- Which wind turbines are the most efficient

- Chinese electronic alternative

- How to connect the controller to the wind generator?

- Connecting the windmill to the battery

- Connecting a single-phase wind generator to a three-phase controller

- The legal side of the issue

- DIY

- The simplest wind generator for dacha lighting

- DIY windmill from a car generator

- Wind generator from a washing machine

- Chinese electronic alternative

- Key nodes

- Varieties and modifications of vertical windmills

- DIY windmills for home, wind turbine mechanics

- What will be required?

- materials

- Tools

- Operating principle

- 1. For high power windmills.

- 2.For low power windmills.

- The basis of a home wind generator

- Material selection

- From PVC pipe

- aluminum

- fiberglass

- The nuances of the use of wind turbines

- What is a charge controller?

Which wind turbines are the most efficient

| Horizontal | vertical |

| This type of equipment has gained the greatest popularity, in which the axis of rotation of the turbine is parallel to the ground. Such wind generators are often called windmills, in which the blades turn against the wind flow. The design of the equipment includes a system for automatic scrolling of the head.It is required to find the wind flow. A device is also needed to turn the blades in order to use even a small force to generate electricity. The use of such equipment is more appropriate in industrial enterprises than in everyday life. In practice, they are more often used to create wind farm systems. | Devices of this type are less effective in practice. The rotation of the turbine blades is carried out parallel to the earth's surface, regardless of the strength of the wind and its vector. The direction of the flow also does not play a role, with any impact, the rotational elements scroll against it. As a result, the wind generator loses part of its power, which leads to a decrease in the energy efficiency of the equipment as a whole. But in terms of installation and maintenance, units in which the blades are arranged vertically are more suitable for home use. This is due to the fact that the gearbox assembly and the generator are mounted on the ground. The disadvantages of such equipment include expensive installation and serious operating costs. Enough space is required to mount the generator. Therefore, the use of vertical devices is more appropriate in small private farms. |

| Two-bladed | Three-bladed | multi-bladed |

| This type of units is characterized by the presence of two elements of rotation. This option is practically inefficient today, but is quite common due to its reliability. | This type of equipment is the most common. Three-bladed units are used not only in agriculture and industry, but also in private households. This type of equipment has gained popularity due to its reliability and efficiency. | The latter can have 50 or more elements of rotation. To ensure the generation of the required amount of electricity, it is not necessary to scroll the blades themselves, but to bring them to the required number of revolutions. The presence of each additional element of rotation provides an increase in the parameter of the total resistance of the wind wheel. As a result, the output of the equipment at the required number of revolutions will be problematic. Carousel devices equipped with a plurality of blades begin to rotate with a small wind force. But their use is more relevant if the very fact of scrolling plays a role, for example, when pumping water is required. In order to effectively ensure the generation of a large amount of energy, multi-bladed units are not used. For their operation, the installation of a gear device is required. This not only complicates the entire design of the equipment as a whole, but also makes it less reliable compared to two- and three-bladed ones. |

| With hard blades | Sailing units |

| The cost of such units is higher due to the high cost of production of rotation parts. But compared to sailing equipment, generators with rigid blades are more reliable and have a long service life. Since the air contains dust and sand, the rotating elements are subjected to a high load. When the equipment is operating in stable conditions, it requires an annual replacement of the anti-corrosion film that is applied to the ends of the blades. Without this, the rotation element begins to lose its working properties over time. | This type of blades is simpler in terms of production and less expensive than metal or fiberglass.But savings in manufacturing can lead to serious costs in the future. With a wind wheel diameter of three meters, the speed of the tip of the blade can be up to 500 km / h, when the equipment revolutions are about 600 per minute. This is a serious load even for rigid parts. Practice shows that the elements of rotation on sailing equipment have to be changed often, especially if the wind force is high. |

In accordance with the type of rotary mechanism, all units can be divided into several types:

- orthogonal Darier devices;

- units with a Savonius rotary assembly;

- devices with a vertical-axial design of the unit;

- equipment with a helicoid type of rotary mechanism.

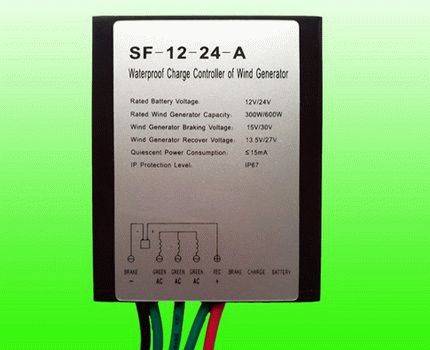

Chinese electronic alternative

Making a wind turbine controller with your own hands is a prestigious business. But given the speed of development of electronic technologies, the meaning of self-assembly often loses its relevance. In addition, most of the proposed schemes are already obsolete.

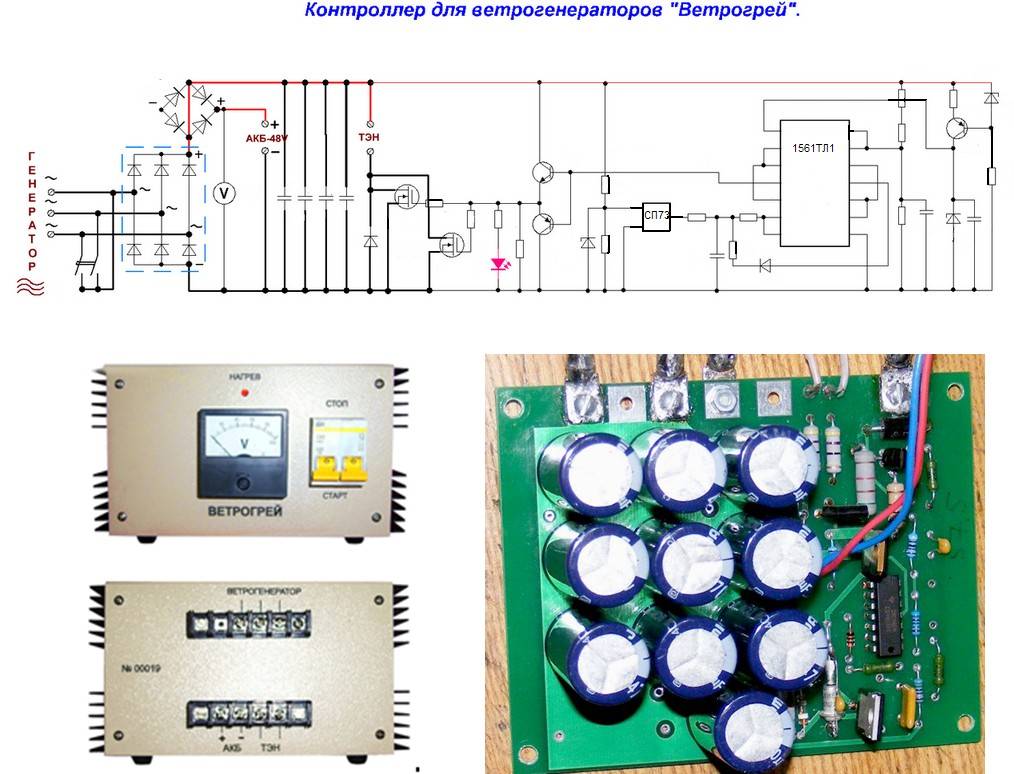

Quite decent, designed for a 600-watt wind generator, a Chinese-made charge controller. Such a device can be ordered from China and received by mail in about a month and a half.

The high-quality all-weather case of the controller with dimensions of 100 x 90 mm is equipped with a powerful cooling radiator. The housing design corresponds to the protection class IP67. The range of external temperatures is from - 35 to + 75ºС. A light indication of the wind generator state modes is displayed on the case.

The question is, what is the reason to spend time and effort on assembling a simple structure with your own hands, if there is a real opportunity to buy something similar and technically serious? Well, if this model is not enough, the Chinese have very “cool” options. So, among the new arrivals, a model with a power of 2 kW for an operating voltage of 96 volts was noted.

Chinese product from the new arrival list. Provides battery charge control, working in tandem with a 2 kW wind generator. Accepts input voltage up to 96 volts

True, the cost of this controller is already five times more expensive than the previous development. But then again, if you compare the costs of producing something similar with your own hands, the purchase looks like a rational decision.

The only thing that confuses about Chinese products is that they tend to suddenly stop working in the most inopportune cases. Therefore, the purchased device often has to be brought to mind - naturally, with your own hands. But it is much easier and simpler than making a do-it-yourself wind turbine charge controller from scratch.

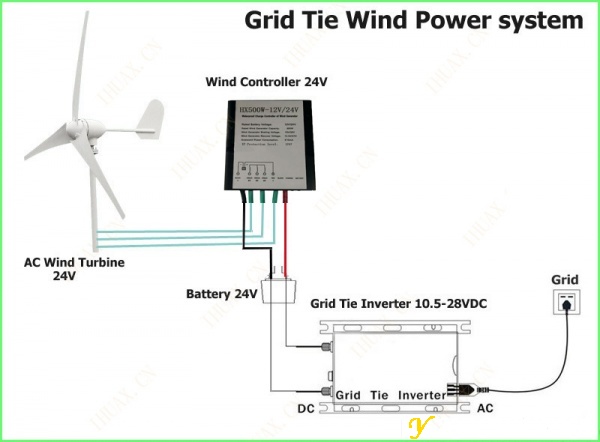

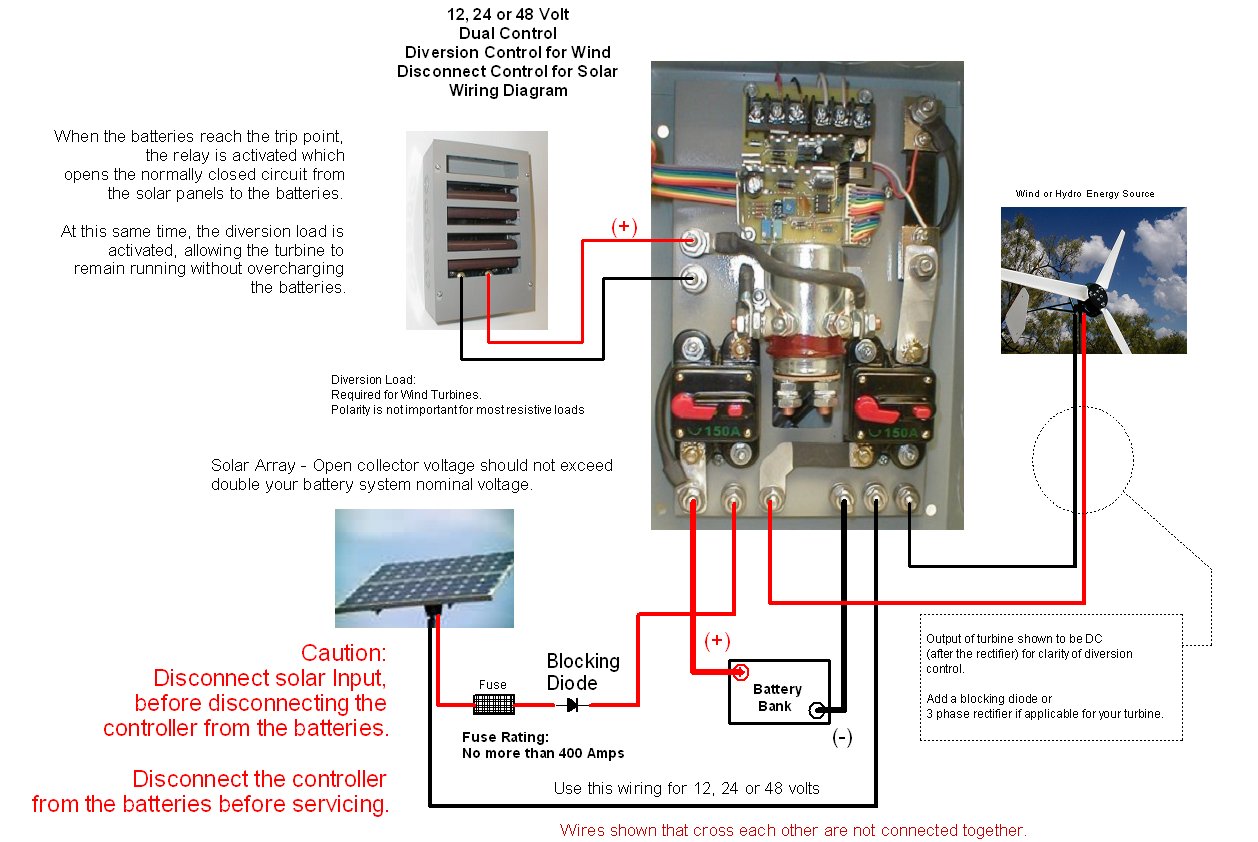

How to connect the controller to the wind generator?

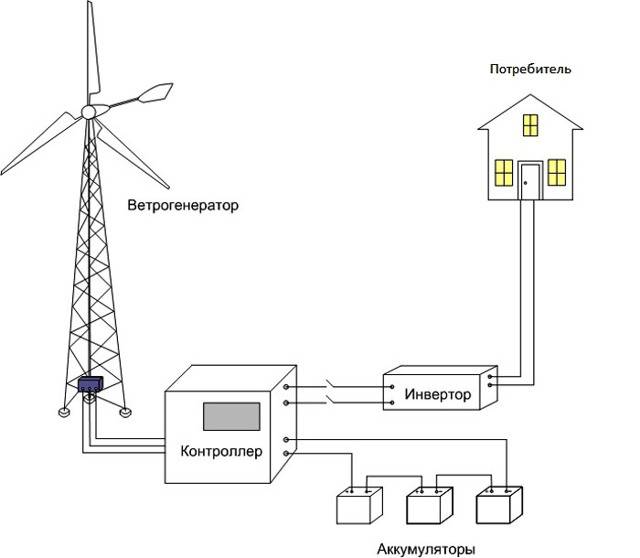

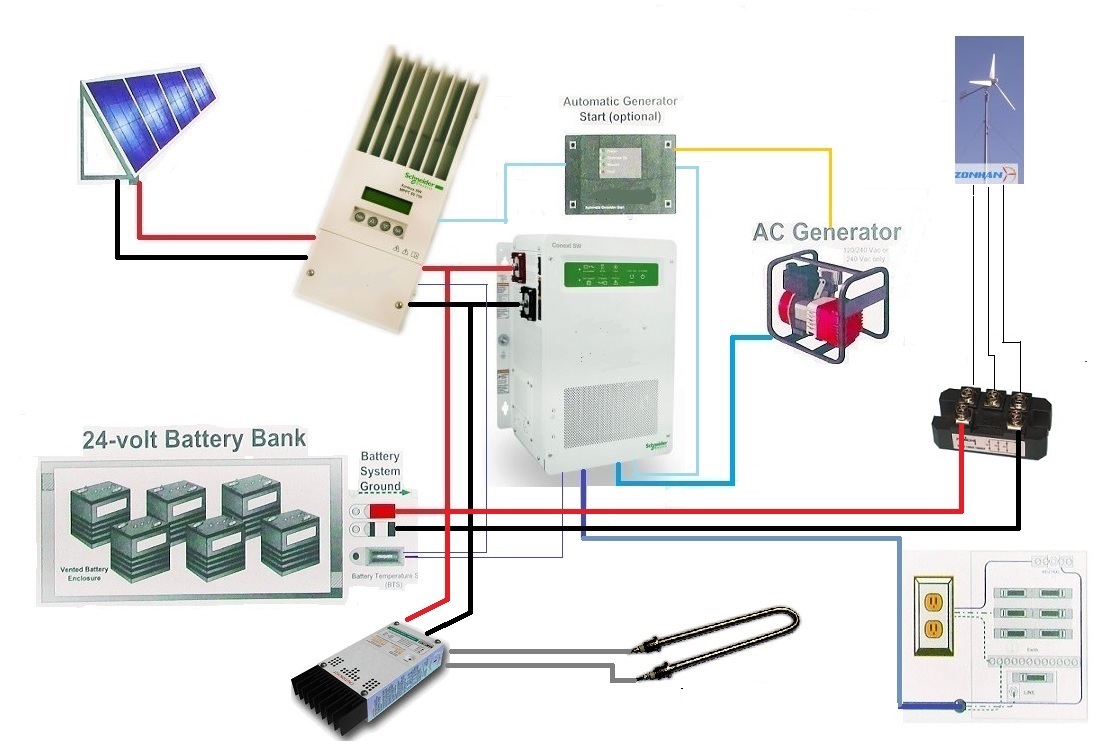

The controller is the very first device to which the voltage generated by the generator is applied. The controller is connected using special terminals. The generator is connected to the input, and the output terminals are connected to the batteries.

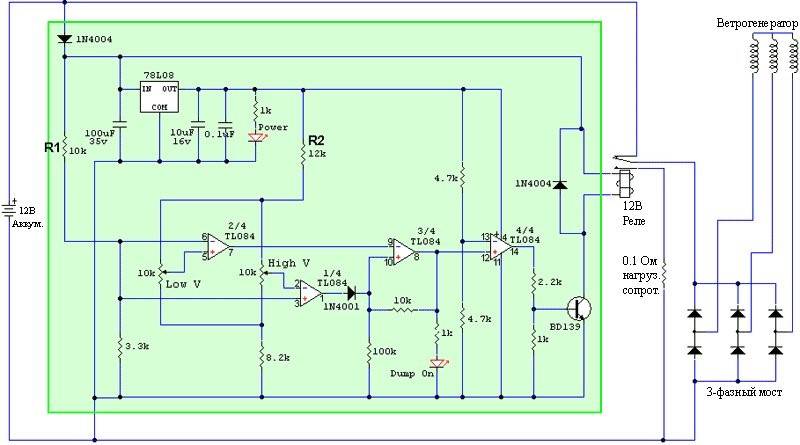

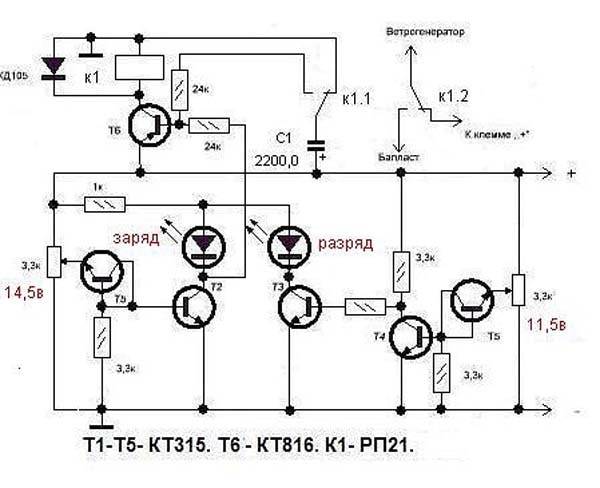

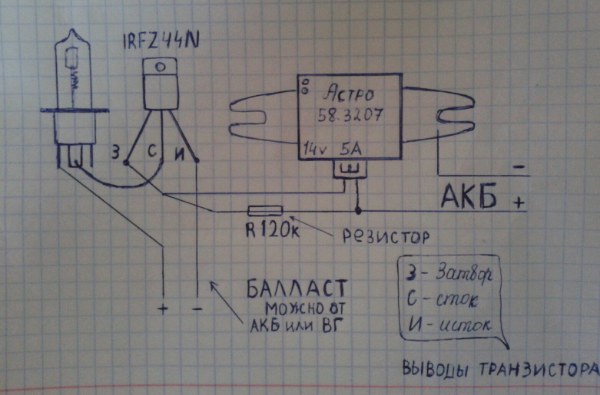

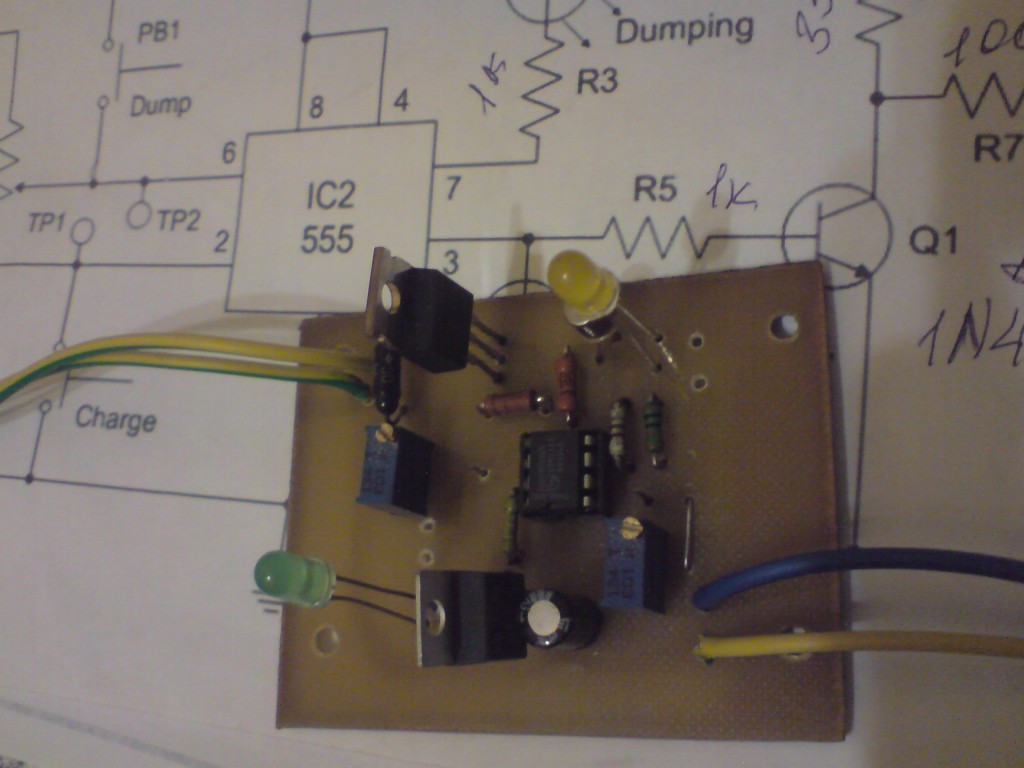

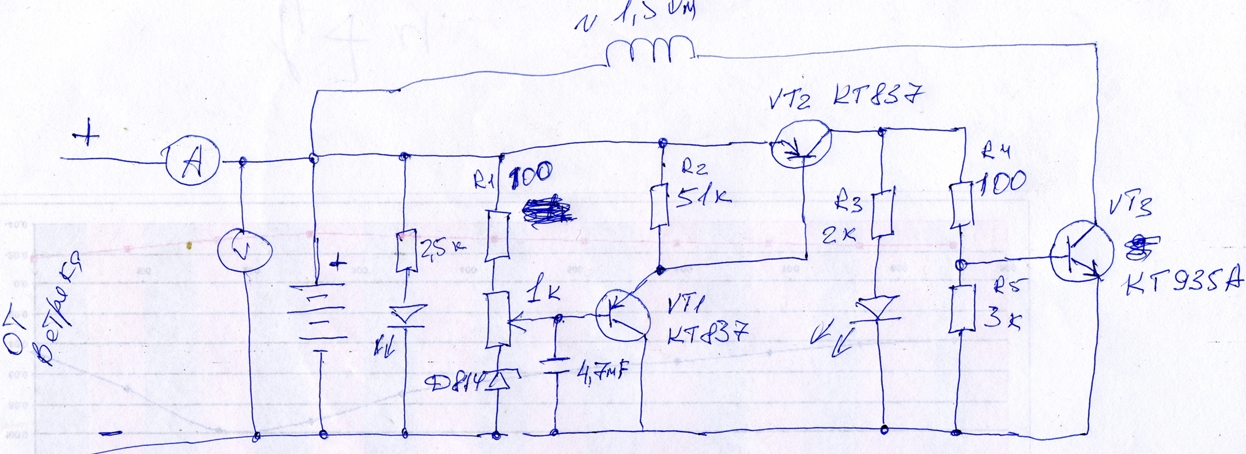

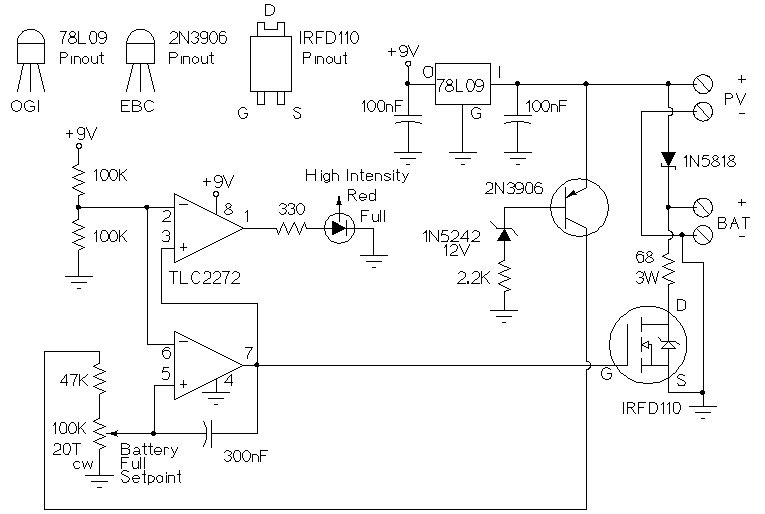

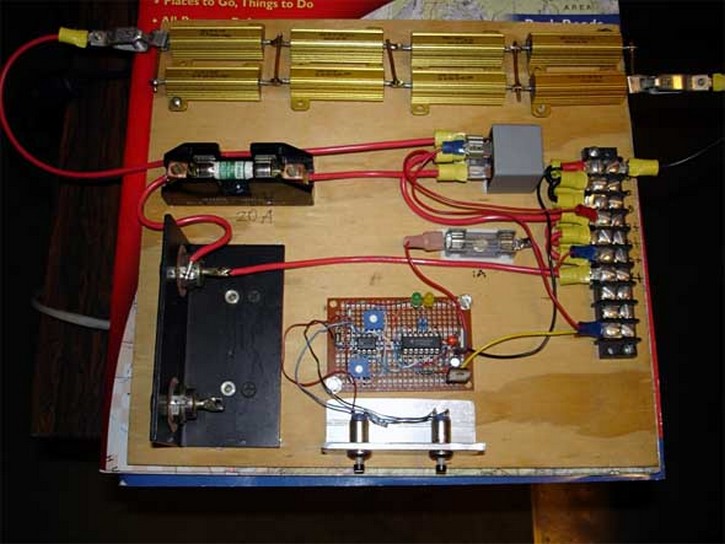

There are many schemes for self-production, in which there are only a few simple parts. Such schemes are easily implemented even by people with initial training, they are reliable and undemanding.With self-manufacturing of a windmill, such schemes provide full-fledged functioning, and the absence of any additional features is not a significant disadvantage. The fewer elements in the circuit, the more reliable it is and less prone to failures or breakdowns, so the option is the most successful.

Connecting the windmill to the battery

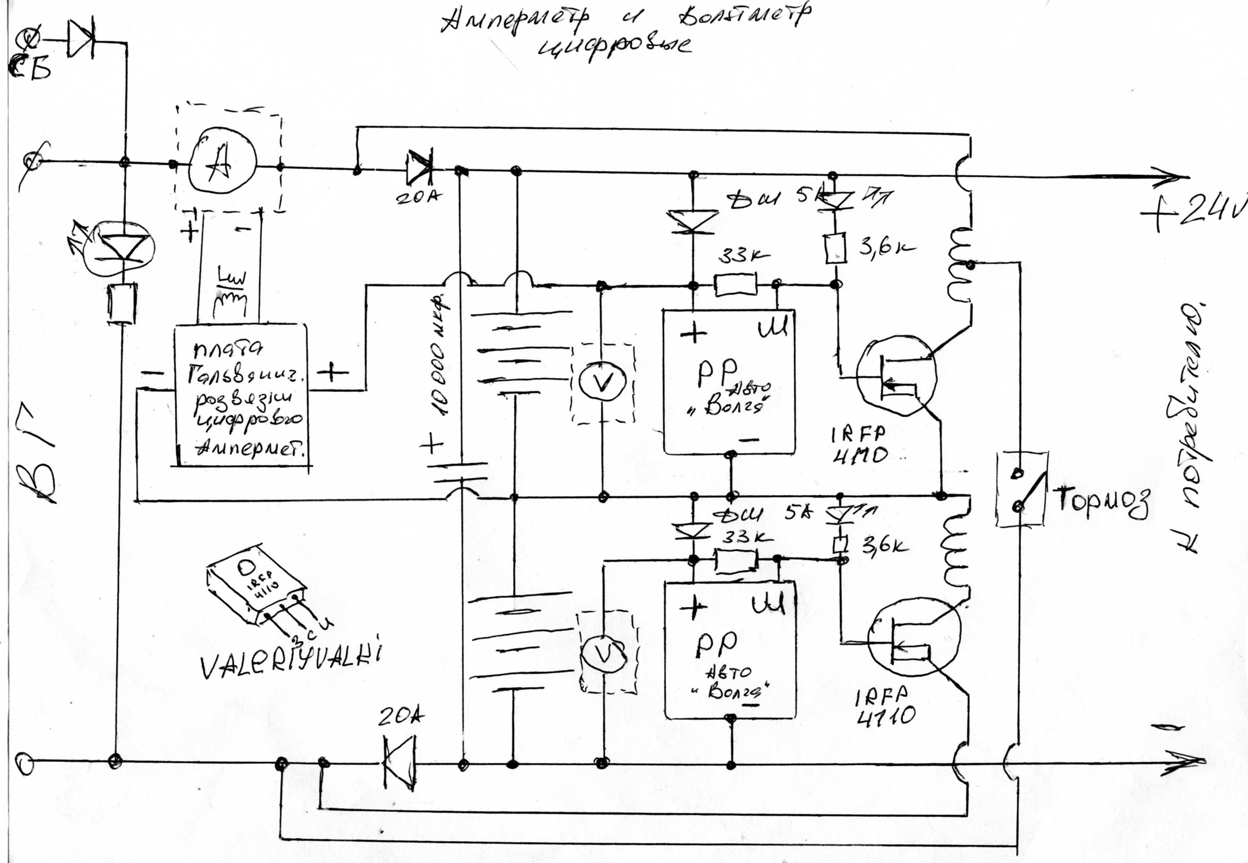

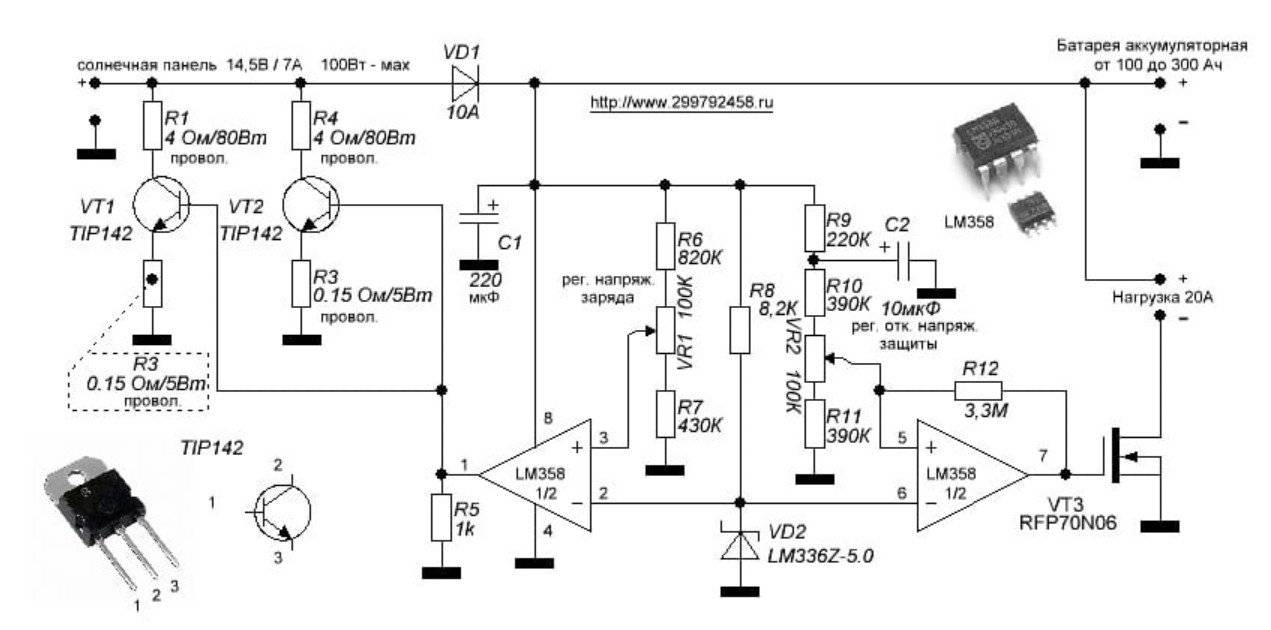

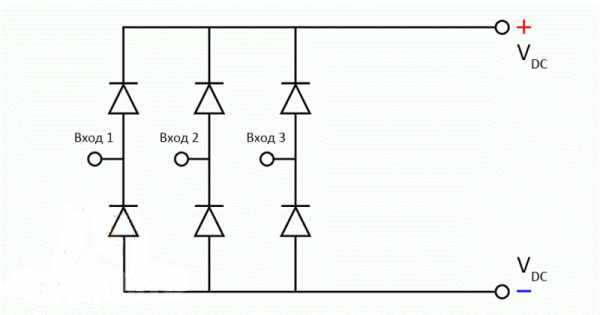

The battery is connected to the generator through a rectifier - a diode bridge. Batteries need direct current, and the windmill generator produces a change, moreover, very unstable in amplitude. The rectifier changes the alternating current, modifying it to direct

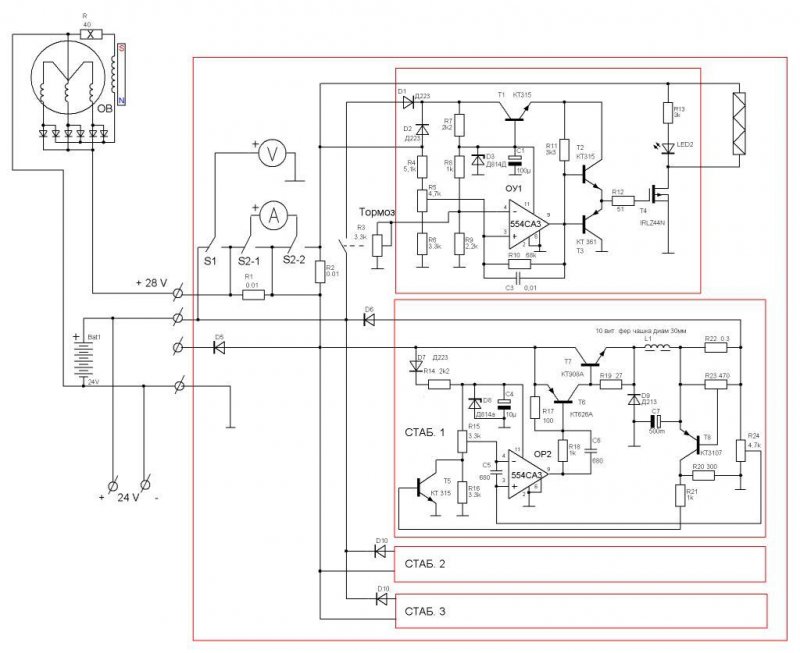

If the generator is three-phase, then it is necessary to use a three-phase rectifier, special attention must be paid to this

Batteries are usually not new, they are able to boil. Therefore, it is strongly recommended to use at least a simple controller made from a relay regulator. It will turn off the charging in time and keep the batteries working. In any case, you should not save on equipment and reduce the composition of the kit, since the full operation of the entire wind turbine depends on it.

Connecting a single-phase wind generator to a three-phase controller

A single-phase generator can be connected to a three-phase controller either for one phase or in parallel for all three. A more correct option is to use one phase, i.e. the windmill is connected to two contacts - a pinching and one phase. This will ensure the correct processing of the voltage and its output to consumer devices.

In general, the use of such dissimilar devices is impractical.In addition, confusion with connection options can create a significant threat to the integrity of the equipment, which is unacceptable. When assembling the kit, you must immediately determine its composition and the type of adjacent devices in order to prevent the use of diverse devices in a single bundle. Only trained people who are specialists in electrical engineering can allow risky connections, although they themselves strongly reject such actions.

The legal side of the issue

A home-made wind generator for a home does not fall under prohibitions, its manufacture and use does not entail administrative or criminal punishment. If the power of the wind generator does not exceed 5 kW, it belongs to household appliances, and does not require any coordination with the local energy company. Moreover, you do not need to pay any taxes if you do not make a profit from the sale of electricity. In addition, a home-made generating windmill, even with such a performance, requires complex engineering solutions: it is easy to make it. Therefore, homemade power rarely exceeds 2 kW. Actually, this power is usually enough to power a private house (of course, if you do not have a boiler and a powerful air conditioner).

In this case, we are talking about federal law. Therefore, before deciding to make a windmill with your own hands, it would not be superfluous to check the presence (absence) of subject and municipal regulatory legal acts that may impose some restrictions and prohibitions. For example, if your home is located in a specially protected natural area, the use of wind energy (and this is a natural resource) may require additional approvals.

Problems with the law can arise in the presence of restless neighbors. Windmills for the home are individual buildings, so they are also subject to some restrictions:

- The height of the mast (even if the wind turbine is without blades) cannot exceed the norms established in your region. In addition, there may be restrictions related to the location of your site. For example, a landing glide path to the nearest airfield may pass over you. Or in the immediate vicinity of your site there is a power line. If dropped, the structure may damage poles or wires. General limits under normal wind load are 15 meters in height (some makeshift windmills soar up to 30 meters). If the mast and body of the device have a large cross-sectional area, neighbors may make claims against you, on whose plot the shadow falls. It is clear that such complaints usually arise “out of harm”, but there is a legal basis.

- Blade noise. The main source of problems with neighbors. When operating a classic horizontal design, the windmill emits infrasound. This is not just an unpleasant noise, when a certain level is reached, the wave vibrations of the air have an adverse effect on the human body and domestic animals. A homemade windmill generator is usually not a "masterpiece" of engineering, and by itself can make a lot of noise. It is highly desirable to officially test your device in the supervisory authorities (for example, in the SES), and obtain a written opinion that the established noise standards are not exceeded.

- Electromagnetic radiation. Any electrical device emits radio interference. Take, for example, a windmill from a car generator.To reduce the interference level of the car receiver, capacitor filters are installed in the car. When developing a project, be sure to consider this point.

Claims can be made not only from neighbors who have problems with receiving TV and radio signals. If there are industrial or military reception centers nearby, it is not superfluous to check the level of interference in the electronic interference control (EW) unit.

- Ecology. It sounds paradoxical: it would seem that you are using an environmentally friendly unit, what problems can there be? A propeller located at a height of 15 meters and above can become an obstacle to the migration of birds. The rotating blades are invisible to birds and they are easily hit.

DIY

The purchase of a ready-made wind generator is beyond the reach of most users. In addition, the desire to make various mechanisms and devices is ineradicable among the people, and if there is also urgent need to resolve the issue clearly. Consider how to make a wind generator with your own hands.

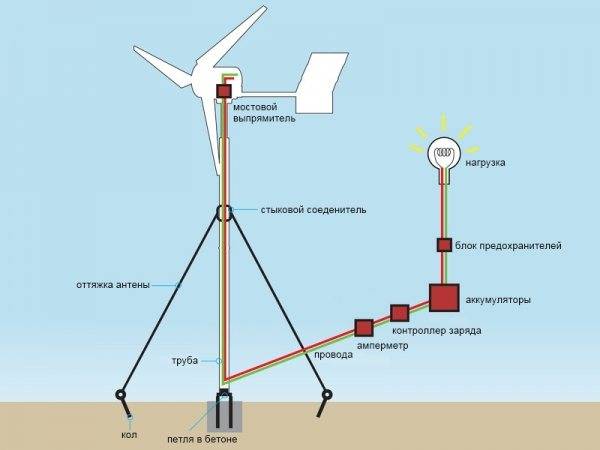

The simplest wind generator for dacha lighting

The simplest designs are used to illuminate a site or power a pump that supplies water. The process involves, as a rule, consumption devices that are not afraid of power surges. The windmill rotates the generator, directly connected to consumers, without an intermediate voltage stabilizing kit.

DIY windmill from a car generator

A generator from a car is the best option when creating a homemade windmill. It needs minimal reconstruction, mainly rewinding the coil with thinner wire with more turns.The modification is minimal, and the resulting effect allows you to use a windmill to provide a home. You will need a sufficiently high-speed and powerful rotor capable of rotating devices with high resistance.

Wind generator from a washing machine

The electric motor from the washing machine is often used to create a generator. The best option is to install strong neodymium magnets on the rotor to excite the windings. To do this, it is necessary to drill recesses in the rotor with a diameter equal to the size of the magnets.

Then they are installed in sockets with alternating polarity and filled with epoxy. The finished generator is installed on a platform rotating around a vertical axis, an impeller with a fairing is mounted on the shaft. A tail stabilizer is attached to the site at the back, which provides guidance for the device.

Chinese electronic alternative

Making a wind turbine controller with your own hands is a prestigious business. But given the speed of development of electronic technologies, the meaning of self-assembly often loses its relevance. In addition, most of the proposed schemes are already obsolete.

It turns out cheaper to buy a ready-made product, made professionally, with high quality installation, on modern electronic components. For example, you can purchase a suitable device at a reasonable cost on Aliexpress.

Quite decent, designed for a 600-watt wind generator, a Chinese-made charge controller. Such a device can be ordered from China and received by mail in about a month and a half.

The high-quality all-weather case of the controller with dimensions of 100 x 90 mm is equipped with a powerful cooling radiator. The housing design corresponds to the protection class IP67.The range of external temperatures is from - 35 to + 75ºС. A light indication of the wind generator state modes is displayed on the case.

The question is, what is the reason to spend time and effort on assembling a simple structure with your own hands, if there is a real opportunity to buy something similar and technically serious? Well, if this model is not enough, the Chinese have very “cool” options. So, among the new arrivals, a model with a power of 2 kW for an operating voltage of 96 volts was noted.

Chinese product from the new arrival list. Provides battery charge control, working in tandem with a 2 kW wind generator. Accepts input voltage up to 96 volts

True, the cost of this controller is already five times more expensive than the previous development. But then again, if you compare the costs of producing something similar with your own hands, the purchase looks like a rational decision.

The only thing that confuses about Chinese products is that they tend to suddenly stop working in the most inopportune cases. Therefore, the purchased device often has to be brought to mind - naturally, with your own hands. But it is much easier and simpler than making a do-it-yourself wind turbine charge controller from scratch.

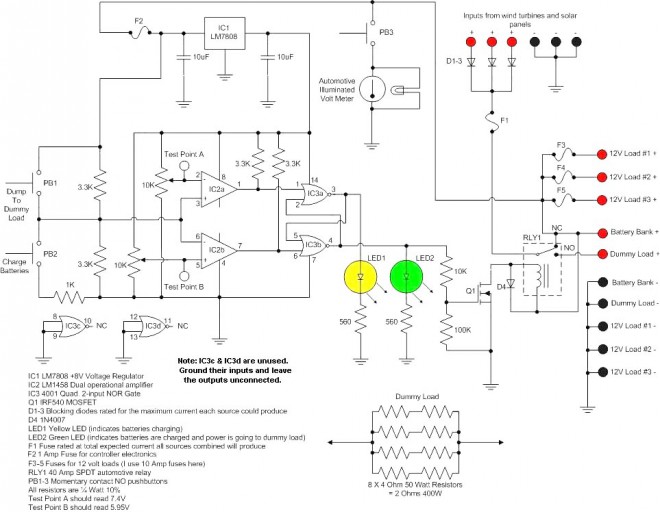

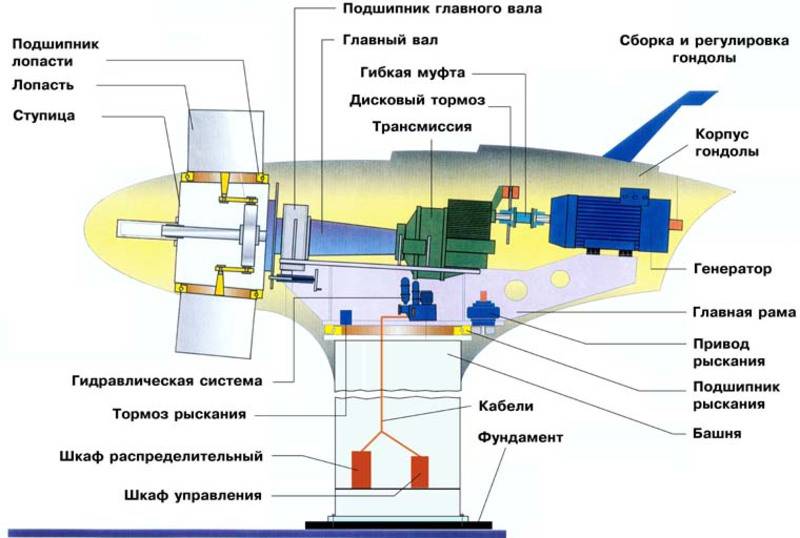

Key nodes

As mentioned, a wind generator can be made at home. It is necessary to prepare certain nodes for its reliable functioning. These include:

- Blades. They can be made from different materials.

- Generator. You can also assemble it yourself or buy ready-made.

- Tail zone. Used to move the blades in the direction of the vector, providing the highest possible efficiency.

- Multiplier. Increases the speed of rotation of the rotor.

- Mast for fasteners.It plays the role of an element on which all specified nodes are fixed.

- Tension ropes. Necessary for fixing the structure as a whole and protecting it from destruction under the influence of wind.

- Battery, inverter and charge controller. Contribute to the transformation, stabilization of energy and its accumulation.

Beginners should consider simple rotary wind generator circuits.

Varieties and modifications of vertical windmills

An orthogonal wind generator is equipped with several blades located at a certain distance parallel to the axis of rotation. These windmills are also known as the Darrieus rotor. These units have proven to be the most efficient and functional.

The rotation of the blades is provided by their wing-like shape, which creates the necessary lifting force. However, the normal operation of the device requires considerable effort, so the performance of the generator can be increased by installing additional static screens. As disadvantages, it should be noted excessive noise, high dynamic loads (vibration), which often lead to premature wear of the support units and failure of the bearings.

There are wind turbines with a Savonius rotor that are most suitable for domestic conditions. The wind wheel consists of several semi-cylinders that rotate continuously around their axis. Rotation is always carried out in the same direction and does not depend on the direction of the wind.

The disadvantage of such installations is the rocking of the structure under the action of the wind. Due to this, tension is created in the axis and the rotor rotation bearing fails.In addition, the rotation cannot start on its own if only two or three blades are installed in the wind generator. In this regard, it is recommended to fix two rotors on the axis at an angle of 90 degrees relative to each other.

The vertical multiblade wind generator is one of the most functional devices of this model range. It has high performance with little load on the load-bearing elements.

The internal part of the structure consists of additional static blades placed in one row. They compress the air flow and regulate its direction, thereby increasing the efficiency of the rotor. The main disadvantage is the high price due to the large number of parts and elements.

DIY windmills for home, wind turbine mechanics

essence operation of the wind generator - the transformation of the kinetic wind energy into electricity. Each element of the system performs its function:

Wind wheel, blades. They catch the movement of air masses, rotate and set the shaft in motion.

A generator can be immediately installed on the shaft, or there may be an angular gearbox that will transfer the downward movement to the cardan. Through the use of a gearbox, it is possible to achieve an increase in speed (multiplier).

Generator - converts rotational energy into electrical energy. If the generator produces a stable current, then it is connected to the batteries. If not, a voltage regulator relay is installed intermediately.

There may not be batteries in the system, but with them the work is more stable - they use the windy clock for recharging and use up the accumulated potential when the wind subsides.

Inverter - is used to convert the voltage to the desired value, for example, 220V.Needed for convenience, since most devices are designed for such a voltage. But the purpose of the windmill can be different, so not every circuit includes an inverter.

Anemoscope is a device that is used for powerful wind turbines. It collects data on wind speed and direction. Almost never found in homemade designs

Usually they make a small weather vane and a rotary mechanism.

Mast - or support on which the propeller will be fixed

At altitude, you are more likely to catch a stable and strong wind, so it is important to pay attention to the mast, which must withstand loads.

Windmills can be horizontal (with a classic propeller) and vertical (rotary). Horizontal installations have the highest efficiency, so they are most often reproduced by self-manufacturing.

Vertical Type Generator

But such windmills need to be turned towards the wind, because with a side stream it stops working. A do-it-yourself rotary wind generator also has its advantages.

The design of vertical systems can vary greatly, but they have common features.

- Vertically located turbines will catch the wind, no matter where it blows (horizontal models need to be equipped with a guide), which is very convenient if the wind in a particular area is not stable, variable.

- Such a structure can be placed directly on the ground (of course, if there is enough wind).

- Make installation easier than horizontal.

The only negative is the relatively low efficiency.

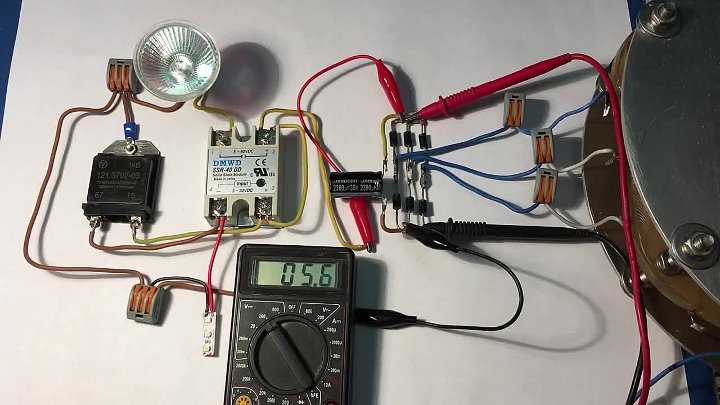

What will be required?

The most common option is to use a washing machine engine for a homemade generator.If there is no old “washer” available, you can find such an engine from junk dealers in the household market, in the nearest service center for household appliances or a specialized store. It is not a problem to order such an engine from China.

Both new and used will last a long time. The power of 200 watts is easily converted to a kilowatt or more.

materials

To assemble the generator, in addition to the motor, you need:

- neodymium magnets in sizes 20, 10 and 5 mm (32 in total);

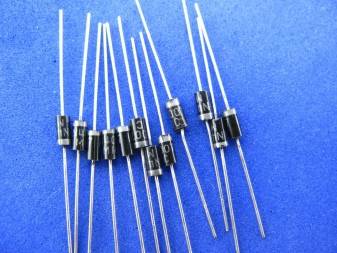

- rectifier diodes or a diode bridge with a current of tens of amperes (follow the rule of a double power margin);

- epoxy adhesive;

- cold welding;

- sandpaper;

- tin from the side of the can.

Magnets are ordered online from China.

Tools

The following tools will speed up the manufacturing process:

- lathe;

- scissors;

- screwdriver with nozzles;

- pliers.

Operating principle

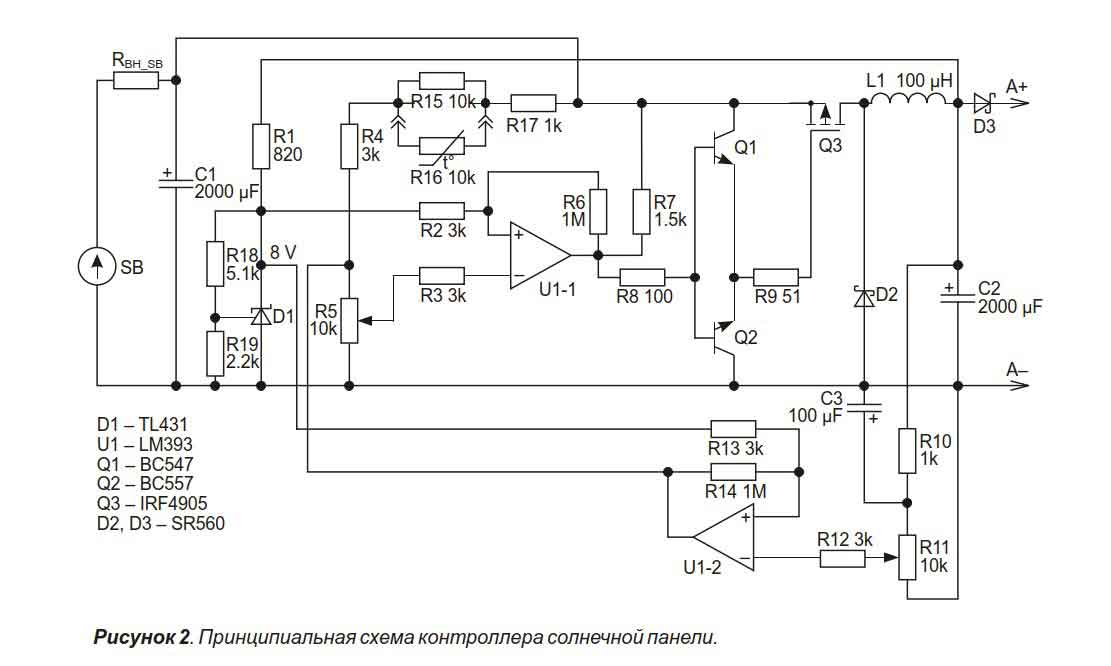

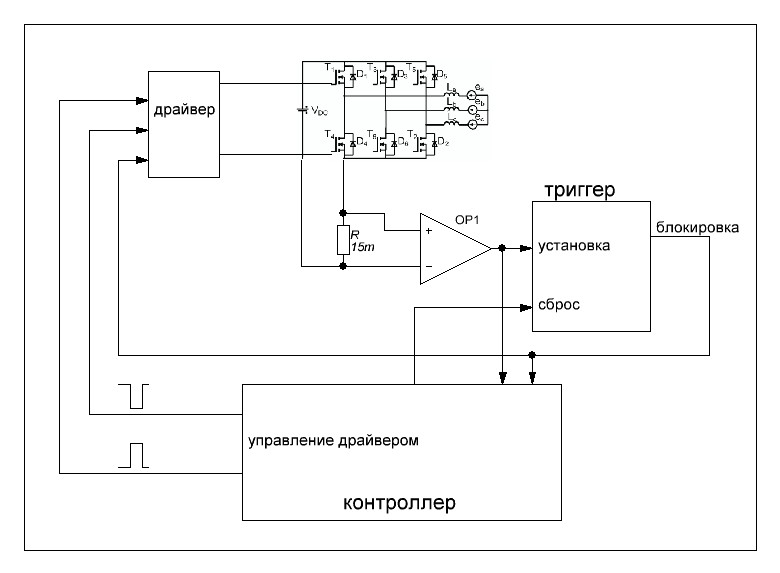

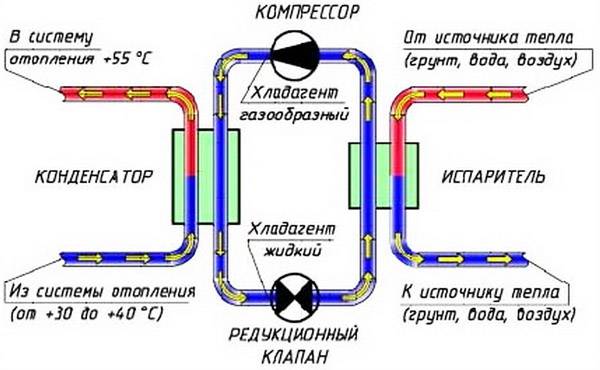

Controllers used in wind turbines are complex technical devices that perform the following functions:

- Carries out control over the charge of rechargeable batteries (ACB), which are the storage of generated electrical energy.

- Converts the alternating electric current produced by the wind generator into direct current, which is the operating current for batteries.

- Controls the rotation of the blades of the wind turbine.

- It redirects the generated electric current, depending on the battery charge and the amount of energy generated.

Operation of controllers providing operation of wind turbines in automatic mode, is carried out, depending on their design and the power of the wind generator, as follows:

1. For high power windmills.

- Complete with the controller, a ballast resistance is mounted in the wind turbine. In this capacity, electric heating elements or other electrical resistors with significant resistance can be used.

- During the operation of the wind turbine, when the voltage on the batteries reaches 14 - 15.0 Volts, the controller disconnects them from the power line and switches the flows of electrical energy generated by the installation to ballast resistance.

2.For low power windmills.

When the battery charge is completed, and the voltage values have reached the maximum possible values, the controller brakes the rotation of the wind turbine blades. This operation is carried out by closing the phases of the wind generator, which leads to braking and stopping the rotation of the installation.

The basis of a home wind generator

The topic of manufacturing and installing homemade wind generators is very widely represented on the Internet. However, most of the material is a banal description of the principles for obtaining electrical energy from natural sources.

The theoretical method for the device (installation) of wind turbines has long been known and is quite understandable. But how things are practically in the domestic sector - a question that is far from being fully disclosed.

Most often, it is recommended to choose car generators or AC induction motors supplemented with neodymium magnets as a current source for home-made home wind generators.

The procedure for converting an asynchronous AC motor into a generator for a windmill. It consists in the manufacture of a “fur coat” of the rotor from neodymium magnets. Extremely complex and lengthy process

However, both options require significant refinement, often complex, expensive, and time-consuming.

It is much simpler and easier in every way to install electric motors like those that were produced before and are now produced by Ametek (example) and others.

For a home wind turbine, DC motors with a voltage of 30 - 100 volts are suitable. In generator mode, approximately 50% of the declared operating voltage can be obtained from them.

It should be noted: when operating in the generation mode, DC motors must be untwisted to a speed higher than the nominal one.

At the same time, each individual motor from a dozen identical copies can show completely different characteristics.

Therefore, the optimal selection of an electric motor for a home wind generator is logical with the following indicators:

- High operating voltage setting.

- Low parameter RPM (angular speed of rotation).

- High operating current.

So, a motor manufactured by Ametek with an operating voltage of 36 volts and an angular speed of rotation of 325 rpm looks good for installation.

It is such an electric motor that is used in the design of a wind generator - an installation that is described below as an example of a home windmill.

DC motor for home wind generator. The best option among the products manufactured by Ametek. Similar electric motors manufactured by other companies are also well suited.

Checking the efficiency of any similar motor is easy. It is enough to connect a conventional 12 volt incandescent automotive lamp to the electrical terminals and turn the motor shaft by hand.With good technical indicators of the electric motor, the lamp will definitely light up.

Material selection

The blades for a wind device can be made of any more or less suitable material, for example:

From PVC pipe

It is probably the easiest thing to build blades from this material. PVC pipes can be found in every hardware store. Pipes should be chosen those that are designed for sewerage with pressure or a gas pipeline. Otherwise, the air flow in strong winds can distort the blades and damage them against the generator mast.

The blades of a wind turbine are subject to severe loads from centrifugal force, and the longer the blades, the greater the load.

The edge of the blade of a two-bladed wheel of a home wind generator rotates at a speed of hundreds of meters per second, such is the speed of a bullet flying out of a pistol. This speed can lead to rupture of PVC pipes. This is especially dangerous because flying pipe fragments can kill or seriously injure people.

You can get out of the situation by shortening the blades to the maximum and increasing their number. Multi-bladed wind wheel is easier to balance and less noisy

Of no small importance is the thickness of the walls of the pipes. For example, for a wind wheel with six blades made of PVC pipe, two meters in diameter, their thickness should not be less than 4 millimeters. To calculate the design of the blades for a home craftsman, you can use ready-made tables and templates

To calculate the design of the blades for a home craftsman, you can use ready-made tables and templates.

The template should be made from paper, attached to the pipe and circled. This should be done as many times as there are blades on the wind turbine.Using a jigsaw, the pipe must be cut according to the marks - the blades are almost ready. The edges of the pipes are polished, the corners and ends are rounded so that the windmill looks nice and makes less noise.

From steel, a disk with six stripes should be made, which will play the role of a structure that combines the blades and fixes the wheel to the turbine.

The dimensions and shape of the connecting structure must correspond to the type of generator and direct current that will be used in the wind farm. Steel must be chosen so thick that it does not deform under wind blows.

aluminum

Compared to PVC pipes, aluminum pipes are more resistant to both bending and tearing. Their disadvantage lies in the large weight, which requires measures to ensure the stability of the entire structure as a whole. In addition, you should carefully balance the wheel.

Consider the features of the execution of aluminum blades for a six-blade wind wheel.

According to the template, a plywood pattern should be made. Already according to the template from a sheet of aluminum, cut blanks of blades in the amount of six pieces. The future blade is rolled into a chute with a depth of 10 millimeters, while the scroll axis should form an angle of 10 degrees with the longitudinal axis of the workpiece. These manipulations will endow the blades with acceptable aerodynamic parameters. A threaded sleeve is attached to the inner side of the blade.

The connecting mechanism of a wind wheel with aluminum blades, unlike a wheel with blades made of PVC pipes, does not have strips on the disk, but studs, which are pieces of a steel rod with a thread suitable for the thread of the bushings.

fiberglass

Blades made from fiberglass-specific fiberglass are the most flawless, given their aerodynamic parameters, strength, weight. These blades are the most difficult to construct, because you need to be able to process wood and fiberglass.

We will consider the implementation of fiberglass blades for a wheel with a diameter of two meters.

The most scrupulous approach should be taken to the implementation of the matrix of wood. It is machined from the bars according to the finished template and serves as a blade model. Having finished working on the matrix, you can begin to make blades, which will consist of two parts.

First, the matrix must be treated with wax, one of its sides should be covered with epoxy resin, and fiberglass should be spread on it. Apply epoxy to it again, and again a layer of fiberglass. The number of layers can be three or four.

Then you need to keep the resulting puff right on the matrix for about a day until it dries completely. So one part of the blade is ready. On the other side of the matrix, the same sequence of actions is performed.

The finished parts of the blades should be connected with epoxy. Inside, you can put a wooden cork, fix it with glue, this will fix the blades to the wheel hub. A threaded bushing should be inserted into the plug. The connecting node will become the hub in the same way as in the previous examples.

The nuances of the use of wind turbines

Currently, wind turbines are used in various sectors of the national economy. Industrial models of different capacities are used by oil and gas companies, telecommunications companies, drilling and exploration stations, production facilities and government agencies.

The windmill can be used as an additional source of energy in hospitals and other institutions to ensure a continuous supply of electricity in emergency situations.

Of particular note is the importance of using wind turbines for the prompt restoration of broken electricity during cataclysms and natural disasters. For this purpose, wind turbines are often used by the Ministry of Emergency Situations.

Household wind turbines are perfect for organizing lighting and heating of cottage settlements and private houses, as well as for household purposes on farms.

In this case, some points should be taken into account:

- Devices up to 1 kW can only provide enough electricity in windy places. Usually, the energy generated by them is only enough for LED lighting and powering small electronic devices.

- To fully provide electricity to a dacha (country house), you will need a wind generator with a capacity of over 1 kW. This indicator is enough to power lighting fixtures, as well as a computer and a TV, but its power is not enough to supply electricity to a modern refrigerator that works around the clock.

- To provide energy to the cottage, you will need a windmill with a capacity of 3-5 kW, but even this indicator is not enough to heat houses. To use this function, you need a powerful option, starting from 10 kW.

When choosing a model, it should be noted that the power indicator indicated on the device is only achieved at maximum wind speed. So, a 300V installation will produce the indicated amount of energy only at an air flow speed of 10-12 m / s.

For those wishing to build a wind turbine with their own hands, we offer the following article, which details useful information.

What is a charge controller?

The function of controlling the amount of charge is performed by a ballast regulator, or controller. This is an electronic device that turns off the battery when the voltage rises, or dumps excess energy on the consumer - a heater, lamp or other simple and undemanding device for some power changes. When the charge drops, the controller switches the battery into charge mode, helping to replenish the energy reserve.

The first designs of controllers were simple and only allowed turning on the shaft braking. Subsequently, the functions of the device were revised, and the excess energy began to be used more rationally. And with the beginning of the use of wind turbines as the main power source for summer cottages or private houses, the problem of using excess energy disappeared by itself, since at present there is always something to connect in any house.