- Do-it-yourself manual tornado cultivator drawings

- Advantages

- The main types of breakdowns

- How a fan heater works

- Modernization of an existing fan

- Electric heat gun in action

- Self-installation of a fan heater

- Homemade electric walk-behind tractor

- Homemade # - based on the heater "Good Heat"

- Diesel Separator Configuration Fuel Filter Heater

- What will be needed?

- Action algorithm

- Video: features of the use of fuel heaters

- Difficult choice

- Basic provisions for designing a heat gun

- Design and types of fan heaters

- We make ventilation with our own hands

- Forced

- Natural

- Combined ventilation

- Principle of operation

- The use of homemade fan heaters

Do-it-yourself manual tornado cultivator drawings

Euro homemade products - only the best homemade products of Runet! How to do it yourself, master classes, photos, drawings, instructions, books, videos.

7 country miracle helpers!

Unusual hand gardening tool (photo, video, drawings)

1. Fokine flat cutter

The flat cutter is a great achievement of the agricultural mind. This is the first truly versatile garden tool.Not just for tillage, but a tool for comprehensive cohabitation with the cultivated plant community and soil.

Fokin flat cutter drawing:

Fokine flat cutter "Swift"

2. Ripper Wonder-shovel "Plowman"

Ripper Wonder-shovel "Plowman" blueprints:

A shovel, which can be attributed to the category of cultivators-cultivators - "Plowman". The mechanism of the ripper Plowman is simple and quite effective. The raising of the earth is carried out by the work of a simple lever. The main load falls on the legs, with which the working forks are pressed into the ground. The lifting of the soil comes from the effort of the hands, which unloads the back and is therefore attractive to the elderly and gardeners suffering from back pain. Two opposite forks, passing one through the other, loosen the ground without wrapping it, providing a loosening depth of 15-20 cm.

Miracle shovel Prokopenko

Advantages of the design of a shovel or soil cultivator or potato digger

1. Deep tillage without seam turnover.

2.High productivity.

3. Significant physical effort is not required when processing the formation.

4.Available in production.

A feature of tillage with a miracle shovel is that the garden is not dug across, but along. With both outstretched hands we take the miracle shovel by the edges of the upper bar, step on the platform (footboard) and it easily enters the ground. With a slight movement (can be combined with a slight shaking), stepping back two steps, we transfer the shovel from a vertical position to an almost horizontal one. After that we take a step forward, pull the shovel back 30 cm, give the shovel a vertical position, drive it into the ground and repeat the cycles until the row ends. Then we proceed to the processing of the next row.

Materials: half an inch of labor, round timber (or hexagon) with a diameter of 15 mm.

For ease of transportation, you can make a collapsible design.

Miracle shovel Prokopenko blueprints:

3. Miracle forks swivel

Miracle pitchforks allow you to dig up the ground without loading your back at all due to the unique rotary way of working. Miracle pitchforks do not require you to bend down or squat. Efforts are applied only to the "steering wheel". At the same time, the productivity of digging increases by 3-4 times.

Miracle forks are adjustable in height over a wide range, which allows you to perfectly fit the tool to your height.

Miracle pitchfork swivel photo:

4. Miracle shovel of a monk - Father Gennady

The miracle shovel of the monk - father Gennady photos and drawings:

5. Miracle Cleaver

The Miracle Cleaver is a tool for easy and safe wood splitting. You can chop three times as much wood with the same amount of time and effort as with a regular cleaver. At the same time, even women and children will be able to chop wood, because the main work consists only in raising and lowering a kettlebell weighing 3.3 kg.

One Wonder Cleaver replaces four tools: Cleaver, Axe, Hammer and Chisel. If you follow the instructions for use, the tool is absolutely safe.

The Miracle Cleaver allows you to chop even very thick logs. However, it does not require any special skills and is very easy to operate.

Miracle Cleaver photo:

6. Miracle potato hiller

The miracle hiller is designed for loosening the soil on potato ridges and hilling up the sprouted potatoes.

Thanks to an optimally calculated design, the new invention contributes to high-quality soil cultivation (loosening and hilling) and the correct formation of the ridge of the potato ridge.The distance between the discs is adjustable, which allows you to loosen the soil near the bushes, and hill the bushes.

The miracle hiller will allow you to hill potatoes without much effort and in the shortest possible time, avoiding the laborious and tedious work of cultivating the soil with a hand chopper. You need two people to work as a potato grower.

Miracle potato hiller photos and drawings:

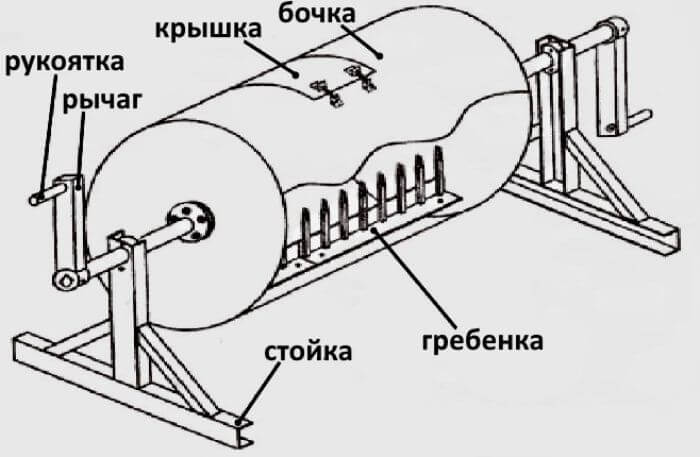

7. Ripper soil "Tornado"

Soil cultivator "Tornado" loosens the ground, and easily copes with perennial weeds such as wheatgrass or field bindweed.

Soil cultivator "Tornado" photos and drawings:

Advantages

The absolute advantage of electric walk-behind tractors is their compactness. The unit is easy to store and does not take up much space. This point is no less important during transportation. Most models can be transported in the trunk of a car, after dismantling the handles.

Electric models are much easier to drive than petrol or diesel cars. At the same time, as already noted, the units do not pollute the air and do not make noise. The price of most models is significantly lower than the cost of cars with an internal combustion engine or a diesel component. The payback of the unit should also be taken into account. An electric walk-behind tractor is cheaper to operate, does not require fuel and constant complex maintenance.

If the site is small (within 10 acres) and at the same time electrified, the choice seems obvious. It is worth buying an electric walk-behind tractor. In most cases, such a unit will satisfy the needs of the summer resident. And if it is planned to build greenhouses on the site (or they are already present), then such a machine will be simply irreplaceable.

The main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. For efficient operation, it uses gas, rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of unavoidable faults includes:

- water leaks;

- poor heating of the liquid;

- discharging power elements;

- weak water pressure;

- no gas.

Owners of gas boilers can repair some malfunctions on their own. Any person can change the batteries in the power device. It is also easy to eliminate the weak water pressure - perhaps just excessive scale has formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special liquids for descaling.

It is not difficult to solve the problem of poor water heating on your own. The main cause of such a malfunction is often soot contamination of the heat exchanger. The elimination of this problem lies in the removal of the mentioned element and the removal of plaque. In case of more significant malfunctions, you should contact professionals.

Those who have seen enough of the video on YouTube about a homemade gas water heater, which consisted of a coil placed directly on the hob in the kitchen, have probably already been dreaming about how you can get a lot of boiling water cheaply. In fact this is not true. Today we will talk about why you should not do a gas water heater with your own hands.

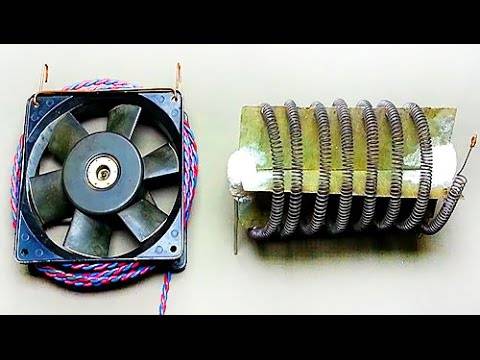

How a fan heater works

To make the right choice, you should first familiarize yourself with the structure of the fan heater. Understand the basic working principle of the device.

Any fan heater includes: a housing made of high-strength plastic or metal, a heating element and, of course, a fan, the blades of which can also be plastic or metal. More expensive models also have a swivel mechanism.

The fan itself can be of two varieties, tangential or axial. During operation of the first, less noise is emitted.

Heating of the room occurs due to the movement of air flows. Cold air enters the device, and after instant heating, it is distributed throughout the room with the help of a fan. This method of heating to this day remains the fastest.

Modernization of an existing fan

Plastic bottles will come in handy in upgrading a store-bought fan. Practically free improvised means will help to significantly increase the performance of the device.

Let's look at how and by what method you can arrange a pleasant sea breeze in an apartment:

We have made parts designed to enhance the airflow. They will provide accelerated cooling of the space around.

Now you need to make the basis for fixing them:

After preparing the device, designed to enhance the performance of the fan, we proceed to the assembly and commissioning:

Electric heat gun in action

At the moment, a wide range of domestic and foreign products is on sale, while prices are quite acceptable, for example, for Resanta products.

Connect the gun to the chimney, check the quality of the ventilation system

It is important to remember that it is almost impossible to heat a plank shed, a large hangar or an iron garage.

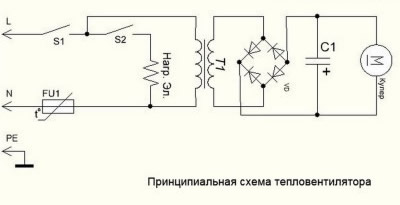

Device and repair of a heat gun. Diagram of a fan heater Connection of a heat gun

Some heat guns are connected to the network in volts.

As a rule, ready-made schemes are used. Fan motor mounted on the rear grille of the heat gun behind the heating elements. General description Electric heat guns, reviews of which indicate extreme efficiency and ease of use in various conditions, usually have a rectangular shape, while the shape of the heating element is M-shaped.

The products of fuel combustion are removed from the chamber using a vertically installed pipe. The electric motor is usually applied on a volt, adapted to work on a wide range of supply voltages, since the mains voltage can deviate greatly from the standard. Some heat guns are connected to the network in volts. This leads to a change in the intensity of air flows that pass through the heating elements.

Installation The electric heat gun can be mounted on walls, and the installation angle can be arbitrary. Fastening the electric motor with a fan, you can use standard fasteners. Fan motor.

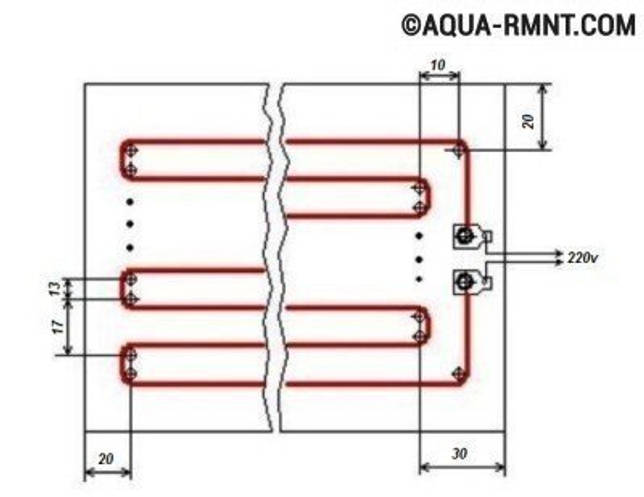

A device of small power no more than 1.5 kilowatts is able to cope with the heating of a room with an area of 15 square meters, with a wall thickness of 15 centimeters or more, and also subject to high-quality thermal insulation. The heating elements of this model, there are 6 of them, look as follows: Depending on the selected mode, either three heaters or all six are used. Several important assembly tips and operation The rules for the safe operation of a homemade gun are practically the same as the operation of other electrical appliances: you must avoid tipping the device and the penetration of moisture into it, do not touch the heated case and do not leave the unit to work unattended. Annoying noise from the operation of the impeller can be reduced if relatively quiet automotive fans are used for the design.

Gas heater By its design, gas equipment resembles a diesel gun device. Direct start is performed by a switch by setting it to a certain position. Switching of modes of operation is carried out by the compact and convenient switch, by means of the built-in relay.

How to read electrical diagrams. Lesson #6

Self-installation of a fan heater

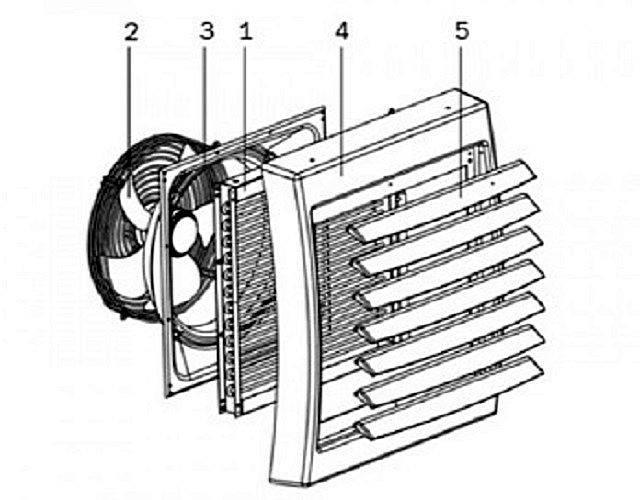

Before self-assembly, it is necessary to carefully study the device of the fan heater. It consists of three main parts:

-

- a separate case (metal or plastic);

- fan

ceramic, spiral or tubular heating element.

The size, power and design of modern fan heaters allow them to be used in rooms of various purposes - from a simple garage to a living room in a house.

The installation method, dimensions and power of heaters are different. The principle of operation is quite simple: the flow of cold air is directed by the fan to the heating element, where its temperature rises by a certain number of degrees, and then, already heated, it spreads around the room. The main advantage of a stationary heater is the efficient, rapid heating of air in a limited area. In addition, a small device is convenient to carry from place to place and use only when necessary.

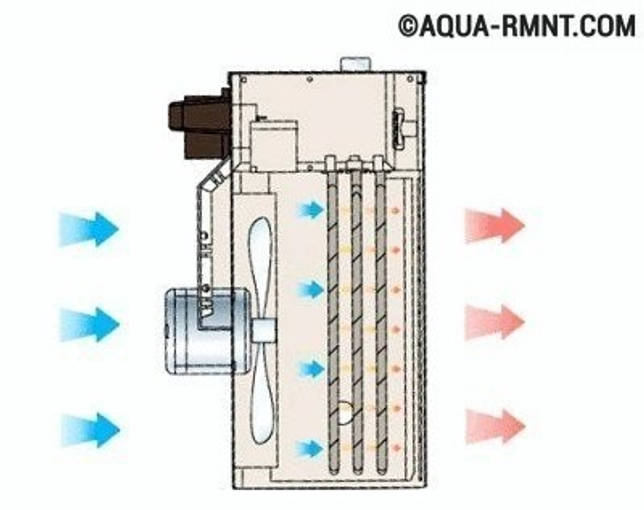

Blue arrows indicate cold air that enters the device case and, under the action of the fan, rushes to the heating elements. Red - heated air, having a certain direction

Many models, including self-made ones, can be used in the heat by turning off the heating elements, thereby turning the device into a regular fan.

Having studied the diagram of the device device, it is necessary to select the parts that are useful for assembly. Most of them do not even have to be purchased: in any home there are faulty devices, suitable materials, wires, fasteners, tools. You can choose one of the proposed options or design your own. We will tell you in more detail how to make a fan heater with your own hands from a duct fan and a power supply.

Homemade electric walk-behind tractor

To make an electric walk-behind tractor with your own hands, you will need some materials that are available to homeowners. The manufacturing process of such a device can be divided into several technical operations:

1.

The carrier frame is one of the main elements of the equipment.For its manufacture you will need a channel and a corner. The width of the frame must match the dimensions of the motor and gearbox. As handles, you can use pieces of pipe of the desired size. Pipes should be welded to both sides of the metal frame. After that, you need to fix the bronze insert to the pipes with screws, which will act as an axis.

2.

For the effect of sliding, ball bearings can be used, which are selected with the appropriate diameter. To fix the handles to the pipe, special brackets must be welded. In order to fix the cultivator and the plow holder, a bracket must be welded in the middle part of the pipe. Using screws, a platform must be installed on the frame body in special slots in the side ribs. To mount the electric motor in the site, special holes should be made.

3.

Through belt pulley on the bronze axle is connected to the same element on the electric motor. With the help of a chain, the movement is transmitted to an asterisk located slightly lower. For these purposes, you can use a regular bicycle chain.

4.

The movement of the walk-behind tractor will be carried out at the expense of a working device that directly cultivates the soil. Curved knives need to be fixed on a square plate, and they will be held by a key located on the lower axis. When the shaft rotates, loosening of the soil and movement of the entire module will occur. The reduction is created by the ratio of pulleys and sprockets.

5.

Movement control is carried out by means of a switch, which must be placed on the handle of the holder. You can connect the engine to the network using a wire wound on a coil.

In general, the manufacture of a home-made electric walk-behind tractor does not require special technical qualifications. In its manufacture, the elementary rules of ergonomics and safety for the owner of such agricultural equipment should be observed.

Homemade # - based on the heater "Good Heat"

Many heating devices work according to the so-called "thermal film principle". For example, the well-known "Kind Heat". Assemble its analogue in not at home will be a lot of work. For this you will need:

- Laminated paper plastic. Two sheets of the same size with an area of \u200b\u200babout 1 sq. m.

- graphite powder. You can grind graphite yourself, for example, old graphite trolley brushes.

- Epoxy adhesive.

- A piece of good wire with a plug on the end.

Heater Good warmth - a prototype for many homemade devices

Heater Good warmth - a prototype for many homemade devices

The work is carried out in stages:

- We mix the glue with graphite powder and carefully stir the resulting mixture. Thus, we get not just an adhesive composition, but a graphite conductor with high resistance. The amount of graphite in the adhesive directly affects the maximum temperature of the future heater. On average, it is about 65 ° C.

- We apply the prepared composition on a sheet of plastic with zigzag wide strokes. For processing, we use the rougher side of the sheet.

- We connect plastic sheets with each other using epoxy glue.

- For greater structural strength, we construct a wooden frame that securely fixes the sheets.

- From different sides of the structure, we attach copper terminals to the graphite conductors.Alternatively, you can also connect a simple thermostat, which will allow you to set the most comfortable heating mode. However, this is not required.

- Dry the structure thoroughly. Even a little moisture will damage a homemade heater the first time you try to turn it on.

- We carry out tests, measure the resistance of the device. Based on the value obtained, we calculate the power and determine whether it is safe to connect the heater to the network.

The device is ready for use. It can be placed both on the floor or on the wall, does not take up much space, is quite effective and safe, provided that it is of high quality insulation.

Graphite is crushed and mixed with epoxy glue - this is how a graphite conductor is obtained.

Graphite is crushed and mixed with epoxy glue - this is how a graphite conductor is obtained.

Scheme of the device of the future heating device

Scheme of the device of the future heating device

Diesel Separator Configuration Fuel Filter Heater

It's important to know

A diesel engine separator configuration fuel filter heater will require a lathe to manufacture.

Before installation, it must also be taken into account that the drain unit in diesel engines is used to remove liquid from the sump. Accordingly, if this device is to be removed, then only proven high-quality fuel must be used.

What will be needed?

Tools and materials required for installation:

- set of wrenches;

- a piece of metal pipe for making a sleeve;

- wires for connection;

- lathe, with which threading will be done.

Action algorithm

You can install a separator configuration diesel fuel filter heater as follows:

- A metal bushing of the required size is made.The external contour of the device must correspond to the drain valve of the system.

- Using a drill, a central hole is drilled.

- The cutting of internal and external threads is carried out. The outer pitch must correspond to the drain element, and the inner pitch to the threads on the glow plugs.

- The assembly of the completed structure with candles is in progress. The resulting mechanism is screwed into the body of the separator device. Directly the shape of the part must be corrected - a hairpin must be made on the hexagon. To do this, a screw or bolt is welded on the side.

- After the installation is completed, the wiring is laid. On the positive line, you need to install a button switch and a four-pin relay. The entire electrical circuit must be protected by a safety device to prevent power surges and wiring short circuits.

- After installation, it remains to connect two leads. Grounding or "mass" goes to the sleeve, and the positive contact must be connected to the glow plug. The installed device is being tested.

Video: features of the use of fuel heaters

Roman Romanov, in his video, spoke about the nuances of using heating devices for fuel filters of a separator design.

Difficult choice

To answer the question of which diesel engine preheater is better to purchase, you need to take into account various nuances. This is the frequency of use of the vehicle, and the features of the car itself, as well as the conditions of its operation and the duration of the motor.

If the climatic conditions are satisfactory, then there is no special need for the device.Also, if the car is in a heated garage most of the time, then a heater is hardly needed. Another thing is if the machine is operated in a harsh climate, where winters are usually long and frosty. Then the preheater will be really in demand.

Naturally, a modern new car will easily start in the cold, but the wear of its engine parts will accelerate, as they are subjected to additional and heavy stress. Therefore, those motorists who want the vehicle to serve as long as possible should take care of it and purchase a diesel engine preheater.

Feedback from those who already use the device is mostly positive. Someone prefers domestically produced models, while someone chooses only imported ones. Both of them have their advantages and disadvantages.

Consider the brands that are most in demand among motorists.

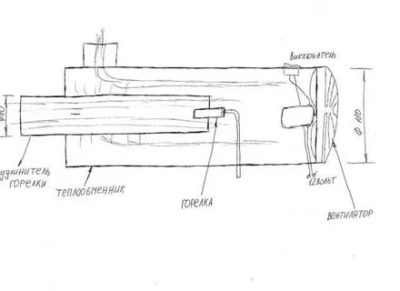

Basic provisions for designing a heat gun

To design a heat gun yourself, you need to find a large-diameter pipe. Then, a little at the two ends on opposite sides, make two holes: one large caliber, the second small. The final products of combustion will exit through the large one, and fuel will flow through the small one. Then it is necessary to install a combustion chamber with an automatic catalyst, which will bring the gas mixture to a burning state.

It is very important to observe a high degree of tightness throughout the structure in order to avoid leakage. Then you need to attach the fan to the end of the pipe, where the small-caliber hole is located, and the design is ready.

How to make an electric heat gun - this question is not difficult, the main thing is to properly follow the safety rules when using it

This position is especially important for a tank with a gas mixture, it must be at least a meter away from other items in the room. If possible, it is advisable to temporarily remove very flammable materials while using a homemade heating device.

Because warm air can catalyze many chemical reactions.

A do-it-yourself electric heat gun does not require specialized skills or professional knowledge, and what is even more important is the absence of any material costs for design. However, when building, it is very important to observe the points that are indicated in the drawing.

(See also: Do-it-yourself greenhouse heating)

A home-made heat gun of the electric type allows you to properly provide heat to a large area.

Since from a practical point of view there is a double heating. The first source of heat is simple warm air, while the second source is a gas mixture, after the combustion of which a sufficiently significant amount of heat is released.

This design is mainly used for heating rooms in which, due to circumstances, it is impossible to ensure proper tightness, for example, repairs in the winter season. An electric-gas gun is mainly used for heating rooms that have a large footage or for quickly heating small residential areas.

For the manufacture of a diesel heat gun, you will need a number of components, namely:

- the combustion chamber;

- diesel fuel tank;

- large-caliber metal pipe;

- catalyst;

- fan.

First you need to make a hole at the two ends of the metal pipe: one large and one small. Then it will be necessary to mount the catalyst in the combustion chamber in the metal pipe itself. In no case should you start designing without having a plan for the future design, since in this case it will either not be possible to assemble the unit, or its final work will simply be energy inefficient. (See also: DIY gas-fired oven)

The smallest diesel heat gun is mainly used for heating a small room and its main advantage is efficiency. The main feature of its design is the use of a small metal pipe and the absence of a fuel tank. That is, such a unit functions solely by converting cold air into warm air. The main thing to remember is that the fan must always have a separate power source in order to avoid a short circuit in the mains.

To build a diesel heat gun, it is necessary to determine the footage of the future room, as well as take into account the degree of air insulation of the room where it is planned to use the future thermal unit. From a practical point of view, it is possible to determine the degree of air insulation by only one parameter: air ventilation is noticeable or not. Depending on this, you need to plan the future design. If the room is sufficiently insulated, then the gas mixture can be dispensed with and, consequently, the energy costs will be much lower.

Often many people ask the question, how to make a diesel heat gun on your own? The answer is very simple, it is paramount to draw up your own plan, and then carefully implement it point by point. The most common practical mistake of many people is just the same non-compliance with all points of the plan or lack of due attention. If you started designing, then take your time, otherwise you will have to redo it many times. The pipe must be wrapped with copper wire to ensure the proper functioning of the self-made heating device.

Design and types of fan heaters

In order to preliminarily estimate the scope of work and select the materials necessary for assembly, it is worth familiarizing yourself with the device of a factory-assembled fan heater. The elements present in the design of all models are:

- Protective case made of plastic or metal.

- Electric motor.

- Impeller with blades.

- Heating element.

- Protective grid.

- Elements of regulation and control.

Depending on the chosen design and purpose of the device, additional components are selected. It is possible to manufacture almost all types of electric heaters with your own hands. For domestic needs, a thermal mini do-it-yourself cannon for heating and drying the room, do-it-yourself electric fireplace will allow you to realize your own design ideas and give the room an atmosphere of comfort, and the duct air heater is built into the supply ventilation or air conditioning system.

We make ventilation with our own hands

To reduce the amount of moisture in the room, one of 3 types of ventilation systems can be installed.

Forced

Here you need to use supply and exhaust fans. Requires access to electricity. The installation algorithm is as follows:

- Creating holes for hoods in the wall surface.

- Installation of fans on the inlet/outlet openings.

- Connection of fans to the electrical network.

Natural

The algorithm for installing natural ventilation looks like this:

- Purchase of ventilation pipes.

- Making 2 holes in the wall surface. They must correspond to the radius of tubular products.

- Pipe installation. The exhaust pipe should rise 150 centimeters above the garage. The inlet should be directed towards the earth's surface.

Combined ventilation

Represents combination of forced and natural ventilation. Instead of 2 holes, you need to create 4. 2 of them need to be equipped with fans, and the remaining 2 will work naturally. The supply pipe must be installed at an angle, at a height of at least 0.2 meters from the floor surface.

Principle of operation

Any, including a home-made heat gun, works according to the same principle: a powerful fan drives air through the heating equipment - heating element, which gives it heat, and already heated air enters the heated zone.

In the diagram, everything is clear enough to get an idea of \u200b\u200bhow such a unit will work.

There are only a few elements in the design:

- Unit body

- heating element

- Fan

- Control devices

- Wire for connecting to the mains

The speed and degree of heating of rooms heated by such heaters is determined by the number and power of heating elements installed in it.The more of them, the more actively the air mass passing through the gun will warm up.

In some models, it is possible to change the fan speed, and, accordingly, the amount of air passing through the unit.

Contrary to the misconception, air flow rate does not affect the speed at which the heated zone warms up. For a heat gun operating on this principle, it is much more important which heating element is installed and how great its power is.

The speed of the air flow in the device can only affect the uniformity of heating the room - the higher it is, the more evenly the room will heat up. And the heating element can either heat the air more or weaker. It already depends on its power.

The use of homemade fan heaters

Electric models can heat small areas, while their water counterpart is used to heat rooms with a large cubic capacity, but several devices may be needed to distribute the heat evenly.

If upon arrival at the dacha you need to immediately heat one of its rooms, then fan heaters will cope with this task faster than other heating devices. It can also be used for heating basements and basements, those rooms where there is high humidity. Home-made devices can significantly reduce its level and maintain a stable temperature in the room for the right period of time.