- Useful tips for pioneers

- Do-it-yourself manual pipe bender how to make the simplest option

- How to make a snail pipe bender

- Necessary materials and tools

- The assembly process of the snail pipe bender

- What are the devices for transforming pipes

- Simple pipe bender

- For round pipe

- From the vise

- Homemade roller

- From the jack

- Crossbow type

- Classification of pipe bending devices

- What to bend?

- Making a winding pipe bender

- Do-it-yourself template pipe bender

- The design of pipe bending machines classification

- What is the unit for?

- Conclusions and useful video on the topic

Useful tips for pioneers

The main recommendation given by experts is that work cannot be forced. Quality is above all, and in no case should it be sacrificed in the name of saving time. There are a number of other features that must be considered when processing profile pipes. No need to try to do everything in one "pass" of the profile. It is better to skip it several times, pressing the bending roller slowly after each cycle. This will not only eliminate the danger of tube deformation, but also increase the service life of the machine.

In the cross section, the profile of the roller must match the shape of the rolled metal. With a complete match, the bend will be perfect.Therefore, it makes sense to make a design with interchangeable rollers and stock up on a set of various sizes. Make a full size template in advance. Apply the product after each deflection. This will be quality control, and will allow you to complete the procedure on time. And the presence of marks will allow you to adapt, and abandon the constant template control.

Do-it-yourself manual pipe bender how to make the simplest option

A simple pipe bending machine can be made from improvised means, using not only metal, but also wood. Finding an unnecessary board is much easier on the farm than a steel base of the required thickness. To begin with, a board is taken, the thickness of which should be thicker than the diameter of the material to be deformed. Further instructions for making a simple pipe bender from boards are as follows:

An arc-shaped template is cut out of the board. The shape should be such that the bending radius of the tooling should be obtained as a result

Fix the resulting template on the base in the form of a sheet of 2-3 sheets of fiberboard or chipboard

It is very important that the template is firmly fixed to the base, as it may come off during the bending process. Additionally, for fixing, you can use a clamp or a small vise

From one edge, an emphasis should be fixed, through which the material to be bent will abut

As such an emphasis, you can use a piece of board fixed to the base

It is not difficult to use such a device, and for this you should put the material between the template and the stop and, making sure that the pipe does not come off, proceed to work.The principle of manufacturing the simplest pipe bender does not require any financial investment, and this method is great when you need to bend a small number of profiles. There are other options for making the simplest pipe benders with your own hands from improvised means, which are described below.

How to make a snail pipe bender

Self-manufacturing a snail pipe bender may seem difficult. In fact, this device is no more difficult to assemble than a roller pipe bender. The process differs only in the parts used and assembly time.

The snail pipe bender allows you to bend the profile along the entire length at once, and not just in one place. For this property, he gained popularity among installers.

Necessary materials and tools

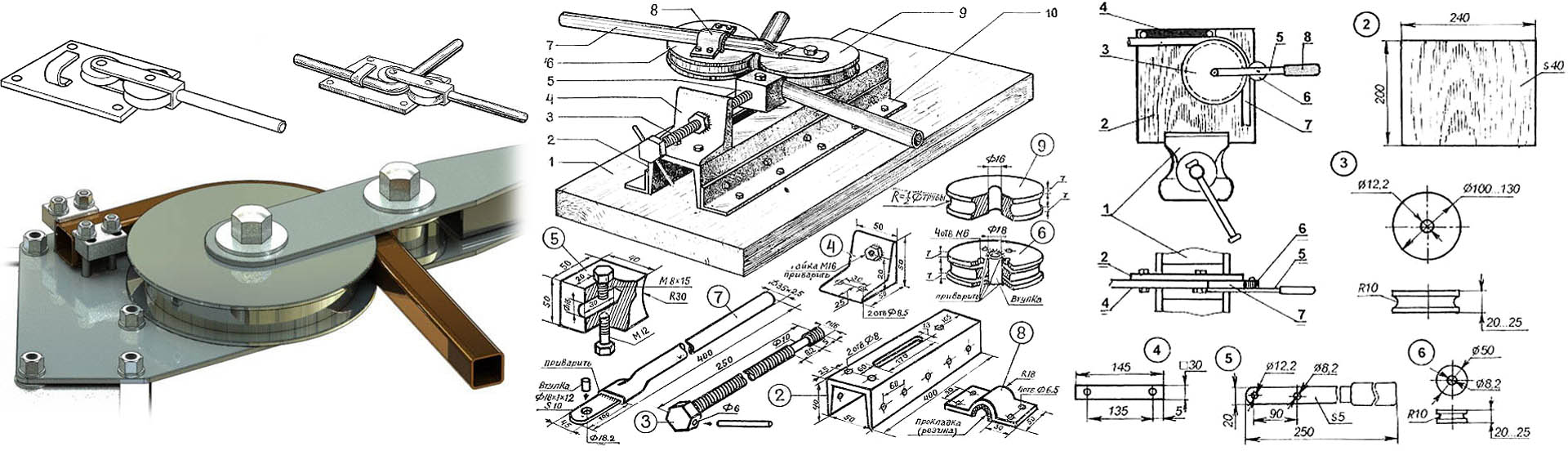

Since the described roller pipe bender does not have a specific working diameter and can be made from any available materials, the proposed materials will not contain specific sizes of parts. The thickness of all metal structural elements should be 4, and preferably 5 mm. To make a pipe bender you will need:

- Channel - 1 meter.

- Sheet iron.

- Three shafts.

- Two stars.

- Metal chain.

- Six bearings.

- Metal 0.5-inch pipe for the manufacture of gates - 2 meters.

- Sleeve with internal thread.

- Clamp screw.

Particular attention is paid to the dimensions of sprockets, shafts and bearings, which must match each other. Asterisks can be taken from old bicycles, but they must be exactly the same size

Steel plates and profiles for the manufacture of a pipe bender should not be with deep rust, because they will have high loads during operation

Before choosing and purchasing all materials, you need to draw a drawing with a schematic representation of all structural elements so as not to buy them in the process of manufacturing a pipe bender.

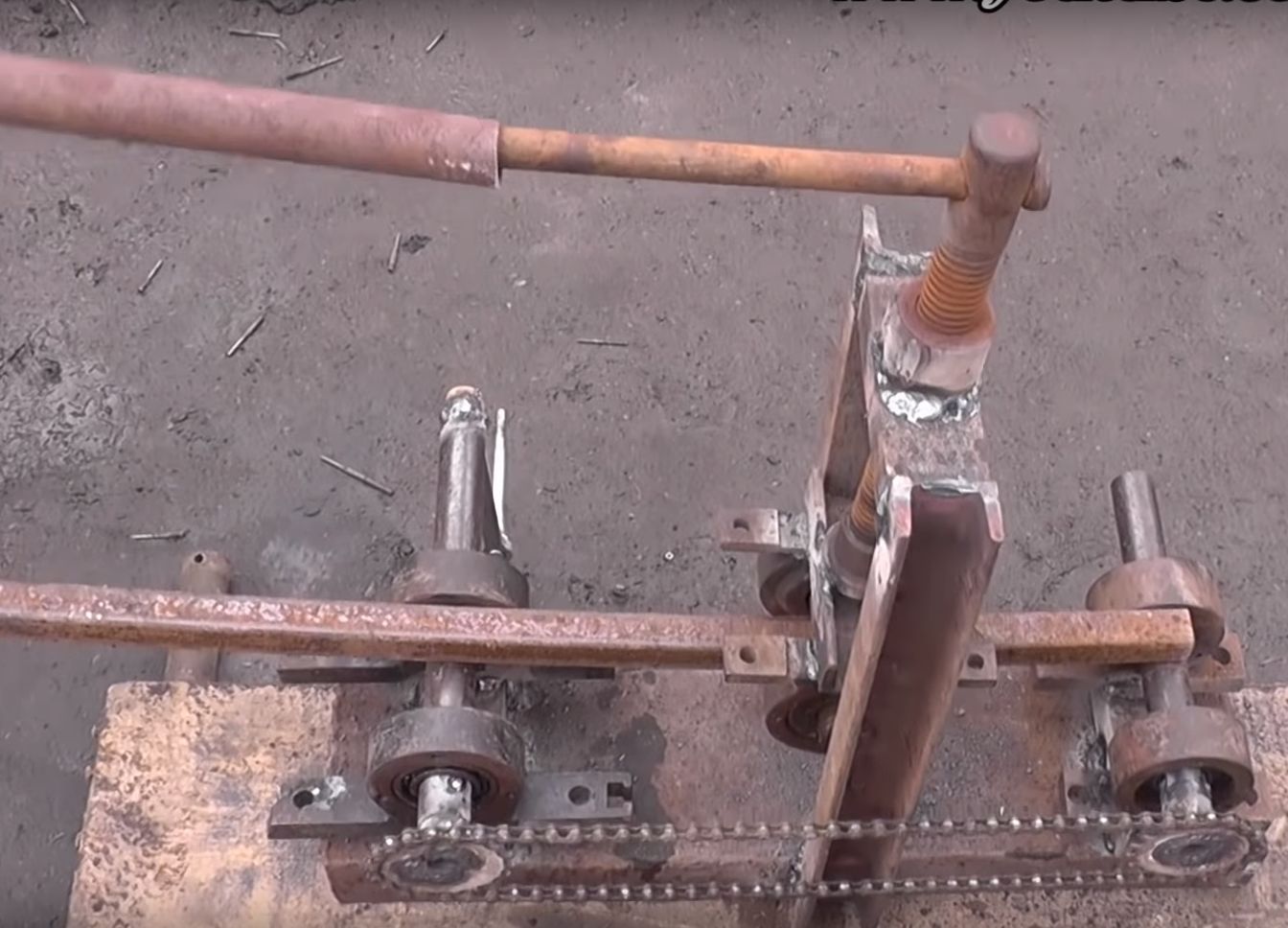

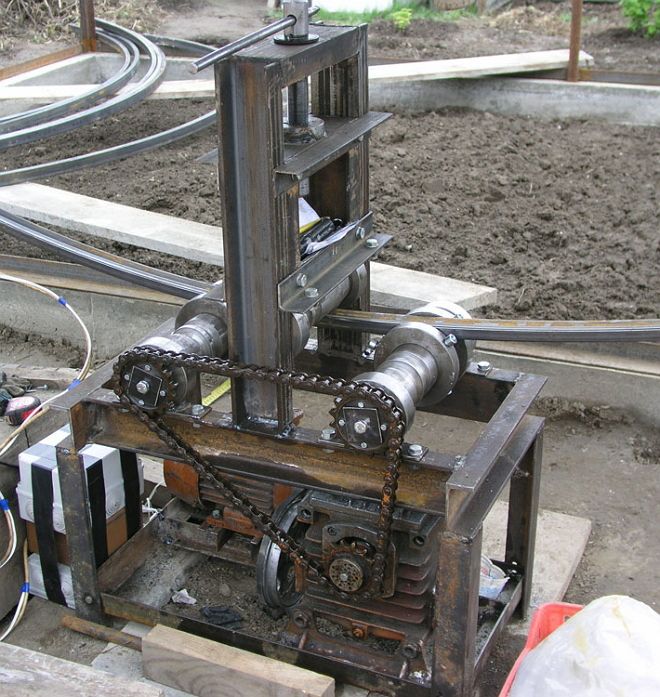

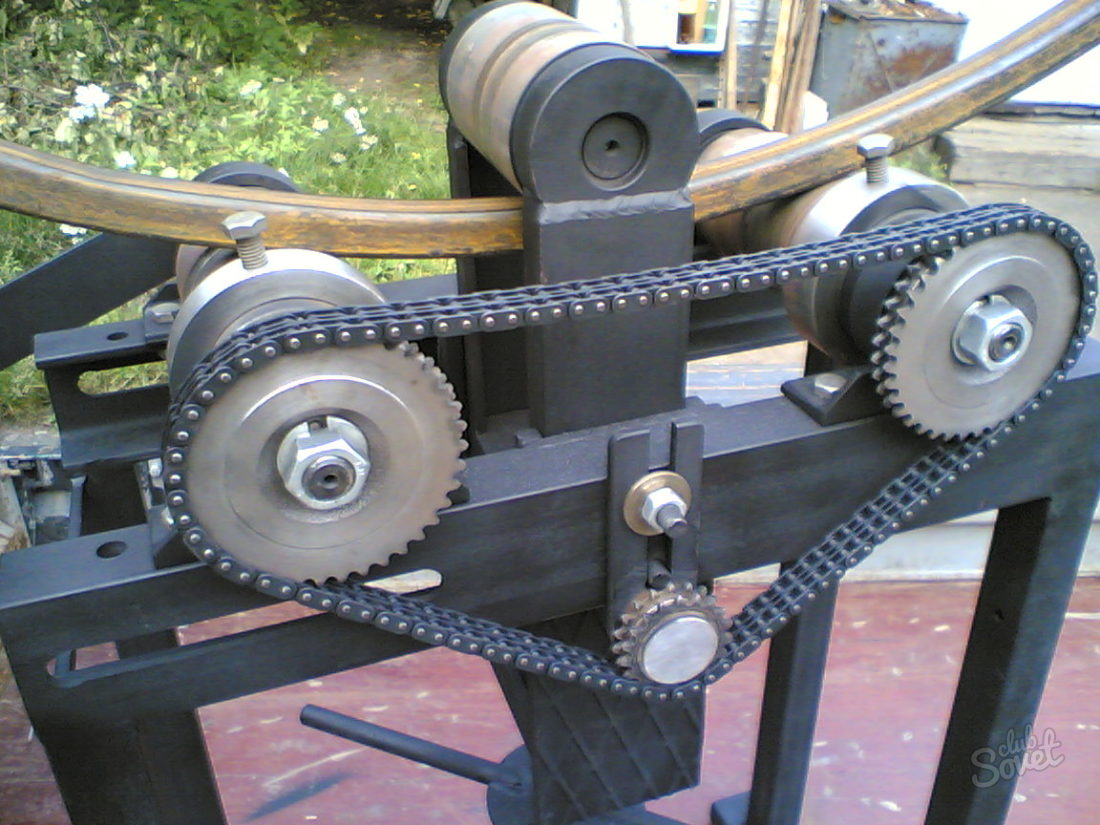

The assembly process of the snail pipe bender

The assembly of any equipment begins with the drawing up of a drawing diagram. After that, you can proceed to the main workflows, which are shown in the photo instructions.

- Weld the base of the tool from two parallel channels. If desired, you can use just a metal plate 5 mm thick or one wide channel.

- Put bearings on the shafts and weld two such structures to the base. It is desirable to limit the shafts with metal strips or place them in the inner cavity of the channels.

- Put on the sprockets and weld them, after stretching the chain between them.

- Cut and weld to the base the side guides of the clamping mechanism.

- Put the bearings on the pressure shaft and assemble the press structure with side stops from strips or channels.

- Make a base for the bushing and weld it to the plate. Screw in the clamping screw.

- Weld to the upper edge of the clamping screw and to the driving shaft of the pipe gate.

- Lubricate the bearings with engine oil.

Some helpful tips.

Image gallery

Photo from

Instead of using channels, a pipe bender can be welded to an existing metal frame

There is a strong shear pressure on the shaft, so the outer weld must be strong

In the event of a chain break, it can be made slightly loose and put on already welded sprockets

The guide bars must be strictly parallel, otherwise the press will constantly jam

Pieces of the remaining channel can be used as guides for the pressure roller.

The sleeve and the screw must have a wide and deep thread so that it does not stick together after several pressings.

It is better not to save on the length of the lever handle: the longer it is, the more torque can be developed

The base of the pipe bender must be firmly screwed to the support, otherwise the tool will wobble and tip over.

Welding two channels together

Welding the shaft to the base of the pipe bender

Putting the chain on the sprockets

Welding the vertical guide bar

Assembling the pressure shaft from the channel

Welding the threaded bushing to the plate

Gates on screw and drive shaft

Spiral pipe bender at work

After assembling the pipe bender and testing it, you can paint the structure with anti-corrosion paint to better preserve the welds. To increase the convenience of work, a spring is additionally attached to the guides to return the press to the upper position.

What are the devices for transforming pipes

The transformation of the curvature of a thin-walled pipe of small diameter is a quite accessible stage in the production of metal blanks for frame-type structures.

It is enough to consider the drawings and photos of pipe benders, as it becomes obvious that structurally they have much in common:

- base (support, emphasis);

- frame or frame (open or closed type);

- straps, pipe stops or holders;

- screws or vise for fasteners;

- pressure, mechanical or working device (alternative power part).

The forming of aluminum, standard steel and metal-plastic pipes can be done on the simplest manual template-type device.

Most pipe benders resemble a compact machine, but they have their own classification:

- by type of impact on pipes (running, winding, broaching, rolling);

- possible to move (stationary and portable).

The type of drive is also different:

- electric;

- manual;

- hydraulic;

- electrohydraulic.

If you use an electric drive or a hydraulic jack, it will take on all the power load, saving time and effort. But for its construction, at least elementary knowledge and experience in the construction of household machines for metal processing are needed. But such devices are many times cheaper than ready-made devices and their multiple rentals.

The most popular and simple in their design are considered to be template-type manual pipe benders. By bending around a profile or ordinary pipe along a part of its circumference, the pipe segment is transformed at a given angle or the required curvature.

Simple pipe bender

In a home workshop, several types of pipe benders can be made. Much here depends on the needs of the user of the device. In a situation where a person needs to constantly bend a small diameter copper tube at a right angle, making a stationary pipe bender with a breaking frame based on a jack seems to be a waste of time and effort.

Below are the simplest and easiest to manufacture types of pipe benders for various needs.

For round pipe

The simplest pipe bender with a minimum of parts is a manual device consisting of a base, two pulleys, an emphasis and a lever.

It is designed for bending round pipes at right angles or less.

The base can be a simple metal plate. A pulley is fixed in its center. A U-shaped bracket is fixed on the axis of the first pulley. The end of the bracket continues with a lever, and in the middle a second pulley is fixed to the eyes, which rotates freely. Below the first pulley is a stop that prevents the pipe from turning.

The mechanism of such a pipe bender is extremely simple. The round tube is inserted between the stop and the first pulley. The bracket touches the stop with one of the edges, and the pipe is sandwiched between two pulleys. Turning the bracket with a lever, the master puts pressure on the end of the pipe and gradually the second pulley describes a circle around the first, motionless one. The pipe clamped between them is bent along the radius of the fixed pulley.

From the vise

The task of assembly is facilitated by the fact that the vise bender does not require a frame connecting the upper pressure and lower thrust rollers. For him, two channels of sufficient depth are enough so that holes can be drilled in the walls for the roller shafts.

Thrust rollers are mounted on a wide base at a distance of at least 400-600 mm from each other. On a narrow base, one roller is assembled, rotated by a lever of sufficient length. Then the structure is inserted into a vise, a pipe is placed between the rollers and tightened. By rotating the handle of the lever, the pipe or profile is pulled through the roller rollers.

This model is convenient in that it is as portable as possible and can be removed from the toolbox only when necessary.

Homemade roller

The roller pipe bender can have a different configuration.It can be either a simple manual mechanism, consisting of two levers, a pulley and a pressure roller, or a fairly complex rolling device with an electric or even gasoline drive.

A key feature of this pipe bender is the rollers, which either compress the pipe by rolling over it, or squeeze it from different sides. Depending on the cross section of the rollers, the device will be sharpened for a round or shaped pipe.

In the first case, the inner surface of the roller between the two ridges will be concave, in the second case it will be even.

Blueprints:

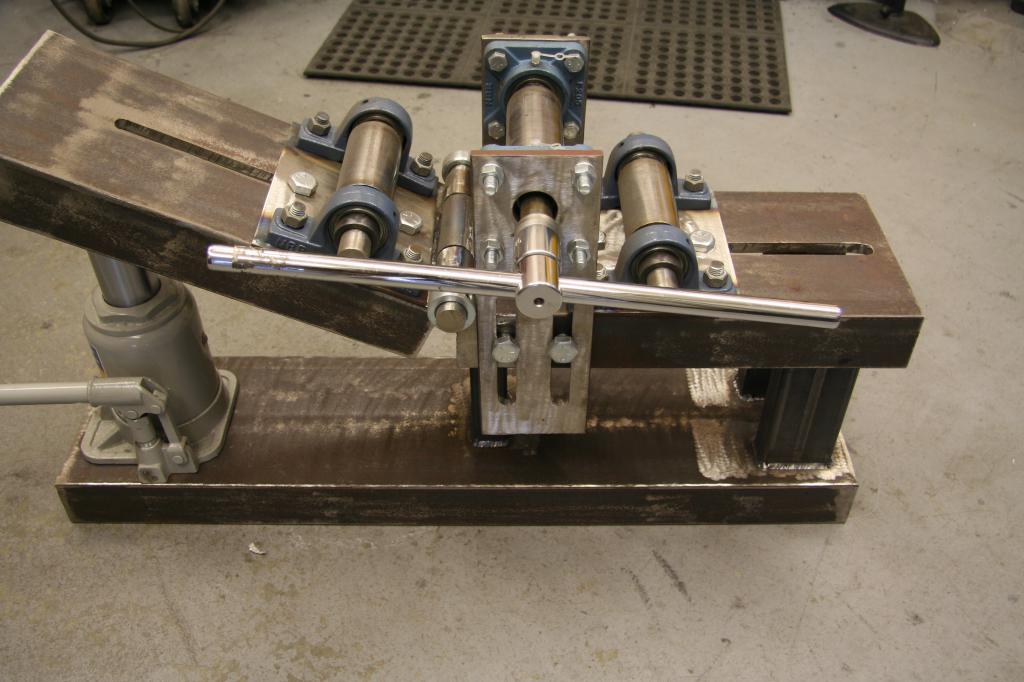

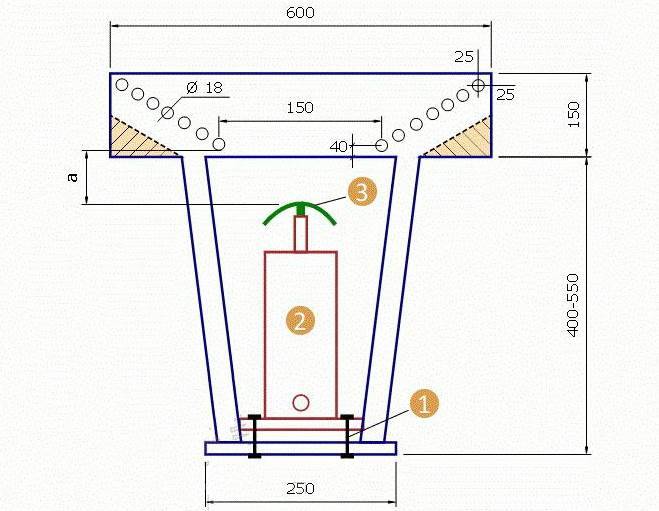

From the jack

It is convenient to use a hydraulic jack to press the pipe. Its use is justified with round and shaped steel pipes, large diameters or thick walls. Considering that a hydraulic jack can lift more than three tons, it turns out that the diameter and thickness of the pipe that you can bend is rather limited by the design of the system itself and whether you can scroll the lever while pulling the workpiece.

Drawing and dimensions:

With a sufficient length of the roller handle lever, this type of pipe bender requires the least physical strength when working with serious materials.

Crossbow type

It is used when the product bends to a short length.

The pipe bender got its name for a metal triangular frame located parallel to the ground.

At the tops of this frame there are two supports oriented to a round or shaped pipe (this depends on the shape of the notch on the stops). At the third vertex there is a rod with a punch, that is, an arc curved outward. To press the punch against the pipe, which is deformed between two stops, a hydraulic cylinder is usually used. In everyday life, it is easiest to replace it with a hydraulic jack.

Drawing of a homemade crossbow-type pipe bender:

Thus, for the manufacture of a crossbow pipe bender equipped with a hydraulic jack, it is necessary to weld a triangular frame, at the tops of which stops and a clamping rod will be located.

Classification of pipe bending devices

Devices for bending steel pipes are classified:

- by degree of mobility (stationary and portable);

- by type of drive (manual, electric, hydraulic, electro-hydraulic);

- according to the method of action (running (roller), winding, action with a rod (crossbow), rolling).

The essence of the methods of impact of the pipe bender on the pipe is as follows.

Running in

With this method, one end of the pipe is clamped, and a fixed template is used to give it the required bend. Pinch rollers are used to roll the product around the template.

Break-in pipe bender drawings

winding

In such a device, the pipe is pressed against a movable template (roller), on which it is wound, stretching between a rotating roller and a special stop installed at the beginning of the bending point.

Scheme of a pipe bender operating on the principle of winding

Crossbow pipe benders

In such a pipe bender, the pipe rests on two fixed rollers, and the bending is performed by a template, which is fixed on a movable rod. The template presses on the middle of the fixed section of the pipe, thereby giving it the required bending angle.

Diagram of a crossbow pipe bender: 2 - jack, 3 - shoe (punch)

Rolling or rolling

The required bending radius is obtained using a three-roll device, the design of which is based on two support and one central roller.The central roller exerts pressure on the pipe, the position of which determines the radius of its bend. is more universal, in all other machines the bending radius depends on the template used.

Manual rolling tube bender with compact dimensions

The manufacture of a pipe bender operating on the principle of winding is not simple, therefore such a device is made mainly in an industrial way. The crossbow method has another significant drawback: the pressure from the stock with the template attached to it, which is called the shoe, is concentrated in its upper part. This method of impact on the pipe leads to its significant stretching along the outer radius of the bend, which may be accompanied by a decrease in wall thickness and even its rupture. It is especially not recommended to use the crossbow method for bending thin-walled products.

An example of a homemade pipe bender of a rolling (rolling) type

A machine operating on the principle of rolling (rolling) practically does not have all of the above disadvantages; this technology is used in the production of bends in the factory.

A do-it-yourself pipe bending machine can have a different design. Choose its type should be based on what radius you need. There is a list of recommendations, in accordance with which the choice of a specific model of a device for bending steel pipes is carried out. Important parameters to consider are the wall thickness of the pipe and its overall diameter. Before starting work with a pipe bender, it does not hurt to familiarize yourself with the data in the table that displays the maximum possible radii for bending steel pipes.

The dependence of the bending radius on the diameter and wall thickness of the pipe

To obtain a bend radius smaller than specified in such recommendations, it is necessary to use either hot rolling, which is used mainly in production conditions. A device with a mandrel is more difficult to create at home, so they are much less often made on their own, preferring rolling ones.

In order to independently perform hot rolling of the pipe, you can resort to using a do-it-yourself pipe bender, but on condition that it is completely made of metal and its frame is highly reliable. To perform such a technological operation, you will additionally need a blowtorch or a gas burner.

What to bend?

I mean, what kind of curves do you need? This is the second factor that determines the type of pipe bender required for a given job.

In the household sphere, most often there is a need for a trace. types of pipe bends (see also Fig.):

Types of pipe bends

- General purpose - various kinds of distribution pipelines, ventilation devices, inputs of wired communications, parts of industrial equipment, machines, mechanisms, etc. Bending most of all in size or for reassembly on small; less often - along the middle radii. In the details of water pipes and inlet devices, permissible defects are acceptable. Bends of parts of gas and steam pipelines, parts of technical devices are defect-free by default, unless otherwise specified in the specifications for the product.

- Building arcs are tubular curved parts of building structures that can carry an operational load for a long time without the danger of sudden destruction. Bending almost exclusively along the profile in size along large radii, occasionally - along medium ones.In private household plots, the most popular type of this kind of detail is arches from a professional pipe for greenhouses and other outbuildings. Of the permissible defects, toffee is acceptable for no more than 5% of the cross-sectional area of the pipe lumen.

- Architectural forms - the bending radius is sign-changing (sometimes in one direction, then in the other direction) from small to large. Due to the "failures" of the bending profile, the bearing capacity is much lower than that of building arches of comparable sizes. For the same reason, sudden destruction of a non-worn part is possible. Bending - according to the profile for disassembly; rarely - in size. Scope of application light non-residential structures for landscape design: gazebos, alcoves, flower corridors and tunnels, decorative trellises, fences, etc. In the constructions of residential and temporarily inhabited structures, they are used only in conjunction with additional load-bearing elements. Permissible defects are acceptable, most often even at 20-25% of the lumen area.

Making a winding pipe bender

The principle of operation of such a pipe bender is similar to the previous one, but instead of a swivel roller, the bending of the workpiece produces a moving stop that slides along horizontal guides.

The winding pipe bender contains:

- Profiled sector, the angle of which determines the maximum allowable bending angle.

- A short vertical axis that can rotate freely in a ball bearing assembly.

- Two adjacent rollers forming a movable stop.

- Single sided guides.

- Stop stroke limiter, which eliminates its spontaneous displacement during operation.

- A safety fork that covers the profiled sector, increasing the positioning accuracy of the workpiece.

Structurally, the device is more complex, however, it allows deformation in conditions of limited space, and changing the angle is not by changing the rollers, but by simply adjusting the initial position of the clamping device. Such a pipe bender is available with a hydraulic or electric drive option.

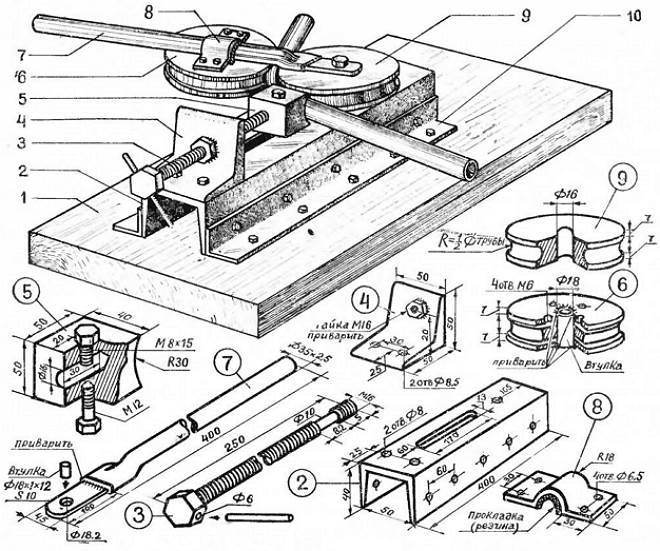

Do-it-yourself template pipe bender

Manual bending according to a template is the simplest technology for any (including spatial) pipe bending. Often it is used with a workpiece heated at the bend (for example, a gas flame burner or a blowtorch): the plasticity of the metal increases, and the deformation force decreases.

Description of template pipe bender:

- Anchor-shaped retainer where the pipe is inserted.

- Movable / replaceable stop, along the axis of which there is a recess corresponding to the arc of the outer diameter of the pipe.

- Plate with fixing holes.

On the opposite side of the stop, a bevel is made, the angle of which corresponds to the required (after bending!) value of the bending angle.

All parts can also be made from ordinary structural steel (for example, steel 45), however, the stop will last longer if it is made from tool steel of the U10A steel type.

Step by step installation is as follows. A latch is installed on the base plate, then an emphasis is attached coaxially to it. The distance between the parts must be taken into account the known range of ratios R / d

It is very important to maintain the recommended value of the radius of curvature when passing to the bent part of the pipe.

In accordance with GOST 17685-71, they are accepted as follows:

- S/d

- S/d

- S/d

- S/d

These restrictions apply to cold bending.By heating the deformable part (not more than up to 1500C), the given values can be reduced by 12…15%. This type of pipe bender does not limit the maximum angle, however, at angles exceeding 450, folds form on the workpiece, and the pipe section loses its original shape.

The design of pipe bending machines classification

Before you start making a pipe bender with your own hands, you should find out what device options are. Knowing the options for pipe bending machines, it will not be difficult to choose the best one for yourself in order to implement it at home from improvised means. The devices under consideration are classified according to the following factors:

Type of accommodation - stationary and mobile

Type of drive mechanism - manual, electric and hydraulic

Method of influence on the material

It is this criterion that needs to be given special attention, because according to the type of impact, pipe benders are roller, crossbow, winding and rolling

Many do not understand how all these devices differ in terms of the method of exposure, therefore, before describing the instructions on how to make a curved pipe with a pipe bender, we will find out the features of each variety.

What is the unit for?

To bend a profile pipe, you do not need to seek help from metal rolling or buy a special tool. This can be done with the help of two metal posts buried in the ground. However, this method has a significant drawback - the need for physical effort. The result is an inaccurately curved pipe, which is not suitable for the construction of a greenhouse, arch or other products.

The pipe bender is designed to be able to produce neatly curved pipe shapes.These units are subsequently used for the construction of arches, greenhouses, ceilings, arbors, fences, etc. If you set out to build a greenhouse at home, then you need to design a home-made pipe bender. If there are improvised products and tools for this, then it will not be difficult to implement the design of the device with your own hands.

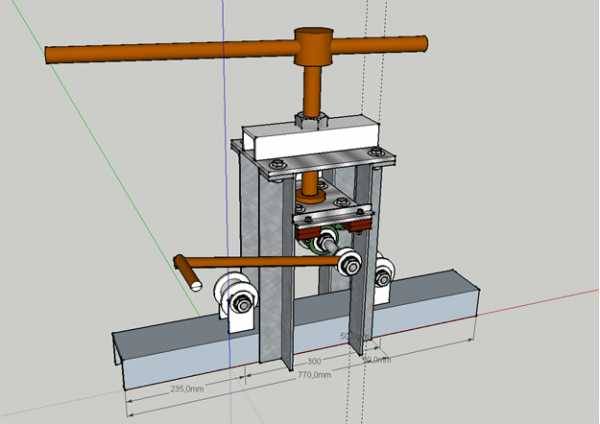

To make a do-it-yourself roller pipe bender for a profile pipe, you need to take care of the drawings. They are used to calculate the required amount of material, as well as the cost of producing a home-made unit.

The planned design of the product is applied to the drawing, which depends on the materials available.

Most craftsmen stop at the manufacture of front-type pipe bending machines. Such products consist of the following components:

- Rollers presented in the form of a round steel tube (the number of required rollers is 3 pieces).

- A chain that drives the shafts.

- Axes of rotation.

- The mechanism that drives the device.

- Profiles that are used to make a base or frame.

It is worth noting that there are a huge number of manufacturing options for the products in question, but they all operate on the principle of rolling or rolling. It is this principle of pipe bending that makes it possible to reduce the risk of pipe fracture and cracking.

A simple pipe bender has the form of a unit into which a profile pipe is inserted, after which the handle is turned, during the rotation of which the pipe begins to move, and a bend is formed

When designing a home-made unit at home, it is important to consider that the bending parameters will depend on the design itself.The closer the pressure rollers are to each other, the smaller the angle. This is interesting: How to make a chicken coop for laying hens: we understand in detail

This is interesting: How to make a chicken coop for laying hens: we understand in detail

Conclusions and useful video on the topic

The presented videos will help you see the above recommendations for making homemade pipe benders in dynamics, as well as introduce you to additional options for assembling these tools from improvised materials.

Video #1 Roll type jack bender:

Video #2 Making a jack pipe bender:

Video #3 Assembling a pipe bender from hubs:

Video #4 Production of a snail pipe bender:

The types of home-grown tools for bending a metal profile are not limited to the proposed options, because a do-it-yourself pipe bender can be made from any parts available on the farm.

The main thing is to build a clamping mechanism that will push the pipe between two racks or a roller system to deform the entire profile at once.

Do you want to talk about how you made a pipe bender with your own hands? Do you have a variant of the tool in your arsenal that is not described in the article? Please write in the block below, share useful information, photos on the topic of the article, ask questions.