- Manufacturing steps

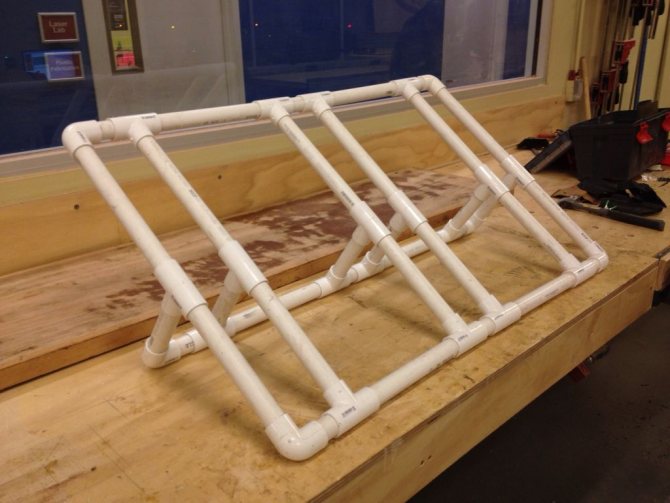

- simple model

- With adjustable legs and back

- From polypropylene pipes

- Folding chair

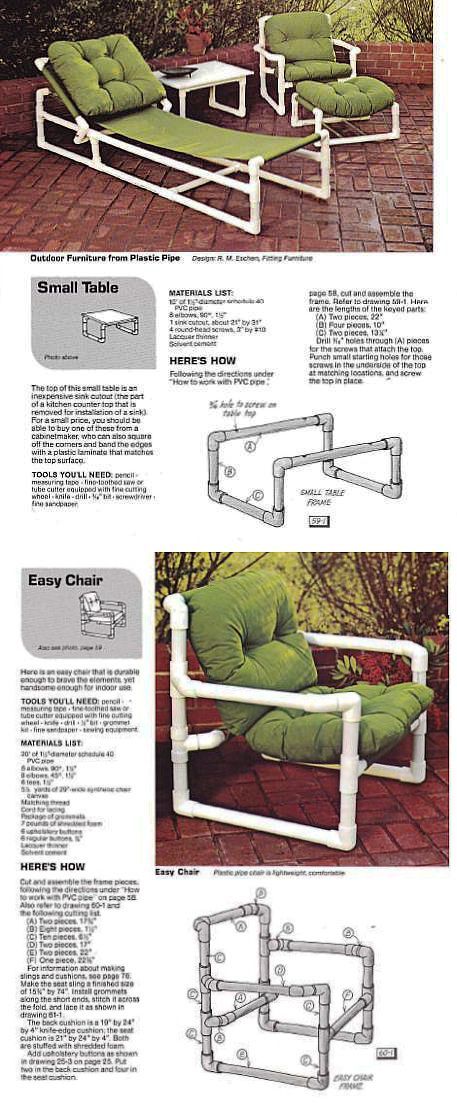

- Pipe outdoor table

- How to make a kitchen table from pipes and a solid board

- Calculations and drawings

- canopy

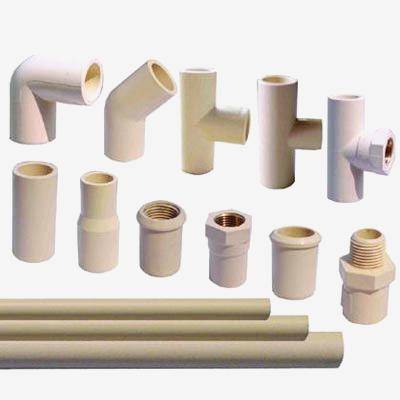

- What do you need to make furniture?

- Plastic pipes. Ideas for the interior

- Work organizer

- Frames for mirrors and openwork partition

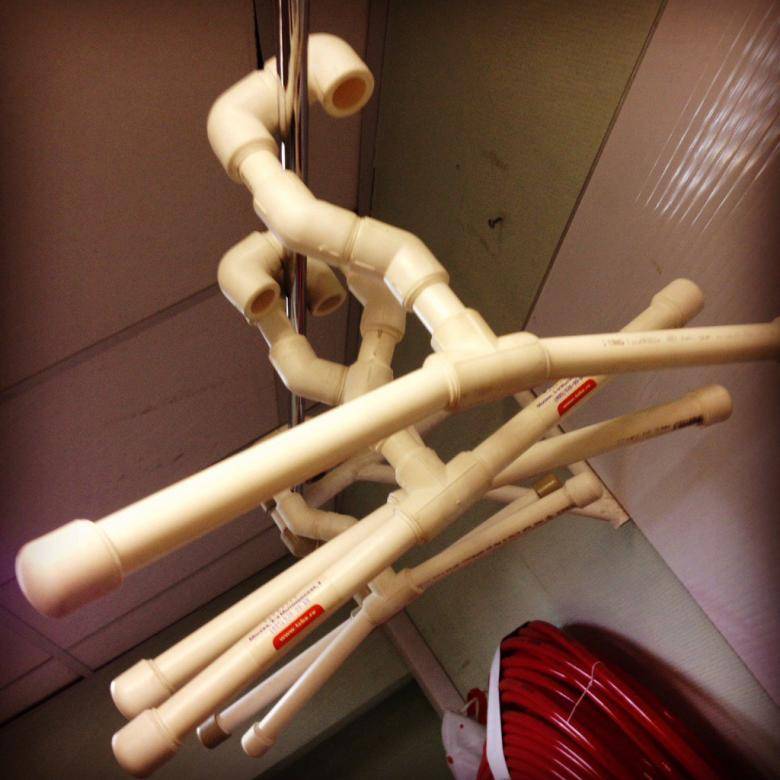

- Clothes hanger

- Pots and vases for flowers

- Shoe rack

- Coffee table

- Making a metal chair

- Material: wood, plywood, pipes and metal

- Assembling a chair with an upholstered seat

Manufacturing steps

Given your own skills in making products from different materials, as well as personal wishes, you can build chairs for feeder fishing of varying complexity with your own hands.

simple model

To make the simplest model of a feeder chair, you will need three interlocking metal pipes with a diameter of 20 mm, material for the seat and back, strong threads, 4 bolts and nuts each. Necessary tools: electric drill, hacksaw, grinder. Manufacturing technology:

- The short sides of the seat are stitched with two wide strips, fixed from below with a thin strip limiter. In this case, the fabric is sewn immediately onto 2 metal pipes, which will serve as the legs of the chair.The material on the back is also stitched on the short sides.

- At the junction of the legs in the middle of the long sides, holes are drilled and connected crosswise with fasteners.

- A pipe is attached to one of the legs, which will act as a backrest.

With adjustable legs and back

A chair with a back is a complicated version of a feeder chair. The material required to assemble such a chair: a steel pipe for a frame with a diameter of 20 mm, fasteners (bolts, nuts), textiles for the seat and back, threads, rubber nozzles for the legs, anti-corrosion compound. The tools used are the same as for the simple model. Assembly algorithm:

- The metal pipe is cut into several parts: for the legs and seat - 8 pieces of 55 cm, for the back - two pieces of 70 cm, one piece - 30 cm.

- On pipes in the amount of two pieces, which are intended for sitting, two fasteners are installed at a distance of 6 cm from the beginning and end.

- Fasteners are attached to one of these pipes, with which the back will be mounted. Fasteners are located at a distance of 9 cm from the beginning of the pipe.

- To complete the manufacture of the chair frame, the prepared professional pipes with fasteners are connected by two more pipes. Thus, 4 metal pieces 55 cm in size were used.

- 70 cm pipes prepared for the back are connected to a 30 cm pipe using fasteners.

- The remaining four pieces of 55 cm in size are attached to the ends of the frame tubes, which will act as legs. They are fitted with rubber caps.

- At the last stage of manufacturing the chair, textiles are stretched on the seat and back. Holes are made on the short sides of the tarpaulin, with the help of an elastic band the material is pulled together.The elastic will allow the seat to sag a little under the weight of the angler. The textile back is pulled together on the long sides.

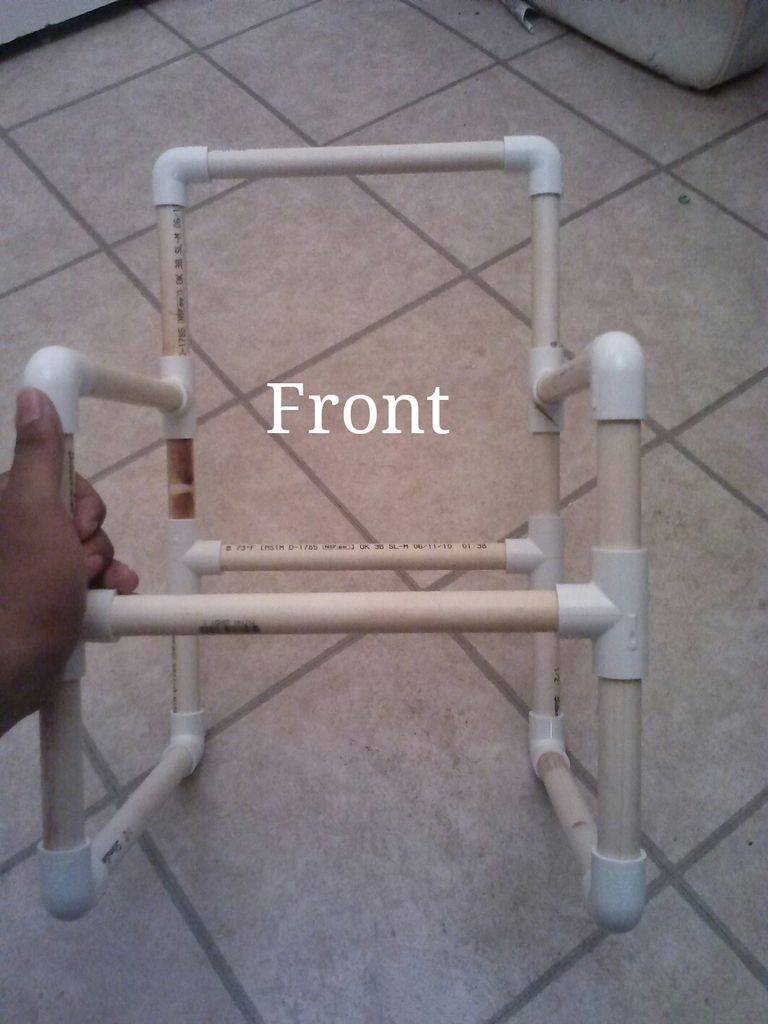

From polypropylene pipes

A simple option for making a feeder chair, for which you will need: PVC pipes with a diameter of 25-32 mm, fittings connecting the parts of the chair, durable seat textiles, fasteners, threads. Assembly tool: pipe cutter or hacksaw, soldering iron. A guide on how to make a fishing chair from polypropylene pipes with your own hands:

- The tube is cut into segments: 16 parts for the back, legs, seat, the length of which can be chosen independently.

- We connect pipe sections with fittings. For convenience, the assembly must be started from the back, then the seat and handles are fastened.

- For the seat and back, take the material that is stitched along the short sides with holes for inserting pipes.

- After checking the structure for stability, it is disassembled, the material is stretched over the corresponding pipe sections.

- At the final stage of assembly, the parts are soldered or fixed with glue.

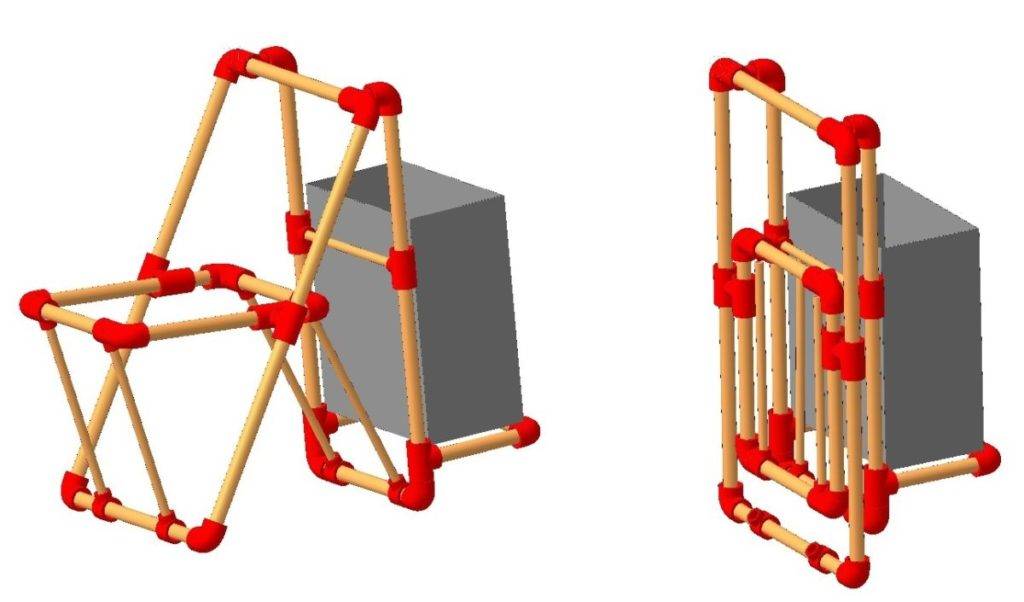

Folding chair

To assemble a folding chair, you will need a 25 mm polypropylene pipe, fittings, seat material, threads, 2 bolts, 2 nuts. Guide how to make a folding chair:

- A fabric of 18 cm in size is cut off. It is stitched along the short sides so that holes are obtained into which pipes will be inserted.

- The pipe is cut into segments: 4 pieces of 40 cm and 4 pieces of 20 cm.

- In long pipes, holes are drilled in the middle for fastening with bolts.

- Short 20cm lengths of tubing are inserted into the prepared tissue. Corners are put on the ends.

- 2 rectangles are formed from all pipe sections measuring 20 x 40 cm. They must be connected with a cloth.

- Rectangles are connected to each other by bolts and nuts in drilled places. It is not recommended to tighten the nuts too tight so that the chair folds without effort.

For structural strength, glue or welding can be used at the points of fastening with fittings. Such a folding fishing chair will serve for a long time thanks to the material from which it is made, it will be easy to carry, the chair will not take up much space in the backpack.

Pipe outdoor table

It's a great idea to make an outdoor garden table with a base made from water pipes. The build looks solid and assembly is easier than you might think. The table top of the outdoor table is made of pipes, these are three durable boards 2x12 fastened with transverse slats. It is clear that they need to be well prepared - sanded, stained, varnished or painted, as you like. To fix the three boards, screw the 1x4 strips from the bottom, as shown in the photo. Then screw the flanges of the water pipes to these crossbars.

Then, using adapters, assemble the table frame. It is very easy and even fun, it will take about 20 minutes. If you bought black pipes, it is advisable to cover them with silver so that they do not rust. One more piece of advice regarding water pipes: be sure to check the threads and threads by screwing the pipes into a flange or tee. If it doesn't spin well, ask the store to adjust the shear or re-tighten the pipe, which should also help. Since the table is on casters, you also need a fitting that would accept the wheel's threaded stem. This is a small plastic socket that you drive into 4 tubes. You can add some epoxy to make it perfect.If you decide not to put the table on casters, you will need to compensate for the height of the pipes (or whatever you choose for the table legs) by about 12 cm. This table is designed for 6 people. You need at least 15cm of overhang at both ends of the table to accommodate the chairs. But, if you want the table to be for 4 people, you can expand the meter tube to about 127 cm, thereby freeing up four more leg and elbow room.

How to make a kitchen table from pipes and a solid board

Using the diagrams below, you can easily assemble a pipe frame for this beautiful kitchen table. To create a style, you will need a solid board. How to assemble a kitchen table with your own hands. As with most projects, the exact order in which you assemble the structure can vary and depends on your approach to the build process. Below is a recommended step-by-step guide to building a pipe kitchen table. First install the horizontal support on the frame. The support uses six tee fittings.

Follow the diagram shown (fig. 2) to assemble the horizontal support. Be sure to tighten the set screw on each fitting to secure it to the pipe.

From there, insert the length of pipe used for the legs into the open sockets on the horizontal support (Figure 3). Tighten the set screws to secure it to the pipe. Then insert the rollers. After that, slide the flange fittings onto the ends of the pipe at the top of the frame (Figure 5). Once the frame is fully assembled, attach the tabletop. This project used a solid board, but you can attach any wood.Place the tabletop over the flange fittings and screw on (Figure 6)

Please note that the flange fittings have four holes for countertop mounting. Now that the countertop is attached, you should have a fully stocked kitchen table.

Source

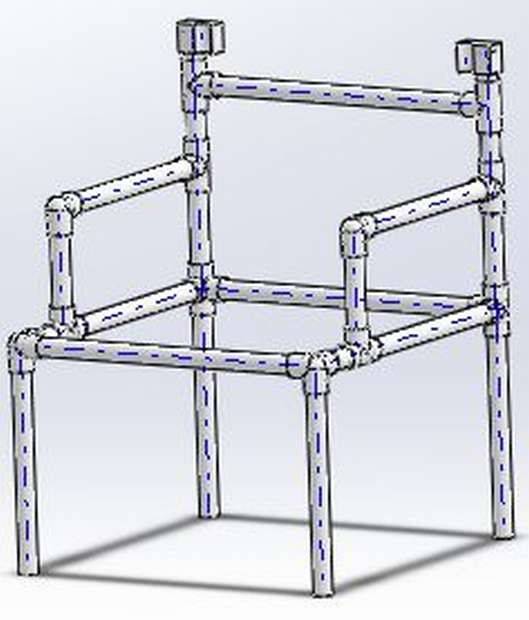

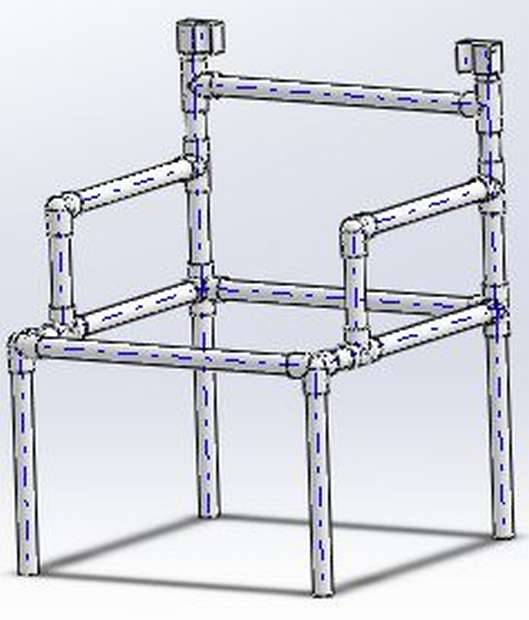

Calculations and drawings

You can design a chair from pipes on a piece of paper or a personal computer. Complicated calculations do not need to be done, since the products have a simple design.

When planning work, the following nuances should be taken into account:

- Using the curvature factor. Curved fragments look more interesting and attractive than straight links. A chair with a sloping back will fit better into any interior. It is possible to give the workpiece a curvilinear shape by slowly heating it over an open flame. Then it is gently bent and fixed until it cools completely. Another way is to use factory-made contours.

- The length of the pipes is selected taking into account the fact that part of the workpiece will be immersed in the fitting. This distance is 20-50 mm depending on the type of plastic pipes. Before drawing up a drawing, it is necessary to experimentally measure how far the links go into the opening of the coupling.

- It is better to take a sample that is comfortable to sit on as the basis of the project. You can add your ideas to it. Keep in mind that plastic bends under pressure. To increase the strength of the finished product, transverse ties on the legs and the seat are provided. Reinforced plastic is much more practical than analogues without aluminum inserts.

- The diagram is drawn to scale with an accuracy of 1 mm. It displays all the details, places and order of joining blanks to each other, screeds and partitions.A variant of cutting blanks is provided, in which the amount of waste will be minimal.

- If the workpieces are connected without glue and soldering, then the joint must be strengthened. For this, screws are used, which are screwed in so that they tighten and fix both fragments. It is better to screw the hardware on the underside of the pipe and from the back. So they will be almost invisible.

The finished scheme is the basis for the calculation of building materials.

What do you do with old furniture?

Poll Options are limited because JavaScript is disabled in your browser.

Increasingly, it pleases with unusual innovations, expanding the traditional perception of things. So today we present to your attention a home-made stool made of PVC pipes, which any master can do. Let's go! Materials:

- PVC pipe, diameter 25-32 mm;

- Fittings: cross - 2 pcs, straight connecting tee - 8 pcs, plug without thread - 8 pcs;

- Plywood, thickness 10-16 mm;

- Self-tapping screws for screed benches;

- Varnish or paint on wood.

Tools:

- Soldering iron for PVC pipes;

- Electric jigsaw;

- Screwdriver or Phillips screwdriver;

- Sandpaper or grinder;

- Plumbing scissors or hacksaw;

- Paint knife;

- Tape measure, pencil or marker.

canopy

Similarly, a canopy is made, for example, for a car. However, in this case it is better not to bend the pipes, but to install them vertically. In this way, greater stability can be achieved. On one side, place 4 columns, on the other the same number. Between themselves, connect them with crosshairs from shorter pipes.

From above, along the perimeter, horizontally connect using pipes and adapters. As a roof, you can use the same awning fabric that is used to create the gazebo.

It is worth noting that such a canopy is relevant only in the warm season. In winter, if there is a strong wind, the awning can be blown away if it is not firmly attached to the ground.

What do you need to make furniture?

Collect DIY PVC furniture not difficult at all - you need a minimum set of tools, basic skills in working with them and a little creativity. The result is sure to be comfortable chairs, armchairs, shelves and even tables - the range of possible products is limited only by your imagination.

The assembly process will take no more than an hour for each item - and this includes design. By the way, in order to quickly figure out how to form a particular piece of furniture, on our website you can see a variety of photographs of plastic products. For example, the photo above shows a very convenient and stylish rack for books and magazines, and when supplemented with flat shelves, other items can be placed on it.

The minimum set of necessary tools is as follows:

- roulette;

- marker;

- hacksaw for metal.

Other items that can be found at any summer resident may come in handy - a file for smoothing cuts of plastic pipes, a drill, a soldering iron. But the level, for example, is not needed - all parts, as in the assembly of ordinary water pipes, will be connected with special fittings - it will not be possible to deviate from the desired angle with all desire. Because of this feature of PVC products, separate fasteners are not needed - screws or glue.

Plastic pipes. Ideas for the interior

Crafts from pipes look fresh and not hackneyed in the interior, a considerable plus should be seen in the cost of the material. You can create unique things without investing only your time in it! Below are examples of what you can easily make from leftover pipes.

Work organizer

We advise you to start making crafts from the organizer. You can’t imagine easier - cut the pipes at the same angle and glue them to a solid base. You can arrange them in a fancy shape, paint them in your favorite color or leave them natural. Now the workplace will be in perfect order.

Frames for mirrors and openwork partition

To make a frame, you will need pipes of different diameters, thick paper (cardboard), a jigsaw, glue and a mirror. On cardboard, trace the outline of your mirror and remove it. Now, cut the desired number of pieces and create a beautiful frame for your mirror. In places of contact, smear the pieces with glue, ensure that the parts fit together and leave the frame alone until the next day.

By the same principle, you can make an openwork partition for zoning a living space. This design of circles of large diameter looks beautiful.

Clothes hanger

Hangers in our time there is a huge variety. Everything depends on the task at hand. If you have a small corridor, then a hanger-rack will be what you need, if you need to make a hanger for a child in a room, then a U-shape with a stable base and additional branches to hang a backpack will be a great solution. For little money you get a designer item! It should be noted that you can decorate the resulting product in a color suitable for the interior.

Pots and vases for flowers

Crazy hands make cool flower pots from sewer pipes of large diameters, and flowerpots from thin ones. You can get a stylish composition from such flowerpots by placing them on a common base made of painted plywood. You can decorate pots with stickers, you can paint them with acrylic paints and open them with varnish, you can print family photos on self-adhesive film and wrap home-made flowerpots.

Shoe rack

Use the remaining sewer pipe as a stylish shoe rack. The diameter of the pipe must be at least 150 mm so that you can comfortably accommodate your pair of shoes. Cut the pipe into pieces 25-30 cm long (slightly longer than the length of the boots).

Coffee table

Do not think that this item in the interior will look ridiculous, massive. If you assemble it correctly, add decorative elements, paint in one or more colors, then this attribute will fit into any design.

Turn on your imagination and look for non-trivial approaches.

Turn on your imagination and look for non-trivial approaches.

At the first stages of drawing up drawings, you need to decide on the material for the countertop. It can be plastic, tempered glass, wood, steel. You can use the old surface of the out-of-service table.

On top of the plastic frame, as a rule, a glass tabletop is attached.

On top of the plastic frame, as a rule, a glass tabletop is attached.

After that, pipes are cut, connected by means of fittings. If you provide jumpers in the design, this will make the coffee table more durable. The tabletop can be fixed with self-tapping screws. A great idea is to attach wheels to furniture fittings on the legs. This will make this product mobile.

Think carefully about the size and design of the future piece of furniture.

Think carefully about the size and design of the future piece of furniture.

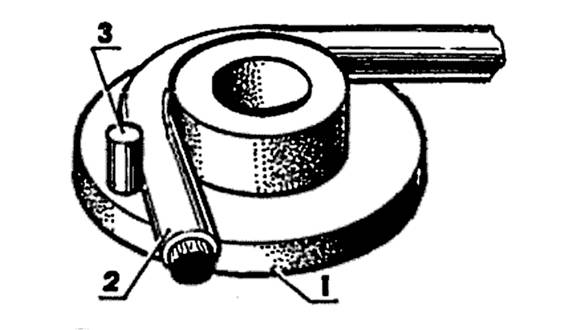

Making a metal chair

Metal furniture is easy to make by connecting straight pipe sections and applying the method of bending tubular elements on a Snail-type machine. The order of operations is as follows:

- The tube is plugged at one end.

- The blank is filled with fine sand.

- Close the second end.

- The piece is placed in the machine, fixing it between the pin and the protrusion on the disk.

- Applying force, bend the section of the profile pipe to the required angle.

- To apply less effort, you can heat the place of the bend with a blowtorch until it turns red.

- In order for the bend to turn out as it should, you will need to use a plaz (cardboard or plywood with a printed outline of the part).

- The elements can be connected by welding or threaded connection. For fasteners, it is permissible to use wooden bushings into which self-tapping screws or screws are screwed.

- After welding, the resulting seam is cleaned with a file or grinder so that the joint becomes even.

To make a simple chair from a profile tube (20x20 or 20x40), you will need:

- welding machine with electrodes No. 3;

- angle grinder (grinder);

- file, sandpaper;

- measuring tool;

- drill with nozzle.

The dimensions of the frame are selected, focusing on personal preferences. You can make a seat from boards, plywood or furniture board. If you want to get an all-metal chair, you should cut the required number of tubular elements for the seat and attach them to the frame by welding or bolts.

Material: wood, plywood, pipes and metal

Having decided to build a practical and functional folding chair, in addition to its design, construction and dimensions, it is necessary to carefully select the materials of manufacture. Most often, home masters prefer:

-

Natural wood. Such products have interesting designs. They can be both stationary (that is, quite massive) and portable (used mainly for outdoor recreation). From wood, you can build a real work of art. The main thing is to correctly calculate your strength, because all wood is divided into: hard, soft and durable.

For example, with oak, a novice master will not cope. Since this material is quite difficult to process. It is better for beginners to try to make furniture items from softer species: linden, pine, birch.

These lumber have good technical qualities and are more affordable cost. It is worth adding to the advantages of natural wood: resistance to negative factors (with proper treatment with antiseptics and pesticides), safety and environmental friendliness, long service life, pleasant aroma of wood and a delicate texture to the touch.

A wooden chair with a folding mechanism will make you proud and delight every time. It will harmoniously fit into any exterior of the yard, and will become its decoration.

- Plywood. This material has many advantages. The versatility of plywood allows you to create chairs of any design and for different purposes. Such products can be installed in any residential area due to the naturalness of the material, or on the street. A special plywood production technology guarantees it: environmental friendliness, strength, reliability and durability. Plywood is easy to process with paints and varnishes. Therefore, a piece of furniture can be colorful and original. In addition, coating with varnish or paint will significantly extend the life of the chair.If you choose laminated plywood for the manufacture of a chair, then its surface will be perfectly flat, smooth and pleasant to the touch. The positive aspects of making furniture from plywood include the fact that it is able to withstand heavy loads, and even in its raw form it is not at all afraid of moisture.

-

PVC pipes. Such an original approach to the manufacture of easy-to-use chairs is in demand among lovers of original ideas. The biggest plus of furniture manufacturing from PVC pipes - saving money. As a rule, men begin to assemble furniture with pipe sections available.

The most important thing here is to have a special soldering iron and be able to use it. To make bent shapes from a plastic pipe product, it must first be heated with a gas burner. A feature of furniture made of PVC pipes is that they do not need finishing. This material is not afraid of any sudden changes in temperature, or high humidity, or direct sunlight. It copes well with the exerted loads with a properly assembled frame and has a high service life of more than 50 years.

- profile pipes. This material differs in diameter and cross section. Pipes can be round, rectangular or square. To work with a profiled pipe, you must have a special tool - a snail, so that you can bend the material. The advantages of profile pipe products include: high resistance to mechanical damage and negative factors, reliability, durability and affordability. If you choose a thin-walled pipe, then the furniture product will have a small weight.A wide choice of geometric shapes of the profile tube allows you to create unique and original designs of folding chairs.

- Metal. Such products are distinguished by: low weight, compactness, variety of shapes. Their seat and back can be either fabric or wood. The features of metal products include: a small investment in manufacturing and a simple type of design. The only thing is that for the manufacture of a folding model of a chair made of metal, you must be able to work with a welding machine.

Attention: to use the chair indoors, you can opt for common furniture fabrics: leatherette, tapestry, jacquard. If the furniture will be used outdoors, it is better to choose a tarpaulin or bologna material.

Assembling a chair with an upholstered seat

The chair can be made with your own hands from the remnants of plastic pipes. The dimensions of the product are arbitrary, you can, for example, take measurements from a regular chair. Assembly work includes the following steps:

Markup. Marking is applied to the pipes in accordance with the removed parameters. After that, the material must be cut into fragments. Seat assembly. To form the base of the seat, a cross is used, to which 4 short pieces of pipe are soldered, they will go from the cross to the legs

It is important that the joints are sufficiently secure, because this part of the chair must support the weight of a person.Soldering is carried out as follows: the soldering iron must be placed on a level place, screw the drone, as well as a sleeve of suitable dimensions, set the thermostat to 260 degrees, and then plug the tool into a power outlet and switch the toggle switch to working position

When the nozzles are warmed up, it is necessary to install the edge of the pipe and the coupling in them, wait a few seconds. After that, you should remove the products, join the elements at a right angle. Then you need to wait for freezing. If the master does not have a soldering tool, then glue can be used for assembly, another possible option is to fasten parts with self-tapping screws. However, it should be remembered that self-tapping screws can spoil the appearance of the product. Leg mounting. You need to weld a tee to the free edges of the plastic pipes, and then insert the legs into the lower holes of the tees with your own hands. The lower ends of the legs are closed with plugs. You can also make a rocking chair, for its manufacture it is necessary to take PVC pipes of large diameter, bend with a blowtorch, attach to the legs from below (instead of plugs). Handrail assembly. For each pipe that will be used as a handrail, you need to attach an elbow fitting on one side and a tee on the other side. Then a short piece of PVC pipe should be attached to the fittings. After that, the handrails are attached to the seat (inserted into the tees connecting the legs to the seat). In this case, the tees of the handrails should be on the back side, where the back of the chair will be attached. Back assembly. To the ends of the PVC tube, which is designed for the back, you need to weld along the fitting-turn about half the length of the back.Tees are soldered to the edges of these segments, which are interconnected by another tube that acts as a stiffener. If necessary, you can make several of these ribs. Then two more pieces of pipe half the length of the back connect the back to the crosses of the railing. Seat installation. At the last stage of making a stylish chair with your own hands, you need to cut the seat out of a piece of plywood, screw it to the cross with self-tapping screws, and then upholster it with foam rubber, sheathe it with a cloth.

On this, the work on assembling a chair from plastic pipes is completed, the furniture is ready for use.