- Self-assembly

- Appointment of sewer manholes

- Material for the manufacture of drainage wells

- Making a tank from plastic pipes

- Applicable materials

- Several ways to make a sewer for your home

- DIY drainage well

- Materials and working principle

- Types of drainage systems

- Construction order

- Digging a trench

- The device of sewer wells of different types

- Types of filtering facilities

- Absorption well in the drainage system

- Filtration structure in the sewer system

- We collect sewer drainage

- Features of using filter containers

- stone wells

Self-assembly

For installation of a drainage well You can use two options that differ from each other in cost. The first option is more expensive. You can buy a ready-made drive equipped with a tray and holes for drains. It must be installed in the pit, drains connected and sprinkled.

To implement it, you need to purchase the necessary tools and materials, perform installation operations.

From the tools you will need a shovel, a hacksaw, a measuring tool, containers for removing soil and mixing cement.

The list of materials required for the work includes:

- Crushed stone of small fraction.

- Screened sand.

- Cement.

- Corrugated pipe: with a diameter of 35-45 cm - under a plastic inspection well without descending a person, with a diameter of 1.0 meters and above - under a tank into which a person will descend.

- Rubber sealing elements of the required diameter.

- Covers for the bottom and the hatch.

- Mastic.

Installation of a drainage well is carried out in accordance with a drawing drawn up in advance, and consists of the following operations:

- The drain pipe must be cut to the correct height. This height should correspond to the future depth of the pit.

- It is necessary to retreat from the lower edge of the pipe, and make holes according to the diameter of the inserted drains. The height of the holes depends on the depth of the drains.

- Using mastic, it is necessary to attach the bottom to the base of the pipe and make sure the connection is tight.

- When the barrel is ready, it is necessary to dig a pit for it. The diameter of the pit should be 30-40 cm larger than the diameter of the pipe.

- The bottom of the pit is rammed and covered with rubble to a height of 20-25 cm.

- Crushed stone is poured with cement mortar, 10-15 cm high.

- After the solution hardens, the bottom and walls of the pit are covered with geotextiles.

- A storage or manhole for drainage is installed at the bottom of the pit and connected to the drains. The places where drains enter the mine are sealed with mastic.

- If necessary, a suction pump is installed in the shaft.

- The space between the tank and the walls of the pit is filled with rubble.

- The cover is installed. It should tightly cover the top opening of the tank.

- The top layer is decorated with turf.

Appointment of sewer manholes

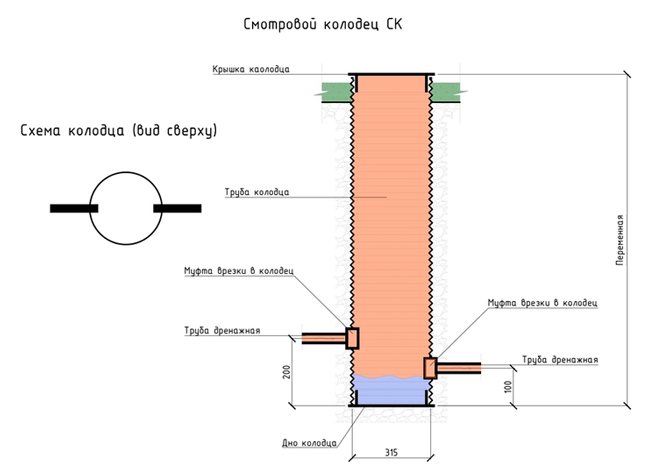

The nodal type of the inspection shaft is provided at the junction of several pipelines.The connection of the sewer line with the tray is performed by a smooth rounding. Wells designed for inspection on large collectors are called connecting chambers.

The structure in question is mounted on a straight section of the laid working network and acts as a point for inspection and maintenance of the system. The working distance is primarily determined by the diameter of the laid pipe. Based on the indicators:

- up to 155 mm - 3500 mm;

- from 200 mm to 450 mm - 500 m;

- from 500 mm to 600 mm - 750 m;

- from 700 mm to 900 mm - 100 m;

- from 1000 mm to 1400 mm - 150 m;

- from 1500 mm to 2000 mm - 200 m;

- more than 2000 mm - 250000-300 m.

Watch the video

A rotary well for sewerage is mounted on sections of the pipeline in order to change the direction of the network section. In this case, the angle of rotation should be more than 450 (degrees).

To reduce high hydraulic pressure between the outlet pipe and the connected pipe, the working angle must be at least 900 (degrees). From 1 to 5 pipes are laid in the turning radius, where the tray has a smooth curvature. Its purpose: cleaning the intake pipes from possible blockages.

Material for the manufacture of drainage wells

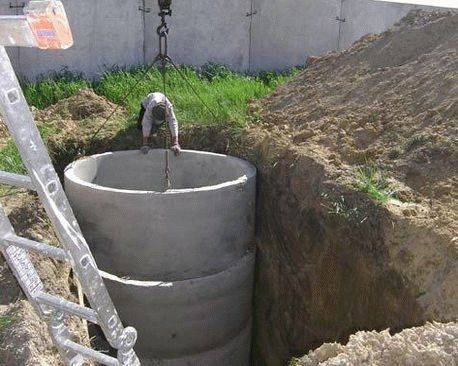

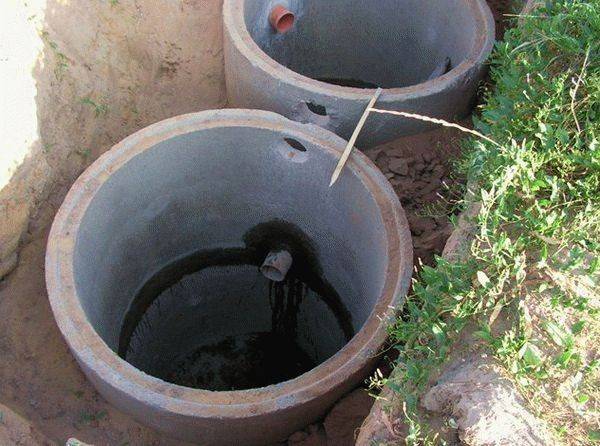

wells for arrangement of the drainage system you can make it yourself from concrete rings, or buy ready-made plastic containers of the right size and install them on the site. It is up to you to decide how to make a drainage well, but it is worth considering that the first option is cheaper, but much more difficult in terms of labor intensity of manufacture, the second is simpler, but somewhat more expensive.

The manufacture of a well from concrete rings is associated with a number of problems. Due to the heavy weight of concrete structures, it may be necessary to hire special equipment and invite assistants.They need to make holes for pipes, which is also quite difficult.

However, the complexity of installing a concrete well is justified by its great reliability, strength and durability. Concrete structures are practically invulnerable to any negative impacts.

They can be mounted in any place and even in areas standing on soils subject to hydrothermal movement and heaving during freezing, where plastic structures can be deformed.

Modern plastic containers are also very reliable, and in addition, they are convenient and easy to install, weigh little and are easy to mount. On their body there are already holes of the required diameter for connecting pipes.

Many, in order to save money, resort to a combined installation option. For inspection and rotary wells, plastic tanks are purchased, and filter and storage tanks are made of concrete rings. There is another available option - to make a well from plastic pipes yourself, how to do this is described below.

Plastic containers are available in different sizes, their body already has taps of the required diameter for connecting pipes

Making a tank from plastic pipes

If a decision is made to make a well out of a plastic container, but it is missing, you can make it yourself. To do this, you should buy a plastic pipe with a diameter of 35-45 centimeters, if you plan to build viewing and turning objects, and a product with a cross section of 63-95 centimeters for absorption and collector structures.

In addition, you will need a round bottom and a plastic hatch, the dimensions of which must match the pipes. You will also need rubber gaskets.

The sequence of manufacturing a plastic container:

- Cut off a piece of plastic pipe of the desired size, which is determined taking into account the depth of the well.

- At a distance of 40-50 centimeters from the bottom, a hole is made for connecting pipelines and equipped with gaskets.

- The bottom is attached to the plastic tank and the resulting seams are sealed with sealant or bituminous mastic. The installation process of a do-it-yourself drainage tank is carried out as described above.

Applicable materials

Whether it is a catchment or revision well, concrete rings are perfect for arranging it. But for all their strength and durability, resistance to aggressive environmental influences and other advantages, they have a significant drawback. Due to their heavy weight, it is difficult to install them on your own; you need to rent special equipment for these purposes, and this will increase the cost of the well.

There is another option - to buy a ready-made plastic container, especially since they are produced in different sizes. Such a container is more expensive than rings, but it is easy to install. At the same time, modern plastic containers are quite reliable, they are also not subject to corrosion and other aggressive influences. And besides, they have one more advantage - many manufacturers produce containers, in the cases of which there are already holes for pipes. And when choosing concrete rings, you need to remember that you will have to make the holes yourself.

Sometimes you can find a combined version:

- rotary and manholes are made of plastic containers;

- drain and storage - from concrete rings.

Several ways to make a sewer for your home

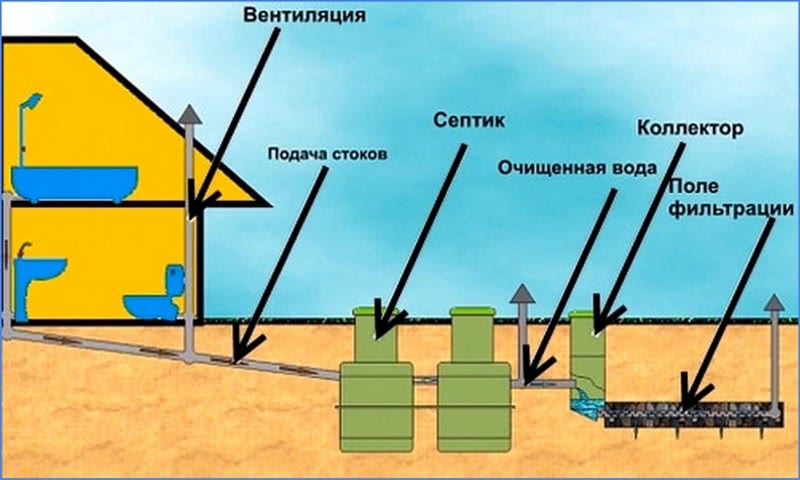

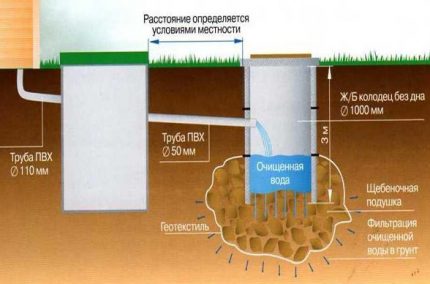

sewage house water for cleaning enter the septic tank, then into the drainage well, from which they go into the ground.

These sediments must be periodically removed from the septic tank using a sewage truck. From the first chamber, water overflows into the next chamber, where fine particles are also deposited.

But not all substances are able to process anaerobes. Therefore, from the septic tank, clarified water is sent to the drainage well. Another type of bacteria lives there - aerobes and the processes of decomposition of organic residues are carried out with the participation of oxygen. Purified water from the drainage well goes into the ground.

The depth of the septic tank should not exceed 3 meters. This parameter is dictated by the capabilities of the sewage machine.

A drainage well is also made in the pit.

The choice of the size of the drainage well depends on both the volume of effluents and the filtering ability of the soil. The drainage well is made in the following order.

The pit breaks out. There should be at least 1 meter between the bottom of the pit and the groundwater level.

During the construction of a septic tank and a drainage well, it is necessary to observe the following distances, which are provided for by regulatory enactments:

- to the well - 50 meters;

- to the reservoir - 30 meters;

- from the septic tank to the house - 5 meters;

– from the well to the house - 8 meters.

The biotreatment station is a complex structure, which accommodates a whole complex of treatment facilities. But the size of the station is quite modest. The peculiarity is that it requires electricity to operate. It is also not allowed that the temperature inside drops below zero degrees. There may also be restrictions on the presence of fluorine and clean water (without organic matter) in the drains, as this can lead to the death of bacterial colonies.Installation and maintenance of such stations is carried out by specialized organizations.

Advantage biological treatment stations in compactness, in the absence of the need to find places for filtering areas, and in the fact that at the outlet of the station almost pure water is obtained (at least 95% purification), which can be dumped anywhere, for example, used for watering a garden. A small amount of sediment that needs to be periodically removed from the station can be used as fertilizer (if there is not much chemistry in the wastewater). Those. call of cesspools is not required. In cases of dense development, biological treatment plants become an uncontested option.

Wastewater collection tank.

If no one lives permanently in the country, then just a container for collecting wastewater can help out. Actually we are talking about a single-chamber septic tank without a discharge. Cleaning of such a container should be carried out by vacuum trucks as it is filled. But the cost of such services is not small. For their implementation, an agreement is concluded with the organization, which indicates the frequency of cleaning. Therefore, it is worth thinking about the volume of wastewater in advance. The average volume per person is 0.15 cubic meters. If the container is made with a volume of 5 cubic meters, then for one permanent resident, the frequency of waste removal will be 33.3 days. And for 4 people - 8.3 days. Will waste disposal services be prohibitively expensive? But if water discharges occur only occasionally, during periods of visiting the dacha, then perhaps this method will be beneficial.

The drainage well can be replaced with a biofilter or aeration tank.

These are complex systems, but they allow you to replace the drainage well if its creation is not feasible due to the location conditions or the composition of the soil.

DIY drainage well

It is unlikely that anyone would think of building a house on a sandy area. For construction, places with groundwater are selected so that in the future there will be no problems with drinking water. But this plus of the area can turn into waterlogging of the soil, and the destruction of the foundation of the building. To protect yourself from this problem, you need to build a drainage well. This design serves for groundwater disposal from the site.

Materials and working principle

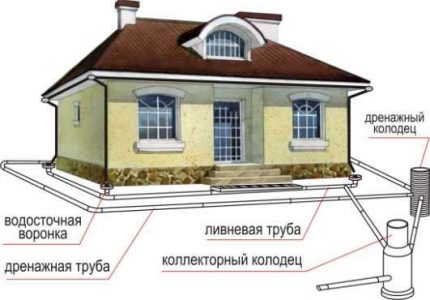

The work of the well is simple. A trench is pulled out on the site to collect and drain water - a drain. One or more drains are connected to it, which drain the liquid into a reservoir located nearby with the site or into a special reservoir.

Types of drainage systems

Drainage wells are divided into four kind by type soil and groundwater movement. The principle of operation of each is different, and before you make a drainage well, decide what system you need.

Collector well

This version of the drainage system is able to collect and accumulate moisture, which can later be dumped into a ditch or used for watering plants. Its construction is appropriate in the lowest part of the terrain.

Rotary wells

They are mounted on drainage bends or in places where several sewers are connected. In such places, there is a high probability of contamination of the internal cavities.

absorption well

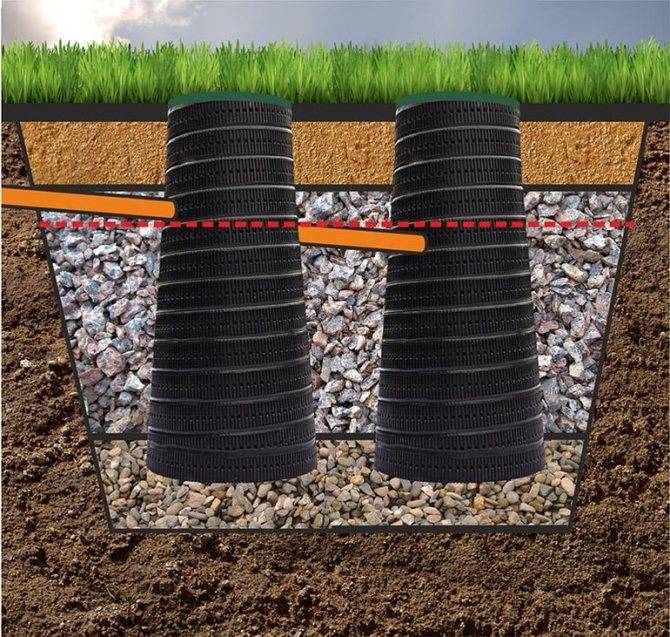

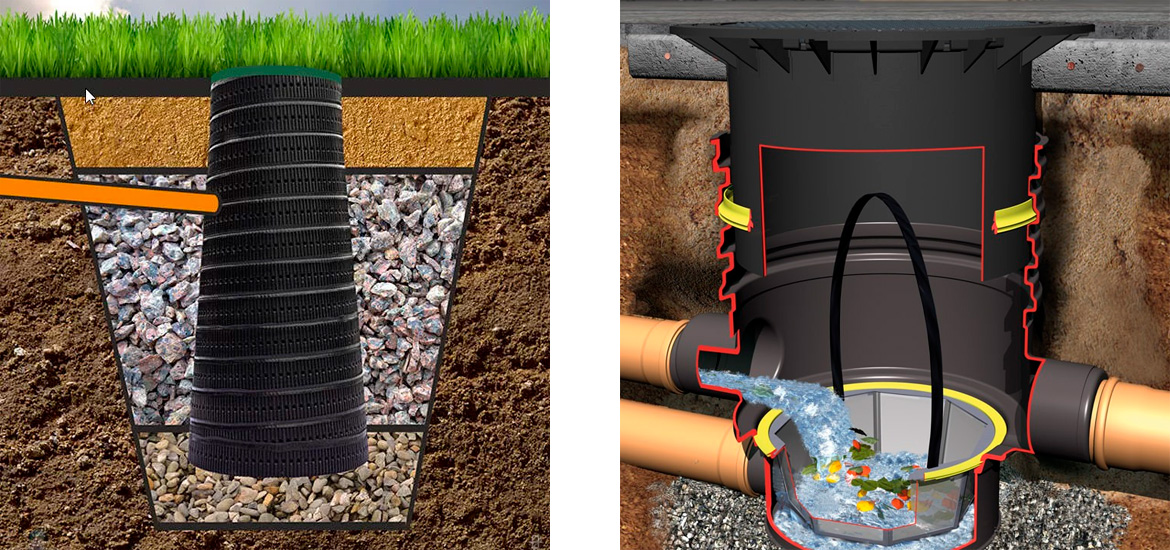

Such a well must be equipped in those places where it is impossible to lay pipes to drain liquid, due to the lack of a reservoir for discharge or sewerage.This is the deepest type of drainage system, and the minimum depth must be at least 3 m. The bottom in the well is made of crushed stone or sand, this will allow the liquid to be discharged into the groundwater.

manhole

This option is used to access the drainage system and possible repairs. For convenience, its width should be at least 1 m. In principle, such wells can be made in other systems, because repairs and preventive cleaning will not be superfluous.

Construction order

When choosing the size of the future well, the area of \u200b\u200bthe site is taken into account, namely the part that needs to be drained.

When all the materials are ready, work can begin. We dig a hole at least 2 meters deep, depending on the type of drainage system. At the bottom you need to equip a special pillow. Coarse sand is best suited for this. The bedding should be from 30 to 40 cm thick, in the process of arranging it must be well tamped.

On the backfill, you need to make a square formwork for arranging the foundation, which will serve as the bottom of the well. It should be laid reinforcing mesh, preferably small. This structure is filled with concrete mortar.

After the concrete has set, it is installed on the base internal and external formwork. The walls from above must be connected with wooden planks. Concreting of the walls of the well is carried out according to the level. After 2 - 3 weeks, when the concrete is completely dry, we remove the formwork and backfill the base. It is better to use fine gravel or expanded clay for this.

Digging a trench

To drain liquid from the well, polyethylene or asbestos pipes are used.Just digging a trench and laying pipes towards the dump site will not be enough. In order for the reset to occur correctly, you need to perform the following steps.

- Fill the bottom of the trench with sand.

- Lay a layer of fine gravel on top of it.

- A drainage pipe is laid on such a pillow, which is also covered with sand and gravel.

Together, the layer of sand and gravel should be half the depth of the trench. The remaining depth is covered with loam, and a fertile layer of earth is laid on top.

When arranging drainage on an already built-up site, work should be carried out in small sections of 15–20 meters each. During operation, the soil removed from the excavated section is poured into the previous section of the trench. It is better to start work in late July - early August. At this time, the groundwater level is the lowest.

The device of sewer wells of different types

The sewerage system has a very ancient history, so its design and technology have been brought to a very high quality state. This article will address the main issues related to the use of sewer wells in the sewer system.

The normative act regulating the requirements for sewer wells and the procedure for their installation is SNiP 2.04.03-85 “Sewerage. External networks and structures”. The document displays all factors related to sewer wells, including their location, classification, dimensions and performance.

For the arrangement of sewage in a private area, it is imperative to use manholes, placing them on the pipeline section between the building and the wastewater receiver.In addition, one of the possible options for the disposal of wastewater after it has passed through a septic tank is a filtering sewer well. Manholes must be installed not only in private households, but also on local sewer systems. The installation site should be located behind the so-called red building line, which is a conditional boundary that divides the target area into certain segments. The SNiP states that sewer wells must be installed every 35 meters if the pipeline diameter is up to 150 mm, or every 50 meters - with a pipeline with a cross section of 200 mm.

In addition, manholes are installed if the system contains:

- twists and turns;

- changes in pipe diameter or slope;

- branches of the structure.

Requirements for the performance of reinforced concrete wells are displayed in GOST 2080-90, and for polymer wells - in GOST-R No. 0260760. Most plastic structures are also supplied with manufacturer's instructions, which set out the conditions for using the well.

Brick, concrete or reinforced concrete is used to make stone sewer wells, and rubble stone is used to create filter wells. Polymer wells can be made of PVC, polypropylene or polyethylene. In addition to structures made from a single material, there are structures on the market made from compounds of various resources.

According to SNiP, the dimensions of sewer wells vary as follows:

- when using pipelines with a diameter of up to 150 mm - at least 700 mm;

- up to 600 mm - 1000 mm;

- up to 700 mm - 1250 mm;

- from 800 to 1000 mm - 1500 mm;

- from 1200 - 2000 mm;

- from 1500 mm with a system laying depth of 3 m.

The volume of the structure is not indicated anywhere, but knowing the initial depth and diameter, you can calculate this indicator yourself.

Order of actions will look like this way:

first, the place on the site where the well will be located is precisely determined;

then the selected area is cleared of any plants (bushes, trees, etc.);

if necessary, buildings located on the construction site are demolished or transferred;

it is very important to ensure unhindered access to the site.

Next, the preparation of the pit for the sewer well begins.

As a rule, a pit is created according to this principle:

- first of all, a hole of the required dimensions is dug;

- next, the bottom is cleaned;

- it is imperative to check for compliance with the depth of laying the structure and the angles of the slopes of the walls of the pit;

- in the case of stone structures at the bottom of the pit, a 20-cm waterproofing layer must be laid, ramming it as tightly as possible.

Types of filtering facilities

There are two types of filtration well structures that operate on the same principle and are installed in a similar way. Their differences are in the field of application. The former are used in the drainage and storm system, the latter in the sewer.

Absorption well in the drainage system

In this case, drainage absorption wells are the end point of a complex drainage system of the site, where groundwater or rainwater rushes through the pipeline, so that later, after passing through a natural filter, it goes into the ground. Its main purpose is to divert water from the house and clean it. from silt and sand.

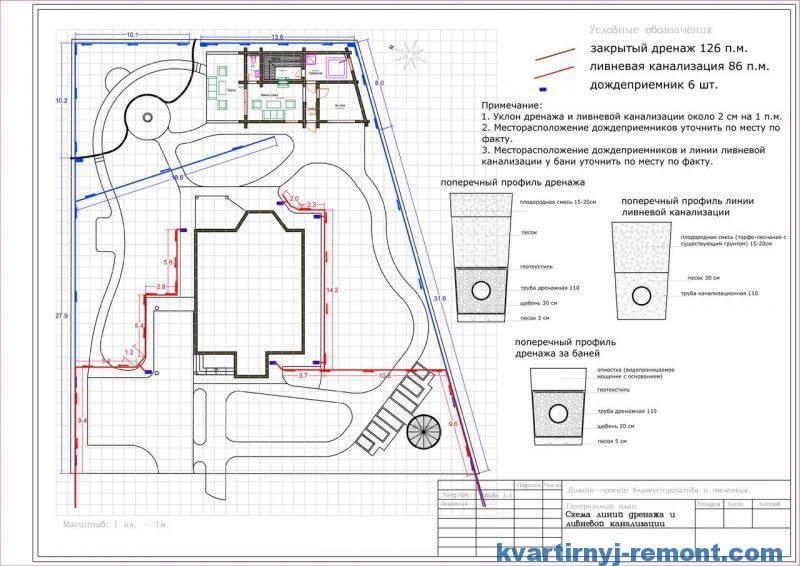

The diagram shows the organization of storm and drainage sewerage of a site with a drive. In soils with a high absorption capacity, instead of a collector, a filtration well is installed

The diagram shows the organization of storm and drainage sewerage of a site with a drive. In soils with a high absorption capacity, instead of a collector, a filtration well is installed

The diameter of such wells, as a rule, is no more than one and a half, and the depth of occurrence is up to two meters. It is allowed to drain both systems into one well. The filter container is installed in the the lowest point of the plotso that the water flows into it by natural gravity.

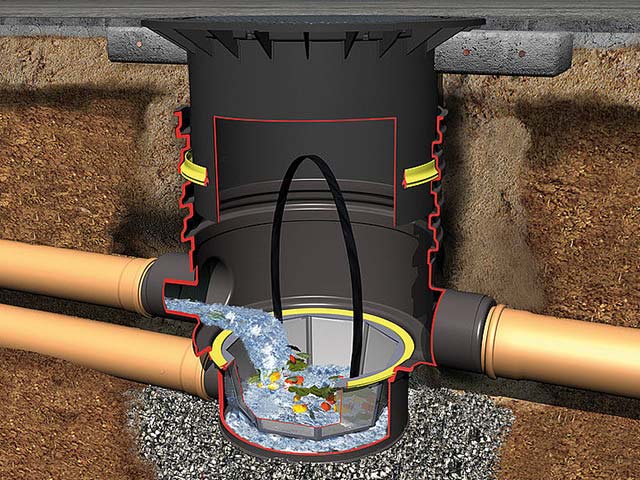

Filtration structure in the sewer system

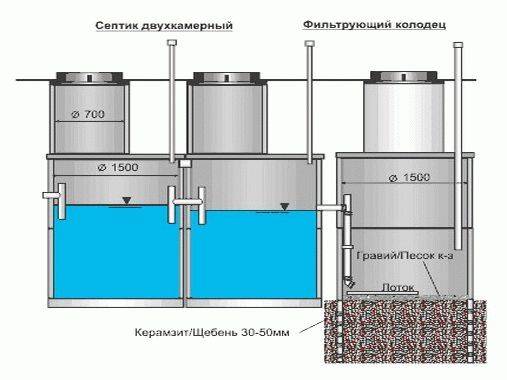

In the sewer system of the site, absorption wells are used for post-treatment of wastewater coming from a hermetically sealed reservoir, in which wastewater undergoes primary biological treatment. The tank is made of concrete rings, brick or rubble stone, or a ready-made septic tank is used.

Scheme of installation of a filtration well with a septic tank, in which sewage flows undergo primary treatment, and then they enter the absorption tank through the pipe and go into the soil through the filter system

Scheme of installation of a filtration well with a septic tank, in which sewage flows undergo primary treatment, and then they enter the absorption tank through the pipe and go into the soil through the filter system

The principle of operation of the system is as follows: sewage from the house sewer enters a sealed container, where it is oxidized for two to three days under the influence of anaerobic bacteria living in an airless space.

Then the wastewater enters the filtration well, where other bacteria - aerobes - are already present. Their vital activity is activated under the influence of oxygen.

As a result of double purification, the liquid entering the soil from the absorption well is almost completely rid of harmful microorganisms and organic substances.

Wastewater disposal can be organized in two ways:

- Separate.Water from the kitchen, bath, washing machines goes into the septic tank, and sewage with feces goes into the cesspool.

- Joint. All household waste goes to a septic tank or storage tank.

As a rule, in the first case, gray effluents are sent to different sewer facilities. For example, fecal - into a storage well with subsequent pumping and removal, gray domestic wastewater from kitchen sinks, bathtubs, washbasins, etc. devices - in absorption wells.

In the second case, a septic tank is required, consisting of at least two chambers, in each of which its own cleaning stage is sequentially carried out. Fecal masses settle in the first chamber, from where they are periodically pumped out by a sewage machine.

A single-chamber septic tank is usually installed in individual farms in which a separate sewerage system is organized

A single-chamber septic tank is usually installed in individual farms in which a separate sewerage system is organized

The second chamber receives liquid waste without suspended particles with a minimum amount of impurities, where they undergo further purification. After that, the water passes through the pipes into the filtration well, from where, after passing through a natural filter, it goes into the soil.

The second variant of the joint scheme is the complete pumping and removal of wastewater.

We collect sewer drainage

Now you know where and where you will remove rainwater. Although plastic structures are smaller than concrete ones in size, you still have to tinker with mother earth.The trenches, from the installation points of the storm water inlets (pipes with finely dispersed perforation, to prevent sand from entering the system, can be wrapped with filter fabrics for high wastewater treatment), go with a slope of at least 30mm, for every 1000mm of sewer pipes.

Try not to mess with the knots of turns, if the system can be made straight as an arrow - this is an unconditional success. Thus, we will reduce the number of inspection (inspection) wells to a minimum. And the sewerage system is good, and savings for you: less digging and less pay.

The assembly is absolutely no different from the standard sewage system, everything is the same, only it is better to purchase high-density plastic elements, they will last longer. Such elements have a characteristic orange color, but they are also available in a classic gray version. It is quite clear that the trench must be deepened to a zone of constant positive temperatures, with reinsurance - this is about 2000 mm. It is recommended to carry out sand filling under the drainage route 20-30mm.

We carefully dig in the trenches, and ram even more carefully. Take this procedure lightly, you will know what it means to go knee-deep into blurred ground.

Features of using filter containers

Absorption tanks are installed in areas where there is slightly moist soil, located at a great distance from natural reservoirs and not equipped with drainage systems. The volume of water required to be pumped out must not exceed one cubic meter in 24 hours.

The shape of this type of wells is round with a diameter of up to 150 centimeters or rectangular, having an area of \u200b\u200bmaximum 6 sq.m. Usually, plastic containers are used to build a filter tank. or concrete rings.

Absorption-type structures are distinguished by the fact that they are a drainage well without a bottom. Instead, they equip a filtering "cushion" that passes the sewage dirty liquid and cleans it of debris. Further, the water is directed to the deep layers of the soil. The depth of such a well in the ground should be at least two meters, and the thickness of the filter pad should be at least 30 centimeters.

stone wells

Insulation of pipes in a well with bitumen After that, the following work is performed for a concrete or reinforced concrete well:

- Foundation preparation. Laying a slab or placing a concrete pad 100 mm thick from concrete M-50

- Arrangement of a tray of the desired shape made of M-100 concrete with steel mesh reinforcement

- Concrete and bitumen sealing of pipe ends

- Bitumen insulation of the inner surface of concrete rings

- Rings of sewer wells are installed (carried out after the curing of the concrete of the tray, 2-3 days after laying) and the floor slab on the M-50 mortar

- Grouting with cement mortar the joints between the prefabricated parts of the well

- Waterproofing joints with bitumen

- Finishing the tray with cement plaster, followed by ironing

- Arrangement at the entry points of pipes of a clay lock with a width of 300 mm and a height of 600 mm more than the outer diameter of the pipes

- Well testing (carried out during the day by filling with water to the upper edge, with the installation of temporary plugs on the pipes). Considered successful if no visible leaks are found

- External backfilling of the walls of the well, followed by tamping

- The device of a concrete blind area 1.5 m wide around the neck of the well

- Insulation of all remaining joints with hot bitumen

Similarly, brick sewer wells are installed, but here, instead of installing prefabricated elements, masonry is made.

Waterproofing is done in exactly the same way.

Thus, the installation of wells made of stone materials is carried out for all types of sewerage: domestic, storm or drainage.

However, in the case of a storm well, lattice hatches can be installed on the well, which simultaneously perform the function of a catchment area.

For drainage - the well itself can be an element of drainage, through special holes in the walls, but this design requires a special calculation.

At the same time, there are slight differences in the components that the series defines: sewer wells KFK and KDK - for domestic wastewater, KLV and KLK - for storm water, KDV and KDN - for drainage.

The table of sewer wells by standard sizes is as follows:

Table of sewer wells

The process for differential wells looks a little more complicated due to their more complex configuration.

drop well

Here, depending on the specific design, in addition to the tray device, in some cases it is necessary:

- Riser installation

- Water breaking equipment

- Installation of a water barrier wall

- Create a practice profile

- Pit device

The very installation of the body of the mine, base and ceiling is carried out according to the same rules.

The only exception concerns a drop well with a riser - at its base it is supposed to lay a metal plate that prevents the destruction of the concrete part of the structure.

It looks like this:

- Riser

- water cushion

- Metal plate at the base of the pillow

- Riser intake funnel

Design of a well with a riser The intake funnel is designed to compensate for the rarefaction that can be created in the riser due to the rapid movement of wastewater.

It is necessary to create differential sewer wells with your own hands using a practical profile only in exceptional cases - a similar design is provided for pipelines with a diameter of 600 mm and a drop height of up to 3 m.

Similar pipe diameters are not used in individual drainage systems. But other types of wells can be used in local sewage with success.

In accordance with the requirements of SNiP sewer wells installed:

- If necessary, reduce the depth of the pipeline

- At intersections with other underground utilities

- For flow control

- In the last flooded well before the discharge of waste into the reservoir

Typical cases when the installation of a drop well in a suburban area is advisable:

- High-speed flow scheme If there is a big difference between the estimated depth of the intra-yard sewerage and the level of effluent discharge into the septic tank or central collector (laying the pipeline at a shallower depth will seriously reduce the amount of excavation)

- If there is a need to bypass other engineering networks underground

- If there is doubt about the consistency of the flow rate in the system with the volume of effluents. With a small volume, too high a speed can prevent self-cleaning (washing out of sediment) of the pipe walls. Equally, if the speed is too low - the sediment may form too intensively, then it makes sense to arrange a fast current for acceleration.

The meaning of such a drop is that due to the creation of a large slope in a short section of the system, the drains begin to move much faster, not having time to cling to the inner walls of the pipe.