- Criterias of choice

- Power calculation

- Top 5 Benefits for Plant Owners

- What to buy - top 5 best pumps

- ALTAL GROUP

- NIBE Industries AB

- Viessmann Group

- OCHSNER

- Heliotherm

- Sources of low-potential energy

- Use of natural waters

- Soil energy

- Heat from wells

- Thermal energy of air

- Assembling a pump from an old refrigerator

- We make a heat pump with our own hands

- Video - Homemade water-to-water heat pump

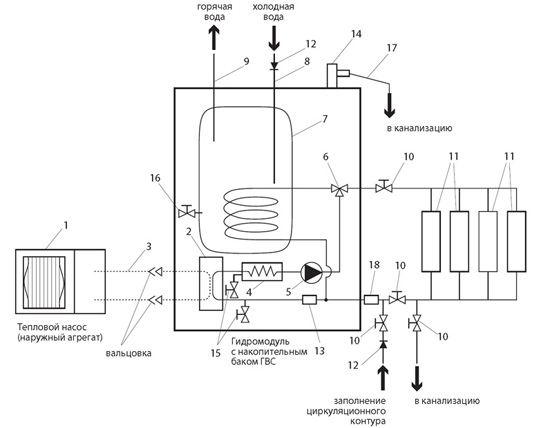

- The main structural elements of heat pumps

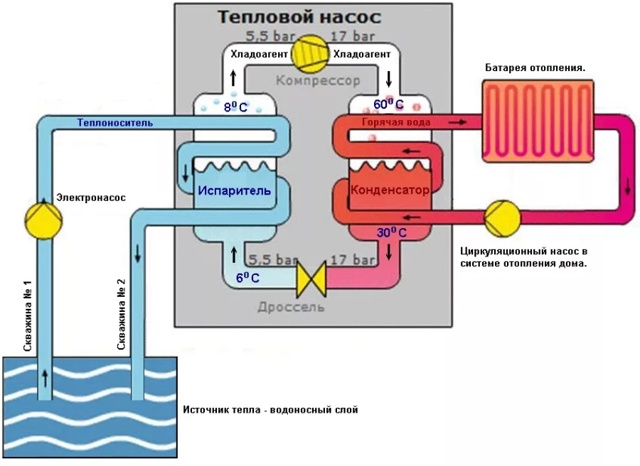

- The principle of operation of heat pumps

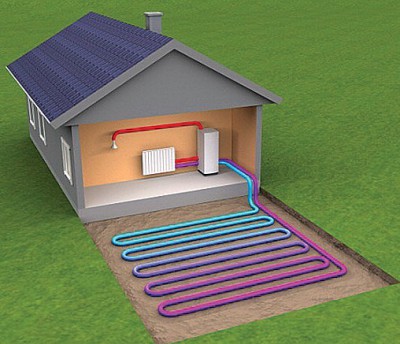

- Geothermal heating at home: how it works

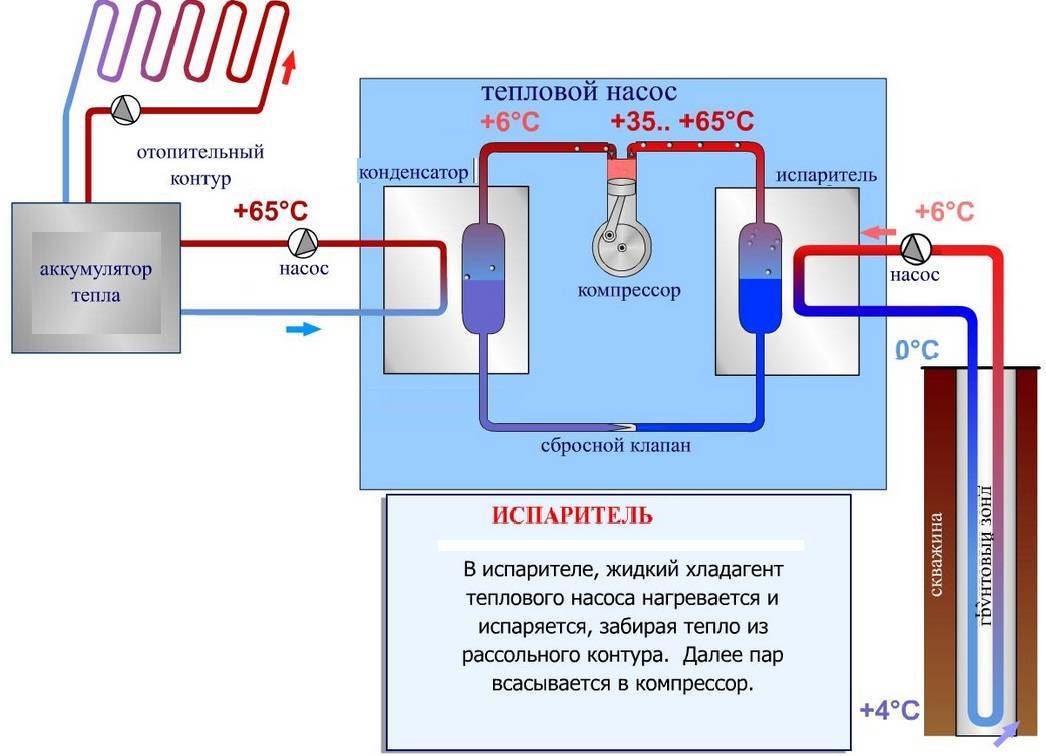

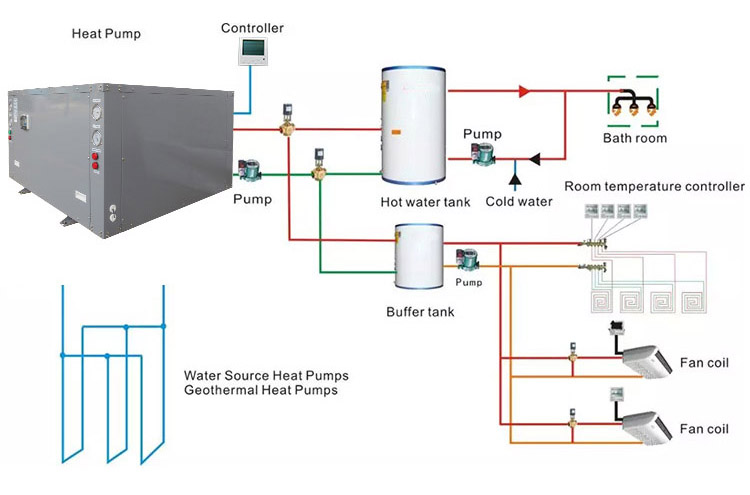

- Heat pumps: ground - water

- Type of water-to-water pump

- Air-to-water pumps

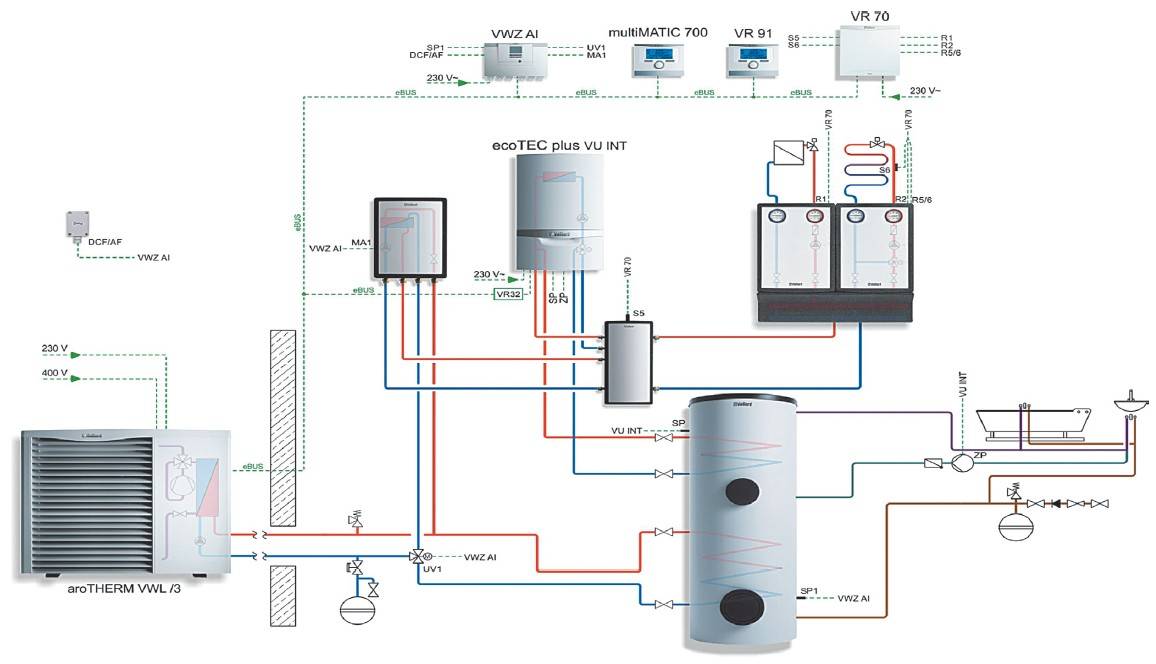

- Bivalent heating scheme ↑

- What is a heat pump and how does it work?

- How to make a do-it-yourself unit?

- Method #1. Assembling from the refrigerator

- Method #2. Air conditioner heat pump

- Specifics of application and work

- Conclusions and useful video on the topic

Criterias of choice

At first glance, it seems doubtful the need for laborious laying of several hundred meters of plastic pipes on the bottom of a reservoir or even more costly drilling of wells for a water-to-water HP. After all, there are air-to-air systems. There is no external collector at all.For example, a very high-quality Japanese inverter air-to-water heat pump manufactured by Mitsubishi Heavy.

It's simple - the density of water is 800 times greater than that of air. And heat too. Therefore, water systems will always be more efficient and economical than Mitsubishi.

Power calculation

For preliminary calculations, a simplified formula is usually used: 700 watts of heat is required per 10 m2 of a heated building. Then for a house with an area of 250 m2, you need to buy a water-to-water heat pump with a capacity of 175 kW.

To ensure hot water supply, the final figure must be increased by 15%.

This does not take into account the large difference between the climatic zones, for example, the Crimea and the Moscow region. The heat loss of the external enclosing structures of different buildings is also very different. There are other factors that must be taken into account in the calculation. This can only be done by specialists.

Top 5 Benefits for Plant Owners

To the benefits heating systems with heat pumps include these:

- Economic efficiency

. With the cost of 1 kW of electrical energy, you can get 3-4 kW of heat. These are average indicators, because. the heat conversion coefficient depends on the type of equipment and design features. - Environmental Safety

. During the operation of the thermal installation, combustion products or other potentially hazardous substances do not enter the environment. The equipment is ozone safe. Its use allows you to get heat without the slightest harm to the environment. - Application versatility

. When installing heating systems powered by traditional energy sources, the owner of the house becomes dependent on monopolists. Solar panels are not always cost-effective.But heat pumps can be installed anywhere. The main thing is to choose the right type of system. - Multifunctionality

. In the cold season, the installations heat the house, and in the summer heat they are able to work in air conditioning mode. The equipment is used in hot water systems, connected to the contours of underfloor heating. - Operational safety

. Heat pumps do not require fuel, they do not emit toxic substances during their operation, and the maximum temperature of equipment units does not exceed 90 degrees. These heating systems are no more dangerous than refrigerators.

There are no ideal devices. Heat pumps are reliable, durable and safe, but their cost directly depends on the power.

High-quality equipment for full-fledged heating and hot water supply of a house of 80 sq.m. will cost about 8000-10000 euros. Homemade products are low-power, they can be used to heat individual rooms or utility rooms.

The efficiency of the installation depends on the heat loss of the house. It makes sense to install the equipment only in those buildings where a high level of insulation is provided, and heat loss rates are not higher than 100 W / m2.

Heat pumps can last 30 years or more. Their use is especially profitable for hot water supply, as well as in combined heating systems, including underfloor heating.

Equipment is reliable and rarely breaks down

If it is homemade, then it is important to choose a high-quality compressor, best of all - from a refrigerator or air conditioner of a proven brand

What to buy - top 5 best pumps

Purchasing a heat pump is an important and responsible procedure.It is possible to give any recommendations in this area only if you have specific information about the size of the house, the material of the walls, the degree of insulation, the configuration of the premises, the type of heating system, etc. Without this data, it is pointless to talk about the best pumps. However, we can consider the most well-known manufacturers who supply quality equipment to the market and are leaders in this field:

ALTAL GROUP

The company is based in Ukraine, Russia and Moldova. The production of equipment is focused on the conditions of the Russian regions and can be used in harsh conditions

NIBE Industries AB

The Swedish company has been on the market since 1949 and is rightfully the leader in its field. Production is carried out according to the most advanced developments, the best materials and components are used.

Viessmann Group

One of the oldest European companies - the foundation of the company dates back to 1928. German specialists have gained vast experience and achieved the highest quality of their products

OCHSNER

An Austrian company that was one of the first to start serial production of heat pumps and was recognized by users due to the quality, reliability and durability of equipment

Heliotherm

Another Austrian company producing heat pumps and other equipment. Sales of products are made in Europe, high quality, reliability and wide functionality of heating systems are noted

Sources of low-potential energy

The sources of low-potential energy include soil, water and air. These resources are renewable, are not consumed during the operation of the pump, and therefore are inexhaustible.They are used for heating residential buildings, heating footpaths and stadiums, and providing hot water.

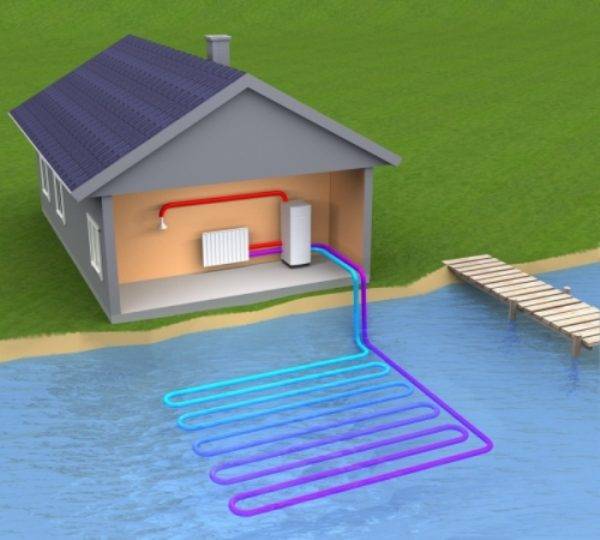

Use of natural waters

- In the northern regions - 3 meters;

- In the southern regions - 1 meter.

For efficient use of the resource, the reservoir should be located at a distance of no more than fifty meters from the object that needs to be heated. If the distance is longer, then there are additional costs. It will take more material to install the pipeline, and there will also be more work to dig trenches. And this is provided that only unused land separates the house from the reservoir. But if the lake is located directly at the dwelling, then it is beneficial to use it. Laying a pipeline in water is not too time-consuming and costly.

Arrangement of a thermal system using a reservoir located next to the house

Arrangement of a thermal system using a reservoir located next to the house

Take a sample before installing the heat pump water from a reservoir for research in the laboratory. It is necessary to determine:

- Water hardness and the content of individual trace elements. Based on these indicators, choose the model of equipment. If the heat pump is chosen incorrectly, the equipment will quickly fail due to corrosion.

- Degree of water pollution. For the successful functioning of the system, filters are installed. With a high degree of pollution, it is worth calculating the economic benefit, since the cleaning system will be expensive.

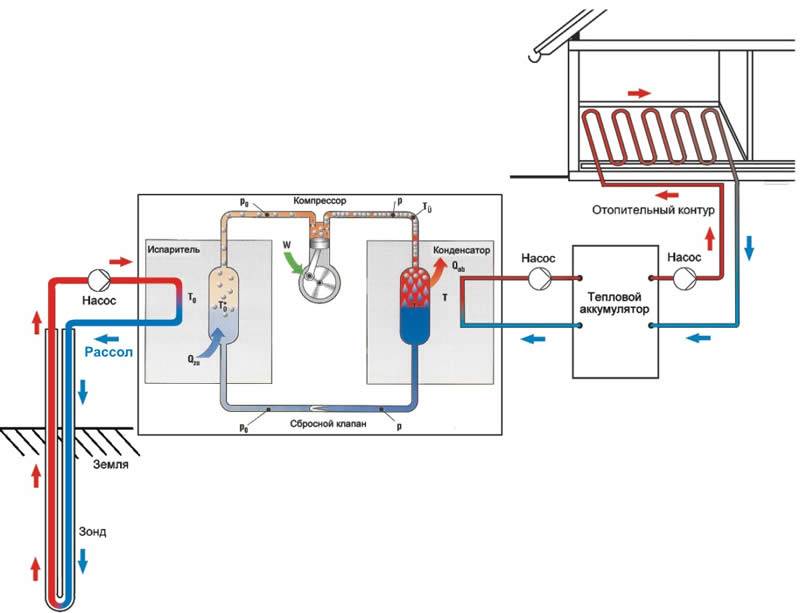

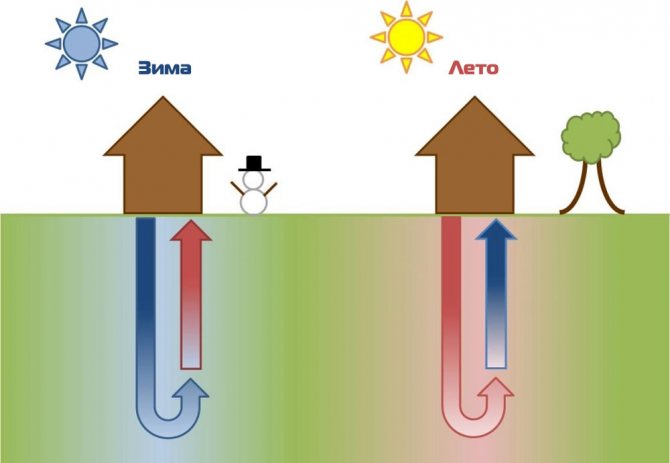

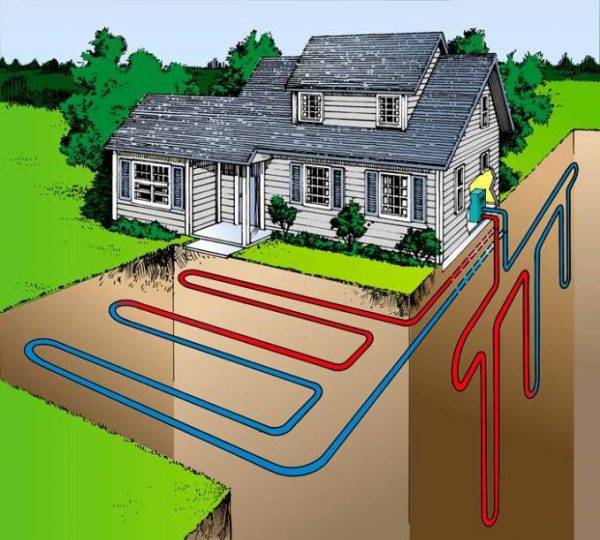

Soil energy

The earth has the ability to accumulate solar heat, as well as receive energy from the earth's core. In fact, the soil is an inexhaustible source of heat. The ground-water and ground-air heat pump normally functions at ground temperature from +5 to +10°C.The lower the ground temperature, the more powerful equipment you need to use. The design of the heat exchange circuit can be horizontal or vertical. The area it occupies is also directly dependent on the temperature of the earth. The branches of the pipeline are laid at a distance of one (maximum 1.5) meters from each other.

Scheme of conducting a thermal system in the ground to help craftsmen

Scheme of conducting a thermal system in the ground to help craftsmen

To use this heat source, you need to allocate a large area. This area is not suitable for planting plants, as they will freeze. Difficulties are the installation of the system and the search for a specialist who will cope with the work.

With a vertical arrangement of the system for heating a house of 200 m², it will be necessary to drill about ten wells 30 m deep (with average heat transfer rates) and 15 cm in diameter. For a horizontal installation, with the same initial data, about 500 meters of pipeline will have to be laid.

Installation difficulties and material costs are compensated:

- The service life of the heat pump, which is 50 - 70 years;

- Saving money on gas heating bills.

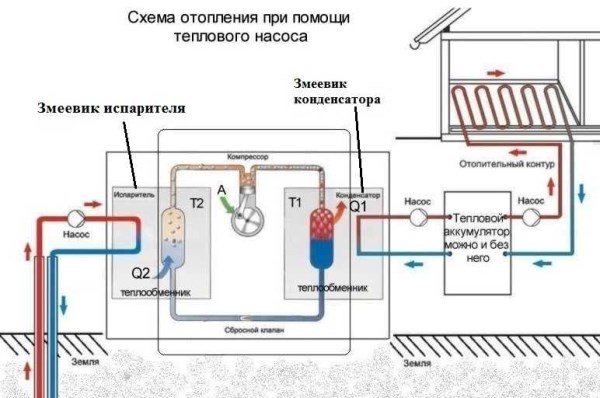

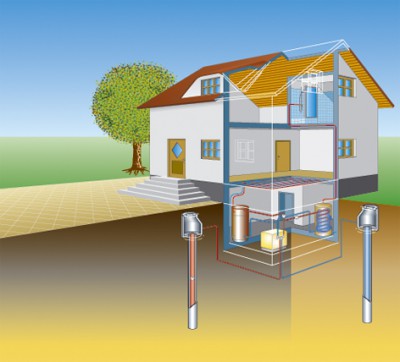

Heat from wells

Ground water from a well for heating housing is rarely used due to the complexity of installation. The system should have two wells. Water is taken from one of them to produce heat. In the second, the liquid passed through the heating system is discharged. The distance between wells should be at least 15 meters.

Before installing the heat pump, determine the direction of groundwater flow. The drain well should be located downstream. In addition, it is necessary to provide water filtration from mechanical and chemical impurities.

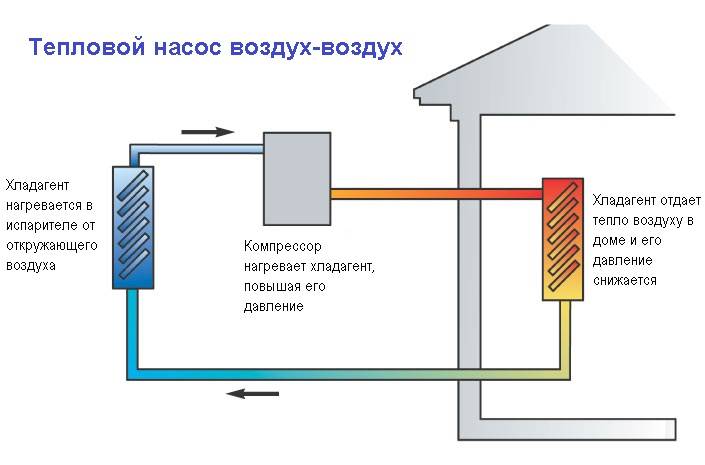

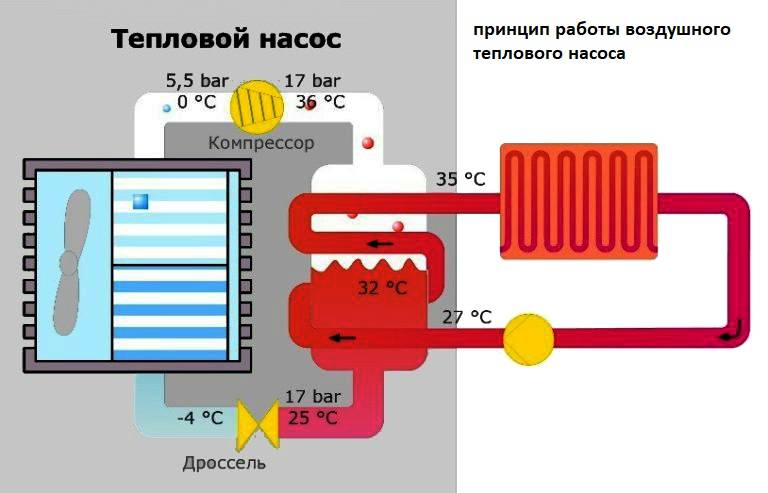

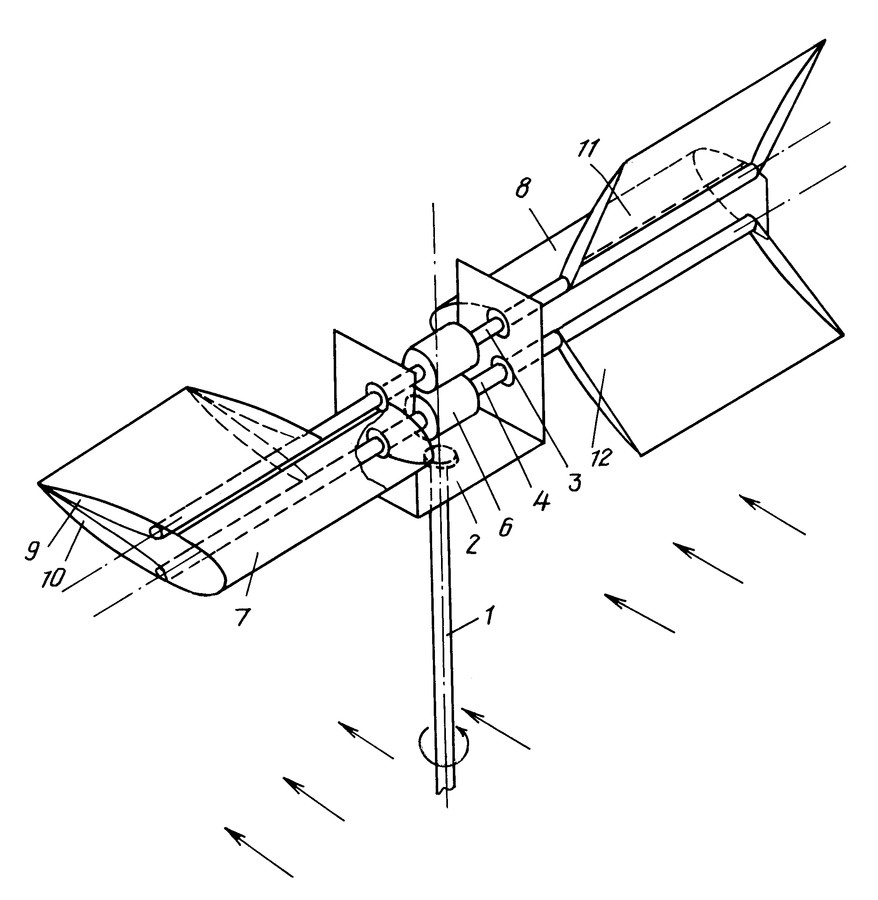

Thermal energy of air

A heat pump that uses air energy is the simplest in design. No piping is required as the air enters the evaporator directly from the environment. The heat is transferred to the refrigerant and then to the coolant in the room. Heat carriers can be air (through the closer fan) and water (in heating radiators and underfloor heating).

The air-to-air heat pump works on the principle of an air conditioner with some differences:

- The system operates at negative temperatures;

- A heat pump may be the only source of heat in a home;

- Efficiency in comparison with standard air conditioners, which work not only for cooling, but also for heating.

The design of a heat pump using air energy is not difficult to implement

The design of a heat pump using air energy is not difficult to implement

Assembling a pump from an old refrigerator

Thermal pump made from old refrigerator in two ways.

In the first case, the refrigerator must be located inside the room, and outside it is required to lay 2 air ducts and cut into the front door. The upper air enters the freezer, the air is cooled, and it leaves the refrigerator through the lower air duct. The room is heated by a heat exchanger, which is located on the rear wall.

According to the second method, making a heat pump with your own hands is also quite simple. To do this, you need an old refrigerator, it only needs to be built in outside the heated room.

Such a heater can work at outside temperature down to minus 5 ºС.

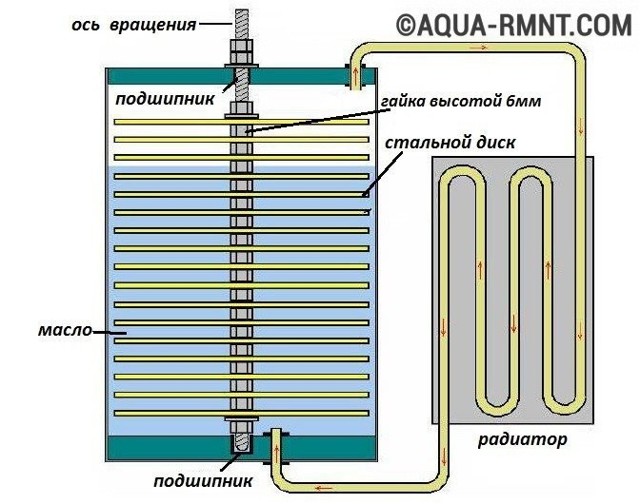

We make a heat pump with our own hands

Yes, heat pumps are really expensive, even if they are their own, so not everyone can afford such a purchase.But you can make it yourself, using used parts or those that are on the farm.

If you plan to install in an old building, then first you need to check condition of the meter and wiring. The order of work is the following.

Step 1

. The first thing you need to do is buy a compressor. A cheaper option is to find a compressor from an old air conditioner. It is ideal for making a pump. Fasten the part to the wall surface using fasteners-brackets (model L 300).

Step 2

. Then it is necessary to make a capacitor, which will require a steel tank V = 100 liters. It must be cut in half, and a copper coil of a suitable diameter with wall thickness more than one millimeter.

Coil manufacturing

Step 3

. When you fix the coil, the halves of the container must be welded back.

Step 4

. Next, make an evaporator. For it, you will need another plastic container, 70 liters. A coil is also mounted in it, only the diameter of the pipe should be smaller. Attach the evaporator to the wall using the same “L” type brackets of the required size.

Step 5

. The next step is to hire a specialist. The fact is that it is not easy to weld pipes and pump freon on your own, especially in the absence of the necessary knowledge. A refrigerator repair expert will do a great job of this.

Step 6

So, the "core" of the system is already ready, it remains to connect it to the distributor and the heat intake. And if there are no problems with the distributor, then a lot of time and effort will have to be spent on the intake. Of course, it is better to turn to a specialist again, but let's try to figure it out, how to do everything by hand.

Features of the installation are different for each type of thermal units.

In this case, waste is inevitable, so how to drill a well, and it is impossible to do this without a drilling rig. The depth of the well should be a minimum of 50 and a maximum of 150 meters. A geothermal probe is lowered into the finished well, which is subsequently connected to the pump.

For horizontal systems, a collector made of pipes is required. Such a collector should be placed below the freezing level of the soil, which depends on the climatic features of the area, but often does not exceed 1.5 meters.

To install the collector, remove the top layer of soil. You can use special equipment for this or do everything with a shovel, which is much cheaper. After laying the pipes, backfill the earth.

There is another technology for laying pipes - to dig a separate ditch for each. There should be several such ditches and all of them should be placed below the freezing level of the soil. We put pipes in them, we fall asleep.

Connect the collector on land using HDPE pipes. After that, fill the coolant into the system and move it to the water. It is desirable to immerse the collector in the central part of the reservoir or simply to the desired depth.

As mentioned above, for this kind of pumps, no large-scale work is required, because the heat is extracted from the air. You just need to choose a place - the roof of a building, for example - and install a collector. Further, the latter is connected to the heating system.

This completes the manufacture and installation of the heat pump. We hope that the article was really useful for you!

Video - Homemade water-to-water heat pump

The owners of country houses have always been sensitive to the issue of hot water supply and heating.

Installing a gas, electric or diesel boiler makes it possible to heat a country house and supply it with hot water and heat, but now there are alternatives to our usual heating.

One of these alternatives is . This is quite an expensive pleasure, but you can make it yourself. We will talk about how to do this in this article.

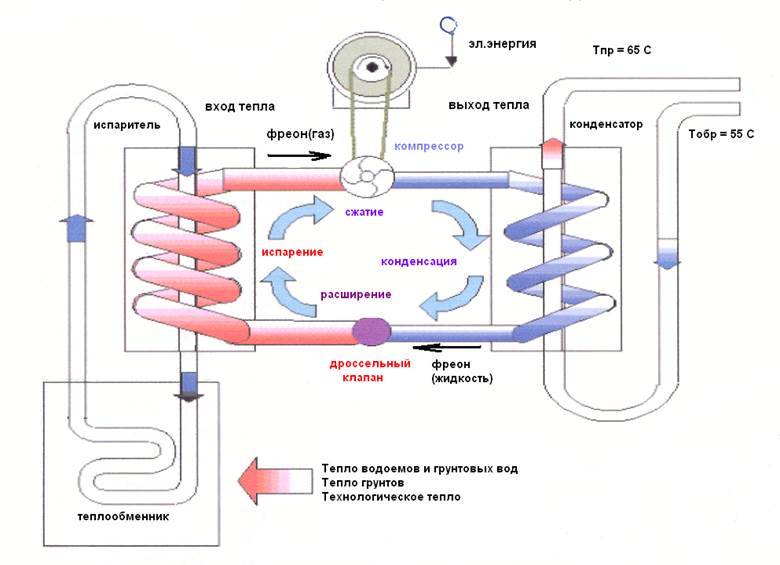

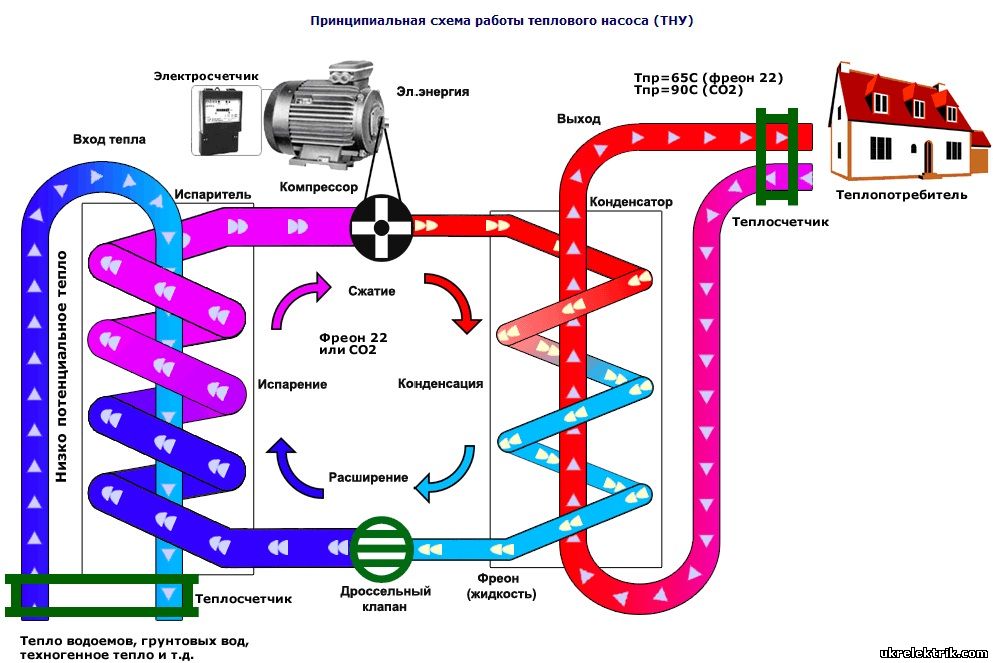

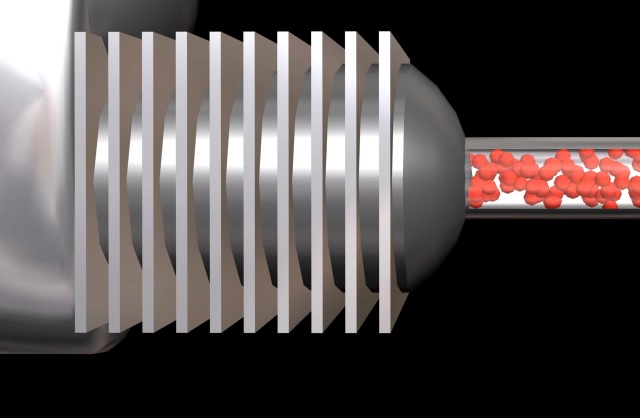

The main structural elements of heat pumps

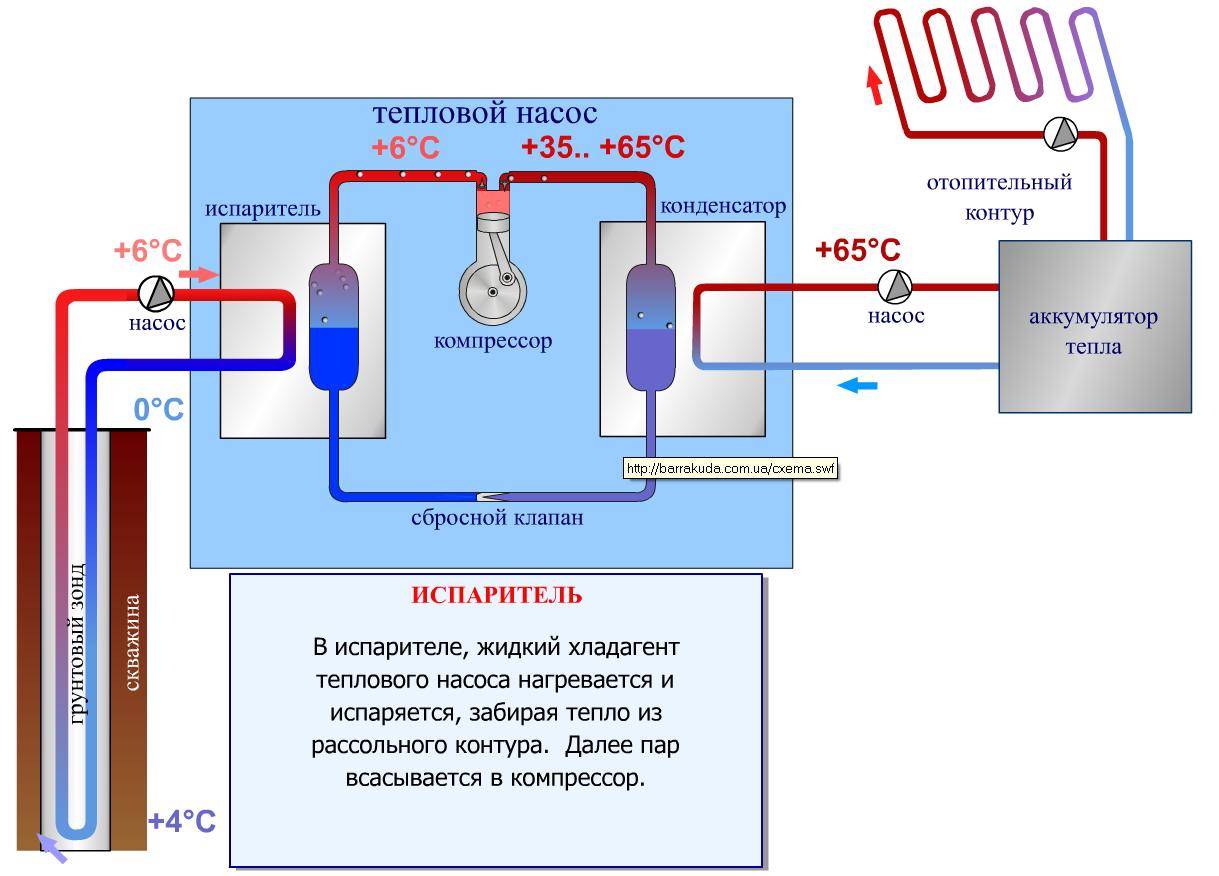

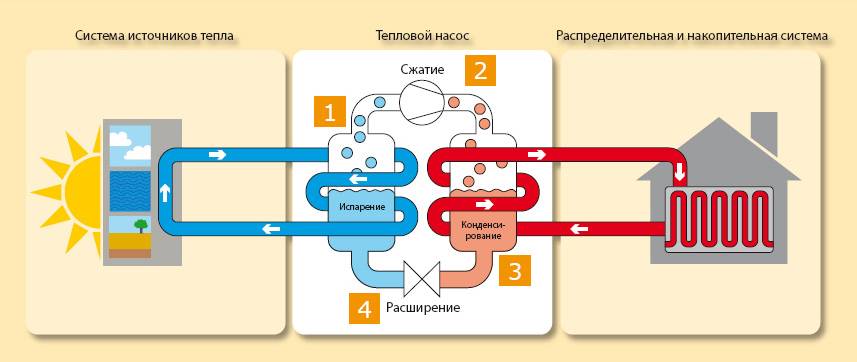

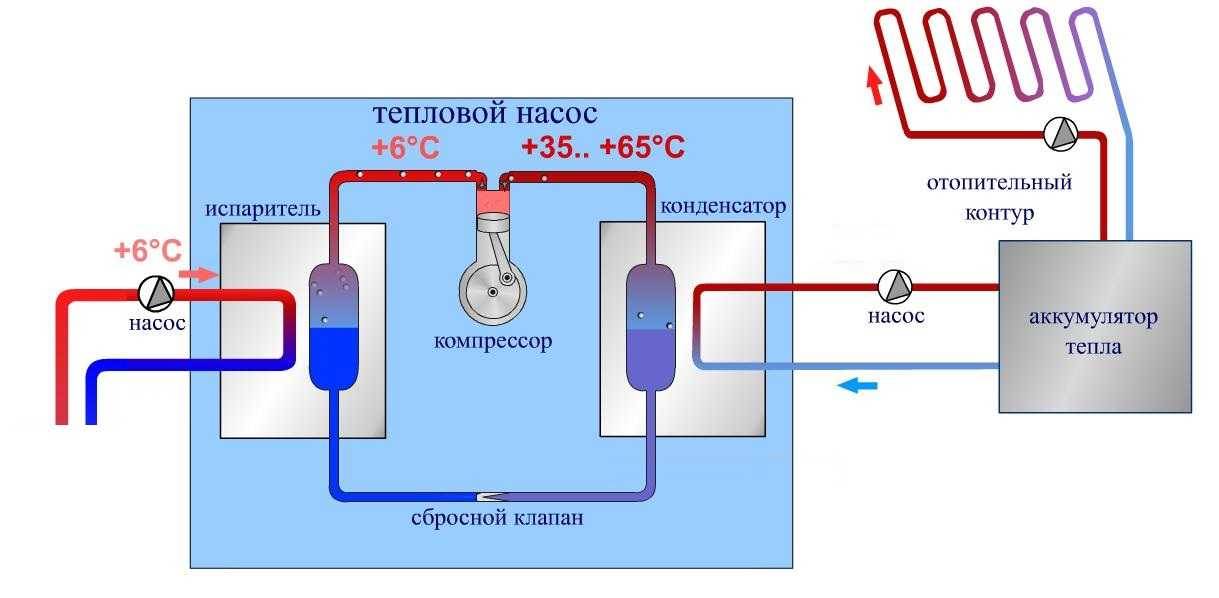

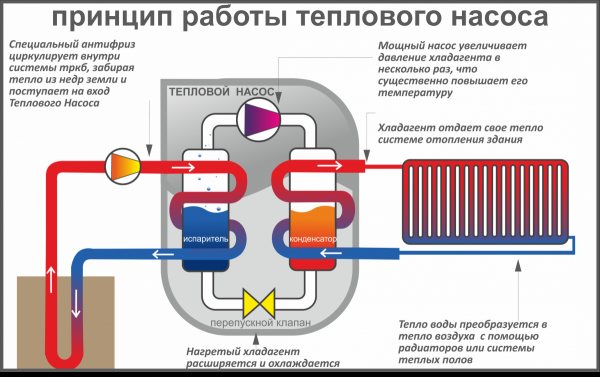

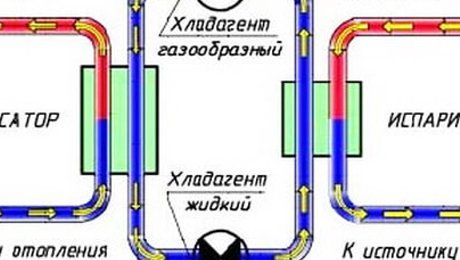

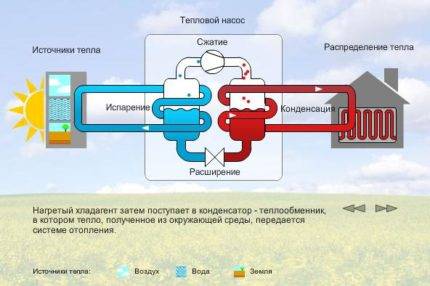

In order for the energy production unit to work according to the principles of operation of a heat pump, 4 main units must be present in its design, these are:

- Compressor.

- Evaporator.

- Capacitor.

- Throttle valve.

An important element in the design of a heat pump is the compressor. Its main function is to increase the pressure and temperature of the vapors resulting from the boiling of the refrigerant. For climate technology and heat pumps, in particular, modern scroll compressors are used.

Liquids with a low boiling point are used as a working fluid that directly transfers thermal energy. As a rule, ammonia and freons are used (+)

Liquids with a low boiling point are used as a working fluid that directly transfers thermal energy. As a rule, ammonia and freons are used (+)

Such compressors are designed for operation at sub-zero temperatures. Unlike other types, scroll compressors produce little noise and operate at both low gas evaporating temperatures and high condensing temperatures. The undoubted advantage is their compact size and low specific weight.

Almost all the energy of the heat pump is spent on transporting heat energy from the outside to the inside of the room.So, about 1 energy unit is spent on the operation of systems in the production of 4 - 6 units (+)

Almost all the energy of the heat pump is spent on transporting heat energy from the outside to the inside of the room.So, about 1 energy unit is spent on the operation of systems in the production of 4 - 6 units (+)

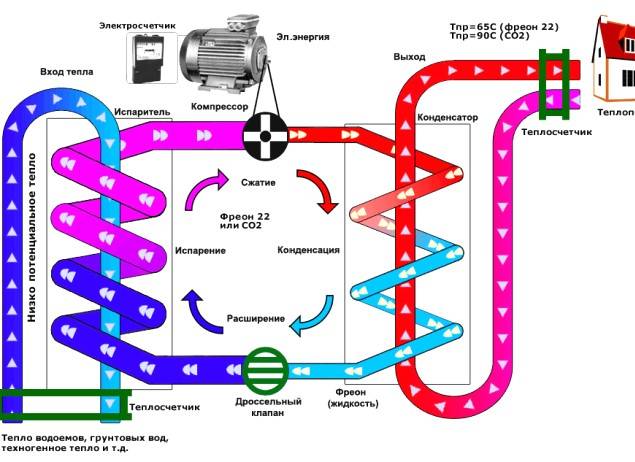

The evaporator as a structural element is a container in which the liquid refrigerant is converted into vapor. The refrigerant, circulating in a closed circuit, passes through the evaporator. In it, the refrigerant is heated and turns into vapor. The resulting low pressure steam is directed towards the compressor.

In the compressor, the refrigerant vapors are subjected to pressure and their temperature rises. The compressor pumps heated steam under high pressure towards the condenser.

The compressor compresses the medium circulating in the circuit, as a result of which its temperature and pressure increase. Then the compressed medium enters the heat exchanger (condenser), where it is cooled, transferring heat to water or air

The next structural element of the system is a capacitor. Its function is reduced to the transfer of thermal energy to the internal circuit of the heating system.

Serial samples manufactured by industrial enterprises are equipped with plate heat exchangers. The main material for such capacitors is alloy steel or copper.

For self-manufacturing of the heat exchanger, a copper tube with a diameter of half an inch is suitable. The wall thickness of the pipes used for the manufacture of the heat exchanger must be at least 1 mm

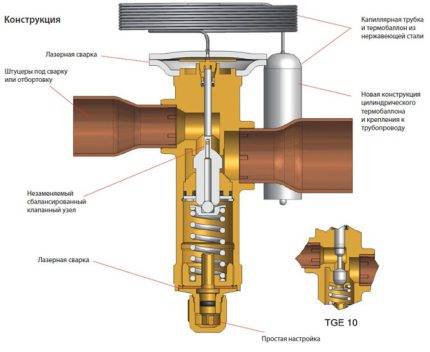

A thermostatic, or otherwise throttle, valve is installed at the beginning of that part of the hydraulic circuit where the high-pressure circulating medium is converted to a low-pressure medium. More precisely, the throttle paired with the compressor divides the heat pump circuit into two parts: one with high pressure parameters, the other with low ones.

When passing through the expansion throttle valve, the liquid circulating in a closed circuit partially evaporates, as a result of which the pressure decreases along with the temperature. Then it enters the heat exchanger communicating with the environment. There it captures the energy of the environment and transfers it back to the system.

The throttle valve regulates the refrigerant flow towards the evaporator. When choosing a valve, system parameters must be taken into account. The valve must comply with these parameters.

When passing through the heat control valve, the heat transfer liquid partially evaporates, and the flow temperature decreases (+)

When passing through the heat control valve, the heat transfer liquid partially evaporates, and the flow temperature decreases (+)

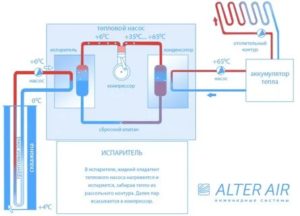

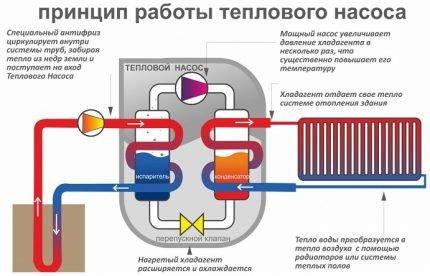

The principle of operation of heat pumps

It should be noted that almost any medium has thermal energy. Why not use the available heat to heat your home? A heat pump will help with this.

The principle of operation of a heat pump is as follows: heat is transferred to the coolant from an energy source with low potential. In practice, everything happens as follows.

The coolant passes through pipes that are buried, for example, in the ground. Then the coolant enters the heat exchanger, where the collected thermal energy is transferred to the second circuit. The refrigerant located in the outer loop, heats up, and turns into a gas. After that, the gaseous refrigerant passes into the compressor, where it is compressed. This causes the refrigerant to heat up even more. Hot gas goes to the condenser, and there the heat passes to the coolant, which already heats the house itself.

Geothermal heating at home: how it works

Refrigeration systems are arranged according to the same principle.This means that refrigeration units can be used to cool indoor air.

Types of heat pumps

There are several types of heat pumps. But most often, devices are classified by the nature of the coolant on the external circuit.

Devices can draw energy from

- water,

- soil,

- air.

The resulting energy in the house can be used for space heating, for heating water. Therefore, there are several types of heat pumps.

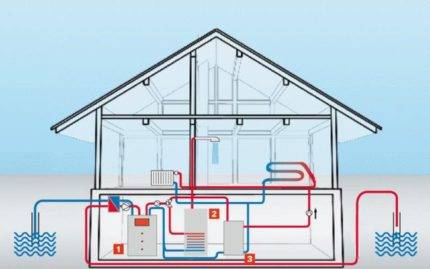

Heat pumps: ground - water

The best option for alternative heating is to obtain thermal energy from the ground. So, already at a depth of six meters, the earth has a constant and unchanging temperature. A special liquid is used as a heat carrier in the pipes. The outer contour of the system is made of plastic pipes. Pipes in the ground can be placed vertically or horizontally. If the pipes are placed horizontally, then a large area must be allocated. Where pipes are installed horizontally, it is impossible to use the land for agricultural purposes. You can only arrange lawns or plant annuals.

To arrange pipes vertically in the ground, you need to do several wells up to 150 meters. This will be an efficient geothermal pump, since the temperature is high at a great depth near the earth. Deep probes are used for heat transfer.

Type of water-to-water pump

In addition, heat can be obtained from water, which is located deep underground. Ponds, groundwater or wastewater can be used.

It should be noted that there are no fundamental differences between the two systems. The smallest costs are required when a system for obtaining heat from a reservoir is created.Pipes must be filled with coolant and immersed in water. A more complex design is needed in order to create a system for generating heat from groundwater.

Air-to-water pumps

It is possible to collect heat from the air, but in regions with very cold winters, such a system is not effective. At the same time, the installation of the system is very simple. You only need to select and install the desired device.

A little more about the principle of operation of geothermal pumps

For heating it is very advantageous to use heat pumps. Houses with an area of more than 400 square meters pay off the costs of the system very quickly. But if your house is not very large, then you can make a heating system with your own hands.

First you need to buy a compressor. A device that is equipped with a conventional air conditioner is suitable. We mount it on the wall. You can make your own capacitor. It is necessary to make a coil from copper pipes. It is placed in a plastic case. The evaporator is also wall mounted. Soldering, refilling with freon and similar work should only be carried out by a professional. Inept actions will not lead to a good result. Moreover, you can get injured.

Before putting the heat pump into operation, it is necessary to check the condition of the electrification of the house. Power counter should be rated for 40 amps.

Homemade thermal geothermal pump

Note that a heat pump created by oneself does not always live up to expectations. The reason for this is the lack of correct thermal calculations. The system is underpowered and maintenance costs are rising

Therefore, it is important to carry out all calculations accurately.

Bivalent heating scheme ↑

The use of such a scheme will help to save at the stage of manufacture and installation of the pump.The fact is that the calculation of the power of the heat pump is based on the minimum possible temperature. But after all, peak low temperatures are outside only for a very short time, which means that for most of the year the heat pump will use only part of its power potential.

In order to be able to install a less powerful pump, an additional heat source is connected in parallel with it - an electric boiler. Then, in severe frosts, you can additionally "heat" the room. Given that there are few such days in a year, such heating will not hit your wallet hard, and you can save a lot on the cost of the pump.

It is also possible to use in as optional equipment solid fuel boilers. In this case, in the heating system must be switched on bypass.

What is a heat pump and how does it work?

The term heat pump refers to a set of specific equipment. The main function of this equipment is the collection of thermal energy and its transportation to the consumer. The source of such energy can be any body or medium with a temperature of +1º and more degrees.

There are more than enough sources of low-temperature heat in our environment. These are industrial waste from enterprises, thermal and nuclear power plants, sewage, etc. For the operation of heat pumps in the field of home heating, three independently recovering natural sources are needed - air, water, earth.

Heat pumps “draw” energy from processes that regularly occur in the environment. The flow of processes never stops, therefore the sources are recognized as inexhaustible according to human criteria.

The three listed potential energy suppliers are directly related to the energy of the sun, which, by heating, sets the air and wind in motion and transfers thermal energy to the earth. It is the choice of source that is the main criterion according to which heat pump systems are classified.

The principle of operation of heat pumps is based on the ability of bodies or media to transfer thermal energy to another body or environment. Recipients and suppliers of energy in heat pump systems usually work in pairs.

So there are the following types of heat pumps:

- Air is water.

- Earth is water.

- Water is air.

- Water is water.

- Earth is air.

- Water - water

- Air is air.

In this case, the first word defines the type of medium from which the system takes low-temperature heat. The second indicates the type of carrier to which this thermal energy is transferred. So, in heat pumps water is water, heat is taken from the aquatic environment and liquid is used as a heat carrier.

Heat pumps by design type are vapor compression plants. They extract heat from natural sources, process and transport it to consumers (+)

Heat pumps by design type are vapor compression plants. They extract heat from natural sources, process and transport it to consumers (+)

Modern heat pumps use three main sources of heat energy. These are soil, water and air. The simplest of these options is an air source heat pump. The popularity of such systems is associated with their rather simple design and ease of installation.

However, despite such popularity, these varieties have a rather low productivity. In addition, the efficiency is unstable and dependent on seasonal temperature fluctuations.

With a decrease in temperature, their performance drops significantly.Such variants of heat pumps can be considered as an addition to the existing main source of thermal energy.

Equipment options that use ground heat are considered more efficient. The soil receives and accumulates thermal energy not only from the Sun, it is constantly heated by the energy of the earth's core.

That is, the soil is a kind of heat accumulator, the power of which is practically unlimited. Moreover, the temperature of the soil, especially at a certain depth, is constant and fluctuates within insignificant limits.

Scope of energy generated by heat pumps:

The constancy of the source temperature is an important factor in the stable and efficient operation of this type of power equipment. Systems in which the aquatic environment is the main source of thermal energy have similar characteristics. The collector of such pumps is located either in the well, where it is in the aquifer, or in the reservoir.

The average annual temperature of sources such as soil and water varies from +7º to + 12º C. This temperature is quite enough to ensure the efficient operation of the system.

The most efficient are heat pumps that extract heat energy from sources with stable temperature indicators, i.e. from water and soil

How to make a do-it-yourself unit?

Regardless of which resource option (land, water or air) is chosen for heating, a pump will be needed for the system to function correctly.

This device consists of such elements as:

- compressor unit (intermediate element of the complex);

- an evaporator that transfers low-potential energy to the coolant;

- throttle valve through which the refrigerant finds its way back to the evaporator;

- condenser, where freon gives off thermal energy and cools to its original temperature.

You can buy a complete system from the manufacturer, but it will cost a decent amount. When there is no free money at hand, it is worth making a heat pump with your own hands from the parts at your disposal and, if necessary, buying the missing spare parts.

When planning the installation of a geothermal heating system in a private house, first of all, you need to take care of reducing the level of heat loss. To do this, the walls must be insulated with a special material, doors and window frames should be provided with foam pads, and the floor and ceiling should be protected with foam panels. Then the heat released by the pump will remain inside the room to the maximum extent.

When the decision to make a heat pump with your own hands is made, it is imperative to check the condition of the electrical wiring and electricity meter available in the house.

If these elements are worn and old, it is necessary to view all areas, to detect possible faults and fix them even before the start of work. Then the system will work flawlessly immediately after launch and will not disturb the owners with short circuits, wiring fires and knocking out traffic jams.

Method #1. Assembling from the refrigerator

To assemble the heat pump with your own hands, the coil located at the back is removed from the old refrigerator. This part is used as a capacitor and placed in a high-strength container that is resistant to aggressive temperatures.A properly working compressor is attached to it, and a simple plastic barrel is used as an evaporator.

If a very old refrigerator is used to create a pump, it is better to replace the freon in it with a new one. This cannot be done on your own, so you will have to invite a master with special equipment. It will quickly replace the working fluid, and the system will work in the desired mode.

The prepared elements are interconnected, and then the created unit is connected to the heating system by means of polymer pipes and the equipment is put into operation.

Method #2. Air conditioner heat pump

In order to make a heat pump, the air conditioner is modified and some of the main components are re-planned. First, the outdoor and indoor units are swapped.

The evaporator responsible for the transfer of low-grade heat is not installed additionally, since it is located in the indoor unit of the unit, and the condenser that transfers thermal energy is in the outdoor unit. Both air and water are suitable as a heat carrier.

If this installation option is not convenient, the condenser is installed in a separate tank designed for correct heat exchange between the heating resource and the coolant.

The system itself is supplied with a four-way valve. For this work, a specialist with professional skills and experience in conducting events of this kind is usually invited.

Modern split systems are ineffective at low temperatures, so professionals do not recommend using them for self-production of heat pumps

In the third option, the air conditioner is completely disassembled into its component parts, and then a pump is assembled from them according to the traditional generally accepted scheme: evaporator, compressor, condenser. The finished device is attached to the equipment heating the house and begin to use.

The site has a series of articles on making heat pumps with your own hands, we advise you to read:

- How to make a heat pump for home heating with your own hands: the principle of operation and assembly diagrams

- How to make an air-to-water heat pump: device diagrams and self-assembly

Specifics of application and work

The heat pump is working productively exclusively in the temperature range from -5 to +7 degrees. At an air temperature of +7, the system will generate more heat than necessary, and at an indicator below -5, it will not be enough for heating. This is due to the fact that the concentrated freon in the structure boils at a temperature of -55 degrees.

- When installing a heat pump, air, water, a small, neat device will appear on the facade of the house.

- Like any heat pump, the air-to-water system consists of two interconnected parts: external and internal.

- The unit of equipment located inside the house recycles the energy borrowed from the air, heating water for heating and hot water circuits.

- If it is necessary to increase the performance of the system, the external complex is supplemented with the required number of modules.

- Air-to-water heat pumps do an excellent job of heating the water involved in heating systems.

- Thermal air-to-water installations will provide warm water to bathrooms and kitchens of private houses with autonomous engineering systems.

- One of the most common energy consumers of air-to-water heat pumps is a water heated floor.

- Low-temperature circuits are connected to the heat pump as an energy source.

Theoretically, the system can generate heat even in 30-degree frost, but it will not be enough for heating, because the heat output directly depends on the difference between the boiling point of the refrigerant and the air temperature.

Therefore, residents of the Northern regions, where colds come earlier, this system will not work, and in the homes of the Southern regions, it can effectively serve for several cold months.

Also, the room itself should be well insulated from the outside, have built-in multi-chamber windows that provide better thermal insulation than ordinary wooden or plastic ones.

The home assembly device is ideal for supplying heat to a garage, greenhouse, utility room, small private pool, etc. The system is usually used as additional heating.

Electric boiler or other traditional heating equipment season will be needed anyway. During severe frosts (-15-30 degrees), it is recommended to turn off the heat pump in order to avoid wasting electricity, because during this period its efficiency is no more than 10%.

Conclusions and useful video on the topic

The video clearly shows how a heating system based on geothermal air-to-water heating equipment is equipped in a large house from a gas silicate block. Some interesting nuances regarding the installation of equipment are revealed and real numbers of utility bills are announced. monthly payments.

How does land-to-water equipment work?A detailed description from a specialist in the installation of geothermal thermal boilers, recommendations and useful tips for home craftsmen from a professional in their field.

A real user of the equipment shares his impressions of the geothermal heat pump.

A professional locksmith tells how to make a heat pump at home based on a powerful compressor and tubular heat exchange parts. Detailed step by step instructions.

Geothermal pump for private heating home ownership is a good way to create comfortable living conditions even where centralized communication systems and more familiar sources of energy are not available.

The choice of system depends on the territorial location of the property and the financial capabilities of the owners.

Do you have experience in manufacturing a geothermal heat pump? Please share information with our readers, suggest your build option. You can leave comments and attach photos of your homemade products in the form below.