- Selected points of use

- Required performance

- Advantages and disadvantages of gas generators

- Hydrogen heating: myth or reality?

- Hydrogen water at home

- How does the assembled structure work?

- 3 Economic feasibility

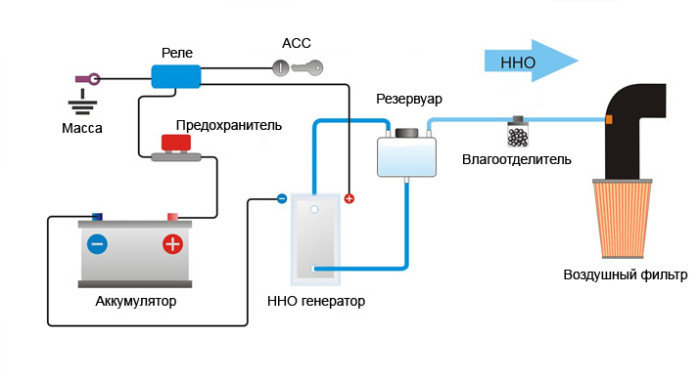

- Do-it-yourself electrolyser for a car

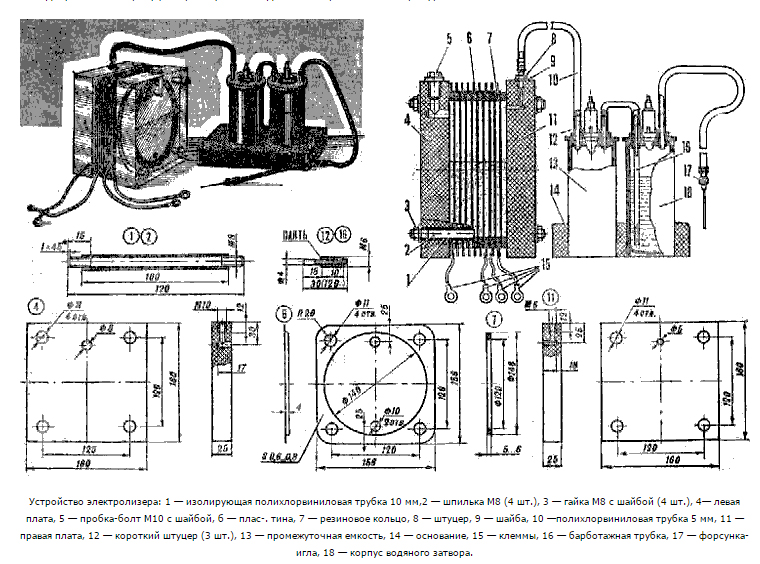

- 2 Device and principle of operation

- Law of conservation of energy ↑

- How to make hydrogen heating with your own hands

- Features of heating with hydrogen

- Pros and cons of hydrogen heating at home

- The device and principle of operation of a hydrogen plant for heating a house

- Hydrogen engine: types, device, principle of operation

- TYPES OF HYDROGEN ENGINES

- DEVICE AND PRINCIPLE OF WORK

- Hydrogen fuel cell engine

Selected points of use

First of all, I would like to note that the traditional method of burning natural gas or propane is not suitable in our case, since the combustion temperature of HHO exceeds that of hydrocarbons by more than three times. As you understand, structural steel will not withstand such a temperature for a long time. Stanley Meyer himself recommended using a burner of an unusual design, the diagram of which we present below.

Scheme of a hydrogen burner designed by S. Meyer

The whole trick of this device lies in the fact that HHO (indicated by the number 72 in the diagram) passes into the combustion chamber through valve 35. The burning hydrogen mixture rises through channel 63 and simultaneously carries out the ejection process, entraining outside air through adjustable openings 13 and 70. Under the cap 40, a certain amount of combustion products (water vapor) is retained, which enters the combustion column through channel 45 and mixes with the burning gas. This allows you to reduce the combustion temperature several times.

The second point that I would like to draw your attention to is the liquid that should be poured into the installation. It is best to use prepared water that does not contain salts of heavy metals. The ideal option is distillate, which can be purchased at any auto shop or pharmacy.

For the successful operation of the electrolyser, potassium hydroxide KOH is added to the water, at the rate of about one tablespoon of the powder per bucket of water.

And the third thing we put special emphasis on is safety. Remember that the mixture of hydrogen and oxygen is not accidentally called explosive. HHO is a hazardous chemical compound which, if handled carelessly, can cause an explosion. Follow safety rules and be especially careful when experimenting with hydrogen. Only in this case, the “brick” that our Universe consists of will bring warmth and comfort to your home.

We hope the article has become a source of inspiration for you, and you, having rolled up your sleeves, start manufacturing a hydrogen fuel cell. Of course, all our calculations are not the ultimate truth, however, they can be used to create a working model of a hydrogen generator.If you want to completely switch to this type of heating, then the issue will have to be studied in more detail. Perhaps it is your installation that will become the cornerstone, thanks to which the redistribution of energy markets will end, and cheap and environmentally friendly heat will enter every home.

Required performance

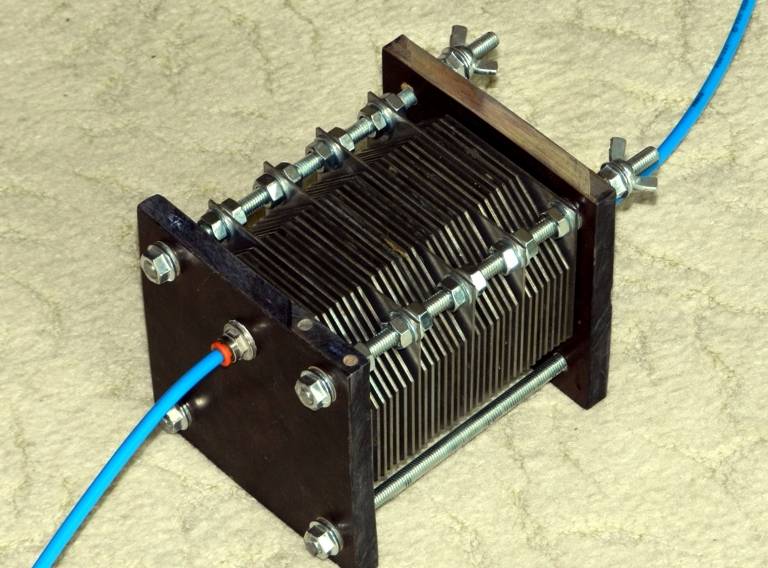

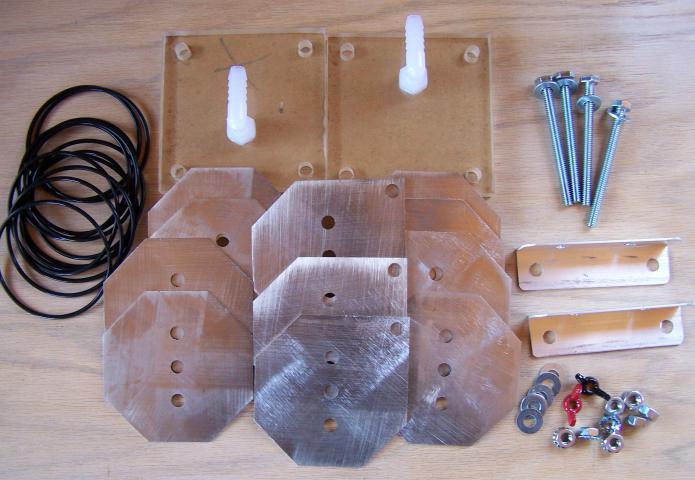

In order to really save fuel, a hydrogen generator for a car must produce gas every minute at the rate of 1 liter per 1000 engine displacement. Based on these requirements, the number of plates for the reactor is selected.

To increase the surface of the electrodes, it is necessary to process the surface with sandpaper in a perpendicular direction. This treatment is extremely important - it will increase the working area and avoid "sticking" of gas bubbles to the surface.

The latter leads to the isolation of the electrode from the liquid and prevents normal electrolysis. Do not forget that for the normal operation of the electrolyzer, the water must be alkaline. Ordinary soda can serve as a catalyst.

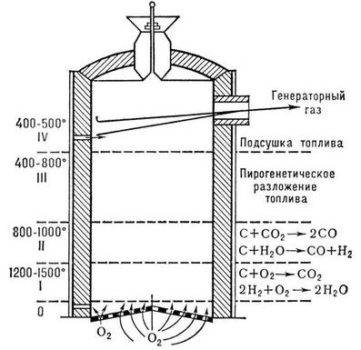

Advantages and disadvantages of gas generators

A factory-made household gas generator will cost 1.5–2 times more than a conventional solid fuel boiler. Is it worth it to spend money on this "miracle technique"?

Among the advantages of using gas generators are:

- complete burning of the fuel loaded into the furnace, and the minimum amount of ash;

- relatively high efficiency when working together with an internal combustion engine or a gas boiler;

- a wide range of solid fuels;

- ease of operation and no need to continuously monitor the operation of the unit;

- the time interval between reboots of the furnace is up to a day on wood and up to a week on coal;

- the possibility of using undried wood - wet raw materials can only be used in some models of gas generators;

- environmental friendliness of the device - this device does not have an exhaust pipe, all the generated gas goes directly into the combustion chamber of the engine or boiler.

When using wet firewood, the generator will work, but gas production will be reduced by 20-25%. The drop in productivity is due to the evaporation of natural moisture from the wood.

This leads to a decrease in the temperature in the furnace, which slows down the pyrolysis process. It is best to dry the logs thoroughly before loading into the pyrolysis chamber. Industrial devices are fully automated; fuel is supplied to them by an auger from a nearby container.

A self-made gas generator does not please with such autonomy, but it is also quite simple to operate. It is only necessary from time to time to load it with fuel to the eyeballs.

Operating temperatures in the gas generator reach values of 1200–1500 ° C, its body must be made of materials that can withstand such loads

The gas generator has fewer disadvantages, but they are:

- poor controllability of the volumes of generated gas - when the temperature in the furnace decreases, pyrolysis stops and instead of a combustible gas mixture, a mixture of resins forms at the outlet;

- cumbersome installation - even a home-made gas generator of average power of 10–15 kW takes up a fairly large space;

- duration of kindling - before the reactor produces the first gas, 20-30 minutes will pass.

After “warming up”, the generator consistently produces a certain volume of the gas mixture, which must be burned or thrown into the air.To make this unit with your own hands, you will need strong gas cylinders or thick steel, and this is a lot of money. But all this pays off with the efficiency of the generator and the cheapness of the initial fuel.

Some models of gas generators are equipped with an air blower, while others are not. The first option allows you to increase the capacity of the installation, but ties it to the power grid. If you need a small generator for cooking food in nature, then you can get by with a compact unit without an air blower.

Most self-made gas generating installations operate due to natural draft.

A portable wood-burning gas generator with a power of 2.4 kW allows you to easily cook dinner outside the city, away from civilization (+)

A portable wood-burning gas generator with a power of 2.4 kW allows you to easily cook dinner outside the city, away from civilization (+)

To heat a private house, a more powerful and volatile device will be needed. However, in this case, it is worth taking care of a backup power generator so that overnight in the event of an accident on the network, you will not be left without both power supply and heating.

Hydrogen heating: myth or reality?

The welding generator is currently the only practical application for electrolytic water splitting. It is not advisable to use it for heating a house, and here's why. Energy costs during gas-flame work are not so important, the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Another thing is home heating, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Mass-produced welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum.You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely succeed in getting combustible gas, but it is unlikely that it will be enough to heat at least one large room, let alone a whole house. And if enough, you will have to pay fabulous electricity bills.

Rather than spending time and effort on getting free fuel, which does not exist a priori, it is easier to make a simple electrode boiler with your own hands. You can be sure that in this way you will use much less energy with greater benefit. However, home craftsmen - enthusiasts can always try their hand and assemble an electrolyzer at home in order to conduct experiments and see for themselves everything. One of these experiments is shown in the video:

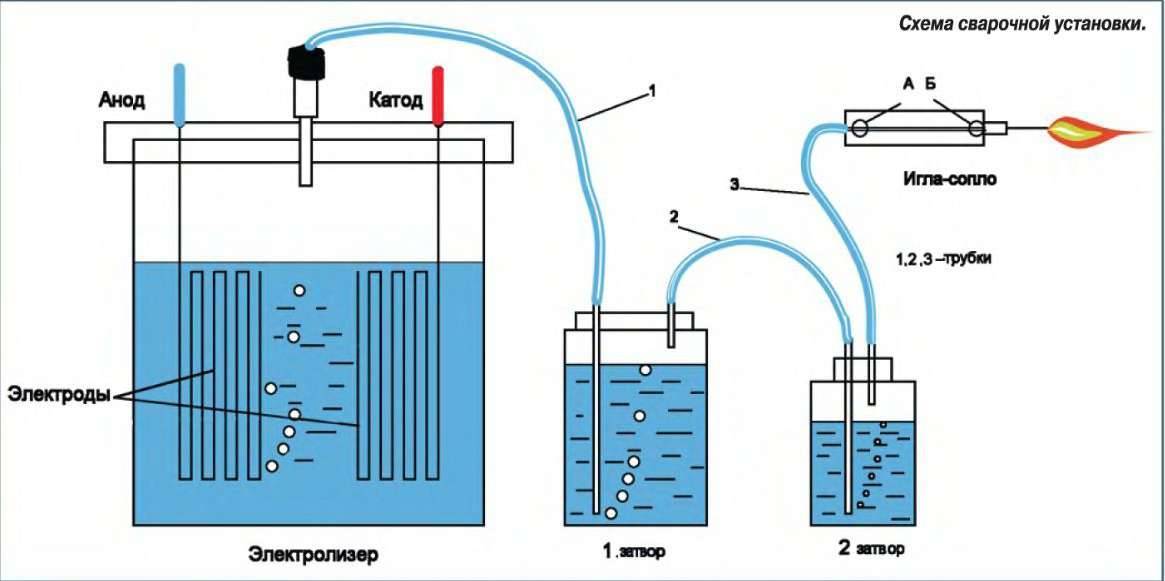

Hydrogen water at home

Theoretically, you can create a hydrogen generator with your own hands at home. But for this you need to have special knowledge, to have the appropriate equipment.

There are two options:

- Saturation is the process of water enrichment with molecular oxygen. By the principle of production of carbonated drinks.

- Electrolysis is the process of passing current through a liquid medium. The essence of the technique is in the reaction of water with metals.

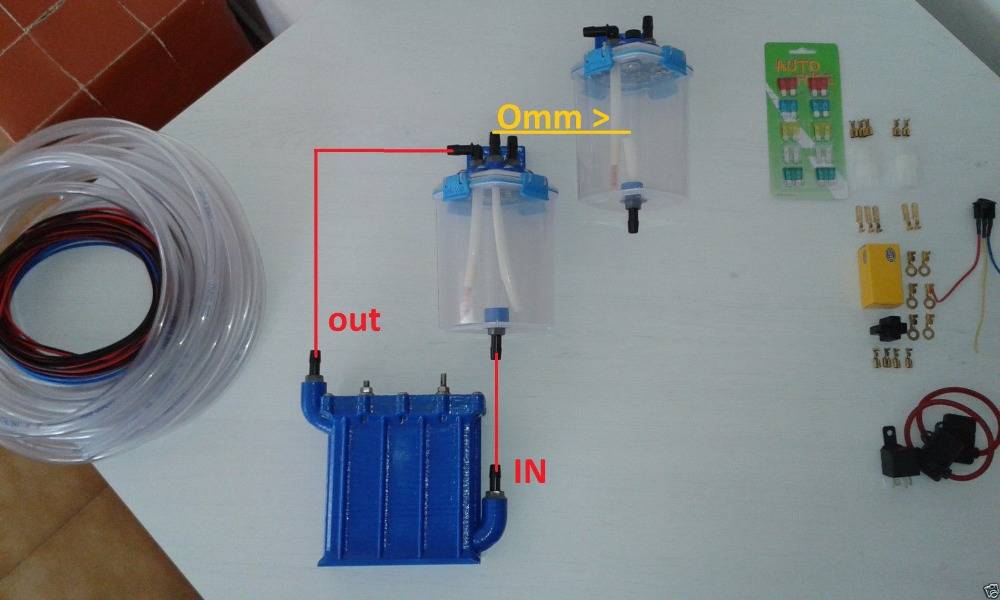

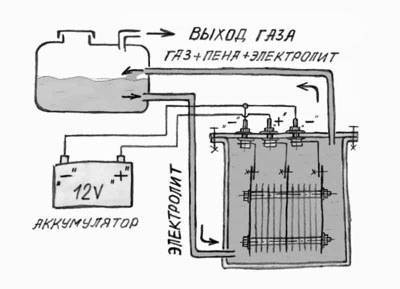

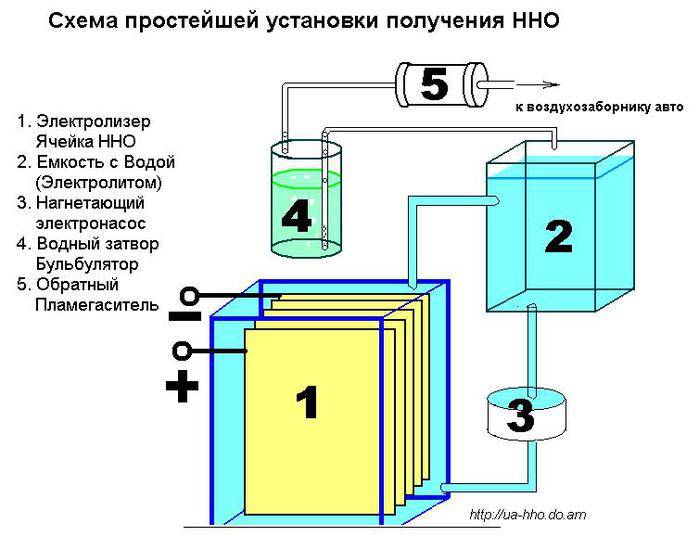

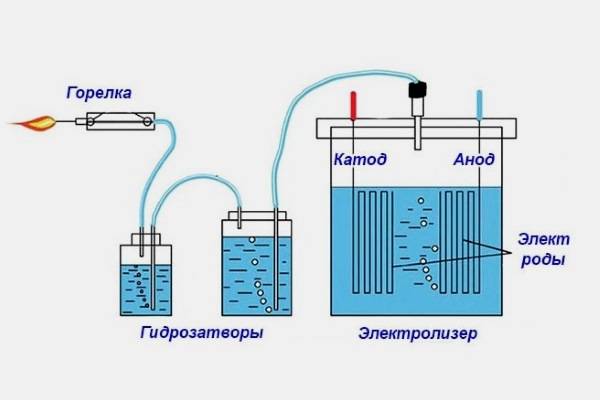

The principle of operation of a home generator is shown in the image:

The simplest electrolyzer consists of:

- thick-walled container (reactor);

- metal electrodes connected to the mains;

- water lock;

- gas outlet tube;

- burners.

How to make a hydrogen generator:

- Immerse the metal electrodes in a container of water, apply voltage. The addition of salt (or alkali, or acid) to the water will improve the reaction.

- A reaction will occur, as a result of which hydrogen will begin to be released near the cathode (minus), and oxygen near the anode (plus).

- The gases are mixed and enter the tube, through which they are then sent to a water seal (hydraulic seal). The purpose of the water seal is to prevent a flash in the reactor, to separate water vapor.

- Dangerous gas from the second tank is transferred to the burner, where it burns out. The result is water.

The creation of a hydrogen generator in practice is as follows:

- Prepare everything you need: 2 wide-mouth glass bottles, caps for them, a dropper system, 20 self-tapping screws, 2 flat wooden sticks, wires.

- Connect the wooden sticks with self-tapping screws with the ends in different directions. Solder the heads of the self-tapping screws and bring the wires to them. Get improvised electrodes.

- Pull the tube from the dropper and wire into the perforated bottle cap. Seal with a glue gun.

- Place the electrodes in the container and screw on the lid.

- Through 2 holes in the other cover, pull the tubes from the dropper. Pour water into the bottle, screw on the cap.

- Pour water into the reactor with the addition of salt.

- Turn on the power source (DC, e.g. car battery, power adapter).

- As soon as bubbles appear, the reaction has begun. Adjust the voltage. Ignite the escaping gas.

For more information on how to make a hydrogen generator yourself, see the video:

But does it make sense to be puzzled by the independent creation of a water ionizer with your own hands, when it is easier and cheaper to buy a ready-made one?

How does the assembled structure work?

Voltage is applied to the PWM, the regulator generates a voltage with the required frequency. The fruitfulness of gas production depends on what the frequency will be.Voltage is then applied to stainless steel tubes or plates containing water. In them, under the influence of current, a "rattle" is released. Then it enters the dryer tank through flexible tubes. And already from the dryer, the gas is supplied to the air supply circuit.

Such an installation can be used for heating: garage cooperatives, country houses, it all depends on the flight of your imagination. To use this installation for heating a house, you need to convert a solid fuel or gas boiler to Brown's gas. If you still decide to assemble and actively use this home-made installation, then you will get cheap fuel. And an environmentally friendly product that does not pollute the air. When assembling Brown's gas generator, you will have questions. Here we will answer the most frequently asked questions.

What kind of water should I use, regular tap water or distilled water?

You can use tap water if it does not contain heavy metals or distilled. But the best effect is achieved when using a sodium hydroxide solution added to distilled water. It is necessary to observe the proportion, for ten liters of water you need to add one tablespoon of sodium hydroxide and mix thoroughly.

What metal to use?

In various manuals and manuals, they write that only rare metals should be used.

You are being misled. Any stainless steel can be used. The best results when working with steel were shown by ferromagnetic steel, which does not attract particles of unnecessary debris. Another important point, the main thing, when choosing a metal, is to give preference to stainless steel, and that it is not subject to oxidation.

How durable are the electrode plates?

There is no need to change the plates for new ones, since they are not destroyed at all during operation.

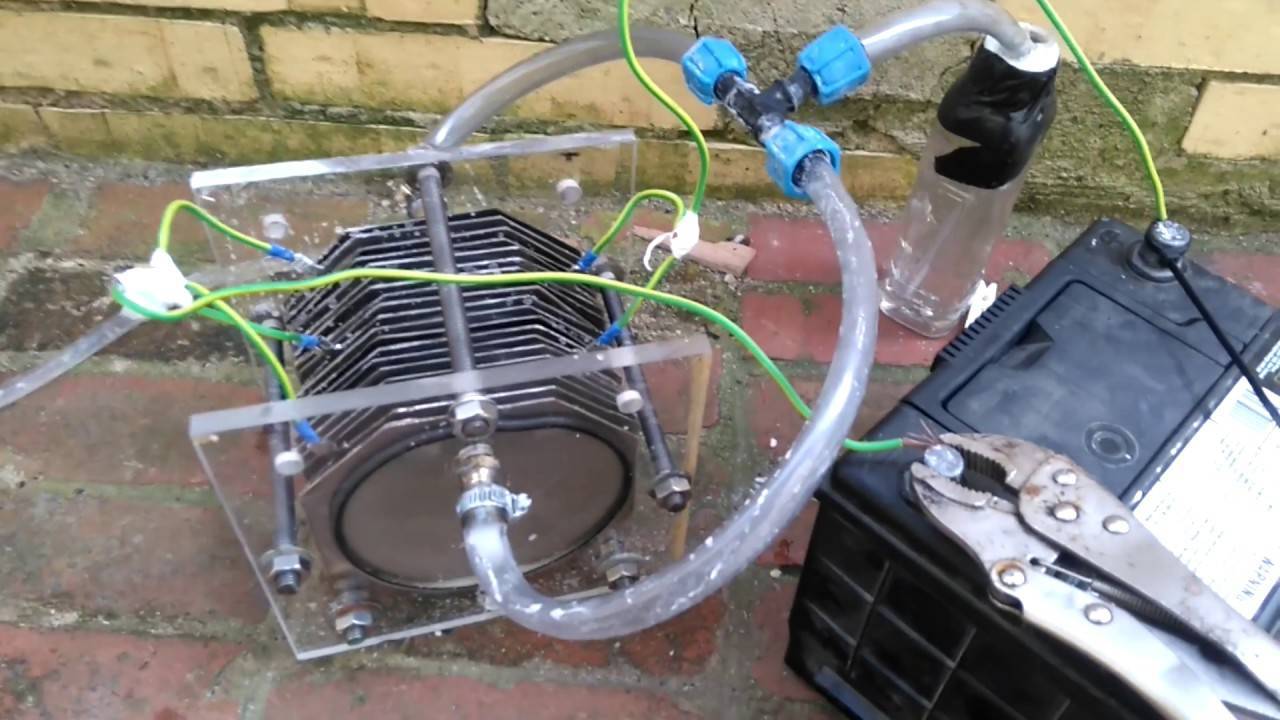

What needs to be done to prepare electrode plates? And how to do it right?

First of all, before assembling the plates, they must be washed very thoroughly in a soapy solution, and then their surface should be treated with an alcohol-containing substance (vodka or alcohol). The electrolyzer needs to be “driven” for some time, periodically replacing dirty water with clean water. Continue until the water has washed away all the dirt. If the water is clean enough, the unit will not heat up.

If you assembled the electrolyser correctly, then when using it, the water and plates will not heat up.

It is important not to overheat the electrolyser above 65 degrees. If the temperature rises above the specified temperature, then dirt, metals with minerals will stick to the plates. And they will have to be removed with sandpaper or replaced with new ones.

And they will have to be removed with sandpaper or replaced with new ones.

3 Economic feasibility

It is very difficult to make a high-quality hydrogen plant at home. The master will have to take into account a lot of parameters. For example, you need to accurately select the metal for the electrodes. It must have certain properties.

Also, when assembling the hydrolyzer, the mounting dimensions must be observed. To get them, you need to make complex calculations, taking into account the quality of the water, the required output power, etc.

In the manufacture of the device, even the cross section of the wires through which current is supplied to the electrodes is important.This is not about the performance of the generator, but about the safety of its operation, but this important nuance must be taken into account.

The main problem of such devices is the high cost of electricity to produce hydrogen oxydine. They exceed the energy that can be obtained from burning such fuel.

Due to the low efficiency, the price of a hydrogen plant for the home makes the production of this gas and its subsequent use for heating unprofitable. Than wasting electricity, it is easier to install any electric boiler. It will be more efficient.

As far as road transport is concerned, the picture is not much different. Yes, you can make a hydrolyzer to save fuel, but this reduces safety and reliability.

The only place where hydrogen can be effectively used as a fuel is gas welding. Hydrogen devices weigh less, they are more compact than oxygen cylinders, but much more efficient. In addition, the cost of obtaining a mixture here does not play any role.

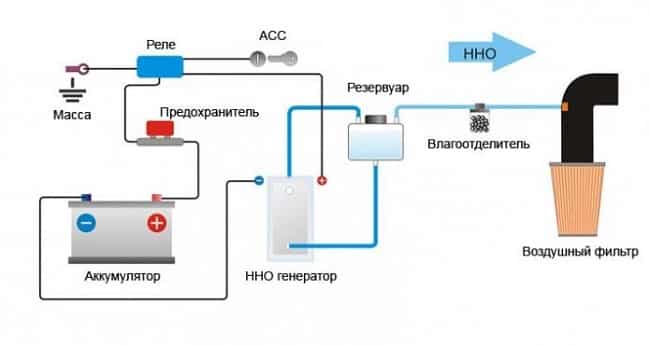

Do-it-yourself electrolyser for a car

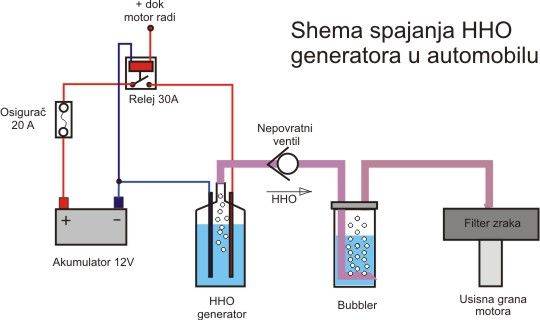

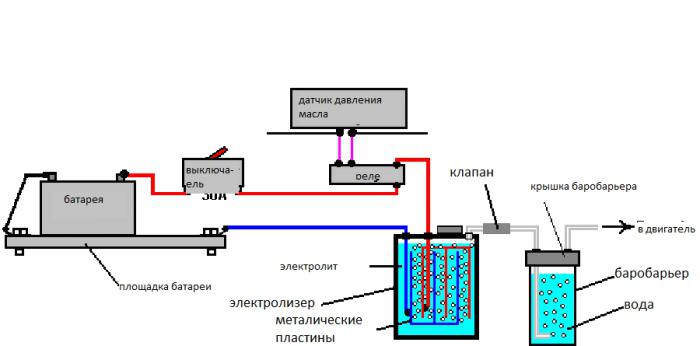

On the Internet you can find many diagrams of HHO systems, which, according to the authors, allow you to save from 30% to 50% of fuel. Such claims are overly optimistic and are generally not supported by any evidence. A simplified diagram of such a system is shown in Figure 11.

In theory, such a device should reduce fuel consumption due to its complete burnout. To do this, Brown's mixture is fed into the air filter of the fuel system. This is hydrogen and oxygen obtained from an electrolyser powered by the car's internal network, which increases fuel consumption. Vicious circle.

Of course, a PWM current regulator circuit can be used, a more efficient switching power supply or other tricks can be used to reduce energy consumption. Sometimes on the Internet there are offers to purchase a low-ampere PSU for an electrolyzer, which is generally nonsense, since the performance of the process directly depends on the current strength.

It's like the Kuznetsov system, the water activator of which is lost, and there is no patent, etc. In the above videos, where they talk about the undeniable advantages of such systems, there are practically no reasoned arguments. This does not mean that the idea has no right to exist, but the claimed savings are "slightly" exaggerated.

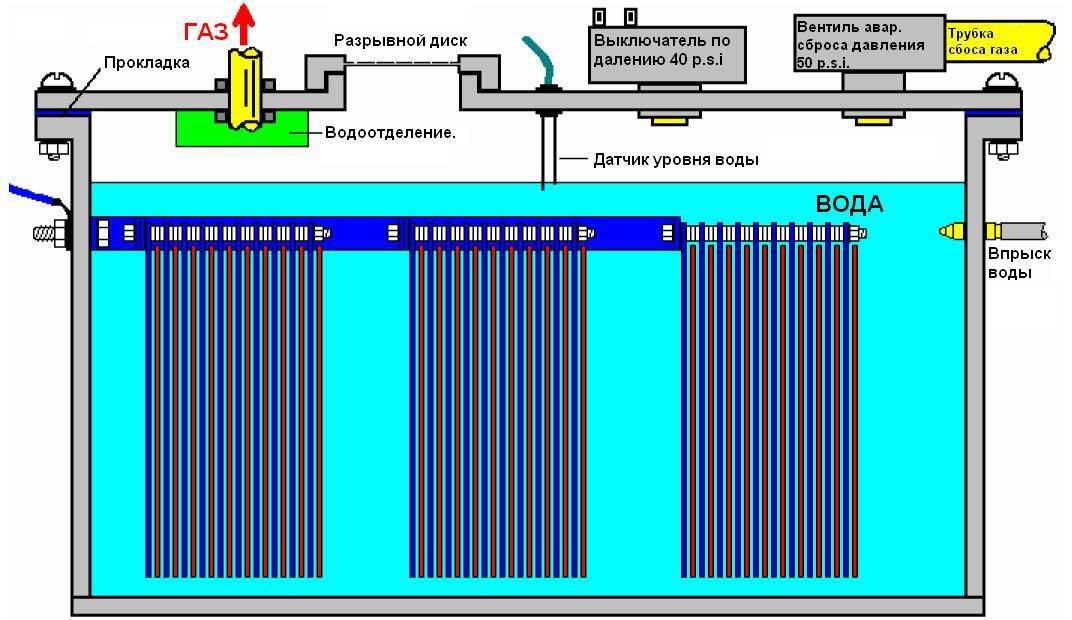

2 Device and principle of operation

Hydrogen home heating was developed by an Italian company. Scientists were able to reduce the combustion temperature by using catalysts from +6000 to +300°C, which made it possible to use traditional materials for the production of heating boilers.

The boiler device includes:

- fuel combustion chamber;

- heat exchanger;

- electrolyzer;

- a reservoir for generating hydrogen with an electrolyte placed inside;

- two-stage protective block.

Hydrogen heating boilers can be of different capacities. The larger the area of the room, the greater the power should be. Some boilers have a modular system, the maximum number of channels for generating hydrogen energy is 6, each channel must contain a catalyst so that the channels can work independently of each other.

Hydrogen boilers work as follows:

- the electrolytic solution enters the electrolyzer and, under the influence of an electric current, hydrogen, oxygen and water vapor are produced;

- gases enter the chemical separator, where hydrogen is separated from the total volume;

- purified hydrogen through a two-stage protective block enters the combustion chamber, where a chemical reaction takes place with the participation of hydrogen, oxygen and catalysts;

- during the reaction, water is formed and heat is released, the heat heats the heat exchanger, due to which heating occurs, and the water again enters the electrolyzer.

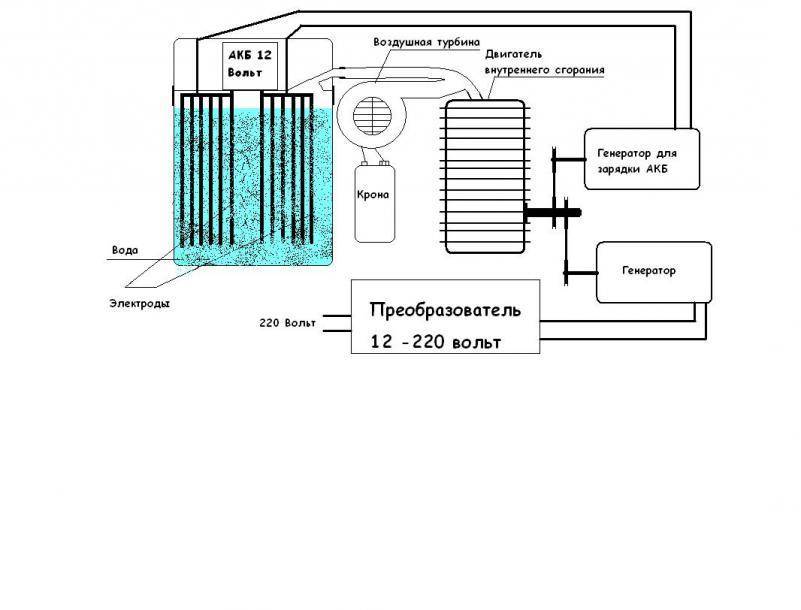

Law of conservation of energy ↑

Everything in nature is interconnected. If something has arrived somewhere, it means that it has departed from somewhere. This folk wisdom, in a simplified but generally correct way, describes the law of conservation of energy. Hydrogen, when burned, releases heat energy. But in order to get gas by electrolysis, you will have to spend a certain amount of electricity. Which, in turn, is mostly obtained by generating heat from the combustion of other fuels. And if we take the pure thermal energy necessary to generate electricity and the energy that hydrogen will give during combustion, even the most advanced installations result in a double loss. We literally throw away half of the money. And these are only operating costs, but you should also take into account the cost of very expensive equipment.

The project of the wind-hydrogen airship Aeromodeller II. The Belgian engineers drew a beautiful picture, it remains to back it up with specific economically viable technologies

According to the INEEL research laboratory, on industrial hydrogen generators in the United States, the cost of one kilogram of hydrogen was:

- Electrolysis from an industrial power grid - 6.5 usd.

- Electrolysis from wind turbines - 9 usd.

- Photoelectrolysis from solar devices - 20 usd.

- Production from biomass - 5.5 usd.

- Conversion of natural gas and coal - 2.5 usd.

- High-temperature electrolysis at nuclear power plants - 2.3 usd. This is the least expensive way and the farthest from home conditions.

Moreover, even the best hydrogen generator at home will be noticeably inferior to the industrial one in efficiency. With such prices, there is no reason to talk about any serious competition for hydrogen fuel compared not only with cheap natural gas, but also with expensive electric heating, diesel fuel, and even heat pumps.

How to make hydrogen heating with your own hands

Do heating on hydrogen any master who has the ability to work with metal can do it with his own hands.

To form the device, you will need the following set of materials:

- stainless steel sheet with parameters 50x50 cm;

- bolts 6x150, equipped with washers and nuts;

- flow-through filter element - useful from an old washing machine;

- a transparent hollow tube 10 m long, for example, from the water level;

- a regular 1.5 liter plastic food container with a strong airtight lid;

- a set of herringbone fittings with a hole diameter of 8 mm;

- grinder for cutting;

- drill;

- silicone sealant.

To make a hydrogen furnace, steel 03X16H1 is suitable, and instead of water, you can take an alkaline solution, which will create an aggressive environment for the passage of current, while extending the life of the steel sheets.

How to make home heating with hydrogen yourself:

- Lay the metal sheet on a flat table, cut into 16 equal parts. Rectangles are obtained for the future burner. Now cut off one corner of all 16 rectangles - this is necessary for the subsequent connection of the parts.

- On the reverse side of each element, drill a hole for the bolt. Of all 16 sheets, 8 will be anodes and 8 will be cathodes. Anodes and cathodes are needed for the passage of electric current through parts with different polarity, this ensures the decomposition of alkali or distillate into hydrogen and oxygen.

- Now put the plates in a plastic container, taking into account the polarity, alternating plus and minus. A transparent tube will serve as an insulator for the plates, which must be cut into rings, and then into strips 1 mm thick.

- The metal plates are fixed to each other with washers in this way - first the washer is put on the bolt leg, then the plate is put on. After the plate, you need to put 3 washers on the bolt, then the plate again. In this way, 8 plates are hung on the anode and 8 plates on the cathode.

Now you need to figure out the stop point for the bolt in the food container, drill a hole in this place. If the bolts are not included in the container, then the bolt leg is cut to the desired length. After that, thread the bolts into the holes, put washers on the legs and clamp the structure with nuts for tightness. Equip the container lid with a hole for the fitting, insert the element into the hole and, for tightness, coat the joint area with sealant. Now blow out the fitting. And if air escapes through the lid, then you will have to seal the lid around the entire perimeter.

The generator is tested by connecting any current source with filling the container with water. A hose is put on the fitting, the second end of which is immersed in a container. If air bubbles form in the liquid, then the circuit is working, if not, you need to check the current supply power. It happens that air bubbles do not form in the water, but they certainly appear in the electrolyzer.

To provide the required amount of thermal energy, it is necessary to increase the production and output of gas by increasing the voltage in the electrolyte. Pour alkali into the water, for example, sodium hydroxide, which is in the Krot pipe cleaner. Reconnect the power supply and check the capacity of the electrolyzer.

The very last stage is the connection of the burner to the pipeline of the heating main. It can be a warm floor, plinth wiring. The joints should be sealed with silicone and the equipment can be put into operation.

Features of heating with hydrogen

This type of heating was developed by Italian engineers. The result of their work was a device that not only did not emit harmful substances into the atmosphere, but also practically did not create noise. And for the manufacture of the boiler, heat-resistant steel or cast iron was not required, since the temperature inside the unit was low.

As mentioned above, as a result of such chemical reactions, harmful substances are not released into the atmosphere, and therefore a complex system for their removal is not required. And getting raw materials is not currently such a serious problem as it used to be. As for the costs, in addition to the fuel itself, it is usually also electricity for the smooth operation of the hydrogen boiler.

Pros and cons of hydrogen heating at home

Such heating systems have recently become more and more popular, due to such advantages as:

- No harmful emissions into the atmosphere.

- There is no fire in low temperature systems as the heat is the result of a chemical reaction.When oxygen and hydrogen are combined, water and heat are obtained, which are transferred to the heat exchanger. As a result, the coolant does not heat up above forty degrees Celsius, which is the ideal temperature for the "warm floor" system.

- Profitability - only the use of gas boilers will allow you to save more, but this type of heating is far from always available in rural areas even now.

- In addition, this allows in the future to reduce the consumption of non-renewable resources such as gas or oil.

But hydrogen heating also has disadvantages:

- It is best to use only low-temperature versions of such devices, since the fuel is explosive.

- It is not easy yet to find a highly qualified specialist for the competent installation and maintenance of such devices.

The device and principle of operation of a hydrogen plant for heating a house

As a result of the reaction of hydrogen and oxygen, water is obtained and a significant amount of heat is released. Such a process, characterized by high efficiency (more than 80 percent), requires large capacities. In addition, you need to constantly connect to a water source, the role of which is usually played by the plumbing system at home; electricity for the electrochemical reaction of electrolysis, the availability and constant renewal of special catalysts.

This process must be accompanied by human control and compliance with all safety requirements. Although those are much less than in the case of gas heating. Usually only periodic visual control of the process is required.

If you want to create such a system with your own hands, then for this you will at least need:

- hydrogen generator;

- burner;

- boiler.

The first device is necessary for electrolysis - the decomposition of water into components, using electricity and catalysts. A burner creates an open flame. The boiler is used as a heat exchange device. All these components can be purchased in stores, and assemble the system yourself.

The hydrogen generator can also be assembled independently. This will require a power source that provides a current of 30A, a tank for the location of all structures, steel tubes, containers for distilled water. Inside the sealed structure, stainless steel platinums are installed - and the more of them, the more hydrogen the installation will produce (but more electricity will be spent on this).

The water entering the tank is split into hydrogen and oxygen under the action of an electric current, the first one is sent to the boiler with a burner. We add that if you use a PWM generator (instead of a 220V network), then the efficiency of the device increases.

Do not forget that only distilled water mixed with sodium hydroxide is used in the system (a solution for the preparation of which is taken 1 tablespoon of the substance per 10 liters of liquid). If distillate is difficult to obtain, then tap water can be used. The main thing is to make sure that heavy metals are not dissolved in such a liquid.

As you can see, if you correctly approach the design and choice of materials, then it is quite possible to make a hydrogen boiler on your own.

Hydrogen engine: types, device, principle of operation

TYPES OF HYDROGEN ENGINES

The first type of hydrogen engine runs on fuel cells. Unfortunately, hydrogen engines of this type still have a high cost.The fact is that the design contains expensive materials like platinum.

The second type includes hydrogen internal combustion engines. The principle of operation of such devices is very similar to propane models. That is why they are often reconfigured to work under hydrogen. Unfortunately, the efficiency of such devices is an order of magnitude lower than those that operate on fuel cells.

DEVICE AND PRINCIPLE OF WORK

The main difference between hydrogen engines and the gasoline or diesel counterparts we are accustomed to today lies in the way the working mixture is supplied and ignited. The principle of converting the reciprocating movements of the crankshaft into useful work remains unchanged. Due to the fact that the combustion of fuel based on petroleum products is slow, the combustion chamber is filled with a fuel-air mixture a little before the piston is raised to its highest position (TDC). The lightning speed of the hydrogen reaction allows you to shift the injection time to the moment when the piston begins its return movement to BDC. At the same time, the pressure in the fuel system does not have to be high (4 atm is enough).

Under ideal conditions, a hydrogen engine can have a closed-type power supply system. The mixing process takes place without the participation of atmospheric air. After the compression stroke, water remains in the combustion chamber in the form of steam, which, passing through the radiator, condenses and turns back into H2O. This type of equipment is possible if an electrolyser is installed on the car, which will separate hydrogen from the resulting water for re-reaction with oxygen.

In practice, this type of system is still difficult to implement.For proper operation and to reduce the friction force in motors, oil is used, the fumes of which are part of the exhaust gases. At the present stage of technology development, stable operation and trouble-free start of an explosive gas engine without the use of atmospheric air are not feasible.

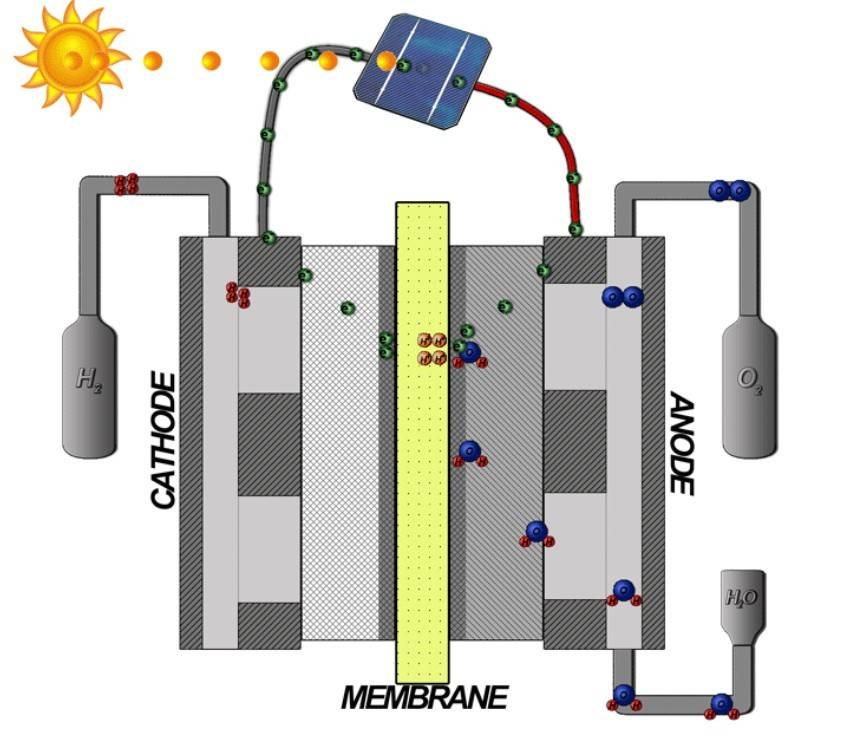

Hydrogen fuel cell engine

Please note that hydrogen engines are understood as units operating on hydrogen (hydrogen internal combustion engine) and motors that use hydrogen fuel cells. We have already considered the first type above, now let's focus on the second option.

A hydrogen fuel cell is actually a "battery". In other words, this is a hydrogen battery with a high efficiency of about 50%. The device is based on physical and chemical processes, in the body of such a fuel cell there is a special membrane that conducts protons. This membrane separates two chambers, in one of which there is an anode, and in the other a cathode.

Hydrogen enters the chamber where the anode is located, and oxygen enters the chamber with the cathode. The electrodes are additionally coated with expensive rare earth metals (often platinum). This allows you to play the role of a catalyst that affects the hydrogen molecules. As a result, hydrogen loses electrons. At the same time, protons go through the membrane to the cathode, while the catalyst also acts on them. As a result, protons combine with electrons that come from outside.

This reaction forms water, while the electrons from the chamber with the anode enter the electrical circuit. The indicated circuit is connected to the motor.In simple terms, electricity is generated that makes the engine run on such a hydrogen fuel cell.

Such hydrogen engines allow you to travel at least 200 km. on one charge.