- Self installation

- Set of tools

- Preparing for installation

- Mounting sequence

- TOP 4 warm skirting boards on the market

- No. 4. Best Board

- Number 3. Mr. Tektum

- No. 2. TERMIA

- No. 1. TherModul

- What is a warm baseboard

- Installation of a warm plinth

- Assembling the water heating system

- Assembling the electric heating system

- Types of baseboard heating

- Water systems

- Electrical systems

- Do-it-yourself installation of water plinth heating

- Varieties

- Water heated skirting boards

- Electric warm skirting boards

- Kinds

- Water

- Electric

Self installation

The owner can install the purchased equipment himself, for this it is not necessary to have the skills of professional work, just a modest set of tools, attentiveness and accuracy are enough.

Installing a warm plinth with your own hands is very simple. The design does not have a coolant, is easy to install and does not require work with pipes.

Set of tools

For self-assembly of the structure, the master will need the following tools:

- Perforator for attaching the plinth to the bearing walls;

- Screwdriver;

- Drill;

- Roulette, ruler and pencil;

- Connecting wires;

- Level;

- Hacksaw for metal;

- Pliers;

- Box for internal socket.

Preparing for installation

First of all, it is necessary to select the cross-section of the wire connecting the electrical network of the house with a warm baseboard. The power of the heater is indicated on its packaging, depending on this value, the necessary wire is selected. The minimum section of the wiring in the house and the wire going from it to the equipment is 1.5 mm². With a smaller wiring size, the electrical network at home may not be able to withstand the load. To prevent a short circuit, it is necessary to mount the baseboard only in houses with a high-quality new electrical network.

If you want to connect a whole block of high-power heating devices, then the diameter of the wires must exceed 2.5 cm².

It is necessary to make sure that the machines installed in the house are able to cope with the load from electric heating. The documents for the plinth indicate the number of amperes for which the device is designed. This value must match the one specified on the machine.

At the connection point, it is necessary to install a box under the internal socket and find the power cable to which the plinth is connected.

Mounting sequence

After completing the preparatory work, installation of a warm skirting board:

- First of all, guides are attached to the wall. They are made of plastic, fastened with self-tapping screws or anchors, depending on the material of the wall. For even fastening on a small elevation above the floor, use a level;

- After that, a material that reflects heat is attached to the wall. It comes with a skirting board, so it matches its size and does not require cutting;

- The master measures the length of the mounting bracket and at this distance fastens the upper rails in the same way as the lower ones are already fixed;

- Mounting brackets are attached between the guide brackets. The distance between them is indicated by the manufacturer on the instructions for the plinth. They bear the main load;

- It is possible to proceed with the installation of heating elements only after preparing the entire perimeter of the room. The main element of the plinth is hung on the brackets;

- First you need to measure the length of the heating element and cut off the excess with a hacksaw. After that, the edges are processed with sandpaper;

- For ease of fastening, 2 or 3 extreme plates are removed with pliers;

- Brass threads are mounted on the pipe;

- A closing loop is screwed onto the threads;

- All bolted connections are additionally stretched;

- The electric plinth is connected to the home network like a regular outlet;

- After connecting, you need to check the operation of the equipment by performing a test run;

- The cladding panel is attached with clips.

It is very important to be able to regulate the temperature separately in each room. It is mounted between the first panel and the power supply. First, a thermostat is attached to the wall at a convenient height, then the wires are connected, after which a test run of the system is carried out

During verification, the skirting boards are checked in all the provided modes of operation, and the uniformity of heating of the panels is checked. After checking, cladding boxes are installed, the places where the equipment is connected to electricity are sealed.

First, a thermostat is attached to the wall at a convenient height, then the wires are connected, after which a test run of the system is carried out. During verification, the skirting boards are checked in all the provided modes of operation, and the uniformity of heating of the panels is checked.After checking, cladding boxes are installed, the places where the equipment is connected to electricity are sealed.

It is convenient to equip each room with its own baseboard and equipment for adjusting its power. This will allow, if necessary, to turn off part of the thermal equipment or reduce its power. Such a system will save energy and reduce heat loss at home.

TOP 4 warm skirting boards on the market

This market is not yet characterized by a huge range of products, but there are plenty to choose from.

No. 4. Best Board

The Austrian manufacturer has been producing warm skirting board systems for over twenty years. To date, more than 20,000 Best Board systems have been installed in Austria alone. The products have been repeatedly awarded international prizes.

Best Board

The plinth is produced in various style concepts and shades. At a coolant temperature of 65 degrees, the system produces a thermal power of 179 W/rm. m. The only drawback of the Best Board plinth is its high cost.

Number 3. Mr. Tektum

The plinth offered by the domestic manufacturer competes with the products of European companies. But its price is much more attractive.

Mr. Tektum

Characteristics Tektum :

- Thermal power - 200 W / 1 rm. m (at a liquid temperature of 65 degrees);

- The volume of the coolant is 8l / 100 sq. m.

The system is offered in various colors (painted according to RAL), products with stone and wood texture are produced. A five-year warranty is given for a warm plinth by the manufacturer.

No. 2. TERMIA

The products of the Ukrainian company are characterized by a good price / quality ratio.Standard colors are white and dark brown, but under the order the plinth can be painted in any color, imitation of different types of wood is also performed.

TERMIA

The thermal power of the heat exchanger is 240 W per 1 linear meter. m length at a heat flux of 70 ° C.

No. 1. TherModul

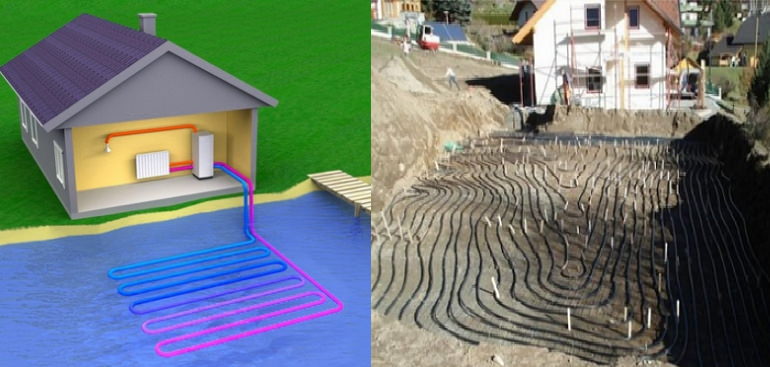

This system can work with any type of heat generator (gas and diesel boiler equipment, geothermal, solar panels, heat pumps, etc.).

TherModul

What distinguishes TherModul skirting board:

- larger tube diameter - 15 mm (this speeds up heating and saves the amount of heated water);

- no plastic parts.

The system is offered in standard white, bronze and aluminum colors. Other colors - according to the RAL catalog. Also available in 8 shades for wood and 2 for stone.

Table. Comparison of models of warm plinth from different manufacturers.

| Skirting board brand | Dimensions, mm | Material | Cost, thousand rubles/linear m. |

|---|---|---|---|

| Mr. Tektrum, Russia | 30 x 140 x 2500 | Copper, brass, aluminum 2 mm thick. | From 4.3 |

| Best Board, Austria | 28 x 137 x 2500 | Profiles are produced from hot-pressed aluminum 2…4 mm thick (with powder coating), pipes are made of copper (wall thickness 2 mm), lamellas are made of brass. | From 7 |

| TERMIA | 40 x 160 x 1000 (1500, 2000) | The tubes are made of copper, the plates and bars are made of aluminium. | From 3 |

| TherModul | 29 x 137 x 2500 | Copper, aluminum | From 7.2 |

Elegant, energy-efficient and practical systems of water heating skirting boards allow you to create comfortable conditions for people in the room in a short time.

What is a warm baseboard

Not everyone is familiar with this technology.Heating skirting boards have started to appear on the market quite recently, but there is already a positive trend. The system is quite simple, but at the same time convenient and able to provide a warm environment not only in residential premises, but also in offices, on a balcony, attic. The main distinguishing features of warm water baseboards are atypical forms. The design consists of several elements:

- Rear panel, which is fixed to the wall and used to create thermal protection;

- Face plate (there are options with holes and without them);

- Plugs located on the sides;

- A heating device used to heat the coolant (boiler, heat pump, central heating system);

- A heat exchange module consisting of two tubes - it is through them that water circulates.

The design of a warm skirting board does not differ in any complexity. Installation can be performed in any type of room. It is not at all necessary that the plinth be around the entire perimeter. Sometimes it can be seen under the window, near the door. The most important thing is that in any place the design will perfectly cope with its immediate function.

Water is most often used as a coolant in a warm baseboard, but sometimes antifreeze, propylene glycol or ethylene glycol solutions are pumped into them. This option makes sense if the heating is installed in a private house, which does not need to be heated constantly, for example, in a country house.

Warm water plinth has a number of positive qualities:

- Compactness (unlike the vast majority of other devices);

- Heating is carried out evenly over the entire area of the room;

- Ease of installation;

- The air does not dry out;

- High efficiency.

Thanks to this technology, everything is heated - floors, walls, ceilings. Accordingly, the likelihood of mold and mildew is eliminated. The skirting board harmonizes perfectly with any floor covering.

Finally, the market offers a wide range, in particular in terms of colors, sizes and shapes. You can purchase the design of the shade that will look best in a particular room.

Installation of a warm plinth

For installation, you will need a tool: adjustable wrenches in a set, a drill with an impact function (or a puncher), a hammer, wire cutters, pliers, scissors (to cut plastic). The plinth heating system is quickly mounted if the connection points are prepared in advance.

Even before purchasing the necessary equipment, you need to plan what power the heating elements need and how to place them around the perimeter of the room.

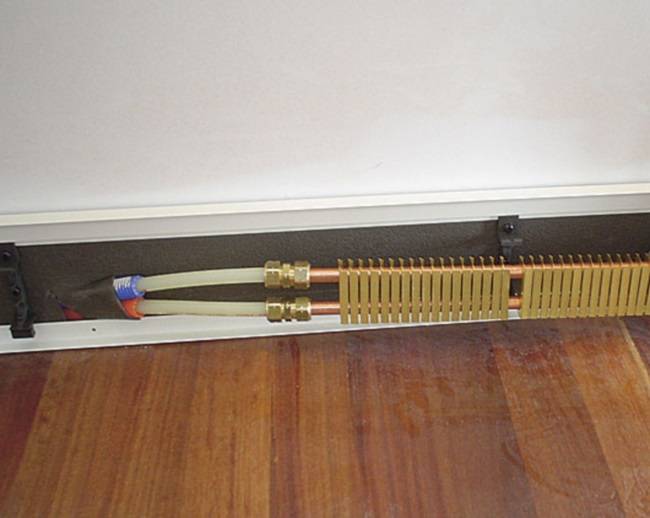

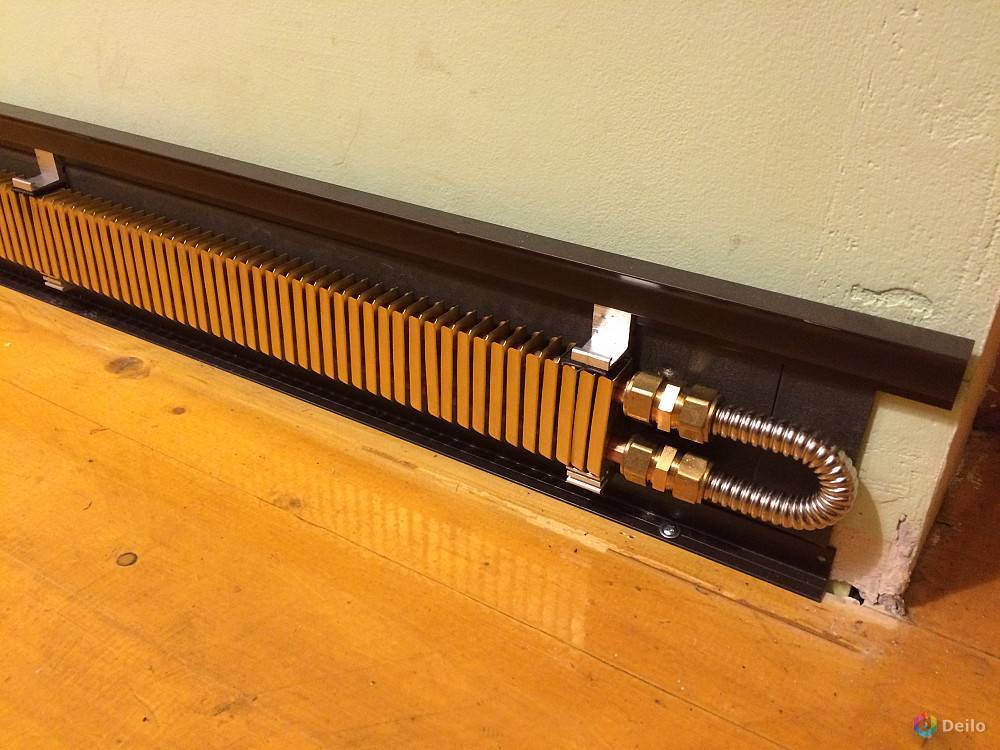

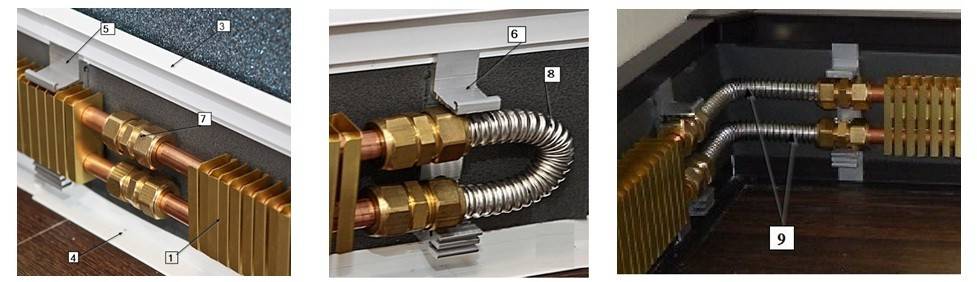

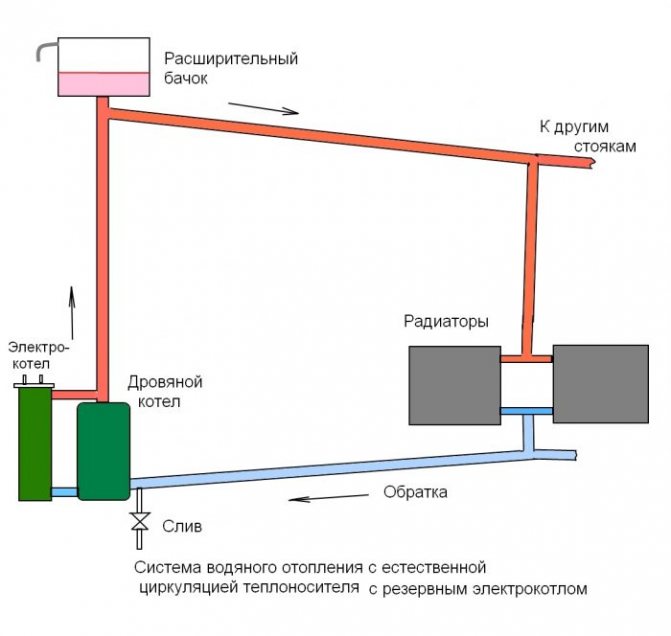

Assembling the water heating system

Stage 1. We measure the distance from the point where the distribution manifold will be located to the location of the plinth. We cut off two lengths of the protective pipe and two with an allowance of 20 cm - connecting. We insert the connecting one into the protective one, clog the ends with adhesive tape to protect against dirt.

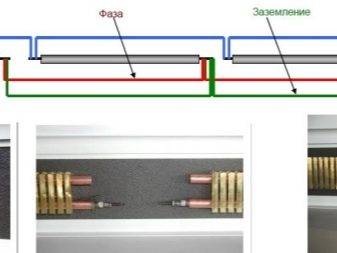

Installation of a baseboard heating water system: red - main flow, blue - reverse. The return pipe must be higher

Stage 2. We pull the pipes along the floor without tension so that, if necessary, an extension can be laid next to one or more. We fix it with mounting tapes, cover it with a protective solution, protecting it from damage, and display it in the right place on the wall 6 cm above the floor and 10-15 cm from the edge of the wall or corner, fix it with cement.

Stage 3. After laying the final floor, we continue to work.We glue the insulating strip along the entire length. We stretch the aluminum edge (also along the entire length of the heating), closing the junction of the wall and floor. We screw it or fix it with adhesive tape, silicone.

Stage 4. We lay a special profile along the top line, put holders on it at a distance of 15 cm from the corners and every 40 cm along the wall.

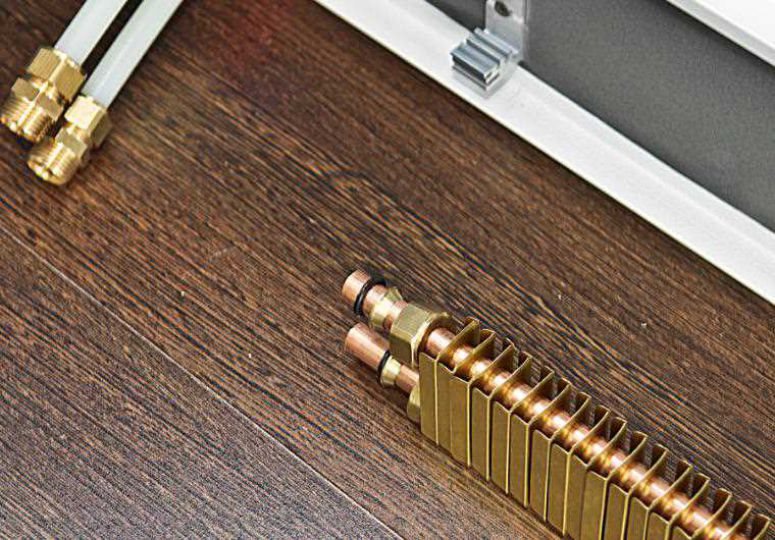

Stage 5. To connect the heating pipes and heating elements, we use couplings with nuts, bushings and gaskets, in the corners - 90º angled swivel tubes, at the ends - 180º end swivel tubes and plugs. Thermosections are interconnected by adapters.

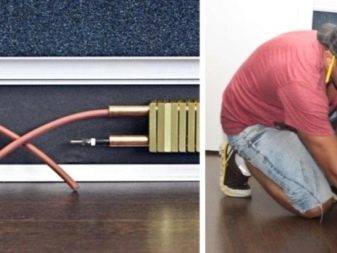

When connecting the heating module, it is necessary to remove 2-3 lamellas from the edge and put connecting nuts, crimping parts, rubber gaskets on the tubes

Stage 6

The connected heating sections are carefully pressed into the holders. We put on decorative panels (we attach with screws or snap them in) and decorative corner elements. We connect the system to the collector, fill in water, test at operating and maximum pressure

Like all collector systems, a heating baseboard requires a circulation pump that stimulates the movement of the coolant. Without a pump, it is difficult for heated water to circulate along an extended circuit. However, the use of technical devices is reflected in the overall cost of the system.

The plinth will work if all technological operations have been performed without violations. When leaking, problematic connections must be squeezed with a wrench. The coolant is supplied through the collector by a circulation pump from the boiler or from a common (centralized) heating system.

Assembling the electric heating system

For a warm baseboard in the electrical panel, you need to make a separate circuit breaker. Its power is determined by the number of heating modules.

Stage 1. We supply power to the junction box, which should be near the location of the system at a height of 4-6 cm from the floor.

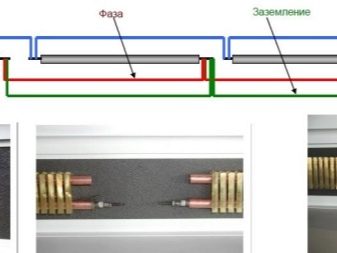

Installation of an electric heating system: most often, an electric system is used where it is possible to supply power of the required power, or in small rooms as additional heating

Stage 2. We stick an insulating tape on the wall.

Stage 3. We install the lower aluminum profile (edge) and the upper one, on which we put the holders at the same distance as for the water system - 15 cm from the corners and in increments of 40 cm along the wall. We install a remote thermostat. It should be located at a height of about 1.5 m opposite the system modules and at a distance of at least 2 meters from them.

Stage 4. We insert the electric heating elements (heaters) into the lower pipe of the heating module, fix the modules in the holders so that they do not touch the wall.

The electrical contacts of the heating elements have a thread, two nuts, a retaining ring on a spring, a heat shrink tube for additional insulation. The modules are connected in parallel with a heat-resistant power cable coated with silicone and heat-resistant up to 180°C.

Stage 5. From above we close the system with a plastic box.

To connect the heating modules, a 3-core cable is used: brown core - phase, blue - zero, green (yellow) - ground. It is necessary to ground the cable

Connecting the installed heating system to the power supply is best left to an electrician. He will check the reliability of the insulation with measuring instruments, supply electricity and adjust the thermostats.

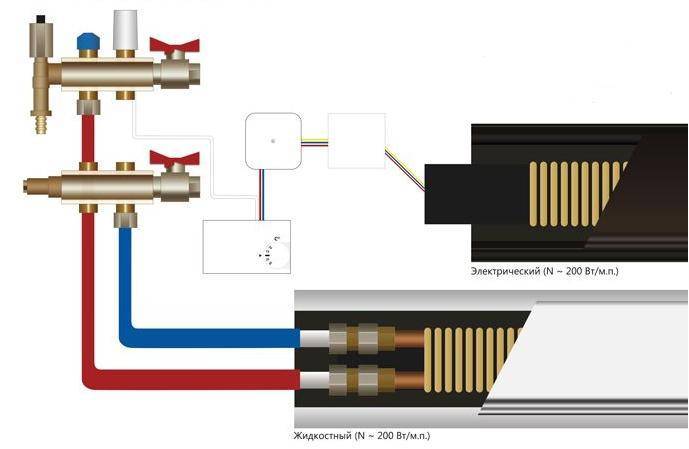

Types of baseboard heating

Baseboard heating is divided into water and electric. Accordingly, water systems operate on the basis of gas or any other boilers. Electrical systems are built on the basis of electric skirting convectors.

Water systems

Water heating systems are built on the basis of the radiators described above, made of non-ferrous metals. Hot coolant circulates through them, prepared by a heating boiler or obtained from a central heating system.

Water plinth heating can be used to heat rooms for any purpose - it can be halls, corridors, kitchens, children's rooms, living rooms, trading floors and much more. In addition, it is well suited for use in rooms with panoramic glazing - baseboard radiators will prevent the penetration of cold, protect against condensation.

The "warm plinth" heating system is recommended for installation in individual households. But its use with a centralized supply of coolant can lead to an accident - skirting heating does not tolerate water hammer. Some experts recommend using an intermediate heat exchanger, but in this case, certain heat losses will be observed.

The water plinth heating system consists of the following parts:

- Radiators - they are miniature convectors made of non-ferrous metal. They are the sources of heat for heating rooms;

- Protective boxes - they close the radiators and pipes themselves;

- Pipes - in most cases, metal-plastic pipes are used here, as they are more resistant to pressure and high temperature.

The installation of a water baseboard heating system is carried out in such a way that it does not form a complete ring around the entire house - this would cause uneven heating. Therefore, it is most often practiced to create separate directions for each room. To do this, distribution manifolds are mounted in the heating system, to which the coolant from the boiler is supplied.

The main advantage of using a distribution manifold is the ease of repair work in the event of an accident. It also allows you to adjust the temperature in each direction separately.

Electrical systems

Electric baseboard heating is designed for use in buildings that are not connected to gas mains. It involves the use of small-sized convectors, which are powered from the mains. By their design, they are similar to water radiators, only instead of tubes with a hot coolant, powerful heating elements are used here.

Electricity in our country is quite expensive, so the use of electric heating can lead to high costs. But in many cases, it remains the only available heating method.

As with water systems, it is desirable to use a circuit with several separate directions in electric heating. That is, each room is powered by a separate electrical cable. A special electrical panel is installed in the building, in which circuit breakers are mounted. From here, the cables diverge throughout the premises.If a room is not in use, it can be turned off - thereby saving energy.

Electric convectors work on the same principle as water convectors - they produce heated air, which, as it were, "sticks" to the walls and goes up. At the same time, cold air masses are sucked into the equipment, passing through the next stage of heating. After a while, the room will become noticeably warmer.

The main advantages of electric baseboard heating over water systems:

- Increased reliability - the use of modern heating elements makes it possible to guarantee a service life of up to 20-25 years, while for water appliances this period is about 10 years;

- There is no coolant - which means there is no risk of flooding the neighbors;

- Easier installation - laying the cable is much easier than fiddling with pipes.

The main disadvantage of any electric heating is its gluttony in terms of electricity consumption - in combination with electricity tariffs, the costs will be high.

Do-it-yourself installation of water plinth heating

So, having considered all the pros and cons, and weighing all the pros and cons, you still made a positive decision. Let's then consider how you can mount skirting water heating with your own hands. As mentioned above, this, in principle, is not so difficult, although certain skills will certainly be required.

So, having considered all the pros and cons, and weighing all the pros and cons, you still made a positive decision. Let's then consider how you can mount skirting water heating with your own hands. As mentioned above, this, in principle, is not so difficult, although certain skills will certainly be required.

Skirting water heating is a system consisting of the following elements:

boiler;

- distribution manifold;

- a set of plastic pipes;

- radiator.

In fact, this is an analogue of water heating.There is also a boiler that heats the heat source, pipes and radiators, but there are still differences, and quite significant ones, between them. For example, in a baseboard heating system, the temperature difference between the water supply and the “return” does not exceed 5 degrees, while in a conventional delta it can reach 20.

Water is heated by a boiler - gas, solid fuel or electric. Be sure to calculate all the parameters in order to choose the right equipment. If in doubt, it is better to consult a specialist. Next, we install the heating system itself. First of all, we install a metal base - it is attached to the wall with self-tapping screws.

The next step is the installation of heating elements. Its individual parts are first connected to each other, after which they should be installed on the base with the help of special fasteners. Next, we connect the system to the boiler using a collector or distribution comb. It uses exactly the same principle as when installing conventional batteries, so there should not be any problems or unforeseen difficulties.

Be sure to check the connections are secure. To do this, start the system, and carefully check everything for leaks. If you notice leaks in the joints, fix this problem. Only after you have made sure that everything is in order, you can close the plinth with a decorative element.

Be sure to check the connections are secure. To do this, start the system, and carefully check everything for leaks. If you notice leaks in the joints, fix this problem. Only after you have made sure that everything is in order, you can close the plinth with a decorative element.

Please note - experts recommend installing several closed circuits if the perimeter of the room is more than 15 meters. Each of them must have a separate connection to the boiler, otherwise the efficiency of the system is reduced.

As you can see, by and large, there is nothing complicated directly in the installation of baseboard water heating - all components of the system are purchased ready-made, after which they are interconnected. The main thing is to calculate everything correctly, and then later you will not have any problems. If, nevertheless, there are any doubts, then it would be best to turn to professionals - their work will ultimately cost less than fixing the problems that have arisen due to mistakes.

Varieties

In this review, we will tell you how to make a warm skirting board with your own hands. But before that, you need to decide what equipment will be used to heat the premises. Skirting heating can be water or electric, and the choice of a particular system depends on the availability of certain energy sources. Water systems are powered by boilers of any modification, and electrical systems need a reliable power supply.

Water heated skirting boards

Do-it-yourself installation of hot water skirting boards is a complex process. The system should turn out not only effective, but also airtight so as not to flood the floors and neighbors (if any). Water plinth heaters are small-sized convectors. The basis for their manufacture are non-ferrous metals - copper and aluminum. The pipes passing inside are made of copper, and the radiators are made of aluminum.

A non-ferrous metal bond provides equipment with maximum efficiency and heat dissipation. By the way, to increase the power, water convectors are made double-row - they are thicker, but more powerful.

When installing warm skirting boards with your own hands, it is necessary to mark the contours - one or two contours for each room, depending on its area. The maximum recommended length for each circuit is 15 meters. Accordingly, if the perimeter is larger, it is recommended to divide it into two circuits. Convectors in separate directions are connected in series.

To ensure uniform heating, a distribution manifold is installed in the system. Each circuit is powered by a separate pipe with a tap - if anything, the coolant supply can be shut off without affecting other circuits. This feature can come in handy in case of an emergency.

When installing a warm water plinth with your own hands, it should be remembered that the operation of this equipment in centralized heating systems is dangerous - convectors may not withstand water hammer or high pressure, which will lead to their destruction. In order to protect the heating from damage, an intermediate heat exchanger is installed in the system. As a result, an independent heating circuit is formed in an apartment with central heating, taking heat from the heating plant.

Electric warm skirting boards

Making an electric warm plinth with your own hands is much easier than installing water radiators. The thing is that this equipment is powered by the mains and does not require a coolant supply. Electric skirting convectors are similar in design to water appliances, but instead of copper pipes, heating elements are located here. They are the source of heat.

Skirting electric convectors can be equipped with built-in thermostats. But the easiest way to control each circuit is with an external thermostat.If necessary, consumers will be able to implement a remote control system via GSM networks or via the Internet.

Kinds

Today, only two types of warm plinth are common - water and electric. Each of them is used in specific conditions for arranging rooms and furnishing the apartment itself. It is worth considering each of the types in detail.

Water

This installation option is quite common - it can be seen in the interior of some modern residential buildings, office buildings, even shopping centers. It is worth noting that the water type of warm plinth is widespread in many Western countries. Such interest is due to such factors as: ease of use and low maintenance requirements. A warm water plinth is an externally metal panel or box, inside of which a heating or heating module with mini-tubes for water supply and heating is placed. The outer or back side of the device is also equipped with a metal panel, which is already designed to protect the wall itself from high temperatures.

This method of connection by technicians is called beam. The difference between this type of warm plinth and electric is a wide range of possible installations in the interior. Water warm plinth can be mounted on attics, loggias, even on a balcony, while the heating efficiency does not decrease, and energy costs remain relatively small. Another feature of the water type is the speed of heating the air, since the physical properties of water make it possible to freely transfer even the hottest streams through pipes. However, it is necessary to constantly monitor the temperature level in boiler rooms.

Electric

If the water version of the warm baseboard is valued for its quick heating and ease of maintenance, the electric type is common due to the following characteristics:

- ease of installation work - unlike the water type, the electric one is installed on site, the installation process is simple and fast, because it is enough to fix the heating panels to the wall;

- the presence of more advanced heat regulation systems - most models of water skirting boards are not equipped with special devices for measuring temperature - for this it is enough to monitor the average water level in boiler rooms. The electric type is often equipped with specialized thermostats that look like conventional thermometers. Thermostats can work both automatically and can be adjusted manually, and their work is aimed at optimizing energy costs.

Here it is worth noting the negative aspects of using such a plinth:

- high energy consumption - when using any equipment with power supply, the question arises of cash costs. The electric type, unfortunately, even with thermostats consumes a large amount of energy;

- installation of the electric type is much simpler, however, the connection process itself can cause some difficulties - this is the preparation of a dedicated line with the correct rating;

- one potential downside for many buyers is the availability of power. The probability of wiring damage and fire is extremely small, however, for some this is a determining factor under certain operating conditions.

If the buyer liked the aquatic variety more, then do not despair and think that these species differ in appearance.

In addition to the presence of terminals or wire attachments to the electrical supply, these varieties are outwardly absolutely similar. It is worth noting such a type of plinth equipment as an infrared warm plinth. The peculiarity of this type is the use of a special film tape, which, under the influence of high temperatures, heats up and becomes a kind of source of infrared radiation, which provides additional and high-quality heating of the room.