- How does the laying of a brick chimney begin?

- Brick chimney laying technology

- Chimney Brick Tips

- Brick chimney as an engineering structure

- Main elements

- Requirements for a brick chimney

- Chimney calculation

- How to install a chimney?

- Types of brick pipes

- Methods for installing a metal chimney for a furnace

- Inside the smoke channel

- Outside a house or building

- Requirements for installation according to SNiP

- Stamps

- Chimney design

- The nuances of using a chimney for a heating boiler

- Errors in the installation of the chimney

- Video description

- Expert advice

- Service life of an outdoor chimney

- Briefly about the main ...

- General building rules

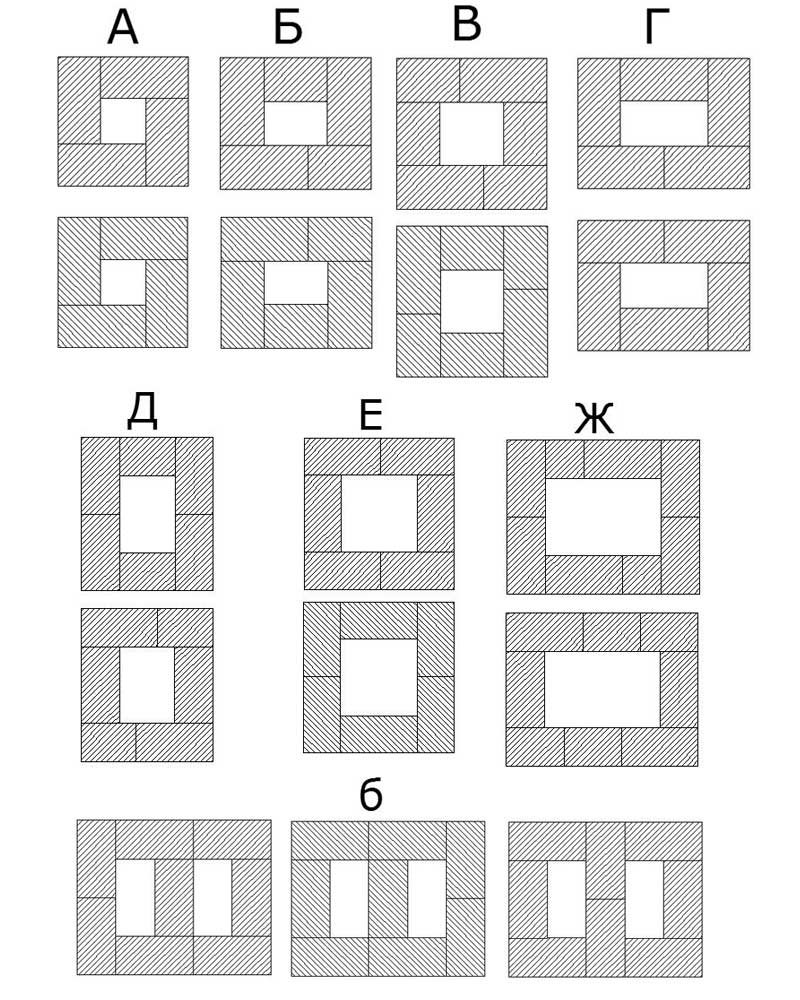

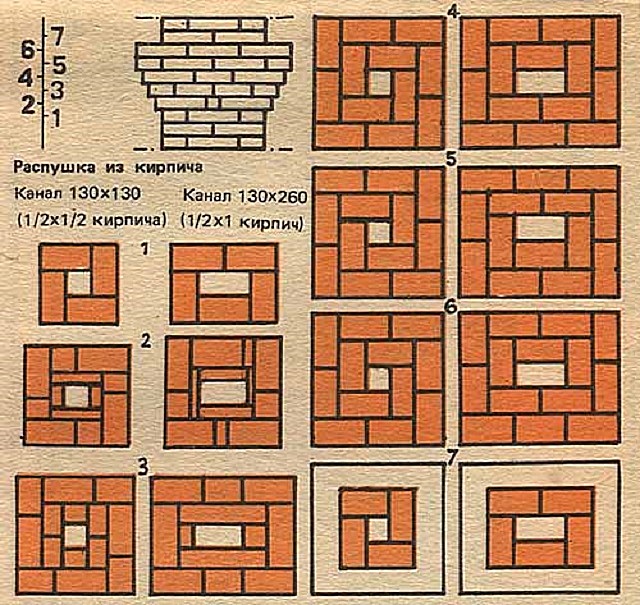

- Cutting the chimney on the roof

- Development of schemes and drawings of the chimney

- What parts does a brick chimney consist of - unusual names

- Special Requirements

- Video: laying a heating and cooking stove

- Switching from brick to sandwich

How does the laying of a brick chimney begin?

The laying of a brick chimney first of all begins with the preparatory work, the purchase of all the necessary materials and tools for laying the chimney with your own hands. As for the tools for laying the chimney, they will not require so much, basically these are well-known tools such as:

- Master OK;

- Hammer - pickaxe;

- Building level;

- Plumb;

- Grater for solution;

- Bulgarian;

As for consumables for installing a chimney with your own hands, contrary to the many advices of craftsmen that a brick chimney should only be laid on a clay mortar, this is not so. For laying a brick chimney, it is better to use a regular sand-cement mortar, the same as for plastering walls.

From my own experience, I can say with a hundred percent accuracy that a brick chimney on cement mortar will not crack or burst during operation. I cannot say the same about a chimney laid out on clay, because once I came across such a chimney in a completely cracked state.

After all the necessary materials and fixtures have been prepared, you can proceed to self-laying a brick chimney.

Brick chimney laying technology

Due to the rather large weight of a brick chimney, it can be said unambiguously and with certainty that a solid and solid foundation is needed for a brick chimney. Therefore, the foundation should not be neglected, and you need to start laying a brick chimney precisely with the manufacture of a monolithic foundation.

For this, a hole is first pulled out, approximately 50 - 60 cm deep. The dimensions of the pit must be made approximately 20-30 cm, larger than the base of the subsequently laid out brick chimney

It is important after pouring the foundation under the brick chimney, wait a few days for the mortar to finally set and harden.

After the foundation for the brick chimney has hardened, you can start laying the first row of the brick chimney

Here it is important to decide how the brick for the chimney will be laid, flat or on the edge.It must be said that it is possible to lay bricks for a chimney both on the edge and in half a brick

However, it is worth noting that in the first option, when laying bricks on the edge, it is possible to save material during the construction of the chimney, but in the second case, the chimney will turn out to be warm and more durable.

Chimney Brick Tips

As mentioned above, for laying a brick chimney with your own hands, you will need an ordinary cement-sand mortar and always a red brick. If there is a refractory brick, then this is even better, in which case the brick chimney will turn out to be as reliable and durable as possible.

Laying a brick chimney with your own hands does not work out, it can be done in one or two days. The thing is that it is recommended to lay no more than 4-5 rows of bricks for the chimney per day. This rule should also be followed and then the income will be laid out correctly, and most importantly evenly.

Be sure when laying bricks, in the inside of the chimney, you need to remove or cover up the mortar, no matter what disturbs the draft of the brick chimney. Ideally, the inside surface of a brick chimney should be smooth and plastered. Only in this version can we say with confidence that there will always be draft in the furnace, and the chimney will last for a long time without problems.

When laying a brick chimney with your own hands, without fail, each level of brickwork is checked for vertical and horizontal evenness using a small building level and a plumb line.

After the installation of a brick chimney with your own hands is completely completed, you can plaster the brick chimney outside and put a cap on the chimney.

In order to make cleaning the chimney with your own hands easy, and during operation it would not be necessary to repair brick chimneys, the following rules for installing a brick chimney should be followed without fail:

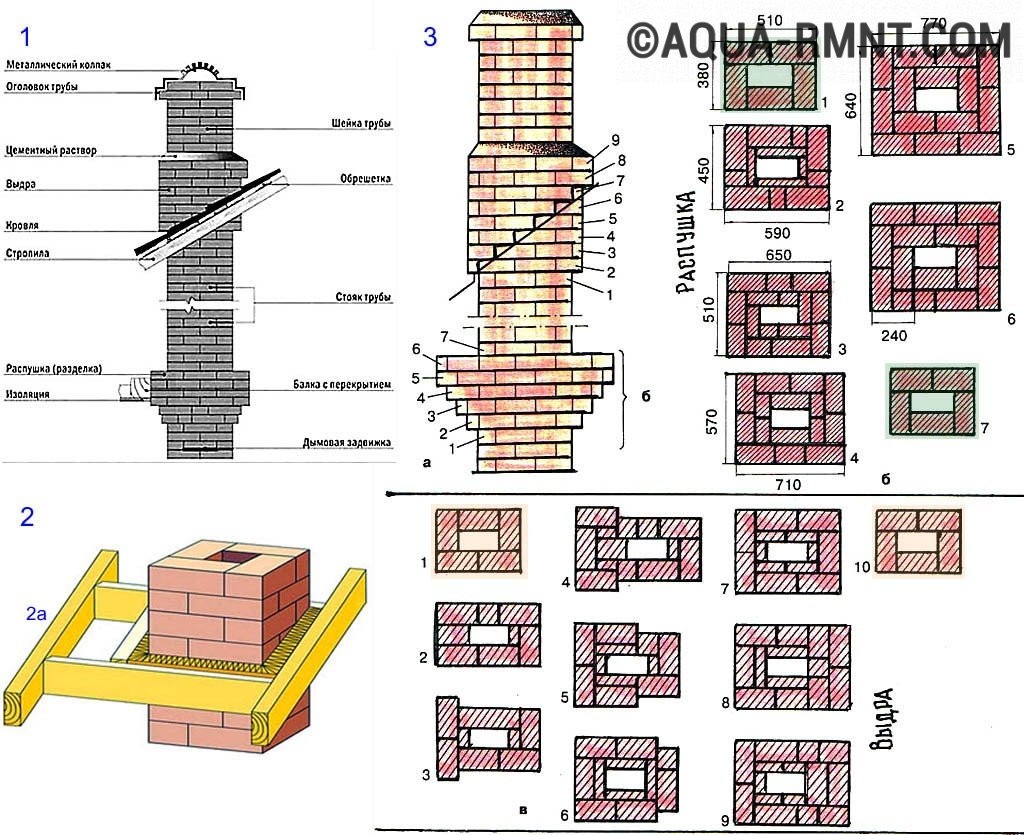

Brick chimney as an engineering structure

The chimney, for all its external unpretentiousness, is a complex engineering structure, to which serious requirements are imposed. They relate to strength, fire safety, the ability to effectively remove hot gases. Therefore, the installation of a chimney in a wooden house should begin with an acquaintance with its device.

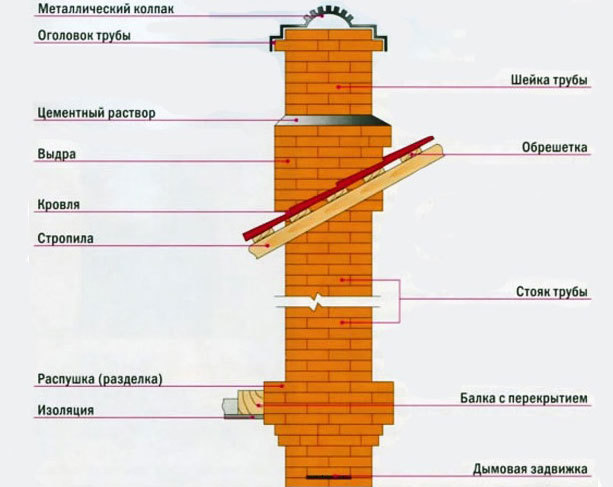

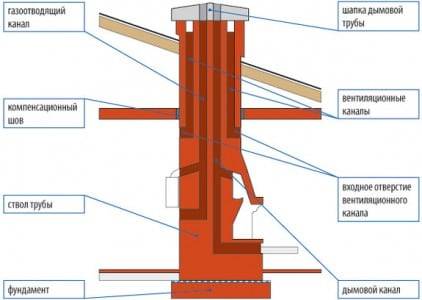

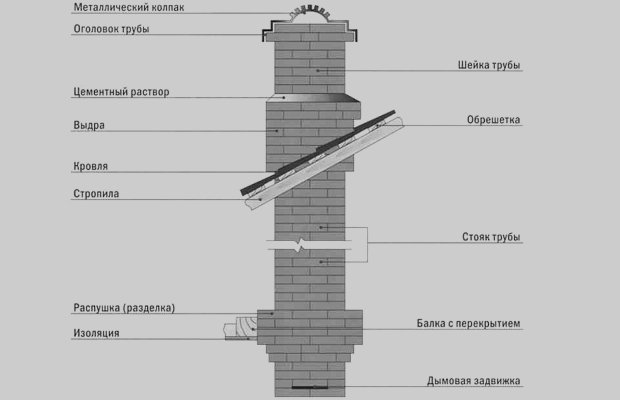

Main elements

- Internal chimney - is conducted from the ceiling of the furnace to a level below the ceiling by four rows of brickwork.

- Cutting (fluffing) - expansion of the wall thickness of the pipe when it passes through the ceiling.

- External chimney - is conducted through the attic to the level of the roof.

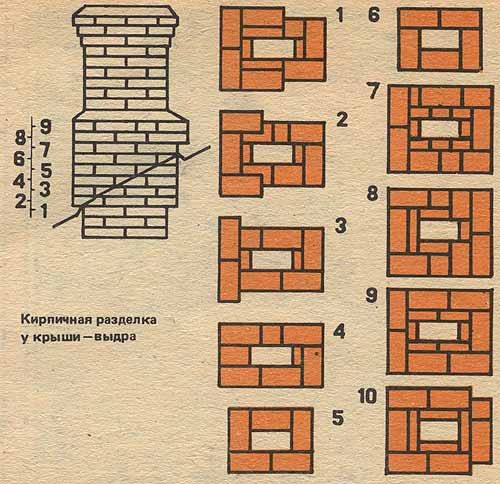

- Otter is another expansion of the chimney wall thickness, arranged to bridge the gap between it, the roof sheathing and its covering.

- The neck is a continuation of the external chimney.

- The head is a thickening of the walls, which plays the role of a deflector.

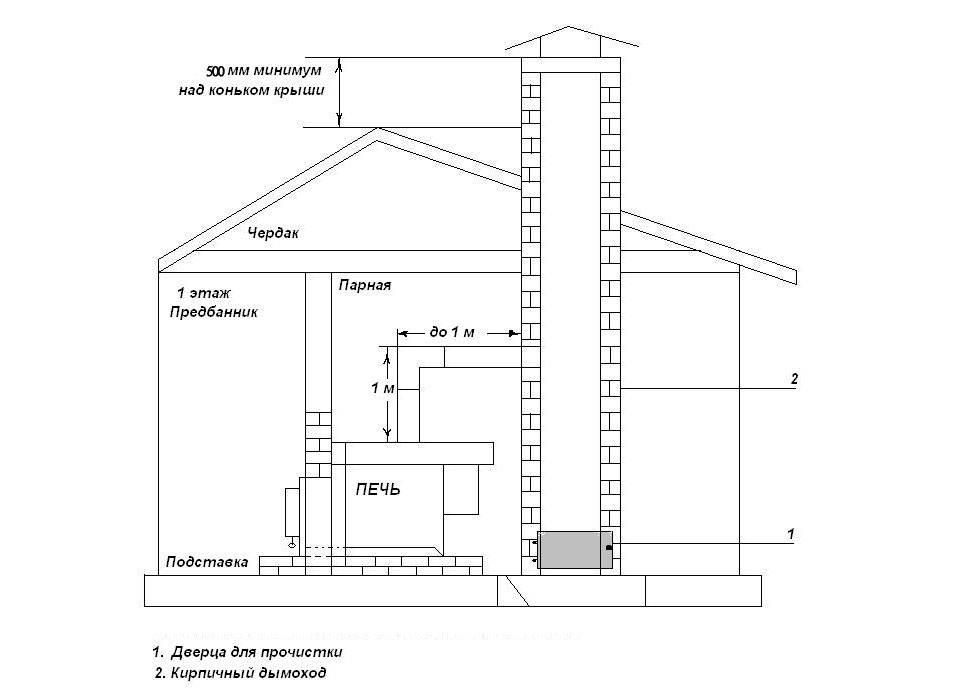

Requirements for a brick chimney

The main one is the distance “from smoke” to combustible structures. It is equal to 250 mm - this is the full length of a solid ceramic brick.

The second requirement is the strict verticality of the structure. Deviation from it by more than 3 degrees (per one meter of height) is not allowed. Also, there should be no through cracks in the brickwork.

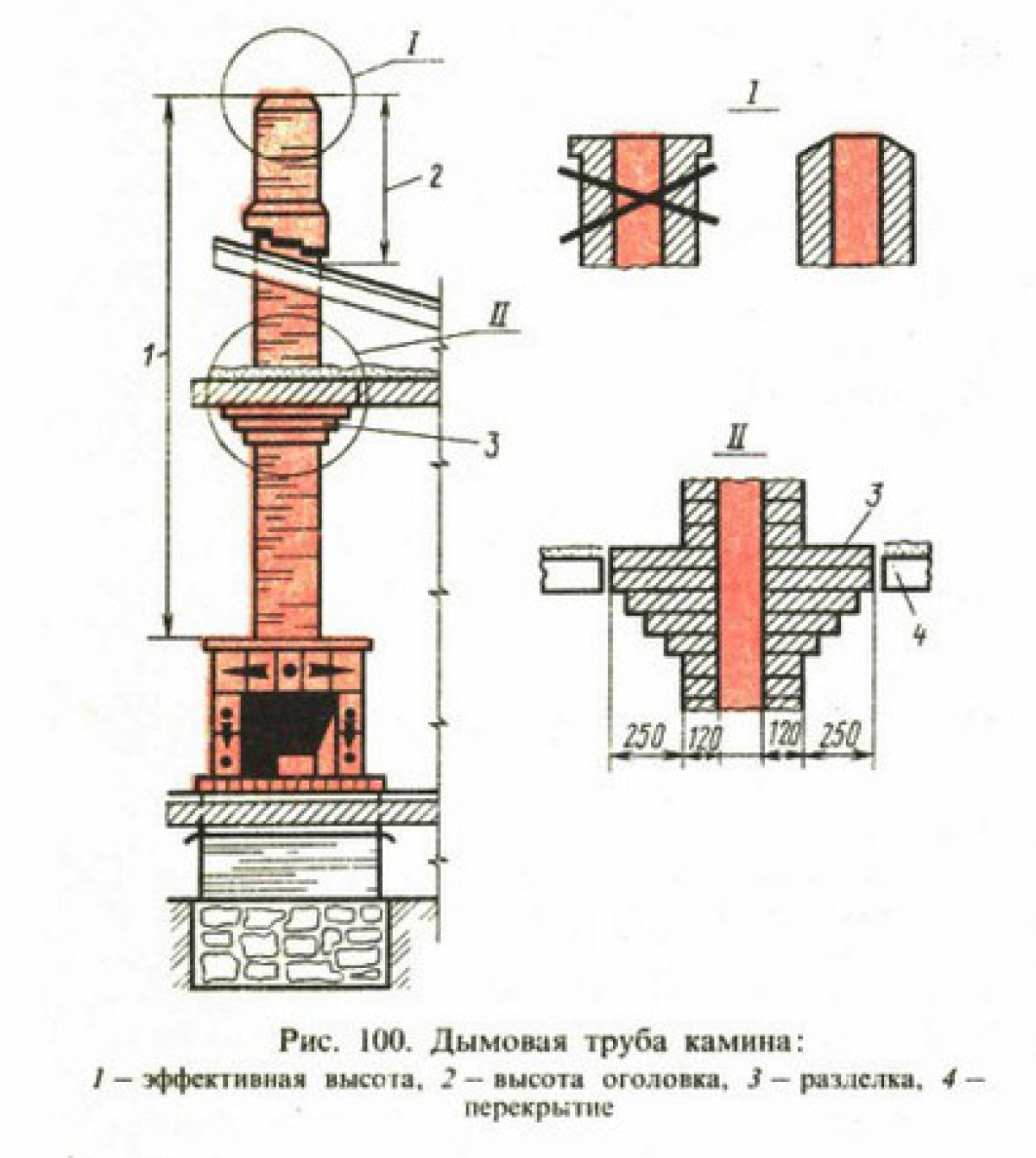

Chimney calculation

The main criterion is the internal section. The ability to remove hot gases mainly depends on it. The more powerful the stove, the wider the chimney should be.There are three standard sizes used for one or another type of heating device.

- "Four" - a row of which is formed by four bricks. Section 125 by 125 mm. It is used for cooking stoves or heating stoves of low power.

- "Five" - a rectangular chimney, formed by a row of five bricks. Section 250 by 125 mm. It is used for heating and heating-cooking furnaces. Chimneys for fireplaces smaller than this section are not recommended.

- "Six" - a square pipe, a row of six bricks. Section 250 by 250 mm. It is used for fireplaces and Russian stoves - wherever a minimum resistance to the movement of hot gases is required.

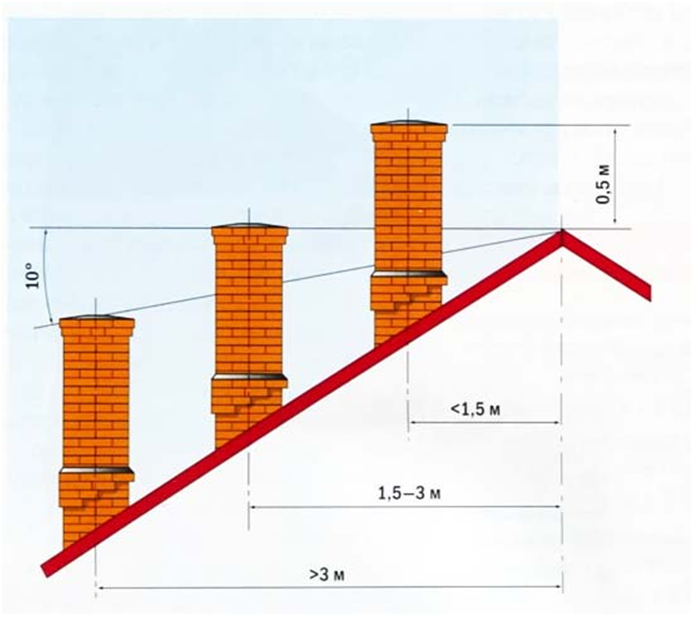

The second most important criterion in the calculation is height. It depends on the place of its output to the roof relative to the ridge:

- Pipes installed on a ridge or at a distance of no more than 1.5 meters from it rise 0.5 meters above the roof.

- Chimneys passing through the roof at a distance of one and a half to three meters to the ridge are made with a height equal to it.

- If the distance is more than three meters, then the angle between the ridge and the upper cut of the pipe should be 10 degrees.

How to install a chimney?

The process of installing a chimney is divided into several main stages, which consist of:

- Preparatory work;

- Installation of fasteners;

- The actual chimney installation.

General stages of work:

It is required to drill a hole in the wall through which the chimney itself will exit, using a special tool. Modern models have adjustable nozzles and active cooling systems to prevent cracks on the surface of the facade.

- Passage through a concrete/brick wall. Concrete and brick walls are the most convenient material that does not require additional processing. It is recommended to additionally putty the place where the hole was created in order to exclude the possibility of an early degradation of the wall of the room.

-

Passage through a wooden wall

When working with wooden surfaces, carefully protect against overheating. Hot air passes through the pipe, which can lead to unintentional ignition of materials.

As an insulating material, ceramic mixtures, heat-resistant insulating materials, and even glass wool are often used. You should not save on thermal insulation, as the consequences can be very sad!

The nuances of mounting the passage of the chimney through a wooden wall

- After that, on the outside of the house, elements are installed that will hold the chimney pipe in a single position. The kit usually contains dowels of the required diameter, with which you can perform this task.

- The chimney itself is assembled from several separate parts, by analogy with the designer. Modern models have convenient mechanisms for fasteners that allow you to complete this step in a matter of minutes.

Examples of finished installation in the photo:

Example 1

Example 2

Example 3

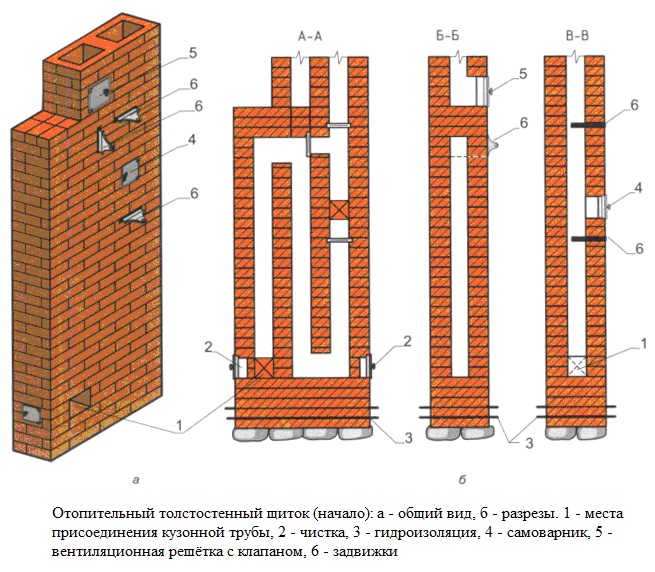

Types of brick pipes

There are three varieties brick chimney structures, which differ from each other by location.

- Indigenous, they are also attached chimneys. They are built separately from the furnace, that is, they are erected next to the heating element, connecting the latter with a chimney outlet (pipe).Typically, such chimneys are installed where it is necessary to connect several stoves or fireplaces.

- Mounted variant. This is the most common type of chimney. By name, it becomes clear that the structure is installed on top of the stove, as if planted on it.

- Wall construction. It is built along the outer wall, that is, the structure is located outside the house, and not inside, like the two previous options. At the same time, the wall pipe can be both mounted and root. This is the easiest option in terms of building a chimney, but more expensive, as it requires a large amount of thermal insulation work.

Chimney wall construction

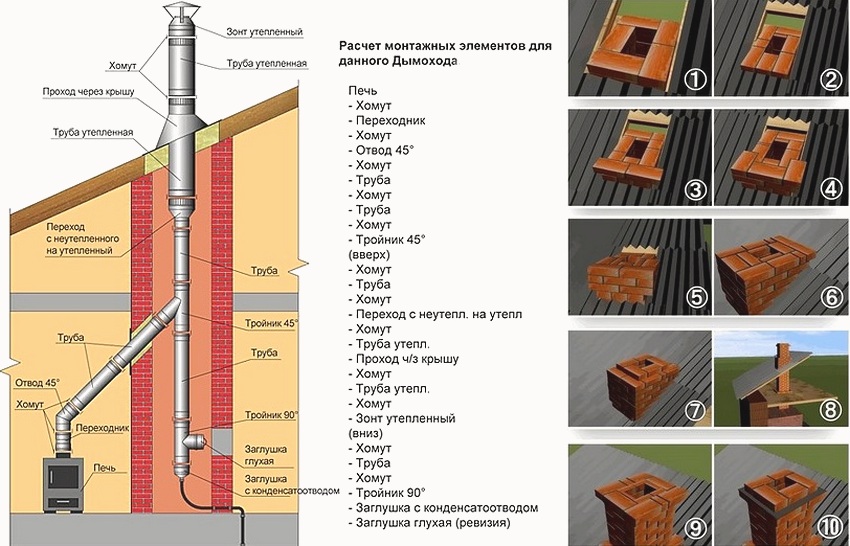

Methods for installing a metal chimney for a furnace

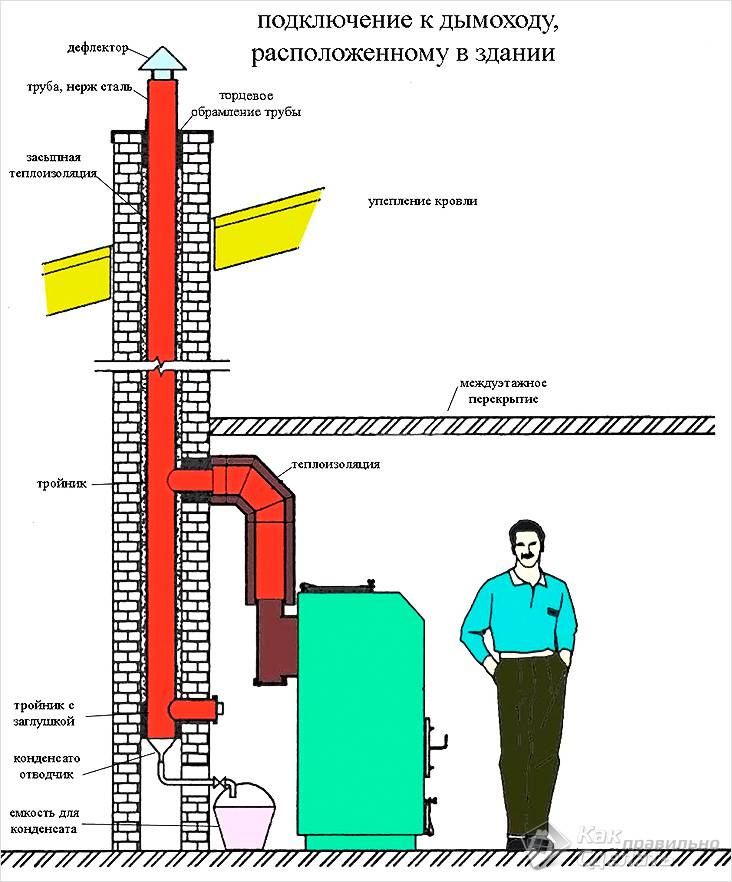

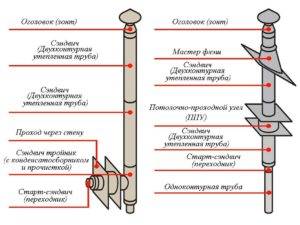

The metal pipe for the furnace can be installed in two ways: inside the smoke channel, as well as along the outer wall of the house. Let's take a closer look at both options.

Inside the smoke channel

If a channel is built at home or it already exists from old heating equipment, then a single-walled steel pipe is placed in it, which serves as a kind of sleeve. Having a perfectly even cross-section and smooth inner surface, it does not create resistance to flue gases.

The channel itself prevents the chimney from cooling down abruptly, and thereby helps to reduce the formation of condensate and increase the service life. This installation is simpler, and the absence of long horizontal sections contributes to better traction.

Scheme of installing a metal pipe in a chimney

Outside a house or building

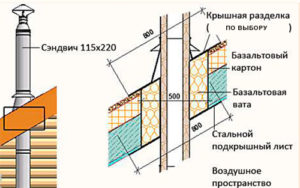

Installation outside is more complicated and costly in contrast to the first option.For this method, a double-walled sandwich pipe is used, since the use of a single-walled pipe will still require mandatory insulation.

The assembly of such a chimney must be very reliable. Despite the small weight of such pipes, negligence in the fasteners of the chimney is unacceptable.

Mounting diagrams

Requirements for installation according to SNiP

- Installation, design and installation of metal chimneys is done in accordance with SNiP number 2.04.50-91, as well as according to fire safety rules. Such responsible work should be carried out only by those individuals and organizations that have the appropriate permits. Work experience and knowledge of such organizations and individuals is of great importance.

- The diameter must be selected and match the power of the furnace.

- The height of the chimney must be at least 5 meters, regardless of the structure.

- It must be mounted strictly vertically, and the permissible deviations from the vertical axis should be no more than 30 degrees in a 2-meter section.

- Horizontal sections longer than 1 meter should not be allowed, this leads to a deterioration in traction. The rise of the pipe in such sections should be at least 5 degrees.

- To avoid possible leakage of condensate, it is necessary to install pipe locks in the direction of condensate flow. The bottom of the top tube should go inside the top of the bottom tube.

- When assembling individual parts and elements, a special heat-resistant sealant designed for 1000 degrees must be used.

- The joints are fastened with special ties or clamps, if such fastening is not provided, the joints should be fastened with self-tapping screws.

- To make it reliable, you need to carefully consider the issue of its fastening. It must be fixed in increments of at least 1.5 meters, with reliable elements.

- It is necessary to use special elements of penetration of floors and roofs to ensure the fire safety of buildings. Their interior must be filled with non-combustible, heat-insulating material.

- When removing a metal chimney through the roof, a universal cut must be used.

- For further revision and cleaning, special inspection hatches and cleaning should be installed.

- To prevent moisture from entering from the outside, fungi are installed. To avoid fire from flying sparks from the pipe, spark arresters are installed.

Stamps

The unique properties of the heat-resistant material make it possible to build pipes from it both at industrial facilities and in private houses and summer cottages. Several of the most popular brands are produced in Russia. In particular, we are talking about:

- HKU. It is distinguished by its ability to withstand enormous temperature changes (it is used for lining in the steel industry).

- broadband. Well proven in the construction of blast furnaces.

- SHAV. They are used for laying out the inside of furnaces in metallurgy.

- SHA, SHB. Produced specifically for the construction of home fireplaces, stoves and chimneys.

In particular, of the varieties of the latter, the ShA-5 will be an ideal choice in our case.

Chimney design

In the article we will talk about the plug-in model, as the most commonly used in the Russian region. The composition of the chimney includes (from the bottom of the stove up):

- Furnace neck. In fact, this is a pipe made of rectangular bricks. The area of the neck is selected according to the power of the furnace. The more power, the larger the cross section. A steel damper is installed in the neck, with the help of which the cross section of the chimney is regulated. With its help, the air supply is regulated.

- Fluff.This is an extended brickwork, which is erected at the overlap between the rooms and the attic. Its purpose is to protect the ceiling from high temperatures. In fact, fluff is still the same pipe, only it has a larger wall thickness.

Flue flue pipe

- Riser. This is the longest part of the chimney that runs through the attic. Its cross section is the same as that of the furnace neck.

- Otter. Same design as fluff. The purpose is to protect the roof structure from high temperatures emanating from the pipe, plus strengthening the chimney in order to withstand wind loads.

- Chimney neck on a brick roof. This is the part visible from the outside, rising above the roof of the house.

- head. Its purpose is to protect the neck of the pipe from smudges, which usually occur on vertical surfaces during precipitation. That is, the outer diameter of the head is larger than the diameter of the pipe neck.

- Cap. This element of the chimney structure is usually made of galvanized steel sheet. Purpose - to protect the chimney shaft from atmospheric precipitation.

A section of a brick chimney above the roof: pipe neck, head and cap

The nuances of using a chimney for a heating boiler

When installing a chimney for a boiler, some nuances must be taken into account. The diameter of the outlet pipe of the heat energy generator must correspond to the cross section of the chimney channel to which it is connected. If two units of thermal equipment are connected to the exhaust device, the cross section of the chimney increases to the total size of the outlet pipes.

The chimney for the boiler can be placed both inside and outside the building

The operation of boiler equipment is associated with a significant formation of condensed moisture. Combining with the products of combustion of fuel, water forms various chemical compounds, in particular, when combined with sulfur, sulfuric acid is obtained. In this case, wet brown spots appear on the outer surface of the brickwork.

To protect the walls of the chimney from the effects of aggressive chemical environments, the structure is sleeved, that is, a pipe made of metal that is not affected by corrosion processes or a cylindrical ceramic liner is inserted inside. The space between the sleeve and the walls of the chimney is filled with a material that does not support combustion.

Dear reader! Your comments, suggestions or feedback will serve as a reward to the author of the material

Thank you for your attention

The following video is carefully selected and will certainly help the perception of the foregoing.

Errors in the installation of the chimney

Since it is not always possible to correctly install the stove in the house and lead the pipe through the wall, the most common installation errors should be considered in order to avoid them. Incorrect design robot is possible in such cases:

- Insufficient amount of insulation at the junction of elements. In this case, the pipe will overheat.

- The presence of joints in places where they pass through a wall or roof overhang. Such installation increases the risk of fire of a capital structure.

Video description

This video clearly shows an example of a violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically.When insulating the main walls with foam plastic or mineral wool, long dowels are used to fasten the chimney.

- There is no ebb on the side slope of the roof. In this case, precipitation can get on the insulation and impair its function.

- Insufficient overall height of the vertical part. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use the following expert advice:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure, it is enough to bring out the horizontal pipe;

- too long horizontal section contributes to slowing down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes

Inspection holes are arranged not only on the outer part of the structure, but also on the inner horizontal element.

Service life of an outdoor chimney

The service life of the structure depends on the material of its manufacture and the correct installation. Ceramic pipes, if used correctly, will perform their function for up to 40 years. A brick chimney can be operated for more than 50 years. Stainless steel will have to be changed after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A quality sandwich system will last up to 20 years.Structures last longer if the heating equipment runs on gas or pellets.

Briefly about the main ...

Chimneys are single- and double-walled. According to the material of manufacture, metal, brick structures and structures made of sandwich pipes are distinguished. The last option is optimal for private houses. At installation of the chimney, the rules of its placement in the room. Its functionality, as well as the presence of traction in heating equipment, depends on the correct determination of the diameter and height of the structure.

The installation technology through a wooden and brick wall is the same, but there are some nuances: wood is more susceptible to ignition and requires maximum protection. During installation, fire regulations must be observed, as well as possible errors must be taken into account.

General building rules

- The height of the pipe above the roof;

- Main material;

- Solution.

The height of the brick pipe is calculated taking into account the slope of the roof and the height of the ridge.

Pipe Height Calculation

Pipe Height Calculation

The laying of the chimney is carried out with red brick of the M200 brand. Red brick is able to withstand temperatures up to 800 degrees Celsius, but for laying channels near the heating part of the furnace, it is better to use fireclay, refractory bricks to avoid splitting or burning the material. All stacked bricks must be of high quality (smooth on the sides). On an uneven surface, the formation of soot will accelerate, which leads to a decrease in traction and even ignition. When laying, the inside must be immediately cleaned at the seams.

There are two types of mortar for laying a chimney. Clay or cement-clay.Usually all furnaces were laid out on clay mortar, since clay is refractory and does not crack, but to increase the strength of the masonry, cement can be added to the masonry mortar.

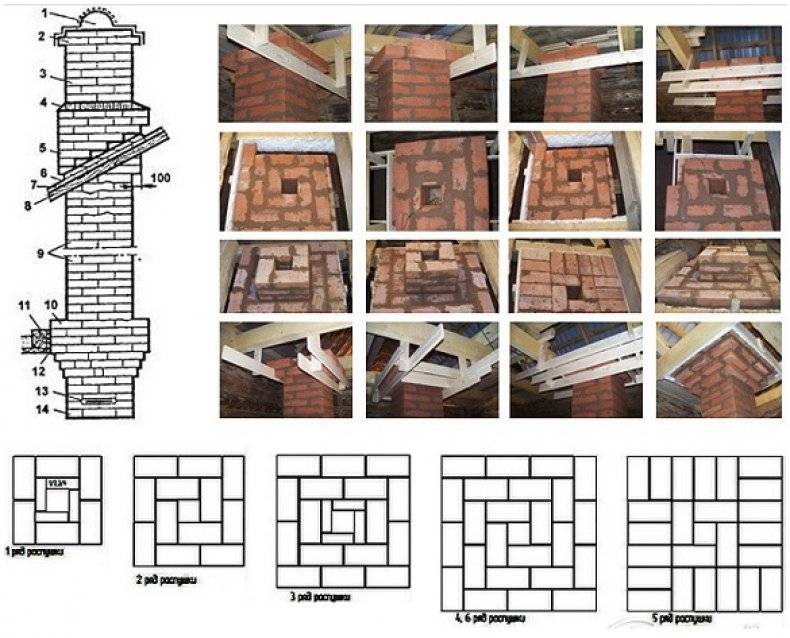

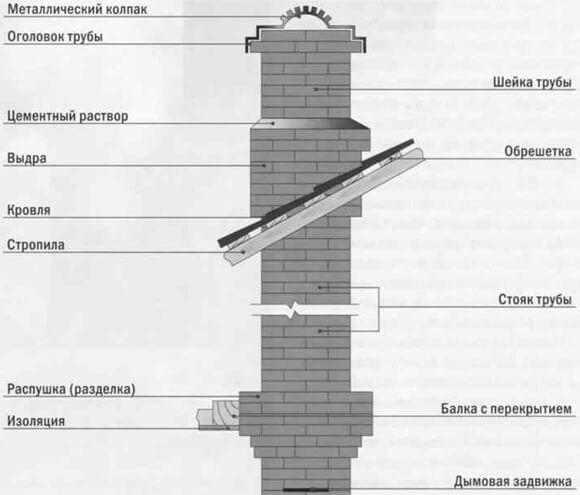

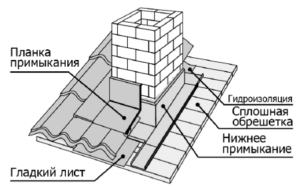

Cutting the chimney on the roof

Cutting the chimney on the roof is carried out taking into account several sizes:

- the minimum distance from the roof surface to the rafters is 250-300 mm;

- if roofing or roofing material is used as a surface coating - the size to the chimney pipe is from 300 mm;

- if metal or concrete parts are used as rafters, this distance is reduced to 200 mm.

Difficulties arise when pipes pass through the layers of roof protection (steam, waterproofing, wooden lathing of the structure and layers of insulation). We carry out the work very carefully, trying not to violate all layers of insulation and construction.

To install the glass, we perform an additional crate, connecting 2 adjacent rafters with 2 jumpers according to the size of the sleeve.

We carefully tighten all the old layers and tuck them inward, fixing the edges with a stapler or nails with hats. We fill all gaps with a layer of thermal insulation and sealant.

Surface waterproofing is carried out in several stages:

- on the roof we lay a groove over the entire surface of the pipe for drainage and removal of possible leaks;

- we fix and fill all the gaps and install the outer waterproofing apron. It can be made from steel or rubber. We wind its edges under the roof covering and fix it on top of the inner apron of the main structure and close up all the joints;

- now water, when passing through small cracks, will fall into the drainage groove or be removed along the cover of the under-roof apron.

After laying the roof covering layer, install the outer apron and hermetically fix it to the surface of the chimney and roof.

Scheme:

The scheme of cutting the chimney on the roof

Installation of a brick chimney

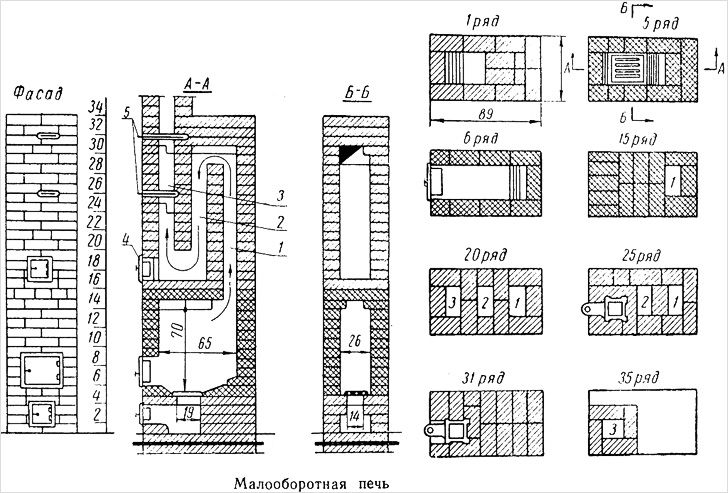

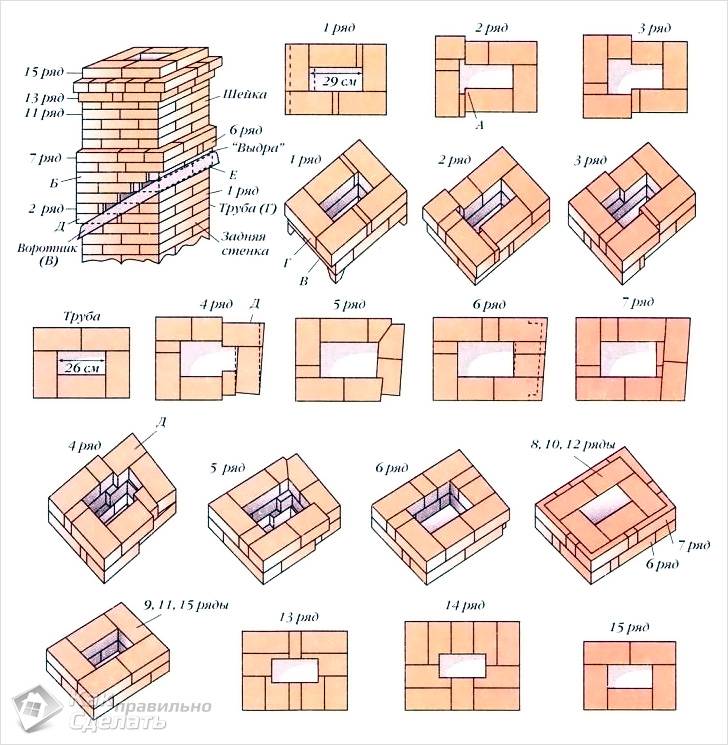

Development of schemes and drawings of the chimney

Even before starting construction, it is necessary to draw with particular accuracy  drawings and diagrams of the functional components of the chimney, a responsible approach to this stage will avoid many mistakes during the construction of the structure. The channel responsible for the removal of smoke from the furnace consists of a pipe, which is fixed directly on top of the heater; a damper equipment option is also possible.

drawings and diagrams of the functional components of the chimney, a responsible approach to this stage will avoid many mistakes during the construction of the structure. The channel responsible for the removal of smoke from the furnace consists of a pipe, which is fixed directly on top of the heater; a damper equipment option is also possible.

Adhere to the rule of laying out bricks by dressing; it is necessary to dress each row. Before overlapping, a distance of 4 rows should be left, in this area the base ends and the expansion of the masonry begins.

What parts does a brick chimney consist of - unusual names

The overhead structure consists of several zones. For an ordinary person, their names may not sound quite ordinary. Next, we give the main parts of brick smoke exhaust structures and describe their features:

- Directly on the heating unit, the lower part of the chimney is mounted - the overhead pipe. Bricks during its installation are stacked with a special dressing.

- After the overhead pipe, there is fluffing (otherwise - cutting). This part is understood as the expansion of the chimney, which they begin to lay out for 5-6 brick rows from the ceiling between the floors of the house. There is one subtlety here. Only the outer part of the fluff is widened by 25–40 cm. But its inner diameter is similar to the cross section of the entire chimney.Fluff protects floors from elevated temperatures. It, in fact, performs the function of thermal insulation. That is why its walls are made so thick.

- The fluff has a neck. It is designed to install a special valve, which makes it possible to change the draft of the furnace by regulating the intensity of combustion of the fuel.

- A pillar of bricks with a smoke channel laid inside it is called a riser. Structurally, it is placed before the fluff and after it - in the attic floor. The riser is laid to the very roof of the building.

- An otter is mounted above the roof - an extension (about 10 cm on each side) of a special kind. It protects the attic from the penetration of precipitation into it.

- Above the otter is another neck. Its parameters are similar to the dimensions of the chimney.

The main parts of a brick smoke exhaust structure

The end of the smoke-removing structure is the head. It consists of an otter platform and a cap protruding above the neck. An umbrella, a deflector or a cap are installed on the head (or rather, on its cap), which prevent wind-borne debris and precipitation from getting into the pipe. Indigenous chimneys have a similar design. But, as was said, several heating units can be connected to them. Therefore, the structure will have several sections and risers.

Special Requirements

We repeat: the advantages are rude - compactness and the possibility of building in an existing house without capital construction work. But it is not so easy to place a more powerful furnace in the structure of the furnace in general of the same dimensions, it will quickly become unusable from excessive heat load. If special requirements are not met for:

- Furnace foundation.

- Masonry solutions.

- Ways of laying the structure of the furnace.

- The choice and methods of installation of furnace fittings.

The design of the foundation for the rough is given in Fig. The crushed stone pillow without sand filling is leveled into the horizon before pouring. Filling mortar M150 - cement M300 and sand 1: 2. The gap between the rubble foundation and flooring is 30-40 mm. Do not forget to support the cut logs! Leaving their ends hanging is a common but gross mistake. The dimensions of the foundation in the plan should protrude on the contour of the furnace by at least 100-150 mm.

The device of the foundation of the furnace-coarse

Note: brick bed on foundation for the oven laid out with dressing in rows and between rows in the same way as the first 2 rows of masonry of the furnace structure, see below.

To fold the rough, 3 types of solutions are used, see fig. below. The bed on the foundation and the chimney are laid out on a lime mortar, as it combines sufficient heat and moisture resistance, but the rubble must be laid only on a completely moisture-resistant cement-sand mortar. Sand for clay mortar is highly desirable to take mountain or ravine, with rough grains. Ordinary clay - purchased oven, guaranteed fat content and, most importantly, purity. Self-digging clay, brought to the desired fat content with sand, is of little use for rough masonry.

Compositions of masonry mortars for a coarse oven

For masonry, a stove is used and, if the order (see below) is provided, fireclay bricks; the red worker is suitable for the highest quality - light red in color (completely annealed), without burn marks, warping and swelling. Dry molded brick is absolutely unsuitable. The masonry of the structure is rough. rules:

- If you are an inexperienced stove-maker, each row of masonry is first laid out dry; detected defects in trimming / chipping of bricks are eliminated.

- Before laying on the mortar, each brick is soaked until the release of air bubbles stops. It is impossible to plump all the bricks into a barrel indiscriminately!

- A layer of mortar 5 mm is applied to the bed and poke of the brick being laid.

- The brick to be laid is laid with a smooth movement slightly with an inclination and moved to the previous one so that there are no air bubbles left in the seam.

- The brick is pressed until the seam converges to 3 mm; can't be tapped!

- Between fireclay and ordinary masonry, the initial seam is 8-10 mm; after pressing - 6 mm.

- The seam between bricks and metal embedded parts (see below) is 10 mm.

- Excess mortar squeezed out of the seam is removed with a trowel (trowel).

- The recesses in the seams found after cleaning the excess mortar are filled with mortar by indentation without transverse movements, but not by rubbing!

Those who prefer to learn visually video lesson on masonry heating and cooking stoves can see below:

Video: laying a heating and cooking stove

Incorrect oven door installation

Fittings and grates for coarse need cast iron; doors and latches - with an installation skirt and holes in it for diagonal wire whiskers. Welded steel or cast iron fittings with lugs for straight whiskers (laid along the corresponding furnace wall) are unsuitable in this case. However, install the doors/latches as in fig. on the right, it’s impossible to be rude; It's not by oven rules at all. For a country Dutch woman 2.5 bricks in plan, which is heated once or twice a season, maybe it will work, but not for being rude.

It is necessary, firstly, to compress the whiskers (wire - galvanized 2-3 mm) with wrapping so that they do not move.Press at first not tight, set at the desired angle (at least 12 mm should remain from the far end of the mustache to the inside of the masonry). Then gently tighten, shake the door/latch lightly. Haven't left? Good. Then, secondly, you need to wrap the skirt tightly with asbestos cord (or basalt fiber), and only now put it in place. You can also watch the following videos about installing accessories in the oven.

Switching from brick to sandwich

Brick chimneys have good draft and last a long time. However, the brickwork of the pipe can collapse, especially under the influence of the external environment. The destroyed layer can prevent the exit of combustion products and reduce traction. To install a new pipe, you can put a transition from a brick pipe to a sandwich.

For docking, a square-shaped adapter is used at the base, and cylindrical, on the other hand. Inside the adapter there is a layer of basalt wool.

When switching from sandwich panels to brick, you need to use two adapters. One above the brick chimney, the other in the attic.

The distance from the sandwich pipe to the combustible structure of the house is filled with fireproof material, about 400 mm.

Refractory sealants are used to seal the seams in the structure.

When switching from a square pipe to a round one, it is impossible to reduce the cross section of the pipe and make additional protrusions so as not to disturb the draft.