- Pit construction: pros and cons

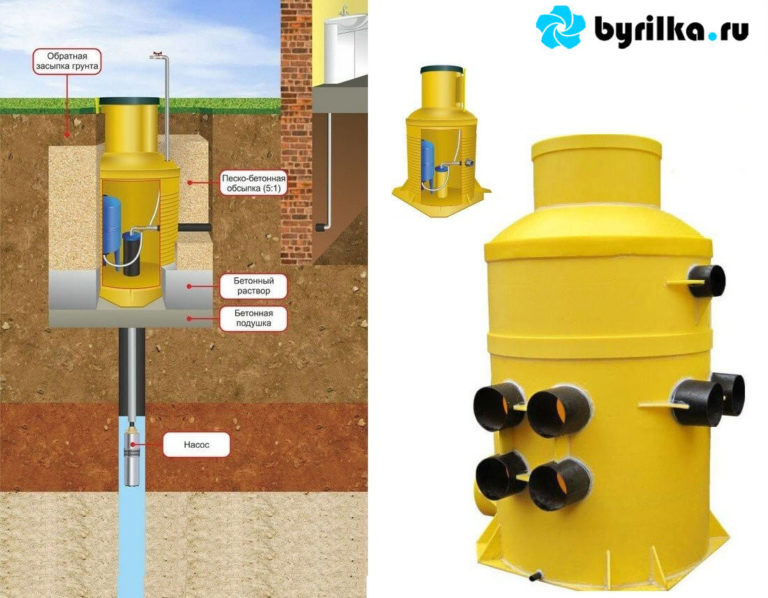

- Installation and installation of the caisson

- Advantages of a well with a caisson

- What materials are made from

- Metal caisson

- Advantages

- Flaws

- Plastic caisson

- Advantages

- Flaws

- Misconceptions about plastic caisson

- Caisson from reinforced concrete rings

- Why rarely used:

- Plastic caisson for wells RODLEX KS 2.0

- Prices for plastic caissons

- Step by step installation instructions

- Prices for water pipes

- How to choose the right plastic caisson

- The device of a concrete caisson structure

- What is a caisson

- Types of caissons

- The device and features of pits for wells

- Concrete caisson for a well

- Table: tools for casting a caisson

- Materials for the caisson

- Step-by-step instructions for casting a concrete caisson hull

- How to make a caisson yourself

- Monolithic concrete structure

- Caisson from concrete rings

- Budget camera made of bricks

- Sealed metal container

- Conclusions and useful video on the topic

Pit construction: pros and cons

If it is not possible to spend impressive funds on the installation of a caisson, the problem is solved in two ways: a pit is built and equipped or a borehole adapter is installed.

The simplest solution in terms of installation is a pit.

The pit is a recess dug around the wellhead, inside which the shutoff valves of the autonomous water supply system are installed.

It is a simplified analogue of the caisson, which simultaneously performs several functions:

- protects the installed equipment from the cold;

- protects the wellhead from precipitation and domestic sewage;

- acts as a structure, inside which it is convenient to place a complex of mechanisms that ensure the smooth operation of the pump.

Due to the insufficient tightness of the structure, the pit is not suitable for areas with groundwater close to the surface. When marking their mirror at a depth of more than 5 m, the construction of a pit is a completely profitable and justified solution.

The pit is most often constructed of concrete rings or bricks, lined with insulating material inside, and covered with a hatch or concrete slab on top.

The pit is most often constructed of concrete rings or bricks, lined with insulating material inside, and covered with a hatch or concrete slab on top.

The only drawback of the design is insufficient tightness. Joints between concrete rings and masonry can pass perched water and precipitation and domestic sewage. For this reason, it is not recommended to install a hydraulic tank and an automation system in the pit.

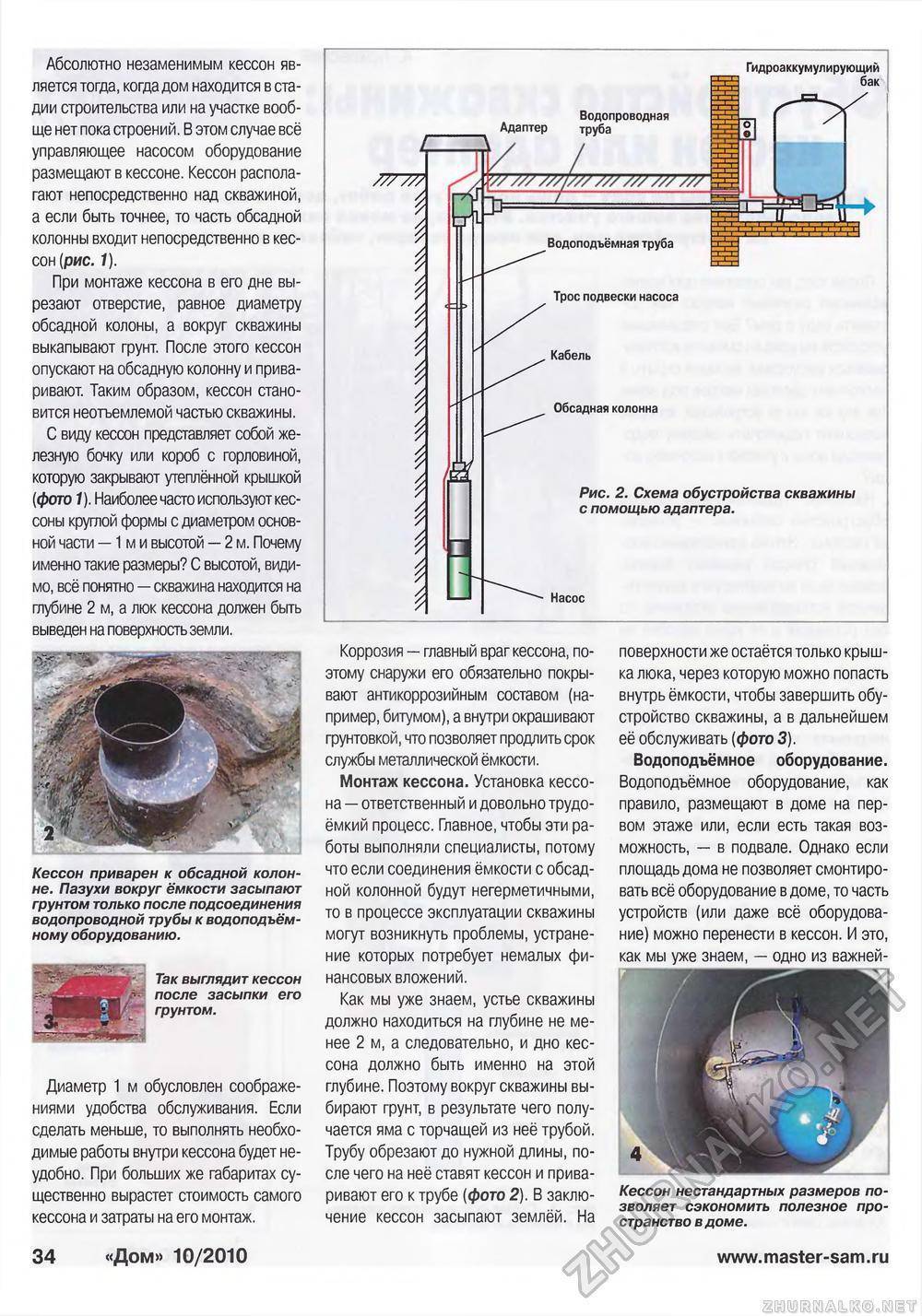

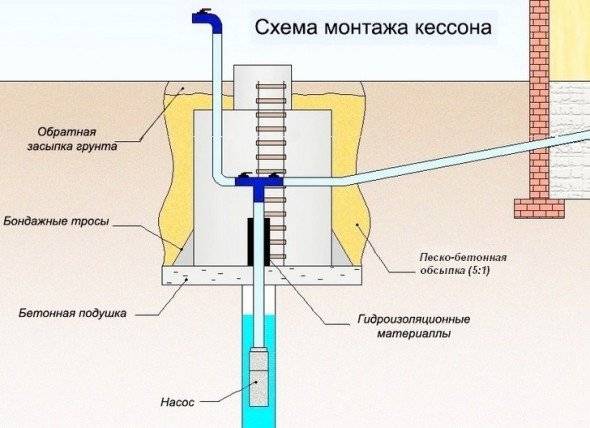

Installation and installation of the caisson

To mount a finished caisson made of plastic or metal, you must follow five steps:

-

Digging a pit 20–30 cm larger than the structure to be installed.

-

Backfilling a sand cushion 15–20 cm at the bottom and creating an “anchor” there (if necessary).

-

Implementation of the installation of the caisson and the equipment of the head inside it on the casing pipe.

-

Summing up electrical wiring and water supply with sealing of inlets in the walls of the structure.

-

External insulation with expanded polystyrene or polystyrene and backfilling of the soil.

The technology of work is extremely simple. Installation of the caisson is always possible to do it yourself. After filling it with earth for external decoration, a facing brick or other moisture-resistant material is suitable for finishing the basement of a private house.

We insulate inside and seal all seams on the outside

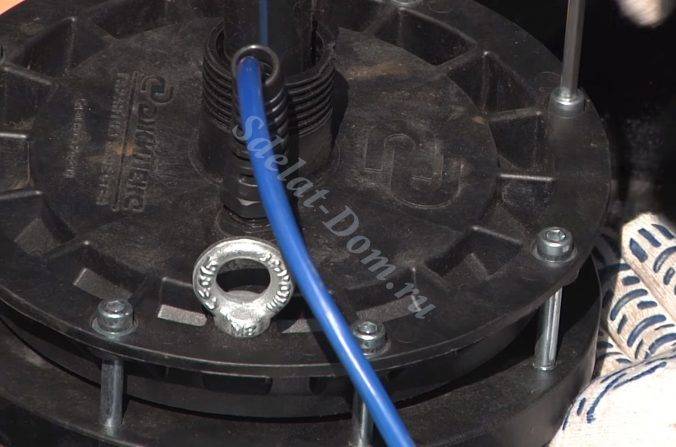

Assembling the pump

We insert the pump

We close the well with a head, from which we remove the water hose and cable

Installing couplings

On them we mount and connect a pressure switch and a pressure gauge to the cable

Connecting the inner line

We connect the hydraulic tank

Connecting external connections

Installation completed

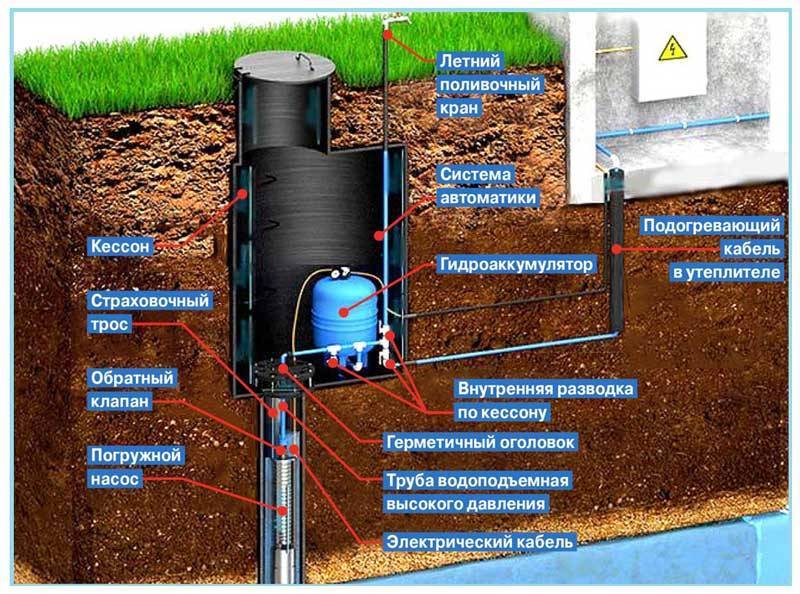

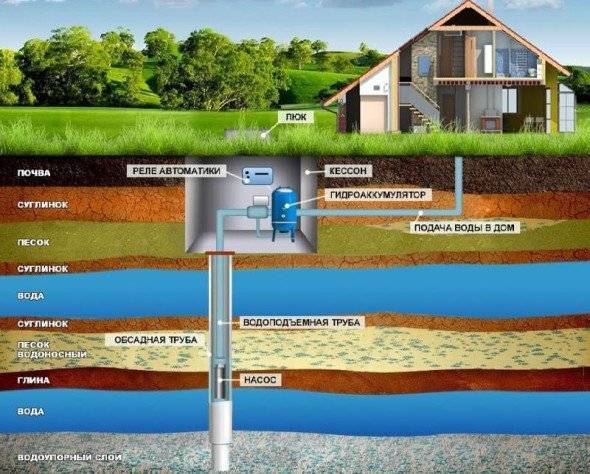

Advantages of a well with a caisson

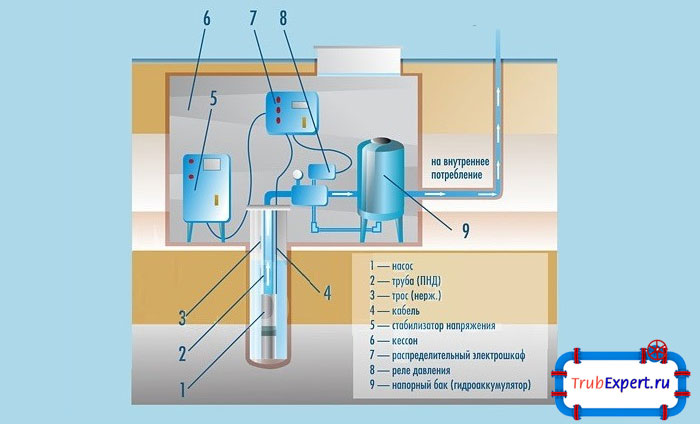

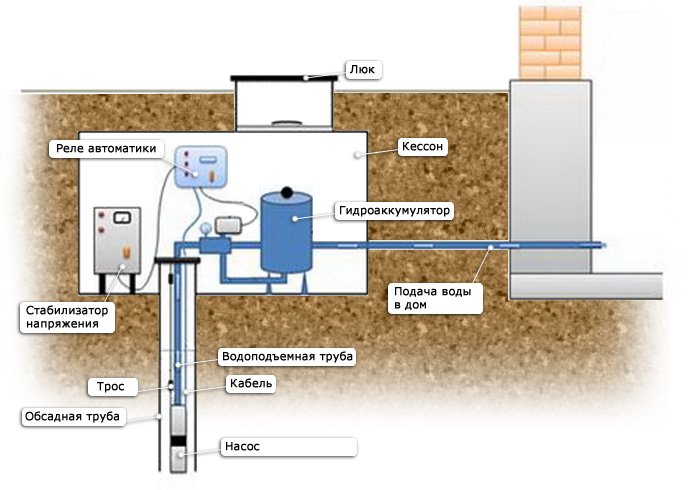

With year-round use of the well, one cannot do without installing a caisson at its mouth. This enclosing structure is a waterproof chamber located in water-saturated soil. From the point of view of ease of maintenance and operation, a well with a caisson is the best option.

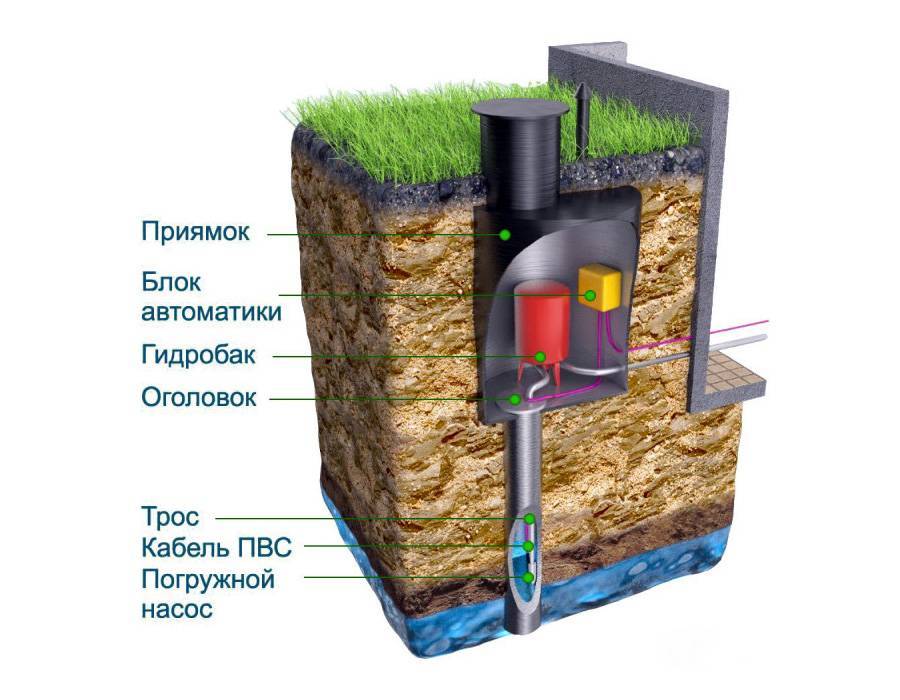

In addition to the caisson, the integral elements of a water well are a hydraulic accumulator, surface pump or submersible type, pipes, shut-off and control valves, if desired, owners and head.

In winter, a stable temperature is maintained inside the caisson. It usually does not fall below 0°C. In such conditions, pumping equipment can be operated all year round.

This solution has a number of advantages:

- All plumbing equipment is placed compactly in the chamber and there is no need to allocate a separate place for it in the house. As in the case of central water supply, only a pipe will need to be brought into the house, as well as a supply cable for the pump.

- If the house is intended exclusively for summer living, then to remove water from the water supply for the winter, you only need to open the drain valve located in the caisson.

- When it is necessary to supply input at several points on the site, then this idea is very simple to implement by removing the required number of pipelines from the caisson. The regulation of the process is carried out by means of valves.

- A winch mounted in the upper section of the chamber will simplify the process of extracting the pump from a deep well in case it needs to be repaired or replaced.

- The chamber will protect the downhole equipment located in it from freezing. If the installation of the caisson is done correctly, you can not worry about the safety of its filling even at a temperature of -35°C.

Thus, in the presence of a caisson, adverse external factors will not affect the quality of the water supply at home.

The main requirement for the caisson is tightness. If this condition is violated, dirty water from the chamber can get into the aquifer through the casing pipe. Pollution of the aquifer is unacceptable, so the head of the well and the caisson must always remain dry.

To supply water to a house and a personal plot, the best option for a caisson is plastic. It provides 100% tightness. Simplifies its delivery and installation light weight

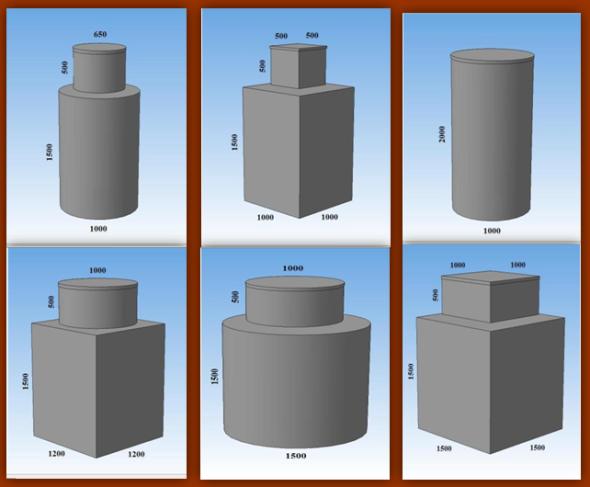

When calculating the height of this structure, one should proceed from the depth of soil freezing. In order for the caisson to be guaranteed to be below this point, the size is assumed to be two meters. For the convenience of performing work inside the caisson, the diameter of the internal space should be within 1–1.5 m.

The chamber is made of metal, plastic, brick or reinforced concrete rings.In its bottom there is a place for fixing the structure on the casing string. Branch pipes for removing pipes and cables are located in the walls. To provide convenient access to the equipment, the caisson is often equipped with a ladder. The chamber is sealed with a sealed lid.

This is interesting: How to choose a pump for a well: types of equipment, what parameters are important know when buying + video

What materials are made from

The most common caissons are round metal. For specific needs, they can be square or rectangular. Less commonly, caissons are made of plastic and reinforced concrete rings.

Metal caisson

Steel box treated on the outside with an anti-corrosion coating with a metal thickness of 3-6 mm.

Advantages

tightness

We pay special attention to the quality of workmanship and the quality of welds;

Due to the tightness, it is possible to install equipment for a well, including electrical equipment, in it;

Ease of installation (relative to concrete rings and plastic caisson);

Mechanical strength, resistance to soil pressure;

Reliable fixation in the ground. Ground loading on the body plus welding with the casing string prevents the caisson from surfacing;

Service life up to 50 years. Our technology of hermetic water drainage from the caisson, in which the metal does not come into contact with water, and internal anti-corrosion treatment allows the caisson to operate as long as possible without repair.

Our technology of hermetic water drainage from the caisson, in which the metal does not come into contact with water, and internal anti-corrosion treatment allows the caisson to operate as long as possible without repair.

Flaws

- Great weight;

- The need for welding.Our caisson can be equipped with a compression joint and sealed bends. In this case, there is no need for welding, which greatly facilitates the installation process;

- Susceptibility to corrosion. Poor anti-corrosion treatment and unskilled installation significantly reduce the life of the caisson.

Plastic caisson

Recently, the method of arranging a well with the help of a plastic caisson is gaining popularity. Let's look at its advantages and disadvantages.

Advantages

- The weight. Compared to a steel caisson or concrete rings, it is several times lighter:

- The weight of a plastic caisson is ≈ 50 to 100 kg, depending on the manufacturer;

- Weight of a metal caisson Ø1 m. ≈ 250 kg;

- The weight of 2 concrete rings with an inner diameter of Ø1 m and a total height of 1.8 m is ≈ 1200 kg.

- Does not corrode;

- The service life is more than 50 years.

Flaws

- Weak strength. Plastic under the pressure of the soil is deformed, in flooded soils, the caisson may emerge. In this regard, the installation is carried out according to a certain technology, hence the following drawback;

- Difficulty of installation:

- Installation is carried out on a reinforced concrete base with a thickness of 10 cm or more, followed by fastening to it. This is necessary to prevent the caisson from surfacing;

- Sprinkling is done with a sand-concrete mixture (cement mortar), to protect against soil pressure and maintain the shape of the caisson.

Misconceptions about plastic caisson

- Good thermal insulation. The non-freezing of water in the caisson is ensured by the heat coming from the ground, and not by thermal insulation.Undoubtedly, the thermal conductivity of metal is higher than that of plastic, only in the case of a caisson this does not matter much;

- Good waterproofing. The plastic caisson itself is airtight, but it must be connected to the casing string and pipeline, and sometimes there are difficulties with sealing these branches. As in most cases, the human factor plays an important role here. Good waterproofing directly depends on the qualifications of the installer, however, as with a steel caisson;

- Low cost.

Let's compare:

| Plastic | Steel | |

| average price | 41000 rubles | 24000 rubles |

| Excavation | For the same size, the prices are equal | |

| Installation work | • Installation in a pit • Sealing taps A plus + Before starting work, it is necessary to make a reinforced concrete base + Sprinkle with sand-concrete mixture + take into account the time required for additional work (2-3 days) | • Installation in a pit • Sealing taps |

| Total: | The total cost of equipment and installation of a plastic caisson two to three times higher than for a steel caisson. |

Caisson from reinforced concrete rings

Reinforced concrete rings for well construction are rarely used by installation organizations.

Why rarely used:

- Inconvenience of installation due to the large weight of concrete rings;

- Structural leaks. Theoretically, it is possible to perform work on waterproofing the base, rings and joints; this will require full access to the outer surface of the caisson in the finished state, which is quite labor-intensive;

- For maintenance, it is necessary to provide for the installation of a drainage pump (make a recess), in case of flooding.

A reinforced concrete caisson allows water to be drained from the well below the freezing depth, in all other respects it is inferior to the capabilities of a metal and plastic caisson.

Plastic caisson for wells RODLEX KS 2.0

The new generation model developed by the company was named RODLEX KS2. The use of the most modern technologies in the production increases the functionality and ease of use of this caisson.

RODLEX KS2

RODLEX KS2

Prices for plastic caissons

Plastic caisson

The ease of use of this model of the caisson is increased by the use of the following new elements in the design:

- located in the lower part of the loading skirt, which eliminates the need for time-consuming construction of a concrete slab under the base for cable fastening;

- increasing the strength of the structure with the help of additional stiffeners located at the bottom;

- refinement of the landing site for the use of casing pipes of all standard sizes with a cross section from 12.4 to 15.9 cm.

Tanks are made of special food-grade polyethylene LLDPE. In a material that is environmentally friendly, not only do corrosion processes not develop, but it is not even subject to decay, which leads to a long service life of products made from it, often exceeding half a century.

Step by step installation instructions

With self-assembly of the caisson "Rolex", the following sequence of actions is performed:

Step 1. Earthwork

The initial stage is characterized by significant labor costs when working manually. Under the capacity to be installed, it is necessary to dig a pit and a trench for laying a pipeline water supply system.The pit must exceed the dimensions of the caisson by 300 mm to adjust the position of the hull when entering casing pipe into sleeve. If necessary, a heater is laid in the gap.

Pit and trench for laying communications

Pit and trench for laying communications

Step 2. Arrangement of the base

Since the design provides for a special loading skirt, there is no need for an expensive construction of a concrete slab for anchoring the product using cables. To make a base for installing a container, it is enough to pour a 200 mm layer of sifted sand onto the bottom of the pit. To compact the backfill, the sand cushion is abundantly wetted with water.

Foundation arrangement

Step 3. Laying and insulation of the water supply network

At this stage, pipes are laid in the trench dug from the well to the residential building, through which water will be supplied. To prevent freezing of the liquid at negative ambient temperatures, the pipeline network is carefully insulated.

Laying of water pipes

Laying of water pipes

Prices for water pipes

Water pipes

Step 4. Connecting the casing

The casing pipe is carefully inserted into the bottom of the caisson, while making sure that the tank body takes a strictly vertical position. To prevent moisture seepage, the connection is carefully sealed with an adhesive that fixes PVC products.

Installation of the lower part of the structure

Installation of the lower part of the structure

Step 4. Connecting the water supply network and power cable

Pipes for supplying water from an underground source are inserted into the tank body through the holes provided for this purpose to the point of connection to the house water distribution. Electrical cable is being laid pumping station and other equipment, which ensures the functioning of the autonomous water supply system.

Connecting the water supply network and power cable

Step 5 Backfill

Backfilling of the installed caisson with sifted sand is carried out sequentially in layers of 300 mm thick.

Pit filled with sand

Pit filled with sand

At the final stage, the site is concreted around the neck of the caisson. After complete curing of the solution, the neck is closed with a hatch.

manhole container

manhole container

For security reasons and to prevent acts of vandalism, eyelets should be attached to the cover and a reliable lock should be hung, especially in seasonal residences, such as summer cottages.

How to choose the right plastic caisson

So, having described the properties of different materials, we gradually came to understand what a good caisson should be. The main selection criteria are strength, low thermal conductivity and tightness. Optimal properties can be achieved not only due to materials, but also due to the design of the product.

In order for the temperature regime to be established inside without drops, it is necessary that the vessel be completely sealed. The first place through which intensive heat exchange will pass is the manhole cover, so it is better to purchase a caisson with a tight-fitting lid, and additional thermal insulation of this unit will not be superfluous. Some models of caissons are equipped with a double drop door, the first of which is installed at the zero level, and the second one rises 30 cm above the ground. Such systems are additionally equipped with ventilation systems.

Compact and neat

Compact and neat

Another important point is the size of the caisson, which is determined by the volume occupied by the pumping equipment. Keep in mind that it should be convenient for you to go down and carry out repairs in which case.

Otherwise, the models will differ only functionally: different locking systems (folding, screw, etc.), the presence of a ladder.

The device of a concrete caisson structure

A concrete caisson is made by making formwork and pouring concrete. The sequence of actions is as follows:

- First, formwork is constructed from boards, plywood or chipboard. To facilitate its removal, the surface is treated with mining or other oily composition. The configuration of the structure and dimensions are selected depending on the size and quantity of equipment. At the same time, it is necessary to leave a margin of free space 10-20 cm wide around the perimeter of the chamber for insulating backfill.

- To ensure the rigidity of the structure, reinforcement is installed in the formwork before pouring concrete.

- Concrete is poured into the formwork in one pass. This will ensure good adhesion, integrity and durability of the structure.

- During the week, while the concrete is solidifying, the surface of the chamber must be moistened and protected from precipitation and sunlight, covered with a film. After that, the formwork can be removed.

- When the walls of the structure gain full strength (after 28 days), you can fill the roof.

To perform a monolithic reinforced concrete floor with a hatch (roof), do the following:

An example of a reinforced concrete caisson from prefabricated rings

- Above the walls, the lower supporting surface of the formwork is installed. At the same time, it should provide holes for a manhole hatch and a ventilation pipe.They can be made using metal pipe sections 20-25 cm high. Formwork is laid on bars attached to the inside of the walls. At the same time, it is necessary to indent down the thickness of the formwork boards, this will allow the poured slab to lie directly on the walls of the structure.

- Formwork along the perimeter is carried out using boards 20-25 cm high. The boards are fastened together in the corners and attached to the outer surface of the walls.

- Waterproofing is spread on top of the formwork boards with an overlap on the side walls. It will protect against the flow of the solution and ensure the smoothness of the surface. To protect the waterproofing from sticking to concrete, its surface is lubricated with oil or mining.

- When the formwork is ready, reinforcement is performed. For this, two layers of reinforcing mesh are used from a bar with a diameter of 5-8 mm with a mesh size of 10x10 or 15x15 cm. There should be a distance of 5-7 cm between the two layers of reinforcement. To maintain this gap, reinforcing bars 10-15 cm long are used.

- Filling is performed at a time.

- Then the surface of the plate is covered with a film and wetted three times a day for a week. All this time, the monolithic slab must be protected from sunlight, rain and debris.

When concrete work is completed, waterproofing material is laid on the outer surface of the walls and roof. When laying, the adjacent strips are overlapped by 7-12 cm. Then the gaps between the walls of the structure and the soil are backfilled. Thanks to the backfill, the waterproofing will firmly press against the walls of the chamber, so additional fastening is not needed.

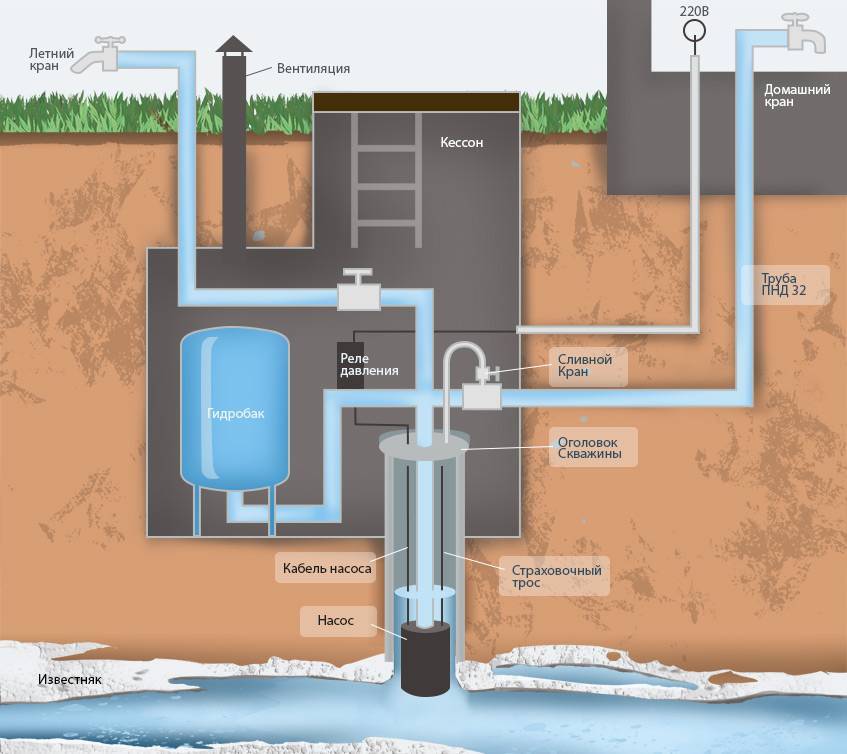

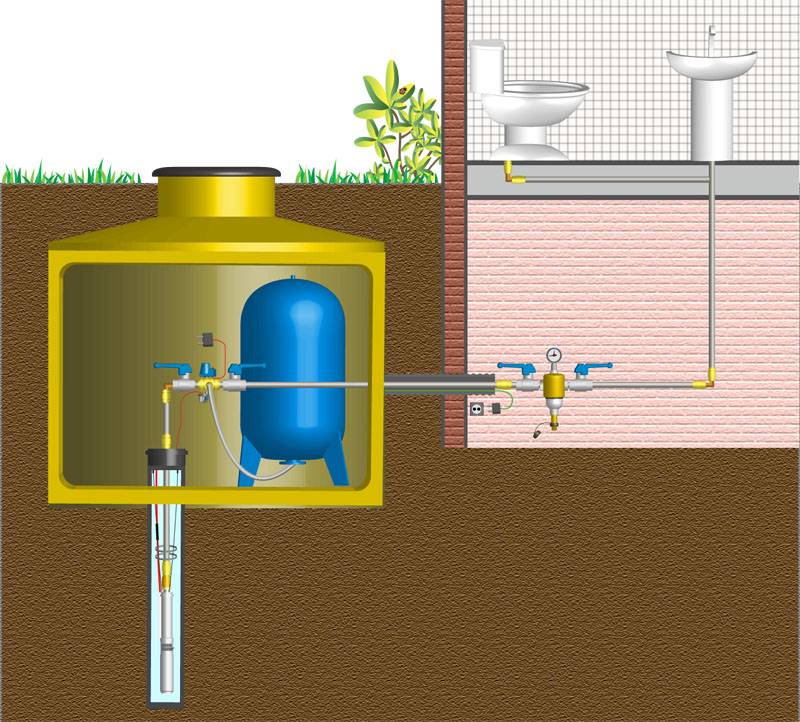

What is a caisson

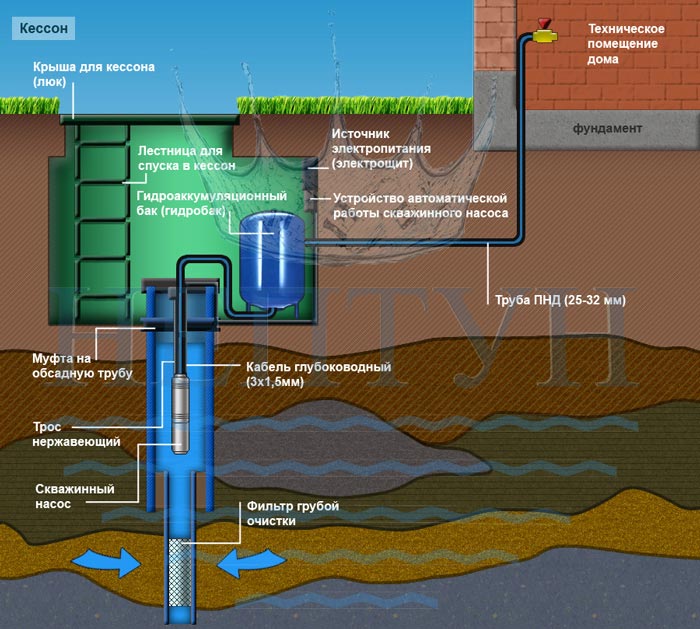

In order for an autonomous water supply system to please with its reliable, trouble-free operation, when arranging it, it is necessary to think over not only technical points, but also issues related to the installation and protection of equipment from external factors. Despite the fact that underground water aquifers lie at considerable depths, equipment for uninterrupted water supply is installed on the surface. Of course, if the water intake takes place near the house, then it is possible to install a hydraulic accumulator and automation in the basement of the building. If the well is located at a considerable distance, then it is necessary to protect the pipes, wellhead and pumping equipment from moisture and low temperatures.

The caisson is an integral part of the autonomous water supply system of a suburban area

In order to prevent the harmful effects of precipitation and frost on the devices of the autonomous water supply system, a caisson is installed above the well. In fact, it is a large insulated reservoir, equipped at a sufficient depth. Thanks to the insulation of the walls and the lid of the tank, all the equipment installed in it can function all year round. The advantages of this structure include not only the possibility of installing and protecting a hydraulic accumulator and automation devices, but also providing convenient access for their maintenance and repair.

Types of caissons

Standard dimensions of caissons of various types

Caissons can be metal, concrete (reinforced concrete) or brick. Very convenient to install and operate are plastic containers that have appeared in the distribution network in recent years. In form, all protective structures can be divided into several types:

- round pits - most often made of concrete rings or plastic;

- square caissons - welded from metal sheets, brick, concrete or plastic tanks;

- rectangular tanks - made mainly from the same materials as square products, but are used in case of installation of additional equipment - expansion tanks, filters, etc.

Metal caissons are at the top of the rating of devices of this type. Most often, structural or stainless steel, as well as aluminum-based alloys, are used for their manufacture. Due to its strength, the metal perfectly resists mechanical stress, and its flexibility allows it to resist the appearance of cracks. For the manufacture of metal caissons, rolled steel with a thickness of at least 3 mm is used. After welding, the caisson is painted inside, and an anti-corrosion coating is applied on the outside. This allows the containers to serve for decades, justifying the rather high cost of manufacture.

Plastic caisson has many advantages over other designs

Plastic containers have the highest performance, excellent hydro and thermal insulation, low weight and long service life. Their cost is lower than metal and reinforced concrete counterparts. If you look for an option suitable for making your own hands, then there is nothing simpler and cheaper than a caisson built of brick or concrete.

The device and features of pits for wells

The caisson, first of all, must provide positive temperatures inside, so the tank is made airtight, and it is insulated by installation in the lower, non-freezing layers of the soil.Since the head necessary for access to pumping equipment is brought to the surface, the caisson is equipped with a heat-insulated hinged lid or a removable hatch. Often the drain door is a double structure - one head cover is equipped at ground level, and the second is about 20 - 30 cm higher. In addition, the design is equipped with ventilation, outlets (the so-called sleeves, nipples or barrels) are provided for the neck of the well, water supply and input of the supply cable. Often, an outlet with a ball valve is installed next to the lid - a kind of water column. This design allows the selection of water for irrigation and household needs in the summer.

Schematic representation of a caisson for a well

When constructing a caisson, the size of the pressure tank and the installed equipment must be taken into account. Depending on this, the casing pipe entry is shifted away from the center of the tank to provide convenient access for servicing the water supply system. All barrels are oriented in the right direction at the installation stage and carefully sealed to prevent groundwater from entering the structure.

Concrete caisson for a well

We take the dimensions of the device the same - a depth of 2 m with a dimension of 2.5 m. To cast a caisson from concrete, you will need tools:

Table: tools for casting a caisson

| Name | Purpose | Notes |

| Shovel shovel | Preparing the concrete mix and mixing the solution | |

| Capacity | Solution preparation | |

| Concrete mixer | Solution preparation | Rent possible |

| carpentry tool | Formwork installation | |

| Pliers and side cutters | For working with knitting wire for reinforcement | |

| Deep vibrator | Sealing the solution during pouring | Rent possible |

You will also need a tool to apply waterproofing to the outside of the molded body.

Materials for the caisson

We calculate the volume of concrete that will be needed to cast a solid body of the caisson. Sufficient wall thickness will be 20 centimeters. Concrete grade 200 is used. The wall area is 2.7x2 + 2.5x2 = 10.4 m2, the volume at a height of 1.8 meters will be: 10.4 x 1.8 x 0.2 = 3.74 m3.

For the manufacture of high formwork, it is better to use sheet materials: waterproof plywood or metal sheet. The area of the high formwork is 2.7 x 4 x 1.8 = 19.44 m2 on the outer wall and 2.5 x 4 x 1.8 = 18 m2 on the inner wall. The total area is 37.4 m2. Based on this, you need to purchase materials, given their cutability.

To assemble the formwork, you will also need wooden bars 50x50 millimeters in the amount of 12 pieces. The length of each rack is 2 meters, that is, you need 3 six-meter bars. The jibs and spacers can be made from improvised material.

The procedure for preparing for pouring a concrete hull is the same as described above.

Step-by-step instructions for casting a concrete caisson hull

For manufacturing, you need to perform a series of sequential operations:

- Make the base plate as described above. After seven days, you can remove the formwork and proceed to further work.

- Install the formwork for the walls, while mounting the reinforcing mesh.

A metal mesh is laid inside the formwork to form a reinforcing frame

- Pouring concrete into vertical formwork.As it is poured, it is imperative to process the mass with a deep vibrator so that there are no voids and air bubbles.

- Formwork can be removed seven days after pouring.

The concrete mixture hardens within seven days, after which it is possible to continue work on the arrangement of a concrete caisson

- Waterproof the outer surface of the walls with bituminous mastic.

- Backfill with expanded clay.

- Install the top slab using roofing felt waterproofing.

- Mount the cover.

In the process of pouring, you need to install embedded parts to exit water distribution pipes and power cable.

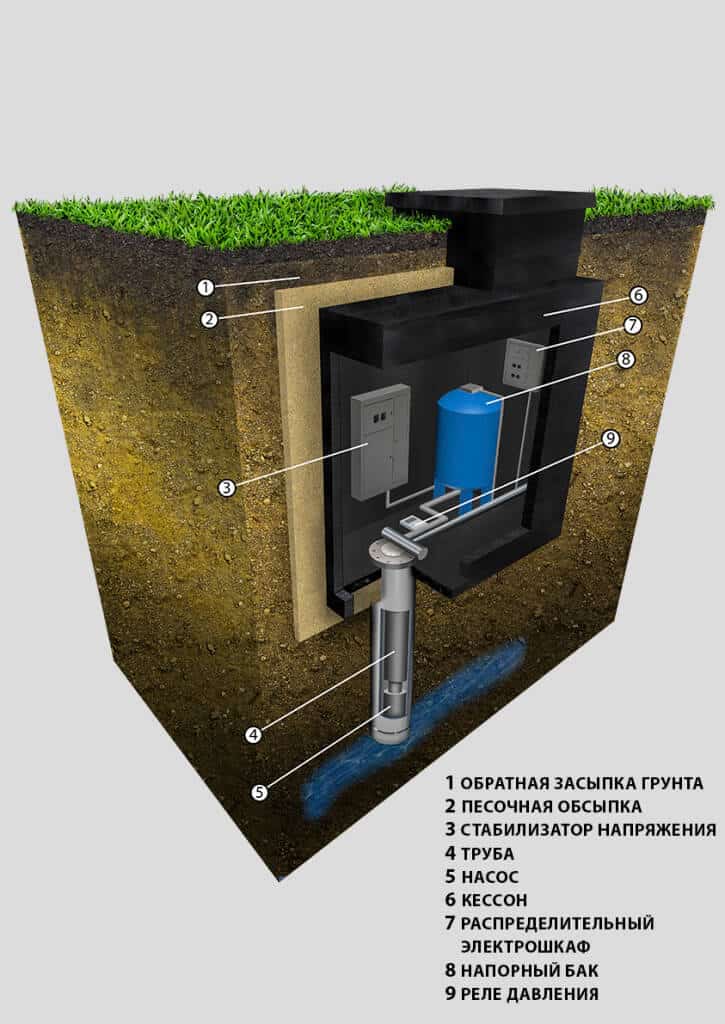

How to make a caisson yourself

To do it yourself, first you need to decide on the material, system parameters.

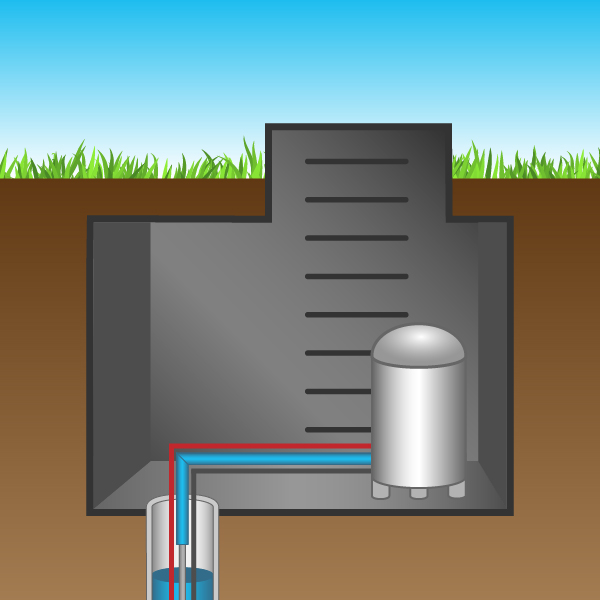

Monolithic concrete structure

A square shape is suitable for the device, it is also much easier to build formwork.

First you need to decide on the size of the pit, which is dug under the structure. The length and width are standardly equal, so they can be calculated as follows: measure the size of the caisson from the inside, add the thickness of 2 walls (10 cm).

It is also necessary to calculate the depth of the pit, which should be 300-400 cm more than the height of the chamber. If everything is calculated, then the drainage layer can be installed at the bottom of the pit.

If further concreting of the base of the structure is not planned, then the following procedure is chosen

But when it is necessary to fill the bottom with concrete, the height must be taken into account. In addition, the pit should be such that the surface of the cover of the structure is flush with the soil.In order to have more space for a person when repairing the system, it is best to place the camera not in the middle in relation to the casing, but on the side

And the equipment will be conveniently placed

In order to have more space for a person when repairing the system, it is best to place the camera not in the middle in relation to the casing, but on the side. And the equipment will be conveniently placed.

Construction of a monolithic concrete caisson.

The work is carried out as follows:

- Start by digging a hole. At this point, you can immediately dig a trench for water pipes to the house. Then they begin to install drainage, which consists of 2 layers: sand (up to 10 cm high) and crushed stone (up to 15 cm). With such drainage, even if water gets inside the caisson, it will not stay inside, but will quickly go into the soil.

- After you need to equip the formwork. Often the wall of the pit is used as the outer layer of the formwork. The side of the pit must be covered with polyethylene to avoid seepage of water from the concrete into the soil. After you need to make a frame using reinforcement.

- Mix concrete solution. Pour it in small parts, compacting well with an electric vibrator. If there is no device, then you can use a pin, a thin pipe and weld the handles. This device is quickly lowered into the concrete, and then slowly pulled out to get rid of air and water bubbles, thereby making the concrete denser.

- After that, it is necessary to dry the structures, regularly spraying the surface with water so that the concrete does not crack. If it's hot, you can cover it with a damp cloth.

- After a week, the formwork can be removed. And in 4 weeks to install the equipment.

Caisson from concrete rings

The borehole system of concrete rings provides for the following:

- First, the pit is prepared. The calculations are the same as in the previous manufacturing method.

- Fill the bottom with concrete and drill a hole for the pipe.

- They take concrete rings, which are pre-coated with a special waterproofing compound. Let dry.

- After each ring is lowered into the pit, while connecting the joints with a mixture for bonding. The seams are foamy.

- There may be voids around the structure that need to be filled.

From concrete rings caisson for a well.

Budget camera made of bricks

Brick caisson device:

- First, a foundation pit is dug out, a strip foundation and a trench are installed at the bottom, which are covered with sand and rammed.

- It is necessary to lay waterproofing on the foundation (for example, roofing material).

- Brick laying starts from the corner, be sure to fill the seams with a special solution.

- After bringing the masonry to the desired height, let it dry, plaster.

Sealed metal container

The process is like this:

- Dig a hole again, suitable for the size and shape of the chamber.

- A hole for the casing pipe is cut out at the bottom.

- Install the cover, clean the seams of slag. The seams must be double-sided to ensure the tightness of the caisson.

- The structure must be treated with a protective layer.

If necessary, the chamber can be insulated, after which the caisson can be lowered into the pit and a column, sleeves, and cable can be installed. The sleeve is welded, everyone falls asleep.

Conclusions and useful video on the topic

Arrangement of a well with a concrete caisson:

A visual aid for the installation of the caisson and equipment for the well:

Making a well with your own hands is a responsible and time-consuming process. It is possible to perform the work competently only if you have certain knowledge and skills.But nothing is impossible, the key to success is the right approach and careful preparation.

It is necessary to adopt a key rule: there are no secondary nodes in the well device. If at some point is problematic for you, entrust the solution of the issue to specialists so that later you do not have to equip a new well.

Tell us about how you built a caisson over the wellhead in a suburban area with your own hands. Share technological nuances that will be useful to site visitors. Please leave comments in the block below, ask questions, post photos on the topic of the article.