- Making a generator on your own

- Tips for assembling and operating the generator

- domestic use

- Methods for producing hydrogen

- electrolysis method

- Production of hydrogen by concentration

- Condensation at low temperatures

- Adsorption method

- Industrial generator

- The best brands of ionizers for home and office

- Nevoton IC-112

- Aquapribor AP-1

- Keosan Actimo KS-9610

- AkvaLIFE SPA AQUA

- IVA-2 Silver

- Tech-380

- Paino Premium GW PGW-1000

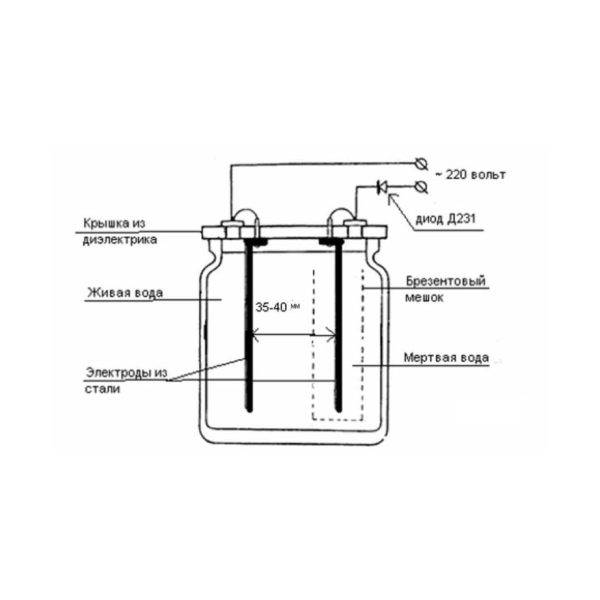

- Manufacturing Recommendations

- Material selection

- Device assembly

- The principle of operation of the hydrogen generator

- Getting Brown's Gas

- DIY hydrogen generator

- How to install a hydrogen boiler?

- Security questions

- The device and principle of operation of the hydrogen generator

- How it works

- electrolysis method

- Stanley Meyer fuel cell

- Benefits of Brown's gas as an energy source

Making a generator on your own

On the Internet you can find a lot of instructions on how to make a hydrogen generator. It should be noted that it is quite possible to assemble such an installation for a house with your own hands - the design is quite simple.

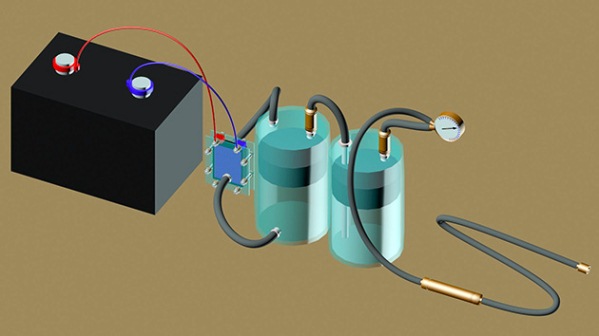

Do-it-yourself hydrogen generator components for heating in a private house

But what will you do with the resulting hydrogen? Once again, pay attention to the combustion temperature of this fuel in air. It is 2800-3000°С

Considering that metals and other solid materials are cut with burning hydrogen, it becomes clear that installing a burner in a conventional gas, liquid fuel or solid fuel boiler with a water jacket will not work - it will simply burn out.

Craftsmen on the forums advise laying out the firebox from the inside with fireclay bricks. But the melting temperature of even the best materials of this type does not exceed 1600 ° C, such a furnace will not last long. The second option is to use a special burner, which is able to lower the flame temperature to acceptable values. Thus, until you find such a burner, you should not start mounting a homemade hydrogen generator.

Tips for assembling and operating the generator

Having solved the issue with the boiler, select the appropriate scheme and instructions on how to make a hydrogen generator for heating a private house.

A homemade device will be effective only if:

- sufficient surface area of plate electrodes;

- correct choice of material for the manufacture of electrodes;

- high quality electrolysis fluid.

What size should be the unit that generates hydrogen in sufficient quantities to heat the house, you will have to determine "by eye" (based on someone else's experience), or by assembling a small installation to begin with. The second option is more practical - it will allow you to understand whether it is worth spending money and time on installing a full-fledged generator.

Rare metals are ideally used as electrodes, but this is too expensive for a home unit. It is recommended to choose stainless steel plates, preferably ferromagnetic.

Hydrogen generator design

There are certain requirements for water quality.It should not contain mechanical impurities and heavy metals. The generator works as efficiently as possible on distilled water, but to reduce the cost of construction, you can limit yourself to filters to purify water from unnecessary impurities. In order for the electrical reaction to proceed more intensively, sodium hydroxide is added to the water in the ratio of 1 tablespoon per 10 liters of water.

domestic use

There are also uses for hydrogen in everyday life. First of all, these are autonomous heating systems. But here are some features. Pure hydrogen plants are significantly more expensive than Brown's gas generators, and you can even assemble the latter yourself. But when organizing home heating, it must be taken into account that the combustion temperature of Brown's gas is much higher than that of methane, so a special boiler is required, which is somewhat more expensive than usual.

On the Internet, you can find many articles that say that ordinary boilers can be used for explosive gas, but this is absolutely impossible. At best, they will quickly fail, and at worst, they can cause sad or even tragic consequences. For Brown's mix, special designs with a more heat resistant nozzle are provided.

It should be noted that the profitability of heating systems based on hydrogen generators is highly questionable due to low efficiency. In such systems, there are double losses, firstly, in the process of gas generation, and secondly, when water is heated in the boiler. It is cheaper to immediately heat water in an electric boiler for heating.

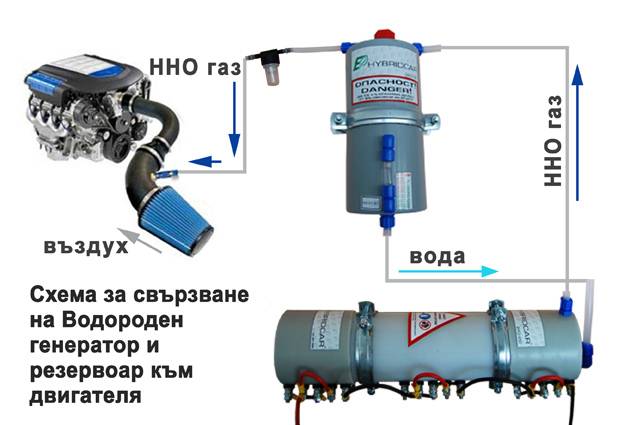

An equally controversial implementation for domestic use, in which Brown's gas is enriched with gasoline in the fuel system of a car engine in order to save money.

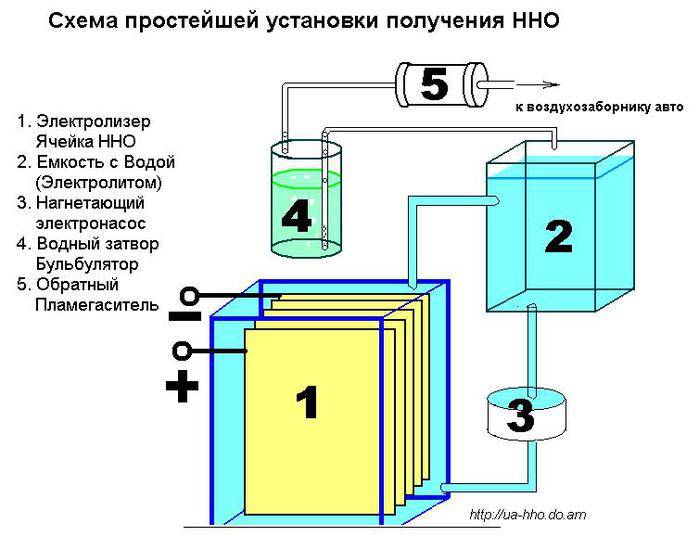

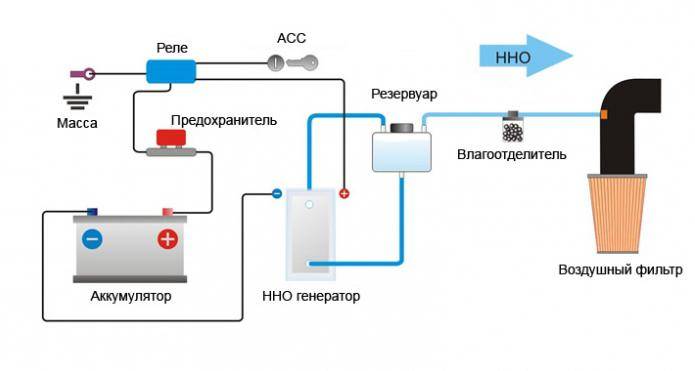

Designations:

- a - HHO generator (accepted designation for Brown's gas);

- b - gas outlet to the drying chamber;

- c - compartment for removing water vapor;

- d - return of condensate to the generator;

- e - supply of dried gas to the air filter of the fuel system;

- f - car engine;

- g - connection to the battery and power generator.

It should be noted that in some cases such a system even works (if it is assembled correctly). But you will not find the exact parameters, the power gain, the percentage of savings. These data are highly blurred, and their reliability is questionable. Again, the question is not clear how much the engine resource will decrease.

But demand generates offers, on the Internet you can find detailed drawings of such devices and instructions for connecting them. There are also ready-made models made in the country of the Rising Sun.

Methods for producing hydrogen

Hydrogen is a colorless and odorless gaseous element with a density of 1/14 relative to air. It is rarely found in the free state. Usually hydrogen is combined with other chemical elements: oxygen, carbon.

Hydrogen production for industrial needs and energy is carried out by several methods. The most popular are:

- water electrolysis;

- concentration method;

- low temperature condensation;

- adsorption.

Hydrogen can be isolated not only from gas or water compounds. Hydrogen is produced by exposing wood and coal to high temperatures, as well as by processing biowaste.

Atomic hydrogen for power engineering is obtained using the method of thermal dissociation of a molecular substance on a wire made of platinum, tungsten or palladium. It is heated in a hydrogen environment at a pressure of less than 1.33 Pa.Radioactive elements are also used to produce hydrogen.

Thermal dissociation

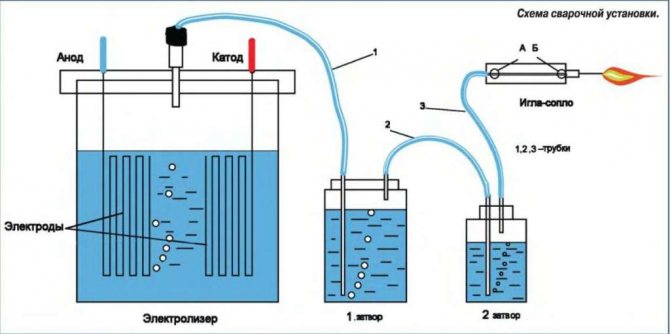

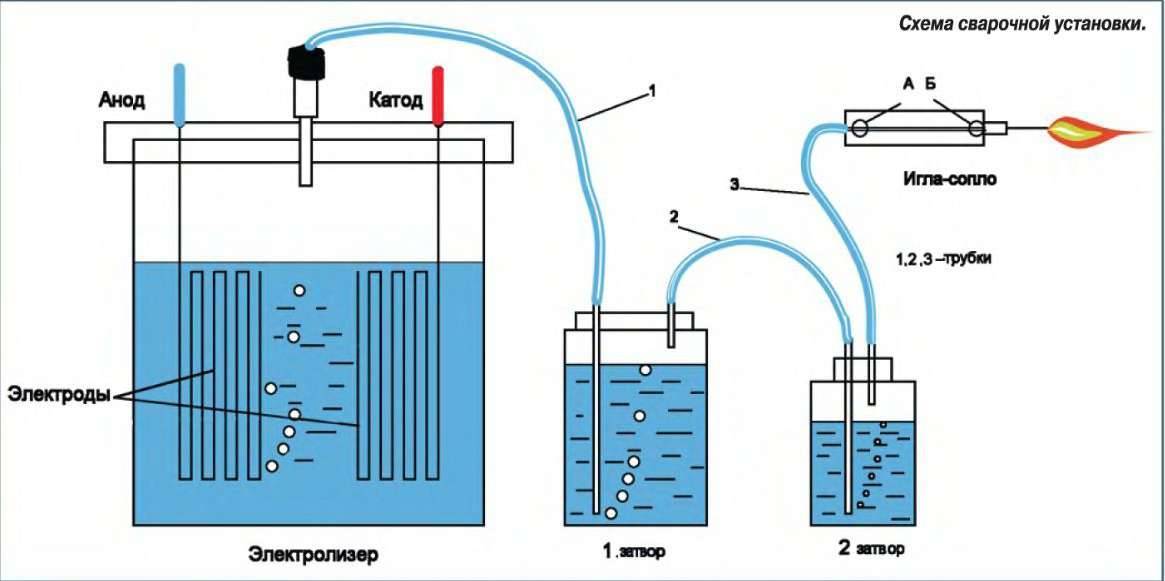

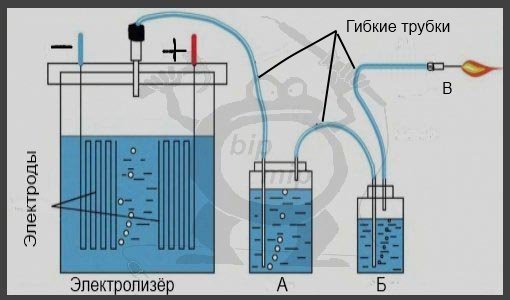

electrolysis method

The simplest and most popular method of hydrogen extraction is water electrolysis. It allows obtaining practically pure hydrogen. Other advantages of this method are:

The principle of operation of the electrolysis hydrogen generator

- availability of raw materials;

- obtaining an element under pressure;

- the possibility of automating the process due to the lack of moving parts.

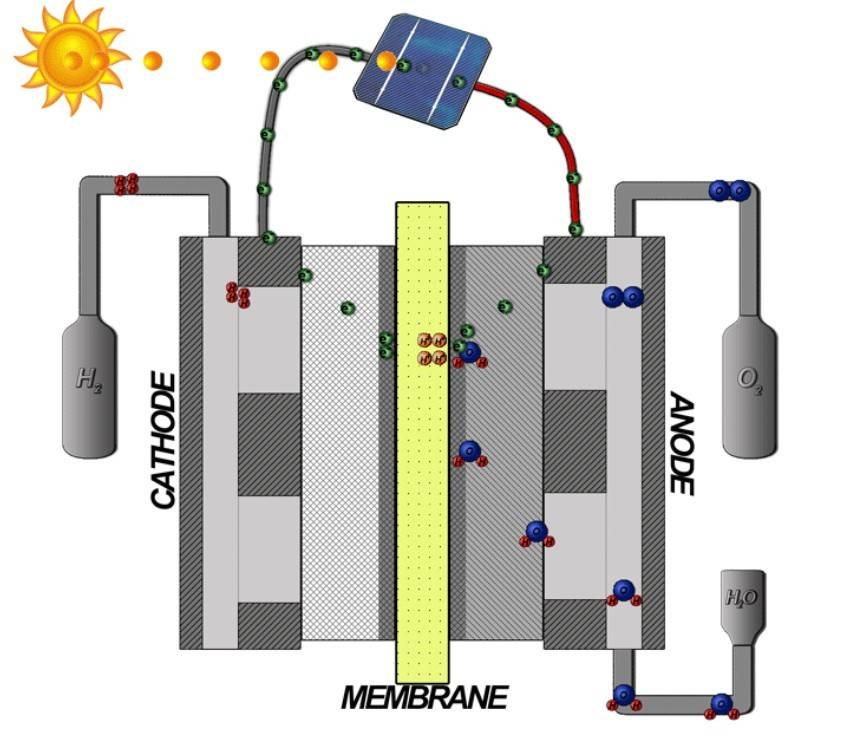

The procedure for splitting a liquid by electrolysis is the reverse of hydrogen combustion. Its essence is that under the influence of direct current, oxygen and hydrogen are released on electrodes dipped into an aqueous electrolyte solution.

An additional advantage is the production of by-products with industrial value. Thus, oxygen in a large volume is necessary for catalyzing technological processes in the energy sector, cleaning soil and water bodies, and disposing of household waste. Heavy water produced by electrolysis is used in the power industry in nuclear reactors.

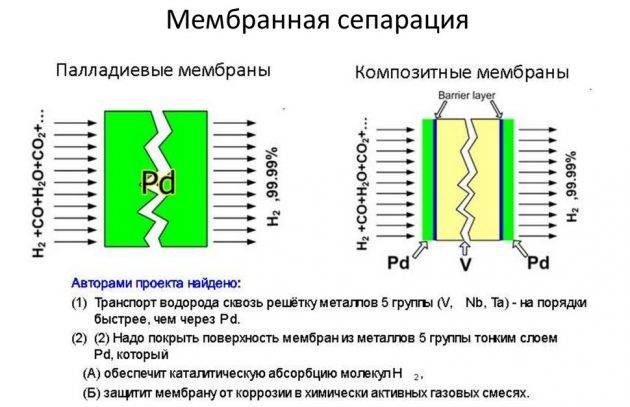

Production of hydrogen by concentration

This method is based on the separation of the element from the gas mixtures containing it. Thus, the largest part of the substance produced in industrial volumes is extracted using steam reforming of methane. Hydrogen produced in this process is used in energy, oil refining, rocket industry, as well as for the production of nitrogen fertilizers. The process of obtaining H2 is carried out in different ways:

- short cycle;

- cryogenic;

- membrane.

The latter method is considered the most effective and less expensive.

Condensation at low temperatures

This technique for obtaining H2 consists in the strong cooling of gas compounds under pressure. As a result, they are transformed into a two-phase system, which is subsequently separated by a separator into a liquid component and a gas. Liquid media are used for cooling:

- water;

- liquefied ethane or propane;

- liquid ammonia.

This procedure is not as simple as it seems. It will not be possible to cleanly separate hydrocarbon gases at a time. Part of the components will leave with the gas taken from the separation compartment, which is not economical. The problem can be solved by deep cooling of the raw material before separation. But this requires a lot of energy.

In modern systems of low-temperature condensers, demethanization or deethanization columns are additionally provided. The gas phase is removed from the last separation stage, and the liquid is sent to the distillation column with the raw gas flow after heat exchange.

Adsorption method

During adsorption, adsorbents are used to release hydrogen - solid substances that absorb the necessary components of the gas mixture. Activated carbon, silicate gel, zeolites are used as adsorbents. To carry out this process, special devices are used - cyclic adsorbers or molecular sieves. When implemented under pressure, this method can recover 85 percent hydrogen.

If we compare adsorption with low-temperature condensation, we can note the lower material and operational costs of the process - on average, by 30 percent. The adsorption method produces hydrogen for energy and with the use of solvents. This method allows the extraction of 90 percent of H2 from the gas mixture and the production of the final product with a hydrogen concentration of up to 99.9%.

Industrial generator

At the level of industrial production, technologies for manufacturing hydrogen generators for domestic purposes are gradually being mastered and developed. As a rule, power stations for home use are produced, the power of which does not exceed 1 kW.

Such a device is designed for the production of hydrogen fuel in the mode of continuous operation for no more than 8 hours. Their main purpose is the energy supply of heating systems.

We also develop and manufacture installations for operation as part of condominiums. These are already more powerful structures (5-7 kW), the purpose of which is not only the energy of heating systems, but also the generation of electricity. This combined version is rapidly gaining popularity in Western countries and in Japan.

Combined hydrogen generators are characterized as systems with high efficiency and low carbon dioxide emissions.

An example of a really operating industrially manufactured station with a power of up to 5 kW. In the future, similar installations are planned to be made for equipping cottages and condominiums.

Russian industry has also begun to engage in this promising type of fuel production. In particular, Norilsk Nickel is mastering technologies for the production of hydrogen plants, including household ones.

It is planned to use a variety of types of fuel cells in the development and production process:

- proton-exchange membrane;

- phosphoric acid;

- proton-exchange methanol;

- alkaline;

- solid oxide.

Meanwhile, the electrolysis process is reversible. This fact suggests that it is possible to obtain already heated water without burning hydrogen.

It seems that this is another idea, seizing on which you can start a new round of passions associated with the free extraction of fuel for a home boiler.

The best brands of ionizers for home and office

Overview of hydrogen generators for home and office.

Nevoton IC-112

Nevoton IS-112 is the best silver water ionizer. Disinfects water with silver ions, killing bacteria. It helps during the period of colds, but there is no point in daily use. The plates fail after a few years and cannot be replaced. The price of a hydrogen generator is from 3000 rubles.

Aquapribor AP-1

Aquapribor AP-1 is the best value for money. Hydrogen generator in the form of a stationary bowl. The material is ceramic, it breaks easily, so you need to be careful in operation. Water activates quickly, but during prolonged operation the device overheats. The water has some taste. Regular cleaning with vinegar is required. The cost of a hydrogen generator is from 4000 rubles.

Keosan Actimo KS-9610

The Keosan Actimo KS-9610 ionizer saturates the water with oxygen and minerals. The stationary model of the hydrogen generator is presented in the form of a cube with grooves and holes for 1.5 liters. The filter lasts for a year, then you need to buy more on the manufacturer's website (not found in stores). During operation, the hydrogen generator vibrates strongly and makes noise. Cost - 20000 r.

AkvaLIFE SPA AQUA

The Aqualife water ionizer is made in the form of a jug, roomy (3.5 liters), with a large selection of modes (over 300). Of the negative points - the filters quickly fail, sometimes they burst in the center. Price - 21000 rubles.

IVA-2 Silver

IVA-2 Silver is a generator that produces living, dead and silver water. Stationary option for the home.It activates the water in a matter of minutes, you need to turn it off yourself. Includes 5 filters. Replacement of components is free. Possible yellowing of the bowl from tap water. Cost - from 6000 r.

Tech-380

Hydrogen generator Tech-380 is ideal for daily use, long service life. Similar to luxury models of hydrogen generators, only there is no display. Designed for 6000 liters of water. There is a nozzle on the crane, it is possible to purchase a switch. The cost of a hydrogen generator is about 30,000 rubles.

Paino Premium GW PGW-1000

Desktop hydrogen generator Paino Premium GW PGW-1000 due to clear control is the best among stationary models. Charges any water (including tap water). Able to automatically clean the circulation system and tank, thereby ensuring cleanliness and hygiene. Built-in 800 ml tank. The cost of a hydrogen generator is 40,000 rubles.

In summary, the HydroLife is the best portable hydrogen generator and the Paino Premium GW is the best stationary.

Prices for hydrogen water generators start from 4000 rubles. (but cheap does not mean high quality) and can reach 60,000 rubles. (the most versatile new models). The average cost of hydrogen ionizers that are optimal in quality and price is about 20,000 rubles.

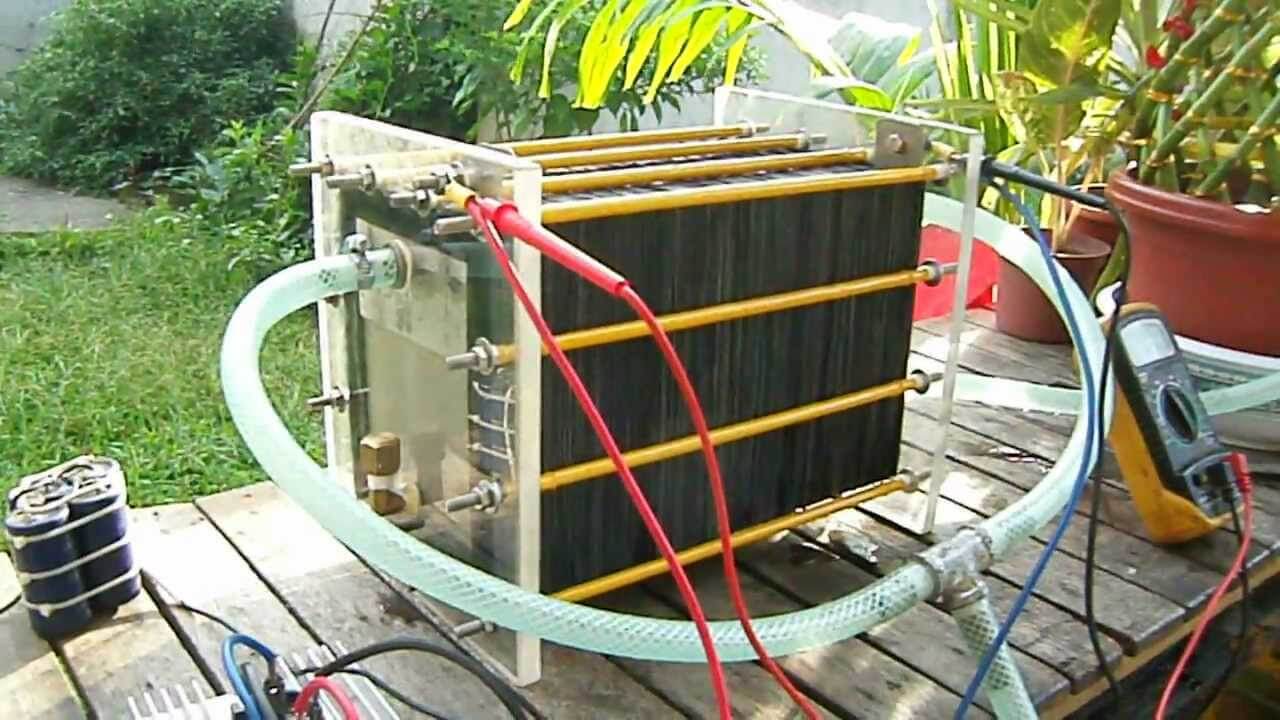

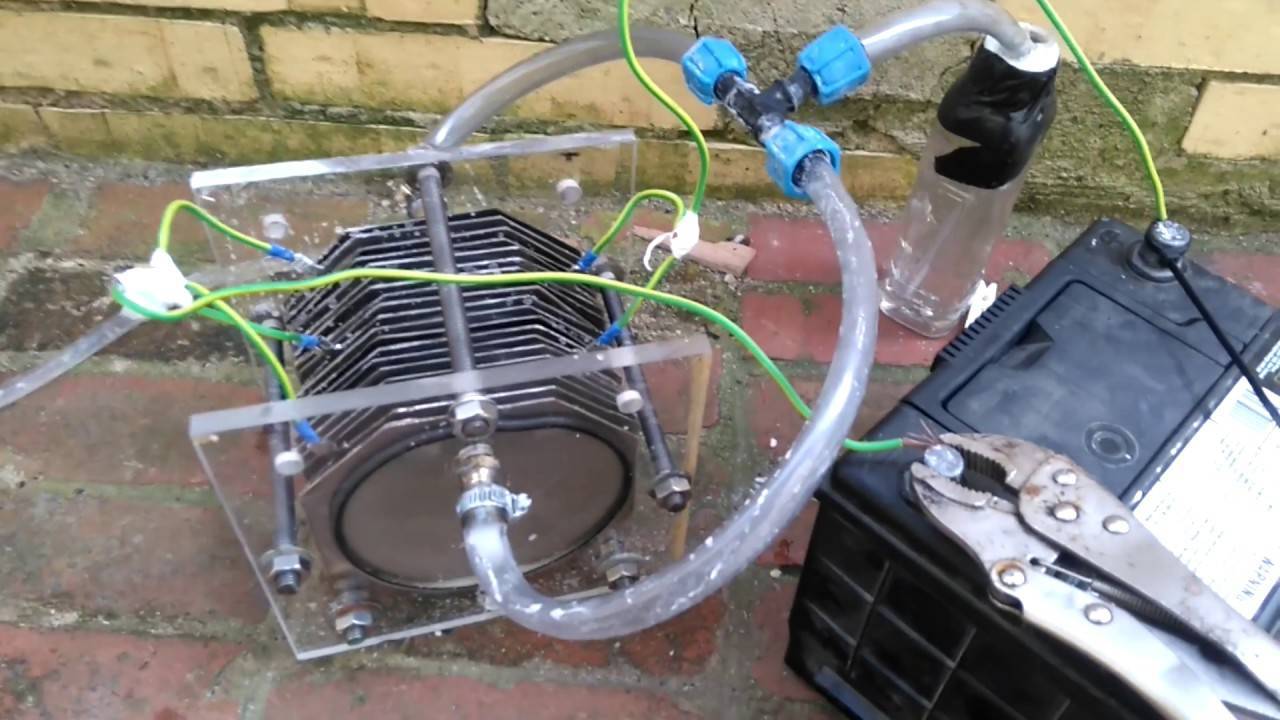

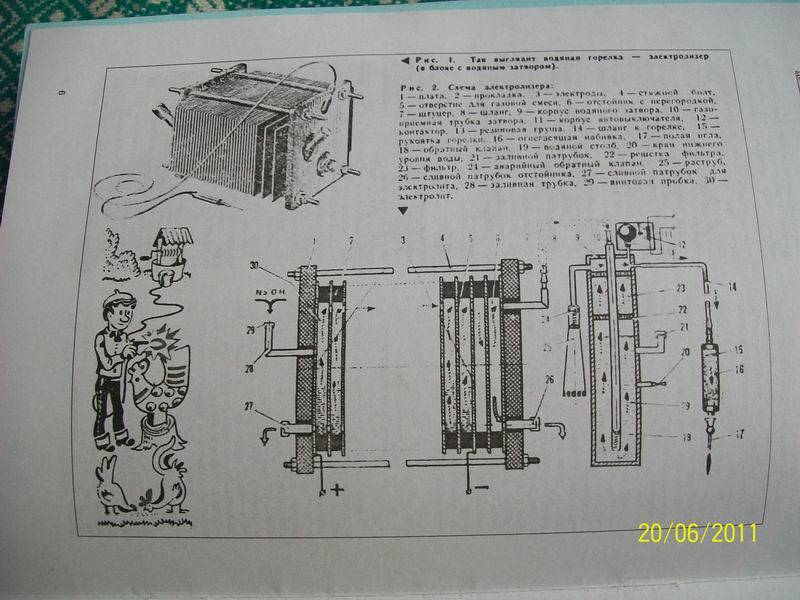

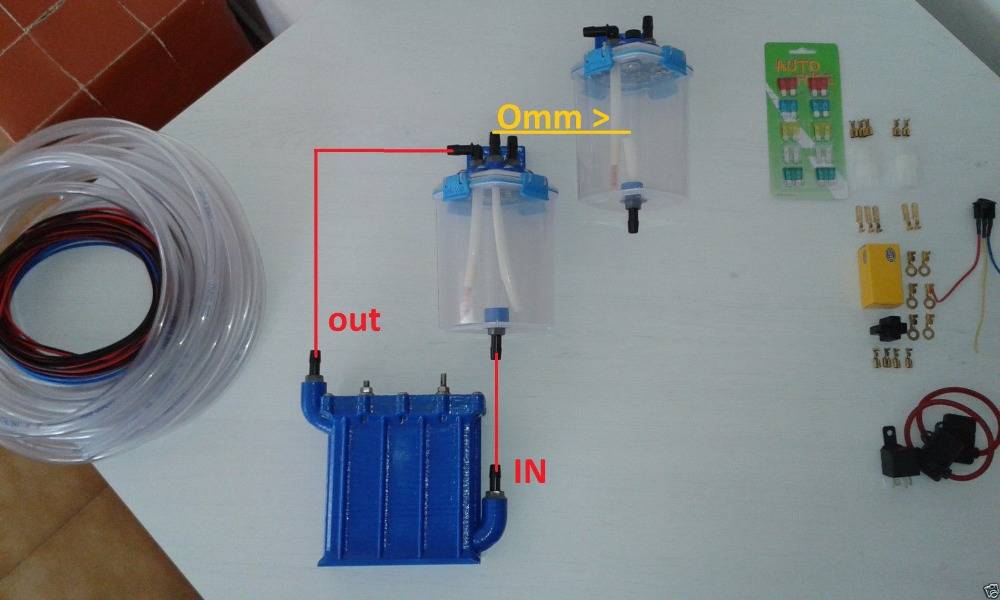

Manufacturing Recommendations

Knowing the technology for producing hydrogen fuel and having certain skills, at home you can make a hydrogen generator with your own hands. Today, there are several workable schemes that allow you to create such an installation.Moreover, unlike the classic device, in a home-made device, the electrodes are not placed in a container with water, but the liquid itself enters the gaps between the plates. Before starting work on the manufacture of a hydrogen plant with your own hands, you should carefully study the drawings.

Knowing the technology for producing hydrogen fuel and having certain skills, at home you can make a hydrogen generator with your own hands. Today, there are several workable schemes that allow you to create such an installation.Moreover, unlike the classic device, in a home-made device, the electrodes are not placed in a container with water, but the liquid itself enters the gaps between the plates. Before starting work on the manufacture of a hydrogen plant with your own hands, you should carefully study the drawings.

Material selection

Most often, home craftsmen are faced with the problem of choosing electrodes. With the creation of a fuel cell, the situation is simpler and today there are two main types of hydrogen generators - “wet” and “dry”. To create the first, you can use any container that has a sufficient margin of safety and gas tightness. The best choice can be considered an old-style battery case for a passenger car.

The best electrodes are stainless steel plates (tubes). In principle, ferrous metal can also be used, but it quickly corrodes and such electrodes require frequent replacement. The situation is completely different when using high-carbon alloys alloyed with chromium. An example of such a material is 316L stainless steel.

When using tubes, they must be selected so that when one element is installed in another, a gap of no more than one millimeter is provided between them.

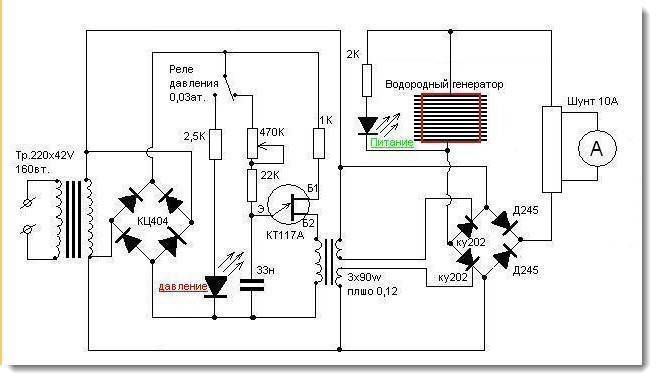

An equally important part of a hydrogen generator for a car is a PWM generator. It is thanks to a properly assembled electrical circuit that it is possible to regulate the frequency of the current, and without this it is not possible to produce hydrogen.

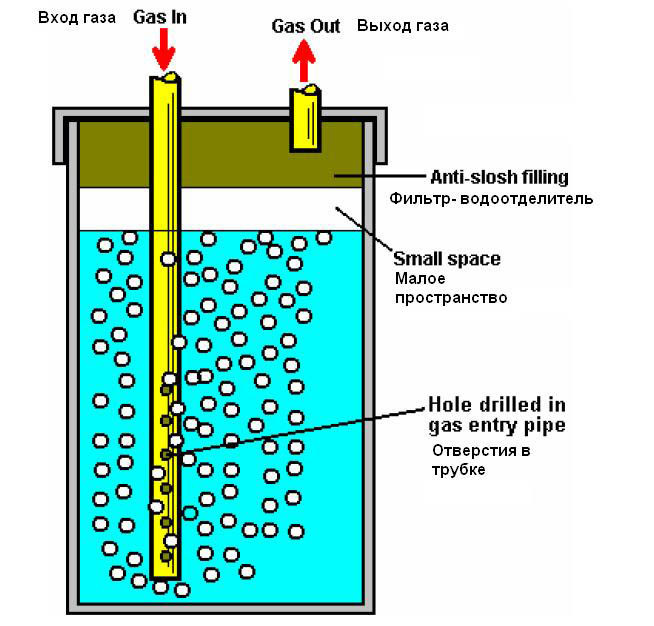

To create a water seal (bubbler), you can use any container that has a sufficient tightness indicator.At the same time, it is desirable to equip it with a lid that closes tightly, but if the HNO ignites, it will immediately be torn off inside. To prevent Brown's gas from returning to the fuel cell, it is recommended to install an isolator between the water seal and the cell.

Device assembly

To create an oxygen generator, it is better to choose a “dry” fuel cell, and the electrodes should be made of stainless steel. It is she who is most popular among home craftsmen.

It is also important to follow a certain sequence of actions:

According to the size of the generator, it is necessary to cut plates of organic glass or organite, which will be used as side walls. The optimal dimensions for a fuel cell are 150x150 or 250x250 mm.

In the body parts, it is necessary to drill holes for installing fittings for liquid, one for HNO and 4 fasteners.

Electrodes are made of steel grade 316L, the size of which should be 10–20 mm smaller in comparison with the side walls. In one of the corners of each electrode, it is necessary to make a contact pad for connecting them into groups, as well as connecting them to a power source.

To increase the amount of brown gas produced in the generator, the electrodes should be sanded on each side.

Holes with a diameter of 6 mm (water supply) and 8–10 mm (gas outlet) are drilled in the plates. When calculating the drilling locations, the location of the nozzles must be taken into account.

First, fittings are mounted in Plexiglas plates and sealed well.

Studs are installed in one of the body parts, and then the electrodes are laid.

The electrode plates are separated from the side walls by gaskets made of paronite or silicone. Similarly, it is necessary to isolate the electrodes themselves.

After installing the last electrode, sealing rings are mounted and the generator is closed with a second wall. The structure itself is fastened with nuts and washers.

At this point, it is extremely important to monitor the uniformity of tightening the fasteners and prevent distortions.

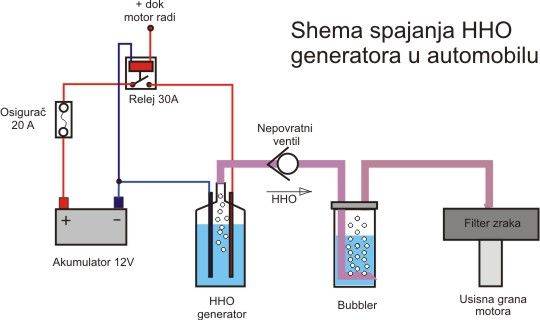

The fuel cell is connected to a liquid container and a water seal.

After connecting the groups of electrodes in accordance with their pole, the generator is connected to the PWM generator.

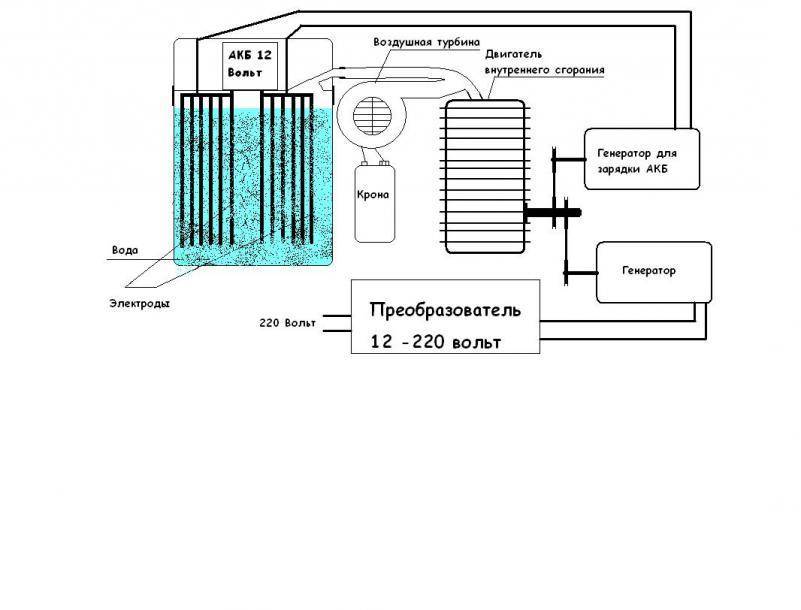

The principle of operation of the hydrogen generator

The water molecule is a combination of hydrogen and oxygen. Atoms have the ability to create ions. If you have watched experiments that use a Tesla coil, then you should know that atoms ionize when exposed to an electric field. In this case, hydrogen will form positive ions, and oxygen will form negative ions. In hydrogen generators, an electric field is used to detach water molecules from each other.

The water molecule is a combination of hydrogen and oxygen. Atoms have the ability to create ions. If you have watched experiments that use a Tesla coil, then you should know that atoms ionize when exposed to an electric field. In this case, hydrogen will form positive ions, and oxygen will form negative ions. In hydrogen generators, an electric field is used to detach water molecules from each other.

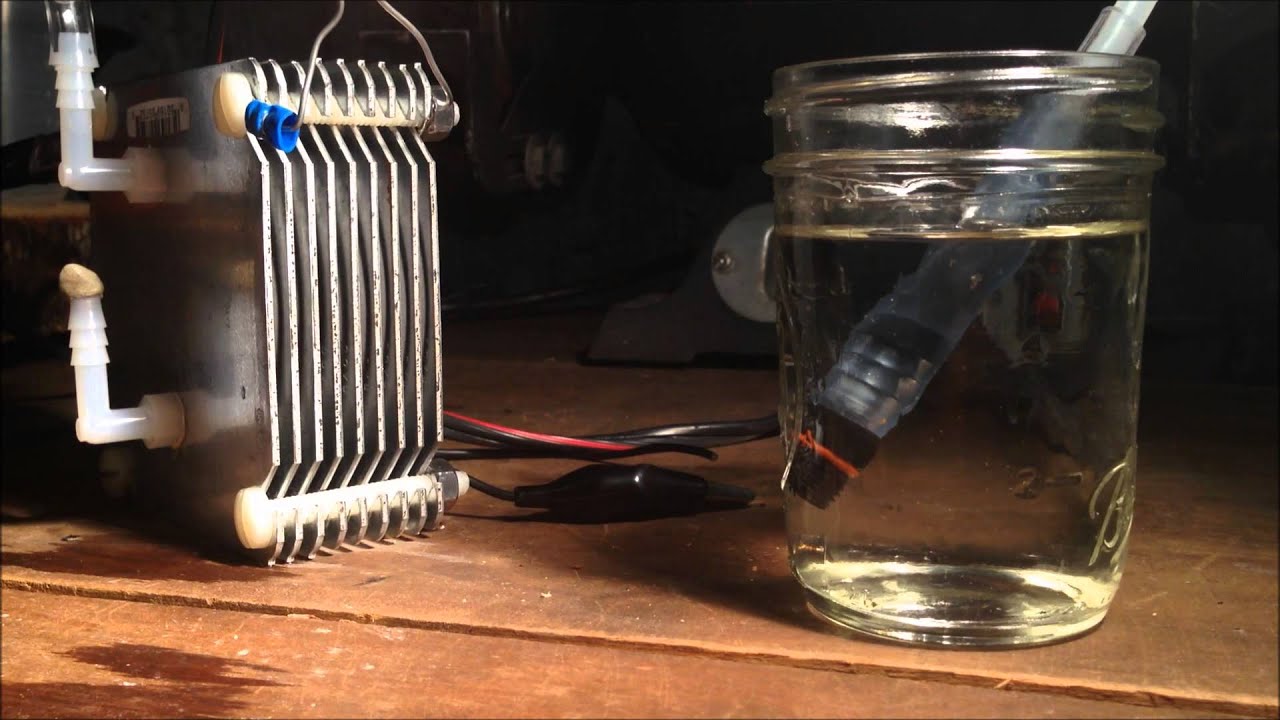

So, by placing two electrodes in water, we need to create an electric field among them. To do this, they must be connected to the terminals of the battery or any other power source. The anode is the positive and the cathode is the negative electrode. The ions that are formed in the water will be pulled towards the electrode, whose polarity is opposite. When ions come into contact with electrodes, their charge is neutralized due to the addition or removal of electrons. When the gas that appears between the electrodes comes to the surface, it must be sent to the engine.

Hydrogen cells for cars include a vessel with water, which is located under the hood. Ordinary tap water is poured into a vessel and a teaspoon of catalyst and soda are added there. Plates connected to the battery are immersed inside. When turned on in auto ignition, the design (hydrogen generator) produces gas.

Getting Brown's Gas

In order to split water by electrolysis, it is necessary to spend 442.4 kilocalories per mole. As a result, from one liter of water it will turn out - 1866.6 liters of detonating gas. When hydrogen, which has reacted with oxygen, burns, 3.8 times more energy is returned than was spent on its production. By extracting hydrogen in this way, it can be used to power buildings and structures.

Many fellow citizens, having heard about such a system, have questions:

- Is it possible to use a "rattler" for heating a house?

- How much is released during electrolysis - Brown's gas?

- How will the combustion process take place?

- Is there a ready-made patented device on the Russian and foreign markets that will convert water into a "rattle"?

- Of course, many more are concerned about the question - the efficiency and safety of such a system.

Heating houses with Brown's gas at the moment, due to its novelty, has not yet become widely used. Manufacturers of hydrogen boilers are just beginning to gain momentum in the manufacture and supply of them to the Russian and Western markets.

DIY hydrogen generator

Factory-made models differ little from home-made counterparts and are more expensive.The total price of a finished generator ranges from 20 to 60 thousand rubles, so many craftsmen are trying to create hydrogen-powered heating devices on their own. But before starting work, it is necessary to weigh even the slightest doubts. If they are present, then it is better to refuse work. But if desires and opportunities give the green light, then the entire production process can be divided into the following steps:

drawing and search for materials. This step includes a thorough reading of all the nodes of the structure, the calculation of the required power and the general view of the generator;

the electrolyzer is a high quality stainless steel case;

electrolyzer plates

To create this important part, you will need a steel sheet, which must be cut into 18 equal strips. Next, you need to drill a hole for mounting and dividing the plates into cathodes and anodes

It remains only to connect the current to the structure;

Gas Generator

- the burner should ideally be purchased, because it can be problematic to assemble this part without errors. In addition, in special stores, the choice of such elements is sufficient;

- the separator is connected to the structure to extract only the hydrogen component from the gas mixture;

- pipes are connected according to the area of the building.

In order for the system to work fully, it is necessary to have great knowledge and skills, otherwise you can build a dangerous structure. Also, self-made generators require an investment of material resources and a lot of time. The high risk of failure and the total waste of time leads to the fact that it is better to choose the purchase of a hydrogen heating system in the factory version.

How to make hydrogen heating at home?

How to install a hydrogen boiler?

At the moment, many people prefer to independently produce hydrogen generators for their heating systems. And this is not surprising, because the "shop" analogues are not only very expensive, but also do not have a very high efficiency. But if this device is made by hand, then its efficiency will be an order of magnitude higher.

There are several options for how to assemble a generator that runs on hydrogen. But in any case, for its manufacture at home, the following consumables will be required.

12 volt power supply.

Several tubes made of stainless steel and having different diameters.

The tank in which the structure will be located.

PWM controller

It is important that its power is at least 30 amperes. These are the main components that homemade hydrogen generators usually consist of. In addition, do not forget about the distilled water tank - it is also a must.

Water must be supplied to a sealed structure with a dialectic inside. In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material. It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

In addition, do not forget about the tank for distilled water - its presence is also required. Water must be supplied to a sealed structure with a dialectic inside.In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material.

It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

These are the main components that homemade hydrogen generators usually consist of. In addition, do not forget about the tank for distilled water - its presence is also required. Water must be supplied to a sealed structure with a dialectic inside. In the same design there will be a set made of stainless steel plates adjacent to one another by means of an insulating material.

It is important that the 12-volt voltage is applied to these plates. If everything is done correctly, then when voltage is applied, the water will decompose into 2 gaseous elements

Note! More efficient in this regard is the use of direct current (it must have a specific frequency) produced by a PWM type generator. In this case, the pulsed current (or alternating) will be replaced by a constant one. As a result, the efficiency of the equipment will increase significantly.

As a result, the efficiency of the equipment will increase significantly.

Security questions

The safety of the use of "explosive" gas causes particular disagreement among consumers, since the combination of hydrogen and oxygen is explosive.

The following are guidelines for the safe use of the Brown generator:

Tanks made of fragile plastic are not allowed. The mixture detonates with lightning speed, emitting a powerful pop and releasing a large amount of energy.In this case, the fragile tank will be torn to shreds, and if it is plastic, a lot of small and sharp fragments will be formed, flying at high speed.

Gas accumulation must not be allowed. The entire volume of gas must be consumed immediately. Cannot lock the lyzer when there is no gas demand

It is also categorically not recommended to divert gas outside the building.

You can not put the electrolyzer in the basement.

It is necessary to avoid the so-called "pockets" without ventilation under the ceiling of the room.

When installing equipment, it is very important to check the connections for leaks. The check is carried out using a soapy solution and increasing the pressure in the system.

In case of depressurization, alkali can get on the skin or in the eyes

There is no particular danger for the skin - it is enough to wash off the alkali with soap and water. However, alkali is very dangerous for the eyes, so the use of goggles is mandatory.

An uncontrolled increase in pressure in the electrolysis must be avoided. A relief valve is required to control the pressure.

The device and principle of operation of the hydrogen generator

How it works

The classic apparatus for generating hydrogen includes a tube of small diameter, often with a circular cross section. Under it are special cells with electrolyte. The aluminum particles themselves are located in the lower vessel. The electrolyte in this case is suitable only for the alkaline type. A tank is installed above the feed pump, where condensate is collected. Some models use 2 pumps. The temperature is controlled directly in the cells.

The generator gets gas from the water. Its quality directly affects the amount of impurities in the finished product.So, if water with a high concentration of foreign ions enters the generator, then it will first have to pass through a deionization filter.

Here is how the process of obtaining gas occurs:

- The distillate is split into oxygen (O) and hydrogen (H) during the electrolysis process.

- O2 enters the feed tank and then escapes to the atmosphere as a by-product.

- H2 is supplied to the separator, separated from the water, which then returns to the supply tank.

- Hydrogen is re-passed through a separating membrane, which extracts the remaining oxygen from it, and then enters the chromatographic equipment.

electrolysis method

As mentioned above, there are practically no such inexhaustible energy sources in the world as hydrogen. It should not be forgotten that 2/3 of the World Ocean consists of this element, and in the entire Universe, H2, together with helium, occupies the largest volume. But to get pure hydrogen, you need to split water into particles, and this is not very easy to do.

Scientists after many years of tricks invented the method of electrolysis. This method is based on placing two metal plates close to each other in water, which are connected to a high voltage source. Next, power is applied - and a large electrical potential actually breaks the water molecule into components, as a result of which 2 hydrogen atoms (HH) and 1 oxygen (O) are released.

This gas (HHO) was named after Australian scientist Yull Brown, who in 1974 patented the creation of an electrolyzer.

Stanley Meyer fuel cell

The US scientist Stanley Meyer invented such an installation that did not use a strong electrical potential, but currents of a certain frequency.The water molecule oscillates in time with the changing electrical impulses and enters into resonance. Gradually, it gains power, which is enough to separate the molecule into components. For such an impact, currents are ten times smaller than for the operation of a standard electrolysis unit.

Benefits of Brown's gas as an energy source

- The water from which HHO is obtained is present on our planet in huge quantities. Accordingly, the sources of hydrogen are practically inexhaustible.

- The combustion of Brown's gas produces water vapor. It can be re-condensed into a liquid and used as a raw material again.

- The combustion of HHO does not release any harmful substances into the atmosphere and does not form by-products other than water. We can say that Brown's gas is the most environmentally friendly fuel in the world.

- When using a hydrogen generator, water vapor is released. Its quantity is enough to maintain a comfortable humidity in the room for a long time.

This is interesting: How to make a brick chimney with your own hands - a diagram, a device, etc.