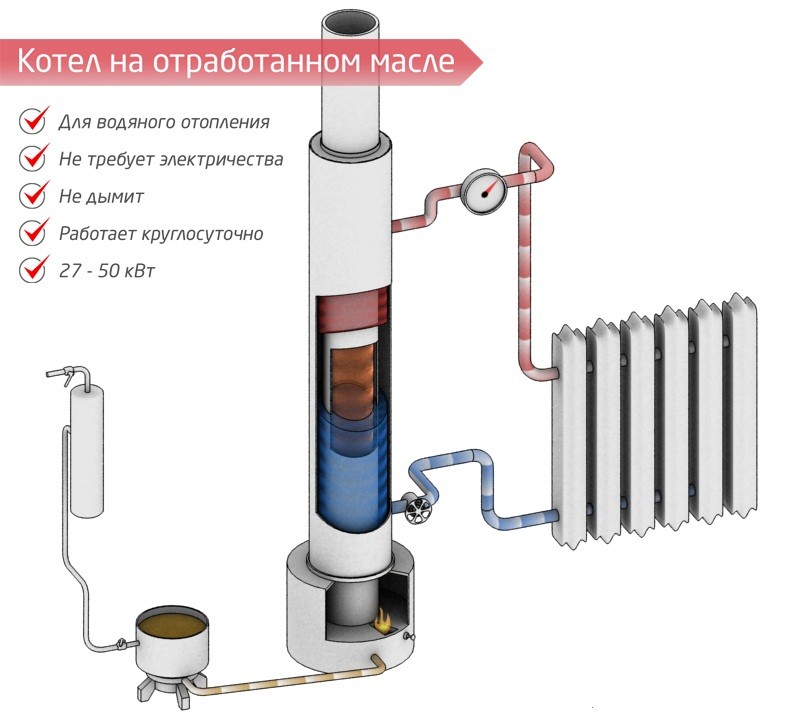

- How to make a waste oil boiler with your own hands

- Tools and materials

- Manufacturing process

- Construction of a more powerful boiler

- Russian-made equipment

- BELAMOS Series NT

- Furnaces "ZHAR"

- Boilers and furnaces "Teploterm"

- Hot water boilers TEPLAMOS series TK-603

- Making a boiler with your own hands

- Necessary tools and materials

- Assembly order

- Assembling a homemade heater

- Boiler body manufacturing

- Burner installation

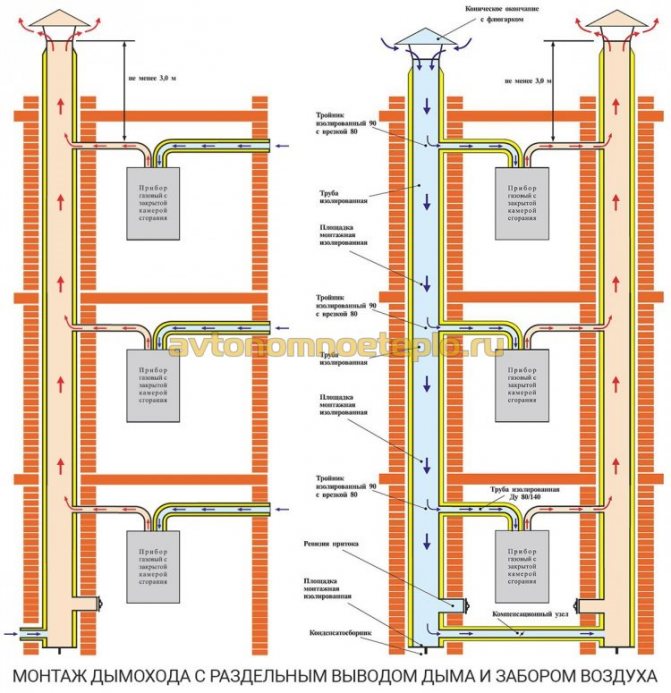

- Preparing the site for installing the system and removing the chimney

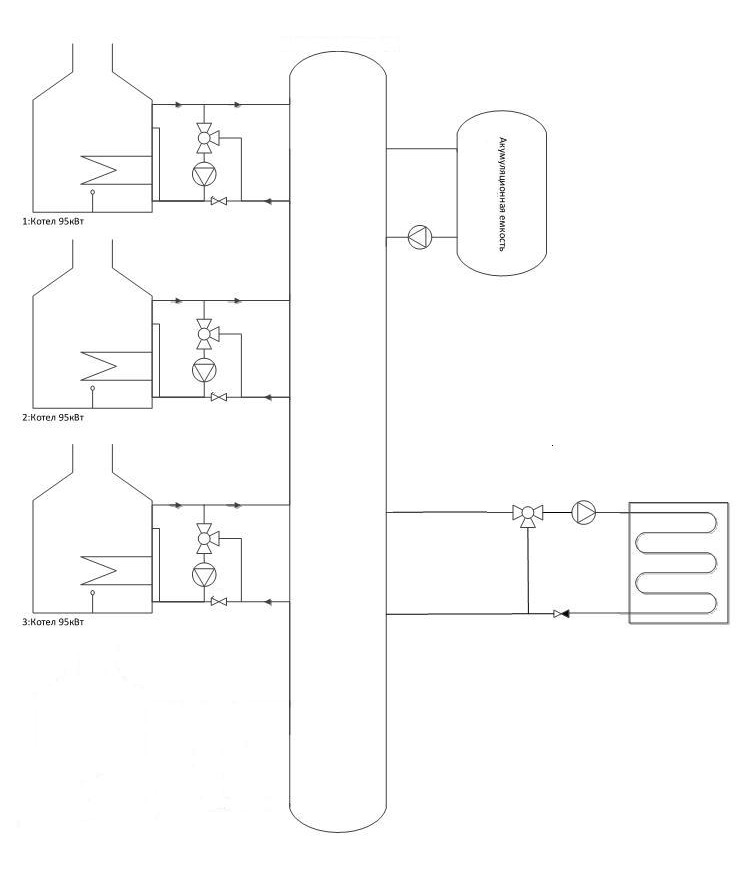

- How to connect the water circuit?

- Waste oil heating for a private house

- Features of use

- Types of fuel. How much heat is produced by burning one liter?

- Pros and cons

- How is oil processed?

- What does not apply to such fuel?

- Types of homemade stoves in development

- The device and disadvantages of an open-type potbelly stove

- Pros and cons of a dropper

- Material selection

- How does a heater work

- Conclusions and useful video on the topic

How to make a waste oil boiler with your own hands

The simplicity of the design of such heaters allows you to make them yourself. In this case, it is necessary to have locksmith and welding skills.

Tools and materials

To make do-it-yourself boiler the following fixtures are required:

- Bulgarian;

- welding machine;

- a hammer.

To make a waste oil boiler with your own hands, do not forget the grinder

As a material for the heating structure, you must purchase:

- refractory asbestos cloth;

- heat-resistant sealant;

- steel sheet 4 mm thick;

- metal pipe with a cross section of 20 and 50 centimeters;

- compressor;

- ventilation pipe;

- drives;

- bolts;

- steel adapters;

- half-inch corners;

- tees;

- reinforcement with a cross section of 8 millimeters;

- pump;

- expansion tank.

The body of the boiler for heating small rooms can be made from a pipe; for a device with a higher power, it is best to use steel sheets.

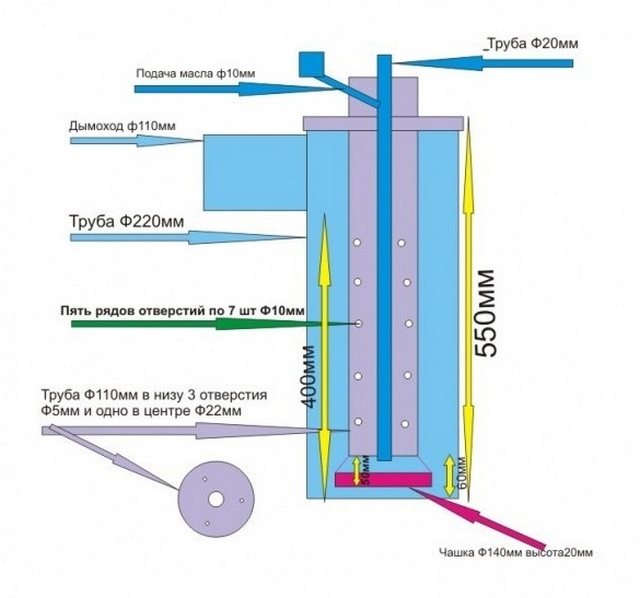

Manufacturing process

The waste oil unit can be built in any shape. To heat a garage or small agricultural buildings, it is best to make a small boiler out of pipes.

The manufacture of such a heating device consists of the following steps:

- A metal pipe with a large cross section is cut so that its size corresponds to one meter. Two circles corresponding to a diameter of 50 centimeters are prepared from steel.

- The second pipe with a smaller diameter is shortened to 20 centimeters.

- In the prepared round plate, which will serve as a cover, a hole is cut corresponding to the size of the chimney.

- In the second metal circle, intended for the bottom of the structure, an opening is made, to which the end of a pipe of a smaller diameter is joined by welding.

- We cut out a cover for a pipe with a cross section of 20 centimeters. All prepared circles are welded as intended.

- Legs are constructed from reinforcement, which are attached to the bottom of the case.

- Small holes are drilled in the pipe for ventilation. A small container is installed below.

- In the lower part of the case, with the help of a grinder, an opening for the door is cut out.

- A chimney is attached to the top of the structure.

To operate such a simple boiler in mining, you just need to pour oil into the tank from below and set it on fire with a wick. Before this, the new design should be checked for tightness and integrity of all seams.

Construction of a more powerful boiler

Two boxes are made of strong sheet steel, which are connected using a perforated pipe. In the design, it is used as an air vent.

The subsequent manufacturing process of the heater has some features:

- A hole is made in the lower body of the boiler to supply oil to the evaporation tank. A damper is fixed opposite this container.

- The box located in the upper part is complemented by a special hole for the chimney pipe.

- The design is equipped with an air compressor, an oil supply pump and a container into which fuel is poured.

Do-it-yourself waste oil boiler

If water heating is required, then an additional circuit is connected, which requires the installation of a burner. You can build it yourself:

- half-inch corners are connected by spurs and tees;

- a fitting is fixed to the oil pipeline using adapters;

- all connections are pre-treated with a sealant;

- a burner cover is cut out of sheet steel, corresponding to the nests on the manufactured boiler;

- two different sizes of steel plates are used to install the burner;

- the inside of the tube adapter is tightly covered with an asbestos sheet, which is fastened with sealant and fixed with wire;

- the burner is inserted into the housing intended for it;

- after that, a smaller plate is fixed in the nest and covered with four layers of asbestos;

- a large plate is mounted as a mounting plate;

- holes are drilled in it for fastenings, and an asbestos sheet is applied on top;

- two prepared plates are connected with bolts.

To prevent the burner from disintegrating during the operation of the boiler, all parts should be carefully and tightly fastened. The device is ignited by a glow plug.

Waste oil boilers are considered economical and practical appliances. They can be purchased at a specialized store or built independently. When using such heating devices, it is necessary to remember the safety rules, which include the mandatory installation of a chimney, the presence of a ventilation system and the proper storage of liquid fuel.

Russian-made equipment

In most Russian boilers, a different technology is implemented: the oil is first evaporated, and then its vapors are ignited. Thus, two main problems with burners are eliminated: dependence on the quality of spent fuel, its multi-stage preparation, and a clogged nozzle.

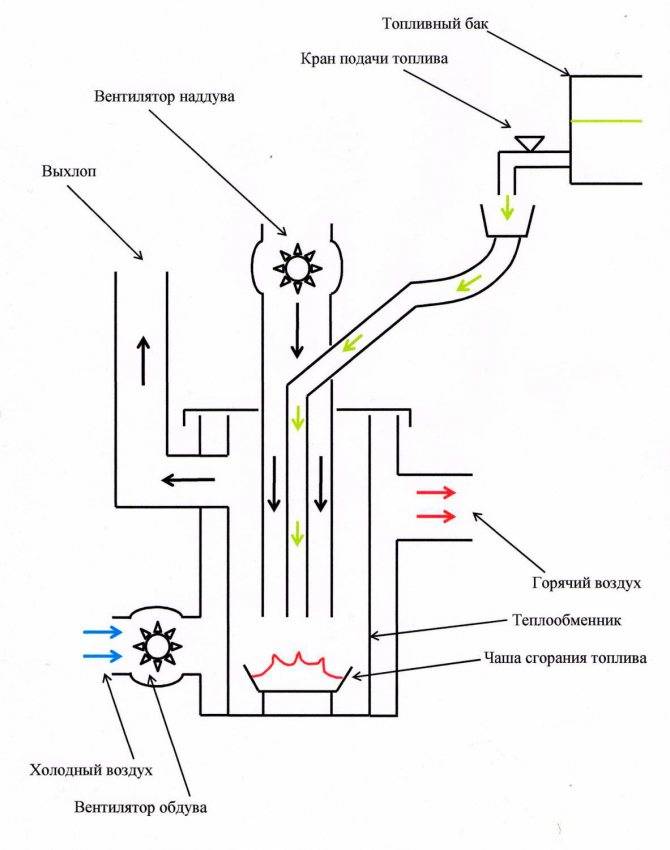

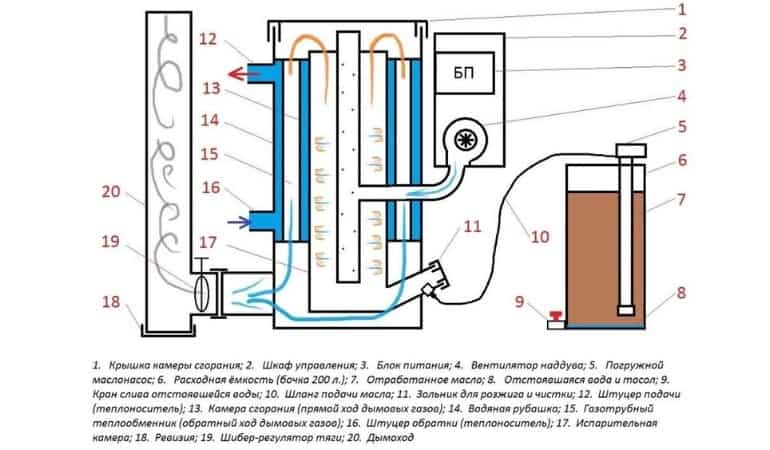

Waste oil boiler for air heating

The design of such devices is simple: a plate is located at the bottom of the combustion chamber. Before starting the oil supply, it is heated, then oil is applied dropwise to the hot metal. The fuel evaporates, the vapor rises higher, where it mixes with air and burns out.

With a properly configured combustion mode (temperature around 600oC), complete oxidation of all components, including heavy bituminous ones, occurs. As a result, we get nitrogen, water vapor and carbon dioxide at the output.When the temperature changes in one direction or another by 200oC, the “exhaust” contains a lot of harmful substances that are carcinogens, mutogens, cause poisoning and a whole range of negative consequences. Therefore, it is worth buying industrial certified units. Despite their considerable price (compared to home-made units), they pay off in the first year, a maximum of two (due to the cheapness of fuel).

BELAMOS Series NT

Hot water boilers running on waste oil "Belamos NT" do not require pre-filtering of the fuel and its heating. The built-in heat exchanger allows to achieve a sufficiently high efficiency. The electronics controls the operation, which controls the temperature of the coolant, the flow of oil, turns off the boiler when the flame goes out. For ease of maintenance (cleaning of the combustion chamber and bowl is required), there are technological hatches. Boilers are produced at the development of "Belamos NT" with a capacity of 10 kW to 70 kW.

Boilers for mining BELAMOS Series NT

Furnaces "ZHAR"

Furnaces "Zhar" work on waste oil, diesel fuel, their mixtures. The transition from one fuel to another occurs by moving the switch to the desired position. In the furnaces at the “Heat” mining, a drip method of fuel supply is used, that is, they do not have a burner and nozzles that become clogged and require cleaning. All boilers are equipped with automation that controls the process.

Basically, "Zhar" - heat generators for heating industrial premises, but there are also hot water boilers. This is the Zhar-20 model with a power of 30 kW and a fuel consumption of 3 l/h.The boiler has a tank for diesel fuel with a volume of 20 liters, and for working out 60 liters.

Waste oil heating furnaces "ZHAR

Boilers and furnaces "Teploterm"

Boilers "Teploterm" are produced with power from 5 kW to 50 kW, efficiency 90%. The water jacket allows you to effectively remove heat from the body and provide heating for rooms with an area of 50 m2. The remote oil pump can be lowered into a canister or other container with fuel, the built-in blower fan and the oil pump power supply ensure the operation of the system.

The coolant temperature is controlled. There are two modes for adjustment, switching occurs automatically (built-in thermal relay at the outlet of the coolant). Oil consumption from 0.6 liter/hour to 5.5 liter/hour.

Boilers and furnaces "Teploterm"

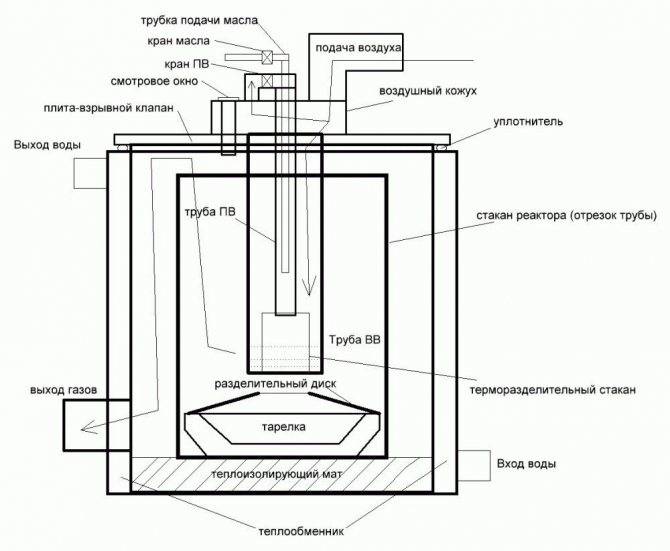

Hot water boilers TEPLAMOS series TK-603

Waste oil boilers "Teplamos TK" operate on the principle of an evaporator. The oil drips onto a hot plate. There are almost no special restrictions on the quality of the fuel used, no preheating (if the oil is in a heated room) or other preparation is required. Only pre-filtration is needed to remove foreign bodies.

"Teplamos" are produced both single-circuit and double-circuit. Equipment power from 15 kW to 50 kW, fuel consumption 1.5 liter/hour - 5 liter/hour.

Boilers in development Russian production is not so much, but people find a way out in any situation. For example, they put a burner on a regular liquid fuel for testing, they use it with this type of fuel. It is easier and cheaper to buy a burner than a new boiler. There are these knots of handicraft production, and there are industrial ones. For example, like in this video.

Similar burners are installed on KChM boilers, which can then work on mining.

There are boilers for testing and home-made.

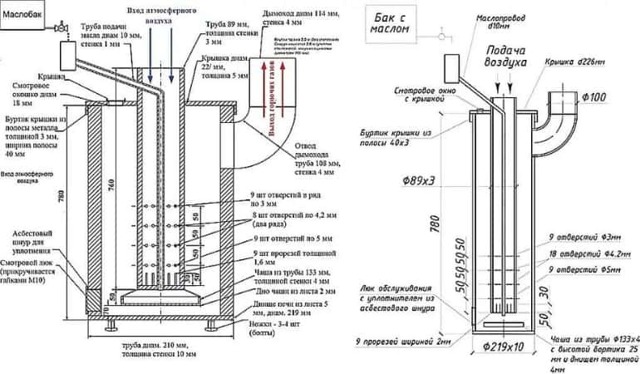

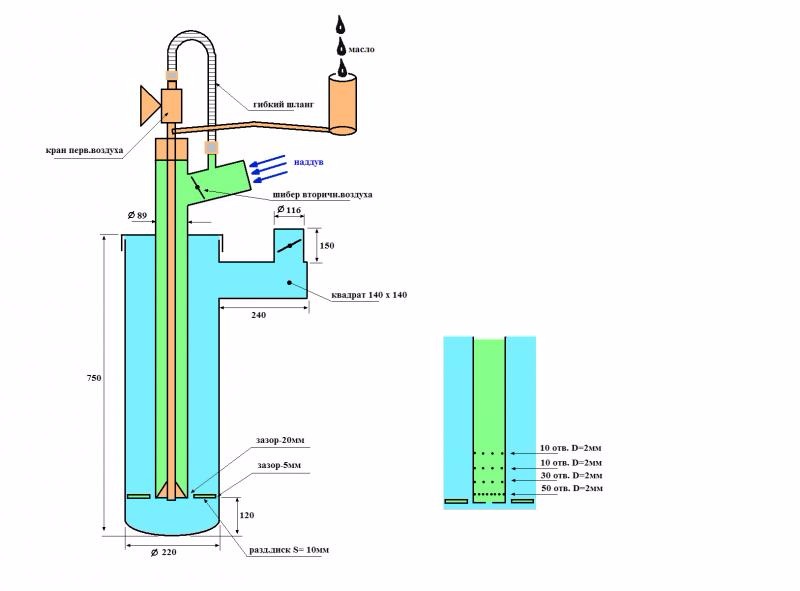

Making a boiler with your own hands

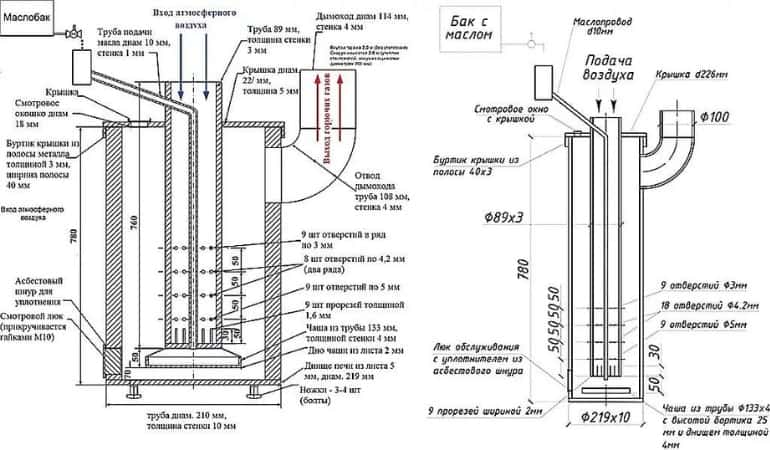

Any solid fuel or gas furnace can be converted to liquid fuel. But for self-production, it is better to choose a drawing of a boiler for mining with a water circuit with a flame bowl.

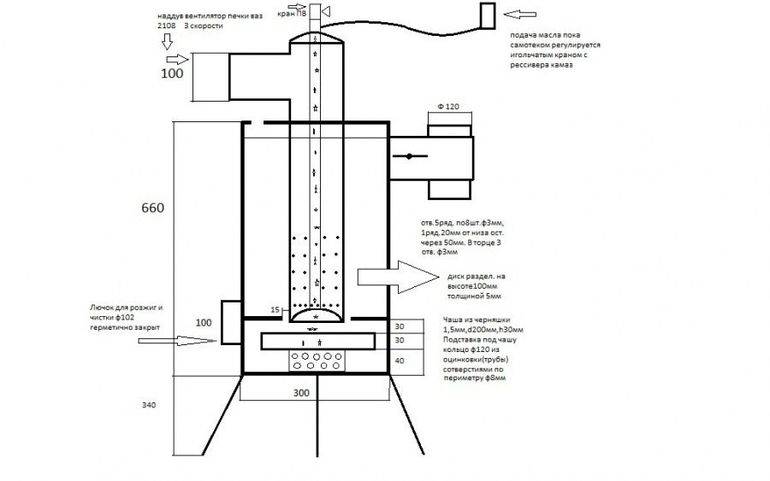

The home-made boiler is small in size, but at the same time provides 15 kW of thermal power. In an hour, he consumes no more than 1.5 liters of mining per hour. Air is forced into the combustion chamber using a small turbine, so you will need to take care of supplying electricity to the unit. Fuel enters the combustion zone in portions from a separate tank equipped with a valve. The latter can serve as a heating regulator.

To improve afterburning, the central tube has a large number of holes and horizontal slots. The smoke from the combustion of fuel leaves through the chimney, fixed at the outlet of the combustion chamber.

Necessary tools and materials

It is necessary to prepare in advance the container from which the case will be made. A gas bottle is best suited for this. You need to choose a copy with a volume of 50 liters.

You will also need the following materials:

- Steel pipe Ø 100 mm with a wall thickness of at least 2 mm. It needs a chimney.

- Metal sheet half a centimeter. With it, the combustion chamber will be separated from the evaporation zone.

- Iron pipe Ø 100 mm with a wall thickness of 6 mm. She will go to make a burner.

- Brake disc from the car. Its diameter must be at least 20 cm.

- Coupling for connecting pipes.

- Half inch ball valve

- fuel hose.

- Fuel storage tank.

- Leg preparations.

- Branch pipes.

>After assembling the device, it will need to be protected from corrosion. To do this, you must additionally purchase the necessary chemistry and enamel.

As for tools, the first thing you need is a welding machine. It is best to use an inverter, as it allows you to make high-quality welds. Also useful: drill, angle grinder with a set of discs, drills, threading dies, keys, electric emery.

There will be a lot of work with metal. To speed up the work, you need to prepare a container with water to quickly cool the tools.

Assembly order

Before starting work with the cylinder, it must be completely emptied of gas residues. This is done by simply closing the valve and turning the container over to remove condensate. After flushing the cylinder, you can begin to assemble the boiler:

- 2 openings are cut in the cylinder one above the other. Between them a jumper 50 mm wide is left. The upper window is 2 times larger than the lower one.

- Hinges and latches are welded to the edges of the pieces left after cutting the openings. These will be the opening doors.

- From a sheet of metal with a thickness of 5 mm, a disk is cut along the diameter of the cylinder. In the center of the resulting part, a hole is made for a pipe Ø 100 mm. The disk is adjusted in place in the cylinder.

- A piece of pipe with thick walls 200 mm long is cut off. Holes Ø12 mm are drilled in it with a step of no more than 40 mm. Moreover, perforation should occupy only half of the workpiece.

- A previously prepared disk is welded in the center of the resulting burner. It should be placed over the holes.

Create a boiler with your own hands

Create a boiler with your own hands

- The baffle with the burner is inserted into the cylinder and welded to the baffle between the openings.

- The evaporator bowl is assembled from the brake disc.The holes in it are welded using a metal disc.

- A lid is made for the bowl with a hole for the burner. A sleeve made of steel pipe is welded to its edges.

- The body of the water jacket is welded from two sheets of metal around the cylinder. Holes are cut out in the upper and lower parts of the casing for the subsequent fastening of the water inlet and outlet pipes.

- From above, the almost finished boiler is closed with a lid with an embedded chimney pipe.

- A fuel tube cuts into the side wall of the cylinder at the level of the lower chamber. Its tip should be located exactly above the fuel supply window into the bowl.

- The fuel tank is attached through a ball valve.

After completing the assembly work, you need to check the performance of the unit. It is better to do this before putting it into the heating system. To check, used oil is poured into the lower furnace through a ball valve. A little kerosene is added on top and set on fire. If everything is fine, then you can embed the boiler into the heating system.

Assembling a homemade heater

The boiler can be made in various shapes depending on the desire of the owner. As a rule, it is made round and rectangular.

In order to start the assembly, you should prepare the necessary materials and tools for work. Their standard list looks like this:

- steel sheets with a thickness of more than 4 mm;

- pipe for air duct;

- pieces of reinforcement (4 pcs.);

- pump and compressor;

- expansion tank;

- welding tools;

- asbestos sheet.

Since the boiler can be of different configurations, improvised means can be used instead of the base material, for example, a cylinder or a thick-walled pipe of a sufficiently large diameter.

Boiler body manufacturing

To assemble the boiler body, you first need to take a pipe of the largest diameter and cut it on both sides to obtain a cylinder, the length of which should not exceed 1 m. The same cylindrical shape is made from a pipe of a smaller section, but 20 cm high.

After that, holes are cut out in the plates, in which the diameter of one should be equal to 20 cm, and the second - in accordance with the dimensions of the chimney. Then a cylinder of larger diameter is welded on both sides with pre-prepared plates so that a 20-centimeter hole is made from below.

A cylinder of smaller diameter is built into it and welded. The bottom of the pipe should also be closed with a plate and fixed by welding. Then legs made of reinforcement are attached to the body, and ventilation holes are also drilled. After that, a chimney is installed on top of the cylindrical device, and a door is cut out in the lower part with the help of a grinder.

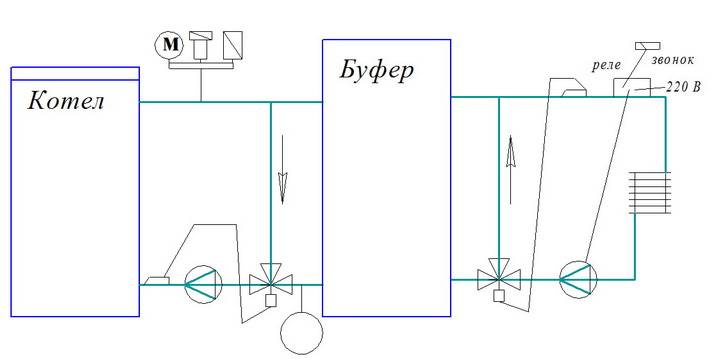

This case has the simplest configuration, but even a water circuit can be connected to it. For this, a fuel supply tank, a pump and an air compressor are additionally connected. At the same time, a circuit is also drawn to ensure the circulation of water.

Burner installation

To ensure uniform heating of water in the boiler for a device with a two-circuit system, it is necessary to install a reliable burner.

A finished burner can be purchased at a store or ordered from a specialist, but you can also make it yourself using a specific scheme.

Preparing the site for installing the system and removing the chimney

The mounted parts of the heating device operating in mining are usually installed in the corner of the building. Since the boiler heats up very quickly, the floor and walls should be prepared for this.

In the place where the system will stand, it is necessary to make a concrete screed or perform ceramic tiling. The walls adjacent to the device must not be made of flammable materials.

After the body of the heating system is fixed in the chosen place, it is necessary to proceed with the installation of the chimney. As a rule, it is made at least 4 m long.

In the area of the ceiling covering, where the pipe goes outside, a heat-resistant casing is placed, the function of which can be performed by several layers of asbestos. To ensure draft adjustment, the chimney is equipped with a metal damper.

How to connect the water circuit?

Do-it-yourself drawings of waste oil boilers.

Do-it-yourself drawings of waste oil boilers.

In order to put a water circuit on a mining structure with your own hands, you first need to install the pipeline and batteries, which are connected to each other and fixed around the perimeter of the room along the walls. After that, it is necessary to select a water tank and securely fasten it to the boiler body using bolts or welding.

A hole is cut out from the top of the container and a pipe is welded to supply the heated liquid to the system. Another pipe is attached at the bottom of the circuit so that the cooled water returns to the boiler.

Do-it-yourself heating system for working out - a convenient and simple design, not only during installation, but also during use. By installing this equipment, you can spend more time in the garage, even in severe frosts.

Waste oil heating for a private house

Waste oil for heating was originally used together with diesel fuel. This method has proven to be effective and economical. Then they decided to reduce the cost of the product even more and removed the diesel fuel from the composition. Waste oil is similar in its characteristics to diesel fuel, but it costs an order of magnitude cheaper.

Photo 1. This is what used oil looks like, which is used for heating. Dark brown liquid.

Features of use

Mining as fuel is used in a special boiler or in a furnace. Only this guarantees complete combustion of the product without the formation of a fumes. The refurbishment of the heating system or the installation of a new circuit pays off in the first year of using the product.

Types of fuel. How much heat is produced by burning one liter?

Burning one liter of such fuel gives 10-11 kW of heat in 60 minutes. The pre-treated product has more power. Burning it gives 25% more heat.

Types of used oils:

- engine oils and lubricants used in various modes of transport;

- industrial products.

Pros and cons

Fuel advantages:

- Economic benefit. Consumers save money on fuel, but businesses benefit the most. The implementation of mining eliminates the costs of storage, transportation and disposal of the product.

- Conservation of energy resources. Refusing to use gas and electricity for heating prevents the depletion of sources.

- Environmental Protection. Due to the high cost of disposal, business and vehicle owners disposed of oil by dumping it into water bodies or into the ground.This had a negative impact on the environment. With the beginning of the use of mining as a fuel, such manipulations ceased.

Fuel cons:

- represents a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- the difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- the operation of the boiler leads to the combustion of oxygen and the evaporation of moisture from the air.

How is oil processed?

Mining is obtained by burning any type of oil, but oil refining from internal combustion engines is usually used for space heating.

Also from industrial mechanisms, compressors and power equipment.

What does not apply to such fuel?

List of products not related to mining:

- processed oils of vegetable and animal origin, which are used for domestic purposes;

- solid waste with mining;

- solvents;

- products that are not subject to the same processing as mining;

- oil fuel of natural origin from the spill;

- other unused petroleum products.

Types of homemade stoves in development

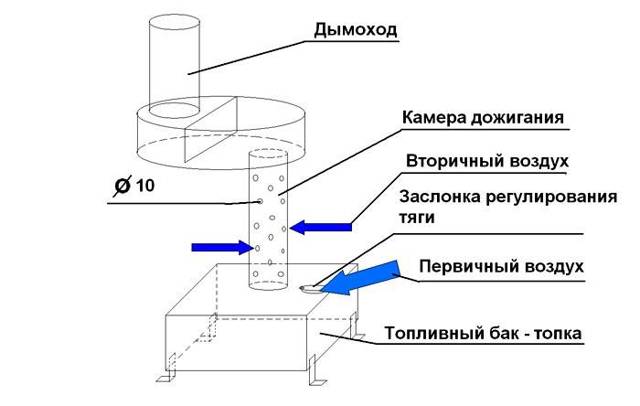

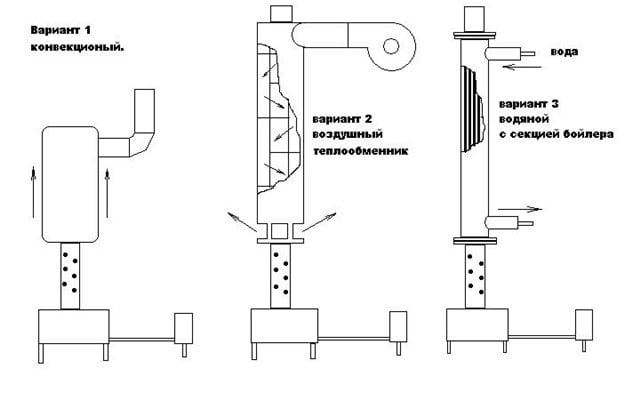

Engine oil contaminated with impurities does not itself ignite. Therefore, the principle of operation of any oil potbelly stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, mining must be heated, evaporated and burned in the furnace furnace, supplying excess air. There are 3 types of devices where this principle is implemented in various ways:

- The simplest and most popular design of direct combustion with afterburning of oil vapors in an open-type perforated pipe (the so-called miracle stove).

- Waste oil drip furnace with closed afterburner;

- Babington burner.How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on factory heat generators with an efficiency of 85% (for a complete picture and comparison of oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Consider this fact, taking up the manufacture of the furnace for testing.

The device and disadvantages of an open-type potbelly stove

The pyrolysis stove shown in the photo is a cylindrical or square container, a quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is the afterburning chamber with a baffle to remove the heat of combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of mining and its primary combustion will begin, causing pyrolysis. Combustible gases, getting into a perforated pipe, flare up from contact with an oxygen stream and are completely burned. The intensity of the flame in the firebox is regulated by an air damper.

This mining stove has only two advantages: simplicity with low cost and independence from electricity. The rest are solid cons:

- stable natural draft is required for operation, without it the unit begins to smoke into the room and fade;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, which causes fire drops from the afterburner to splash in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l / h with poor heat transfer (the lion's share of energy flies into the pipe);

- one-piece housing is difficult to clean from soot.

Although outwardly the potbelly stoves differ, but they operate according to the same principle, in the right photo, fuel vapors burn out inside a wood-burning stove

Some of these shortcomings can be leveled with the help of successful technical solutions, which will be discussed below. During operation, fire safety rules should be followed and used oil should be prepared - defended and filtered.

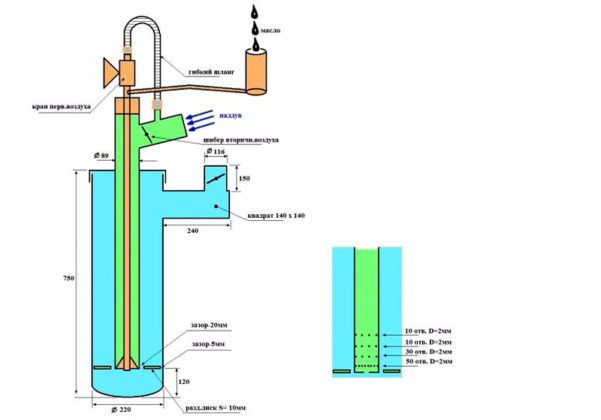

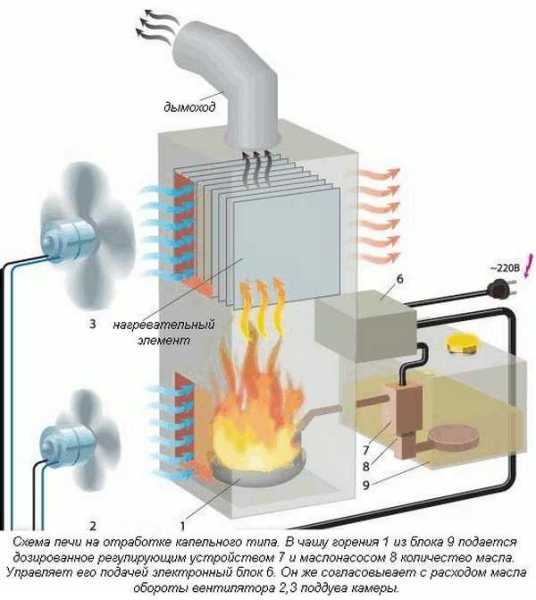

Pros and cons of a dropper

The cardinal difference of this furnace is as follows:

- the perforated pipe is placed inside a steel case from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of droplets falling to the bottom of the bowl located under the afterburner;

- To increase efficiency, the unit is equipped with forced air by means of a fan, as shown in the diagram.

Scheme of a dropper with a bottom supply of fuel from a fuel tank by gravity

The real disadvantage of a drip stove is the difficulty for a beginner. The fact is that you cannot rely entirely on other people's drawings and calculations, the heater must be manufactured and adjusted to suit your operating conditions and properly organize the fuel supply. That is, it will require repeated improvements.

The flame heats up the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves.In them, a jet of flame constantly hits one place of the body, which is why the latter will burn out pretty quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe in operation, since the combustion zone is completely covered with an iron case.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and remake the furnace for working out into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Pressurized air boiler burning used engine oil and diesel fuel

Material selection

The choice of boiler components should be guided by the principle of expediency. If you plan to heat a small room, used oil equipment can be made from a gas cylinder.

A small modernization is sufficient, including the manufacture of a pipe with holes, an inlet for supplying fuel and a flue.

If it is necessary to make the oven completely from improvised materials, you should choose the right accessories. When choosing, experts recommend adhering to the following requirements:

- Marcastal and its thickness. Can use 15Ki or 20K. They withstand significant temperatures without changing the configuration. The thickness of the steel for the combustion chamber is from 3 mm or more. The body is made of 2mm metal. The use of cast iron is impractical, since it is difficult to process;

- Welding. The main condition is the tightness of the structure and the reliability of the welding seams;

- Position regulation. To do this, the legs are welded to the bottom with the function of changing the height.

After the manufacture of the boiler, it is necessary to check its reliability and the quality of the welds. When testing, the power must be increased gradually, while monitoring the preservation of the integrity of the elements.

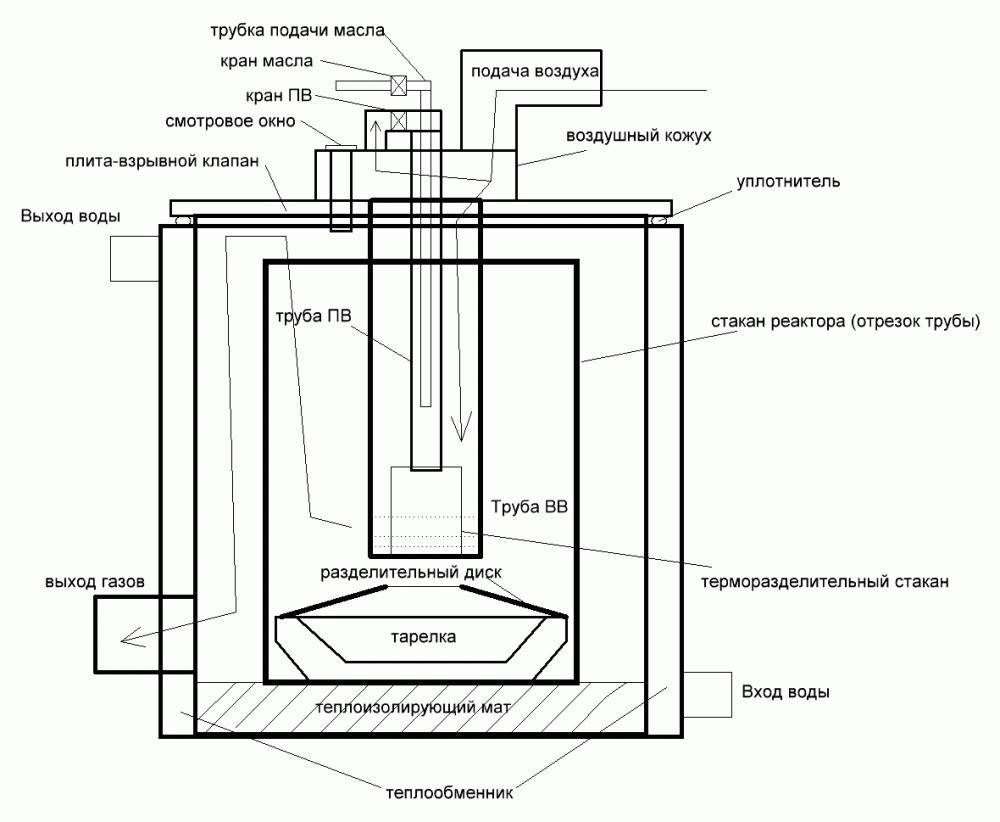

How does a heater work

The design of the boiler is extremely simple. It includes two compartments: evaporation and combustion. In the first, the process of preparing the oil for combustion takes place, in the second, it burns out.

Everything happens as follows. From the recovery tank, the pump supplies the waste oil to the evaporation chamber, which is located at the bottom of the device. It maintains a temperature sufficient for the mining to heat up and begin to evaporate.

This is how a boiler works with oil evaporation and forced air supply (+)

Oil vapor rises to the top of the housing where the combustion chamber is located. It is equipped with an air duct, which is a pipe with holes. With the help of a fan, air is supplied through the duct and mixed with oil vapor.

The oil-air mixture burns almost without residue - the resulting heat heats up the heat exchanger, the combustion products are sent to the chimney.

Oil preheating is an essential part of the process. It must be understood that mining contains a large amount of impurities and toxic substances. All this is decomposed into simple carbohydrates, which are subsequently burned.

After that, water vapor, carbon dioxide and nitrogen are formed - completely harmless elements. However, this result is only possible under certain temperature conditions.

Complete oxidation or combustion of hydrocarbons occurs only at a temperature of +600°C.If it is lower or higher by 150-200°C, then a large amount of various toxic substances is formed during the combustion process. They are not safe for humans, so the combustion temperature must be exactly observed.

Conclusions and useful video on the topic

Craftsmen do not make secrets from their own developments and are always ready to share their achievements, show homemade products at work

Pay attention to the video, which shows the same oven as in option #2, but with some modifications

See how it works, what is the result of its use in conditions of external frost to heat a fairly spacious garage space.

Once again, we draw your attention to the safety precautions that should be observed when using home-made stoves for testing.

Waste fuel, which you can get, if not for nothing, then for mere pennies, always attracts the attention of handy owners of garage workshops, greenhouses or other non-residential premises that require heating. Yes, talented people can literally make a necessary household item out of waste

But skill does not come from outside: it is acquired. Perhaps our information will help not only those who already know how, but also those who want to learn how to do everything with their own hands.

Yes, talented people can literally make a necessary household item out of waste. But skill does not come from outside: it is acquired. Perhaps our information will help not only those who already know how, but also those who want to learn how to do everything with their own hands.

Do you want to share your own experience in the construction of a heating device for testing? Do you have information that will be useful to site visitors who want to make a garage stove with their own hands? Please write comments in the block below, post photos on the topic, ask questions.