- Required material

- 2 How do long burning stoves work?

- Do-it-yourself potbelly stove - varieties

- quality products

- Working ovens of the middle class

- Which brick to choose for masonry?

- What you need for work: tools and materials

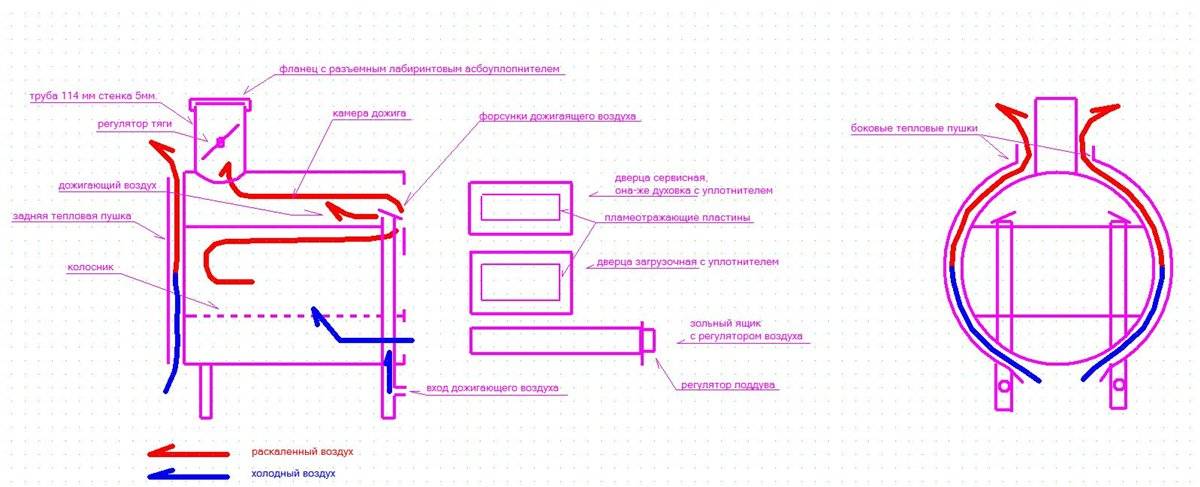

- How to increase the efficiency of the furnace?

- How to increase the heat output of the furnace

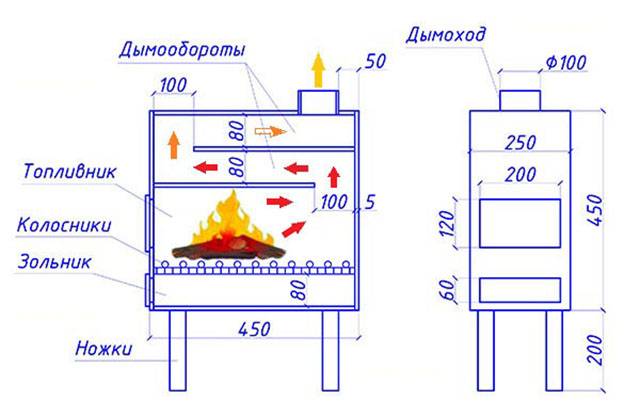

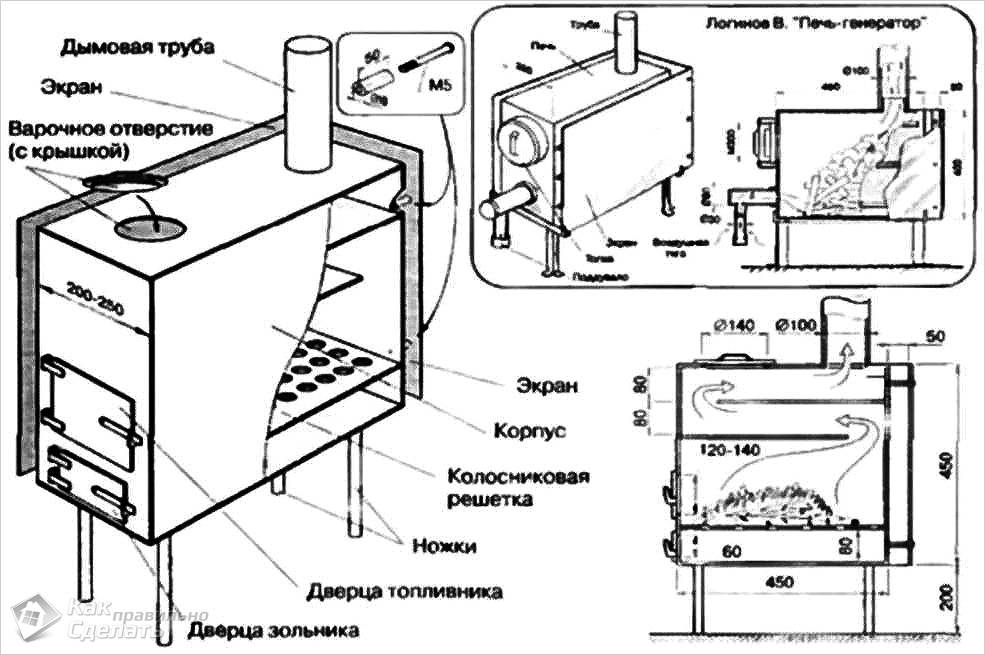

- Rectangular potbelly stove from a profile pipe

- 1 Description, device and principle of operation

- Important Points

- Voting: what is the best modern stove-stove?

- Brunner IRON DOG

- Fixing the pipe

- Seam sealing

- Scope of bourgeoisie

- Advantages and disadvantages of a potbelly stove

- Structural modernization

Required material

First of all, depending on the model chosen, you will need empty gas cylinders, one or two.

In addition to them, you will need:

In addition to them, you will need:

- A sheet of steel from 3 mm, for arranging a jumper between the ash pan of the firebox, as well as a hob.

- To make the stove look more solid, you need a finished cast iron door with a cast pattern.

- If the appearance of the product is not fundamental, then a piece of metal is suitable for the door. It can be cut from a steel sheet or from the cylinder itself.

- Chimney pipe. Its diameter should be 9-10 cm.

- For the grate and legs, you will need a steel corner or reinforcing bar d (diameter) 1.2-1.5 cm.

- Ready-made cast-iron grate can be bought at a specialized store. Also, its role can be played by the bottom (holes are drilled in it) of a horizontally lying cylinder.

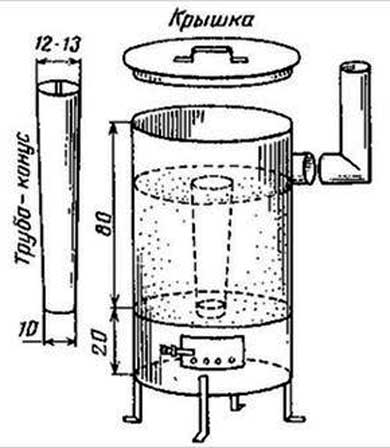

That one, that the second model can be made from a large balloon, or from a small one. Accordingly, the result will be a large or small potbelly stove from a cylinder. It all depends on what type and size of room it is intended for.

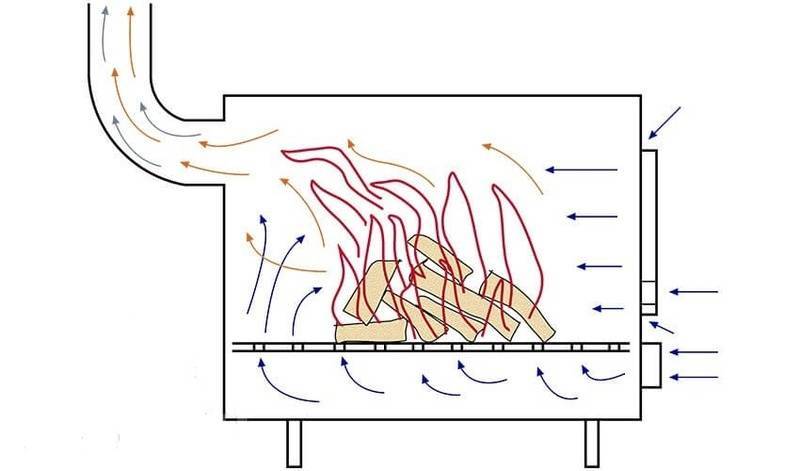

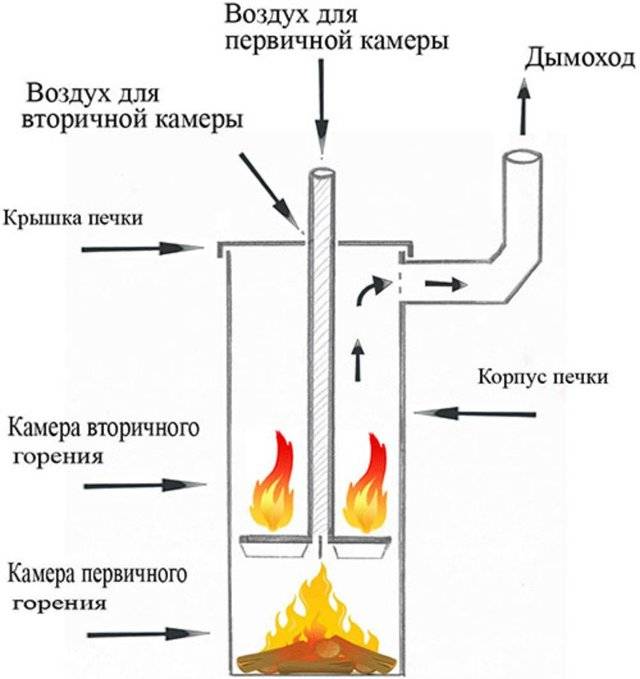

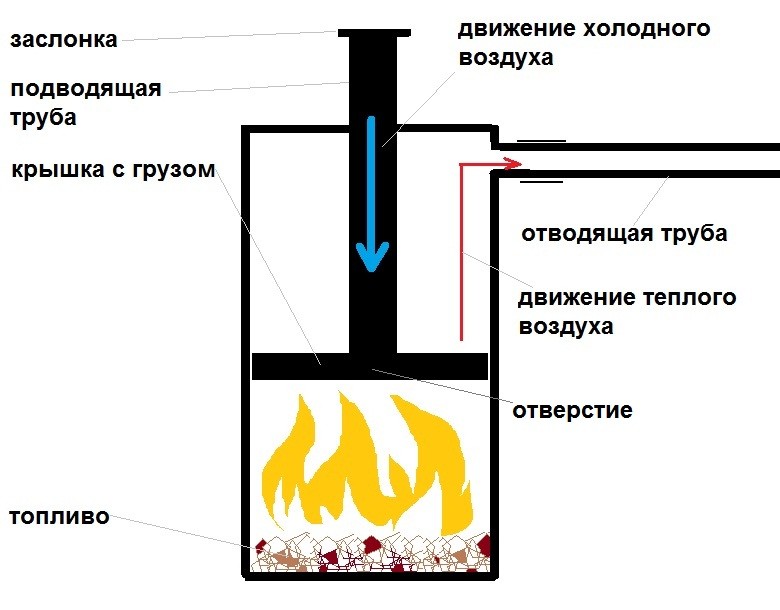

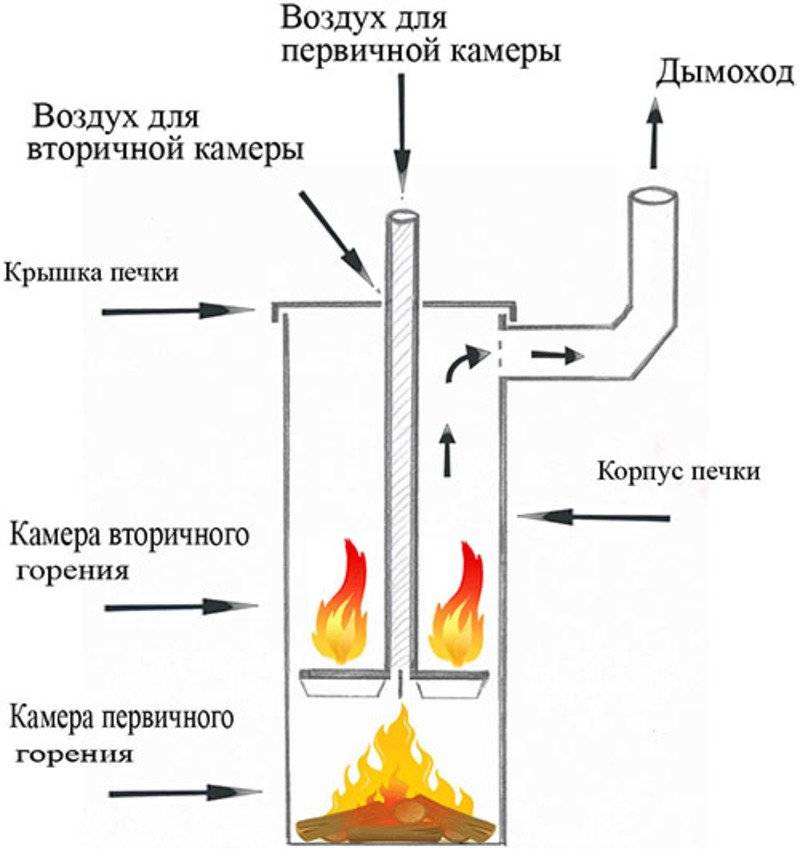

2 How do long burning stoves work?

designs long burning stoves developed a lot, but all work on the same principle. Heat is obtained not in the process of open combustion, but as a result of pyrolysis. Under the influence of high temperature, the fuel smolders, combustible gases are released. They ignite and burn, releasing a lot of heat. The slow combustion process occurs by regulating the supply of oxygen. When the fuel flares up, the air supply is blocked to a minimum.

Gas from such a stove does not enter the room, thanks to hermetic doors and dampers

It is impossible to use an ordinary Russian stove in this version; such an attempt will, in all likelihood, lead to disastrous consequences. Gases can enter the room, which threatens to poison people. Stoves with a long burning process are equipped with sealed doors, dampers, and adjustment devices, which prevents gas from entering the room. Heating devices of this kind deserve attention for many reasons:

can work on one tab without supervision for 10–20 hours;

light weight, can be installed without a foundation;

fuel of any kind is suitable, burns out completely, efficiency up to 90%;

can be used occasionally, which is important for giving;

no foreign smells and smoke;

the ability to assemble yourself from inexpensive materials.

The undoubted advantages also include low cost, since little material is required. If you do it yourself, using a metal barrel, a gas cylinder, it will come out even cheaper.

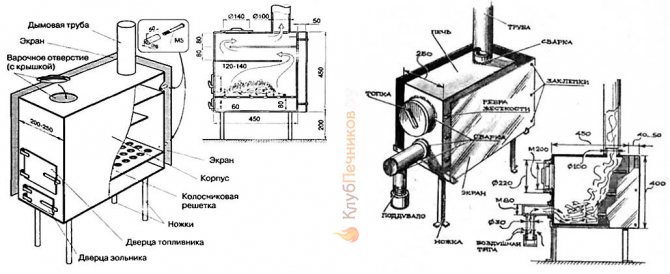

Do-it-yourself potbelly stove - varieties

Potbelly stoves, which are made by hand, can be divided into 3 types:

- Well-thought-out designs that embody useful heating ideas.

- Workable products, but not fully developed.

- Homemade devices created from improvised materials of low quality.

quality products

Model PETIT GODIN

These types of do-it-yourself bourgeoisie include:

- Brick oven for a bath. Brick was not originally used as a material for this type of stove. However, with a reasonable approach, it is possible to make a design with an efficiency of 40%.

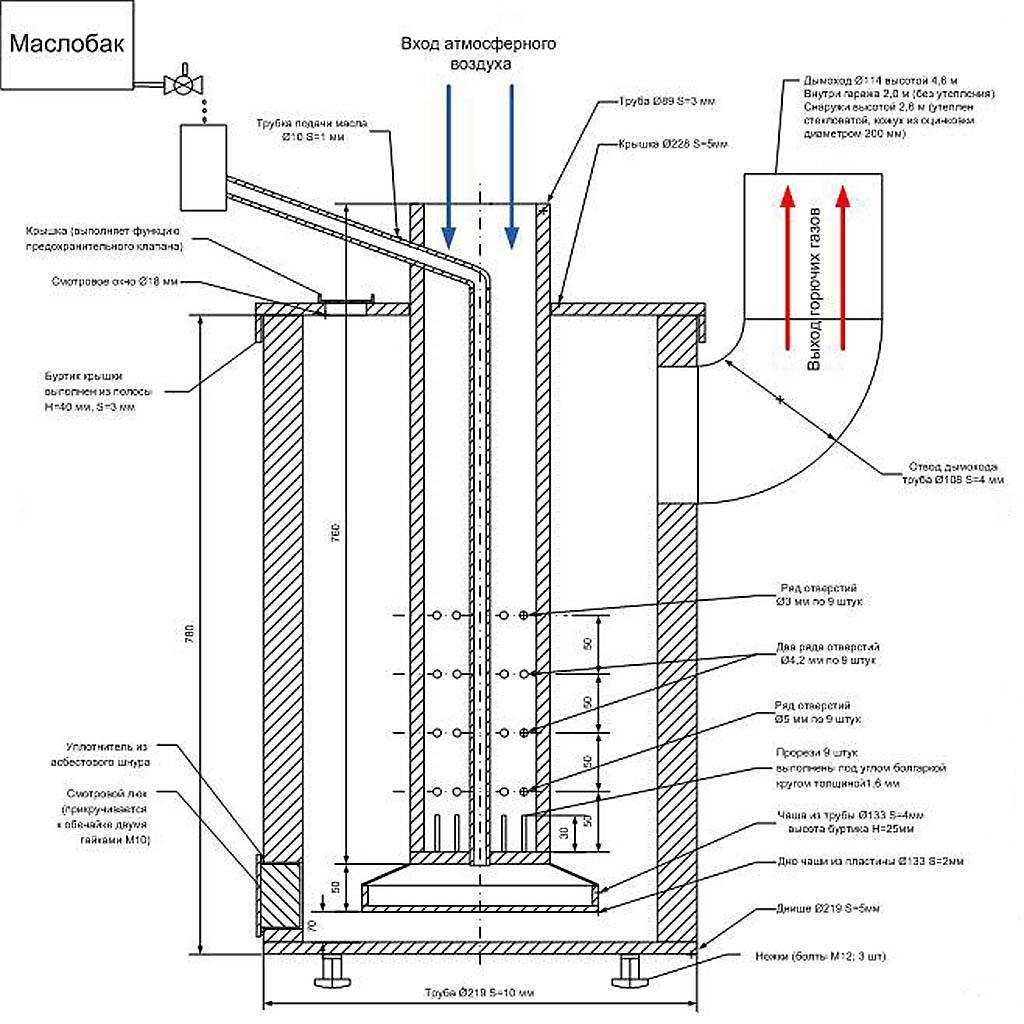

- Potbelly stove at work. This is an efficient and fairly economical version of the stove, which is suitable for heating a garage or other utility room. The filling hole should be located in the far corner of the tank. To top up the used oil, a funnel with a curved spout is constructed. At the same time, fire safety rules must be observed.

Working ovens of the middle class

Among the most common bourgeois women of this category, it is worth highlighting:

- Barrel construction. This is the most practical option, which is made from a conventional 200-liter barrel with a diameter of 600 mm. In such a circle, it is necessary to mount a hexagon with a side of 314 mm. The efficiency of such a potbelly stove is no more than 15%.

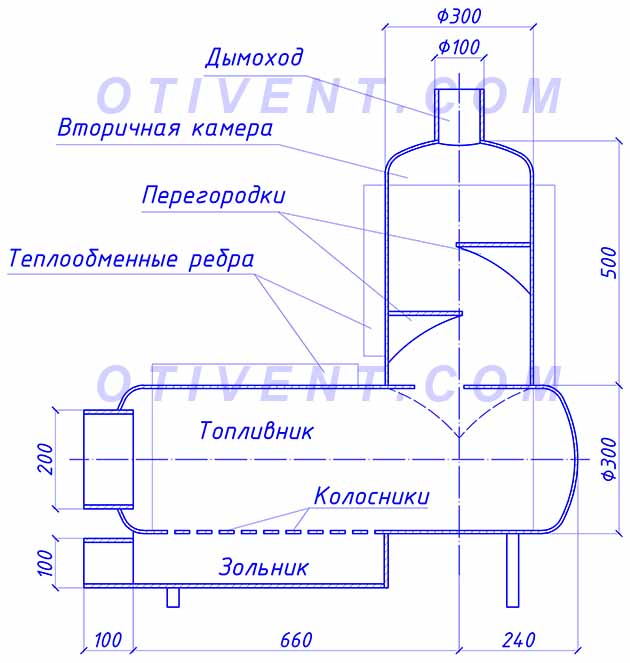

- A balloon stove. For this option, a household gas cylinder is suitable, which is laid on its side.The chimney is located in the far part of the furnace.

The barrel is taken as a basis

Both in the first and in the second model of the potbelly stove, the arch of the furnace turns out to be curved, spherical or cylindrical.

The easiest home-made potbelly stove to implement is gas. A propane burner is inserted into the furnace, and the design is ready. Furnaces on such fuel should have a developed heat exchange surface, since gas is an energy fuel, and combustion products easily and quickly evaporate through the pipe.

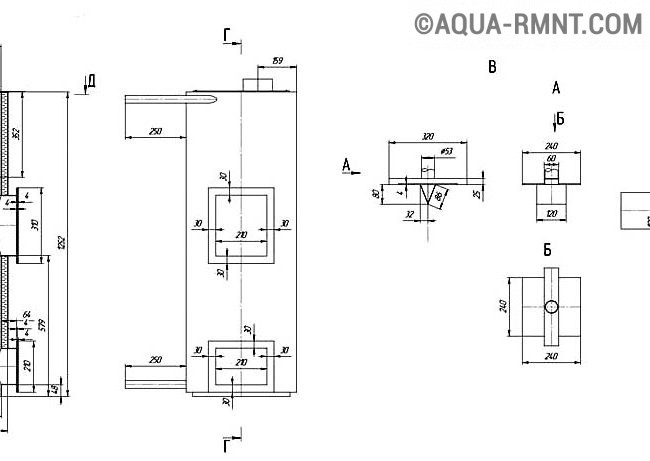

Which brick to choose for masonry?

Each section of the furnace uses its own brick. The highest temperature in the furnace. The material must withstand such a load. Only fireclay bricks are suitable here.

All flue ducts and the furnace area are also subjected to a temperature test, although not as high. Here we will use refractory ceramic bricks. It is cheaper than fireclay and is able to withstand the load.

As a base, we will use a frost-resistant brick that can withstand great pressure. The weight of the entire structure will be distributed on it.

General recommendation - use a brick:

- full-bodied;

- qualitative;

- with good heat dissipation and heat capacity.

The brick must have different sizes. Before buying, you need to clarify under which order is calculated. Below is a step-by-step instruction for laying a potbelly stove from DIY bricks. There you can use a brick with a size of 250x120x65. Also, it is he who is taken into account in the order in photo No. 2 (below, in the section "Laying the furnace").

If desired, you can use various decorative types of bricks for cladding. This will give the stove a more aesthetic appearance.

In our case, we need 60 refractory ceramic bricks and 35 pieces of fireclay bricks (taking into account possible losses).

What you need for work: tools and materials

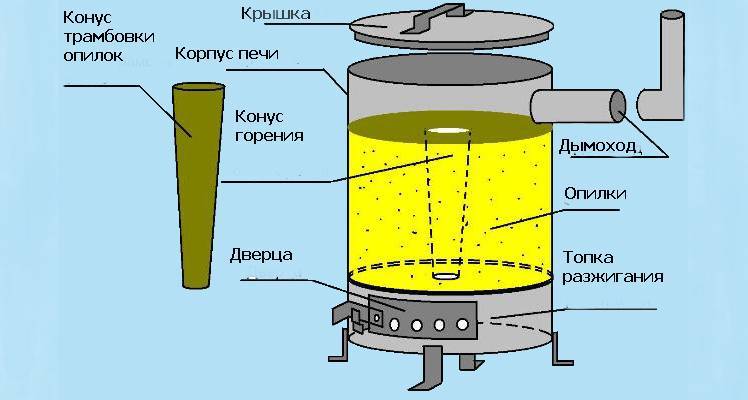

This model of a "long-playing" stove can be made in just a few hours. All that is needed for this is a great desire and the correct organization of the workflow. You will also need to thoroughly understand the design of the unit and prepare everything you need in advance.

Of the tools you will need:

- welding machine - a small, lightweight inverter with the ability to adjust the current strength up to 200 A is best suited for these purposes;

- angle grinder (colloquially a grinder or "grinder");

- cutting and grinding discs designed for metal work;

- drilling machine or electric drill;

- set of drills;

- hammer with a medium-sized striker;

- blowtorch;

- chisel;

- sledgehammer;

- tape measure and metal ruler;

- core (device designed for applying marks to facilitate drilling);

- scriber for marking on metal surfaces.

As for the materials, there is no need to follow the list exactly. The beauty of homemade structures lies precisely in the fact that any iron that can be found in the backyard or in the corners of the garage (workshop) will do for them.

For the manufacture of the furnace body, any overall container is suitable, for example, an unnecessary metal barrel

So, the list of necessary materials:

- steel pipes with a diameter of 80 to 250 mm, which will be needed for the manufacture of an air supply riser and a chimney;

- a suitable metal container with a diameter of 300 to 600 mm with a wall thickness of at least 2.5 mm (you can use a gas cylinder that has served its time, a fuel barrel or a pipe length of at least 120 cm);

- a metal sheet with a thickness of at least 4-5 mm, from which the air distribution piston will be made;

- strong metal hinges that will be needed to fasten the furnace and ash doors;

- asbestos cord (it is needed to seal the loading window and other operational openings);

- corners with a shelf from 50 mm, channels and profile pipes - for the manufacture of air distributor blades, support legs and other structural elements;

- a round metal pancake with a thickness of at least 5 mm and a diameter of 120–150 mm (you can take any suitable gear or sprocket from automotive equipment);

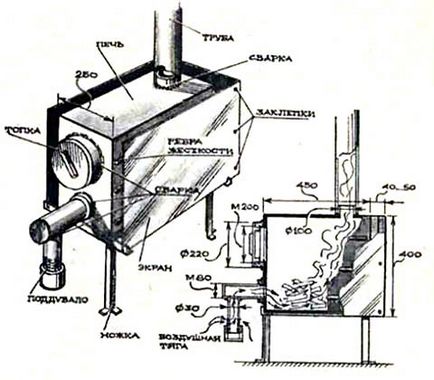

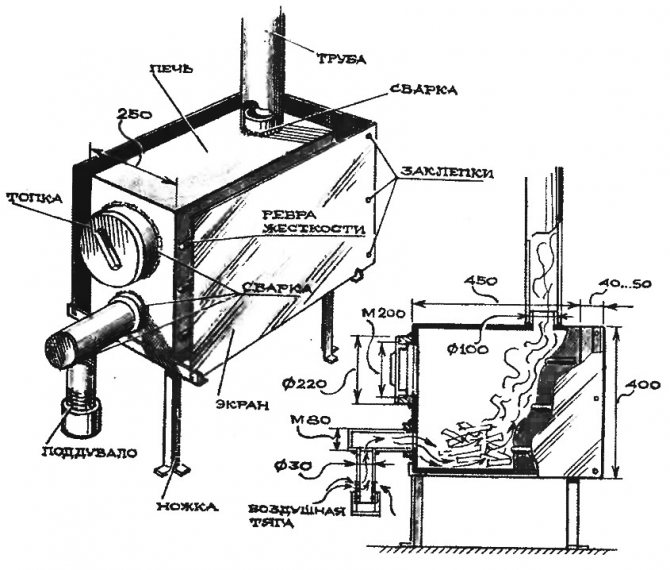

How to increase the efficiency of the furnace?

Chimney diameter

When using potbelly stoves, the main thing is to make sure that a smaller amount of flue gas comes out through this chimney compared to the volume produced by the furnace. If this problem is successfully solved, the gases will remain in the pipe and move through the furnace space a certain number of times. This will lead to air circulation, which is a prerequisite for fuel combustion. As a result, when leaving through the chimney, these gases will already have a lower temperature.

This problem can be solved by determining the optimal chimney diameter. This can be considered a size that is three times the volume of the furnace furnace in cubic meters. However, in the case of gas circulation in a metal box, it will quickly lose its temperature.

In order to avoid rapid cooling of gases and to ensure their complete combustion, it is necessary to change the fuel combustion process so that it takes place in the pyrolysis mode. You can create it with the help of high temperature. Moreover, even if you try to use dry furniture as fuel, you will not be able to achieve the desired effect.

You can try to regularly add coal, but with the help of such raw materials it is impossible to create optimal conditions for the pyrolysis process. This is possible only on condition that the furnace will operate in the smoldering mode and will naturally switch from one mode of operation to another.

Now we come to the next important point.

Steel three-sided protective screen

heat generation

Keeping in mind that the supply of firewood and coal is constantly in short supply, it is important to make sure that the very first portions of heat are in the room, and do not go into the chimney. Among the currently known methods of heat transfer, in terms of efficiency, there is no equal to convection.

In practice, it is implemented in that, after heating the air near the stove, make it so that it spreads throughout the room. This problem can be solved using the screen

Among the currently known methods of heat transfer in terms of efficiency, there is no equal to convection. In practice, it is implemented in that, after heating the air near the stove, make it so that it spreads throughout the room. This problem can be solved using the screen.

Although the heating temperature of the lower layer of the potbelly stove is not so high, the heat still comes down from it. Because of this, there is a risk of fire in the room.For this reason, it is necessary to use a metal sheet as the base on which the potbelly stove will be placed, providing for a removal of 30-40 cm from the stove. Moreover, under it it is necessary to place an additional sheet, which can be made of asbestos or basalt.

It is worth noting that the potbelly stove is not able to 100% maintain the pyrolysis mode. This is due to the fact that after entering the chimney, the gases leave it without having time to give up their heat. This can be achieved if the right approach is taken. chimney pipe installation, choosing the most optimal design for it.

This problem is solved as follows: a vertical part must be provided in the design of the chimney, reaching a height of at least 1 meter. It should also provide for a layer of thermal insulation, which can be used as basalt wool.

special name - boar

Ever since its appearance and popularization of the potbelly stove, changes have been made to their design. As a result, today they are long-burning kilns, characterized by ease of operation and a high level of efficiency. The modern version of these furnaces no longer provides for grates, while an air choke appeared at the blower, the main purpose of which is to regulate the heat output and combustion mode. To ensure long-term combustion, air enters the fuel from above.

Among the various options for bourgeois stoves, cast-iron stoves demonstrate the highest energy intensity. Such devices could work even without a screen. It was this feature that was taken into account when it was decided to use them to heat the army barracks.In our country, they have long been engaged in the manufacture of army bourgeois, and there are no complaints about the quality of their work. These installations differ in many parameters, including dimensions.

How to increase the heat output of the furnace

So, how to increase the efficiency of such a stove? There are several easy ways. The most elementary is to lay a brick screen around the stove. Bricks can not even be fastened together with clay, just put them on top of each other. You can fold such a screen near the side walls, or you can - at both side and rear walls. The brick will heat up during the burning of the fire, and when it becomes small or goes out, it will give off heat. You don't have to fill up fuel often. One of the features of the potbelly stove is that the stove is light and mobile. With such a screen, it will not lose its mobility, because the bricks can be dismantled at any time, rearrange the furnace and fold the screen in a new place.

There is another way with a screen, which also increases heat transfer. In this case, the screen sheet metal fastened at some distance from the side and / or rear wall of the stove. Sheets can be fixed with long bolts. In this case, the effect of convection is added.

There is another simple way to increase heat transfer. This time, the chimney of the potbelly stove is being modernized. Typically, these stoves have a straight chimney. It is taken out through the roof of the room in which the furnace is installed. If you add several elbows to the pipe, then the heat transfer will increase, however, not by much. In this case, the pipe will resemble the letter S.

If you want it to be much warmer, then you need to take 2 washing machine tanks old sample. The tanks are welded together, and a chimney is passed through them.Thus, above the potbelly stove, which is heated by firewood, there is also a stove of the same size, heated by hot smoke. Heat transfer is almost doubled.

Another method is to weld additional ribs on the stove and chimney, for example, from metal squares. In this case, the chimney must be made of thick metal. Such ribs significantly increase the area of the heated surface. Increasing the area leads to faster heating of the surrounding air. The room is getting warmer. In addition, thick metal retains heat even when the fire in the furnace is no longer burning.

But still, it will not work to infinitely increase the efficiency of this heater. And if you want to have a full-fledged stove in the room, then you will have to fold it out of brick according to all the rules, so that the stove retains heat for a long time, for example, all night. For example, it is not required to increase the efficiency of the Russian stove; it retains heat for a very long time. True, in order to fold it correctly, you will have to call a stove specialist.

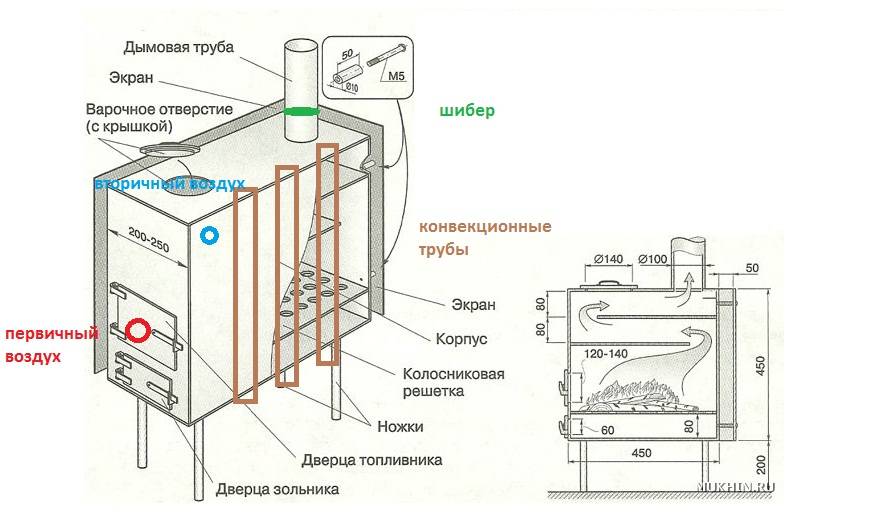

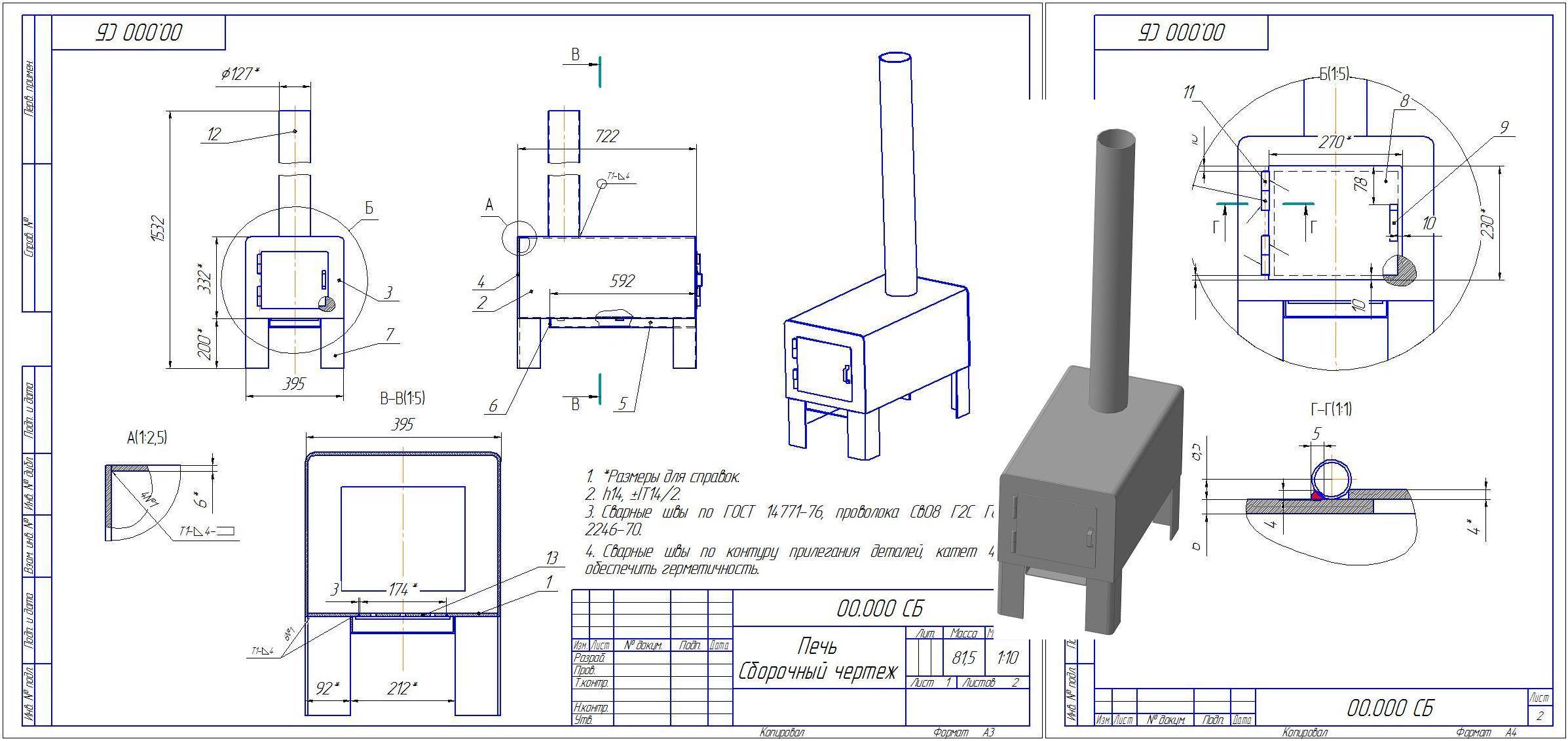

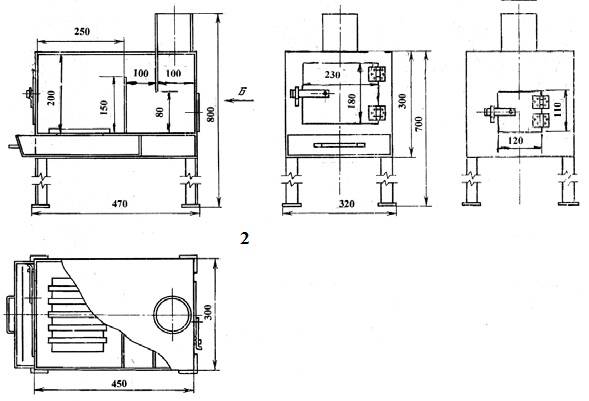

Rectangular potbelly stove from a profile pipe

This version of a potbelly stove made by hand according to the drawing is the most effective. The potbelly stove of this option, like the previous model, is rectangular in shape, but its walls consist of a welded profile pipe of rectangular section. The air will pass between the pipes and heat up more, thereby increasing the efficiency of the furnace.

Let's get to work:

- We cut the profile pipe into pieces forty centimeters long. So many pieces are needed to weld them and get the chosen length of the bottom and top. We put the pieces of the pipe next to each other.On the one hand, we pass with a continuous seam, and on the other hand, we only make tacks in three places.

- In the same way, we make the second wall and the back wall. Upon completion of work on the manufacture of walls from a profile pipe, we assemble the shape of a potbelly stove. In this case, continuous seams should be placed in the middle of the device.

- On the upper part, using a pipe for the chimney, we mark its location. Cut out the circle. We weld a corner to the lower and upper parts of the front side. Slightly above the lower corner, we weld a piece of a profile pipe of the same section as the walls.

- We measure the front part, according to the obtained dimensions, we cut it out of sheet metal. In the place where the pipe is welded, cut the workpiece into two parts. We put the upper part in its place, fix two loops.

- The lower piece of small thickness, leave in place. Approximately in the middle of the bottom we fix a piece of the corner, as shown in the image. We weld a small handle to the same part. We also fix the handle on the combustion chamber door.

- We drill a through hole in the pipe with a diameter suitable for any thread. We prepare a circle that will fit the diameter of the pipe, and weld it in the middle of the pipe to the thread.

- We measure the length of the furnace. We cut off a rectangular pipe in size, weld reinforcement on the surface of at least 14mm. We weld small legs and install them in the middle. We attach a pipe to the upper part to the cut hole and scald it in a circle with a continuous seam. If necessary, the oven can be painted with heat-resistant enamel.

Potbelly stove is ready for use. As our testing showed, at a temperature of minus one degree, a garage of 24 square meters warms up to 19 degrees in half an hour.

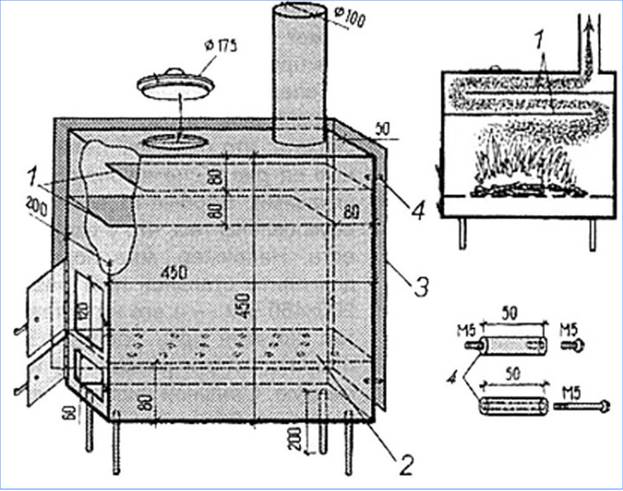

1 Description, device and principle of operation

In ordinary potbelly stoves, which have long been known to everyone, firewood burns out quickly, and it takes a lot of them to heat the room. To make from a potbelly stove long burning stove, it was necessary to equip it with an additional device for long-term burning of fuel. Craftsmen found a way out of this situation, and various options for such units appeared: Slobozhanka, pyrolysis, bubafonya and others. They are very economical, you can heat firewood, sawdust, wood chips and other combustible waste from firewood. They can burn, or rather, smolder, for a whole day, and their efficiency exceeds 90%. They don't need constant supervision.

It is convenient to install these stoves in greenhouses, garages, cottages and small wooden houses. The disadvantage will be in them a special organization of the chimney, in which several branches cannot be made. As soon as the firewood burns out, the potbelly stove cools down, but during combustion it heats up very much. You can make a potbelly stove from anything, and its design is quite simple. You can cut it out of metal, and then it turns out to be a rectangular shape.

You can make a potbelly stove for long burning from an ordinary steel barrel or a used gas cylinder. The principle of operation is the same everywhere - decay. A feature of such heaters are two chambers, which are divided into two parts: for fuel and for further combustion of coal and gases. A piston is provided in the furnace device, which:

- supplies air to the furnace;

- exerts uniform strong pressure on the firewood, they smolder and evenly fall down.

As the firewood burns, the chamber itself also decreases, on which a damper presses from above, which regulates air circulation.

Important Points

No oven elements may be installed near the main heat source!

When performing such heating equipment as a cylinder-based or bubafon oven, you should pay attention to some important points:

- Some sections of the chimney pipe are mounted strictly in the opposite direction from the one along which the gas flows will move.

- Before making a furnace, it is necessary to determine the place of its installation, so that the surrounding space can without fail withstand a sufficiently high temperature regime.

- The chimney must be designed in such a way that even after a long time it is possible to disassemble it for cleaning purposes.

- Before a bubafonya or a long-burning stove from a cylinder is started, the device must first be tested. This process is desirable to carry out in different modes. This is required in order to find out the optimal temperature and operation of the equipment.

Voting: what is the best modern stove-stove?

| A photo | Name | Rating | Price | |

|---|---|---|---|---|

| The best factory models of Russian-made stoves | ||||

| #1 | Potbelly stove POV-57 | 99 / 1005 - votes | Learn more | |

| #2 | Termofor Fire-battery 5B | 98 / 100 | Learn more | |

| #3 | META Gnome 2 | 97 / 100 | Learn more | |

| #4 | Furnace Potbelly stove Teplostal | 96 / 1003 - votes | Learn more | |

| Popular potbelly stoves from world brands | ||||

| #1 | Keddy | 99 / 100 | Learn more | |

| #2 | Guca Lava | 98 / 100 | Learn more | |

| #3 | Vermont Castings | 97 / 1001 - voice | Learn more | |

| #4 | JOTUL | 96 / 1001 - voice | Learn more | |

| #5 | Brunner IRON DOG | 95 / 100 | Learn more |

What would you choose from modern bourgeois stoves or would you advise to purchase?

Brunner IRON DOG

Save the voting results so you don't forget!

You must vote to see the results

After the potbelly stove is installed and ready for operation, it is necessary to install a chimney that can function properly, keep the heat in the room and at the same time prevent combustion waste from entering the air of the room where the stove is installed. To do this, you need to correctly calculate the diameter of the pipe, its length and think about how it will bring smoke to fresh air.

position output pipes above the roof follow certain rules:

- The chimney is located at a distance of up to 1500 millimeters from the roof ridge, which means that the outlet of the pipe should be located at a height of 50 centimeters above the top of the ridge,

- With a distance to the visor of 150-300 centimeters, the outlet of the pipeline can be placed on the same level with it,

- If the chimney is located near the edge of the roof, then its outlet should be slightly lower than the ridge, or on the same level with it,

The second option for the pipe exit is through the wall, and not through the roof. In this case, the end of the chimney should be located just below the top of the roof ridge.

Do-it-yourself installation work should begin with the choice of a place where the outer and inner elements of the furnace should be connected. An attic is perfect for this purpose or roof space. The first element of the future chimney is installed on the potbelly stove itself, on which the second, third and so on are placed next (depending on how many sections the chimney will include).

It is necessary to extend the flue pipe until it reaches the previously determined place at the junction of the two elements.

In the ceiling, you need to make a hole, the diameter of which will be 5-10 cm larger than the diameter of the pipe: this will be required in order to cover the pipe at the point where it passes through the floors with heat-insulating material. If there are insulating materials or other easily flammable objects in the cracks between the ceilings or near the pipe, they must be removed: when the pipe warms up from the smoke and its temperature rises, the risk of fire of the heat-insulating material will increase with it.

A passage glass is inserted into the cut hole in the ceiling, through which the chimney pipe must be passed. Then you need to dock the pipe coming from the inside of the room with the outside of the chimney. The chimney should end above the roof level, approximately 10 cm above it. The place where the hole for the pipe outlet will be cut out is equipped according to the same principle as the pipe outlet inside the building:

- the hole must be larger than the chimney pipe itself;

- a layer of heat-insulating material must be placed between the roofing materials and the pipe.

Fixing the pipe

The smoke outlet pipe is passed through a hole in the roof and fixed with a sheet of tin or other metal. As an alternative to tin, you can also use another non-combustible fixative - bricks, which are installed in the gap between the chimney and the roof. However, in order for the bricks to hold the pipe firmly, a stand must be built for them from the inside. All cracks in this place are covered with ordinary clay.

Seam sealing

After the entire structure is assembled, you need to take the sealant and, without sparing it, lubricate all the joints and seams to prevent smoke from entering the living room from the chimney

Sealant for these purposes must be selected with special attention - only one that is not afraid of high temperatures is suitable

Unfortunately, some sealants will simply "melt" on a hot pipe, while others will dry out easily. One way or another, but the sealant, which is unstable to high temperatures, will lose its properties and will not be able to protect the room from smoke.

Scope of bourgeoisie

These simple stoves are in great demand. For their work, they use firewood, coal, coke, wood waste and many other types of fuel, pleasing with their unpretentiousness and stability of work. Such a stove can be put in the garage - it will take up a minimum of space, but will provide the room with pleasant warmth. If there is a large supply of firewood or access to a cheap source of solid fuel, feel free to build a potbelly stove for long burning.

Wood is the simplest, cheapest and most widely available type of fuel. for stoves. However, its consumption leaves much to be desired.

A mini potbelly stove can be used to heat a barn or home utility room that does not have heating. Agree, doing something in the winter here is not so comfortable - your teeth are chattering and your muscles are cramping. And with the stove, things immediately go smoothly - just have time to throw firewood so as not to freeze.

Long-burning potbelly stoves are useful not only for the garage, but also for any other premises, including residential ones - these can be temporary buildings, cottages, poultry houses, livestock facilities and much more. In general, the scope of their application is huge. They are most in demand in towns and villages where there is no gas, but you need to somehow heat residential and non-residential buildings.

Advantages and disadvantages of a potbelly stove

The widespread use of potbelly stoves was received for a number of main advantages. Among them there are positive and negative sides, everyone chooses the type for themselves and is able to make the oven on their own. Main positive aspects:

- The universal design allows you to use any options for igniting the stove. The type of fuel does not actually matter, it can be any combustible solid raw material. With some modifications, used engine oil is used for heating.

- Simple structure, lightweight installation structure. Do-it-yourself manufacturing does not require financial costs, there is enough knowledge in the fields of welding and locksmith work.

- A large number of varieties allows you to manufacture, install in accordance with the area of \u200b\u200bheating, premises and other needs from the device.

- No foundation or large structures are required.

Almost any equipment, especially those that can be made by hand, has several disadvantages.

The potbelly stove is no exception, before choosing this heater, you should pay attention to irreversible facts:

Great attention is paid to fire safety. The sealed chimney must lead the spent fuel to the outside, the doors are securely fastened to prevent embers or other combustible elements from falling out.

It is possible to get burns in contact with a potbelly stove during the combustion process.

The long time of work of a do-it-yourself potbelly stove will not give you rest when harvesting firewood

Increased fuel consumption allows the stove to be used only for the required time.

Some varieties cannot be used indoors, there are types for heating or heating only

It is important to make a universal device that will help at any moment.

Structural modernization

To increase the efficiency of the potbelly stove, you can use sheet metal, which closes the structure from three parts. The metal protects the case. However, this is not all - there is a draft inside, convection occurs. In this regard, the efficiency of the furnace increases.

Another stage of modernization is the arrangement of a certain bend on the chimney. The issue is that heat is eliminated through it. By extending the chimney length with a horizontal section, it can be used for area heating. The disadvantage of this approach is the deposition of a huge amount of soot.

Another invention is a potbelly stove, equipped on the water. It will provide an opportunity to increase heating efficiency, as well as minimize fuel consumption. Such a potbelly stove functions with water.

In this embodiment, a converter is used that splits the steam. As a result of its functioning, a flame forms in the chamber. It will not be possible to carry out such modernization on its own, but in the future it is quite possible.