- What you need to know when choosing a formwork material

- Do-it-yourself formwork for the foundation from improvised materials

- What to consider when choosing a formwork material

- Preparation and calculations

- Mounting conditions for a support-column structure for a future home

- Evaluation of the bearing capacity of the soil

- Formwork types

- Fixed formwork

- Features of wooden stationary formwork

- Mixed formwork option

- Types of lubricant for formwork

- Emulsol

- Molding oil

- Water based products

- Video: applying lubricant with a sprayer

- Manufacturing and installation

- Shield assembly

- Installation Features

- strengthening

- Auxiliary materials and necessary tools

- metal studs

- Braces

- Polyethylene film

- Materials used

What you need to know when choosing a formwork material

The forming structures used to pour the foundation can be assembled from different materials. The choice of formwork type is influenced by such criteria: the type of foundation, its width, length, etc. The following materials are most often used to assemble the form:

- wood;

- expanded polystyrene;

- metal;

- reinforced concrete.

Wood. As mentioned above, forms for the foundation of this material are most common.Formwork panels in this case may differ in their design. The most common use is plywood, which is fixed to spacers made from a wooden board.

The advantage of a wooden structure is its accessibility. It is also worth noting that the cost of such a form is quite low. Wooden elements are mounted relatively easily. All that is needed for this is to know the technology of work and adhere to it. To install this design, complex specialized tools are not used.

Expanded polystyrene formwork has become very popular due to its practicality and functionality.

The main disadvantage of concrete formwork made from wood is the need to use additional elements. This is necessary in order to strengthen the structure. Most often, such a need is due to the overall differences in the individual parts of the form. The organization of this formwork requires a mandatory preliminary calculation of materials.

Styrofoam. The second most popular item. The constituent elements of a fixed structure are made from it. In addition to performing a forming function, it is a good insulation, protecting the foundation of the building from low temperatures, wind and water. This design is easy to install, but its cost is not very affordable. Problems can also arise in the selection of individual constituent elements.

Reinforced concrete. People wondering what to make formwork from often choose other, less popular materials. An example is reinforced concrete. In private construction, this method is practically not used, since the final cost of the work is too high.It is also worth noting the complexity of organizing such formwork.

The reinforced concrete structure is assembled from individual slabs. The main advantage of such formwork is that its installation allows to reduce the thickness of the foundation itself.

Metal. A metal mold is an excellent option when you need to build a strip foundation. It is also used for monolithic structures. The indisputable advantage of this method is that, if desired, the reinforcement that reinforces the concrete can be welded directly to the metal formwork panels. This design is highly durable and reliable.

Metal structures for formwork have one drawback - high cost

Another advantage of metal is its versatility. Such sheets can be bent, changing their shape as needed. The disadvantage of this option is the high cost of construction.

Do-it-yourself formwork for the foundation from improvised materials

For the assembly of formwork, not only specialized materials are used. For example, a small form for the foundation can be made from improvised means. These can be old doors, pieces of furniture, boards, slate, etc. The main advantage of this method is its cheapness.

It is worth noting that it is quite difficult to design such a form, since it is quite difficult to find the right details. It is very difficult to achieve the tightness of formwork made from improvised means. That is why this method is not popular. It can be used in the construction of a concrete fence. A form for fencing made using this technology requires taking into account possible problems that sometimes arise during operation.

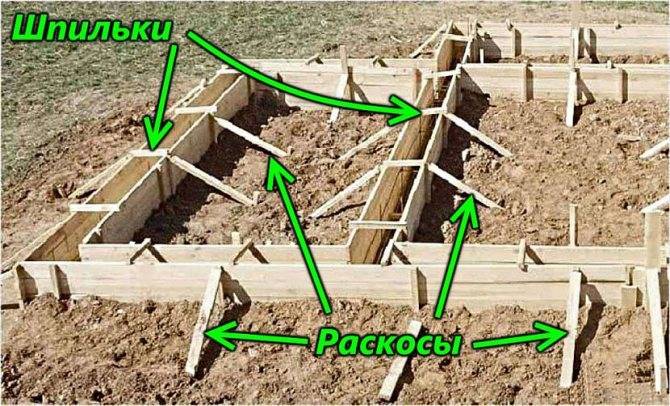

To tighten the walls of the formwork, special studs are used.

When using any materials, it is recommended to use special formwork studs. They are necessary to tighten the walls of the structure. The rigidity of arbitrary formwork is much lower than this indicator of forms assembled from specialized parts. When organizing this option, the risk of leakage of the solution increases.

It is recommended to take into account that in this case you can not do without additional fasteners. To ensure good rigidity and stability of the structure, it is necessary to set special wedges and supports. It should be remembered that this method cannot be categorically used when organizing the foundation for residential buildings.

What to consider when choosing a formwork material

Its components can be made from various materials. The type of construction is selected taking into account a number of criteria: the type of base being built, its width, length, and so on. When constructing formwork, you can use:

- Wood. As previously mentioned, base formwork is in most cases made from it. Shields made of wood can have a different design. In many situations, sheets of plywood are used, the fixation of which is carried out by means of spacers made from a wooden board. Its advantages include affordable cost and a fairly high ease of installation, if you are familiar with the technology and follow it when carrying out work. During the installation of wood structures, it is not necessary to resort to the use of complex special tools. The main disadvantage of formwork made of this material is the need to use additional elements to strengthen it.In most cases, this need arises due to the overall differences in some of the components of the structure. Before erecting such a formwork, it is imperative to calculate the amount of material spent.

- Styrofoam. It is also in high demand, although less than wood. Parts of fixed formwork are made from this material. In addition to the forming function, it acts as a heater, protecting the base of the structure from wind, cold and water. Installation of the structure is not difficult, but it is quite expensive. Difficulties can also arise when choosing some of the component parts.

- Metal. The material is excellent for structures intended for a strip foundation, and is also periodically used for a monolithic one. One of the main advantages of its use is that, if necessary, the reinforcement through which the concrete is strengthened can be welded to metal shields. Such formwork has significant reliability and strength. In addition, the versatility of the material is among the advantages. Metal sheets can be bent to the required shape. The disadvantage of such structures is their high cost.

- Reinforced concrete. This material is practically not used in private construction, since work with its use is very expensive, and the installation process requires significant effort. Reinforced concrete formwork is assembled from individual slabs. The key advantage of the design is that, thanks to its installation, it is possible to reduce the thickness of the foundation under construction.

Note! Metal formwork, unlike that built from wooden boards, does not need to use additional spacers.

Preparation and calculations

The calculation of dimensions, reinforcement and the amount of concrete of a monolithic strip foundation depends on the dimensions of the base. The amount of concrete and reinforcement is related to:

- type of foundation (only the contour of the house is laid or there are breakdowns inside into sectors);

- brand of concrete;

- width and length of the "tape";

- base thickness and height.

The type of strip foundation is determined by the load level:

- Recessed - for massive buildings built on soft soil.

- Shallow - used for light-weight buildings, as well as for fences and wooden houses.

According to the depth of laying, in a shallow version, a concrete belt in low-rise construction is installed 20-50 cm into the ground. In the second case, it is deepened below 50 cm.

To calculate the amount of materials, you need to determine the area of \u200b\u200bthe foundation, find the required volume of concrete for pouring and the amount of metal that will be required. You will also need to determine the amount of wood for formwork.

To calculate the reinforcement yourself, watch the video:

The calculation of the foundation for the bearing load is reflected in the video:

Read more about the calculation of strip foundations here.

Mounting conditions for a support-column structure for a future home

The use of strip concrete foundations carries an impressive financial burden on the total estimated cost of construction. The device of the supporting-columnar foundation allows you to save money costs.

Its construction is possible under certain conditions:

- The calculated resistance of the soil base (R0) must be equal to or less than the same indicator of the point support. This will prevent the house from sinking under its own weight.

- It is advisable to arrange pillars on rocky, coarse soils. Such a foundation is not erected on heaving and swampy soils.

- The heel of the point support should be below or above the groundwater level.

- The foundation material must withstand the load and have a safety margin of + 10%.

- The bottom of the foundation should be below the freezing depth of the soil.

Evaluation of the bearing capacity of the soil

Before proceeding with the design of the foundation, it is necessary to examine the conditions and physical characteristics of the soil to a depth of at least 2 meters from the surface. You can do this yourself by taking soil samples with a hand drill.

Formwork types

When the frame is installed in the design position, it is filled with a concrete mixture. After the mixture has hardened, stripping is performed.

Properly arranged formwork must be strong, stable, retain its shape under heavy loads that appear during the installation of the foundation.

Concrete milk escaping during tamping of the mixture should not seep through the casing. If the gap in the wooden formwork does not exceed 3 mm, it will tighten itself when the boards swell. Gaps 5-10 mm wide should be closed with tow, and if the gaps are even wider, they are closed with slats.

The surface of the boards must be flat. Otherwise, the foundation may have such defects as shells, sagging, all kinds of deformations.

Regardless of the type, all formworks have a standard device, therefore, they are similar to each other. Conventionally, all types of formwork are classified as collapsible and fixed.

Formwork installation is a laborious and rather complicated process. Its type is chosen in advance. The design depends on the type of foundation. Based on this parameter, the materials necessary for construction are selected.

Fixed formwork

This is a prefabricated structure, which is part of the foundation and usually consists of slabs or blocks of expanded polystyrene. To ensure reliability, they are connected by means of jumpers with locking grooves. The plates are lightweight - only about 1.5 kg.

Good adhesion to concrete occurs due to the porosity of the inner surface.

The design effectively provides protection against external influences, fungi. It is hydro and thermal insulation. The installation algorithm is as follows:

- Formwork elements are laid by analogy with brickwork.

- A reinforcing cage is installed inside.

- Filled with concrete.

Concrete formwork is chosen when it is necessary to obtain a reinforced structure of great thickness. To make it, you need a pair of relatively thin concrete slabs.

Connect them with metal jumpers. Due to the unevenness of the inner walls of the slabs, adhesion to the concrete solution is improved. After pouring the mixture, reinforcement is attached to the jumpers. The result is a monolithic structure.

The advantage of the solution is a small consumption of concrete, structural strength. The disadvantage is the high cost, the large weight of the material, the need to attract additional labor.

For a columnar foundation, asbestos or metal pipes are often used as fixed formwork. On the plus side, the amount of earthwork is small, since no space is required for dismantling.

Features of wooden stationary formwork

This formwork is used once. The expediency of application is due to the need to manufacture structures of complex shape. At the end of the work, it is usually disposed of. It is simple, easy to install.

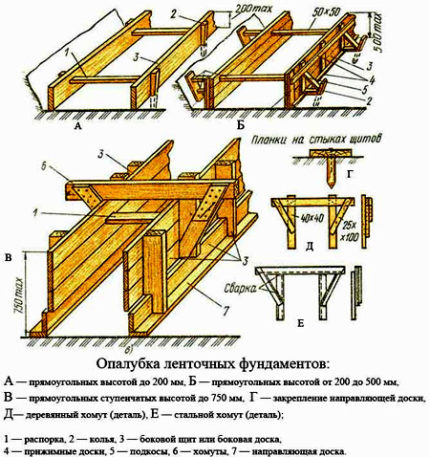

Its main elements are wooden shields, which are assembled from boards. Stiffening ribs and connecting elements are made from timber. When assembling the formwork for the foundation, all parts are fixed by means of struts, ties, wire twists. This type of formwork is very popular in private construction.

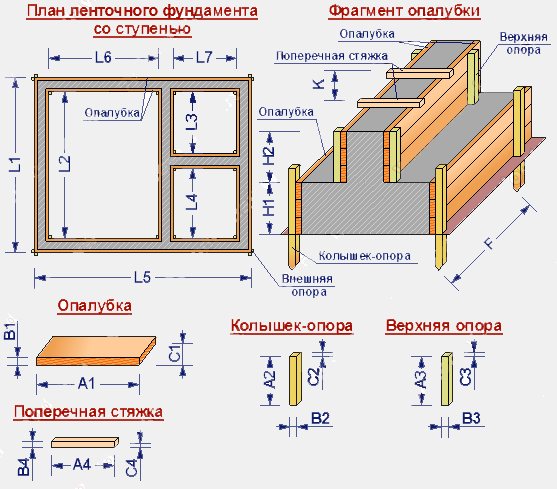

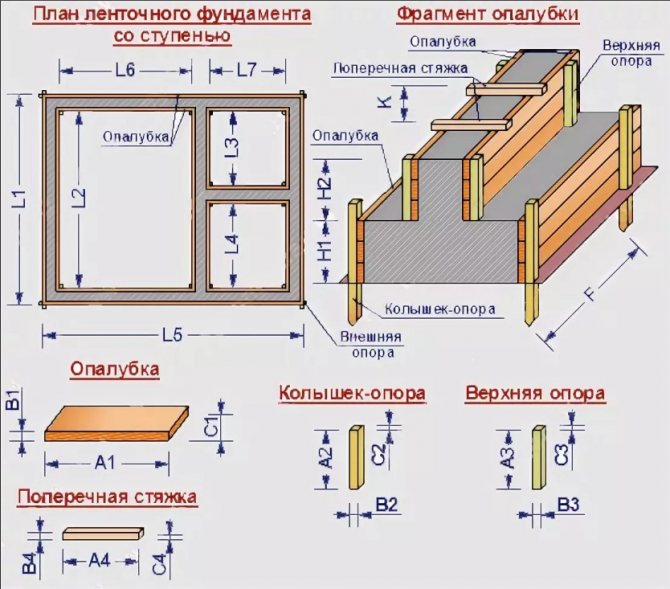

When constructing a rectangular stepped foundation with a height of 0.5-0.75 m, shields are used equal in height to the corresponding parameter of the base of the house. The inner dimension of the formwork is identical to the width of the foundation. Set the last size by stretching the cords along the bottom of the trench.

To fix the shields, spacers and clamps are used. The first is from the inside, the second is from the outside. Clamps can be replaced with pegs, struts or spacers with emphasis on the walls of the trench.

The process begins with the installation of guide boards. Having fixed them with stakes, after checking the correct installation, they place the shields on one side of the foundation. The plane of the shields must coincide with the edge of the board. Vertically they are fixed with braces.

Next, proceed to install the shields on the other side of the foundation. In the design position, they are fixed with spacers. After that, temporary additional spacers, clamps are installed.

Mixed formwork option

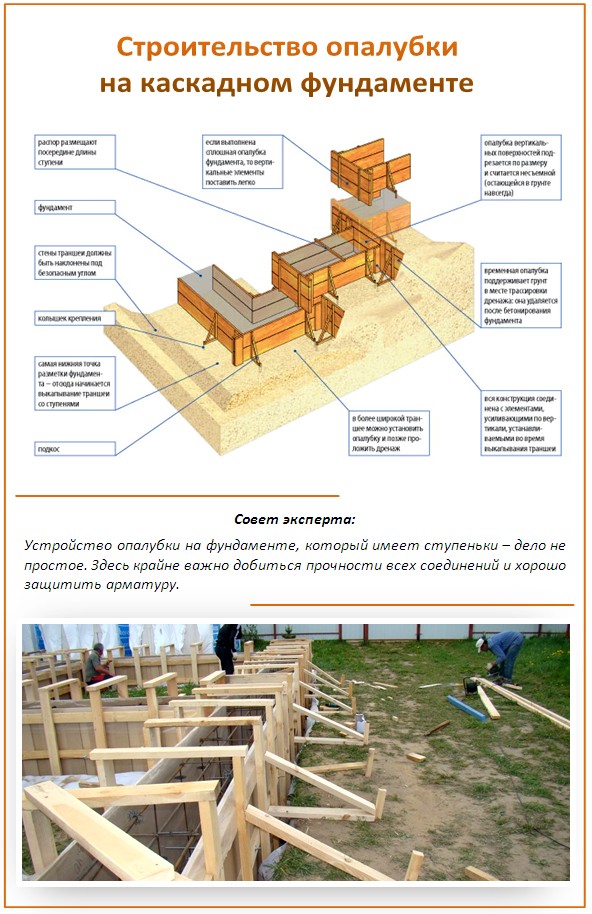

Sometimes there is a need for a combined formwork when both removable and non-removable elements are present in the structure. Experts recommend choosing this option in the case of erecting a structure on loose soils.

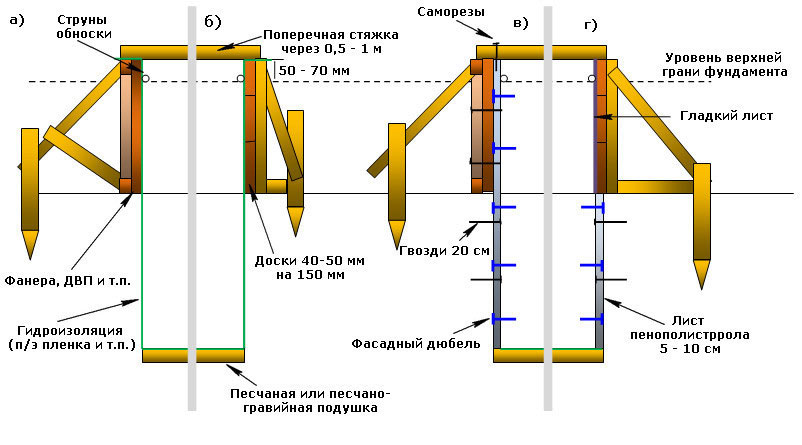

The design has an outer and inner layer. The outer side is made of boards, and the inner side is made of polymer material. Fasten the inner side to the ground with 200 mm nails.

Expanded polystyrene with a tree is connected with self-tapping screws. The design protects the foundation not only from the ends, but in the area of \u200b\u200bthe sole. If the polystyrene blocks need to be fixed to the full depth, it is necessary to insert dowels into them in advance to fix them on the concrete surface.

Types of lubricant for formwork

The main purpose of using lubricants for various types of formwork is to prevent strong adhesion between the concrete mixture and the material from which the form is made. This is necessary to facilitate the dismantling of the removable formwork, carried out after the complete fixation of the concrete. Thanks to the use of lubricants, the geometric shape of the foundation is preserved, and its surface becomes as even as possible. This leads to a reduction in the cost of finishing, achieving the quality and durability of the building foundation.

When using any formwork material other than plastic, lubrication is required.

Lubricants are subject to a set of requirements aimed at maximizing construction efficiency:

- the grease should not leave oily spots on concrete surfaces. The exceptions are those cases when concrete structures are covered with earth, covered with waterproofing;

- the substance should not affect the strength, composition, density of concrete;

- the composition of the lubricant should not contain volatile components that adversely affect human health;

- the agent must be kept on vertical or horizontal surfaces for at least 24 hours.

The action of lubricants is based on the presence of fatty acids in their composition, which form a protective film on the treated surface. As a result, the removable form is easily dismantled, and the concrete retains a high surface quality.

Emulsol

For processing forms, oil mixtures "Emulsol EX-A" and "Emulsol IM" are often used. They provide a smooth concrete surface after removal of the form, without pores and holes, as well as easy dismantling of the device. The composition of "Emulsol" includes corrosion inhibitors, mineral oils, emulsifiers. Due to the proportional ratio of substances, the lubricant has a low fire hazard and does not interact with the additives of the concrete mixture.

Concrete surface with and without lubrication

"Emulsol" provides water-repellent properties, which prevents moisture from affecting the base of the foundation. The product is applied with a paint sprayer or brush. The first option is optimal for processing large surfaces, and the brush is convenient for applying the product to a small area.

Molding oil

The ability to form a thin film on surfaces is possessed by products containing mineral oils. Among those, TiraLux and TiraMin are in demand. They are not diluted with water, have a transparent color with a slight yellowness, do not affect the shade of concrete. Application involves the use of a special sprayer or spray gun. On small surfaces, a brush can be used, but the thickness of the lubricant layer should not exceed 0.3 mm.

Manufacturers produce lubricant in a variety of containers

Means based on mineral oils are safe for human health and can be used in the construction of residential buildings.All high-quality formwork products are characterized by a low level of fire hazard.

Water based products

The lubricant, which contains oils, forms a thin film that provides waterproofing and protection of concrete. There are simpler substances, presented in the form of a dry powder, which are dissolved in water. They are low cost, applied in the same way as oils, that is, by spraying. The main difference between water-based products is the low degree of efficiency and the fact that they are not used to process formwork made of rough materials, such as boards.

Spraying is the most effective formwork lubrication method

Water-based products include powdered components that dissolve well in water. It is easy to prepare the solution yourself by studying the instructions on the package.

Video: applying lubricant with a sprayer

Formworks made of different materials differ in installation technology, technical characteristics and other properties.

Before constructing a building, it is important to determine the best material for the molds used, because this will determine the quality of the concrete structure.

Manufacturing and installation

The whole process can be divided into several key stages:

- Preparatory - calculations and purchase of building materials.

- Transition to field work - marking the site and digging a trench according to the specified parameters.

- Production of blanks for panels (if it is not a stamped formwork material).

- Driving support bars into the ground.

- Installing shutters.

- Strengthening.

Shield assembly

The size of the dampers is chosen taking into account the geometric shape of the base so that their height is greater than the depth of the concrete cushion. The length of the elements is chosen arbitrarily, but the optimal value is considered to be no more than 3 m. The total length of the dampers must correspond to the length of the tape.

Installation Features

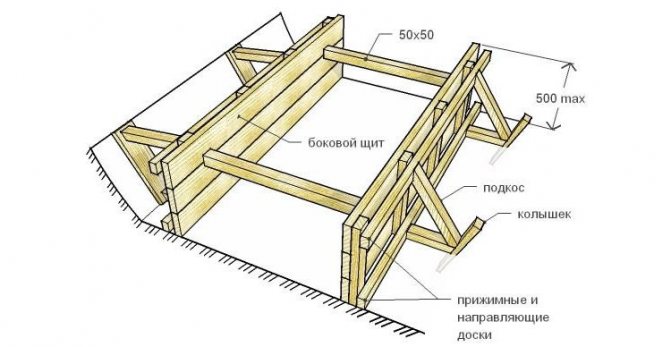

Ready dampers are installed according to the marking strictly in a vertical plane. For convenience, you can drive in vertical bars along the perimeter of the base in advance and set the formwork walls close to them.

Ready dampers are installed according to the marking strictly in a vertical plane. For convenience, you can drive in vertical bars along the perimeter of the base in advance and set the formwork walls close to them.

The worker must achieve a snug fit of the elements so that the concrete does not flow out through the cracks. Armed with a level and a hammer, he needs to set all the shields exactly in the same plane and at the same height.

If the shields do not have long bars that could enter the ground and hold the structure, then vertical bars are first placed along the perimeter of the trench. These elements will serve as a support for the shields, which should be tightly attached to them with the help of spacers and slopes.

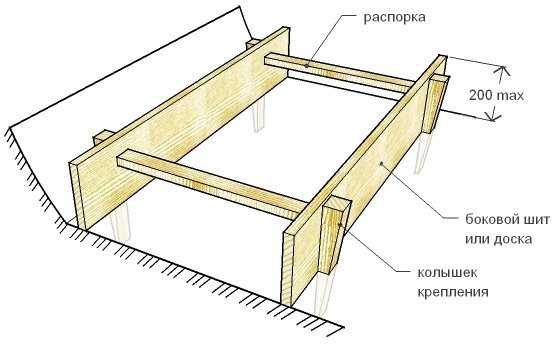

strengthening

Formwork walls are subjected to heavy loads during concrete pouring and may fall apart. To prevent this from happening, additional elements are installed that reinforce the structure.

Outside, the walls hold the braces and supports. They are placed in increments of not less than 1 m.

Particular attention is paid to the corners of the formwork, where support is needed from two sides at once. If the height of the shields is more than 2 m, then the supports are set along the perimeter in two rows: upper and lower

Auxiliary materials and necessary tools

In the process of mounting the formwork for the strip foundation, you have to use various devices. Most often they are needed in the case of the manufacture of wooden structures, especially when scrap sheet material is used.Factory products are usually equipped with everything you need.

metal studs

Needed for tall buildings. It is not possible to provide high-quality fixation of the thickness of the tape over the entire area of the fence in other ways. Studs are not needed for structures less than half a meter high, especially if sufficiently rigid sheet materials or boards are used.

The purpose of this element is to prevent bursting of the formwork walls. For proper functioning, the stud is installed in a plastic pipe. This is done in such a way that when tightening, the walls of the fence from the inside rest against the pipe. From the outside, it is recommended to wear washers on the stud.

Braces

Designed to prevent the walls of the fence from bending outward. They are made from wooden blocks of different lengths. The entrance is all suitable material, including trimmings.

Studs and braces

Polyethylene film

Prevents the concrete mix from flowing out of the formwork. It is mainly used for structures made of boards, including unedged ones. Helps prevent excessive contamination of wood with cement mortar, which gives more opportunities for their subsequent use.

Materials used

When constructing reinforced concrete foundations for a private house, a bathhouse and other capital buildings, 2 types of formwork are used - removable and fixed. The fencing of the first type is reusable, reused at the following construction sites. Disposable formwork structures are not removed from the hardened monolith and remain to serve as the outer shell.

Removable formwork can be made from the following building materials:

- wood - edged board and timber;

- plywood, OSB sheets;

- cement-bonded particle boards (DSP), better known as flat slate;

- improvised materials available on the farm - iron sheets, solid wooden doors, chipboard from old furniture.

Removable type wooden panel structure

The assembly of fixed structures is made from the following materials:

- high density slab foam;

- extruded polystyrene foam;

- the same DSP boards;

- for columnar foundations - steel and asbestos pipes with a diameter of more than 20 cm.

Foundation pillars with fixed formwork made of asbestos-cement pipes

In the vast majority of cases, country cottages and adjoining buildings are erected on a reinforced concrete base in the form of a tape or pillars connected by beams. Pile-screw foundations are arranged without concreting and do not need enclosing structures.

We propose to consider the installation of a collapsible wooden formwork of the strip foundation, shown above in the photo. The assembly technology is quite simple and applicable in the case of using other materials - plywood, DSP, and so on.

An example of using OSB plywood