- How to arrange a septic tank from concrete rings with your own hands, a scheme and stages of work

- The nuances of the process of building a cleaner from concrete rings

- Location of the structure

- Blitz Tips

- General installation rules

- Advantages and disadvantages of concrete septic tanks

- Schemes of sewerage from concrete rings

- Characteristics and types

- The process of installing a septic tank from concrete rings

- Pit preparation

- Do-it-yourself septic tank made of concrete rings. Installation

- Septic tank made of concrete rings: construction stages

- Preparatory stage

- Excavation

- Delivery and installation of reinforced concrete rings

- Waterproofing

- Ventilation

- Overlapping a septic tank

How to arrange a septic tank from concrete rings with your own hands, a scheme and stages of work

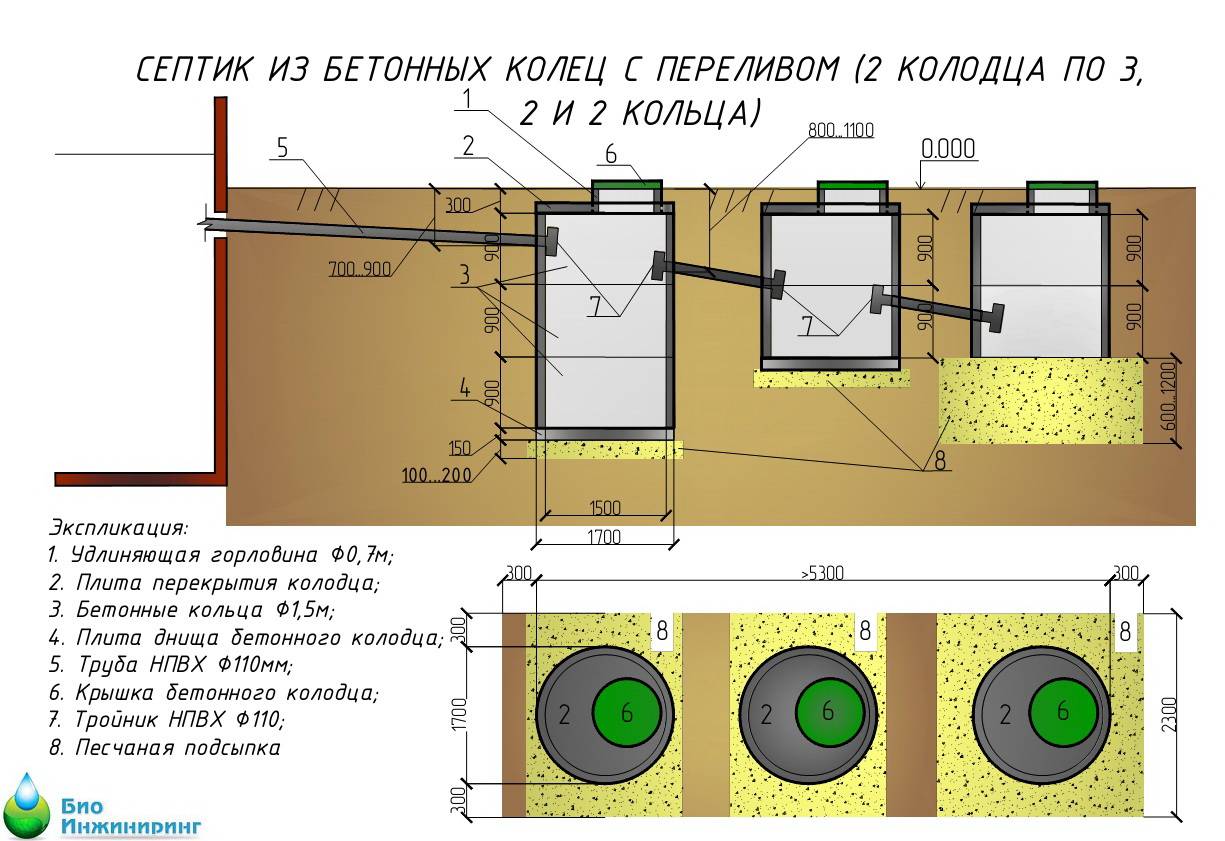

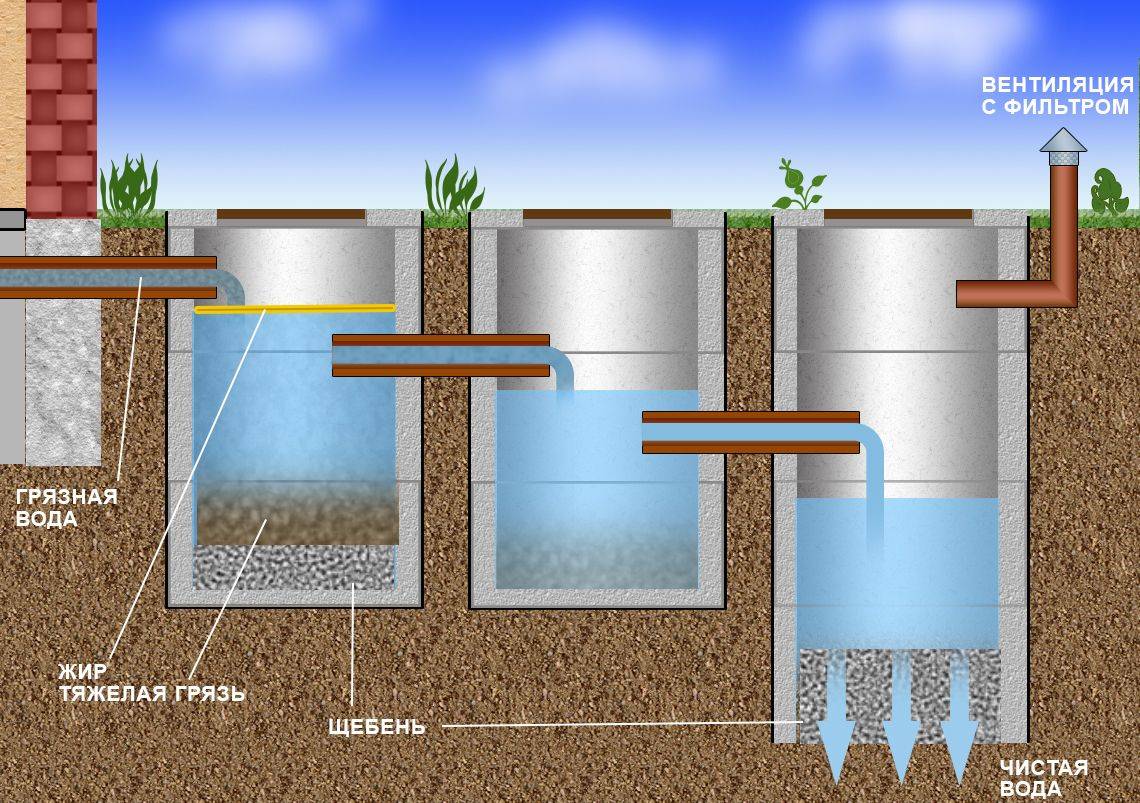

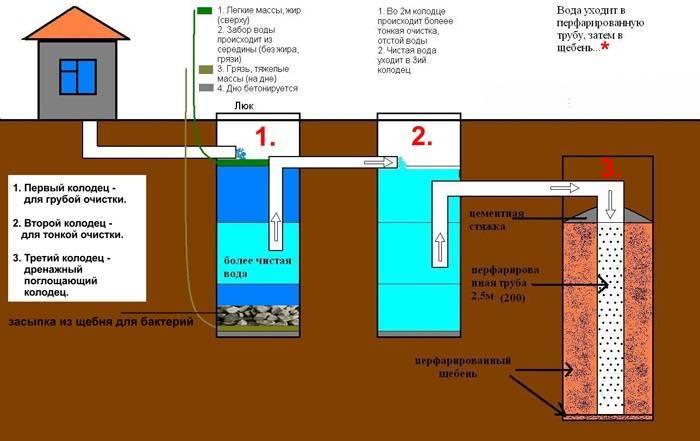

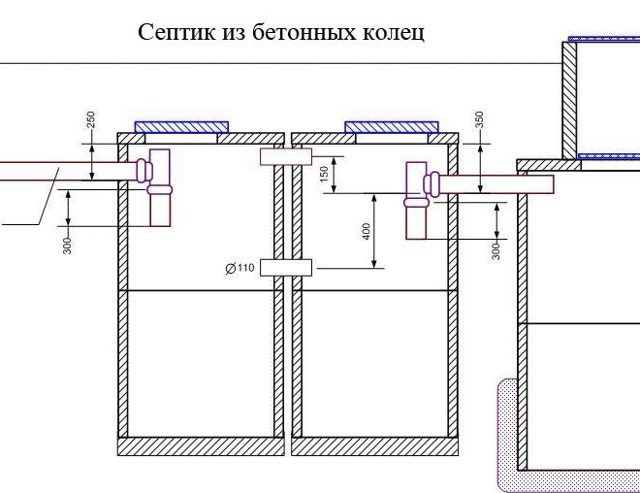

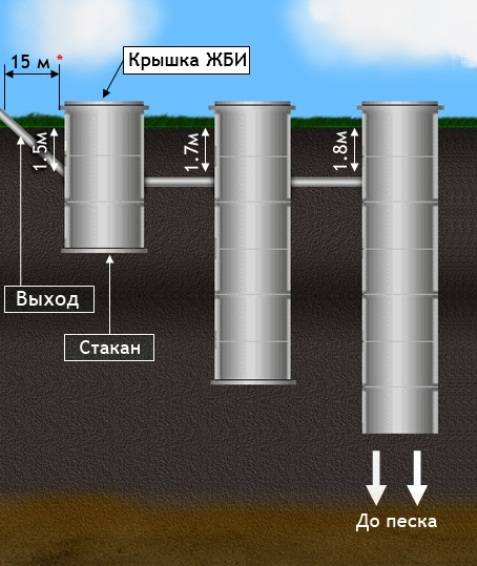

Consider the stages of work on the construction of a septic tank with two chambers. The first will be a sump, and the second a natural soil filter. The total volume of the two chambers must be such as to ensure the reception of wastewater in an amount equal to the volume of liquid coming from the house in 3 days.

It is established that each person spends 200 liters of water per day. This means that for a family of 4 people, the minimum volume of the septic tank will be about 2.5 m³. For this, only two one and a half meter rings are enough. However, the depth of soil freezing must also be taken into account. Therefore, you will need at least two more rings that will be on top.

we unload the rings from the car body at the place where we plan to dig a pit. We put two rings directly into place. We make the distance between them no more than 1 m;

Do-it-yourself septic tank made of concrete rings

Do-it-yourself septic tank made of concrete rings

- in the second ring, using a perforator, we gouge many holes over the entire surface. They are needed for drainage. Their size should not be less than 50x50 mm, since small ones tend to blur over time;

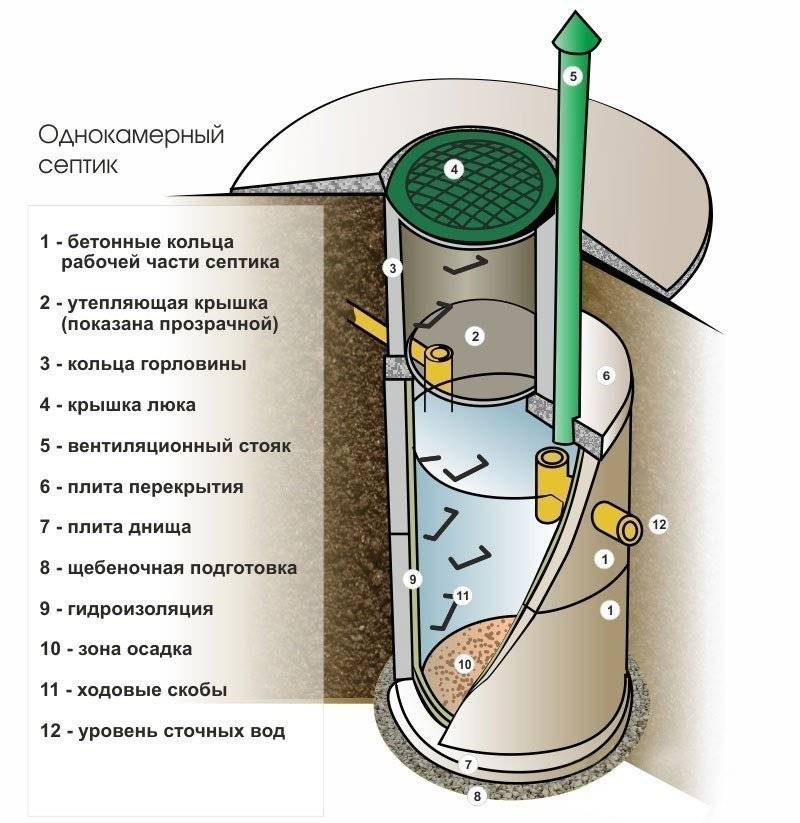

- we start digging the soil right inside the ring. As the soil is excavated, we dig under the walls of the ring. This will allow him to gradually sink into the ground. When the upper edge is level with the ground, we coat it with a cement solution and put a second ring on it. We continue to dig until the second ring is in the ground. After that, we fill the bottom with concrete, having previously rammed it. After the solution has hardened, we arrange coating waterproofing with bituminous mastic, including at the joints between the rings;

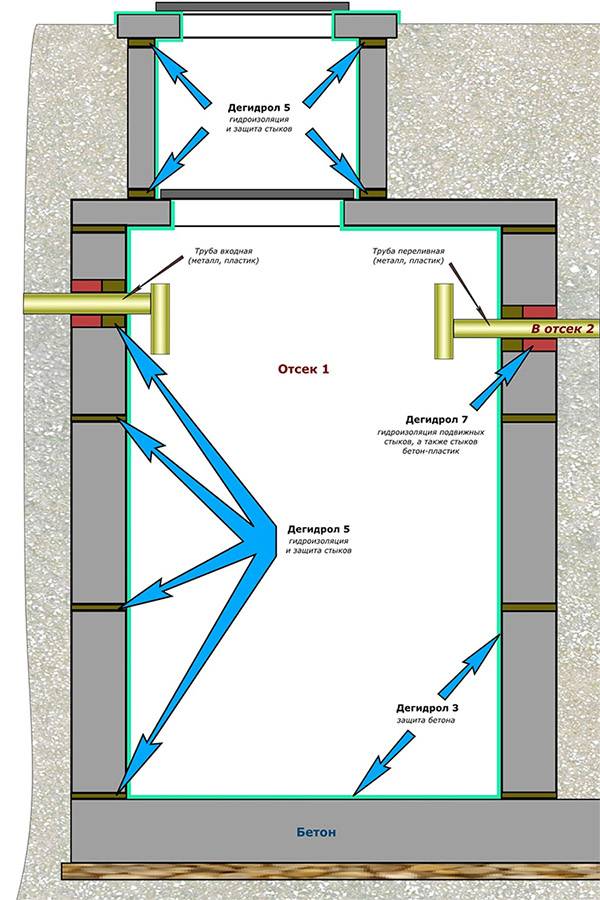

Scheme of sealing seams and joints of concrete rings

Scheme of sealing seams and joints of concrete rings

- we close the upper ring with a lid with a hatch for unloading the substrate, which will gradually accumulate in the compartment. We put sewer pipes into a container below the freezing level of the soil, or we make them thoroughly thermally insulated with a heater;

- similarly we dig in the rings of the second well. Only the bottom does not need to be concreted, but on the contrary, it is worth pouring a layer of rubble there for drainage. The pipe between the first and second compartments is made at the right depth so that it cannot freeze.

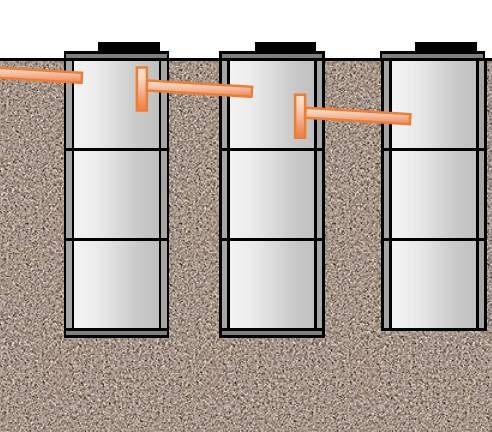

Top view - placement options for concrete septic rings

Top view - placement options for concrete septic rings

Useful advice! If a lot of people live in the house and water consumption exceeds the above volumes, then you should not dig deep pits. It is not comfortable.It is much easier to add a third compartment, by concreted the bottom in the second one.

The nuances of the process of building a cleaner from concrete rings

Do-it-yourself septic tank scheme from concrete rings involves the production of work on concreting the bottom. It is not produced only in the last well. For concreting, it is necessary to compact the bottom tightly and pour a layer of crushed stone 5 cm thick there. Then we lay the reinforcement and fill it with another 5 cm of mortar. The total screed layer will be 10 cm.

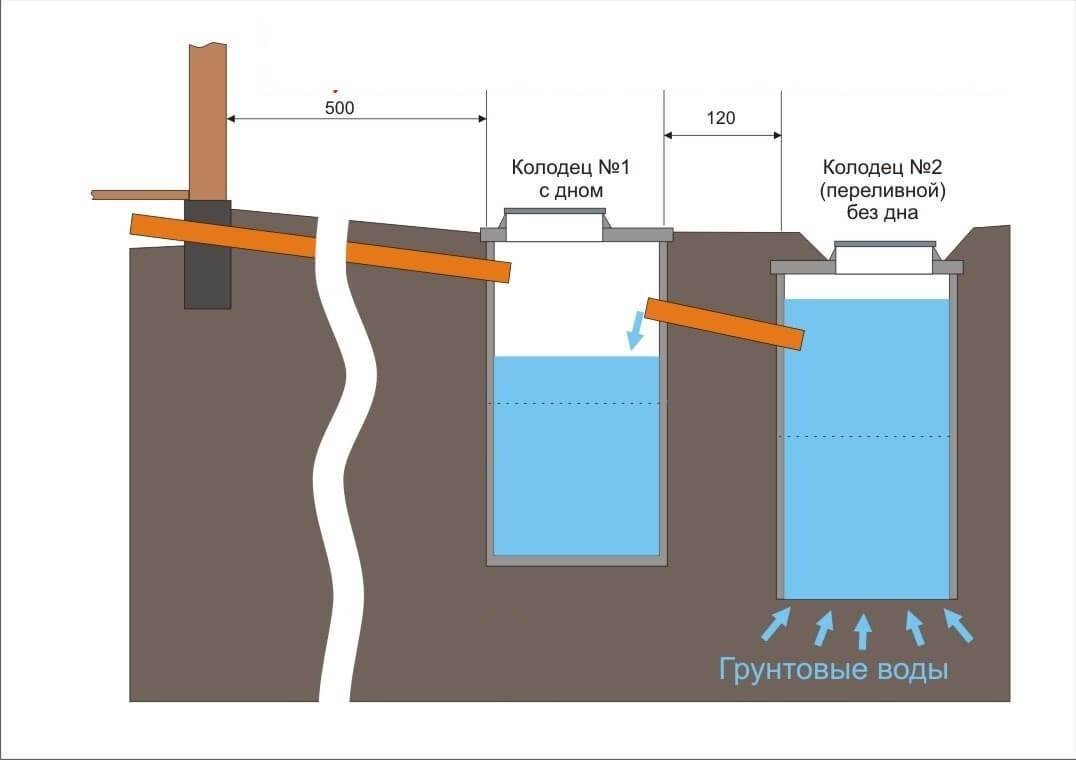

Single-chamber and two-chamber septic tank made of concrete rings

Single-chamber and two-chamber septic tank made of concrete rings

A feature of trenches for sewer pipes is that for each subsequent pipe, the trench will have to be dug 20 cm deeper to ensure a height difference. Therefore, the depth of the wells themselves is greater, the greater their serial number.

Holes punched in the rings for pipes are carefully sealed with any sealant. It is most important to do this in the outlets. Covers for wells must be equipped with sewer manholes. This will allow you to conveniently carry out their maintenance in case of contamination. In addition, holes with a diameter of 100 mm are punched in the covers and cut pieces of pipes from the sewer are inserted into it, equipped with umbrellas on top. They play the role of ventilation pipes.

An example of arranging a concrete septic tank with your own hands

An example of arranging a concrete septic tank with your own hands

Having completed all the proposed steps, we will build a septic tank for a summer residence without pumping out with our own hands. After all, only solid components of waste will accumulate, and liquid ones will go into the ground without causing harm to the environment. The construction process is not difficult, and the result will fully satisfy the needs of any household.

If you do not have the time or basic building skills, you can order the installation of a turnkey concrete ring septic tank. In this case, the cost of the work performed will have to be added to the total construction estimate.

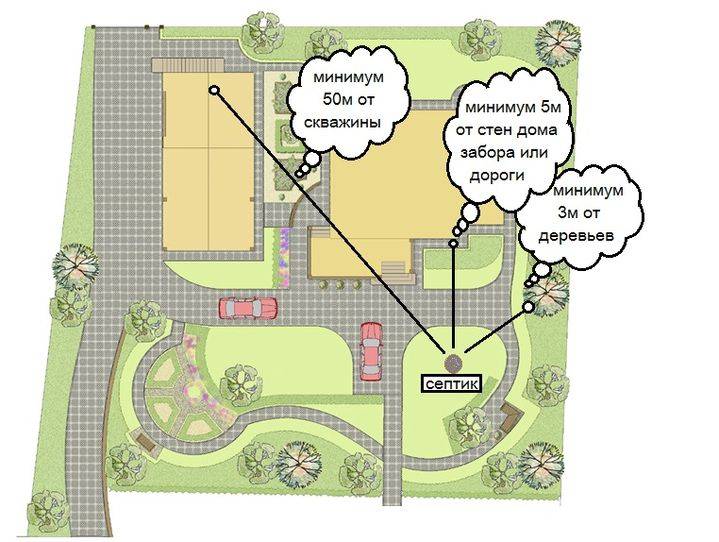

Location of the structure

When designing a septic tank, the sanitary zone is placed in such a way that organic waste cannot penetrate into drinking water and fertile soil. To do this, when choosing a place, you should be guided by sanitary and building codes and regulations.

The correct location of the cleaning system on the site is regulated by:

- SNiP 2.04.03.85. It prescribes the rules for the construction of external sewer structures.

- SanPiN 2.2.1/2.1.1.1200-03. It lists the requirements for creating zones that are environmentally hazardous.

According to the norms, in order to avoid soaking the foundation in case of emergency leaks, the septic tank must be placed lower than the house is located.

Failure to comply with these requirements may lead to the risk of untreated effluent entering the aquifers (+)

When choosing a place, you should definitely take into account the presence of reservoirs with running water, keeping a distance of 5 m from them. The distance from trees should be 3 m, from shrubs - reduced to one meter.

It is also necessary to know where the underground gas pipeline is laid. The distance to it must be at least 5 m.

Since the construction of the cleaner chambers from the rings involves the construction of a pit and the use of special equipment, when choosing a place, it is worth providing free space for its entrance and maneuvering

But keep in mind that machines cannot be placed directly above the place of burial of the treatment plant. With their weight, they can destroy the entire structure.

Blitz Tips

- In conditions where the septic tank is forced to be placed too far from the house and the pipeline between them exceeds 20 meters in length, it is recommended to arrange special revision wells at intervals of 15-20 m, especially at bends. They will allow you to monitor the condition of the pipeline and, if necessary, quickly and efficiently clean the pipes without having to dig them out and dismantle them throughout the entire area.

- On sale you can buy concrete hoops with a completely blank bottom. They are optimal for settling tanks and do not require additional concreting of the bottom.

- To reduce the frequency of calling cesspool equipment, due to the rapid filling of the container with solid waste and to reduce their amount, special bioactive additives can be used.

- To save money and time, it is advisable to first dig a universal pit for a sewer tank, and only then order concrete rings. This will allow you to use the unloading equipment immediately to install the rings from the machine directly into the pit.

- As concrete floors for wells, it is advisable to use slabs with hatches already built into them. This will allow not only to constantly monitor the process of filling the septic tank, cleaning it from impurities until they exceed a critical level, but also to introduce solutions with special bacteria into the tank, which catalyze the decomposition of waste and reduce stench.

- For the most efficient ventilation of the structure, it is desirable to bring ventilation pipes to each well separately.

General installation rules

To create a strong and durable cleaning structure, you should be guided by a number of basic rules:

- The distance between the wells of the septic system should be at least half a meter. The gap filled with bitumen will act as a buffer when soil movements occur.

- The presence of crushed stone or gravel-sand cushion. Such a layer will ensure the immobility of the structure even if the soil under the tanks “walks”. In addition, it is necessary to drain water in case of leakage of wells.

- Do not neglect waterproofing. To seal the seams between adjacent rings, it is recommended to use several types of insulating materials, treating both the inner surface and the outer walls of the tanks.

The better the preparatory work is carried out and the more carefully all the installation conditions are observed, the less often it will be necessary to call for repair and cleaning of the receiving tank.

Advantages and disadvantages of concrete septic tanks

The popularity of concrete rings for the construction of autonomous sewage associated not only with traditions, but also with several positive qualities:

- Concrete products have a relatively low price. Materials for building a tank are cheaper than a ready-made plastic cleaning station.

- Concrete is a durable artificial stone that is resistant to temperature extremes, ground pressure, and large salvo discharges.

- Such rings are durable, and the containers of them are capacious.

The negative qualities of such septic tanks are not less:

- For the delivery and installation of concrete rings, due to their large weight, it is necessary to hire special equipment.

- It is difficult to make holes for pipelines in concrete.

- Cracks and chips form in the walls and joints, which leads to runoff entering the ground.Therefore, a regular revision of the tank is required.

- Due to the large diameter, such treatment facilities require large areas.

- A common problem with these septic tanks is the stench.

If for you the advantages of concrete treatment tanks outweigh the disadvantages, then before proceeding with the purchase of materials and installation, it is necessary to draw up a project correctly.

Schemes of sewerage from concrete rings

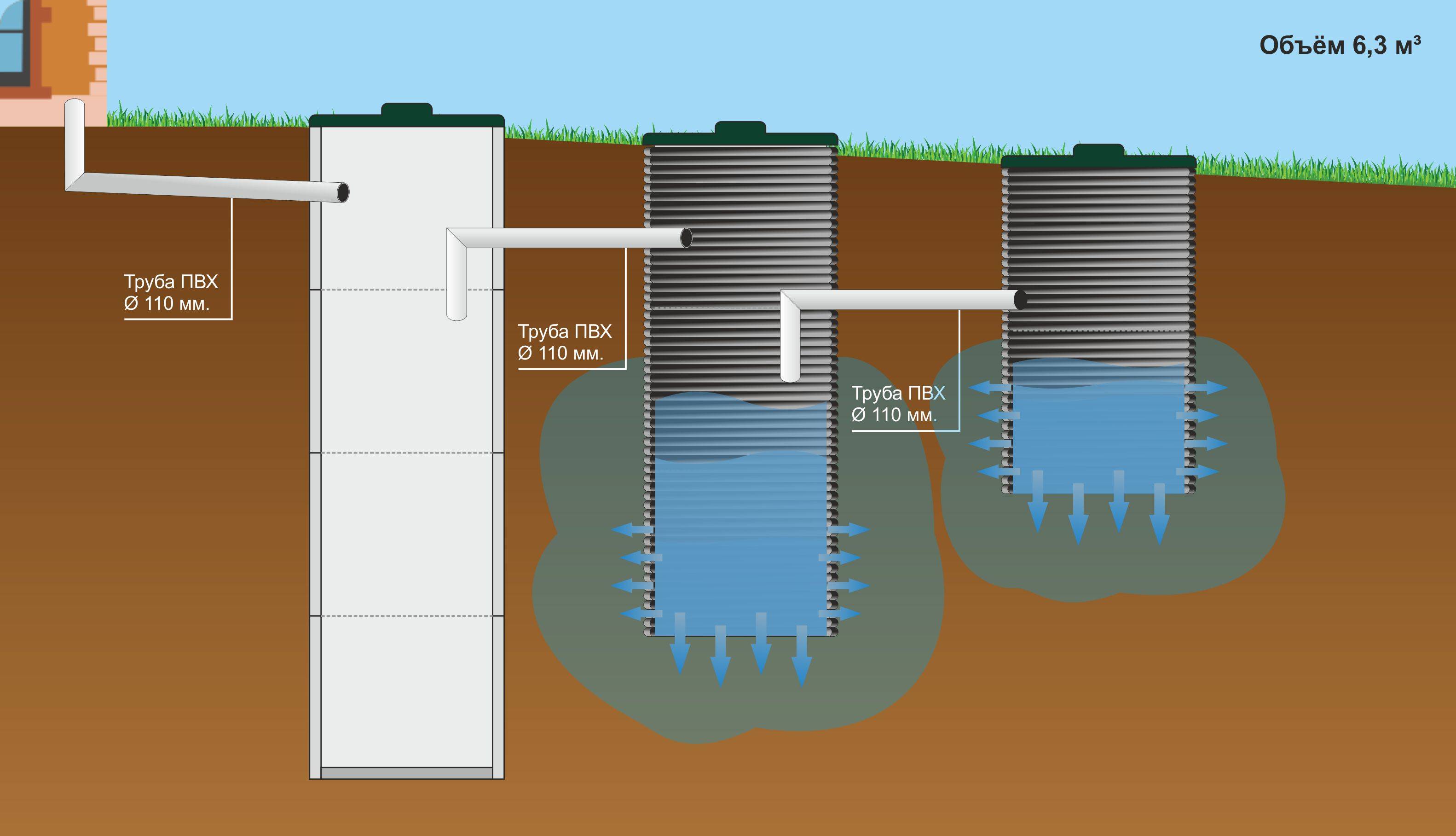

Sewerage from concrete rings is done according to different schemes. The specific type depends on the seasonality of residence, the intensity of operation, the financial possibilities for the purchase of additional equipment and the payment of operating costs.

The following options can be distinguished:

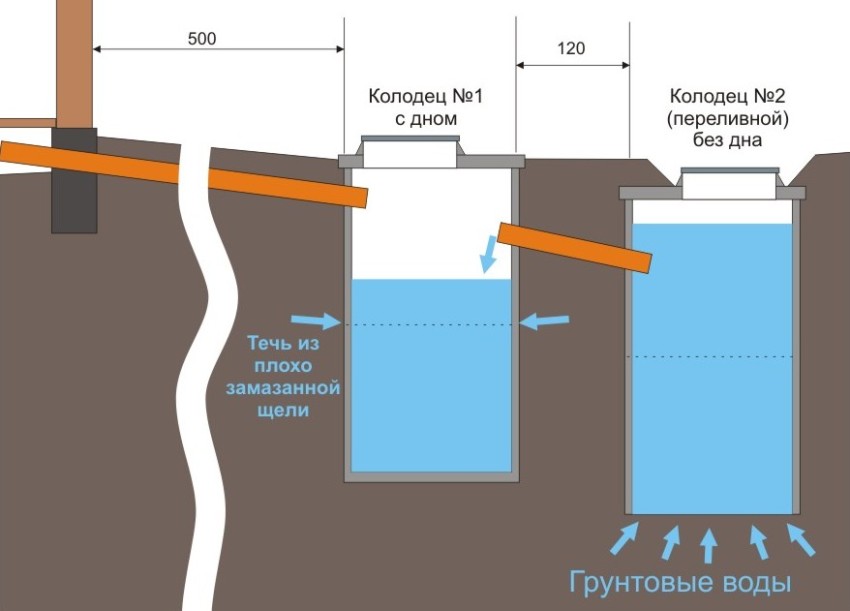

- Storage septic. Behind this name lies an ordinary cesspool with a waterproof bottom and walls. Tightness is a mandatory requirement, failure to comply with which, according to the administrative code of the Russian Federation, is regarded as damage to the land. When the drains fill the tank, they call a sewage truck.

A storage septic tank is simply a container into which wastewater is collected.

The smaller the capacity and the higher the intensity of operation of points connected to the sewer, the more often you need to call the car. Often this is how they arrange country sewage from concrete rings.

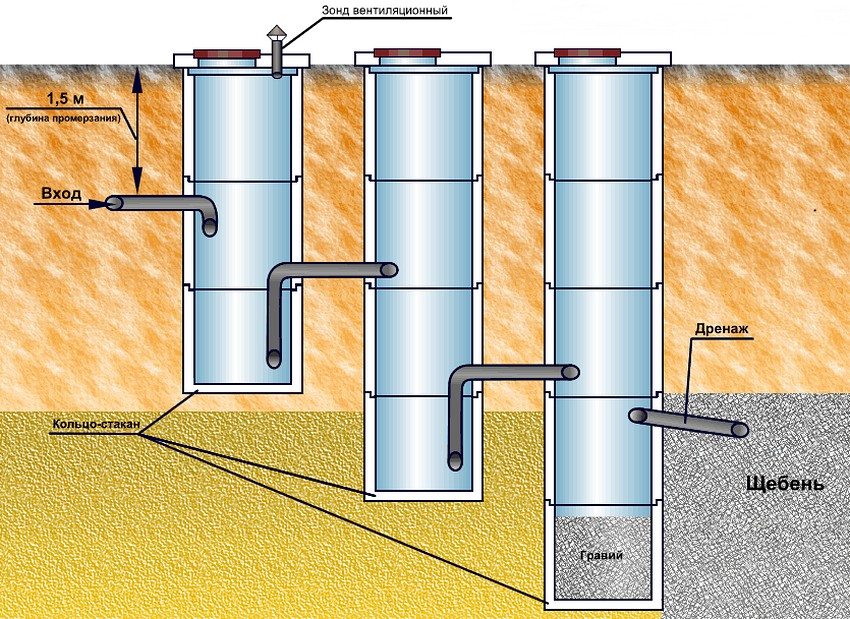

- Anaerobic septic tank. Two-, less often single-chamber, septic tanks, in sealed containers of which wastewater is cleaned by anaerobic bacteria (without oxygen). The number of chambers and their volume are chosen in such a way that the drains at the outlet of the septic tank are cleaned by 65-75%. Post-treatment takes place in filtration wells (“without a bottom”), trenches or fields with aerobic bacteria (it is called “biological treatment”). Only then can the effluent be discharged into the ground.The scheme is very popular among owners of country houses and cottages because of the simplicity of the device and energy independence. The disadvantage of the scheme is that it is necessary to periodically change the sand and gravel in the filtering facilities, while they have to be opened, and the used material to be disposed of (although this is done infrequently).

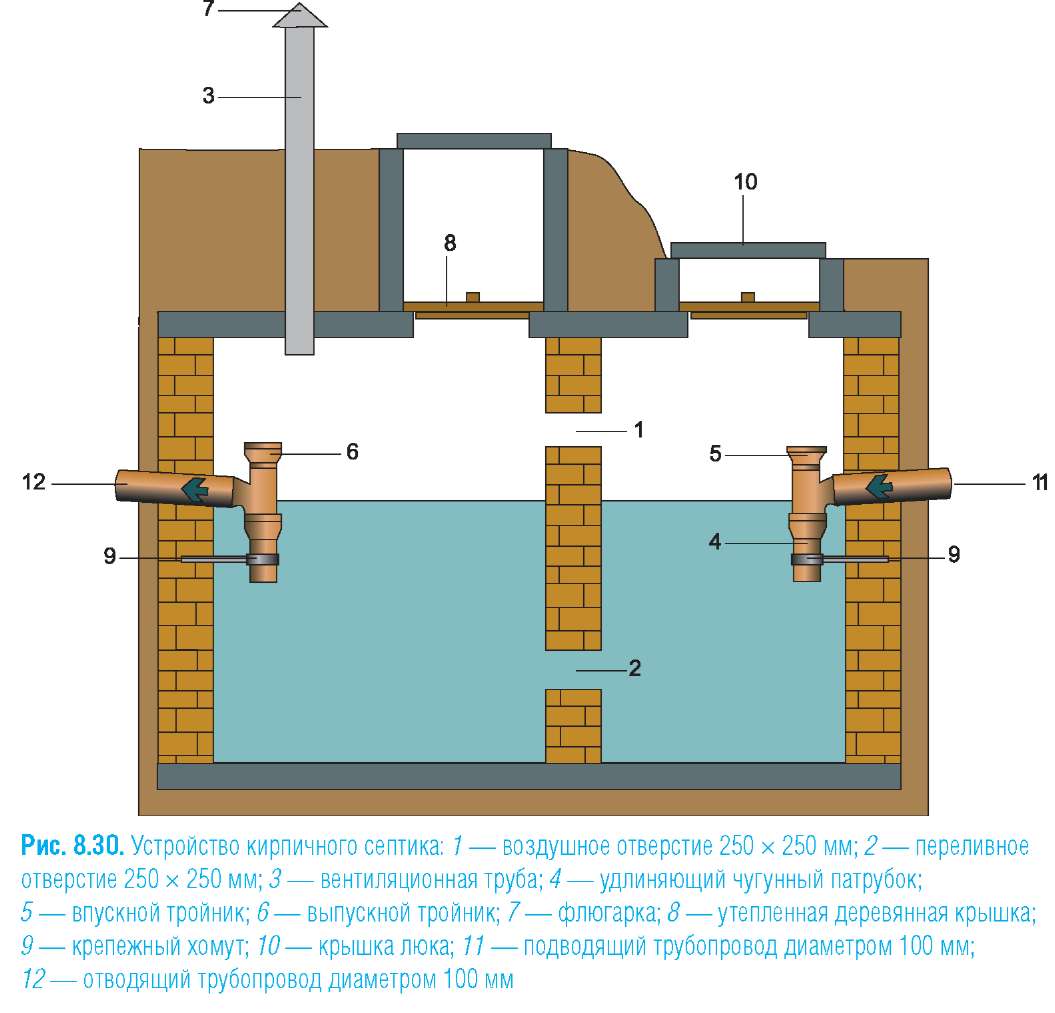

Scheme of an anaerobic septic tank from reinforced concrete rings

- Aerobic septic tanks and biological treatment plants. There is also a phase of primary accumulation and partial processing of faeces with the help of anaerobic bacteria. The principle of operation consists in clarifying wastewater in the absence of oxygen, and post-treatment in the last chamber with aerobic bacteria under conditions of forced air injection. The purity of the wastewater at the outlet is considered to be 95-98%, and they can be discharged into the ground or used for irrigation. The disadvantage is that aerobic bacteria die if the air supply compressor does not work. And this happens with a bad network due to power outages.

The principle of operation of aerobic septic tanks - electricity is required for operation

Characteristics and types

Flexible hose for plumbing is a hose of different lengths, made of non-toxic synthetic rubber. Due to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, the upper reinforcing layer is designed in the form of a braid, which is made of the following materials:

- aluminum. Such models withstand no more than +80 ° C and retain functionality for 3 years. In high humidity, aluminum braid is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water supply is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. Such a braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 ° C and are designed for intensive use for 15 years.

Nut-nut and nut-nipple pairs are used as fasteners, which are made of brass or stainless steel. Devices with different indicators of permissible temperature differ in the color of the braid. The blue ones are used for cold water connections, and the red ones for hot water.

When choosing a water supply, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that excludes the release of toxic components by rubber during operation.

The process of installing a septic tank from concrete rings

Where to place a septic tank

The volume of the septic tank is calculated. Now you need to choose the right place for its installation on your site. In this case, sanitary and building codes provide for the following regulations:

- the septic tank must be removed from groundwater sources by 50 m;

- trees and shrubs should not be closer than 3 meters to the septic tank, as their roots can destroy it;

- the septic tank must be removed from the foundation of residential buildings by at least 5 meters, but not more than 10 m, in order to prevent clogging of the supply pipeline;

- the pipe going from the house to the septic tank, if possible, should not have bends.

It is best to draw a diagram of the site with the selected location, planned and existing communications and buildings.After that, you can proceed to the selection and purchase of materials and tools.

Below is a list of everything you need:

- the rings themselves are made of concrete, including the neck or ceilings, as well as rings with a sealed bottom;

- hatches for septic tanks;

- pipelines for ventilation, connections for treatment stages, drainage from the house, as well as connecting elements;

- building materials for processing joints, dumping the bottom filter;

- tools for cutting and connecting plastic pipes, as well as a shovel, trowel, brush.

It is also necessary to hire digging and lifting equipment and decide on their access to the installation site.

If you have dealt with all of the above, then you can proceed to the arrangement of the pit.

Pit preparation

Digging a pit is best entrusted to an excavator

The configuration of the pit will depend on whether it is planned to arrange the septic tanks in a straight line or in the form of a triangle. The dimensions of the pit should be such that there is at least half a meter from the walls of the pit to the tanks. This will make the formwork and facilitate the installation of rings.

In addition, the septic tank itself should be located below the level of zero soil temperature, typical for the winter period, and each next chamber is installed 0.2-0.3 m below the previous one.

If there is no concrete bottom in the lower ring of the first two chambers of the future septic tank, then a concrete base is poured at the bottom of the pit. For a filtration well, which should not have a bottom, a half-meter pillow of crushed stone is poured.

At the stage of preparing the pit, a trench for the sewer pipe is also usually dripped. In this case, it should be taken into account that the pipeline must pass with a slope of 2-3 cm per meter.

Do-it-yourself septic tank made of concrete rings. Installation

Do-it-yourself septic tank made of concrete rings

The pit is ready, you can proceed directly to the installation.

Step 1. The rings are installed strictly horizontally on top of each other with a crane.

Installation of rings

Step 2 Close up the joints of the rings with liquid glass mixed with cement. As an increase in the strength of the seams, you can additionally coat them with bitumen from the inside of the septic tank, and also fasten them with staples that will not allow the rings to move in a horizontal plane.

Step 3 Lay an external sewer pipe from the house to the septic tank.

Laying sewer pipes

Step 4. Holes are made in the released rings for the supply pipeline and pipes connecting the septic tank chambers. In this case, the pipe between the first two tanks of the septic tank should pass 0.3 meters higher than between the second chamber and the filtration well. Fittings for pipes are installed in all holes.

In the released rings, holes are made for the supply pipeline and pipes connecting the septic tank chambers

Step 5 Lay connecting pipes.

Overflow pipes

Step 6. All pipelines are connected to the septic tank through prepared fittings, and the joints are treated with silicone-based sealant or liquid glass.

Piping connection

Step 7. Outside, the septic tank is covered with roofing material.

Step 8 Backfill the septic tank with a sand-soil mixture to the edge of the upper ring. At the same stage, pipes are poured.

Backfilling a septic tank

Step 9. Install the neck or floor slab, as well as the hatch.Manholes allow maintenance of septic tanks, which consists in pumping out sediment and solid sludge, adding biological products, and in the filtration well - replacing the filter layer every 5 years or earlier, if necessary.

Septic tank neck with manhole

Step 10 Cover the septic tank with insulation, cover it with soil and restore the landscape.

The septic is ready.

Septic tank made of concrete rings: construction stages

Sewerage with a septic tank made of concrete rings is distinguished by reliability, durability and a high level of cleaning of household sewage. The price of such a structure will be relatively low, and with excellent waterproofing and the correct scheme, it will not be necessary to pump out the tanks often. The difficulties of construction include the need to attract heavy equipment and the peculiarities of installing pipes between concrete sections.

Preparatory stage

Installation of a septic tank is carried out in compliance with all sanitary, building rules and regulations. They think over the design of the treatment plant, the location on a private site and coordinate the plan with the relevant authorities. They decide which septic tank is better to install so that the sewerage system in a private house is made as comfortable as possible. Correctly calculate the volume of the septic tank and proceed to construction.

Excavation

The pit for the sewage treatment plant in a private house should be so large that nothing interferes with the installation of the rings. The bottom of the cesspools, at the installation site of the sedimentation tanks, is concreted. This prevents the ingress of untreated water into the soil.

Pit for a septic tank

The base for the second or subsequent chambers is made in such a way that water can go into the soil. To do this, make a filtration pad up to 1 meter deep from gravel and sand.

Advice! If, during the installation of a septic tank, the pit under the filtration well reaches the sandy layer of soil, the water will leave it as quickly and easily as possible.

The shape of the pit does not have to be round, a standard, square one is also suitable, the main thing is that the rings go into it freely. In addition, a ready-made concrete slab can be laid on the bottom of a square pit, while only a cement screed can be made in a round pit. At this stage of work, it is also worth remembering that if each subsequent well is located 20-30 cm lower than the previous one, the septic tank and the sewage system itself will be more functional.

Delivery and installation of reinforced concrete rings

The rings are delivered and installed by freight transport, so it is worthwhile to provide access to the construction site in advance, take into account additional economic costs and the turning radius of the crane boom, gas, telephone or electrical communications should not interfere with it. Between themselves, the rings are usually connected with metal brackets, the joints are coated with a solution of cement and sand.

Installation of reinforced concrete rings

When all the wells are installed, holes are made in them and overflow pipes are installed, the external sewage system is connected to the treatment plant through a drain pipe entering the first tank. Pipe entry points must be sealed. The space between the installed rings and the walls of the pit is covered with soil and carefully compacted in layers. If the septic tank is installed above the freezing level of the soil, it is insulated, otherwise the sewage system will be non-functional during the cold season.

Waterproofing

Good waterproofing of a septic tank is fundamental to its proper operation. Each builder determines which sealant is best for this purpose. Usually, rubber-bitumen mastic is used to process seams, polymer mixtures are less common. For a longer operation of cesspool structures, internal waterproofing of the seams of the tank is also performed.

Waterproofing of well rings

If the sealing is done poorly, then the ingress of untreated drains into the ground will be the lesser of the evils. The septic tanks, especially during the spring thaw, will be filled with water, and all its contents will flow out through the plumbing in the house, repeated pumping will be required.

Ventilation

An exhaust pipe up to 4 meters high above the level of the septic tank must be installed on the first tank. It is necessary so that the gases formed as a result of the fermentation of effluents can escape, and there are no unpleasant odors on the site. If possible, ventilation pipes are installed on each well.

Septic tank ventilation

Overlapping a septic tank

The task of overlapping is not only to close the pit, it must ensure the tightness of the containers. As a rule, the chambers are covered with ready-made reinforced concrete slabs, on which there is a hole for a hatch made of cast iron or thick plastic. Then the structure is covered with a small layer of soil. Manholes on each of the wells will help monitor the condition and filling of the septic tank, and will also make it possible to periodically add a mixture of active bacteria for cesspools.