- Connecting the deep pump to the water supply system

- Methods for laying a conduit

- Equipment selection

- Caisson or adapter

- Pump units

- Accumulator and relay

- Well cap

- Scheme of water supply of the site from the well

- Kinds

- 1st generation

- 2nd generation

- 3rd generation

- Connection order: step by step instructions

- Internal piping

- Water supply insulation

- Device and principle of operation

- Outdoor plumbing

- Self-installation of water supply in the country

- Source of water supply

- Construction type and wiring diagram

- How to choose the right size of pipes for plumbing?

- Photo of water supply in the country with their own hands

Connecting the deep pump to the water supply system

When constructing an individual water supply system, even at the stage of drilling operations, one should know the diameter and material of the pipeline, the depth of the water line, and the operating pressure in the system for which the equipment is designed. When installing and turning on the water supply, the following recommendations are guided:

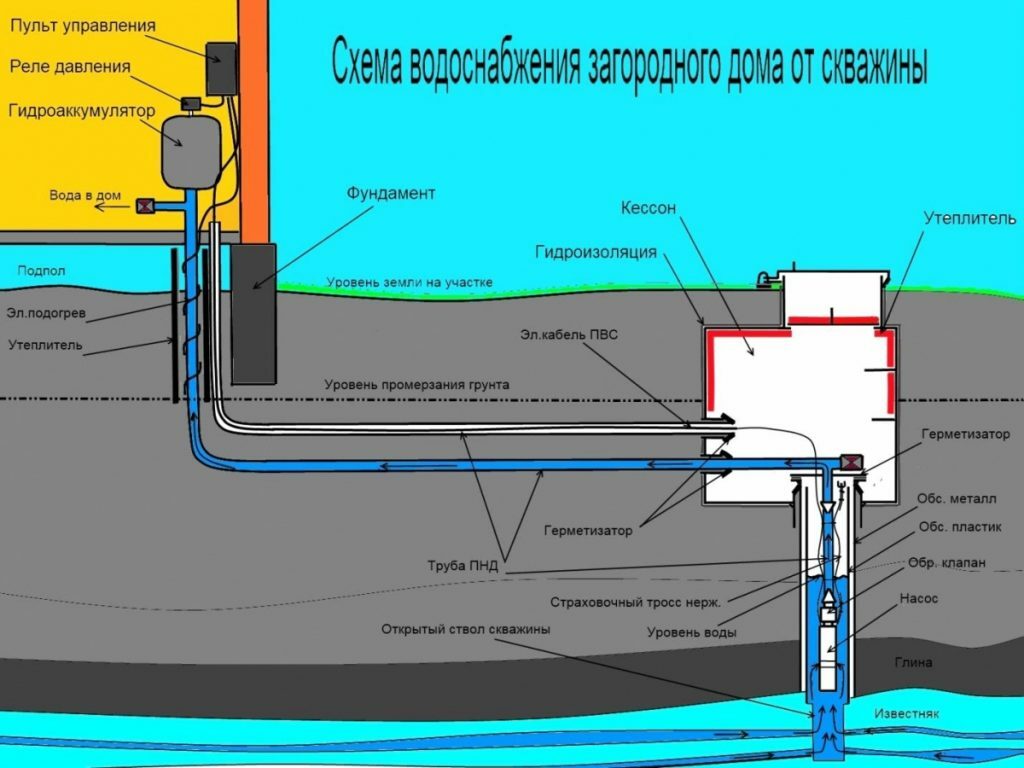

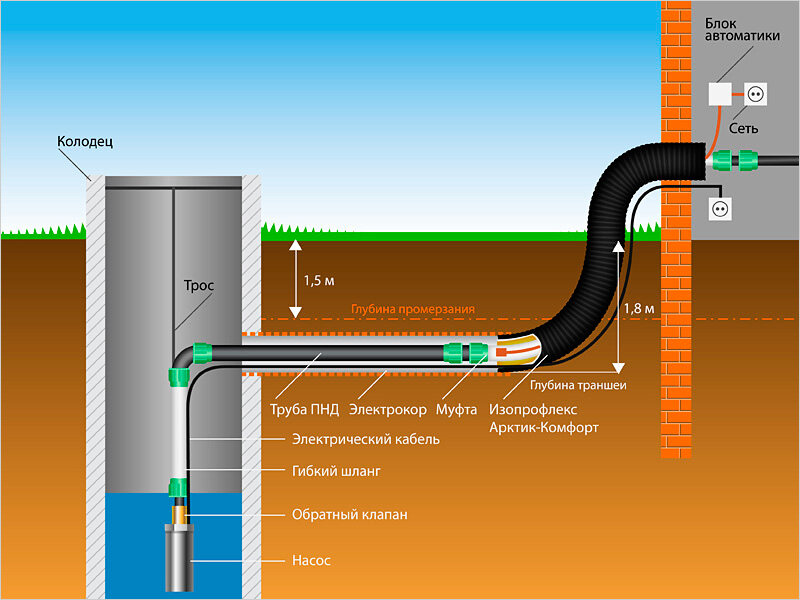

When using the plumbing system in winter, you will have to take measures to protect it from the cold. Typically, pipes are laid underground and they must come out of the head of the well, so a caisson pit will be needed to install and maintain equipment.To make it more convenient and reduce the depth, the water line is insulated and heated with an electric cable.

Rice. 6 Assembling a pumping station with your own hands - the main stages

- When determining the immersion depth of the electric pump, set the dynamic level with the equipment turned on and hang the unit 2 meters below the set mark, the minimum distance to the bottom for deep models is 1 meter.

- When using sand wells, it is mandatory to install sand or coarse filters in the water line before the equipment.

- Electric pumps change their pumping efficiency when the supply voltage changes, so for stable operation it is better to purchase a voltage stabilizer and connect equipment to it.

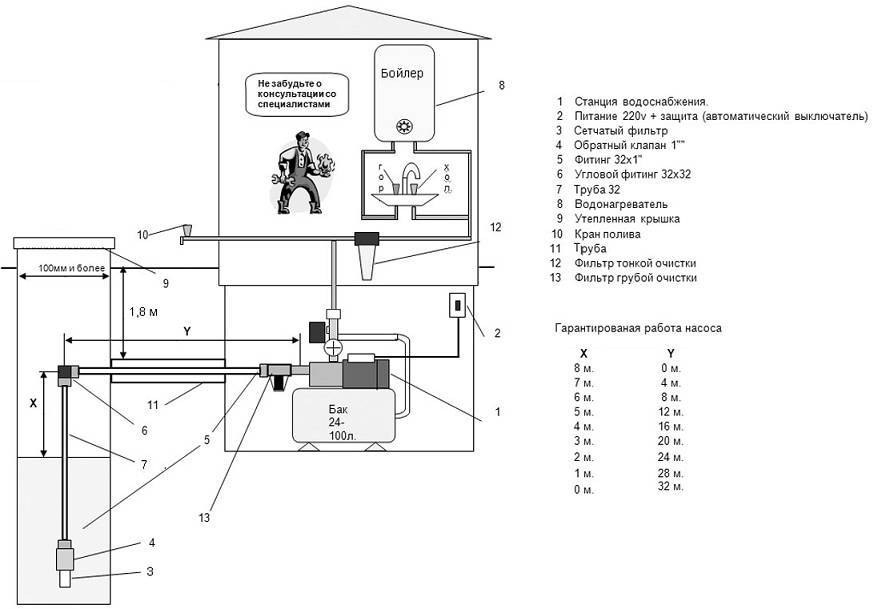

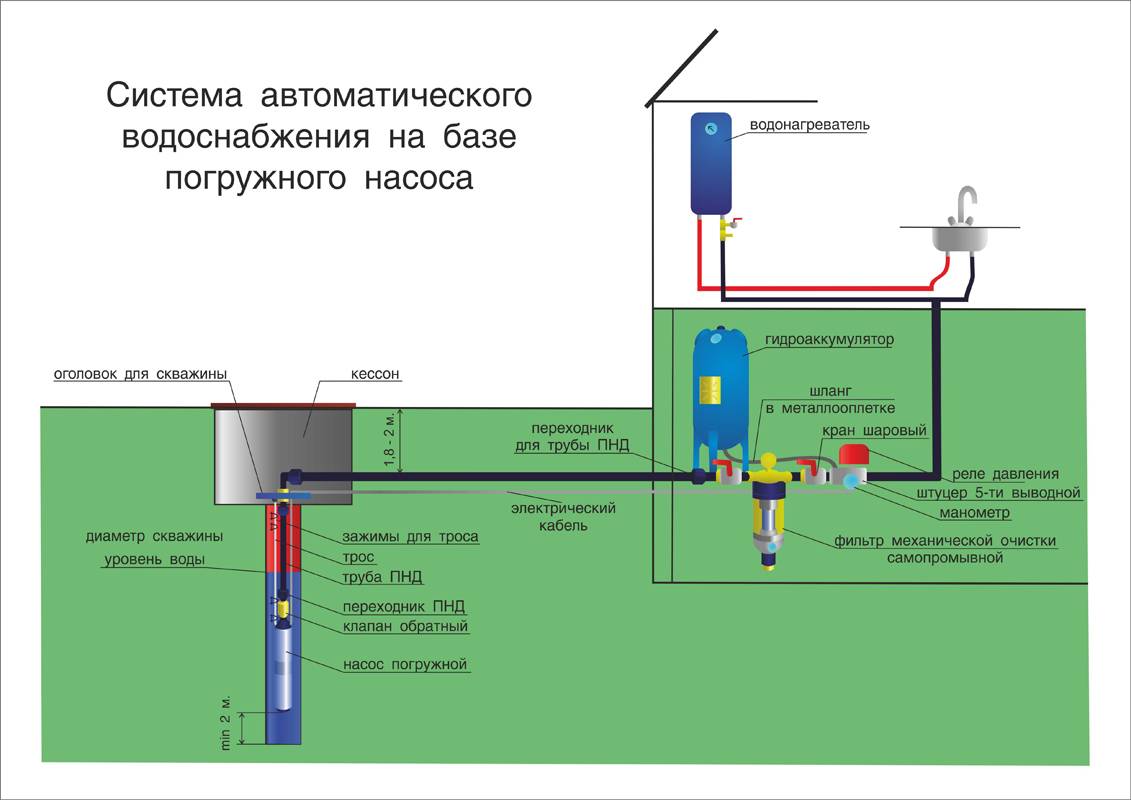

- For ease of operation and maintenance, a do-it-yourself pumping station is often assembled. A pressure gauge and a pressure switch are mounted on the accumulator using a standard five-inlet fitting, but since there is no branch pipe for attaching a dry-running relay, it will have to be installed on an additional tee.

- Often electric pumps have a short power cable, not long enough to connect to the mains. It is extended by soldering, similar to the further insulation of the connection point with a heat shrink sleeve.

- The presence of coarse and fine filters in the plumbing system is mandatory. They must be placed before the automation of the control system, otherwise the ingress of sand and dirt will lead to their incorrect operation and breakdowns.

Rice. 7 Placement of automatic equipment in the caisson pit

Methods for laying a conduit

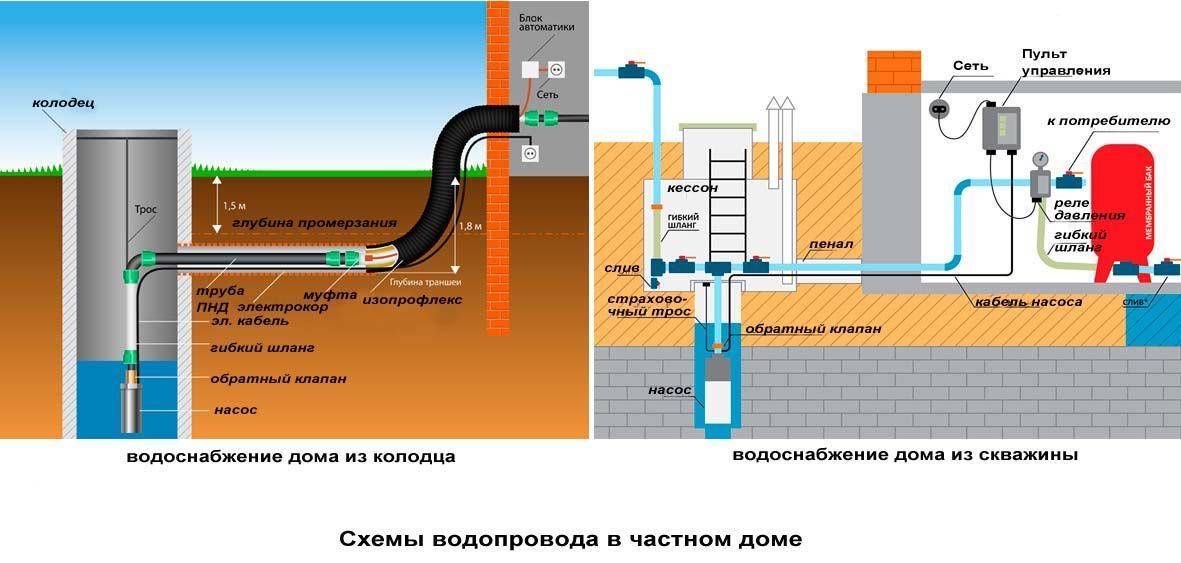

The typology of methods for laying a pipeline for supplying drinking water from a well to a house is made based on the position of the conduit relative to the earth's surface and includes laying:

- underground, below freezing level;

- underground, above the level of freezing;

- above the ground, on the surface or on a slight elevation;

- above the ground, at a height higher than human height.

Water supplied to a private house or country house from a well below the soil freezing level will never freeze even if there is no flow in the pipeline section. However, in order to carry out autonomous water supply from a well in this way, it will be necessary to carry out significant amounts of earthworks, which are not always doable by one's own hands, which will depend on the distance of the pit from the residential building and the required depth of excavation, which is up to 2 meters for the northern regions. When deepening below 1 meter, safety requirements regulate the strengthening of the walls of the trench with wooden formwork and the equipment of stairs for descent and ascent, which increases the cost of work and makes them longer.

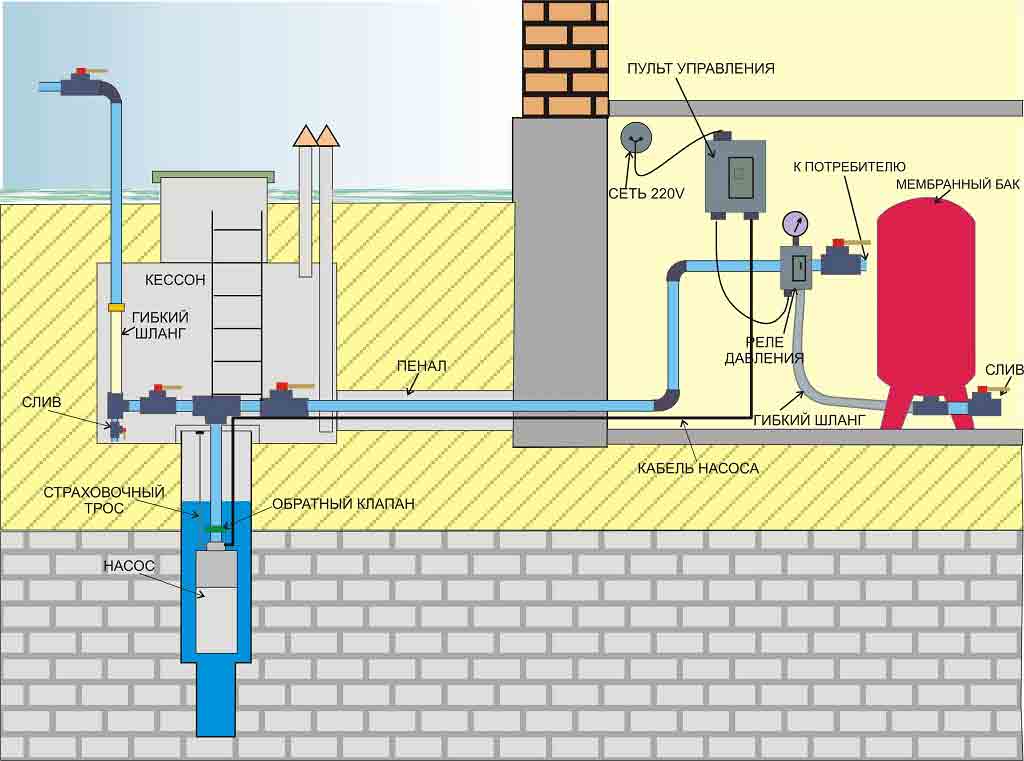

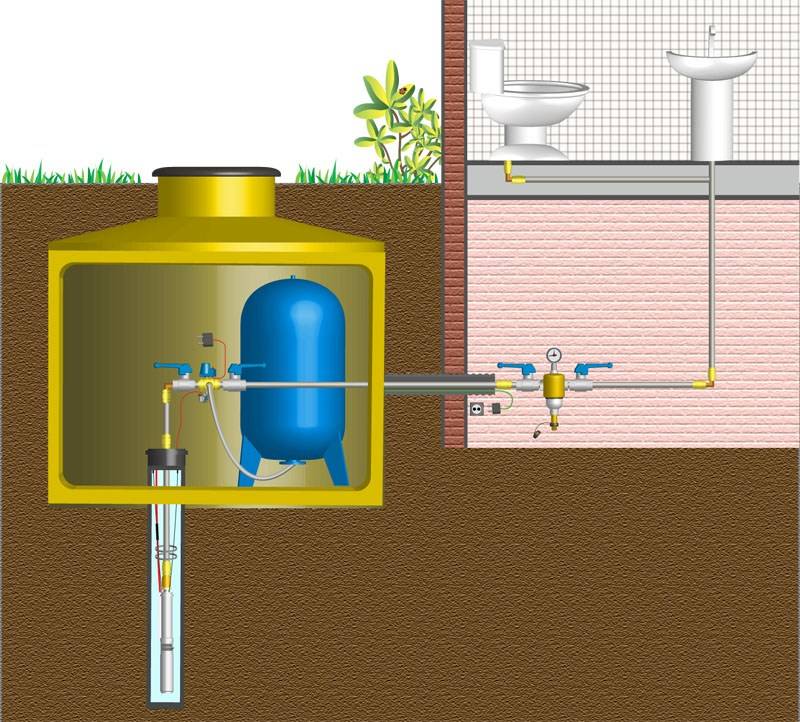

Schematic diagram of the water supply of the house through the caisson, an alternative is a downhole adapter.

Schematic diagram of the water supply of the house through the caisson, an alternative is a downhole adapter.

Reducing the amount of earth dug by one's own hands due to the depth of the trench will lead to the potential possibility of water freezing in the pipe, not only in the "standing" mode, but also in the presence of a constant flow in the system. Thus, such a scheme for connecting water supplied from a well to a house in a country house will require not only additional thermal insulation, but also a heating device using a heating cable or heat tracer.

Having completed the water supply of a private house from a well by laying a pipeline with your own hands on the surface of the earth or laying them on small foundation supports, you can completely get rid of the development of the soil, providing the possibility of constant visual monitoring of the state of the conduit. The absence of earthworks with frozen soil makes it possible to connect a water well to the house with your own hands even in winter, provided that the surface of the pipeline is heated, it is thermally insulated and a tin coating is made that protects the insulation from blowing and damage. Additional costs for the operation of the heating cable quickly offset the savings gained by eliminating excavation.

The above-ground water supply system of a private country house or cottage from a well by raising the pipeline on supports exceeding human height, being a variation of the previous method, seems to be more laborious and less convenient to maintain and operate. The scheme of laying pipes on high racks is justified only if it is necessary to enter the building at an appropriate height, and an additional column of liquid will save on the pressure of the pump, which is otherwise extinguished by the water consumption points of the lower floors.

Equipment selection

The choice of equipment for arranging your future well is one of the most important stages, since the quality and duration of its work will depend on the right choice.

The most important equipment to pay attention to is: a pump, a caisson, a well head and a hydraulic accumulator

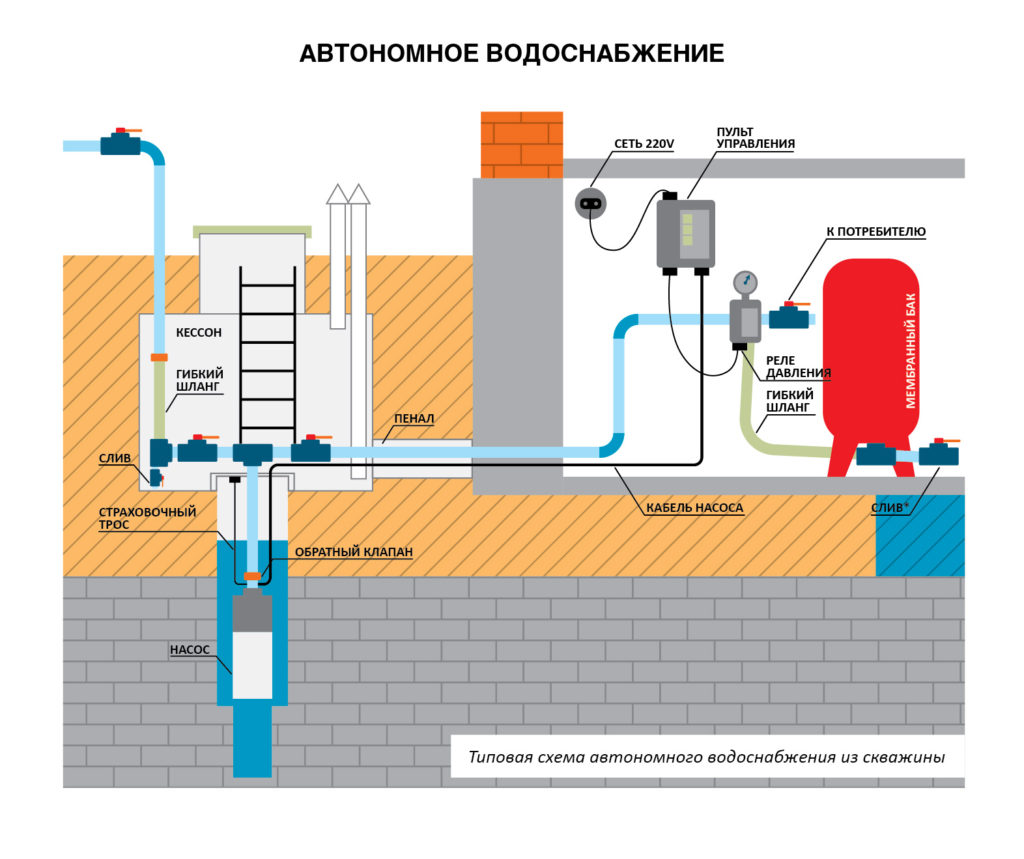

Caisson or adapter

The principle of arrangement with a caisson or adapter

The caisson can be called the main design element of the future well.Outwardly, it resembles a container similar to a barrel and is used to protect equipment from groundwater and freezing.

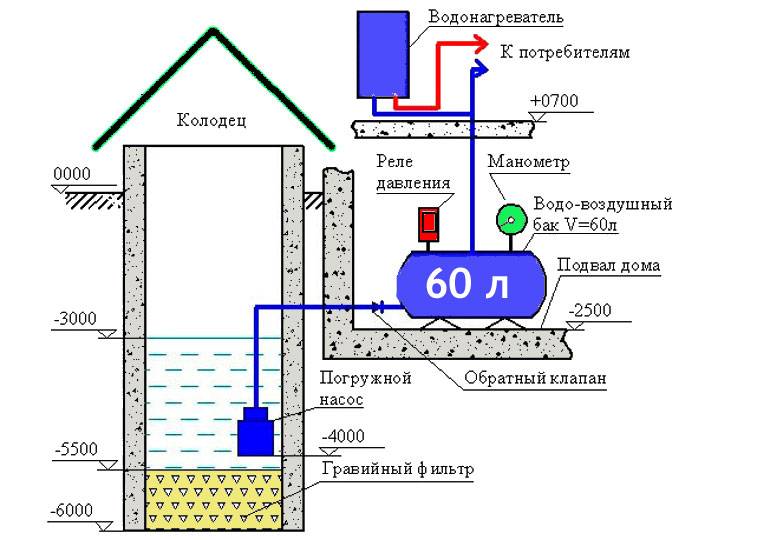

Inside the caisson, you can place all the necessary components for automatic water supply (pressure switch, membrane tank, pressure gauge, various water purification filters, etc.), thus freeing the house from unnecessary equipment.

The caisson is made of metal or plastic. The main condition is that it is not subject to corrosion. The dimensions of the caisson are usually: 1 meter in diameter and 2 meters in height.

In addition to the caisson, you can also use an adapter. It is cheaper and has its own characteristics. Let's consider below what to choose a caisson or adapter and what are the advantages of each.

Caisson:

- All additional equipment can be placed inside the caisson.

- Best suited for cold climates.

- Durable and reliable.

- Quick access to the pump and other equipment.

Adapter:

- To install it, you do not need to dig an additional hole.

- Fast installation.

- Economical.

The choice of caisson or adapter also follows from the type of well

For example, if you have a well in the sand, many experts advise paying attention to the adapter, since the use of a caisson is not always beneficial due to the short life of such a well

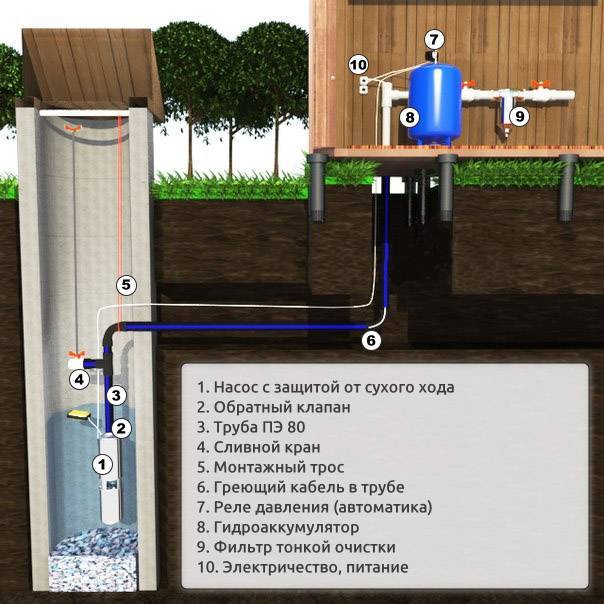

Pump units

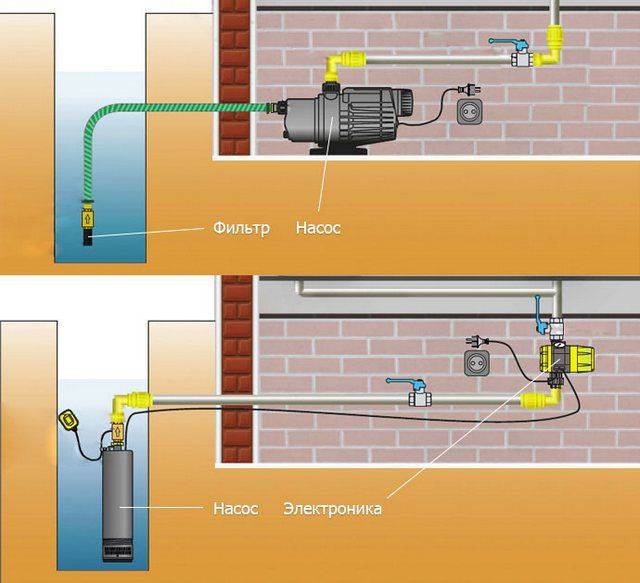

One of the key elements of the entire system is the pump. Basically, three types can be distinguished:

- Surface pump. Suitable only if the dynamic water level in the well does not fall below 7 meters from the ground.

- Submersible vibration pump. A budget solution, it is rarely used specifically for the water supply system, as it has low productivity, and it can also destroy the walls of the well.

- Centrifugal borehole pumps. Profile equipment for water supply systems from a well.

Borehole pumps are widely represented on the market by a large variety of manufacturers, for every taste and budget. The selection of the characteristics of the pump takes place according to the parameters of the well and directly to your water and heat supply system.

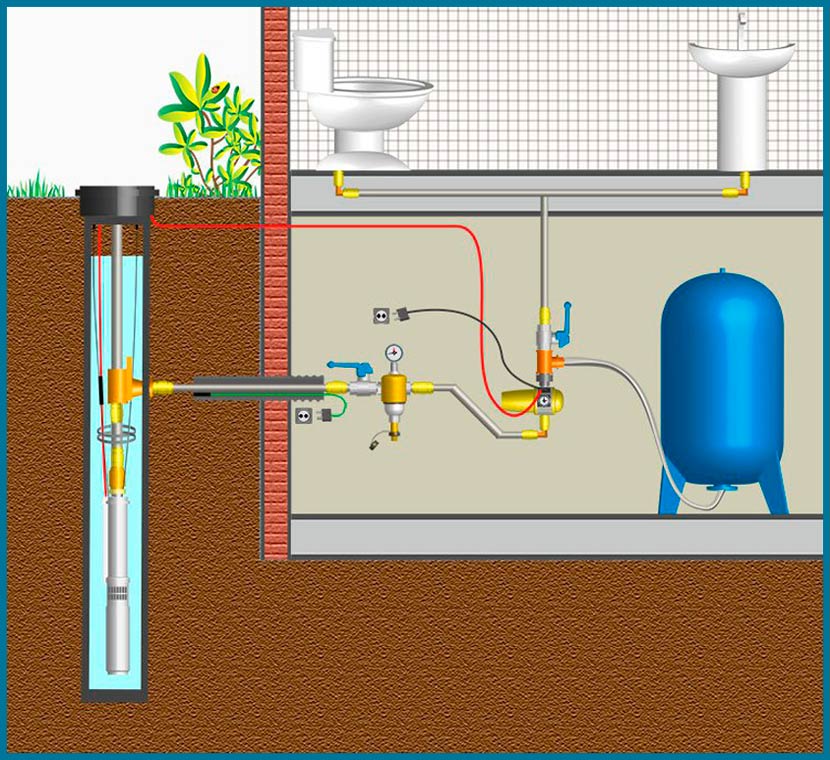

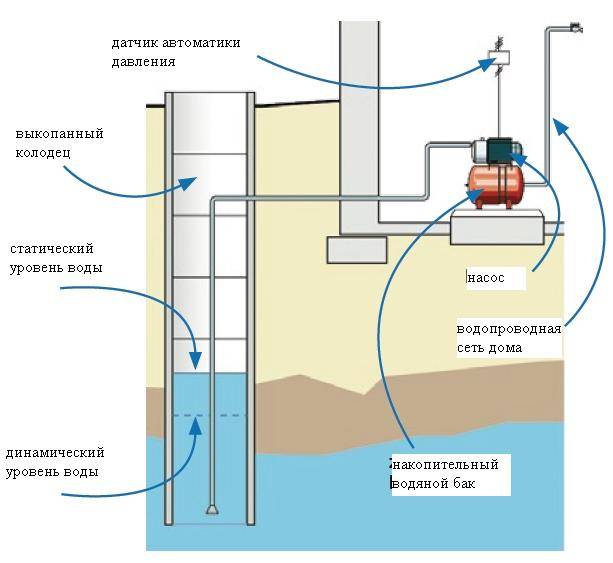

Accumulator and relay

The key function of this equipment is to maintain a constant pressure in the system and to store water. The accumulator and pressure switch control the operation of the pump, when the water in the tank runs out, the pressure drops in it, which catches the relay and starts the pump, respectively, after filling the tank, the relay turns off the pump. In addition, the accumulator protects plumbing equipment from water hammer.

In appearance, the accumulator is similar to a tank made in an oval shape. Its volume, depending on the goals, can range from 10 to 1000 liters. If you have a small country house or cottage, a volume of 100 liters will be enough.

Hydraulic accumulator - accumulates, relay - controls, pressure gauge - displays

Well cap

To equip the well, a head is also installed. Its main purpose is to protect the well from the ingress of various debris and melt water into it. In other words, the cap performs the function of sealing.

headroom

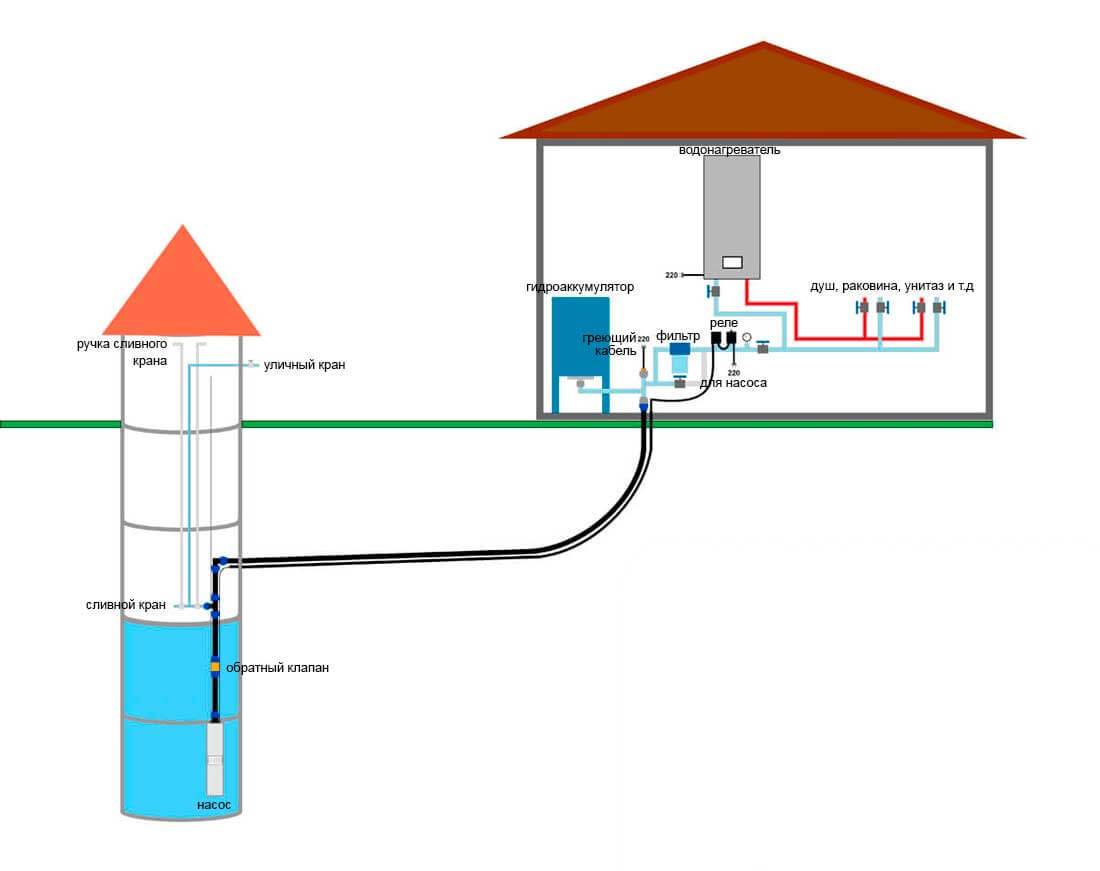

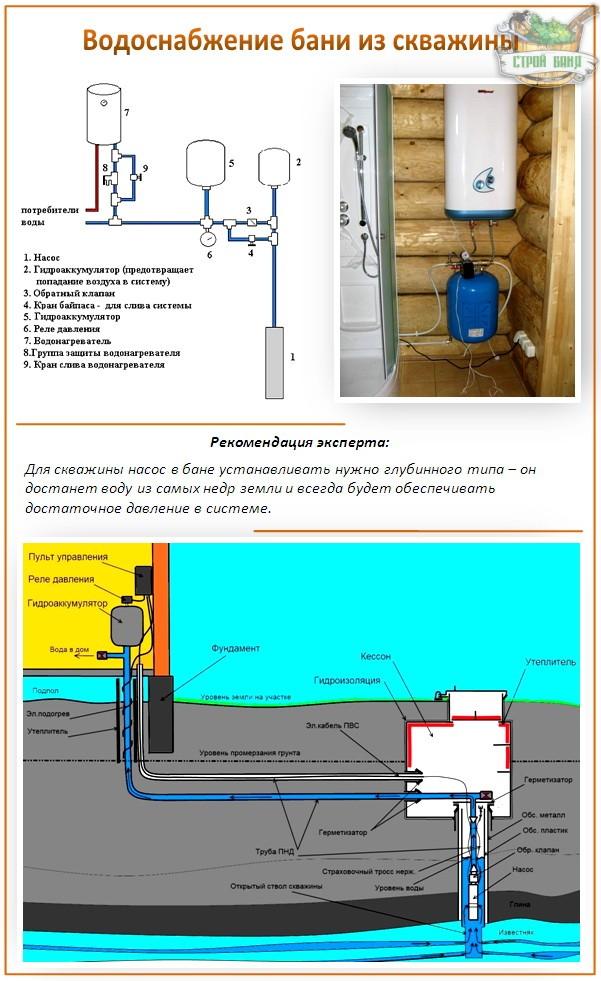

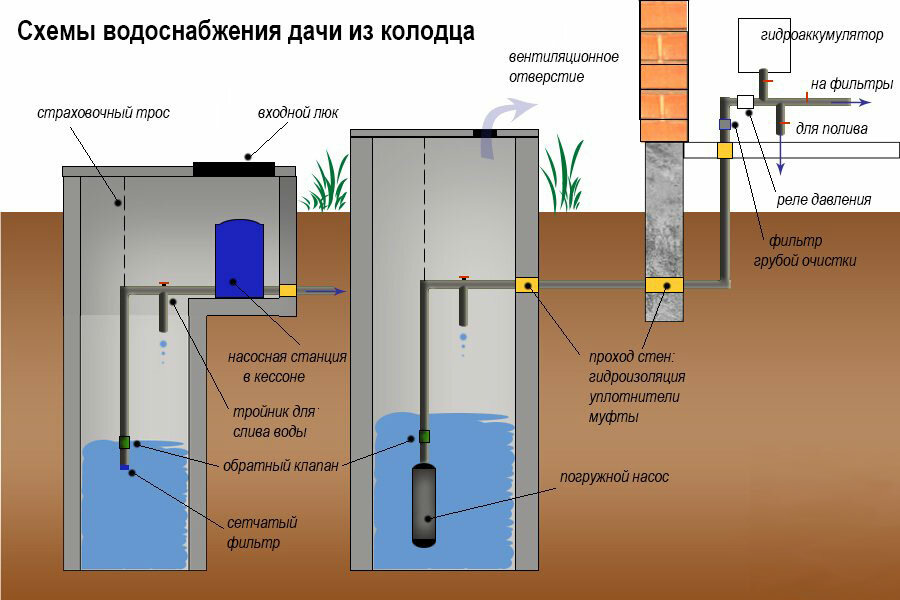

Scheme of water supply of the site from the well

Consider a typical water supply scheme for a private house from a well. The photo shows the main elements of an autonomous system of this type, the only difference is how the water intake is organized - using a submersible pump or a pumping station in a caisson.

The pumping station can also be installed directly in the house or above the well, this type of pump is called surface.

The type and performance of the pump is best chosen depending on the flow of water and how high it will be pumped. The accumulator is used in almost all modern water supply systems for wells. It creates the necessary pressure, protects against drops in water pressure, and also prevents premature wear of the pumps.

In some systems, special water tanks are used instead of pumps. Their task is to ensure the unimpeded flow of water to all systems. The necessary supply of water is created in the tank in case the pump fails for some reason. With a special switch, you can switch to either the pumping type of service or the tank.

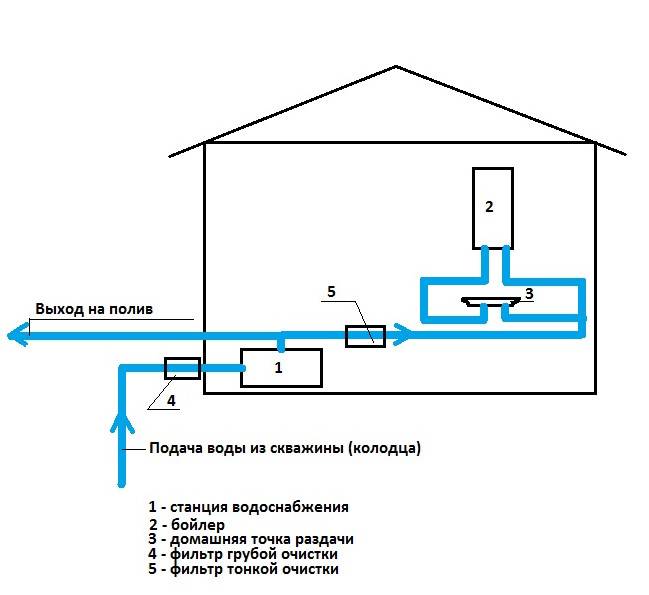

Industrial water used for irrigation and domestic needs does not require treatment. It is usually taken out through a separate pipe with a drain in the area next to the well. Drinking water is usually further purified. This is what that part of the water supply system at home looks like, which is usually located in technical rooms.

Typically, such an analysis includes checking for the following indicators:

- taste, color, smell and the presence of suspensions;

- maximum permissible concentrations of heavy metals and sulfates, chlorides, chemicals of inorganic and organic origin;

- microbiological analysis for harmful microorganisms, including water is tested for the presence of Escherichia coli.

After cleaning, the water enters the pipes and heating tanks. What to consider when choosing a water supply scheme on the site:

- The depth of soil freezing.If pipes are planned to lie above this level, then it is necessary to carry out work on their insulation.

- Sanitary zones are taken into account. It is forbidden to install wells where sewer pits, compost heaps or latrines are located closer than 50 m. Wells cannot be installed at a distance of less than 15 m from residential buildings and buildings and 7 m from fences.

It is best to draw up a water supply scheme for the site in advance, indicating not only the elements of the scheme, but also the location of the pipes, think about how best to bring water into the house from the well, based on its placement on the site.

Kinds

All automation used to control the operation of the pump is divided into 3 types in chronological order according to the sequence of its creation.

1st generation

This is the first and simplest automated control system for pumping equipment. It is used for simple tasks when it is necessary to provide a constant source of water in the house. It consists of three main parts.

- Dry run sensor.It is necessary to turn off the pump in the absence of water, which serves as a cooler, without it the pump will overheat and the winding will burn out. But an additional float switch can also be installed. Its function is similar to a sensor and is repelled by the water level: when it drops, the pump turns off. These simple mechanisms reliably protect expensive equipment from damage.

- Hydraulic accumulator.It is a necessary element for system automation. Performs the function of a water accumulator, inside of which the membrane is located.

- Relay. The device that controls the pressure level must be equipped with a pressure gauge that allows you to set the operating parameters of the relay contacts.

Dry running sensor

Hydraulic accumulator

Pressure switch

Automation of the first generation for deep well pumps is simple due to the absence of complex electrical circuits, and therefore its installation on any pumping equipment is not a problem.

The functionality of the system is as simple as the mechanism of operation, which is based on a decrease in pressure in the accumulator when water is used up. As a result, the pump turns on and fills the tank with new fluid. When full, the pump turns off. This process continues cyclically. Adjustment of the minimum and maximum pressure by means of the relay is possible. The pressure gauge allows you to set the lower and upper limits for the operation of automation.

2nd generation

The second generation differs from the first in the use of an electronic control unit to which the sensors are connected. They are distributed throughout the pumping system and monitor the operation of the pump itself and the condition of the pipeline. All information is sent to the electronic unit, which processes it and makes appropriate decisions.

When using 2nd generation automation, a hydraulic accumulator may not be used, since the pipeline and the sensor installed in it perform a similar function. When the pressure in the pipe drops, the signal from the sensor goes to the control unit, which, in turn, turns on the pump and restores the water pressure to the previous level, and when completed, turns it off.

To install 2nd generation automation, basic skills in handling electronics are required. According to the principle of operation, the systems of the 1st and 2nd generation are similar - pressure control, but the cost of the 2nd generation system is much more expensive, as a result of which it is in less demand.

3rd generation

Such a system is highly reliable and efficient, but also more expensive than its predecessors. The precise operation of the system is ensured by advanced electronics and saves on electricity. To connect this system, a specialist is needed who will not only install, but also configure the correct operation of the unit. Automation provides a full range of equipment protection against breakdown, from dry running and pipeline rupture to protection against power surges in the network. The principle of operation, as in the 2nd generation, is not associated with the use of a hydraulic accumulator.

The main difference is the ability to more accurately regulate the operation of mechanical components.For example, when turned on, the pump normally pumps water at maximum power, which is not necessary with its low consumption, and electricity is consumed to the maximum.

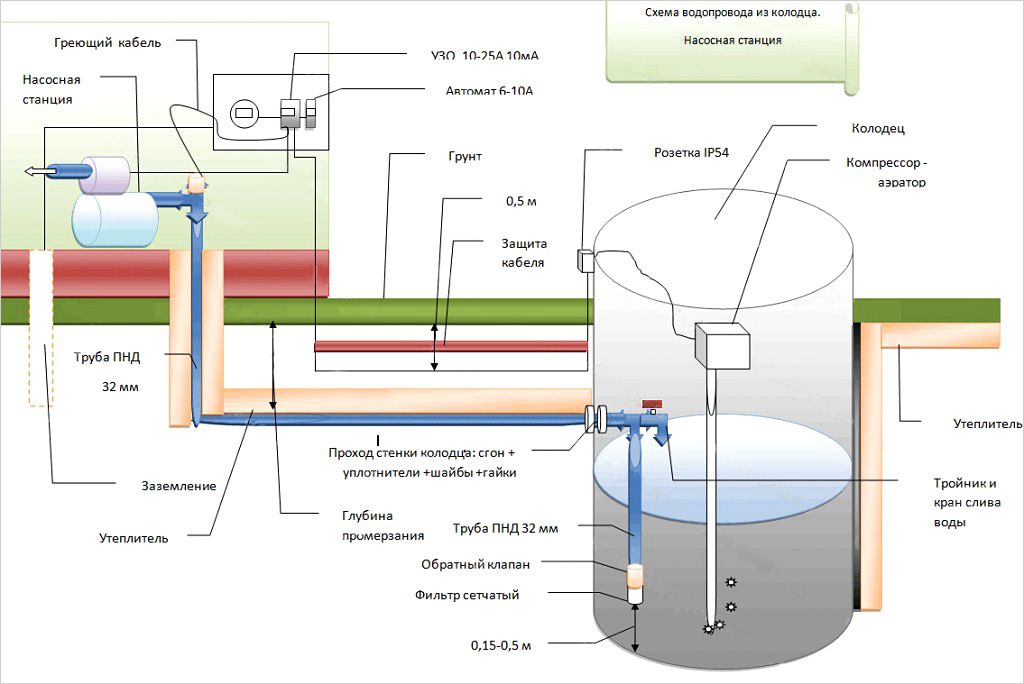

Connection order: step by step instructions

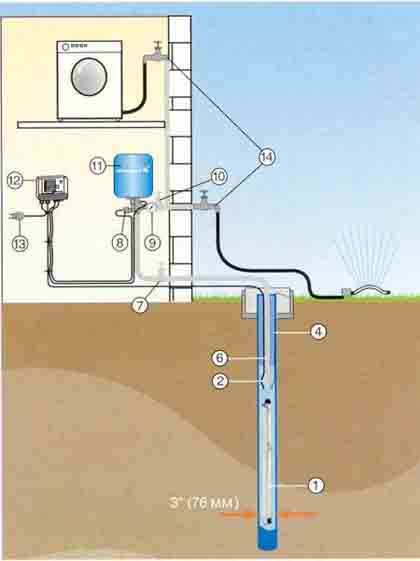

Pumping stations are suitable for equipment with relatively deep water intakes. If the depth of the groundwater table exceeds the maximum value specified by the manufacturer of the equipment, remote ejectors are used.

To install, perform the following steps:

- Lay a trench connecting the well and housing.

- Put pipes in it.

- Install plumbing (if not available).

- Install the unit in the selected location.

- The supply pipe is equipped with a filter and a check valve.

- Connect the line to the receiving pipe.

- Connect the unit to the water supply.

- Connect the equipment to the power supply.

- Fill the hydraulic tank with water.

- Perform a trial run of the station.

- Check joints.

- Set up the pressure switch.

The pipes of the external pipeline of the water supply system must be laid below the level to which the soil freezes. It is recommended to make a slight slope from the house to the well so that the water returns to the pump if it stops working. This will protect the device from overheating and damage due to dry running, i.e. work in the absence of water.

The same protective function is performed by a check valve that does not allow the liquid to leave the pipe and go into the well. When connecting a surface pump equipped with an ejector, it is required to connect another one to the suction pipe, which is connected to the ejector.

This assembly directs part of the incoming liquid to the base of the pipe through which the liquid enters, which greatly increases the productivity of the equipment. If a submersible pump is used, the work is performed differently. It is attached to the suction pipe and suspended on a strong stainless steel cable.

The lower end of the supply pipe should be equipped with a strainer so that sand and other particles do not pollute the water and damage the equipment.

Submersible pumps are conveniently attached to the finished head. Such a device is mounted on the upper part of the casing. It is believed that sealing the well with the help of a head allows to slightly increase its debit. To prevent the cable and cable from getting tangled, they are fixed to the pipe with plastic ties.

If the filter is already in the pump, they are limited to installing a check valve. The edge of the supply line of the surface pump must be located at a height of more than a meter. This minimum distance is half a meter for a submersible pump.

Connections of the unit with pipes must be made using American taps, valves are used to block any section and disconnect it for repair without damage to the rest of the system.

Before the station, it is recommended to install an additional coarse filter, and after it, a filter is installed that will ensure the purity of drinking water by removing unwanted impurities

The downhole filter installed in the working wears out over time, sand begins to seep through it. It is recommended to install an additional coarse filter at the pump inlet.

Power supply is provided by connecting a separate line to the equipment, equipped with an automatic shutdown device, care must be taken to ground it. Before starting, the device is filled with water through the opening provided for this.

In this case, the pressure in the hydraulic tank should be:

- about 1.5 bar for a container of less than 30 l;

- about 1.8 bar for 30-50 l;

- 2 bar or slightly less for a 50-100 l tank.

Then the water inlet hole is closed and the device is connected to the mains. You need to open the valve to let the air out. In a few minutes, water will flow from here. Otherwise, turn off the device and add a little more liquid.

To adjust the pressure switch, it is necessary to remove the case from it in order to gain access to the screws with which the device is adjusted

Repeat switching on so that the device starts to work normally. Now you need to configure the relay. To do this, the GA will have to be emptied and then refilled. The indicators are set by rotating the corresponding screws.

Internal piping

Water supply system of a private house

Plumbing around the cottage can be stretched in two ways:

- Consistent.Each plumbing fixture has its own water supply branch from the main tube. The disadvantage of this method is the decrease in pressure in the system while opening two or more taps. Plus - saving consumables.

- Collector. Each type of equipment is connected to its own separate pipe. The disadvantage of the method is the painstaking work and the large amount of consumables. Plus - stable pressure in the system, regardless of the number of open taps.

For piping in the second way, a collector adapter is used.

For internal plumbing, it is better to use polypropylene tubes or PVC products. Their assembly is carried out using fittings. Polypropylene is mounted by soldering. PVC - using special adapters. For drainage pipes, special sockets with a seal are provided.

Before you start the water supply in the country or in the cottage, you need to fill the accumulator with water

It is important to check all connections for tightness before full operation of the system.

Water supply insulation

Heating cable design for pipes

To further protect the system from the problem of freezing, it is important to take care of the use of insulating materials. The best heating cable

It is mounted along the entire highway from the outside in one of the following ways:

- Linear. The cable is pulled along the pipe from the well home parallel to its position. Fixation is carried out in stages using construction clamps and mounting fiberglass self-adhesive tape. With this method of laying the cable, its consumption is reduced. But the method is suitable for pipes of small diameter. Otherwise, the heating of the entire surface of the line will be defective.

- Spiral.The cable is wound around the pipeline according to the instructions. The pitch of the coil is the greater, the smaller the cross section of the pipe. For example, for a line with a diameter of 100-150 mm, a spiral can be wound in increments of 7-9 cm.

With any method of laying the cable, one nuance should be taken into account - you need to use a protective upper thermal insulation. Otherwise, heat loss cannot be avoided, the line will still freeze through. As a casing, a shell made of foamed polyethylene or expanded polystyrene is used.

Device and principle of operation

Most wells serving summer cottages and residential country houses have a water supply depth of no more than 20 m. This depth is ideal for the use of automatic pumping stations.

This device is a set of equipment designed to fulfill two main purposes:

- Water supply from a water supply source to the intra-house network.

- Maintaining the pressure in the plumbing system necessary for the smooth functioning of plumbing fixtures and household appliances.

In the absence of water in the house, the functioning of such benefits of civilization as showers, washing machines, kitchen faucets, and a sewer system is impossible. Therefore, a pumping station for a private house acts as the basis for its improvement.

In the modern domestic market, you can find a significant number of different automatic water supply devices designed for installation in a private house. But, despite some design differences, all these models have the same principle of operation, and a similar device.

The main functional units of water pumping stations:

- A suction pump for lifting water from a well and supplying it under a certain pressure to the internal pipeline system.Most often, a surface pump is used here. But, if it is required to pump water from a deep artesian well, deep submersible pumps are used as part of the stations.

- Damper storage tank or hydraulic accumulator. This device is intended to create a certain water reserve just in case. For example, in the event of a pump breakdown, a power outage, the accumulator will be able to maintain pressure for some time, allowing residents to use the main plumbing fixtures.

- Pressure sensors (pressure gauges) connected to the relay, and those, in turn, to the pump motor. In case of motor overheating, or emergency disappearance of water in the supply system, the control equipment must independently stop the pump in order to avoid its breakdown.

- Pump station control unit. There are on / off buttons, as well as devices for adjusting the operation of the station. With their help, you can set the indicators of the highest and lowest pressure, at which the device will automatically turn on or off.

- Check valve. It is installed on the water intake pipeline, and does not allow water to roll back into the supply well.

Outdoor plumbing

Laying external water supply networks

When installing a water supply system for a private house from a well with a hydraulic accumulator, it is important to properly lay the pipes outside. The best options are HDPE products

Low-pressure polyethylene withstands temperature changes well, is easy to install, resistant to deformation.

Under the laying of pipes, you need to dig a trench from the caisson to the foundation of the cottage, pool, etc.The depth of the channel is below the freezing level of the soil. This parameter is often 0.8-1.5 m, depending on the region.

Docking of pipes is carried out using special electrical couplings. When heated, they melt the HDPE material and make the joints tight.

It is better to start a line into the house through the foundation. Here you should make a hole with the help of a perforator crown. It is reinforced with a steel sleeve. The water supply to the house from the well is hermetically sealed, and all gaps are additionally coated with bituminous mastic.

Self-installation of water supply in the country

It is quite possible to mount a country water supply from polyethylene pipes with your own hands. You just need to choose the appropriate wiring diagram and select accessories.

Source of water supply

First of all, pay attention to where the power will come from. It is from the source that they are repelled when drawing up a project. It could be:

It could be:

- city or village network;

- well or well;

- river or pond;

- autonomous water tank.

Connection to the central water supply is carried out using an overhead tee with bolting at the point of entry.

Water from a natural reservoir is usually used for watering the garden - it is not clean enough for drinking.

Pure water lies very low in the soil layers and is extracted from an artesian well through deep drilling. The sandy analogue does not differ in such depth, it will be necessary to install filters to remove impurities. The same applies to the country well. In all these cases, it will be necessary to connect the pump through a check valve and specialized fittings.

Construction type and wiring diagram

If the cottage is used only for the summer, for relaxing on the weekends or growing vegetables and fruits, it is more cost-effective to install an external type of water supply. In this situation, the pipeline is carried out along the territory of the site and the walls of the country house. Usually this is a collapsible version of pipes or flexible hoses joined together by adapters. In this case, the elements are simply located on the ground or raised above it.

The outdoor water supply system is easy to assemble and does not require additional work associated with digging trenches and waterproofing pipes.

With frequent trips to the country or permanent residence, a hidden water supply system is equipped, as in ordinary private houses. Otherwise, in winter, the pipes will freeze and may be deformed. To avoid this, they are placed in the ground below the freezing depth of the soil to prevent freezing of water during extreme cold.

The wiring diagram itself may include:

- tapping for drinking water;

- water disposal to the bath, summer shower, pool;

- a branch for watering a garden plot;

- line for drip irrigation of the greenhouse;

- a pipeline to a temporary building or a garage for technical needs.

The wiring begins with a schematic arrangement of all water pipes. Such a scheme will help calculate the amount of materials required and facilitate subsequent installation work. It will allow you to determine the exact location of the lines, which is important when conducting repair or construction work.

How to choose the right size of pipes for plumbing?

In the process of introducing water into the house, it is important to choose the right size of the pipes used. If it is too small, several problems may arise:

- water can noisily pass through the laid pipes;

- plaque forms inside the pipe, which makes it difficult for water to move.

Experts recommend that when choosing a pipe diameter, rely on 2 main indicators: the speed of water advancement, as well as the total length of the pipeline. The first parameter is usually standard: water moves at about 2 meters per second. The second largely depends on the area of \u200b\u200bthe house and the remoteness of the plumbing equipment.

So, if the planned length of the pipeline is up to ten meters, it will be enough to use pipes with a diameter of 20mm, 10-30m - 25mm and over 30m - 32mm.

Compliance with all the rules will help to cope with the introduction of water into the house on their own. Nevertheless, even if builders will bring plumbing into the house, it will be useful to consult with plumbers. They will tell you how best to do it, and what materials to use for this.

It is important to make sewerage and water at a distance of at least half a meter. Pipes leading water into the house should be made a little higher so that they do not flood into the screed. Sewerage can be filled without problems

It may be necessary to connect various devices to the pipes for water: a storage tank or a pump. If you take into account all the nuances, then the pipeline, even organized without the involvement of professional plumbers, will last for many years

Sewerage can be filled without problems. It may be necessary to connect various devices to the pipes for water: a storage tank or a pump. If you take into account all the nuances, then the pipeline, even organized without the involvement of professional plumbers, will last for many years.

Read also:

Photo of water supply in the country with their own hands

We also recommend viewing:

- How to make a cold smoked smokehouse

- Building a smokehouse with your own hands

- How to make a hot smoked smokehouse with your own hands

- How to make a wood splitter with your own hands

- How to make curtains for a gazebo with your own hands

- Efficient rainwater harvesting

- Instructions on how to make furniture from pallets

- Do-it-yourself pool cleaning

- Site watering options

- Instructions on how to easily remove the stump

- How to make a garage door with your own hands

- How to make a snow blower with your own hands

- Wood protection products

- Simple drinker for chickens

- How to clean soot

- Good dry closet for a summer residence

- How to make a barbecue with your own hands

- Good heating for a greenhouse

- Modern winter greenhouse

- Roof drainage system

- How to make a chicken feeder

- Do-it-yourself decking

- How to make molds for paving slabs

- Instructions on how to equip a garage

- How to make grounding in a private house

- Gate lock