- Arrangement of the barn and hygiene of the premises

- Air exchange systems: natural or forced?

- Natural

- Forced

- How to properly draw

- How to make natural ventilation

- How to install forced ventilation

- Pro Tips

- Features of the construction and equipment of the pigsty

- Sheep barn

- How to calculate the size of a pigsty?

- Square

- Height

- Calculation features and type definition

- Automation of ventilation systems in the barn

- How to build a rabbitry

- Video - Rabbit device

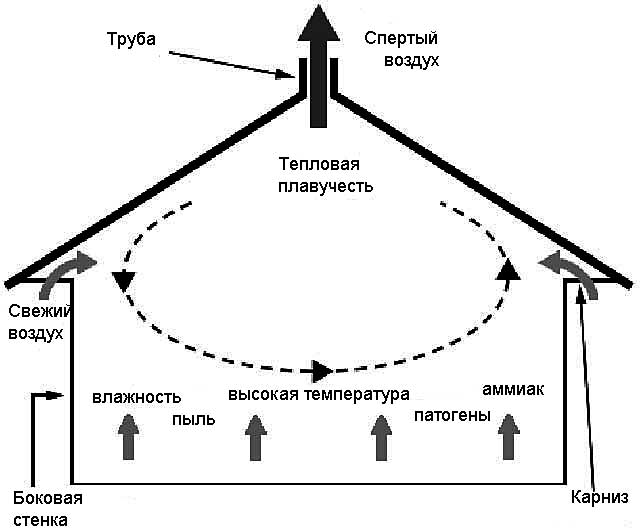

Arrangement of the barn and hygiene of the premises

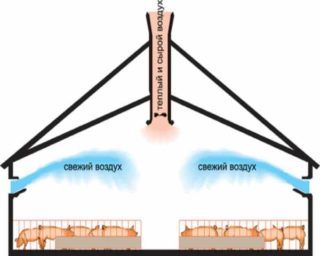

First of all, you need to provide lighting and fresh air. The optimal temperature regime for keeping cows is 8–10 °C. Permissible temperature fluctuation from 4 to 20 С°. Do not allow the animal to overheat. At a comfortable temperature, the metabolic processes in the body do not spend energy on heating the body, thereby increasing the weight gain and milk yield of cows. You also need to organize the correct supply of fresh air. It is not recommended to allow drafts in the room, because of them there are many diseases. The ventilation corridor is constructed from boards with a section of 15x15 cm and is brought out above the ridge to the roof.It must have a damper that will protect against bad weather and precipitation in the form of snow.

To keep the barn dry and comfortable, you need to provide bedding. The cow is warmer from it. Such material absorbs moisture, thereby making the room drier. If you do not want to clean the barn daily, then you can gradually add bedding, which over time will become a kind of pillow. In winter, the cow will be warmer to rest on it.

Equipment in the barn includes:

- Feeders for hay, straw and liquid feed. Should be quite voluminous, convenient for feeding and cleaning. The best solution is to install them in front of the stall. Dimensions per cow: front wall with neckline 35–40 cm, back wall 70–80 cm (so that feed does not fall out), length not less than 1.2 meters. Tray for lick (salt). The body of the animal requires replenishment of minerals; in winter, their shortage is compensated with salt.

- Drinker. Equip it so that the water does not overflow and is not contaminated by waste. Technology has stepped forward, so automatic drinking bowls are installed in modern sheds. They can be connected to the central water supply; if there is no access to it, then to the water tank. An autodrinker makes your work easier, you don’t need to carry buckets and store water.

- If the barn contains several cows of different ages, then a separation grate is needed so that the animals cannot injure each other.

- Calf enclosure.

- Door. Many make a gross mistake when they install several entrances to the room, usually through. When opening such doors, a draft is created, which adversely affects the health of animals. Therefore, we recommend stopping at one entrance to the barn.To further insulate the room, you can make double doors. Between them there will be an air cushion that will not let cold air into the barn.

From time to time, the barn needs to be disinfected. Liquid feed, waste products are a favorable environment for the development of pathogenic microflora. The walls of the barn should be disinfected twice a year (spring and autumn) with a solution of lime. Feeders for liquid feed should be treated with lye. Also, every day in any weather you need to ventilate the room. Drinking bowls and service equipment should be cleaned as necessary. Do not forget about blowing the ventilation ducts. Otherwise, they may become clogged and cease to perform the function assigned to them.

In a subsidiary farm, a livestock shed is an integral part. Here is everything necessary for keeping cattle - equipment, ventilation, windows. In this case, the building must be located in the right place. Construction materials also play an important role. Comfortable habitation will provide livestock with good health, good weight gain, large milk yields. The article discusses the rules for building a room with your own hands, taking into account the basic requirements for keeping animals.

Air exchange systems: natural or forced?

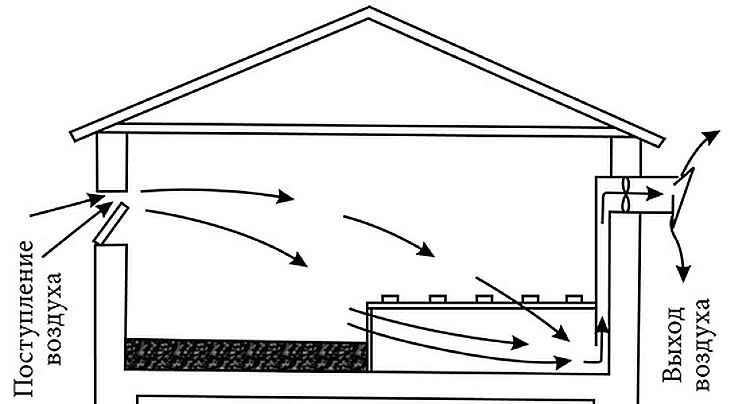

One of the main differences is the principle of creating air exchange - it can be natural or forced. Below we consider each option and how to arrange it with your own hands.

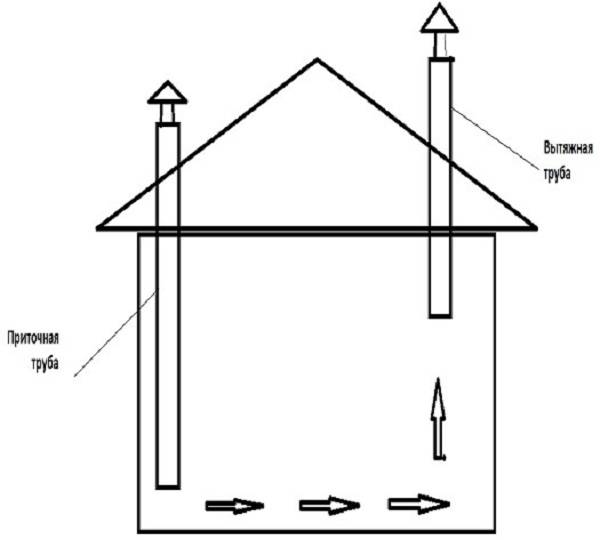

Natural

In this case, air will flow in and out of the room due to the pressure difference. Fans are not used in this circuit. You can read more about the natural system separately.

The scheme is cheap (if you have to buy something, it’s the cheapest products, and you don’t need to spend money on electricity), but ineffective - air exchange largely depends on the weather, and it is difficult to regulate it. Suitable if you have a small house that is used only in the summer.

For inflow in natural ventilation systems, the following can be used:

- Supply valves - wall or window.

- An overflow grate in the front door (suitable if the area of \u200b\u200bthe house does not exceed 20-40 "squares", otherwise you will have to use too large a ventilation grill).

- Windows with micro-ventilation (not relevant for cottages, since expensive windows are rarely installed in seasonal houses).

- In the summer - just open windows or doors (but in the winter, when they are closed, you still have to provide the flow in another way).

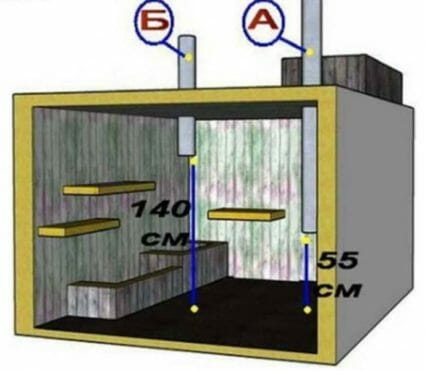

For exhaust - either a stove chimney can be used (that is, nothing else needs to be done if there is already a chimney), or an exhaust duct. It is mounted at a point as far as possible from the inflow point (so that air is drawn through the entire room).

The inflow is placed as low as possible, the hood - as high as possible, under the ceiling. If there are several rooms, the inflow points must be in each, and located opposite the door. The chimney can be removed either through the roof, above the ridge, or through the wall horizontally.

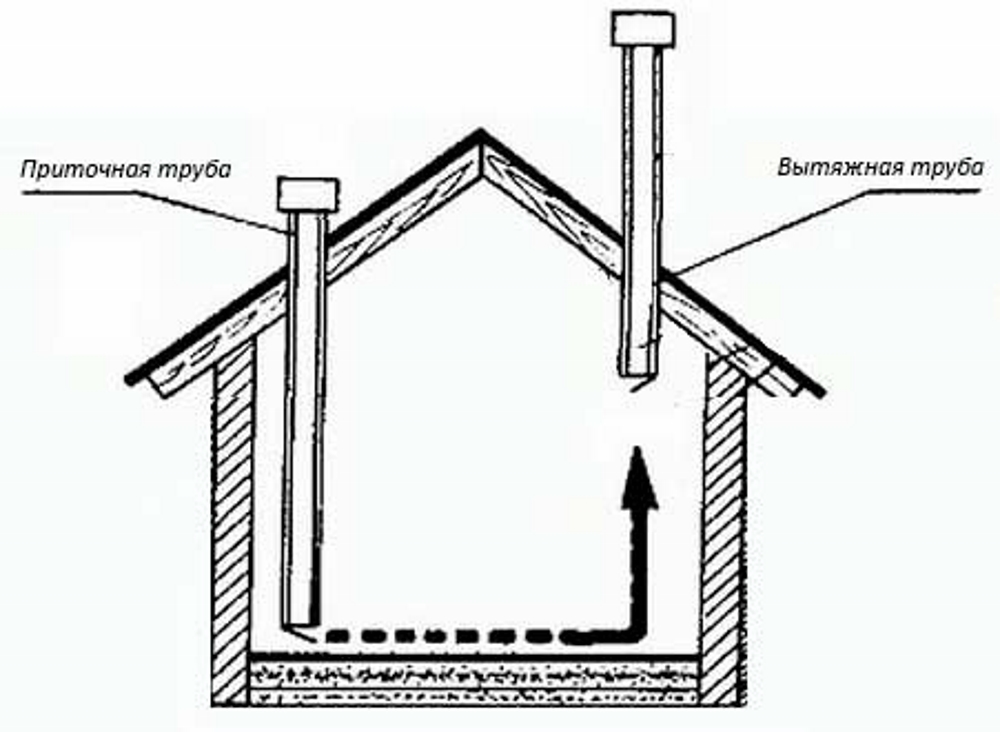

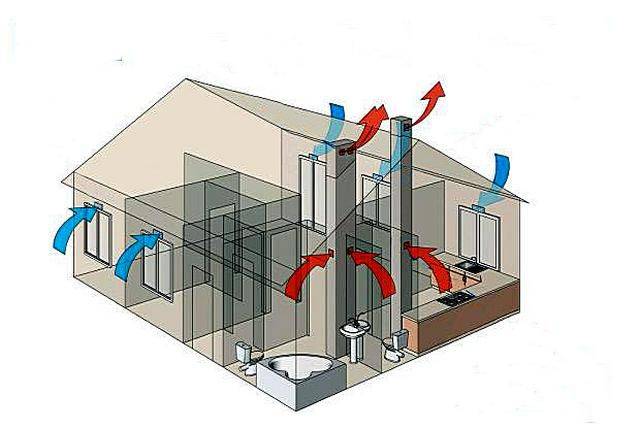

Forced

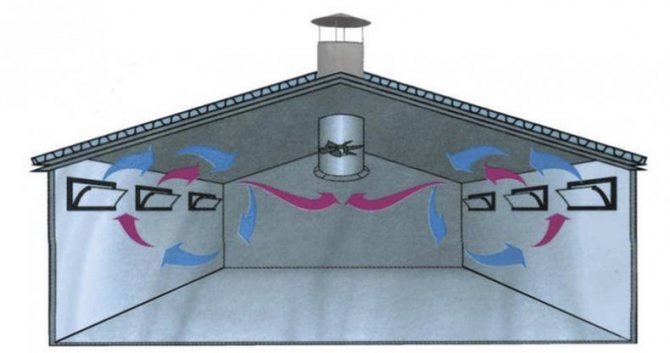

In this case, both supply and exhaust will be carried out using fans. Air exchange in this case is more stable, it can be adjusted. Suitable for larger homes where natural ventilation is more difficult.

Otherwise, all the rules are the same as with the natural ventilation scheme - inflow points should be in each room, and installed opposite the door. Exhaust - is displayed through a pipe either on the roof or through the wall.

There is another option - an air duct system is mounted. 1 pipe with 1 fan enters the room, and branches out: a section is brought into each room through which air will flow.

How to properly draw

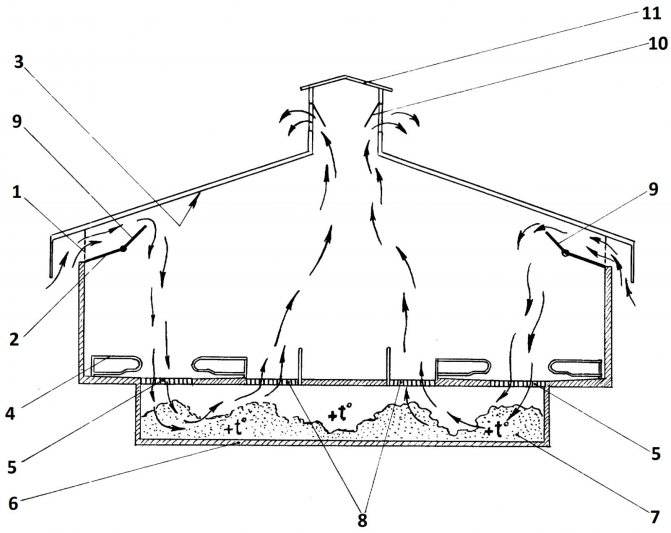

The microclimate in the room depends on the correct installation of the exhaust system. In a barn for a couple of cows, a simple hood will do. For a large number of animals, a more complex system will be required.

Hood option

There are two types of ventilation for sheds:

- Natural extract.

- Forced (mechanical) ventilation.

Hood

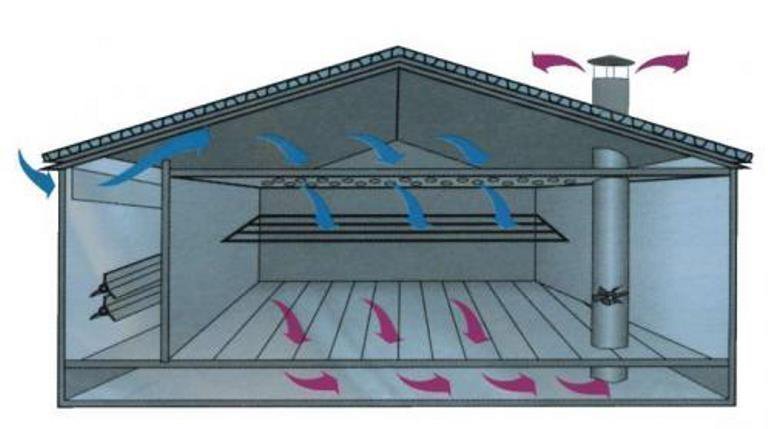

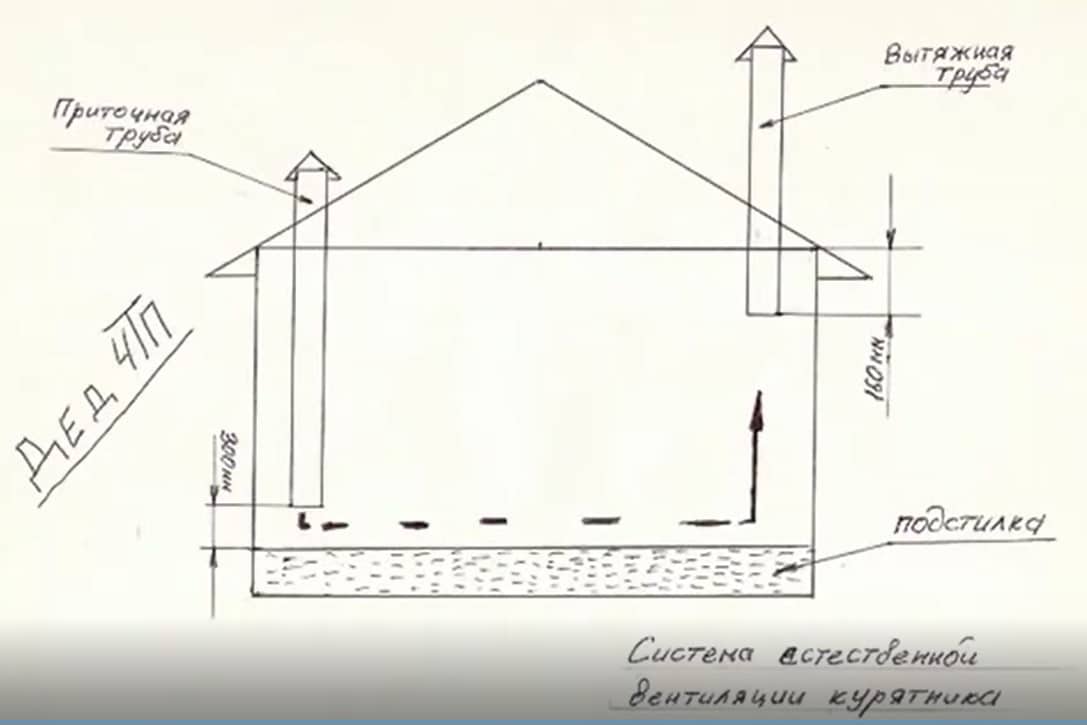

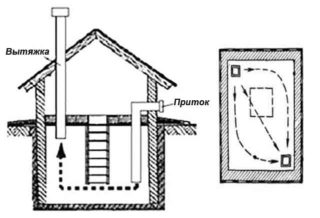

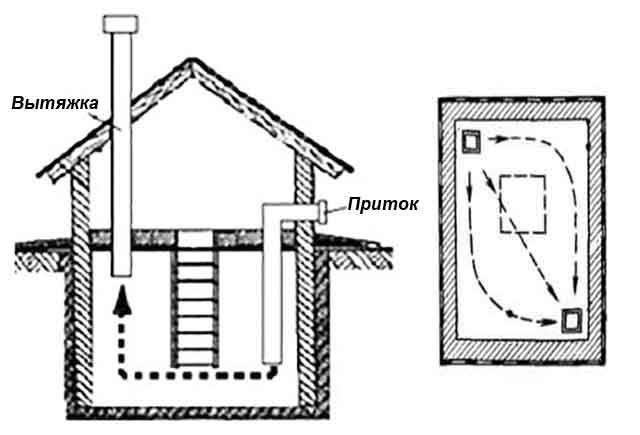

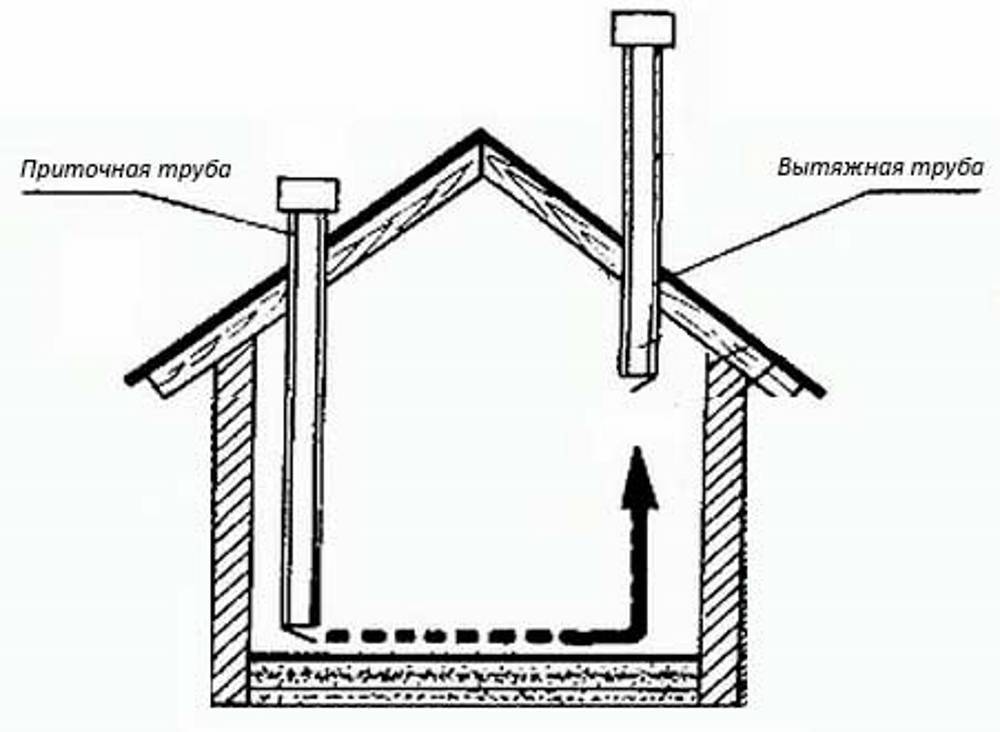

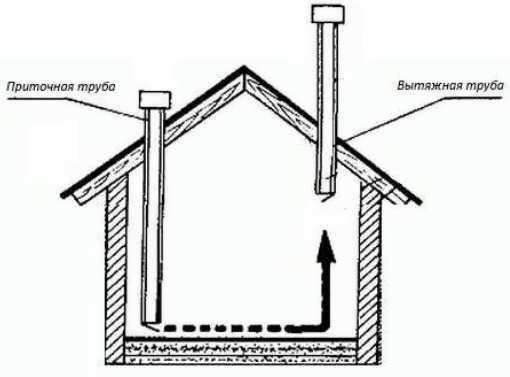

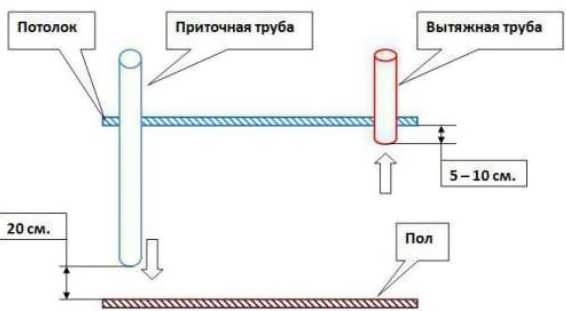

How to make natural ventilation

This type of hood does not cause any particular difficulties during installation. It is inexpensive, but also not very effective. The operation of such a system depends on weather conditions and the location of the barn. In warm weather, the efficiency of the system drops sharply. It is often necessary to ventilate the room.

Installation of such a hood includes 2 stages:

- For air flow, a gap is left under the door or in the window. Holes can be drilled at the bottom of the wall.

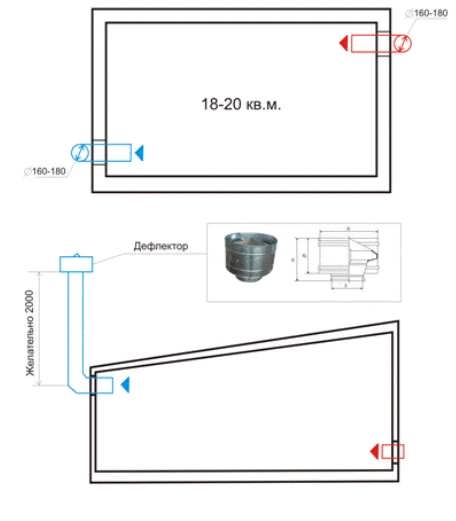

- Mount the hood through the roof up or lead the pipe out through the wall under the ceiling. The end point of the system must be above the ridge. A deflector is put on top to increase traction. When exiting the pipe through the side wall, a bend must be provided to give the hood a vertical direction. This method is more convenient and profitable.When installing the system through the roof, the hole for the pipe must also be sealed.

The described ventilation system does not always justify itself. There are a number of contraindications to its installation:

- barn without foundation or no waterproofing;

- the presence of moisture, which will increase during rain;

- condensation on the internal surfaces of walls and ceilings;

- low level of the barn;

- over 25 sq. m.;

- around tall houses, trees.

These shortcomings significantly reduce the work of natural ventilation.

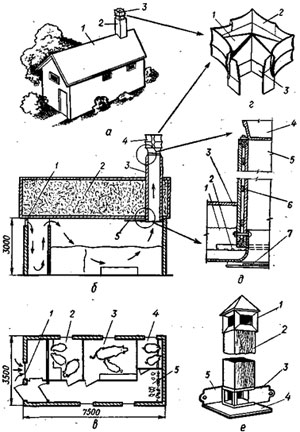

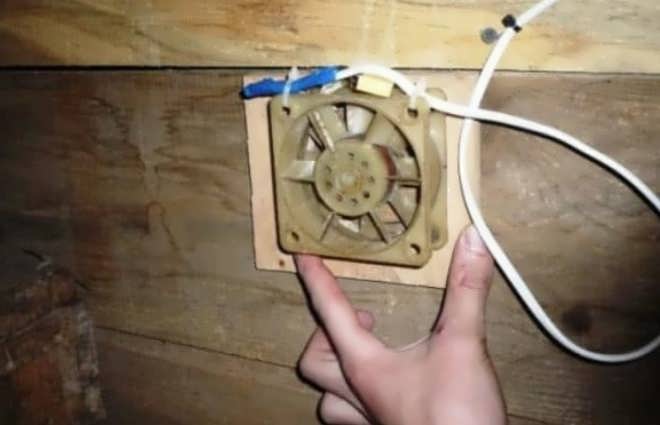

How to install forced ventilation

It is advisable to install mechanical hoods in sheds for pigs, shelters, sheep, when there are a lot of them. The room should also be impressive in size.

Forced exhaust by nature and place of installation repeats the installation of a natural system. Slots or openings in the wall, doors or windows are also used for air flow. To drill them, you need a puncher or drill. The choice of tool depends on the material from which the walls are made. To restrict access to rodents, metal bars are mounted on the holes.

Barn ventilation schemes

The hood can be brought out through the roof or through the wall under the ceiling. The first option is more reliable, but is associated with additional difficulties. We have to break through the ceiling and roof. Upon completion of installation, the hole for the pipe must be hermetically sealed. This will save the wiring from possible short circuits as a result of water entering the conductive elements. Water should also not seep into the barn.

The option of installing an exhaust pipe through a wall under the ceiling is much more convenient. There is no need to seal the hole. It can be bricked up with any mortar or mounting foam.I don’t like the pipe sticking out from the side of the wall in this installation option.

The mechanical system differs from the natural analogue only by the presence of a fan in the pipe. This device is not that expensive. Low-power fans cost from 1000 rubles and are quite suitable for barn ventilation. Their energy consumption is also low.

Pro Tips

Any inexperienced master can make typical errors when installing ventilation. If the design works in such a way that it is absolutely impossible to get rid of stagnant air or the room cools quickly, then somewhere an oversight has crept in when drawing up the scheme. When planning and subsequent installation of the system, it is necessary to correctly position the flows of air masses and calculate the stability of the assembled structure.

Checking the efficiency of the ventilation system is not difficult, for this you need to go inside and spend some time there. If during the past period there is no lack of oxygen and a headache does not begin, then the ventilation is working properly. Otherwise, you will have to change something in the design. Thus, it becomes clear that the ventilation of the chicken coop is designed to provide an influx of clean air and regulate the level of humidity and temperature.

To reduce energy costs, which will still appear, the design is equipped with sensors that automatically control the temperature of the air and humidity. In this case, the ventilation system starts up only when the climate parameters in the chicken coop change. This option is also ideal for chicken coops that have fermentation bedding as flooring, as bacteria generate a lot of heat during the processing of manure and food debris.Excessively high room temperatures can adversely affect both the health of chickens and the vital activity of microorganisms living in the coating.

Typical miscalculations during installation.

- Ventilation openings are located on adjacent walls. In this case, stagnation of the air mass is formed in the side opposite the walls, since it cannot circulate at a right angle. If the chicken coop room has the shape of a rectangle, then it will be correct to place windows or openings on walls of shorter length opposite each other.

- Loud noise when fans are running. Before installation, the devices should be checked for noise. Chickens are very sensitive to loud noises and when frightened, they can reduce their egg production or stop laying altogether.

- Weak building structure. Very often, the flimsy ceilings of the erected chicken coops break from the weight of heavy iron air ducts. This is typical for wooden buildings that have, at first glance, a strong ceiling, but can completely rot in a few years. Therefore, it is desirable to fix metal pipes at the rafters.

- Metal pipes must be insulated in the cold season with mineral insulating materials. Having excellent thermal conductivity, the metal can turn the chicken coop into a cold store in the shortest possible time even with the valves closed. At the same time, the constantly formed condensate is able to freeze, blocking the access to air.

In order for the ventilation system to properly perform its functions, that is, to provide the chicken coop with fresh air, without creating drafts and stagnation, it is necessary to adhere to the following conditions.

- Periodically, it is recommended to clean the chicken coop from droppings, leftover feed and dirty water. Cleanliness in the room where the bird is kept should be a priority.

- Regular checks are required for the presence of small rodent animals and their destruction. The presence of foreign inhabitants can cause anxiety for chickens and excessive air pollution. In some cases, we can talk about the spread of various diseases.

Any chicken coop owner individually decides on the installation of ventilation and ventilation systems. Many do not even think of equipping a chicken coop until they meet with frequent diseases of the livestock or its mass death. Only when faced with an unpleasant situation, poultry farmers begin to choose between natural or forced-air ventilation, further building it without much effort.

How to make ventilation in do-it-yourself chicken coopsee the next video.

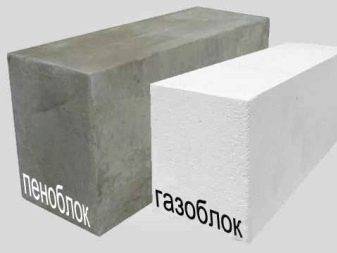

Features of the construction and equipment of the pigsty

The walls of the pigsty are recommended to be made of light but warm materials. Suitable foam concrete, aerated concrete or expanded clay concrete. Such buildings need to be plastered both inside and outside so that they do not accumulate moisture. And also for construction work, wood concrete is suitable, which is still not used so often.

The piglet barn should be cool in summer and warm in winter.

It is important to ensure good ventilation. The room should not have low ceilings

The optimal indicator is 2.3-2.5 m. It is best to plaster the walls inside the pigsty, and then paint or whitewash. Sometimes wall bases are sheathed with boards.

The roof of the pigsty is best made single-pitched.If the width of the building is large, then a gable structure is also suitable. Regardless of which roof was chosen for such a barn, the attic is equipped here in rare cases. The roof is recommended to be insulated with mineral wool. A vapor barrier membrane is nailed inside the room, and a vapor barrier film is laid on the side of the roof. As a roofing material, cheap slate is most often chosen.

The floor in the pig shed can be made in the form of a wooden deck. Edged board 50 mm thick is used. It is nailed either very tightly, or with a small gap.

It is allowed to leave earthen floors in the pigsty. There are not many advantages to this solution. Only low cost attracts. Cleaning a barn with dirt floors is difficult, as well as maintaining cleanliness in general. There will be an unpleasant odor. Pigs are big fans of digging the ground, so the barn will soon turn into a territory dug up by them.

To divert the waste products of pigs, so-called slatted floors are made. This is a modern, convenient solution. With this design, the first layer of the floor is made of concrete, and the 2nd layer is made of slotted parts. This floor is also made at a slight slope.

There should be windows in the pigsty - natural light is important for pigs. It is advisable to install large window structures. They are mounted at a height of 1.5-1.7 m. A ventilation system must be installed. For pigs, machines made of metal pipes or edged boards are equipped.

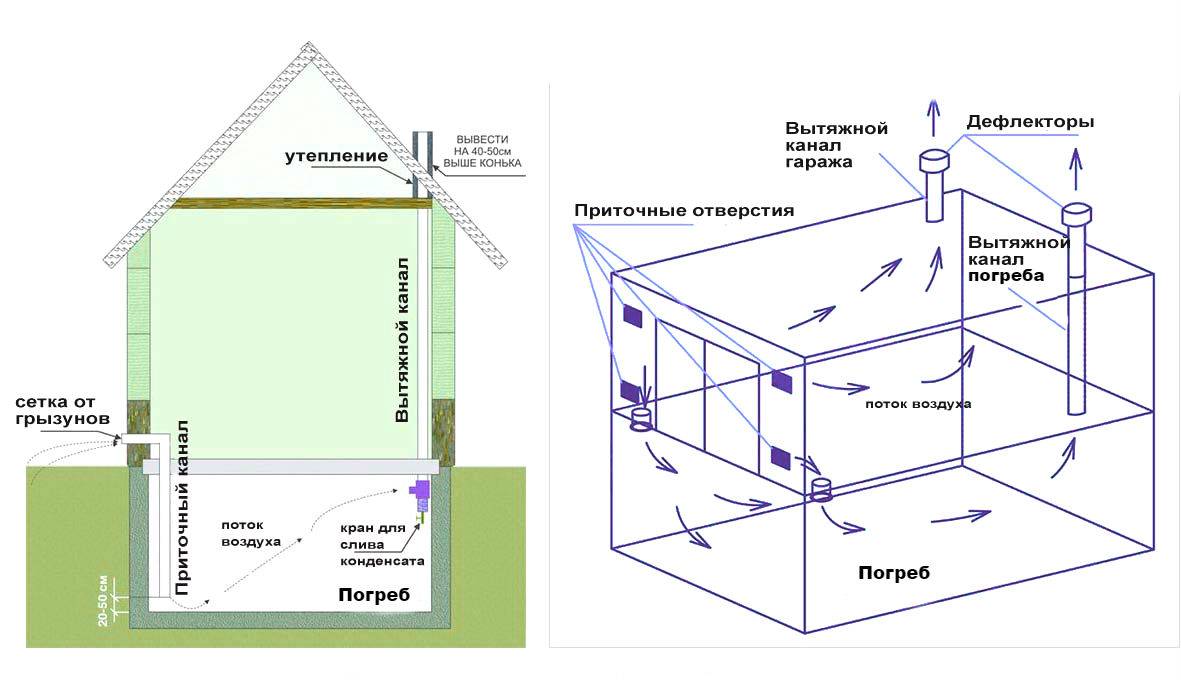

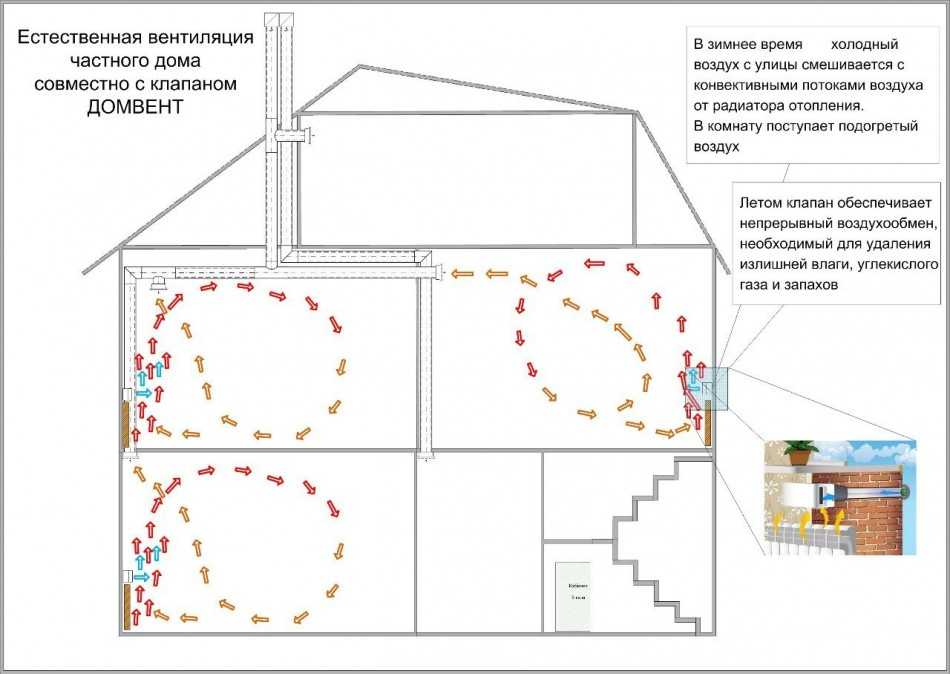

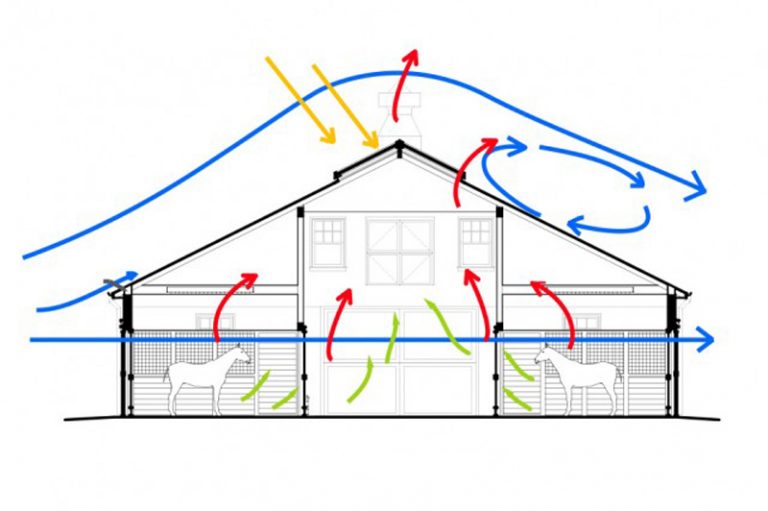

Sheep barn

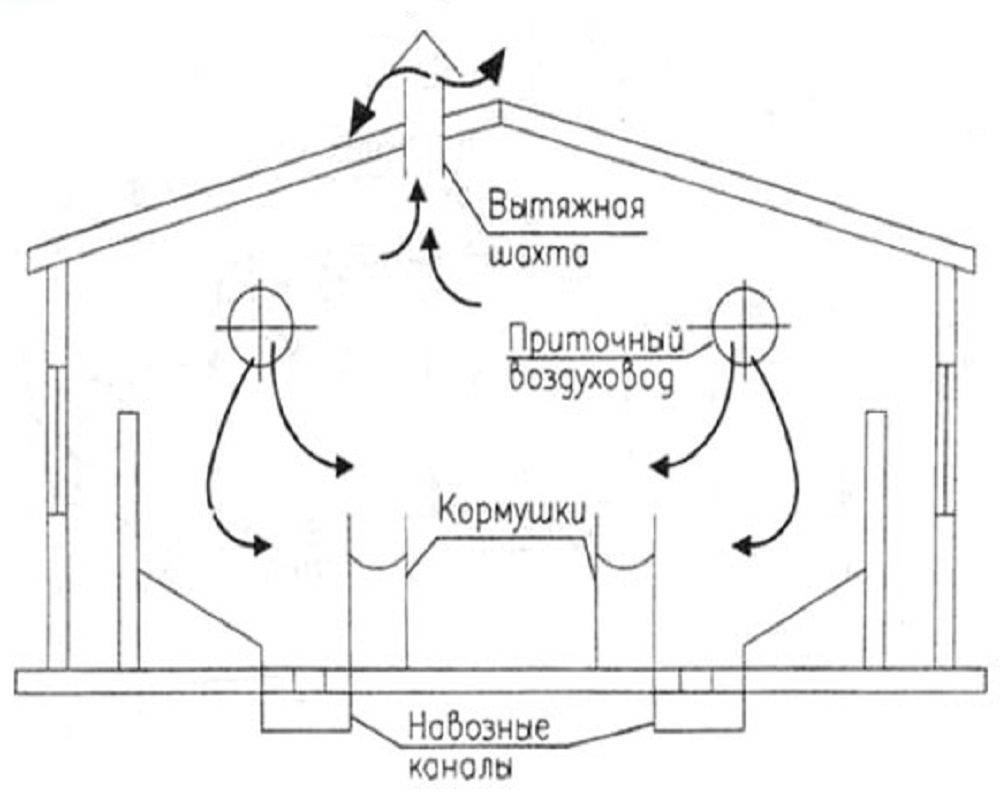

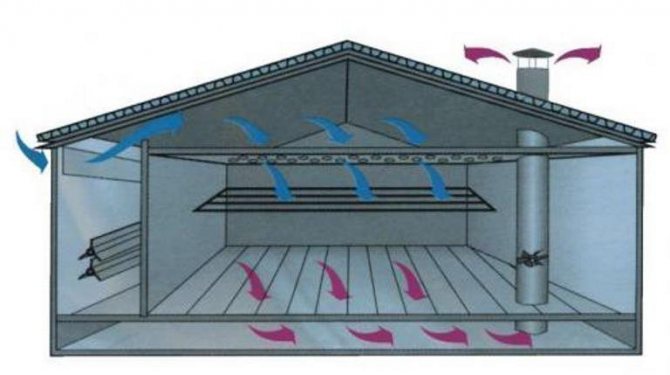

Supply and exhaust ventilation in the sheepfold

Supply and exhaust ventilation in the sheepfold

Growing sheep on a personal farmstead in a adapted barn is possible if there are no drafts in it. A vestibule, sealing holes and crevices will help to avoid them.Another scourge for animals is dampness, leading to the occurrence of helminthic diseases. The stuffy atmosphere will be diluted with an influx of fresh air with a volume of at least 8 cubic meters every hour. It can be provided by supply and exhaust or natural ventilation with a round (square) section hood on the roof ridge. At the lower end, a damper is installed that regulates the outflow of air. At the upper end of the pipe, a deflector is mounted, which rises 0.5-0.7 above the roof.

The decision to keep poultry and animals in the barn requires the organization of normal conditions for them. Ventilation performed according to the rules will prevent the loss of livestock, increase the number of livestock, and optimize feed costs.

How to calculate the size of a pigsty?

In order to properly design the future structure, it is necessary to determine its size. How to calculate the area and height of the barn, consider separately.

Square

It is believed that about 3-5 square meters should come per animal. m. So, if you want to build a pigsty for 10 heads, then its area should be at least 30-40 square meters. m. However, for a more accurate calculation of the area of \u200b\u200bthe premises, it is desirable to take into account the age of the animals, as well as the method of their maintenance - breeding or fattening. Standard rates are given in the table:

| livestock | Number of animals in the pen | Machine area | |

| with breeding | when kept for fattening | ||

| Boars | 1 | 8 sq. m | 8 sq. m |

| Sows: | |||

| single and pregnant up to 2 months | 4 | 3 sq. m | 3 sq. m |

| pregnant at 3 months | 2 | 6 sq. m | 3.5 sq. m |

| suckling with piglets | 1 | 10 sq. m | 7.5 sq. m |

| Pigs: | |||

| young animals up to 5 months | 10-12 | 0.6 sq. m | 0.5 sq. m |

| breeding boars aged 5-8 months | 2-3 | 1.15 sq. m | — |

| fattening piglets at the age of 5-6 months | 20 | — | 0.7 sq. m |

| fattening piglets aged 6-10 months | 15 | — | 1.0 sq. m |

For example, we calculate the optimal dimensions of a pigsty for 100 heads. Suppose there are 5 sows, 90 piglets, 1 stud boar and 3 breeding pigs in the herd. Piglets are expected from 2 farrowings per year, so they need to be kept in pens of different sizes. Based on these data, the calculation is made in the following order:

- Calculate the area for each category of animals:

- for sows with piglets - 5x10 sq. m = 50 sq. m;

- for a boar - 1x8 sq. m = 8 sq. m;

- for older and younger piglets - 45x1 sq. m + 45x0.5 sq. m = 67.5 sq. m;

- for young pigs - 3x1.15 square meters. m = 3.45 sq. m.

- Add up all the values obtained - 50 + 8 + 67.5 + 3.45 \u003d 128.95 square meters. m.

- Calculate the length and width of the area used for the machines. Let's say machines with a depth of 3 m will be located in 2 rows, and passages will be organized along the walls - 2 longitudinal and 1 transverse. To calculate the length of the pigsty, you need to divide the calculated area by twice the depth of the machine and add the width of the passages: 130 / (3x2) + 1.5 = 23 m. As for the width, the calculations are as follows: 3x2 + 2 + 2 = 10 m.

Thus, the optimal area of a pigsty for 100 heads is 130 square meters. m, length and width - 25 m and 10 m, respectively.

Here are examples of pigsty drawings:

Height

When determining the height of the room, the following nuances must be taken into account:

- if the building is planned to be completed without a ceiling with open beams, the maximum wall height is 2.6 m;

- if, for the purpose of insulation, thermal insulation is laid under the roof, the optimal height of the room near the walls to the beams is 1.8 m;

- if the ceilings are flat, they must be mounted at a height of at least 2.2 m.

In any case, the height of the outer walls of the pigsty cannot be less than 1.6-1.8 m, otherwise the air in the room will be poorly ventilated. The highest point of overlap should be at the level of 2.2-2.6 m. It is better to make the roof itself 1- or 2-pitched.

How to correctly calculate the dimensions of a pigsty in order to make it from boards, find out from the video below:

Calculation features and type definition

A rabbit, cattle or bee shed must meet certain criteria. The choice of a specific type of ventilation system is based on the following parameters:

- the volume of supply air coming from outside (depends on the ambient temperature);

- existing air circulation inside the room;

- barn location;

- planned type and number of animals;

- ceiling height and total building area;

- the shape of the premises and the presence of closed areas;

- degree of thermal insulation of the building.

Ventilation in the barn, based on such parameters, can not only fully cover the need for fresh air, but also create the best conditions for keeping animals. In addition, when choosing a specific type of ventilation, it is also necessary to take into account the wind load and the climatic conditions of a particular area.

The main requirement that is put forward for such systems is to provide the necessary volume of fresh air, which is calculated based on the total weight of the livestock, and is 1 m3/hour per 100 kg.

At a room temperature below + 21-22 degrees, the normal indicators of air velocity are 0.1 m / s in winter and 0.2 m / s in summer.With an increase in air temperature, the permissible speed indicators also increase proportionally, which are 0.2 m / s in winter and 0.5-0.7 m / s in summer.

Automation of ventilation systems in the barn

It is desirable to improve the ventilation system if animals are constantly in the room or valuable property is stored.

There are several options for how to properly ventilate a barn:

- using a humidity sensor;

- using a temperature sensor.

If you set the start of the exhaust fan with humidity sensor, then in this case the device will turn off at a normal psychrometer reading. And increase the speed if the fan runs at minimum speed at an acceptable value of air humidity.

For small sheds, a fan with a temperature or humidity sensor is optional. Or, at the very least, it should be done when absolutely necessary.

You can start or stop the fan, as well as change its speed using a temperature sensor. Especially if the building will be used to keep animals. In the summer, the fan will turn on or increase the speed during the heat.

In winter, on the contrary, when the temperature in the room drops, the fan will stop working altogether or slow down the speed.

There are several ways to maintain the temperature at the proper level:

- Ventilation units are combined with heaters - steam, water and electric.

- The heating and ventilation device is installed in a special chamber or under the guise of a monoblock directly in the room.

- You can also save heat energy with the help of heat recovery units built into the ventilation system.

- By installing supply and exhaust ventilation with heat recovery and recirculation.

After installation of ventilation, it is important to test it before the start of operation. Violation of the installation of mechanical fans can increase their noise up to 100-120 dB

The intensity of a properly adjusted system should average 57-80 dB

Violation of the installation of mechanical fans can increase their noise up to 100-120 dB. The intensity of a properly adjusted system should average 57-80 dB

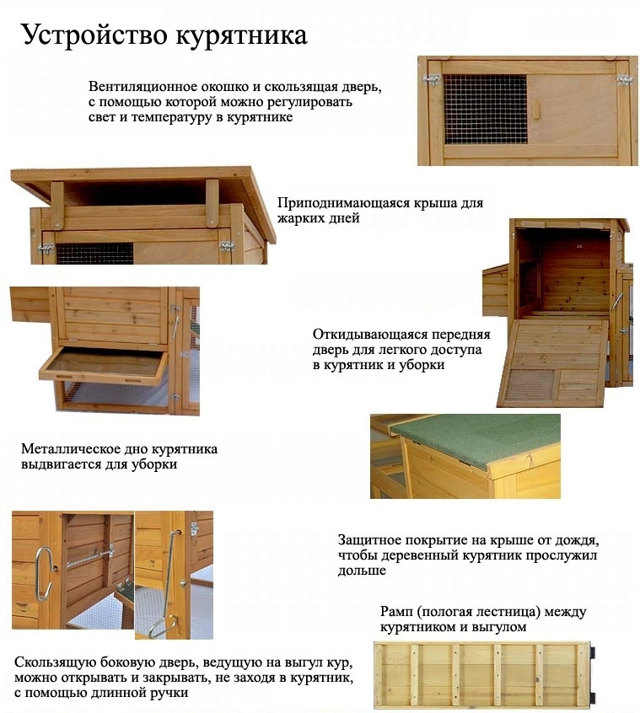

How to build a rabbitry

A dwelling for eared pets can be created according to the type of frame-board construction. Such a barn is not large, but inside it should be divided into zones or separate cages for furry animals should be installed. Rabbits are best kept one at a time to control the breeding process. For females with cubs and unbred young animals, a more spacious corner with insulation and artificial light is allocated.

Video - Rabbit device

In general, the construction of a wooden rabbitry resembles the process of building a poultry house, described above. But in this case, the room should be bigger and taller. It is more convenient to arrange the cells inside in two rows to save space. Therefore, for 10 animals, a barn with dimensions of 3x5 m and a height of 2-2.5 m is needed. buildings need a stable foundation on reinforcing cage filled with concrete. A structure made of timber, sheathed with an edged board, is installed on it.

Tips for a rabbit shed

Shred cages are mounted inside the rabbitry: adjacent cells with a front mesh wall. Most often they are installed in several tiers - in two or three. Feeders and drinkers are hung on the front.

Rabbit barn