- Kinds

- Used tools and materials

- foundation of the foundations

- Third: step to the right, step to the left...

- What is this building?

- Characteristics

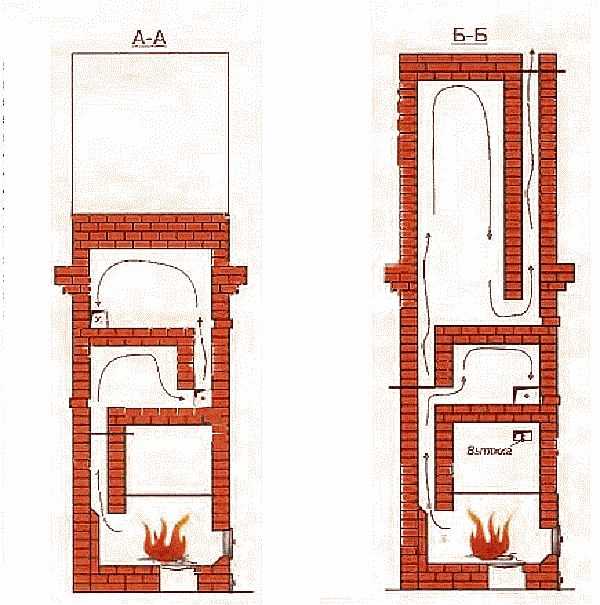

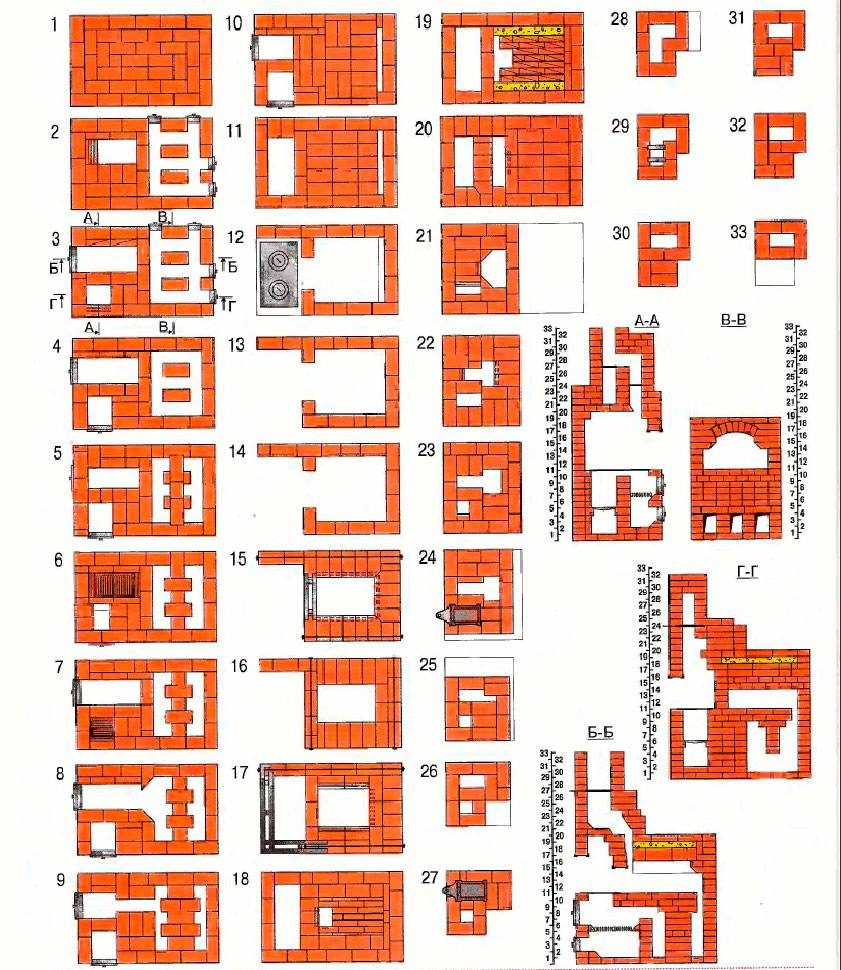

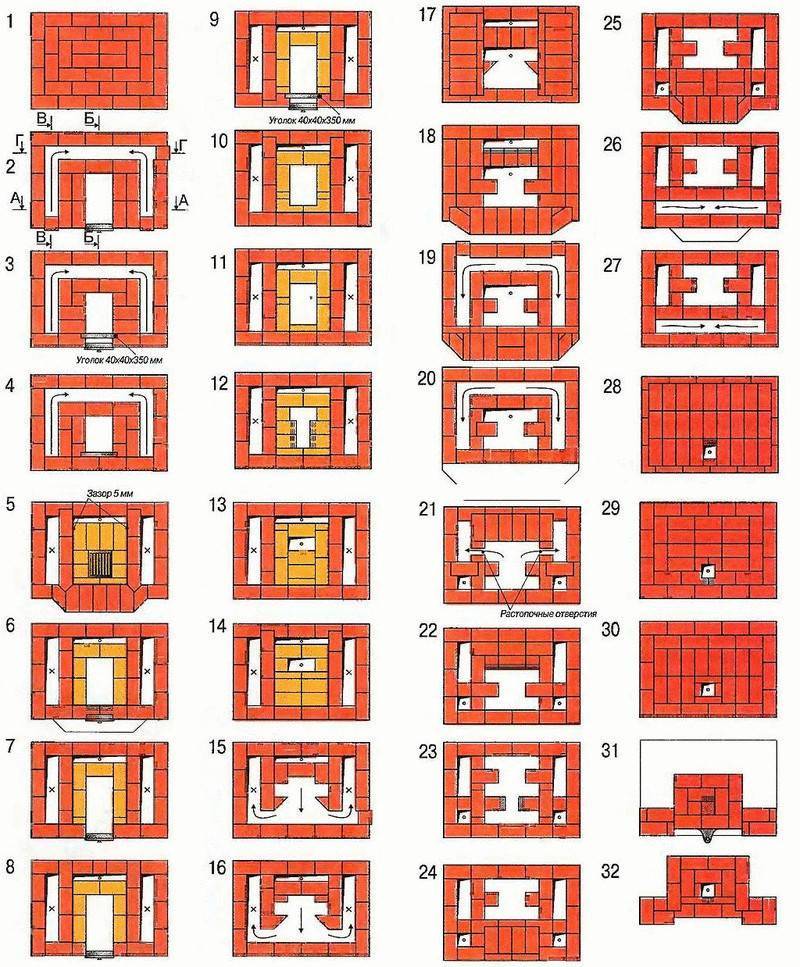

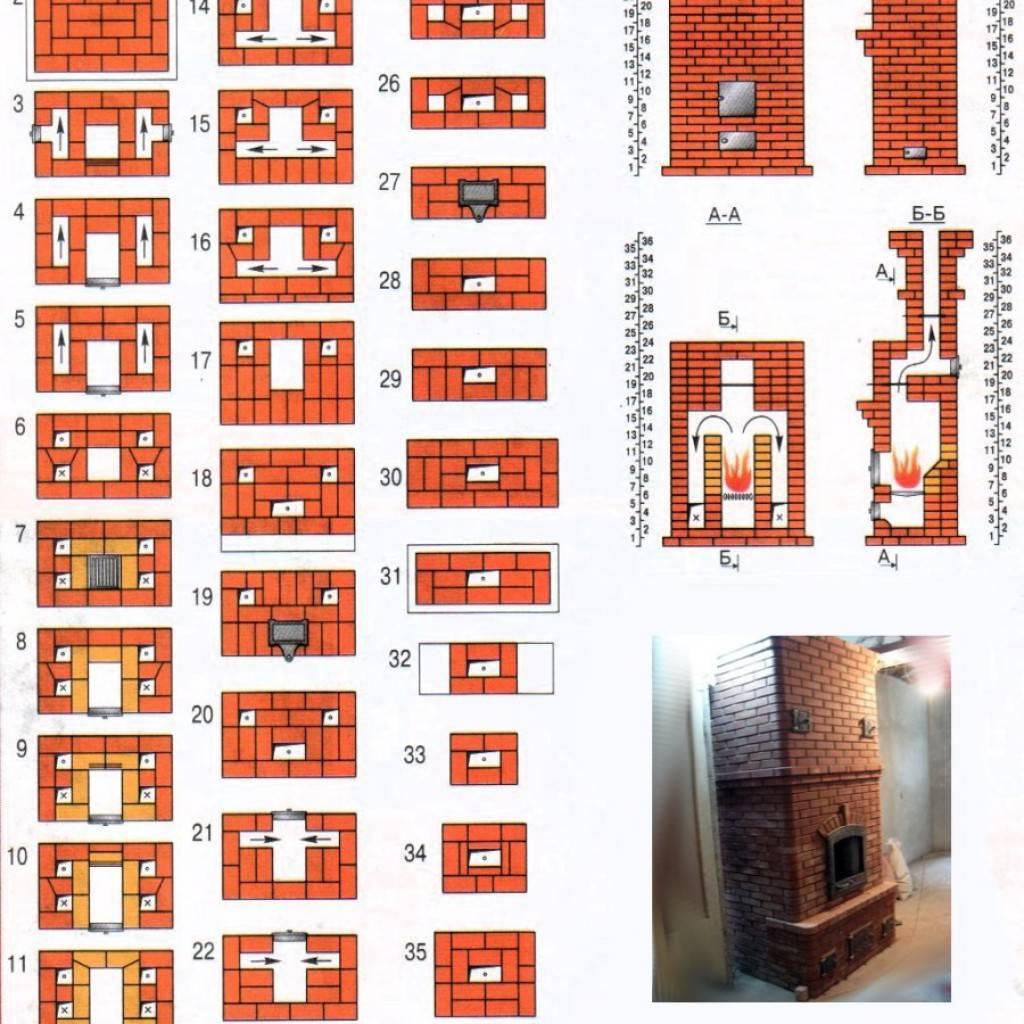

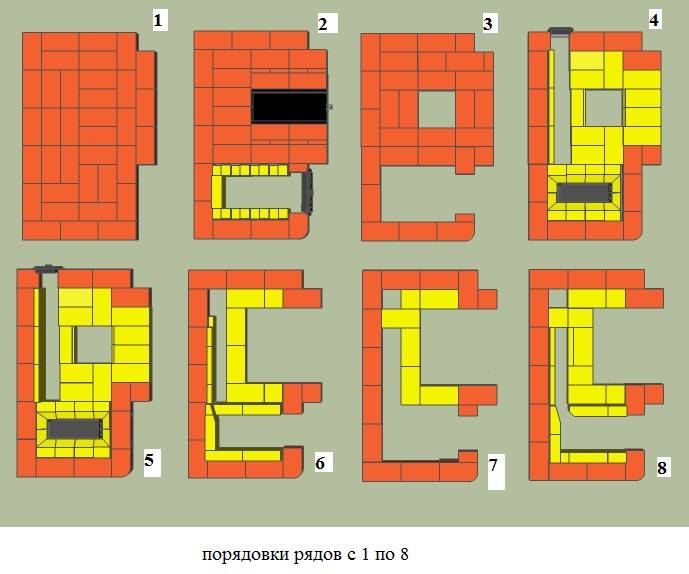

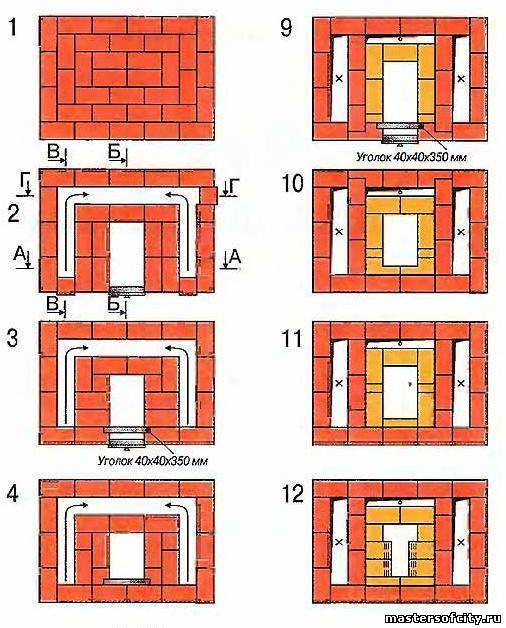

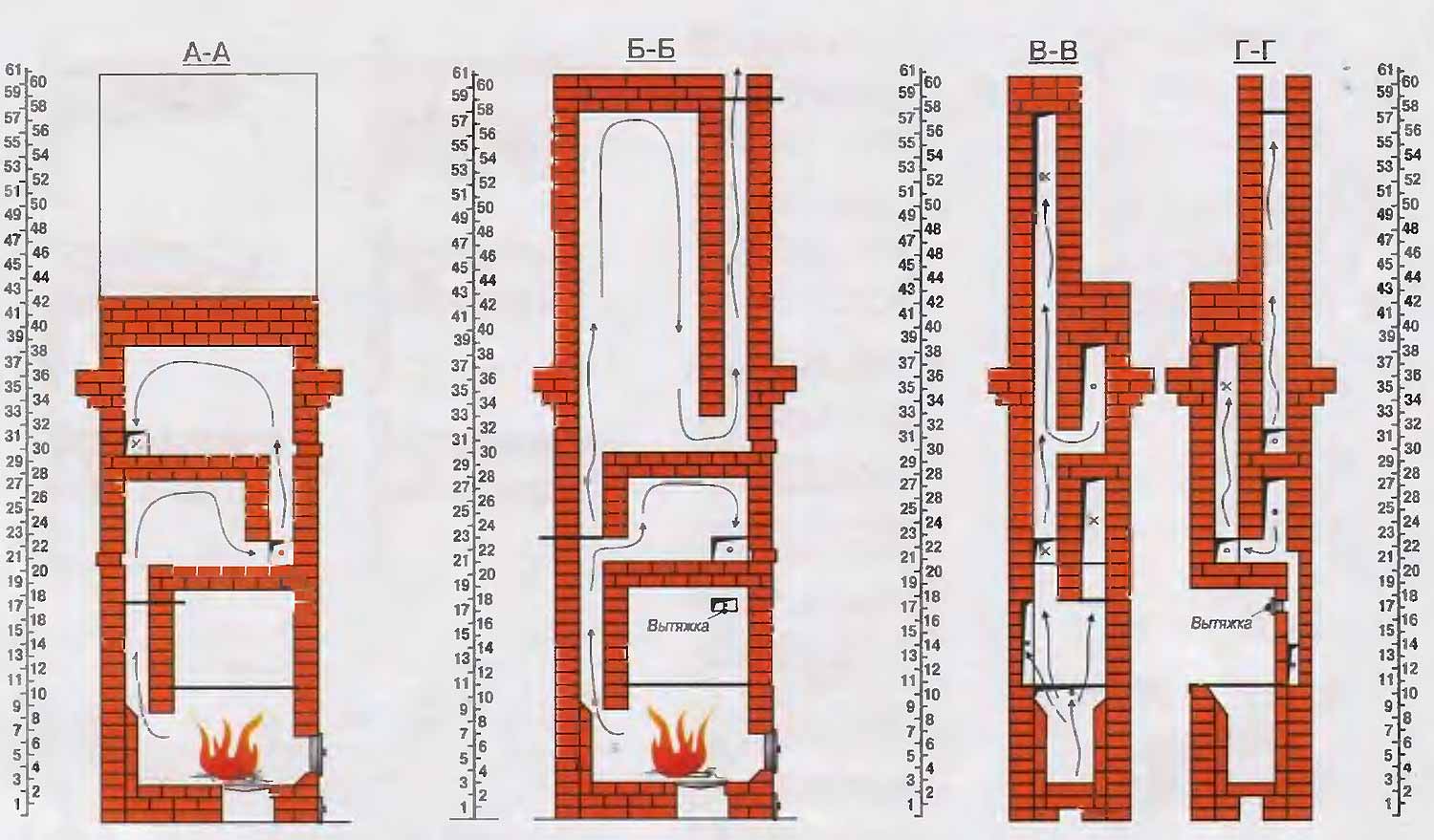

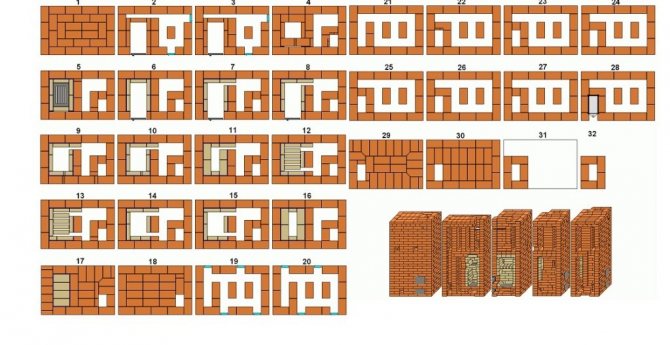

- Orders of Kuznetsov furnaces

- Recommendations for masonry

- ordering

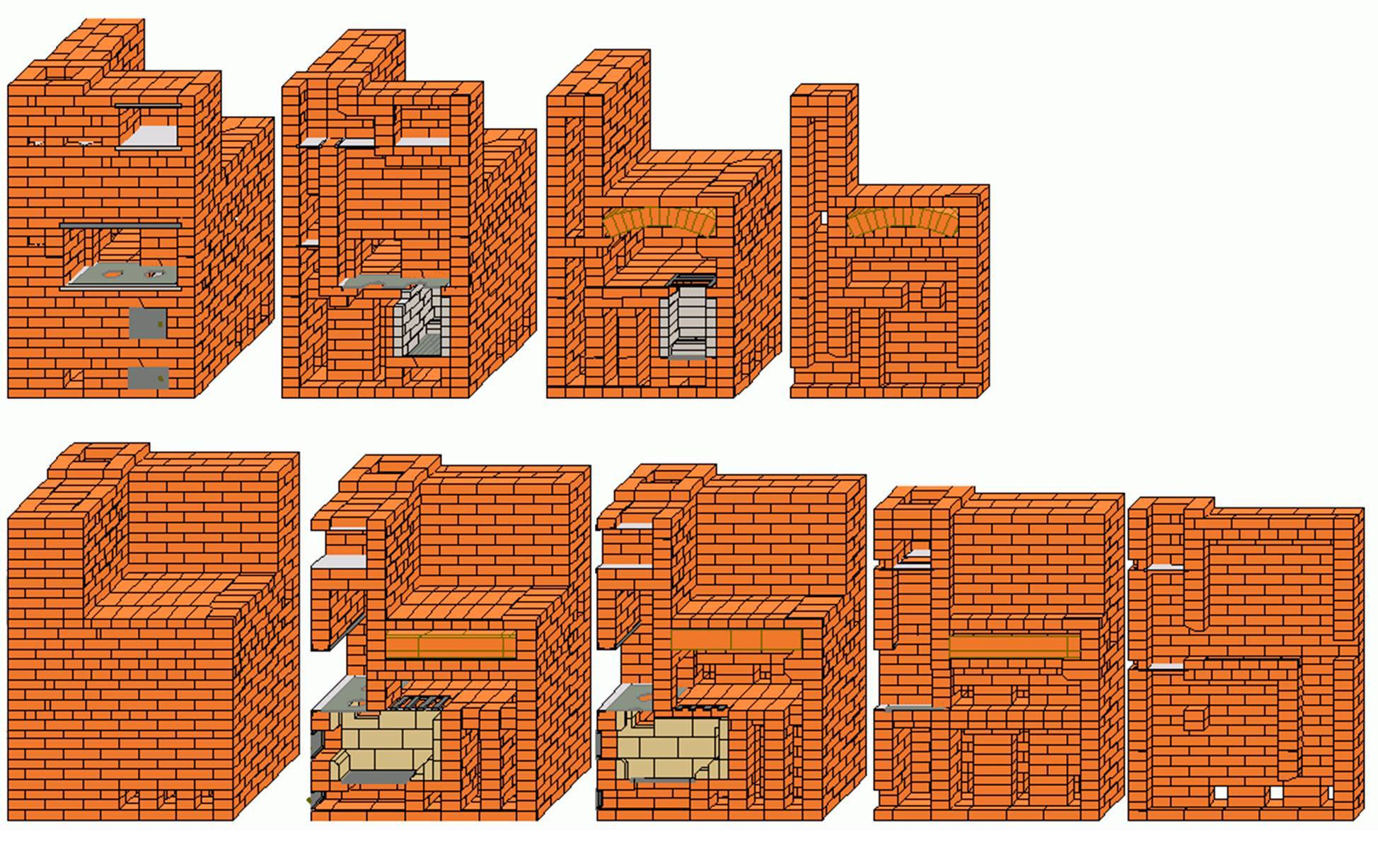

- Types of structures

- The principle of operation of Kuznetsov's bell-type furnaces: ordering

- Preparatory work

- Types of Kuznetsov furnaces

- What can give such a strange chimney?

- Strengthening the structure with wire

- Furnace foundation

- Basic rules for creating a heating furnace

- What is needed for the construction of Kuznetsov furnaces

- Stove with stove bench

- Design features

Kinds

By purpose and design features "Blacksmiths" can be divided into several types:

- Heating. The devices are designed for efficient and safe space heating.

- Cooking. Used for cooking. This includes ovens for baking bread and bakery products.

- Bath. The Kuznetsov sauna stove is designed for simultaneous heating of the main bath rooms. Such devices have high heat transfer with minimal fuel consumption.

- Street. Oven complex, consisting of a grill or barbecue, for outdoor cooking.

- Fireplace. The equipment is used as a decorative element of the interior or as an additional heating option.Some fireplace stoves are equipped with special loungers for a pleasant pastime.

The most popular are complex devices that are distinguished by their multitasking. A striking example is the Kuznetsov heating and cooking stove, which is intended both for heating residential premises and for cooking.

Despite their functional features, all stoves work on the same principle - the efficient distribution of heated gases in the hood into separate streams.

It is noteworthy that furnace bells can be equipped with additional equipment - electric heaters, hot water tanks, steam generators, oven and hob.

A well-designed and erected Kuznetsov sauna stove will provide reliable heating in all functional areas: a steam room, a washing room, a dressing room, and a rest room. In addition, it will allow you to quickly heat water, accumulate hot steam and purify the air.

Used tools and materials

To complete the work, you will need grinder with discs for brick cutting, puncher or drill, equipped with a mixing nozzle for mixing the mortar.

The following materials must be delivered to the construction site:

- Two types of bricks - fireclay (having refractory qualities) and ordinary clay, grade M150.

- Brick volumes are determined by a specialist according to the drawing.

- High-quality clay - about a centner.

- Sifted sand, in an amount exceeding clay twice.

The above two components can be replaced with an already prepared mixture, which can be purchased at a hardware store. This option is more convenient and requires less time and effort to prepare the solution.

And you will also need different metal products:

- firebox and blower doors;

- valve;

- top;

- steel wire;

- corners.

foundation of the foundations

Most of the advantages of Kuznetsov furnaces are provided by the principle of free passage of gases. Let's explain again with an example.

Let's imagine a furnace with a complex system of flues: an undermark, a four-five reverse Dutch. In this tight labyrinth, strong turbulences will inevitably arise. Have you heard how the oven hums? This is only an insignificant manifestation of the vortex energy raging in it. And there is nowhere to take it from, except from the fuel tab. If the channels are long and narrow enough, then at first glance there is nothing terrible here: the vortices, while they get to the pipe, will dissipate, cooling down, and still give their energy to the body of the furnace, and it to the room. But in fact, nuances appear, which will be discussed later in the text. Because of them, the efficiency of a channel furnace over 60% is an exceptional rarity.

In a channel stove, while it is heating, a huge flow of energy rushes about, and only a small part of it can be taken for heating or heating water without disturbing its operation. Such a furnace is somewhat similar to a nuclear reactor. Do not be afraid, only in terms of synergy, i.e. along the paths of energy circulation in it. In a nuclear reactor, it is necessary to put dozens of times more fuel than is necessary to ensure the design energy yield. Otherwise, neutrons will simply fly out without having time to meet uranium atoms ready to receive them. In a channel furnace, hot whirlwinds, not having time to cool down, will fly out into the chimney or, conversely, cool down immediately, giving off smoke and soot.

But the blacksmiths (details below) are already closer in terms of synergetics to the thermonuclear reactors of the future. "Thermonuclear" sounds scary, but it's only in association with the hydrogen bomb.In fact, fusion reactors are quite safe.

Why? Because they produce exactly as much energy as the consumer should consume, and the technological power reserve for rarefied plasma is scanty. If suddenly the chamber of a tokamak or stellarator is suddenly completely destroyed, the plasma will completely light up (there are no heavy atoms in it) and cool down before it reaches the walls of the room. The repairmen will swear - whether it's the duty to sharpen the laces - but after 5 minutes. will be able to blunt to elimination without protective equipment.

So what do Kuznetsov furnaces have in common with fusion reactors? The fact that the energy of flue gases, thanks to the principle of free passage, does not scroll many times in the stream until it is pushed into the body of the furnace, but immediately impregnates it. And now she has nowhere to go from there, except to the room and / or the hot water register.

Third: step to the right, step to the left...

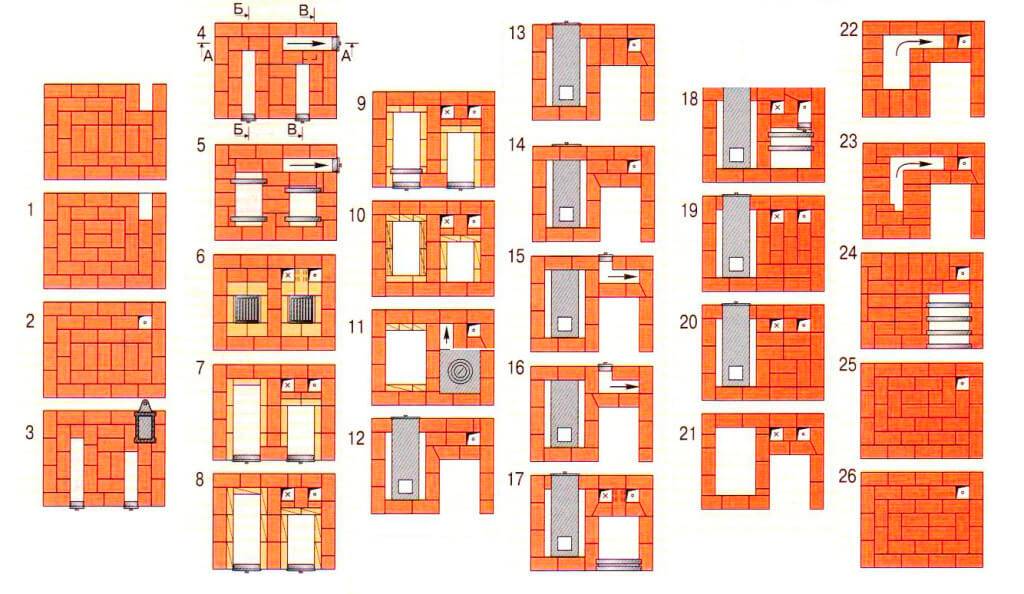

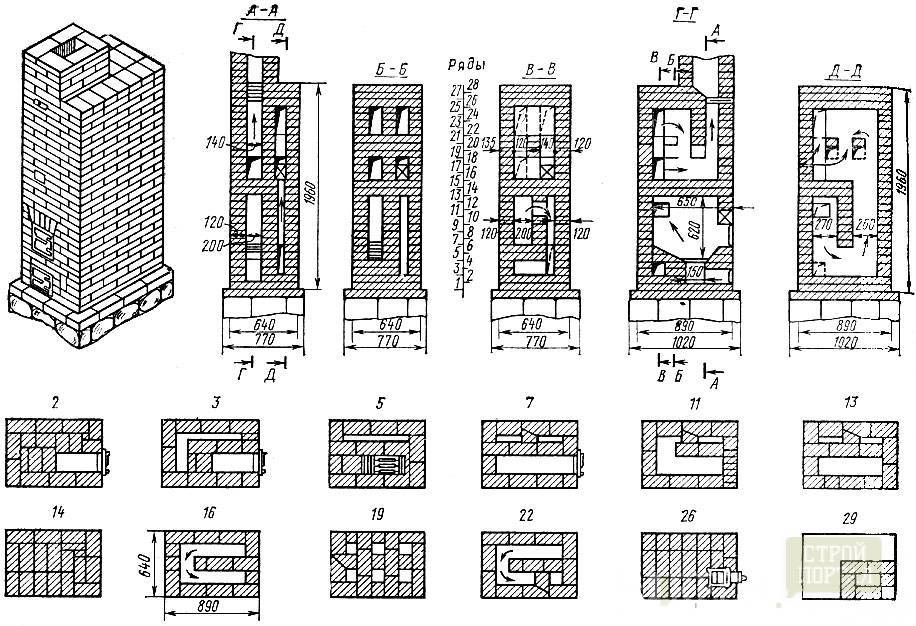

High loads on the material in Kuznetsov furnaces require not only careful design development, but also compliance with some fundamental design principles. The main one is a floating firebox made of fireclay bricks of the ShB-8 or Sh-5 brand. The body of the furnace is laid out of ceramic bricks of grade not lower than M150.

What does floating fire mean? First, around it entirely, or in the places exactly calculated by the author, there must be a dry seam. It is not so easy to make it: after laying out the last row of fireclay (unless otherwise specified in the specification for the furnace), the clay mortar is picked out from the seams between the fireclay and ordinary bricks, and mineral cardboard pads are inserted instead of it - basalt, kaolin, etc. .

Unrelated and related building modules

Secondly, it is necessary to strictly observe the principle of incoherence of modules. What it is is shown in Fig. No protrusions of fireclay should enter the grooves of ordinary bricks, and vice versa, even with damping joints. TKR and heat capacity of fireclay differ significantly from "brick", and the firebox associated with the furnace body will tear the masonry during kindling. The blacksmith firebox should be a compact module installed in a nest made of ordinary bricks. How to arrange her exit into the chimney, the author explains in detail on the site.

It is also strictly necessary to follow his recommendations regarding the selection and preparation of materials. "Kuznetsovka" though brick, but high-tech, and endure replacement for ersatz and negligence no more than a rocket or a submarine - the replacement of titanium and composites with a tin can. The consequences, however, will not be so catastrophic, but they will also have to be seen at home, and not read in the news. And pay out of your own pocket.

In general, according to technology: a diligent, attentive and accurate beginner can build a Kuznetsov furnace. But a really experienced stove-maker, half-drunk, but thoughtlessly laying out a really very good stove or a Dutch stove, will definitely misfire on Kuznetsov's stove.

What is this building?

Kuznetsov's devices were created more than 50 years ago and at the moment more than 150 variants of various projects have been developed, which have their own characteristics and purpose. Main varieties:

- Cooking. This type of device is used for cooking. In such ovens, mainly cast-iron stoves are installed, on which the entire cooking process is carried out.

- Bread with oven.Cooking types of buildings are often combined with a bread machine.

- Heating. A two-bell stove for a house according to the Kuznetsov system is an excellent alternative to gas or electric heating. Provided the correct laying and firebox is able to heat the room even in severe frosts.

- Bath. Kuznetsov's stoves for baths are the most popular among other types. According to Kuznetsov's projects, most of these buildings are being built, which can be found in almost every country house or dacha.

- Fireplaces with a water circuit. Useful household appliances. People who seek to equip their homes with hot water by heating the stove will certainly build a structure with a water boiler. Kuznetsov's bell-type furnace with a water heating boiler is widely used in villages.

- Russian two-story. Wood-burning fireplaces with a bench have not lost their relevance, therefore they are actively used in everyday life.

Characteristics

Kuznetsov's bell-type furnaces have a number of distinctive characteristics and advantages that distinguish them from the main competitors in the market for heating equipment for home and baths.

The principle of operation of such a device is quite simple: the lower level (tier) and the firebox are a single structure - a cap, which is designed to effectively move gases formed during the combustion of fuel. In this case, the accumulation of light gases is carried out at the top of the cap, and heavy gases - at the bottom. Gases with an average heating temperature are concentrated in the middle.

"Kuznetsovka" made of bricks provides for a long-term retention of heated air inside the hood for efficient heat accumulation inside the room, and then the rapid removal of combustion waste through the chimney.

A feature of the furnace is to maintain the maximum combustion temperature. In addition, the Kuznetsov stove has a high efficiency, which is several times higher than that of a classic Russian stove.

The specific advantages of such ovens are as follows:

- High efficiency - up to 94%.

- High temperature mode of combustion of the fuel material.

- Fast accumulation and long keeping warm.

- Low level of soot deposition.

- Ease of care and unpretentiousness.

- Insignificant material consumption with high heat output.

- Possibility of additional embedding of a contour for hot water supply.

- Increased draft with small dimensions of the chimney.

- Attractive design and wide choice of constructive forms. An improved version is the two-bell Kuznetsov furnace, which can be designed for any type of room.

- Fast distribution of thrust between channels in automatic mode.

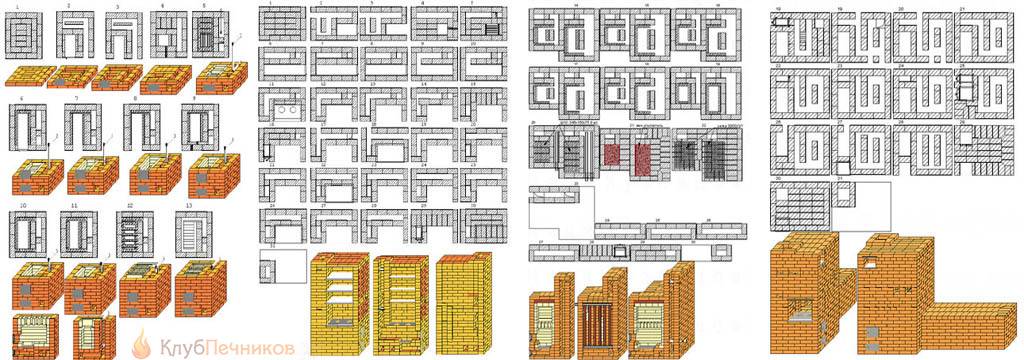

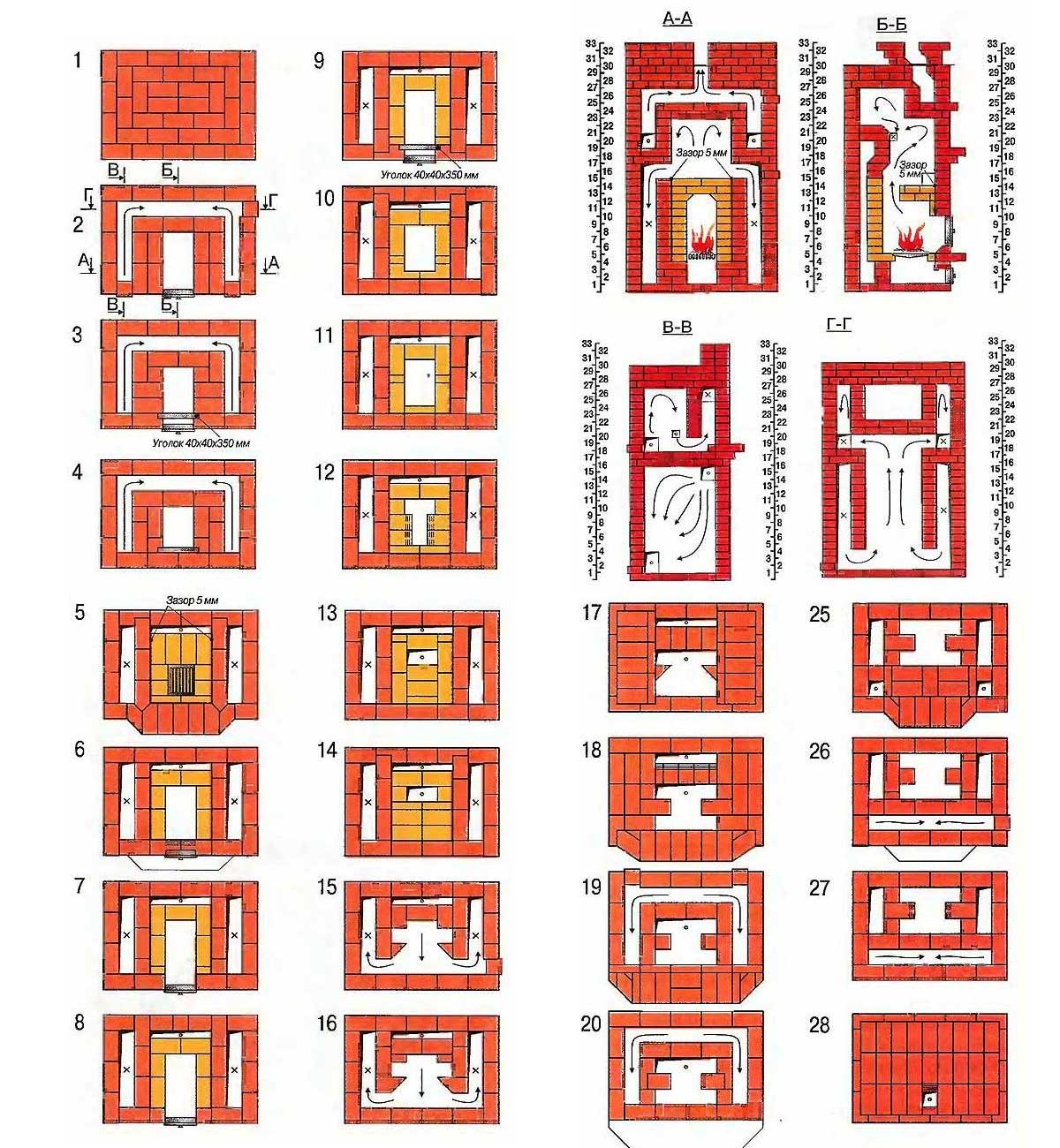

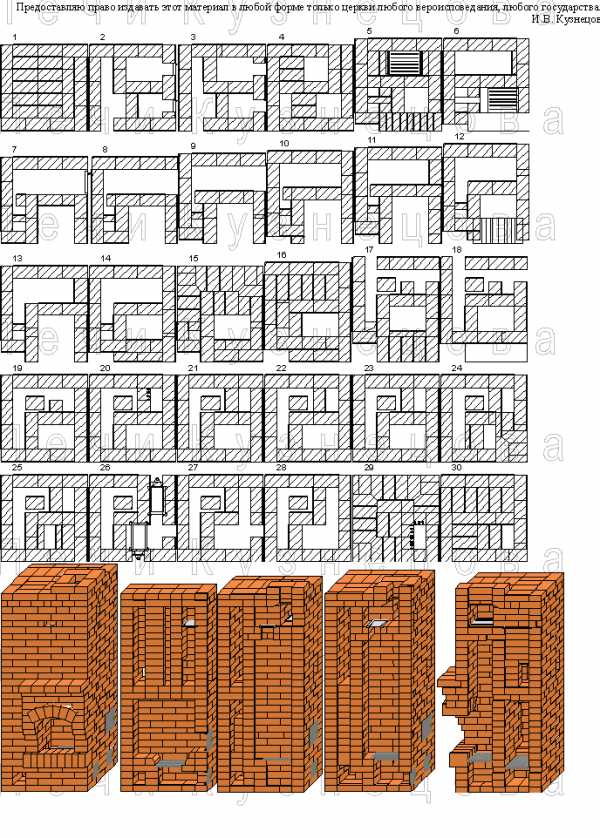

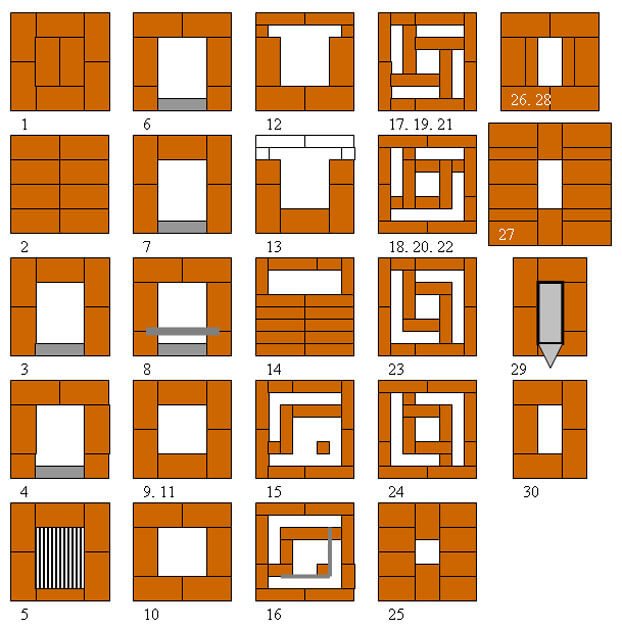

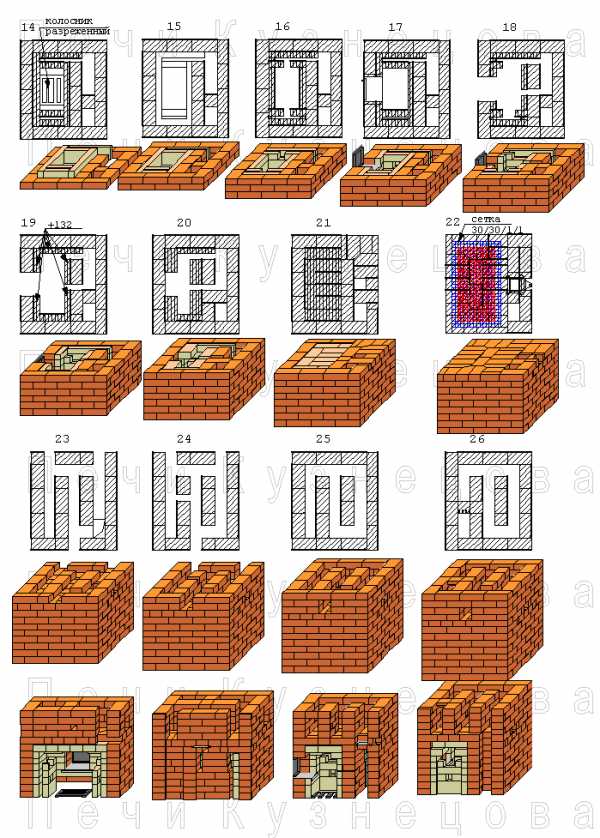

Orders of Kuznetsov furnaces

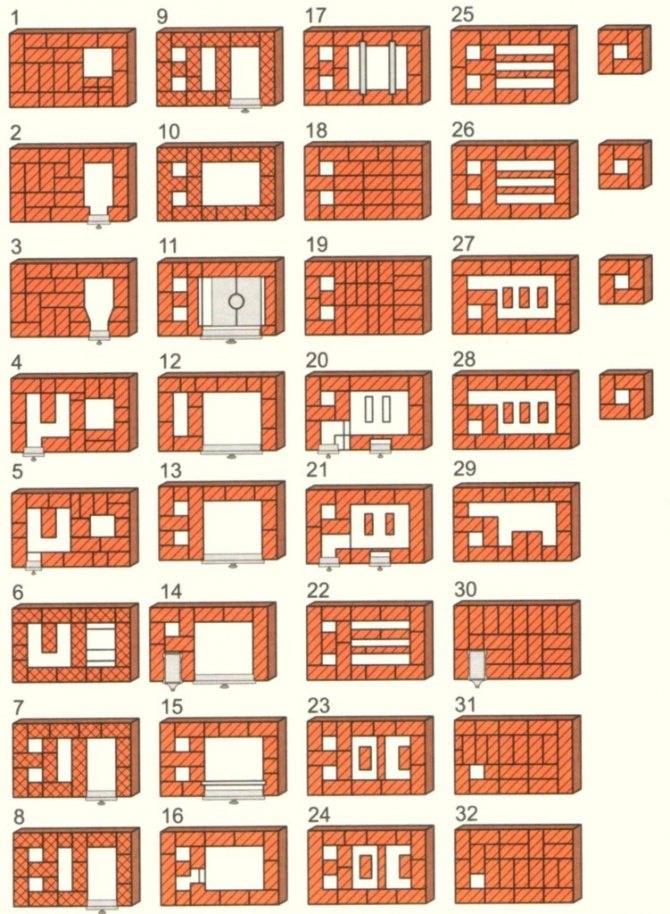

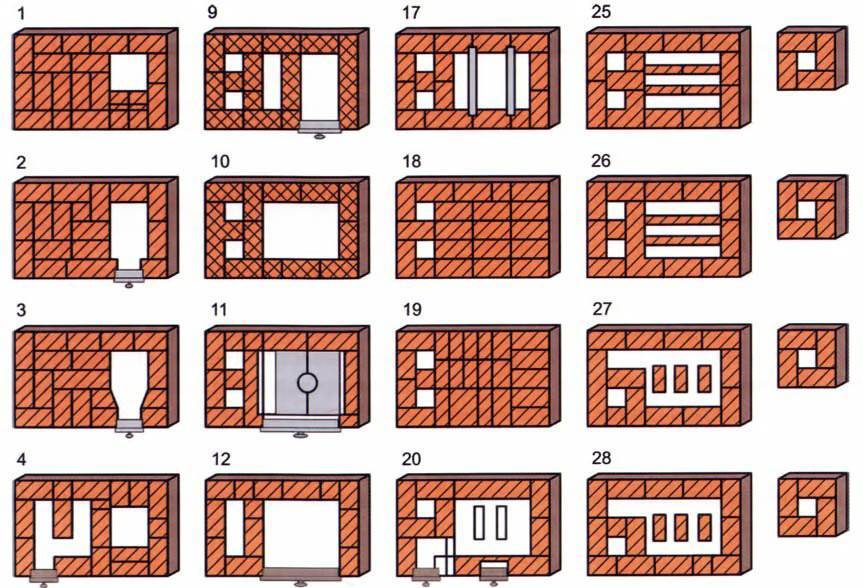

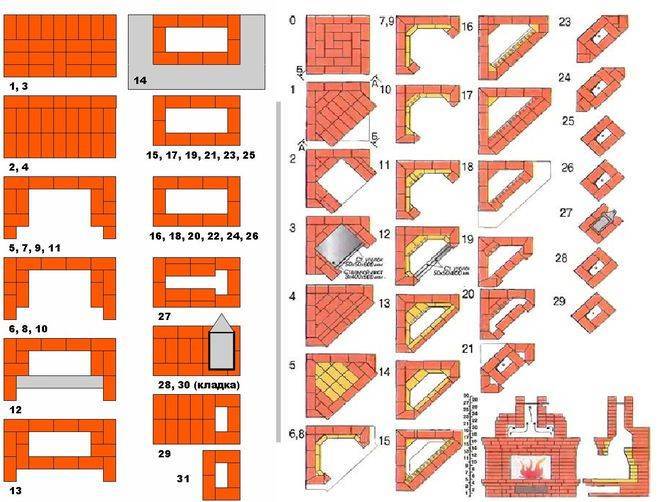

The construction of the Kuznetsov furnace does not imply the presence of special knowledge and skills. If the hands are sharpened for the simplest tool, it is enough to follow the order and a few simple rules to successfully build a structure. Ordering is simply a system of drawings and instructions describing the process of laying out the oven step by step, down to each row of bricks separately. Why such precision? The fact is that Kuznetsov spent decades making the design work perfectly, and if you miss any little thing, the stove will not work correctly. Here is a sample order:

This is interesting: Cast iron radiators (batteries) for heating - technical overview

Recommendations for masonry

For laying the shield, only clay of medium fat content with sand impurities is used.

To fold brick shield for a metal furnace in the bath or at home, you need to follow the recommendations:

- The solution should be only on the basis of clay. Do not use cement.

- During laying, immediately remove the remains of the mixture from the inside of the structure.

- Construction must begin with the installation of the foundation. It should be separate, not connected with the foundation of the house. First, the brick is laid dry to check the horizontal position. After checking all the parameters, the foundation is fixed with a solution.

- To limit the draft of smoke, you need to install a slide damper in the upper part of the structure.

The first two rows are laid out deaf, they do not make smoke channels. This is necessary in accordance with fire safety requirements.

ordering

Doors for cleaning must be installed on the brick shield channels from soot

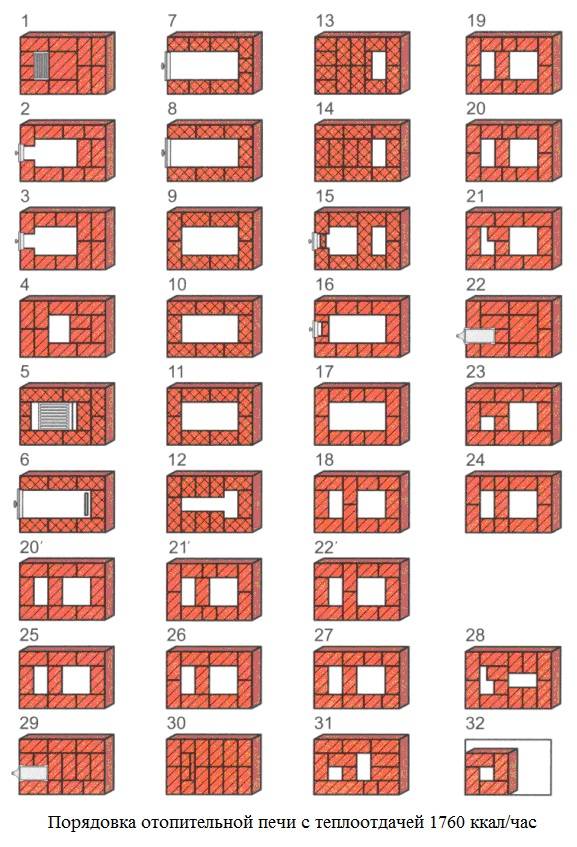

The order of the bell-type heating shield is as follows:

- Rows from the first to the third are laid out in a standard way. In the third row, it is necessary to leave an empty space in which the furnace door will be installed.

- On the fourth and fifth row, a blower and a cleaning door are mounted, two plugs are also installed here.

- In the sixth row, they begin to gradually reduce the number of channels, a heating tank is installed.

- The seventh row is for mounting the grille. In order for it to be securely fixed, you need to cut off all the bricks that may interfere. The channel is blocked in order to make two branches in the future.

-

The eighth row is designed to install two doors.

- On the ninth and tenth, a steel strip tab is placed.

- The next stage is the implementation of door overlaps. From above, they should be smeared with a solution of clay.

- On the twelfth row, a cast-iron stove is installed.

- On the sixteenth tier, you need to cut bricks in the area of \u200b\u200bthe right corner, and on the nineteenth, a valve is installed.

- The twenty-second row is reserved for mounting the shield and the samovar.

- To expand on the thirty-first row, the bricks are pressed together, and at the next stage a ventilation grill is placed.

Types of structures

The hoods inside the oven can be positioned in different ways, so there are many types of ovens. You can build a stove with your own hands for two-story houses, and both floors will be heated equally. You can even make a building with a stove bench (heating of this type is convection) or you can put a heat exchanger inside. This type of construction is called a boiler, it is marked KIK.

There is a type of building in the form of a fireplace, they are usually built in houses outside the city. Heating gas stoves are designated IOK, and if they have a stove bench, then the letter “L” is added. If an oven is also present in such designs, then the letter “D” is indicated.

Real Russian Kuznetsov bell-type stoves are marked RTIK, there are about 10 models, two of which have stove benches. Such furnaces are built most often in baths. But it’s hard to install a massive brick oven there, so many people choose a metal structure for baths. Sauna stoves are labeled BIK, Kuznetsov designed them so that they were small-sized, looked presentable and occupied a small area.

Heating polycarbonate greenhouses infrared heater

The principle of operation of Kuznetsov's bell-type furnaces: ordering

The principle of operation of Kuznetsov furnaces is not complicated.During the construction of the furnace, it is necessary to carry out all work in accordance with the drawings, diagrams and, of course, use the orders.

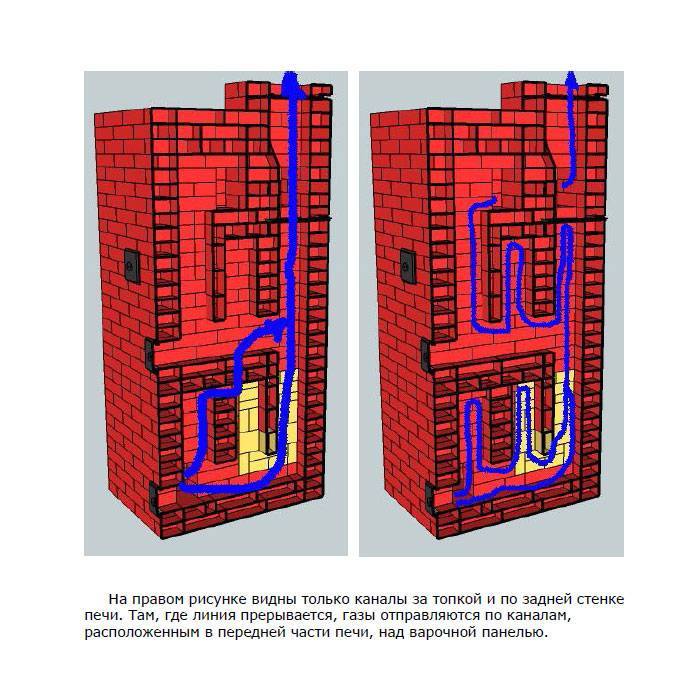

All Kuznetsov bell-type furnaces operate on the principle of separation of combustion products. This principle lies in the fact that the gas resulting from the combustion of fuel is divided into two streams: cold and hot. The movement of gases inside the furnace design is very well thought out. Hot air lingers in the oven and retains heat for a long time. Cold air quickly flies into the chimney, along a specially made recess. A furnace operating according to this principle is called a bell-type (dome) furnace. Inside such a furnace, the hearth is combined with its lower part and forms something like a cap. He then acts as a gas separator into two streams. The flow of hot air rises and lingers in the bell, thus the heat is concentrated.

Advantages of Kuznetsov furnaces:

- Profitability;

- Long-term heat retention;

- Small soot formation;

- No need for frequent cleanings;

- You can choose from different shapes and designs.

The high efficiency factor (95%) of Kuznetsov furnaces is the result of a fundamentally new development and design features. For comparison, a traditional Russian stove has an efficiency of 25-40%. If Kuznetsov's furnaces have flaws, then there are few of them, and they are lost against the background of advantages.

Preparatory work

First of all, you need to choose a place for the construction of the furnace. The easiest way to do this is before building a house - then both the stove and the building are designed together so that three or at least two rooms are heated. With a ready-made house, the situation is more complicated.In this case, they tend to build the furnace into an interior partition, since its introduction into a load-bearing wall requires complex calculations and dangerous labor-intensive work (part of the wall will have to be dismantled, keeping the load from overlapping with a system of lintels and columns).

You can, of course, limit yourself to a simple wall-mounted location option, but then only one room will be heated.

A reinforced concrete foundation must be built at the selected location. Its dimensions must exceed the dimensions of the oven by at least 100 mm on each side. It is not allowed to combine the foundation of the furnace with the foundation of the building - both structures give a different draft and one of the bases will pull the other along, causing it to skew.

Under the furnace, a reinforced concrete foundation must be equipped

The depth of the foundation depends on the bearing capacity of the soil, the depth of its freezing, the method of building operation (periodically / constantly). Usually in buildings with year-round residence of people located on stable ground, the foundation is deepened by 400–600 mm. Crushed stone should be poured at the bottom of the excavation as a reinforcing layer, and a sand cushion should be placed on top of it.

Then everything is done according to traditional technology - formwork is installed, the reinforcing cage is fixed and poured with concrete. It is necessary to proceed to the construction of the furnace only after the concrete has fully matured and gained sufficient strength - this usually takes about a month.

Types of Kuznetsov furnaces

The design received enormous value due to its amazing versatility. The Kuznetsov stove, drawings of which are presented in more than 150 variants, can be used in any room as efficiently as possible.Each of the drawings takes into account the features of the premises for a specific purpose, which is why the furnace works with such a high efficiency for a certain type of building.

It makes no sense to list all Kuznetsov's furnaces, here are just some of the options that are most in demand:

- bread ovens, for cooking, combined with cooking surfaces;

- bath stoves;

- outdoor stoves;

- fireplace stoves;

- heating furnaces.

This is not a complete list of specialized Kuznetsov furnaces. It is possible to create combined views, which is very convenient if you use them in everyday life in small areas.

What can give such a strange chimney?

- Stratification of flue gases by temperature immediately after the combustion chamber.

- On the path of gases, you can install not one, but two or three caps at once. As a result, the smoke will give off more heat, and the structure itself will consist of several zones with a permanent temperature.

- The hood is located next to the firebox and smoke gases that have not yet given up their heat enter it. As a result, ash, carbon monoxide and volatile hydrocarbons, which are carried away by the chimney in a conventional furnace, burn out under the hood in this design. This leads to an increase in heat transfer and minimizes the amount of soot in the chimney.

- Due to natural convection, the products of combustion are physically unable to leave the furnace before all the heat is released.

- The heat exchanger in the Kuznetsov furnace, unlike other types of construction, is located in the hood, that is, outside the combustion chamber. It cannot affect the temperature of the fire in any way and, as a result, does not reduce the efficiency.

Now - directly to the construction process.

Strengthening the structure with wire

Every third row should be laid with metal wire, this is a small but necessary detail that will make the structure reliable. Iron components must be inserted into the masonry with a gap of 0.5 cm, and the resulting void filled with refractory wool.

To make a Kuznetsov bath stove with your own hands, it is not necessary to have masonry skills. If you have a diagram and drawings, if you work carefully, everything will definitely work out. To find the scheme, just go to Kuznetsov's website, there is information available to everyone, which anyone can use.

If you have masonry experience, then there will be no problems, the main thing is to follow the instructions.

Furnace foundation

As with every brick structure, the foundation must be prepared in advance for the furnace. In the event that this is not done when building a house, this process can be time consuming. But you can’t get around it, because the construction turns out to be quite weighty and neither the cement screed nor the floor logs can withstand this. So, so that the furnace structure does not crack in the future, the construction of the foundation should take place according to the following rules:

Fig.1. Scheme of ordering the furnace.

- The base of the furnace must not be connected to a common foundation, otherwise this will cause deformation of the structure and lead to cracks or even a complete rupture.

- If the furnace structure is planned to be located against the wall, then the furnace foundation under construction should not touch the main one and be located at a distance of no more than 5 cm. After the concrete has hardened, the resulting gap is filled with sand.

- It is necessary to observe the correspondence between the climatic zone of soil freezing and the depth of the excavated pit.

- It is necessary to isolate the foundation from moisture on it with a sand cushion laid on the bottom of the pit, and after solidification, wrap it with roofing material or other waterproofing material.

- Be sure to reinforce the concrete part of the foundation with a metal frame of reinforcing bars.

After this stage is completed, the process of building the furnace begins. For someone who has ever encountered such work, it will not be difficult to master the bricklaying technology using the Kuznetsov fireplace as an example, modern models of which are very diverse and fit perfectly into the interior.

Basic rules for creating a heating furnace

- To make Kuznetsov's ovens, the order (masonry schemes) should be printed in advance.

- The refractory shell located inside the furnace must be free on all sides, since the brick expands during the heating process.

- Internal refractory masonry in the case of using fireclay bricks is always carried out on edge. If the bricks are made of clay, on the inner walls and on the posts, they are laid at the discretion of the stove-maker.

- To strengthen the bond, a wire is laid every two brick rows.

- When a Kuznetsov oven is created, the ordering of brick ovens for the house provides that various elements (for example, doors) are installed in such a way that there is room for expansion. A special gasket is placed between the brick and the metal element.

- After the construction of a brick structure is completed, it should be treated with a refractory compound.

- The first kindling begins with a minimum temperature and in the future it is gradually increased.

What is needed for the construction of Kuznetsov furnaces

For its masonry, according to all the rules, it is important to strictly follow the scheme. Experts advise to start with a “rehearsal” of this process, laying out the structure “dry”, without the use of cement mortar

When calculating the main parameters, it should be borne in mind that the concrete base must be 10 centimeters larger than the dimensions of the furnace on all sides. The pit is dug to a depth of about 40 to 60 centimeters.

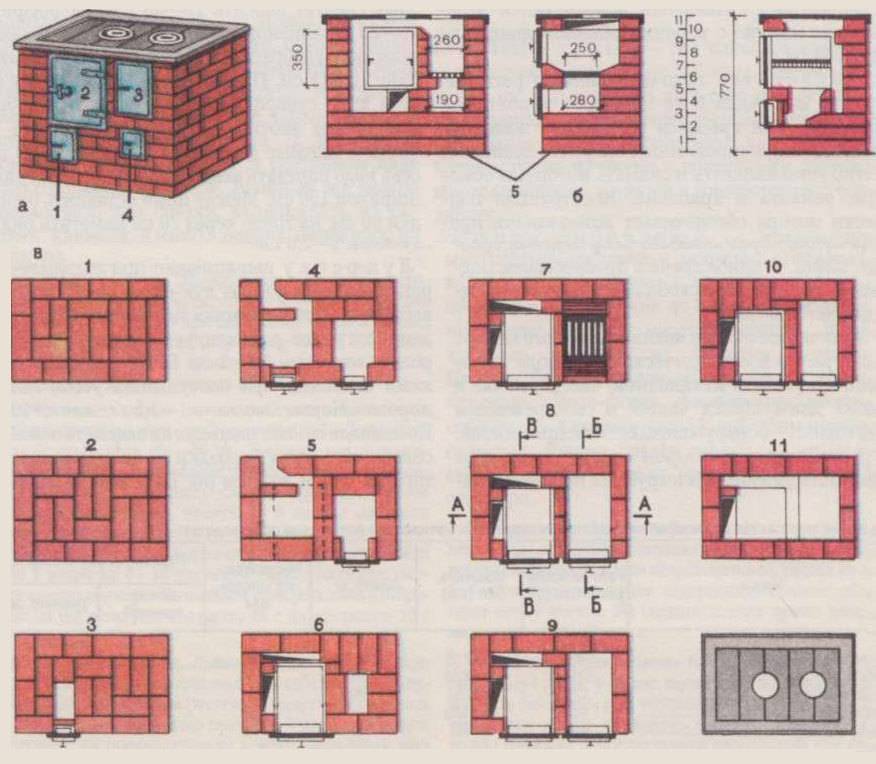

Today, more than 150 schemes are available for public viewing on the Internet - drawings with designs of Kuznetsov furnaces. To build any of these models, you need to stock up on the necessary materials and tools. For example, for the construction of an OVIK-9 oven, which has a cooking chamber with a 2-burner stove and steel doors, and is also equipped with a separate exhaust duct, the following materials are needed in a certain amount.

- Red brick - about 450 pieces.

- Refractory bricks of the SHA-8 brand for the installation of a firebox - 22 pieces.

- Doors: for the firebox of the DT-3 brand with a size of 210 * 250mm and for a blower (WPC) with a size of 140 * 250mm.

- Grate grate, size 250*252 mm.

- Cooking panel (stove) with 2 burners 586 * 336 mm in size.

- Doors for the cooking furnace size 510 * 340 mm - 2 pieces.

- Gate valves: for the firebox - 130 * 130 mm, for the chimney pipe - 130 * 250 mm, "summer" valve - size 130 * 130 mm.

- Metal corner 36*36*4*600 mm and metal strip 40*4*600 mm.

- Metal sheet 600*550*3 mm.

- Pre-ceiling metal sheet 500*700*3 mm. Also, instead of it, you can use ceramic tiles or other material with refractory properties.

As for the tools, for the workflow you will need a trowel, a plumb line, a building level, a mortar container, spatulas, a building corner, a puncher, a grinder and a mixer nozzle.

Stove with stove bench

Especially popular with our people is a stove with a stove bench. This design is also possible with bell-type furnaces. They are burning wood. Such models are used mainly in summer cottages or in country houses. All stoves with benches consist of the following elements:

- oven for heating;

- couch;

- hob;

- oven;

- ash pan;

- woodcutter;

- place for kitchen utensils.

As for any furnace design, a separate foundation is required for such models. First, the base of the furnace is built. It consists of several brick rows aligned horizontally. They must have right angles. You should also adhere to the distance from the rows of the base to the wall of the room of about 15 cm (or more). Then a blower and air vents are laid, thanks to which the air heated in the furnace rises, is evenly distributed throughout the furnace structure and optimally heats the stove bench.

At the level of 8–9 rows, floors should be laid on the stove bench and firebox. After that, you need to continue, according to the order, the laying of brick rows for the oven and hob. Without fail, a row is laid separating the latter from the wall of the room.

The next step: laying out the jumpers. In the area of the oven, it is necessary to use ordinary or figured masonry in the form of an arch or a wedge for this purpose, and it is advisable to install metal corners and a decorative shelf above the casing of the stove. Subsequent brick rows connect all the chimneys together.Windows are made on the walls, near the oven - letnik (it can be used in the summer season). Those that are higher will heat the room in winter.

The pipes are mounted higher and have a square section. It is recommended to lay 2.5 bricks. Those floors that are laid in the area of \u200b\u200bthe location of the chimney should be insulated in several layers with basalt slabs.

It is desirable to overlay the outer surface of the chimney with silicate brick, since it is characterized by resistance to temperature fluctuations and climatic precipitation. After its erection, all available fittings are mounted on the furnace.

For example, you can not limit yourself to simple brickwork (although it looks quite solid), but paint the structure with heat-resistant paint and decorate it with ornaments and drawings. Such a model will look beautiful in any interior. Financially, the finish will be more expensive, the higher the quality of the tiles used for it. And the tiles are worn not only aesthetic function - they keep heat very well. And in the care of these elements are unpretentious. If you can’t do the finishing with your own hands, professional craftsmen can come to the rescue.

Design features

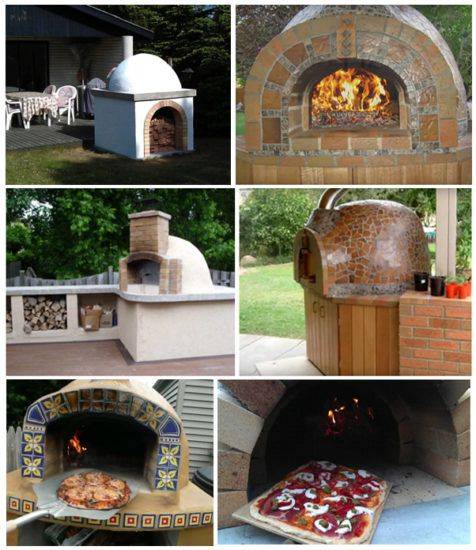

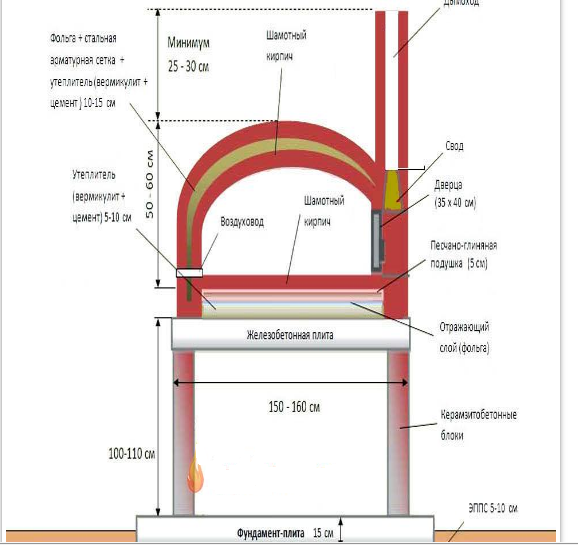

Due to the special internal structure of the oven, it heats up quickly and retains heat for a long time. Historians claim that the Pompeian oven appeared on the Iberian Peninsula and was originally used specifically for making an open cheese pie, where the structure was not needed to heat the room.

Decoration of the Pompeian oven

Later it spread throughout the world. It is also called the Neapolitan, Italian oven, tandoor.

The Pompeian oven will not only be an ideal design for making pizza, pies and bread, but will also decorate any suburban area. In combination with a gazebo or barbecue, it becomes a real landscape decoration, becoming a favorite vacation spot for the whole family.

Oven in the yard

Basically, such a stove is installed in suburban areas on the street, in a barbecue area, in an outdoor garden, but if desired and some technical improvements are made, a Pompeian stove can also be built in the house. To do this, of course, it will be necessary to provide not only a reliable solid foundation, but also a chimney.

In this article, we will look at the classic option for building an Italian outdoor stove. Before proceeding with the step-by-step instructions, I would like to warn you that the laying of the Pompeii oven is a very difficult and expensive undertaking.

But if you do everything right, then such an oven will delight you for decades, giving an authentic look to the cottage and helping to cook delicious homemade cakes. Thanks to our clear and simple instructions, even a beginner can master the laying of the Pompeian oven with his own hands.

The device of the Pompeian oven is somewhat similar to the design of the ancient Slavic oven.

Construction of the Pompeian oven

But, unlike the traditional Russian stove, it heats up much faster. You can cook pies in it literally 30 minutes after heating, while the Russian oven will take at least 3-4 hours before reaching the optimum temperature for cooking.

Such a heating rate in the Pompeian furnace is achieved due to the lower thermal mass. The layer of brick that is heated is only 12 cm.Already 45 minutes after kindling, the temperature in this furnace reaches 260 degrees, and after an hour - 370 degrees.

How is the temperature distribution in the Pompeii oven?

| In 30 minutes | After 45 minutes | After 60 minutes | After 90 minutes | |

|---|---|---|---|---|

| The outer part of the vault | 150 | 260 | 370 | 370 |

| The inner part of the vault | 315 | 370 | 370 | 370 |

The peculiarity and main advantage of the Pompeii oven is that almost any dish can be cooked in it in a short time. Due to the high temperature that is reached inside the vault, pizza and bread are perfectly baked in it. Smoke gives a special piquancy to baking.