- Types of heat exchangers

- "Water - water"

- "Water - air"

- "Air - air"

- "Air - water"

- "Earth - water"

- "Earth - air"

- How to make a heat pump with your own hands from an old refrigerator

- Assembling the units and installing the heat pump

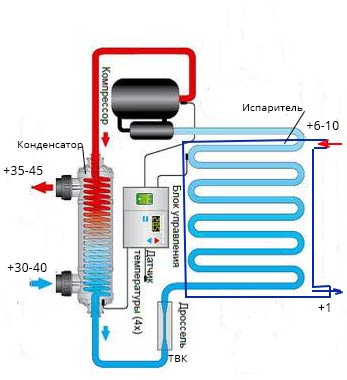

- Principle of operation

- The principle of operation of the air-to-water pump

- Video overview of the system device and its operation

- Inverter heat pumps

- Types of heat pumps for home heating

- Types of homemade heaters from the refrigerator

- Types of pumps

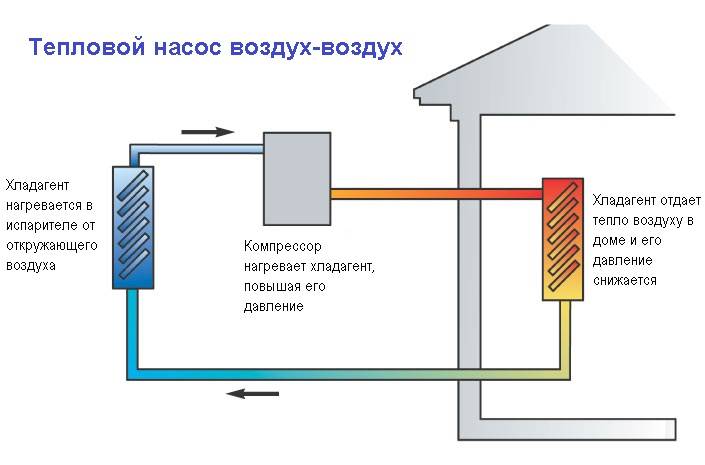

- Air to air

- Air to water

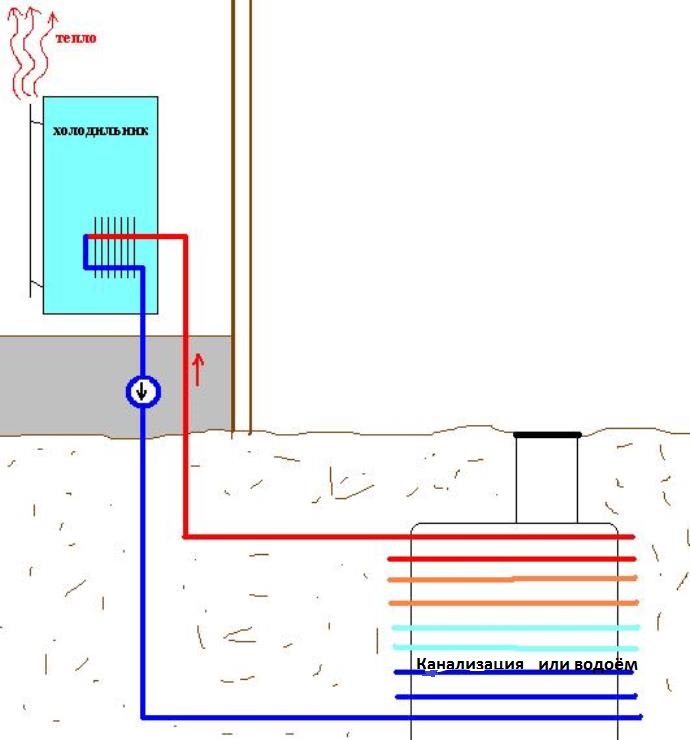

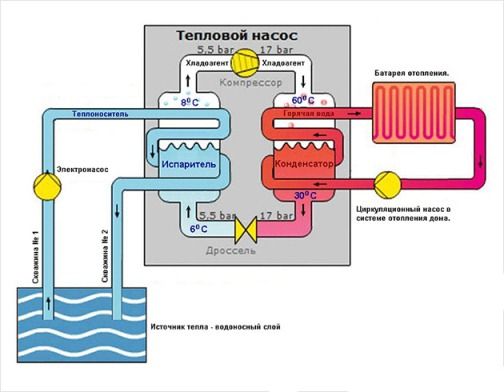

- water-water

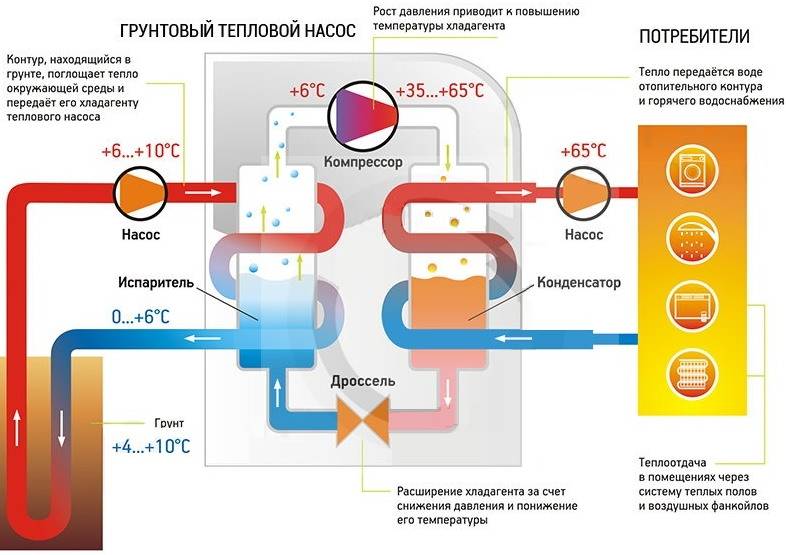

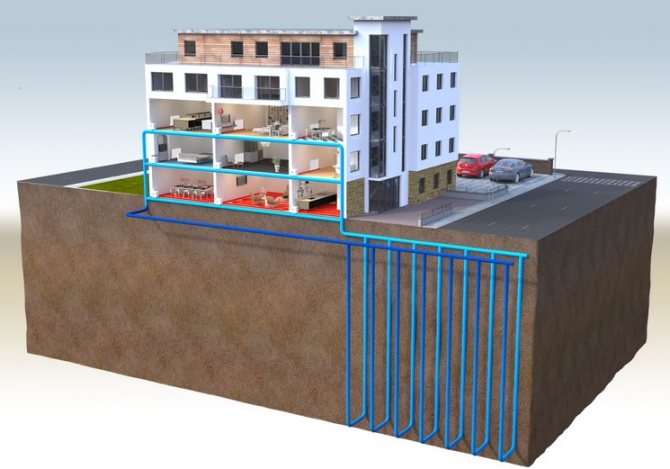

- Geothermal

- Heat pump for home heating, principle of operation

- Pros and cons

- Production of a geothermal installation

- Calculation of the circuit and pump heat exchangers

- Necessary equipment and materials

- How to assemble the heat exchanger

- Arrangement of the soil contour

- Refueling and first start

- Homemade heat pump from the refrigerator: stages of creation

- Characteristics

- Properties and device

- Manufacturing and installation

Types of heat exchangers

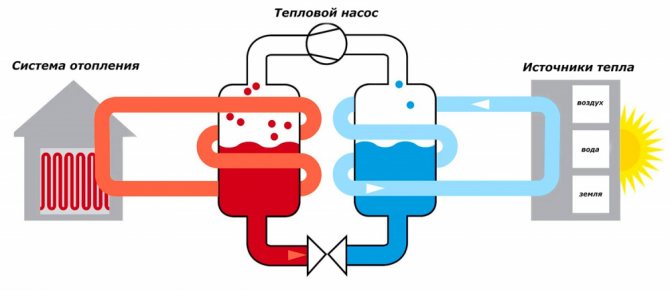

In the type designation of the heat pump heat exchanger, the first indicator determines the method of arranging the external circuit of the heat supply system, and the second - the device of the internal circuit.

"Water - water"

In heat exchangers of this type, heat is taken from water bodies (well, river, lake, etc.), solar energy or other objects.In the primary circuit, a coolant circulates - water, or another liquid. Circulation is carried out by creating pressure through the installation of a pump.

The circuit can be closed or open, which option to choose is determined by the type of coolant. In the heat pump, in the internal circuit, freon circulates, which, receiving energy from the external circuit, evaporates, enters the condenser, where it transfers the received heat to the consumer's coolant.

"Water - air"

In this type of heat exchangers, the energy collected in the external circuit, in which the liquid (water or other energy carrier) circulates, enters the heat pump heat exchangers, where it is transferred to the indoor air.

"Air - air"

In heat exchangers of this type, the external circuit is located on the outside of the building, it is the evaporator in this pump design. The heat from the outside air heats the refrigerant, which evaporates. Further, passing through the compressor, it is compressed and enters the indoor unit - the condenser, which is located inside the building. The condenser gives off heat to the air inside the room in which it is located, the refrigerant again enters the evaporator.

"Air - water"

In this type of heat exchanger, thermal energy is taken from the outside air. The air enters the compressor, where, under the action of pressure, its temperature rises, after which it enters the heat exchanger. In the heat exchanger, the supplied air is condensed and energy is transferred to the energy carrier of the consumer's heating system.

"Earth - water"

Heat exchangers of this type are based on obtaining the energy of the earth and transferring it to consumers. Brine (antifreeze) circulates in a closed external circuit located below the freezing level.Circulation is carried out by installing a pump. The brine enters the heat pump condenser, where it transfers the received energy to the refrigerant, which in turn transfers it to the consumer's heating system by condensation in the pump's heat exchanger.

"Earth - air"

In this type of heat exchangers, the thermal energy received by the brine circulating in the external circuit, which is located under the surface of the earth, is transferred to the indoor air in the heat exchanger chambers.

How to make a heat pump with your own hands from an old refrigerator

Before proceeding with the manufacture of a heat pump, it is necessary to select a heat source and resolve the issue with the scheme of operation of the installation. In addition to the compressor, you will need other equipment, as well as tools. Implementation of diagrams and drawings. To install a heat pump, you need to make a well, because the energy source must be underground. The depth of the well should be such that the temperature of the earth is at least 5 degrees. For this purpose, any reservoirs are also suitable.

The designs of heat pumps are similar, so no matter what the heat source will be, you can use almost any scheme found on the net. When the scheme is selected, it is necessary to complete the drawings and indicate in them the dimensions and junctions of the nodes.

Since it is rather difficult to calculate the power of the installation, you can use the average values. For example, a dwelling with low heat loss will require a heating system with a power of 25 watts per square meter. meter. For a building that is well insulated, this value will be 45 watts per square meter. meter. If the house has sufficiently high heat losses, the installation power should be at least 70 W per sq. meter.

Selecting the required details. If the compressor removed from the refrigerator is broken, then it is preferable to purchase a new one. It is not recommended to repair the old compressor, because in the future this may adversely affect the operation of the heat pump.

A thermostatic valve and 30 cm L-brackets will also be needed to make the device.

Additionally, you will need to purchase the following parts:

- sealed stainless steel container with a volume of 120 liters;

- plastic container with a volume of 90 liters;

- three copper pipes of different diameters;

- plastic pipes.

To work with metal parts, you will need a welding machine and a grinder.

Assembling the units and installing the heat pump

First of all, you should install the compressor on the wall using brackets. The next step is to work with the capacitor. The stainless steel tank must be divided into two parts using a grinder. A copper coil is mounted in one of the halves, then the container must be welded and threaded holes made in it.

To make a heat exchanger, you need to wind a copper pipe around a stainless steel container and fix the ends of the turns with slats. Attach plumbing transitions to the conclusions.

It is also necessary to attach a coil to the plastic tank - it will act as an evaporator. Then fasten it to the wall section with brackets.

As soon as work with the nodes is completed, you need to select a thermostatic valve. The design should be assembled and filled with freon system (R-22 or R-422 brand is suitable for this purpose).

Connection to the intake device. The type of device and the nuances of connecting to it will depend on the scheme:

- "Water-Earth". The collector should be installed below the frost line of the ground.It is necessary that the pipes are at the same level.

- "Water-air". Such a system is easier to install, since there is no need for drilling wells. The collector is mounted anywhere near the house.

- "Water-water". The collector is made of metal-plastic pipes, and then placed in a reservoir.

You can also install a combined heating system to heat your home. In such a system, the heat pump works simultaneously with the electric boiler and is used as an additional source of heating.

It is quite possible to assemble a heat pump for heating a house yourself. Unlike buying a ready-made installation, this will not require large financial costs, and the result will certainly please.

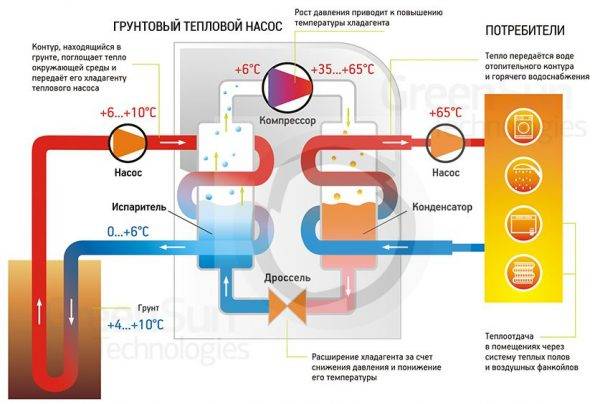

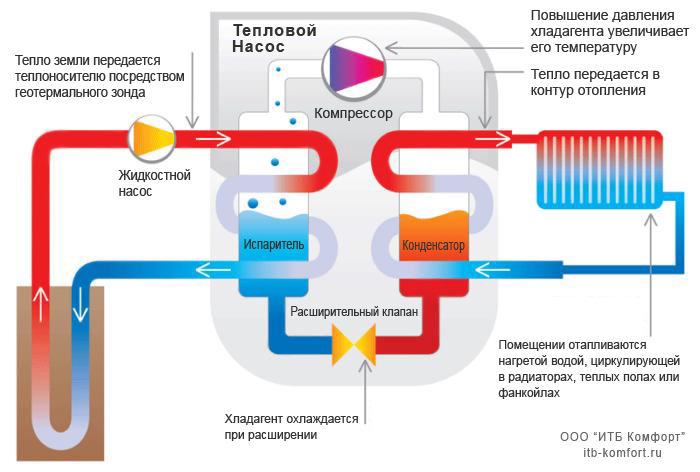

Principle of operation

All the space around us is energy - you just need to know how to use it. For a heat pump, the ambient temperature must be greater than 1C°. Here it should be said that even the earth in winter under snow or at some depth retains heat. The work of a geothermal or any other heat pump is based on the transportation of heat from its source using a heat carrier to the heating circuit of the house.

Scheme of operation of the device by points:

- the heat carrier (water, soil, air) fills the pipeline under the soil and heats it;

- then the coolant is transported to the heat exchanger (evaporator) with subsequent heat transfer to the internal circuit;

- the external circuit contains the refrigerant, a liquid with a low boiling point under low pressure. For example, freon, water with alcohol, glycol mixture. Inside the evaporator, this substance is heated and becomes a gas;

- the gaseous refrigerant is sent to the compressor, compressed under high pressure and heated;

- hot gas enters the condenser and there its thermal energy is transferred to the heat carrier of the house heating system;

- the cycle ends with the conversion of the refrigerant into a liquid, and it, due to heat loss, returns back to the system.

The same principle is used for refrigerators, so home heat pumps can be used as air conditioners to cool a room. Simply put, a heat pump is a kind of refrigerator with the opposite effect: instead of cold, heat is generated.

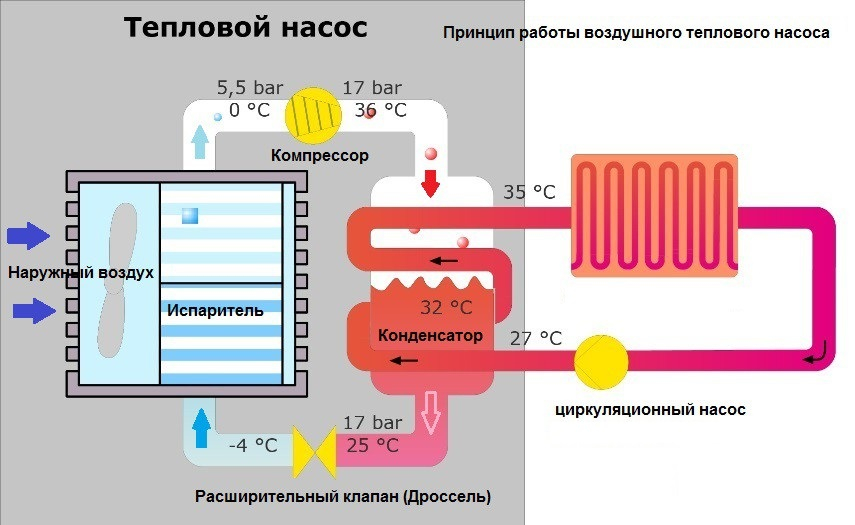

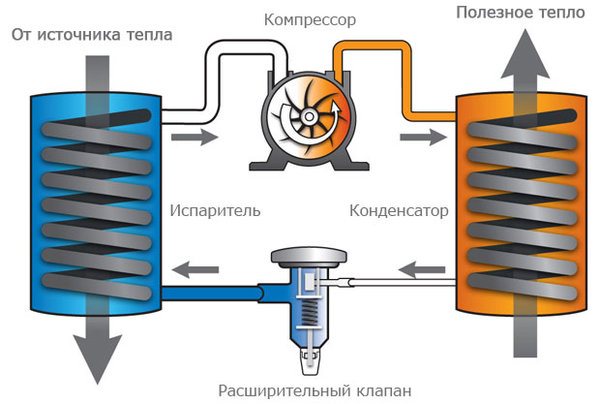

The principle of operation of the air-to-water pump

As already mentioned, the main source of thermal energy for installations of this type is atmospheric air. The fundamental basis of the operation of air pumps is the physical property of liquids to absorb and release heat during the phase transition from a liquid state to a gaseous state, and vice versa. As a result of the change of state, the temperature is released. The system works on the principle of a refrigerator in reverse.

To effectively use these properties of the liquid, a low-boiling refrigerant (freon, freon) circulates in a closed circuit, the design of which includes:

- compressor with electric drive;

- fan blown evaporator;

- throttle (expansion) valve;

- plate heat exchanger;

- copper or metal-plastic circulation tubes connecting the main elements of the circuit.

The movement of the refrigerant along the circuit is carried out due to the pressure developed by the compressor. To reduce heat losses, the pipes are covered with a heat-insulating layer of artificial rubber or polyethylene foam with a protective metallized coating.As a refrigerant, freon or freon is used, which can boil at a negative temperature and does not freeze up to -40 ° C.

The whole process of work consists of the following successive cycles:

- The evaporator radiator contains a liquid refrigerant that is cooler than the outside air. During active radiator blowing, thermal energy from low-potential air is transferred to freon, which boils and passes into a gaseous state. At the same time, its temperature rises.

- The heated gas enters the compressor, where it heats up even more during the compression process.

- In a compressed and heated state, the refrigerant vapor is fed into a plate heat exchanger, where the heat carrier of the heating system circulates through the second circuit. Since the temperature of the coolant is much lower than that of the heated gas, freon actively condenses on the heat exchanger plates, giving off heat to the heating system.

- The cooled vapor-liquid mixture enters the throttle valve, which allows only the cooled low-pressure liquid refrigerant to pass to the evaporator. Then the whole cycle is repeated.

To increase the heat transfer efficiency of the tube, spiral fins are wound on the evaporator. The calculation of the heating system, the choice of circulation pumps and other equipment must take into account the hydraulic resistance and the heat transfer coefficient of the plate heat exchanger of the installation.

Video overview of the system device and its operation

Inverter heat pumps

The presence of an inverter as part of the installation allows for a smooth start-up of the equipment and automatic regulation of modes depending on the outdoor temperature. This maximizes the efficiency of the heat pump by:

- achievement of efficiency at the level of 95-98%;

- reducing energy consumption by 20-25%;

- minimization of loads on the electrical network;

- increase the service life of the plant.

As a result, the indoor temperature is stably maintained at the same level, regardless of weather changes. At the same time, the presence of an inverter complete with an automated control unit will provide not only heating in winter, but also the supply of cooled air in summer in hot weather.

At the same time, it should be taken into account that the presence of additional equipment always entails an increase in its cost and an increase in the payback period.

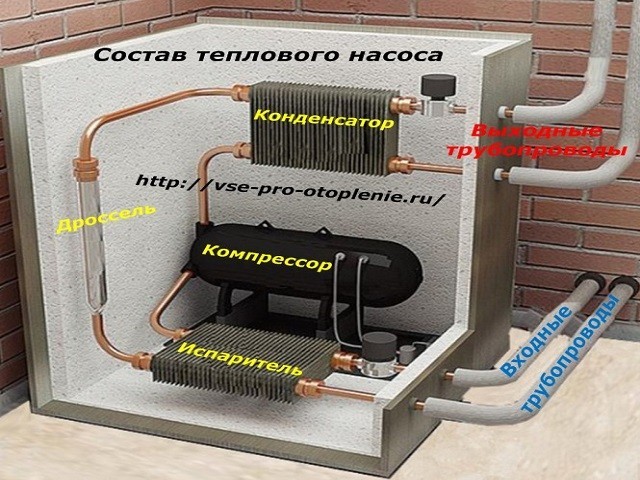

Types of heat pumps for home heating

There are compression and absorption heat pumps. Installations of the first type are the most common, and it is this heat pump that can be assembled from a refrigerator or an old air conditioner using a ready-made compressor.

You will also need an expander, evaporator, condenser. For the operation of absorption plants, an absorbent freon is required.

Heat pumps are most often assembled from units of air conditioners and refrigerators. Such handicraft designs are simple, effective, and if the master has the skills of such work, they can be done in just a few days.

According to the type of heat source, installations are air, geothermal, and also using secondary heat (for example, waste water, etc.). One or two different coolants are used in the inlet and outlet circuits, and depending on this, the following types of equipment are distinguished:

- "air-to-air";

- "water-water";

- "water-air";

- "air-water";

- "ground-water";

- "ice-water".

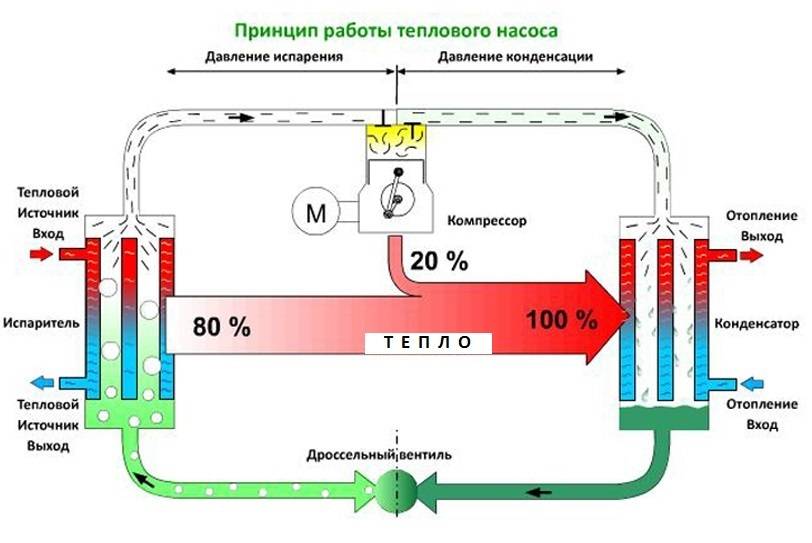

A system can only be efficient if it consumes less energy than it delivers. This difference is called the conversion factor.It depends on many factors, but the most significant is the temperature of the coolant inlet and outlet circuits. The larger the difference, the better the system works.

Image gallery

Photo from

The source of heat is the air from the street. The units are connected to water heating systems. They are able to work effectively while the outdoor air temperature is above -25 degrees. The temperature of the water in the heating system can reach 63 degrees

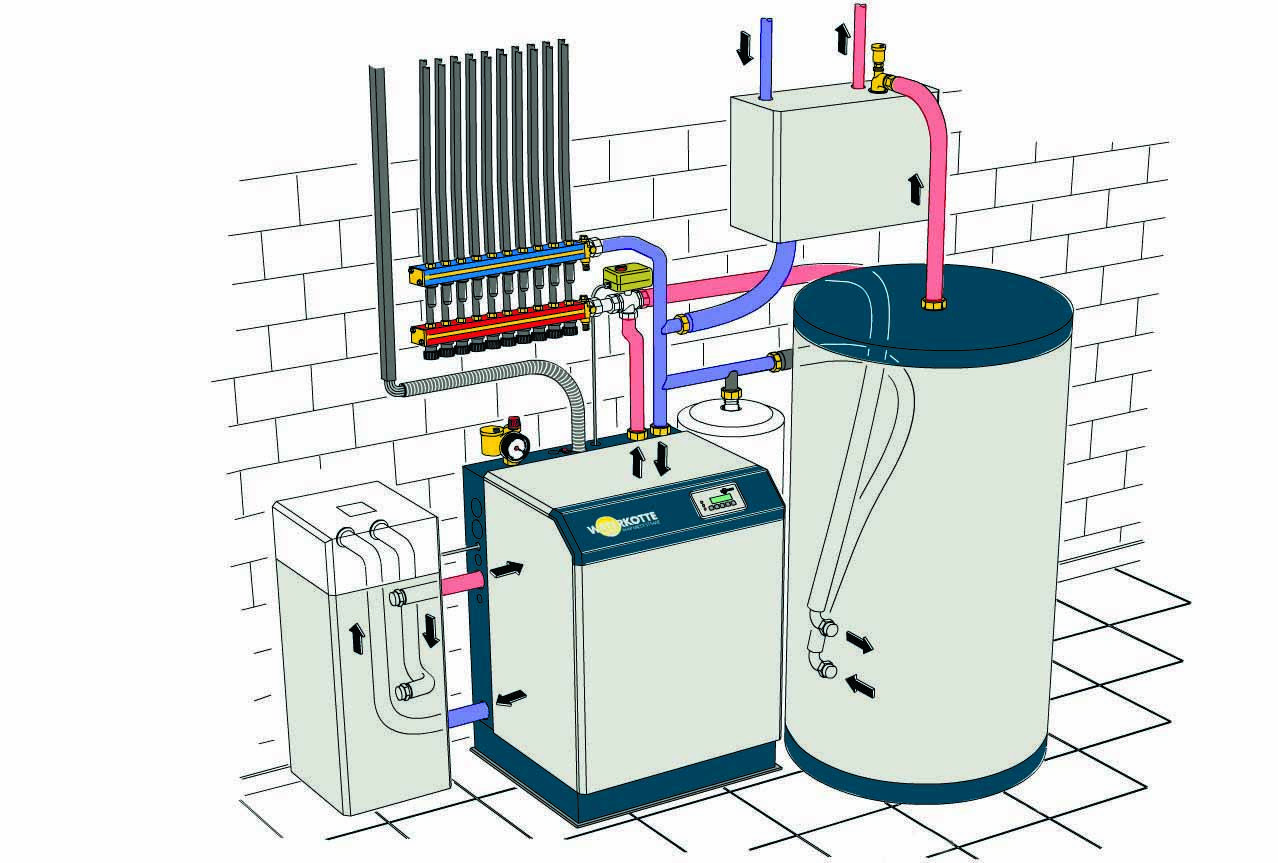

The equipment is intended for heating buildings at the expense of water resources. It is installed in areas located near natural reservoirs. Horizontal heat pumps of this type take energy from the bottom layers of water, and vertical ones are designed to extract heat from groundwater and groundwater.

Professional installation of a geothermal pump is an expensive service, but the cost is repaid through low operating costs. Installations differ in the increased reliability and safety. They are weather-dependent and designed for connection to low-temperature heating systems, which include underfloor heating.

The units generate heat while simultaneously freezing water. By turning 100-200 liters of water into ice, you can get enough energy for 1 hour of heating a medium-sized house. Solar collectors and a tank with plenty of clean water are needed for the system to function.

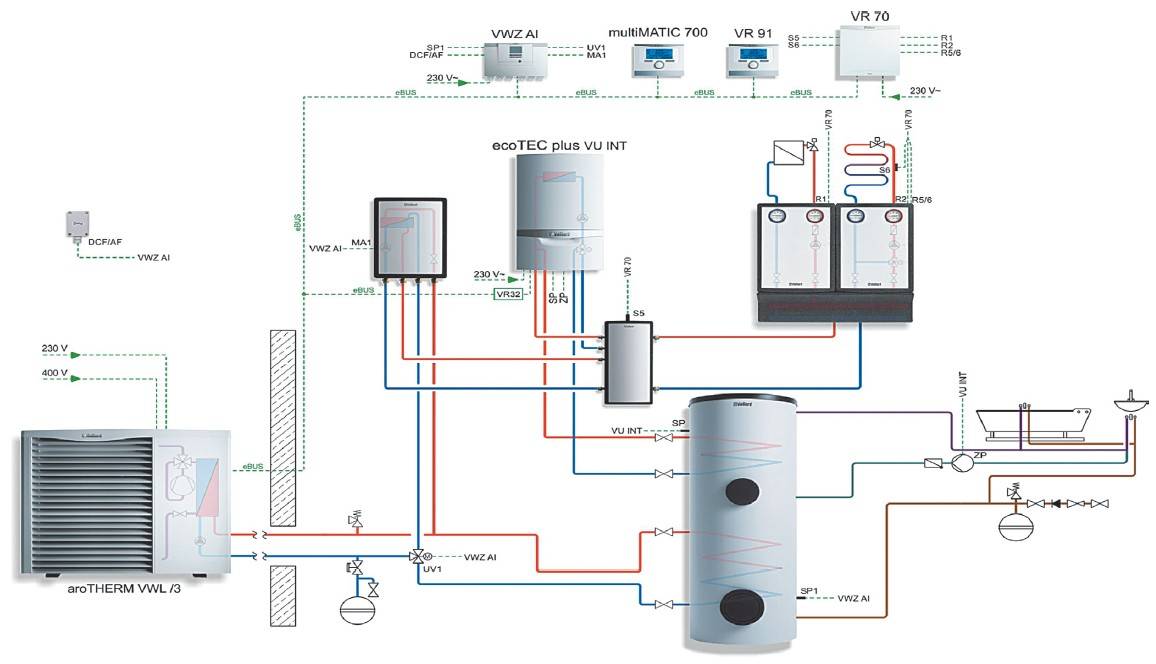

Air-to-water heat pump

Block diagram for several heat pumps

Geothermal heat pump for home

Heat pump "ice-water"

There are no reliable formulas for calculating the performance of heat pumps, because their work depends on many factors.

A self-assembly thermal installation cannot be expected to be as efficient as industrial production equipment, but it is quite enough to create an economical additional heating system.

Types of homemade heaters from the refrigerator

According to the type of energy source used, heat pumps for the home are divided into the following types:

- geothermal (open and closed);

- air.

Units using secondary heat sources are usually installed at enterprises, since their operating cycle is associated with energy generation, which requires additional utilization.

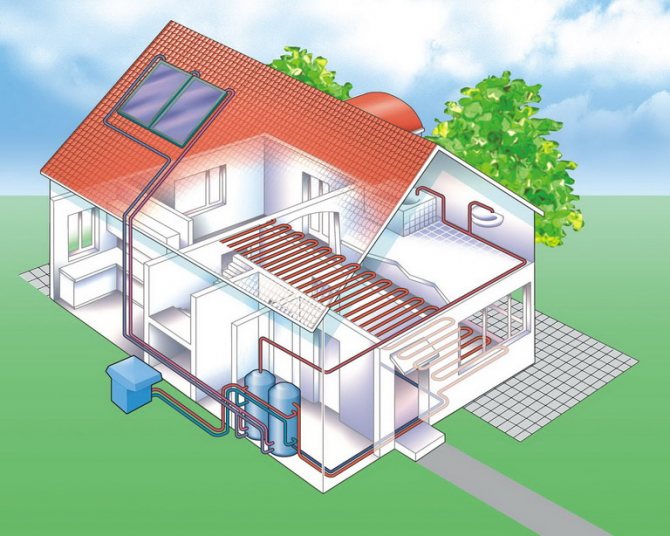

In geothermal pumps, the source of energy is soil or groundwater. Closed-circuit devices are divided into:

- Horizontal. The collector that collects heat is in the form of rings or zigzags. It is placed horizontally in trenches at a depth of more than 1.3 m. The distance between the pipes is about 1.5 m. Such heat pumps are used to heat a small area. If the soil is sandy, then the length of the contour is increased by 2 p., Since it is not able to retain moisture.

- Vertical. Differs in a vertical arrangement of a collector of a heat collector. The depth of the well is about 200 m. They are filled with groundwater, which subsequently gives off heat. This version of the system is used if there is no possibility of its horizontal placement or there is a high threat of damage to the landscape. 1 m of well gives 50-60 W of energy, so for a pump with a power of 10 kW, it is enough to drill 170 m. To get more heat, you need to make several small wells at a distance of 20 m from each other.

- Water.The shape of the collector is identical to the horizontal type of the heat pump, but it is located at the bottom of the reservoir, below the freezing level (depth - from 2 m). This method of system installation is usually less expensive. The cost depends on the location of the reservoir, its depth and the total volume of water.

In open-type pumps, the water used for heat exchange is discharged back into the ground.

The circuit of water heat pumps is made of plastic pipes, which are pressed to the bottom of the reservoir at the rate of 5 kg per 1 m of length. Every 1 p.m. circuit gives about 30 kW of energy. If you need a system with a power of 10 kW, then the length of the circuit should be at least 300 m. The advantages of the design include ease of installation, low cost. The downside is the impossibility of heating the room in severe frosts, since energy is not received.

As the name implies, in air source heat pumps the energy source is air. These units are suitable for areas with a hot climate, since at sub-zero temperatures performance will be greatly reduced. The main advantage is the absence of large material costs for drilling wells. The system is located close to home.

The efficiency of a pump depends on its conversion factor, which is the difference between the input and output energy. The main factor influencing this value is the temperature of the inlet and outlet circuits. The system will work better if the difference between these parameters is large.

Types of pumps

There are various types of heat pumps, but all of them are based on the principle of obtaining heat or cold by separating heat energy and transferring it. Only one Frenette TN is different. The cavitation method of obtaining thermal energy using a hydrodynamic generator is a type of heat pump.

The thermal energy that is used to heat the building is the result of the energy conversion carried out by the heat pump. Moreover, they receive heat without burning fuel, but by cooling the external environment and releasing thermal energy inside the room, that is, in this case, the law of conservation of energy is observed: how much thermal energy is taken from the external environment, the same amount is released inside the building. Most of these household devices use the heat of the sun, which is stored on the ground, water or air.

Therefore, according to the type of primary circuit, all structures can be divided into air, ground and water.

According to the type of coolant (W - water, D - soil) in the circuits, pumps can be divided into eight types:

- B-B;

- G-V;

- G - air;

- air-B;

- air-air;

- To the air;

- refrigerant-B;

- coolant is air.

They can also use the heat of the exhaust air, heating the supply air, that is, they can operate in the recovery mode.

Air to air

The principle of operation of a heat pump is similar to that used in an air conditioner in heating mode, but with one difference. The heat pump is set to heat and the air conditioner to lower the temperature in the room.

The principle of operation of the B-B installation is as follows: even at low temperatures, air has a certain amount of energy. Only at absolute zero is there no thermal energy.Most heat pumps are able to receive heat at a temperature of -15 °C. Currently, some manufacturers produce stations that retain heat extraction at -30 °C. Heat is taken in by the evaporation of freon, which circulates through the internal circuit. For this purpose, an evaporator is used, in which the refrigerant is converted from a liquid state to a gaseous state. This absorbs heat.

The next block, which is located in the B-B heating system, is a compressor, which freon turns from a gaseous state into a liquid one. This releases heat. The efficiency of the B-B installation is directly dependent on the ambient temperature. The lower it is, the lower the productivity of the station.

Air to water

TN type air-water is the most versatile model. It is very effective in the warm season, but in the cold season, performance drops significantly. Easy installation is an advantage of the system. Suitable equipment is mounted anywhere. The heat that is removed from the room in the form of gas or smoke can be reused.

Water HP takes heat from ground water, which is pumped through the evaporator. Such a pump is characterized by good efficiency and increased stability: efficiency is the result of significant heat transfer from water.

Of course, to use an installation of this type, it is necessary that groundwater on the territory be available in sufficient quantities. It is desirable that the water is no deeper than 30 meters.

water-water

With such a system, an easily evaporating liquid, such as freon, circulates in the internal circuit. As an indoor circuit, there can be water pipes, registers or batteries filled with water.

Any reservoir with a sufficiently large amount of water can act as an external contour. It can be a river, lake or pond. In this case, the coolant takes heat from the external circuit and gives it to the internal circuit.

Geothermal

As a source of heat, HP uses the stored thermal energy of the earth. Such pumps are considered the most efficient because the ground temperature remains constant throughout the year.

These systems are divided into horizontal and vertical. But for this method, a rather large area for horizontal pipes is needed, and for vertical systems, significant earthworks must be performed.

Prices for different types of heat pumps

Heat pump

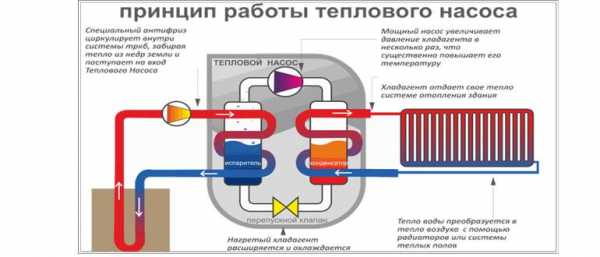

Heat pump for home heating, principle of operation

The operation of the heat pump, refrigerator and air conditioner is based on the Carnot cycle. A heat pump for heating transfers heat from a zone with a lower temperature to a consumer, where the value of this parameter should be higher. In this case, it is taken from outside, where it is accumulated, and after some transformations it goes into the house. It is natural heat, and not the energy released during the combustion of traditional fuel, that increases the temperature of the coolant passing through the pipes of the heating system.

In fact, the principle of operation of the pump is much more complicated. Therefore, devices of this class are often compared with refrigeration units, only working in reverse. But the general order of operation is identical, despite the fact that there is a big difference both in the engineering solution and in the purpose of the main parts of the devices. From a traditional heating system, the circuit assembled on a heat pump differs in the number of circuits and the specifics of their operation.

The external circuit is mounted outside a private house. It is laid where heat accumulates when surfaces are heated by sunlight or for another reason. Energy can be taken, for example, from the air, soil, water. Even from a well, if the house is on rocky soil or there are restrictions on pipe installation. Therefore, there are several modifications of heat pumps, despite the fact that heating is organized according to the same type of scheme.

The principle of operation of the pump

The internal circuit (not to be confused with the heating in the house) is geographically located in the unit itself. The cooled coolant circulating in the external one partially raises its temperature due to the environment. Passing through the evaporator, it transfers the extracted energy to the refrigerant with which the internal circuit is filled. The latter, due to its specific property, boils and passes into a gaseous state. Low pressure and temperatures above -5°C are sufficient for this. That is, the liquid medium turns into a gas.

Further - to the compressor, where the pressure is artificially increased, due to which the refrigerant is heated. It is in this structural element, which is the second heat exchanger, that thermal energy is transferred to a liquid (water or antifreeze) passing through the return of the house heating system. A rather original, efficient and rational heating scheme.

The heat pump needs electricity to operate. But it is still much more profitable than using only an electric heater. Since an electric boiler or electric heater spends exactly the same amount of electricity as it produces heat. For example, if a heater has a power of 2 kW, then it consumes 2 kW per hour and produces 2 kW of heat.A heat pump produces heat 3-7 times more than it consumes electricity. For example, 5.5 kWh is used to operate the compressor and pump, and 17 kWh of heat is obtained. It is this high efficiency that is the main advantage of a heat pump.

It remains to be added that a saline solution or ethylene glycol circulates in the external circuit, and Freon, as a rule, circulates in the internal circuit. The composition of such a heating scheme includes a number of additional devices. The main ones are a valve-reducer and a subcooler.

Pros and cons

The benefits of using a heat pump include:

- Possibility of application in remote villages where there is no gas pipeline.

- Economical consumption of electricity only for the operation of the pump itself. The costs are much lower than when using electrical appliances for space heating. A heat pump consumes no more energy than a household refrigerator.

- Ability to use a diesel generator and solar panels as an energy source. That is, in the event of an emergency power outage, the heating of the house will not stop.

- The autonomy of the system, in which you do not need to add water and control the work.

- Environmental friendliness of the installation. During the operation of the pump, no gases are formed, and there are no emissions into the atmosphere.

- Work safety. The system does not overheat.

- Versatility. You can install a heat pump for heating and cooling.

- Durability of operation. The compressor requires replacement once every 15 to 20 years.

- The release of the premises, which was intended for the boiler room. In addition, there is no need to purchase and store solid fuels.

Disadvantages of heat pumps:

- Installation is expensive, although it pays for itself within five years;

- In the northern regions, the use of additional heating devices will be required;

- The soil installation, although slightly, violates the ecosystem of the site: it will not work to use the territory for a garden or vegetable garden, it will be empty.

Production of a geothermal installation

It is quite possible to make a geothermal installation with your own hands. At the same time, the thermal energy of the earth is used to heat the dwelling. Of course, this is a laborious process, but the benefits are significant.

Calculation of the circuit and pump heat exchangers

The circuit area for HP is calculated at the rate of 30 m² per kilowatt. For a living space of 100 m², about 8 kilowatts / hour of energy is needed. So the area of the circuit will be 240 m².

The heat exchanger can be made from a copper tube. The temperature at the inlet is 60 degrees, at the outlet 30 degrees, the thermal power is 8 kilowatts / hour. The heat exchange area should be 1.1 m². Copper tube with a diameter of 10 millimeters, a safety factor of 1.2.

Circumference in meters: l \u003d 10 × 3.14 / 1000 \u003d 0.0314 m.

Number of copper tube in meters: L = 1.1 × 1.2 / 0.0314 = 42 m.

Necessary equipment and materials

In many ways, success in the manufacture of heat pumps depends on the degree of preparedness and knowledge of the contractor himself, as well as on the availability and quality of everything necessary for the installation of a heat pump.

Before starting work, you need to purchase equipment and materials:

- compressor;

- capacitor;

- controller;

- polyethylene fittings intended for assembly of collectors;

- pipe to the earth circuit;

- circulation pumps;

- water hose or HDPE pipe;

- manometers, thermometers;

- copper tube with a diameter of 10 millimeters;

- insulation for pipelines;

- sealing kit.

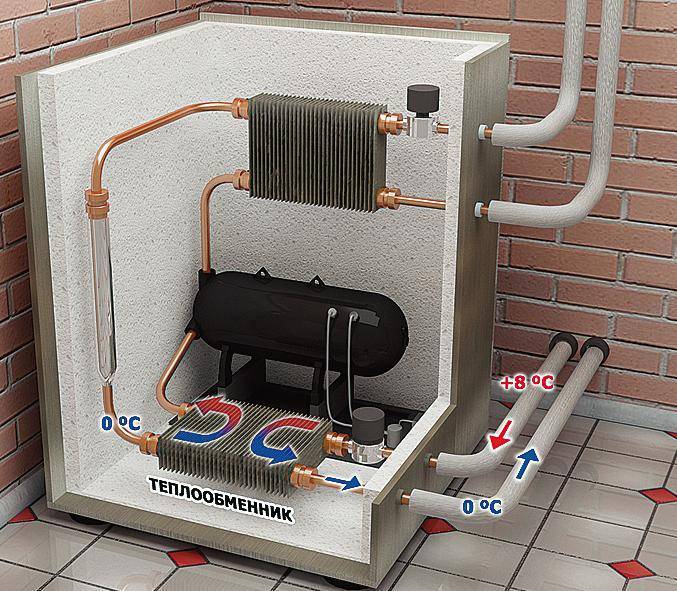

How to assemble the heat exchanger

The heat exchange block consists of two components. The evaporator must be assembled according to the "pipe in pipe" principle. The inner copper tube is filled with freon or other rapidly boiling liquid. On the outside circulates water from the well.

Arrangement of the soil contour

In order to prepare the necessary area for the soil contour, it is necessary to perform a large amount of earthwork, which is desirable to be carried out mechanically.

You can use 2 methods:

- In the first method, it is necessary to remove the top layer of soil to a depth below its freezing. At the bottom of the resulting pit, lay the free part of the outer pipe of the evaporator with a snake and recultivate the soil.

- In the second method, you must first dig a trench over the entire planned area. A pipe is placed in it.

Then you need to check the tightness of all connections and fill the pipe with water. If there are no leaks, you can fill the structure with earth.

Refueling and first start

After installation is complete, the system must be filled with refrigerant. This work is best entrusted to a specialist, because special devices are used to fill the internal circuit with freon. When filling, it is necessary to measure the pressure and temperature at the compressor inlet and outlet.

After refueling, you need to turn on both circulation pumps at the lowest speed, then start the compressor and monitor the operation of the entire system using thermometers. When the line is warmed up, frosting is possible, but after the system is completely warmed up, the frosting should melt.

Homemade heat pump from the refrigerator: stages of creation

A heat pump is quite an expensive device.But if you wish, you can build a device with your own hands from an old refrigerator or air conditioner. The refrigeration device has in its system two parts necessary for the pump - a condenser and a compressor.

Steps for assembling a heat pump from a refrigerator:

- First, the capacitor is assembled. It looks like a wavy element. In the refrigerator, it is located at the back.

- The condenser must be placed in a strong frame that retains heat well and tolerates high temperatures. In certain cases, it is necessary to cut the container in order to install the capacitor without problems. At the end of the installation, the container is welded.

- The next step is to install the compressor. The unit must be in good condition.

- The function of the evaporator is performed by an ordinary plastic barrel.

- When everything is prepared, you should fasten the elements together. The heat exchanger is attached to the heating system with PVC pipes.

So it turns out a homemade heat pump. Freon must be pumped by a professional, as the liquid is not easy to work with. In addition, for its injection, you must have special equipment.

The refrigerator can act as a radiator. You will need to make two air vents that will ensure its circulation. One branch receives cold air, the second - releases hot.

Characteristics

Most zealous owners want to save on heating and water supply of a private house. For such purposes, a heat pump is suitable.

It is quite possible to build it with your own hands, saving money at the same time - a factory device is very expensive.

Properties and device

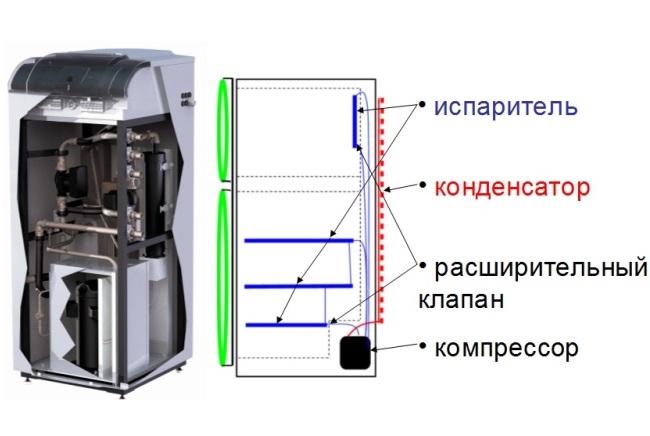

The device has an external and internal circuit along which the coolant moves. The components of a standard appliance are a heat pump, an intake device and a heat distribution device.The internal circuit consists of mains powered compressor, evaporator, throttle valve, condenser. Fans, a pipe system, and geothermal probes are also used in the device.

Heat pump advantages:

- does not emit any harmful substances, absolutely environmentally friendly;

- there are no costs for the purchase and delivery of fuel (electricity is spent only on moving freon);

- no need for additional communications;

- absolutely fire - and explosion-proof;

- full heating in winter and air conditioning in summer;

- a self-built heat pump is an autonomous design that requires a minimum of control effort.

Manufacturing and installation

The pump is made according to the following algorithm:

- the compressor is fixed on the wall;

- a coil is made from pipes (to make it, you need to wrap the pipes around a container of a suitable shape);

- the tank is cut in half, a coil is placed inside it and brewed;

- several holes are left in the tank through which the coil pipes are brought out;

- for the manufacture of the evaporator, a plastic barrel of the same size as the tank is used, pipes of the internal circuit are brought into it;

- pipes are installed (wiring diagrams for warm water floors in the apartment) made of PVC, transporting heated water;

- it is not recommended to fill the unit with freon on your own, it is better to entrust this action to a specialist.

The cost of work in different regions of our country can differ dramatically. In addition, the cost of work and the pump depend on its type and heating system.

- In St. Petersburg, the installation of a heat pump, regardless of its type, will cost the Customer in the amount of 35,000.00 rubles;

- In the cityMoscow installation organizations, regardless of the type of heat pump, are ready to perform turnkey work for more than 45,000.00 rubles;

- In Krasnodar, the installation of a heat pump will cost from 40,000.00 rubles.

- If we talk about the installation of heating systems using heat pumps, then the average prices for a set of works, taking into account the cost of equipment, are as follows:

READ MORE: Motoblock Patriot Ural TOP-3 rating of the best models of 2020 distinctive characteristics of the device user manual and customer reviews

A) Installation of geothermal domestic heat pumps:

- Power - 4-5 kW (50 - 100 m²) - from 130,000.00 to 280,000.00 rubles;

- Power - 6-7 kW (80 - 120 m²) - from 138,000.00 to 300,000.00 rubles;

- Power - 8-9 kW (100 - 160 m²) - from 160,000.00 to 350,000.00 rubles;

- Power - 10-11 kW (130 - 200 m²) - from 170,000.00 to 400,000.00 rubles;

- Power - 12-13 kW (150 - 230 m²) - from 180,000.00 to 440,000.00 rubles;

- Power - 14-17 kW (180 - 300 m²) - from 210,000.00 to 520,000.00 rubles.

B) Installation cost of air source heat pumps:

- Power up to 6.0 kW (50 - 100 m²) - from 110,000.00 to 215,000.00 rubles;

- Power up to 9.0 kW (80 - 120 m²) - from 115,000.00 to 220,000.00 rubles;

- Power up to 12.0 kW (100 - 160 m²) - from 120,000.00 to 225,000.00 rubles;

- Power up to 14.0 kW (130 - 200 m²) - from 127,000.00 to 245,000.00 rubles;

- Power up to 16.0 kW (150 - 230 m²) - from 130,000.00 to 250,000.00 rubles;

- Power up to 18.0 kW (180 - 300 m²) - from 135,000.00 to 255,000.00 rubles.