- Features of homemade filters

- Disadvantages of homemade drinking water filters

- What is a septic tank for?

- Staged production of the Cyclone

- Without cone

- with cone

- Simple Cyclone

- Tips

- Three-flask design for a full plumbing

- Making filters for a well with your own hands

- Features of homemade filters

- Perforated perforated filters

- Necessary tools and materials

- Manufacturing

- Necessary tools and materials

- Manufacturing

- Do-it-yourself filter for water purification in the pool

- How a well filter works

- Device and design

Features of homemade filters

At first glance, tap water appears clean. In fact, it contains a lot of dissolved compounds. The water filter is designed to “retain” these substances: chlorine compounds, iron compounds, etc. Their excess can lead to the development of various diseases, as well as affect the general condition of the body.

What about well water? Many believe that it does not require cleaning, and they will be wrong. It may contain nitrates, a large number of bacteria, pesticides (seep through the treated soil). Also, the design of the well may be subject to corrosion. All this affects the taste and useful qualities of water.

It is not necessary to buy expensive store devices - homemade filter for water is capable of good purification.

Of course, if you want crystal clear water, it's better to get a modern system after some time. This is due not so much to the wear of parts, but to a lower absorbent and cleaning ability in relation to bacteria.

Water pressure also plays a huge role in cleaning. Improper pressure intensity in relation to the filter system reduces performance.

It is not recommended to make a flow-type water filter with your own hands, as it is unprofitable - a ready-made stationary system is more profitable.

Disadvantages of homemade drinking water filters

All this is wonderful, but one cannot fail to mention the shortcomings of self-made filters. And they are quite significant, and they must be remembered when using water for drinking after it has been purified.

- Homemade filter structures are not able to trap serious pollution and contamination. This factor is especially relevant to the purification of water from open reservoirs. The pores of the filter media can retain only a part of the existing contaminants. However, in camping or extreme conditions, when it is necessary to get clean water, such filters become indispensable helpers.

- The traditional problem of any water filters, both homemade and factory-made products, is cartridge contamination. With each water treatment, the concentration of harmful microorganisms and chemicals increases. Due to the fact that self-cleaning is not provided for in such water filters, the materials that make up the backfill must be changed quite often.No other solutions for high-quality filter cleaning have yet been found.

- When tap water passes through the filter, together with polluting substances, absorbent materials also retain minerals useful for humans, that is, they demineralize water to a certain extent. Not everyone likes the taste of such water.

What is a septic tank for?

Even a well-made well filter will not be able to protect against the ingress of small particles. Let even a small amount, but still get into the well. It's unavoidable. In such cases, a special place in which these particles can accumulate will help. This will speed up the process of filling the well. It's about the cesspool.

Scheme of a well with a sump

In addition to better water purification, the sump prevents small particles from entering the pump. Otherwise, the pump will quickly fail, and this is an additional cost and time spent. The sump is made extremely simple: a special space with a blank bottom remains under the filter. Unfiltered particles accumulate in it during pumping out water.

Staged production of the Cyclone

Consider different options for making a Cyclone for a vacuum cleaner with your own hands from sewer pipes and how to make such a device according to step-by-step instructions with drawings and photo examples.

Without cone

For the construction of a bucket and sewer pipes you will need:

- oil filter;

- plastic bucket;

- sewer PVC elbows at 45° and 90°.

- pipe with a cross section of 40 mm and a length of 1 m;

- corrugated pipe 2 m long and 40 mm in diameter.

The design process is:

- We cut a hole in the center of the bucket lid so that a 90 ° angled plastic pipe enters it, to which the vacuum cleaner will be connected.

- Seal the gaps with sealant.

- We cut another hole in the side of the bucket and insert a 45 ° elbow.

- We use corrugation as a connecting element with a knee.

- We join the filter outlet with the knee in the bucket lid.

with cone

To make such a device, you need to prepare:

- traffic cone;

- round wooden sticks;

- large capacity;

- plastic elbows with a diameter of 50 mm at 45° and 90°;

- a piece of PVC pipe 50 mm;

- corrugated pipe;

- thick plywood;

- fixture.

We make the filter in this way:

- From plywood we cut out a platform for a cone in the form of a square measuring 40 * 40 cm and a circle equal to the inner diameter of the cone.

- We fasten the two parts together with self-tapping screws or glue and drill a hole in the center for a 50 mm PVC pipe.

- We make a platform of 40x40 cm from plywood and make a hole in the center, the diameter of which should correspond to the diameter of the top of the cone.

- We fix four round sticks to the platform from item 3 and firmly insert the cone.

- On the side, near the base of the cone, we make a hole with a diameter of 50 mm and insert a pipe into it, smearing the seam with sealant.

- We apply the platform from clause 2 to the vertical posts and fasten the part to the screws. Using wooden holders, we fix the pipe that enters the lower part of the cone, after which we insert another pipe and an elbow into the hole in the center.

- We install the cone on top of the garbage container, connect the vacuum cleaner pipe and the garbage suction pipe, and check the device’s performance.

Simple Cyclone

If you need a vacuum cleaner to clean the workplace after working with a CNC router or similar equipment, you can assemble a simple and compact Cyclone from PVC sewer pipes and plastic bottles.

For assembly you will need:

- 2 corrugated hoses to the vacuum cleaner;

- PVC pipes with a diameter of 40 and 100 mm;

- sheet of metal 0.2-0.5 mm thick;

- 2 plastic bottles for 2.5 liters and one for 5 liters;

- metal scissors;

- electric drill with drills;

- riveter;

- hot glue gun.

We make the filter in this way:

- From a pipe with a cross section of 100 mm we cut off an even piece 50 cm long, which will serve as the body of the device.

- We cut off two pieces of a 40 mm pipe 40 and 15 cm long, after which we draw 3 circles with the inner diameter of the body on a sheet of metal. In the center of these circles we draw more circles with a diameter of a smaller pipe.

- We cut out the metal parts with scissors, then cut them to the middle and cut out the inner circles. Then, using rivets, we connect all the elements together in the form of a spiral, which we put on a 40 mm pipe, evenly distribute the turns and fix them with hot glue.

- We place the spiral in a large pipe and leave a little protrusion outward.

- In the upper part of the body we make a hole for the suction pipe, clean off the burrs for a snug fit.

- We place the pipe in the hole, sealing the junction with hot glue.

- From a 5 liter bottle, cut off the upper part, from which we remove the neck. The resulting hole is adjusted to a 40 mm pipe, after which we put the part on the body and glue it with hot glue.

- We cut off most of the 2.5 l container and put it on the bottom of the case with obligatory gluing.

- We make a connecting element from two plugs, drilling out the middle. We strengthen the bottle that will be used for garbage with welding electrodes. To do this, glue them around the bottle with adhesive tape.We screw the container into place and connect the suction and outlet hoses.

Too thin corrugated tubes should not be used, because during operation they will emit a strong whistle.

You can learn more about making a homemade Cyclone from the video.

Tips

In order for a home-made cleaning system to turn out the first time, it is necessary to take into account some important points:

- The cleaning properties of the filter depend on a correctly formed filling.

The volume of the container should be such that the components in it are located freely and allow water to flow down.

- From a hygiene point of view, natural fabrics are not practical. In a humid environment, they quickly rot, promote the appearance of germs and an unpleasant odor.

As a result, the bottom layer has to be changed frequently. Instead of gauze, it is better to use lutrasil or any other synthetic material.

- Charcoal is recommended to be replaced with activated charcoal. The latter absorbs toxic substances, heavy metals and kills some pathogenic microorganisms.

- If purified water is in doubt, it should be boiled.

- Drinking regularly river water passed through a homemade filter is not recommended.

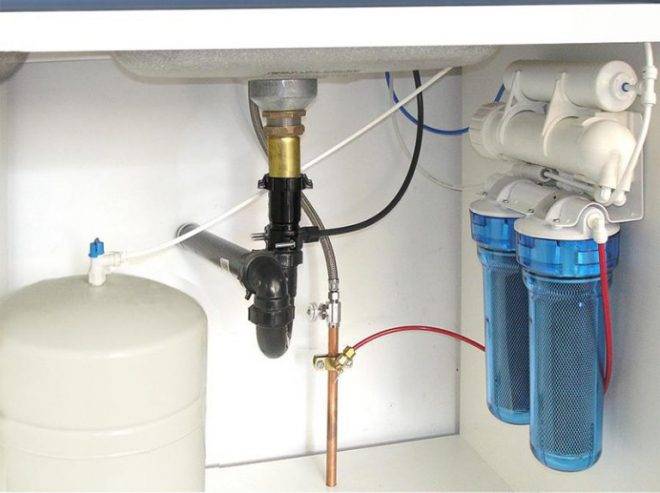

Three-flask design for a full plumbing

Happy owners of a full-fledged water supply in a private house can make a three-flask home-made filter for water purification. For this you need:

- Buy three identical flasks.

- Connect the flasks in series with two quarter-inch nipples. In this case, it is necessary to strictly adhere to the in / out designations in order to observe the direction of water movement. The threads of the nipples should be sealed with FUM tape.

- The end holes of the flasks are connected to the quarter-inch tube with straight adapters.

- Connect the filtration system to the water supply with a tee that is cut into the water supply using a 1/2” connector.

- At the outlet, a standard tap for drinking water is connected to the filter system.

- Fill the flasks with filter material. You can use a polypropylene cartridge, a carbon filter and an anti-scale filler.

Filter cartridges are very diverse and allow you to eliminate a wide variety of water contaminants. It is worth noting that the cost of such a do-it-yourself design may not be much lower than an inexpensive filtration unit from the manufacturer.

Making filters for a well with your own hands

The size of the holes depends on the characteristics of the soil.

The most common cleaning device used by summer residents and owners of private houses is a perforated perforated system. By design, it is a pipe with perforations (holes). The device is very simple, but quite effective. For manufacturing as consumables, you will need a metal or plastic pipe with a length of approximately 4.5-5 m.

When using metal pipes, geological or oil country mix can be used. Using drills, perforate a piece of pipe.

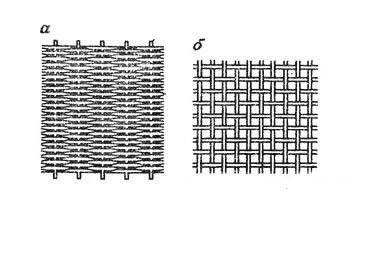

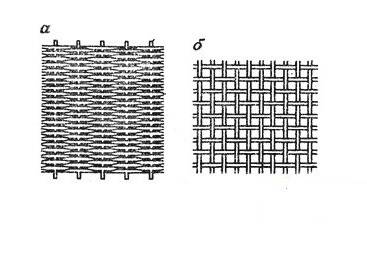

Making a perforated filter with your own hands is carried out according to the following technology. The length of the sump is measured, which should be from 1 to 1.5 m. The length will depend on the depth of the well. Markings are applied to the surface of the pipe, taking into account that the perforated section is at least 25% of the length of the entire pipe, and the required length is determined.The length of the pipe also depends on the depth of the well and can be 5 m. Stepping back from the edge of the pipe, holes are drilled. The pitch of the holes is 1-2 cm, the accepted arrangement is in a checkerboard pattern. It is recommended to drill holes not at a right angle, but at an angle of 30-60 degrees with direction from bottom to top. Upon completion of work, the perforated surface of the pipe is cleaned from sharp protrusions. The inside of the pipe is cleaned of chips and closed with a wooden plug. The perforated zone is wrapped with a finely woven mesh made of brass, and preferably stainless steel. The mesh is fastened with rivets. The use of a mesh avoids the rapid clogging of the filter openings.

Types of nets for the filter: a - Galloon weaving; b - Square.

Large throughput is provided by the slotted design of the filters. The area of the filter slit exceeds the area of the hole by about 100 times. There are no so-called dead zones on the filter surface.

To make a slotted filter with your own hands, instead of a drill, you will need a milling tool. Depending on how the holes are made, a cutting torch may be required. The width of the slots is in the range of 2.5-5 mm, and the length is 20-75 mm, the location of the holes is in the belt and checkerboard pattern. A metal mesh is applied over the holes.

The weave of the mesh is chosen galloon, the material is brass. The choice of the size of the mesh holes is carried out empirically by sifting the sand. The most suitable mesh size is the one in which half of the sand is passed during sifting. For especially fine sand, a mesh that passes 70% is a suitable option, for coarse sand - 25%.

The size of sand particles determines its composition:

- coarse sand - particles 0.5-1 mm;

- medium sand - particles 0.25-0.5 mm;

- fine sand - particles 0.1-0.25 mm.

Before applying the mesh to the perforated surface, stainless steel wire is wound with a pitch of 10-25 mm. The wire diameter should be 3 mm. Structural strength is ensured by point soldering of wire sections along the length of the winding, approximately every 0.5 m. After winding the wire, a mesh is applied and pulled together with wire. The wire pitch during tightening is 50-100 mm. The mesh for fixing can be soldered or twisted with steel wire.

The wire cleaning device for the well is distinguished by the complexity of its design. To make such a filter with your own hands, you need to use a wire of a special section shape. The throughput of the system largely depends on the winding pitch of the wire and the shape of its cross section.

The winding technology is as follows. The slot design of the cleaning system is being prepared. The size of the holes depends on the size of the natural particles. Before proceeding with the winding of the wire, 10-12 rods with a diameter of at least 5 mm are superimposed on the frame.

The simplest filter device has a gravel structure. Such a system is built in soils with clay and fine sands. The filter construction process begins with the preparation of the well, the diameter of the well should be with a margin for gravel filling. Gravel is selected with a one-size fraction and is poured from the wellhead into the well. The thickness of the coating must be at least 50 mm. The particle size of the gravel is chosen relative to the particle size of the rock.Gravel particles should be 5-10 times smaller.

Features of homemade filters

After some time, you will have to replace such a system with a more professional one. This is due not only to the wear of old parts, but because of their low absorbent and cleaning efficiency in relation to microorganisms contained in water.

To ensure the sterility of the reservoir, modern filters are equipped with a mineralizing system. Before buying equipment, it is worth checking the water in the laboratory for mineral content and then, based on the results of the examination, select a filter with the appropriate mineral composition.

There is no such function in homemade equipment, therefore, after the cleaning stage, it is recommended to boil the filtrate.

Also compare the power of the filter with the pressure of the water. Incorrect calculation of the intensity of water pressure in relation to a home-made filtration system can affect the performance of the equipment.

Perforated perforated filters

The most common well water treatment system is perforated. It is an ordinary perforated pipe covered with a mesh, so the manufacture of a filter for do-it-yourself wells is nothing complicated. In addition, this device has excellent performance properties.

Therefore, if you are going to make a filter for a well with your own hands, then you can stop at this design. The main advantage of this system is its low cost. You can use this design in different rocks, most often it is used in artesian wells, which have an unstable aquifer and a small pressure.

The design consists of several parts:

- The filter itself

- above-filter section;

- A sump in which large soil particles accumulate (located at the very bottom of the trunk).

Now let's take a closer look at the manufacturing process of the structure.

plastic filter

Necessary tools and materials

To make the device you will need:

Steel pipe of the required diameter

You can also use a plastic pipe, but you need to pay attention that it is made of a material that can be used for food purposes.

You will also need drills of the required diameter. The size of the holes is selected in accordance with the granulometric composition of the soil.

Electric drill.

Mesh for the filter.

Mesh weaving options

Manufacturing

Manufacturing instructions device looks like this:

- First of all, the length of the sump is measured.

- Then the pipe is laid on a flat horizontal surface, after which markings are applied to it. It should be taken into account that the perforated section, according to the technology, should be about 25 percent of the total length.

- The next step is to make holes. From the edge should retreat at least a meter. The interval between the holes should be 1-2 cm. It is advisable to drill them at an angle of 30-60 degrees from the bottom up.

- After finishing work, it is necessary to clean all sharp edges and carefully tap the product so that there are no metal chips left in it.

- It is desirable to close the lower part of the pipe with a wooden plug.

- To protect the holes from clogging, the pipe is wrapped in a mesh for the well filter.

Slotted plastic filters

Slit filters

Slot-type filters are usually used in rocks that are prone to collapse. Their design is preferred in that it has a greater throughput. There are no "blind" zones on the surface of such a product, and the area of the slot is much larger than the area of the hole.

The main disadvantage of the design is the lower bending strength; areas without perforation.

Necessary tools and materials

For the manufacture of the device, you will need a pipe, the same as in the first case, as well as:

- Gas cutter;

- Wire with a diameter of 3 mm;

- Grid.

Manufacturing

Such do-it-yourself filters for a well are made according to the same principle as perforated ones. The cuts can be made in a checkerboard or belt order. The width of the slots is determined depending on the composition of the rock.

As in the first case, a metal mesh must be used over the pipe. As practice shows, the best option is a brass mesh of galloon weaving.

Before applying the mesh to the pipe, it is necessary to spirally wind stainless steel wire around it with a pitch of about 20 mm. Every half a meter, along the length of the pipe, the wire must be soldered to ensure maximum structural rigidity.

In the photo - a finished filter with a fine mesh made of plastic pipe

Such a homemade well filter is durable and has excellent throughput. At the same time, the cost of its manufacture will be significantly lower than the price of the finished product.

Do-it-yourself filter for water purification in the pool

If you have a pool in the yard of a private house or in the country, you have probably already encountered the problem of water purification in it.To solve this issue without spending huge amounts of money, you can make a filter with your own hands.

Surface contamination (for example, leaves that have fallen into the pool) can be removed mechanically (in other words, caught with a net). If you did not have time to do this, or soluble contaminants got into the water, everything goes into the water column. And here contains a lot of microorganisms and protozoa. If the water warms up well and receives enough light, it will “bloom” very quickly - it will turn green. As the temperature drops, or when the useful substances for algae run out, the algae sink to the bottom. This is how bottom pollution is formed. Insoluble debris that is heavier than water (sand, dust) can also get here.

Adding chemicals does not solve the problem of water purification in the pool. After all, different cleaning methods are used for each type of pollution. If surface pollution is removed with a net, then bottom pollution is removed using a special water “vacuum cleaner”. Contaminants that are in the water column can only be removed by filtration.

To remove contaminants in the water column, it is pumped through special filters using pumps, arranging a water intake in one place of the pool. After pumping through the filter elements, the water is returned to the pool. If the pool is located indoors (for example, in a sauna) and is operated all year round, you can buy a ready-made filter unit, which costs about 2,000 rubles. But if we are talking about an inflatable pool that is in the yard only 2-3 months a year, it is not economically profitable to buy a filter.People solve problems in different ways. Some often change the water, others calmly look at the green water, others think about how to make a water filter with their own hands.

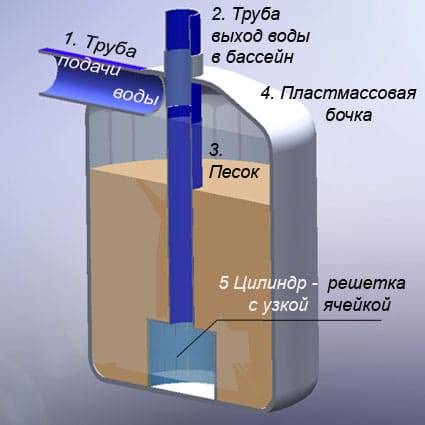

For the pool, you can make a sand filter. How it looks is clearly shown in the figure.

The simplest sand filter is an effective water purification device.

It is made from a replaceable water purification cartridge with an internal diameter of 50 mm. You will also need 2 m of a polypropylene pipe and one corner (turn) for it. The diameter of the pipe and turn is 50 mm, such pipes are used in sewers. The pipe may be shorter if you have a small pool. You will also need a small piece of threaded stud - M10 or longer. By the way, several cartridges can be mounted on a long hairpin, which will significantly increase the power of a floating filter installation if a good pump is connected to it.

First, drill a hole for the stud in the filter plug and turn it for the pipe. Pass it through the turn and the filter, fix it with a nut. Attach an aquarium pump to the other side of the pipe (productivity - 2000 l / h, power - 20 W). Perfect for a small pool.

Put pieces of dense polystyrene foam (styrofoam) on the ends of the pipe to ensure the buoyancy of the filter. The pump sucks water from a depth of half a meter, the water is pumped through the pipe and enters the cartridge, where it is immediately cleaned and goes back into the pool.

It may seem to you that such a homemade filter has low performance, but if you are not too lazy to design and run it, you will soon notice that the quality of the water in the pool has improved significantly.The advantage of the design is that it does not require any hoses or other connection systems to the water intake and outlet of the pool.

The cartridge can be washed. Taking it off is very easy. But so that dirty water from the filter does not get back into the pool, you need to put a plastic bucket under the filter before removing it, which is removed along with the filter when it is removed. Dirty water must be poured out and the filter washed.

The cost of such a homemade filter for purifying water in the pool is several times less than the finished one, and manufacturing and installation will take no more than an hour. Aquarium pumps can be bought at pet stores, pipes in plumbing departments, filter cartridges in any supermarket. In the design of such a filter, you can also show imagination, because a plastic pipe with foam at the ends does not add beauty to your pool. If you design it in the form of a boat, an island, or something else that has enough imagination, the view will be much more attractive.

How a well filter works

There are a lot of well filters, each of which can be made by hand. And it is quite possible to do this without leaving your home. Each filter must include the following elements:

- filter unit;

- special zone above the filter (over-filtered);

- sump.

The quality of the filter installation directly affects its functioning. But first you need to determine the depth of your well, because the cleaning design will depend on this depth. I mean dimensions. After that, it is necessary to measure the diameter of the pipe - the diameter of the manufactured filter should be in a ratio of 1 to 3 with the diameter of the pipe.

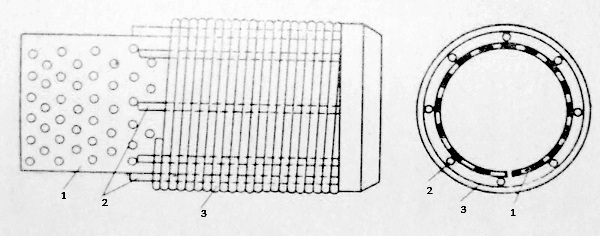

Downhole filter device

The main types of homemade filters:

- wire filter;

- gravitational;

- slotted;

- gravel;

- reticulate;

- perforated.

For a more detailed acquaintance, it is necessary to consider the criteria for their manufacture.

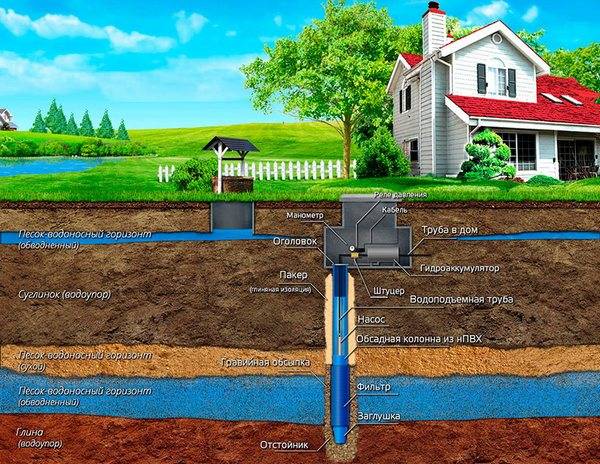

Device and design

Structurally, wells, equipped on sandy horizons, are complex hydraulic structures.

Scheme of arranging a well for sand

- After drilling, a casing string with a diameter of 100 to 150 mm is installed in the wellbore.

- The lower part of the casing pipe is equipped with a mesh or slotted filter tip. The diameter of the holes is selected taking into account the grain size of the sand in the aquifer. This approach avoids clogging and improves water quality.

- In order to protect the source from the effects of precipitation and other atmospheric phenomena, a caisson is installed.

- In some cases, an insulated pavilion is installed above the mouth of the hydraulic structure.

- For sealing the well and fixing the pumping equipment, the mouth of the pipe is equipped with a head of the appropriate diameter.

- The rise of water is carried out by means of a submersible or surface pump.

- The hydraulic accumulator and automation will ensure constant pressure in the system and protect the pump from premature failure.