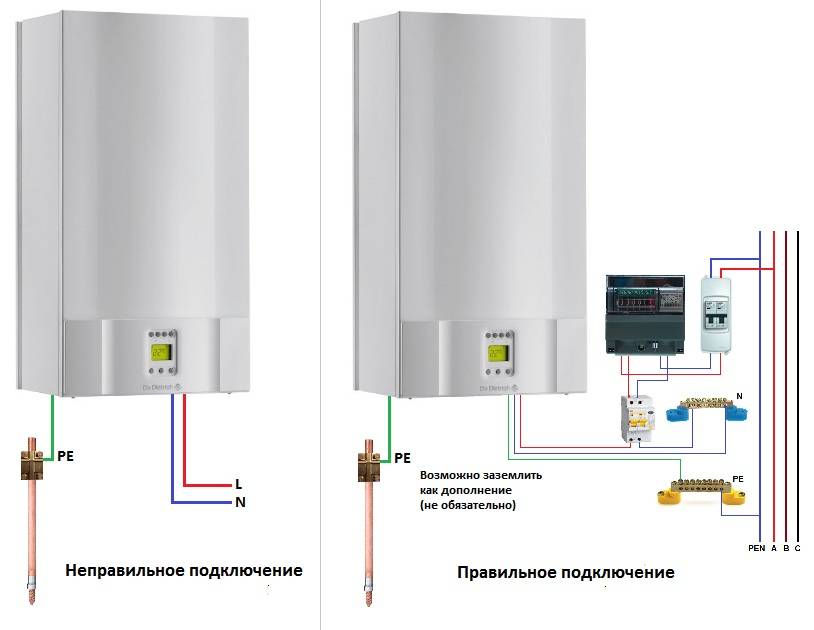

Why is this a mandatory measure?

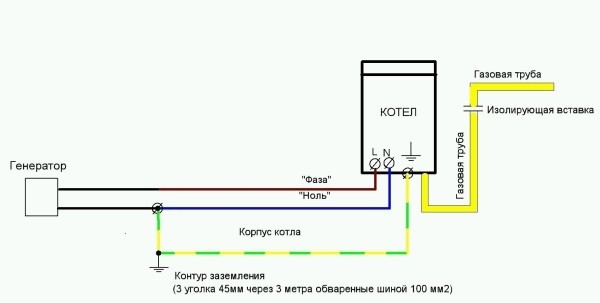

A gas boiler or other gas equipment, like a car, are sources of increased danger. For him, in most cases, the correct connection of the zero and phase of the mains is critical.

It is also necessary that the grounding of metal parts be correctly removed, potential equalization is carried out. Often there are problems with static electricity inside gas pipelines.

Incorrectly connected devices are ways to claim human lives. One caviar is enough for the irreparable to happen. That is why tolerances and norms are so strictly controlled here.When connecting the boiler, electricians have a great responsibility.

There are also situations when the gas boiler is connected to the power grid on its own, by a private person.

At the same time, it is especially important to confirm the compliance of the work performed with safety requirements.

Installation of protective circuit earthing switches

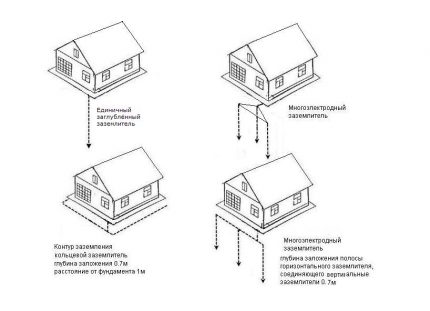

When reconstructing or building a private house, the missing grounding device can also be done by hand. The efficiency of the circuit depends on the selected connection scheme, type and soil resistivity.

The location and number of electrodes can be carried out according to any of the proposed schemes. The required resistance is achieved by increasing either the length of the electrode or the number of ground electrodes.

The resistance of a grounding device used solely to protect a person from being hit by static electricity in an air duct can be increased to 100 ohms. The following article will introduce you to the methods of measuring resistance, which we recommend reading.

It is advisable to photograph all the stages of hidden work during the installation of the ground loop. Printed paper photographs, hand-drawn diagrams with exact dimensions and specified materials, keep with the test reports.

These are serious documents, which are called the passport of the grounding device. With their help, you can control circuit changes, plan repairs, and even reduce insurance company rates when you take out a home policy.

How to choose the right grounding conductor?

As an artificial ground electrode, steel pipes, corners, strips are chosen, which are driven into the ground. The following requirements are imposed on the grounding conductor, the circuit element:

- carrying out special anti-corrosion treatment (copper plating or galvanizing);

- the presence of at least two contacts with separate parts of the boiler surface when using natural grounding.

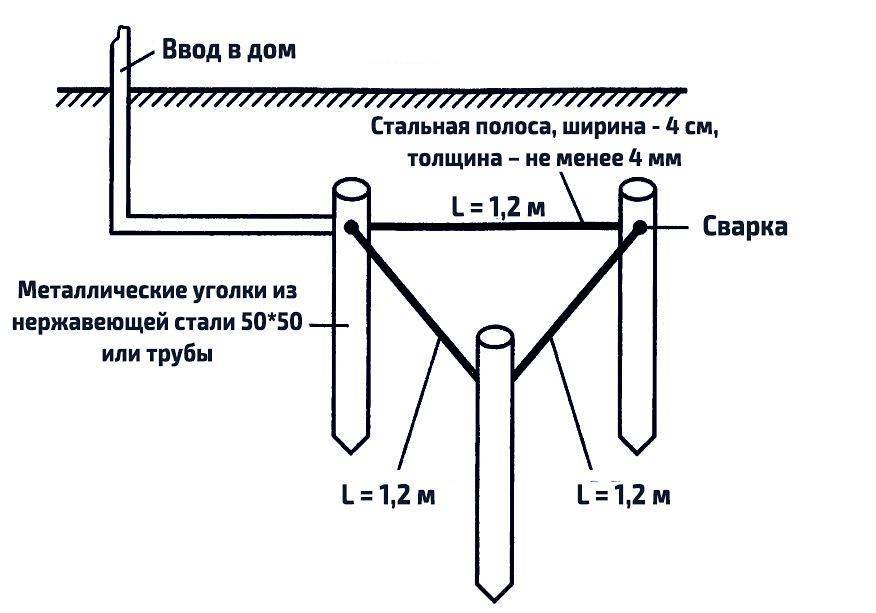

Depending on the resistance level of the circuit (optimally 30 ohms for a voltage of 220/380 volts), the circuit materials, tires, and the number of electrodes are selected. Loop electrodes are made from 2" tubing or angle steel material up to 50 square millimeters in cross section and two meters in length. The tire is knocked out in the form of a steel or copper strip.

Requirements for the quality of grounding

When carrying out the installation of grounding, it is necessary to pay attention to the type of material and the cross-sectional area of \u200b\u200bthe wires that connect the circuit to the zero phase of the switchboard. When using copper wire, the recommended cross section is more than 10, aluminum - at least 16, steel - more than 75 millimeters square. Steel pipes and angles (electrodes) are connected to the bus using spot welding

Steel pipes and angles (electrodes) are connected to the bus using spot welding.

Ground loop resistance

The type of soil also matters. A circuit can be installed in muddy soil if its resistance does not exceed 10 ohms (at a standard voltage of 220 volts or a three-phase value of 380 volts). It is possible to mount a ground loop in sandy soil with a resistance value of up to 50 ohms (for devices operating from 220 or 380 volts). If such requirements are met, there will be no claims from the gas service.

Do I need to ground a gas boiler

All gas boilers have a metal case; when connected to the mains, a dangerous potential may appear on it.In view of its low power, it is not life-threatening and not so painful for a person, but it can lead to other rather serious consequences: from failure of automation to explosive situations.

Therefore, all home floor or wall-mounted volatile boilers that require connection to the mains must be grounded without fail, guided by the Electrical Installation Rules, namely the current seventh edition (PUE-7).

The grounding structure is a conductor between the boiler or the house's electrical network and the ground. It is known that the earth is capable of "absorbing" electric current, therefore, with the correct selection of the wiring section and the resistance of the ground loop, you can be guaranteed to protect yourself and the boiler from dangerous potential and sudden power surges.

In total, grounding is necessary for:

- prevention of breakdown of automation - in addition to the fact that the electrical boards (automatic) of gas boilers are vulnerable to voltage surges that can lead to a complete failure that cannot be restored, the presence of a positive potential on the case can affect the normal operation of the automation during operation;

- electrical shock exceptions - usually a mild charge that does not cause obvious pain, but there are cases of a serious potential dangerous for people with a weak heart. And in general, the presence of potential on the body of an electrical appliance used by a person is not the norm;

- reducing the explosion hazard of the boiler - a static charge can cause spontaneous combustion, especially when it comes to working with natural gas under high pressure.

As a rule, point grounding of a gas boiler does not make sense, because. the scope of work and design practically correspond to the grounding of the entire electrical network of the house. The device is connected to the ground shield through the RCD (residual current device) using a three-wire wire.

Typical mistakes of home masters

Self-grounding can be done flawlessly. But sometimes inattention, haste, low practical skills lead to errors in installation.

The most common common flaws and flaws:

- Weak contact due to the protective coating of detachable connections;

- Non-compliance with the standards of the size of grounding conductors;

- Rapidly collapsing material of the elements of the grounding system;

- Connection of zero working and protective conductors.

For some reason, many people advise to place grounding conductors far from home, choosing the distance numbers from the depths of their consciousness. All these settings are advisory, but optional. The contour does not pose any danger to humans, there are no restrictions in the distance rules.

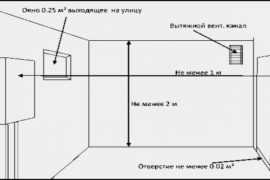

The connection of the grounding of air ducts with the grounding loop of lightning rods is not allowed. The huge current flowing through the ground during a lightning strike can disable the entire ventilation system

Some "experts" advise to pour salt into the ground to the ground electrodes for better conductivity. No need to listen to amateurs, consult with professionals.

Indeed, at the beginning, due to an increase in humidity, a slight decrease in the spreading resistance of the ground loop is possible. But metal elements in such an environment will quickly collapse due to the acceleration of the corrosion processes of ground electrodes.

Types of grounding conductors and grounding methods

Before proceeding with the very procedure for grounding a gas boiler, it is important to choose the right type of ground electrode. The ground electrode is a key element of the grounding device, which is presented in the form of an electrode in contact with the ground. The grounding conductor is a key element of the grounding device, which is presented in the form of an electrode in contact with the ground.

The ground electrode is a key element of the grounding device, which is presented in the form of an electrode in contact with the ground.

There are two types of ground electrodes: natural and artificial.

Natural grounding conductors are metal structures (most often reinforcement for reinforced concrete structures) that are immersed in the ground

There is one very important rule: a natural grounding conductor must have at least two contacts with grounding conductors with boiler equipment. It is unacceptable to use pipelines with explosive or combustible liquids as a natural grounding conductor, and it is also worth immediately abandoning the idea of \u200b\u200busing sewer and heating pipes. Artificial ground electrodes are special devices that are made specifically for these purposes.

Among such products: metal pipes that are mounted vertically, steel corners, metal strips placed horizontally

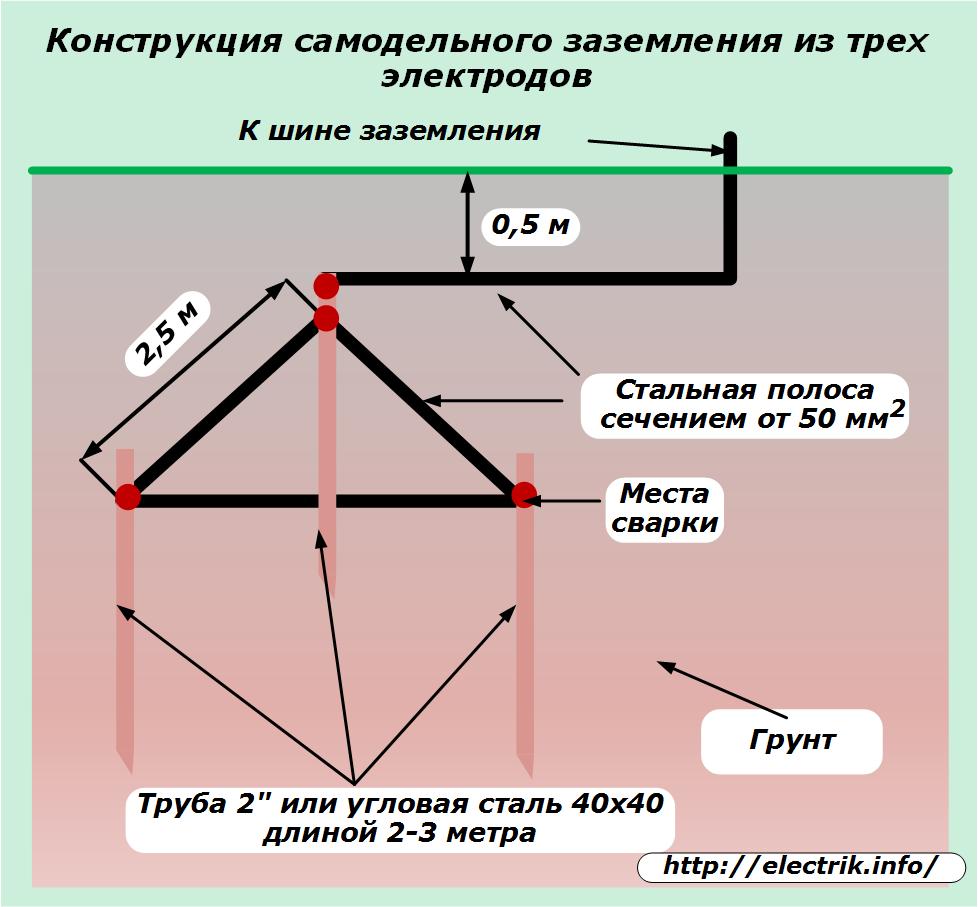

Artificial ground electrodes are special devices that are made specifically for these purposes. Among such products: metal pipes that are mounted vertically, steel corners, metal strips placed horizontally.

Ground electrode made of steel plate and angle

There are also several options for installing a ground loop. Installation stands out:

- by type of device - when you need to perform a separate grounding of the gas boiler. Washing machines, refrigerators, kettles have different requirements and specifications than heating appliances. PUE impose higher requirements for connecting a gas boiler. Therefore, if you are going to install grounding using a socket, then remember that you need to connect it not to the switchboard, but to the circuit itself;

- according to the manufacturing features, the connection process is carried out with a ready-made kit, which is specially made for connecting to a gas boiler, or using improvised materials.

To ground a gas boiler with your own hands, first of all, you need to acquire all the necessary materials:

- the cross section of the ground wire from the shield to the circuit placed in the ground must have the following values: a copper product must be at least 10 mm², aluminum - 16 mm², steel - 75 mm²;

- as vertical pins that are driven into the ground, steel pipes or corners are usually used, fastened to one another by spot welding. Ready-made kits include galvanized or copper-plated electrodes;

- automation and RCD - the boiler is connected to a panel with installed electrical fittings. The PUE does not allow the installation of an RCD with a gas boiler without grounding. It is impossible to duplicate the safety systems in the case when the ground loop is simultaneously installed together with the residual current device.

If you are not confident in your abilities and you do not have experience in similar activities, then it is better to turn to specialists who will perform grounding.

Summing up the above, it is worth saying that the gas grounding system is a very important stage, which in no case should be neglected. A correctly performed procedure is not only a guarantee of the successful operation of the equipment, but also the safety of the residents of the house.

DIY grounding device: step-by-step instructions

If you are wondering: “how to make grounding in the country?”, then the following tool will be required to complete this process:

- welding machine or inverter for welding rolled metal and outputting the circuit to the foundation of the building;

- angle grinder (grinder) for cutting metal into specified pieces;

- nut plugs for bolts with M12 or M14 nuts;

- bayonet and pick-up shovels for digging and digging trenches;

- a sledgehammer for driving electrodes into the ground;

- perforator for breaking stones that can be encountered when digging trenches.

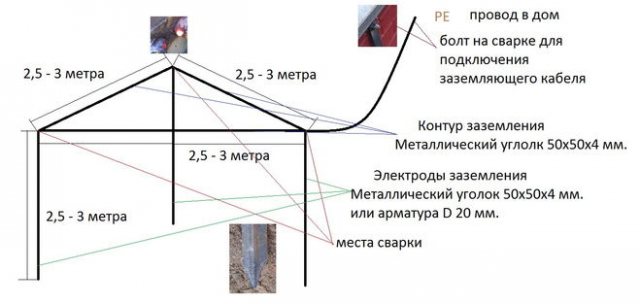

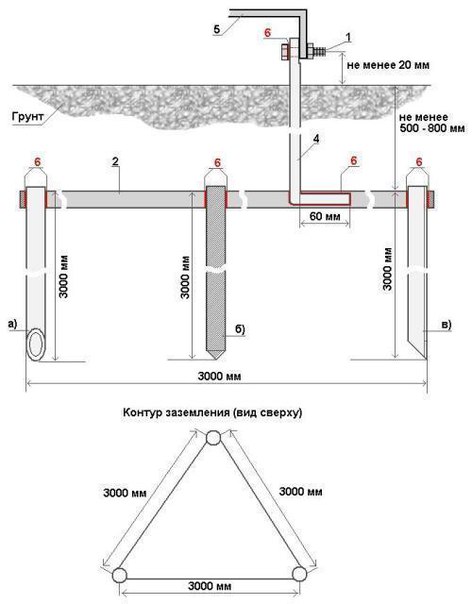

In order to properly and in accordance with regulatory requirements to perform a ground loop in a private house, we need the following materials:

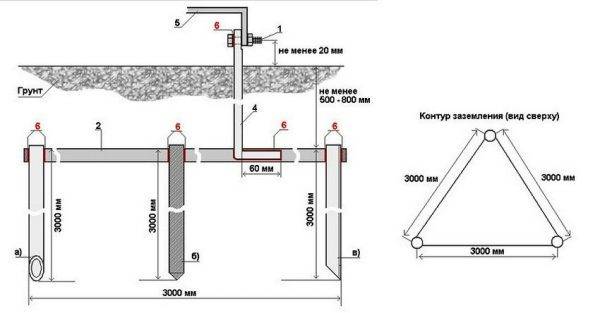

- Corner 50x50x5 - 9 m (3 segments of 3 meters each).

- Steel strip 40x4 (metal thickness 4 mm and product width 40 mm) - 12 m in case of one point of the ground electrode to the building foundation. If you want to make a ground loop throughout the foundation, add the total perimeter of the building to the specified amount and also take a margin for trimming.

- Bolt M12 (M14) with 2 washers and 2 nuts.

- Copper grounding. A grounding conductor of a 3-core cable or a PV-3 wire with a cross section of 6–10 mm² can be used.

After all the necessary materials and tools are available, you can proceed directly to the installation work, which is described in detail in the following chapters.

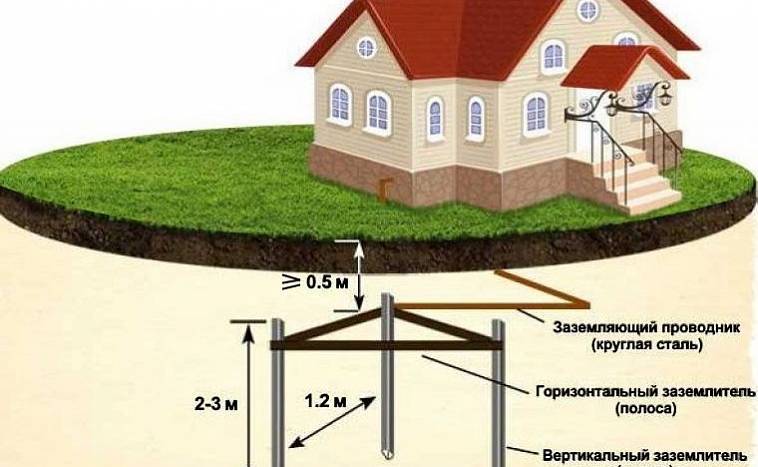

Choosing a place for mounting the ground loop

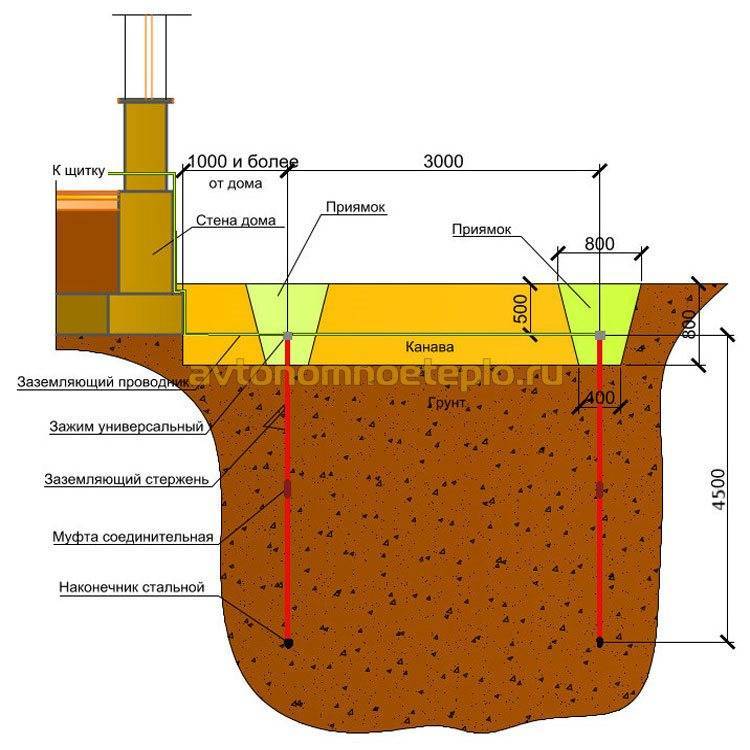

In most cases, it is recommended to mount the ground loop at a distance of 1 m from the foundation of the building in a place where it will be hidden from the human eye and which will be difficult for both people and animals to reach.

Such measures are necessary so that if the insulation in the wiring is damaged, the potential will go to the ground loop and step voltage may occur, which can lead to electrical injury.

Excavation work

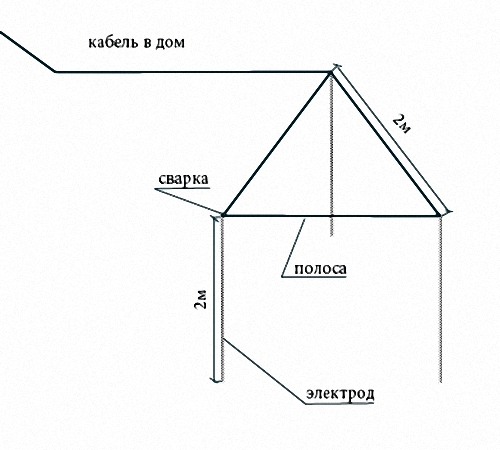

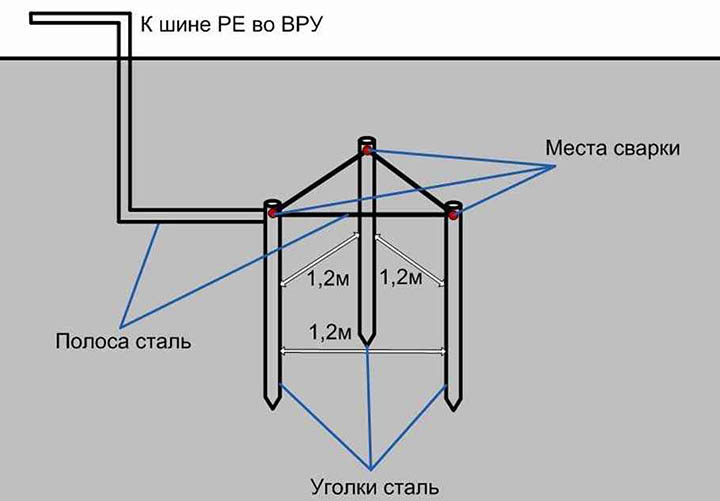

After a place has been chosen, markings have been made (under a triangle with sides of 3 m), the place for the strip with bolts to be placed on the foundation of the building has been determined, earthworks can begin.

To do this, it is necessary to remove a layer of earth of 30–50 cm along the perimeter of the marked triangle with sides of 3 m using a bayonet shovel. This is necessary in order to subsequently weld strip metal to the ground electrodes without any special difficulties.

It is also worth additionally digging a trench of the same depth to bring the strip to the building and bring it to the facade.

Clogging of ground electrodes

After preparing the trench, you can proceed with the installation of the electrodes of the ground loop. To do this, first with the help of a grinder, it is necessary to sharpen the edges of a corner 50x50x5 or round steel with a diameter of 16 (18) mm².

Next, put them at the vertices of the resulting triangle and use a sledgehammer to hammer into the ground to a depth of 3 m

It is also important that the upper parts of the ground electrodes (electrodes) are at the level of the excavated trench so that a strip can be welded to them

Welding

After the electrodes are hammered to the required depth using a 40x4 mm steel strip, it is necessary to weld the ground electrodes together and bring this strip to the foundation of the building where the ground conductor of the house, cottage or cottage will be connected.

Where the strip will go to the foundation at a height of 0.3–1 mot of the earth, it is necessary to weld the M12 (M14) bolt to which the house grounding will be connected in the future.

backfilling

After all welding work has been completed, the resulting trench can be filled up. However, before that, it is recommended to fill the trench with brine in the proportion of 2-3 packs of salt per bucket of water.

After the resulting soil must be well compacted.

Checking the ground loop

After completing all the installation work, the question arises "how to check the grounding in a private house?". For these purposes, of course, an ordinary multimeter is not suitable, since it has a very large error.

To perform this event, devices F4103-M1, Fluke 1630, 1620 ER pliers and so on are suitable.

However, these devices are very expensive, and if you do the grounding in the country with your own hands, then an ordinary 150–200 W light bulb will be enough for you to check the circuit. For this test, you need to connect one terminal of the bulb holder to the phase wire (usually brown) and the other to the ground loop.

If the light bulb shines brightly, everything is fine and the ground loop is fully functional, but if the light bulb shines dimly or does not emit a luminous flux at all, then the circuit is mounted incorrectly and you need to either check the welded joints or mount additional electrodes (which happens with low electrical conductivity of the soil).

Conclusions and useful video on the topic

And finally, we offer a selection of videos where you can get a visual representation of how to safely ground a gas boiler in a private house.

In this video, you can see the construction of a 4-rod ground loop with the task of achieving a resistance of up to 7 ohms:

Another option for arranging a gas boiler circuit for a private house connected from a pole:

The grounding system is an important step that should not be neglected when installing a gas boiler

And if you are not sure that you can correctly install and connect the circuit to the shield, it is better not to take risks and contact the builders, because not only the safety of expensive equipment is at stake, but most importantly, your safety and even life

Tell us about how the grounding system was built in your suburban area. It is possible that you have information that will be useful to future independent installers of grounding systems. Please write comments, post photos on the topic and ask questions in the block below.