- Types of chimneys

- Brick

- galvanized pipe

- coaxial chimney

- Ceramic

- Stainless steel

- Advantages and possible disadvantages

- Power

- Errors in the installation of the chimney

- Video description

- Expert advice

- Service life of an outdoor chimney

- Briefly about the main ...

- Making and installing a chimney with your own hands

- What materials are better to make

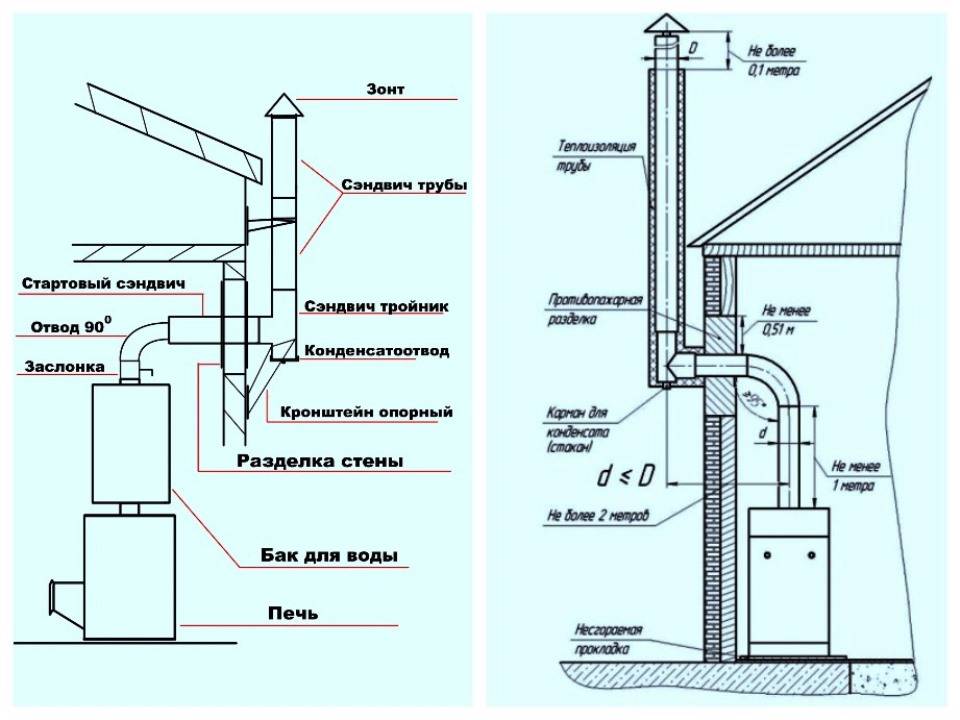

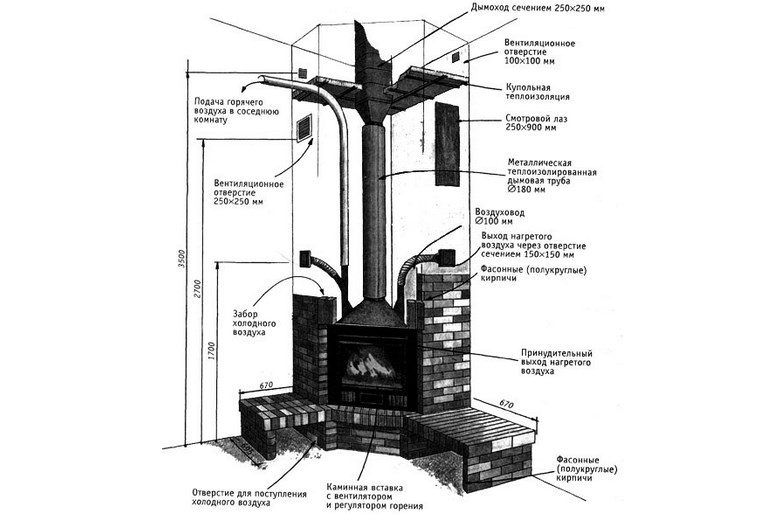

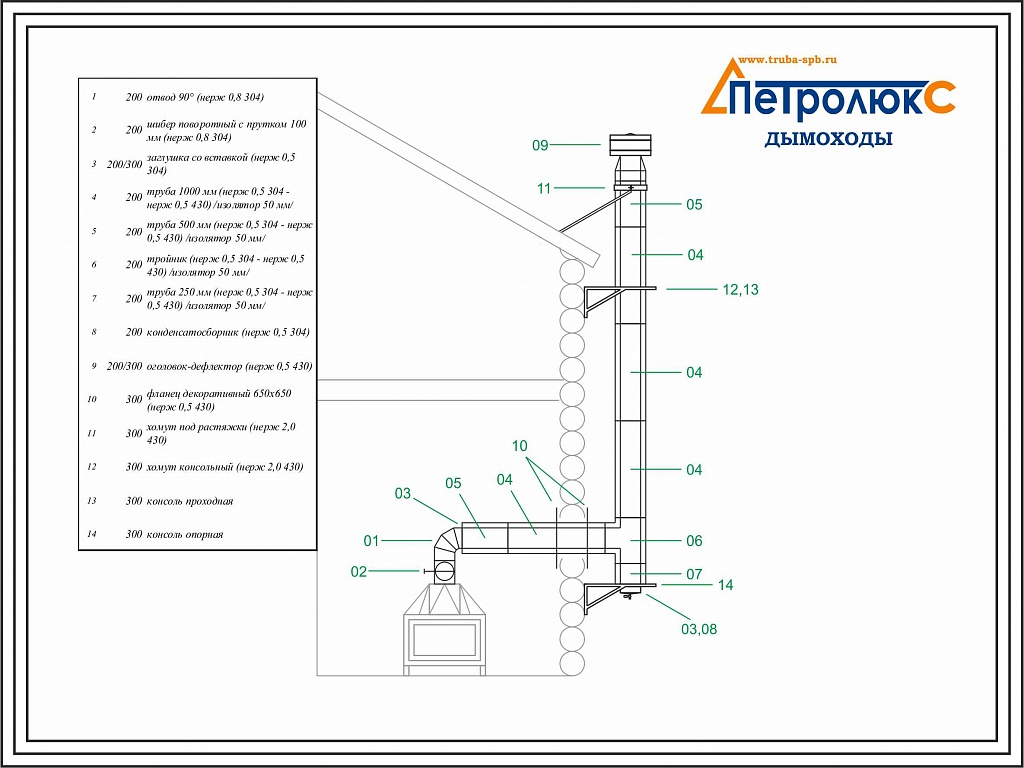

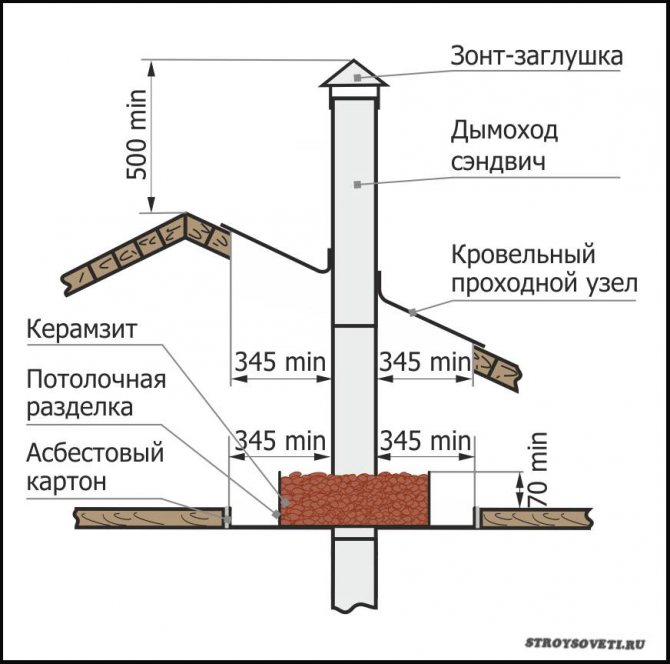

- Drawing and diagrams

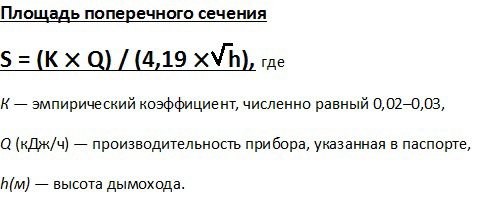

- Size calculation

- About offers on the market and general characteristics

- good old brick

- Proven stainless steel

- Ceramics

- Alternative for homemade

- A few words about calculations and standards

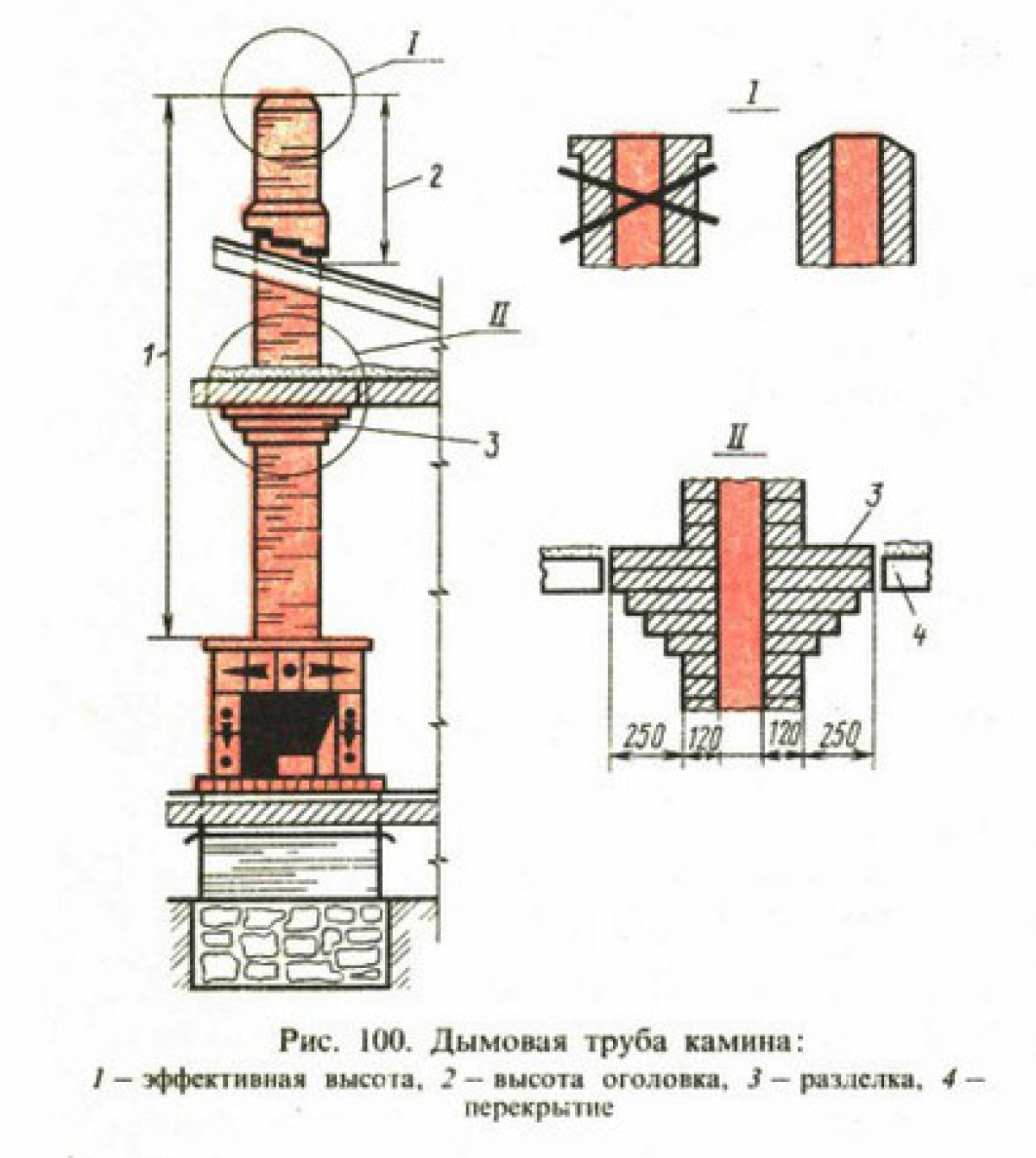

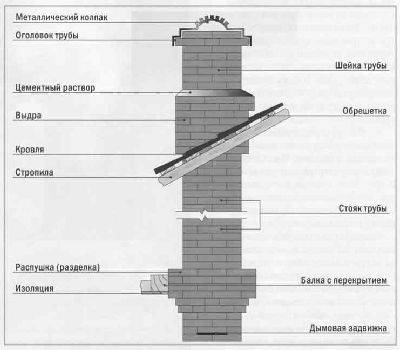

- Brick fluffing scheme

- How to properly lay out fluff?

- Solution preparation

- Placement methods

- Where to start?

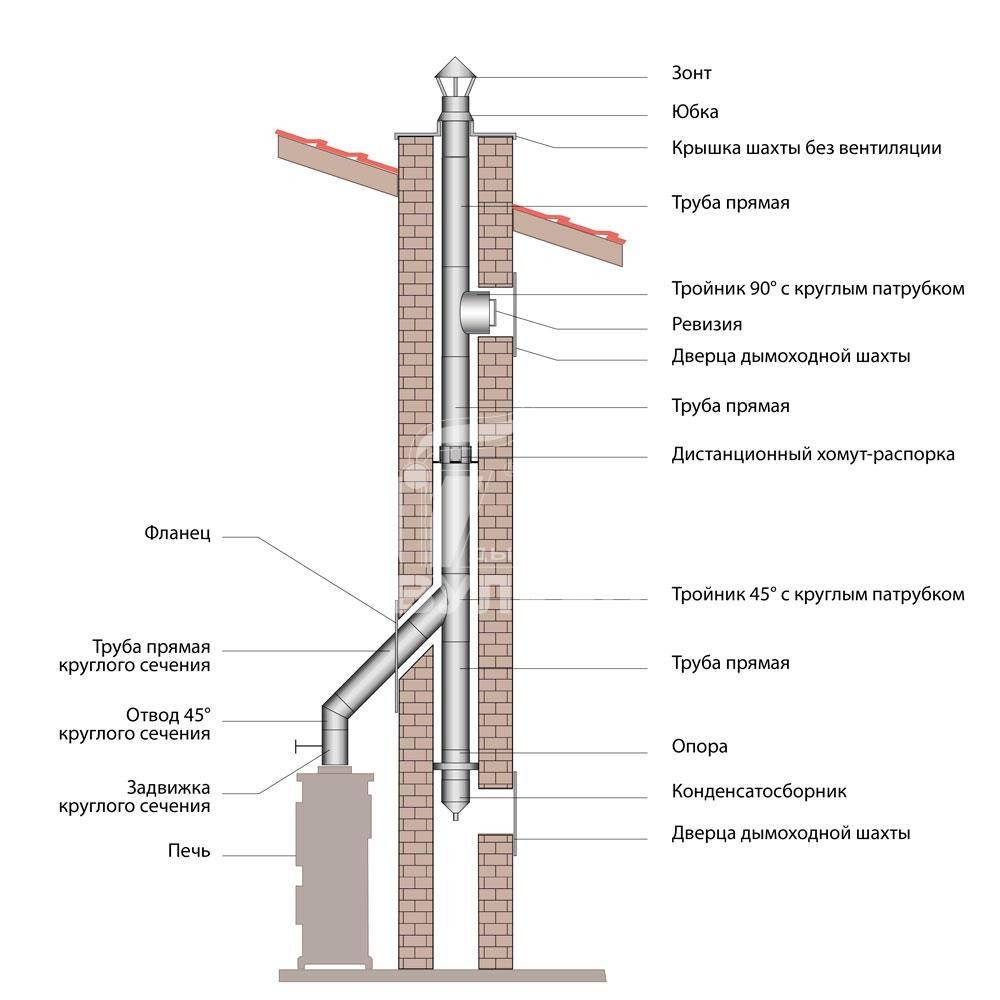

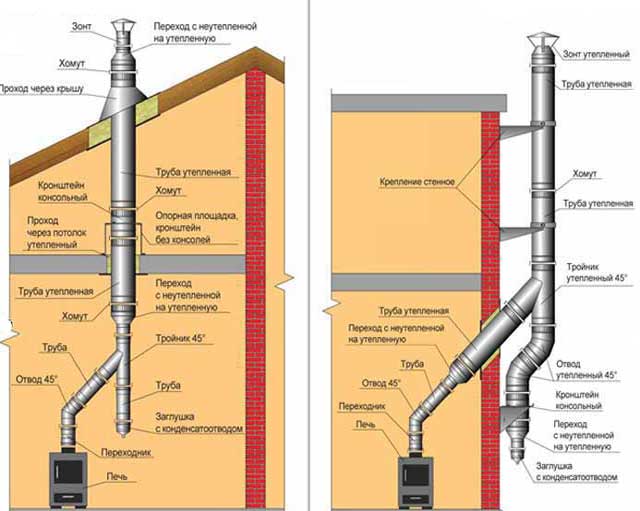

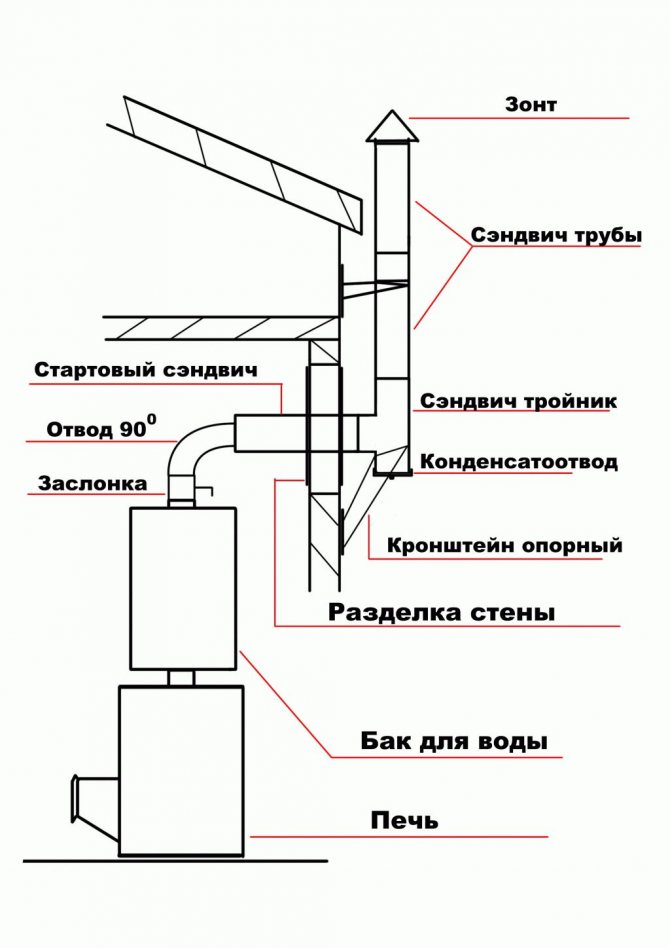

- Stainless steel chimneys

- Conclusions and useful video on the topic

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for a gas boiler are still in demand, regardless of their many disadvantages and poor thermal performance. At the same time, they comply with sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- For the construction of walls, a solution of clay or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge, depending on the distance between them

- The masonry provides tightness.

- At the inner hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

And also the chimney can have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

galvanized pipe

A sandwich device is today the most effective chimney design option. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

coaxial chimney

Currently, gas boilers use closed-type combustion chambers. Here, air intake and smoke removal are produced by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the intake of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipe

And its characteristic difference from ordinary pipes is as follows ... A smaller pipe (60-110mm) is located in a pipe of a larger diameter (100-160mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to the jumpers along the entire length and is a rigid element.The inner pipe serves as a chimney, and the outer pipe serves as fresh air.

Air exchange at different temperatures creates traction and sets the air mass in a directed motion. The air in the room is not used during the operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

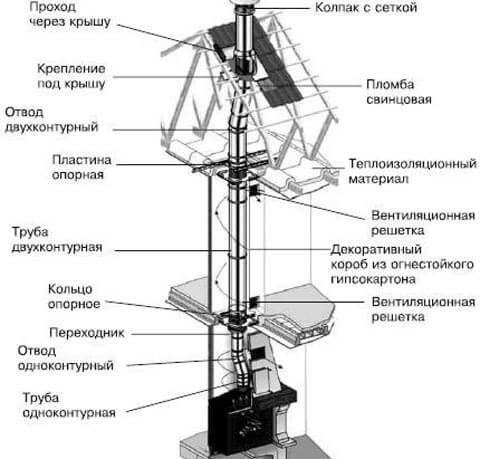

Such a chimney is a composite structure, including:

- Smoke duct made of ceramic material.

- Insulation layer or air space.

- Claydite concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

A ceramic pipe is always located inside a solid block.

Secondly, ceramics has a high thermal conductivity, and therefore it needs reliable insulation. The inner tube of a circular cross section has a smooth surface, while on the outer tube, roughnesses are allowed that do not affect the integrity of the product.

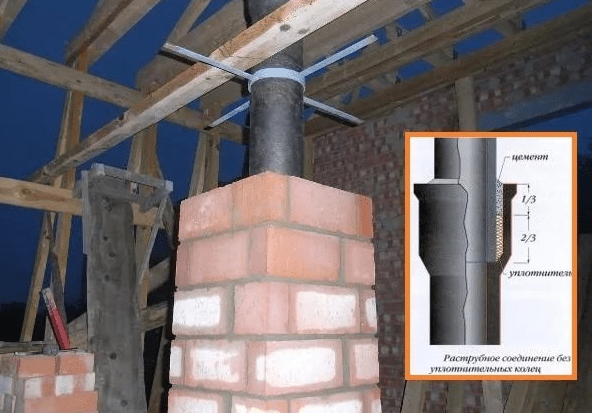

Typically, such chimneys are available in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs by means of a lock, which is a thinning in external size from one end and an expansion of the inner pipe from the other side.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides a place for a heater, which is held by metal jumpers. At the same time, they are fixed on the outer surface and make a reliable fastening for this pipe.

Stainless steel

A gas chimney made of steel seems to be more reliable than a brick one.They are resistant to corrosion, immune to temperature fluctuations, they are not affected by increased air humidity and aggressive environments.

Stainless steel chimney

In addition, such stainless steel pipes have a number of advantages:

- Long period of operation.

- Multifunctionality.

- Relatively low cost.

- Great strength.

- Probable realization of a product of any complexity.

For chimneys made of this material, an assembly of modules is characteristic, which allows the replacement of a damaged segment if necessary. The installation of chimneys is made with the help of special bends, which allow them to harmoniously fit into certain elements of the roof.

Advantages and possible disadvantages

Before you bring the pipe from the furnace through the wall, you should consider the positive and negative sides of the design. Its advantages are highlighted:

- saving space inside the premises;

- construction not at the initial stage of the construction of the building, but after its completion (it is the best option if it is necessary to reconstruct the house);

- ease of maintenance and repair;

- less construction work;

- ease of regulation of the chimney, if necessary, change the thrust force;

- high level of fire safety of the building and heating equipment;

Chimney fire protection

- no need to violate the integrity of the truss system, there is no need to make holes in the ceiling, roof;

- optimum level of safety in terms of leakage of toxic gases.

However, this design also has disadvantages:

- requires mandatory thermal insulation;

- low efficiency (the heat from them enters the atmosphere);

- at a high altitude, the operation of the structure is difficult due to the large windage, therefore, additional fastening is required;

- with a large number of bends, the rate of removal of combustion products decreases.

To prevent water from the slope from entering the chimney, it is required to install special ebbs. Sometimes the design is able to violate the exterior of the building.

Power

To clarify the values, there is the NF D 35376 standard, which was developed in France. It allows you to find out the rated power of the furnace in kW - the amount of heat that the model can provide in three hours of operation.

It is very important not to confuse it with the maximum values that are usually indicated in the specifications for finished products. The fireplace reaches its maximum heating in 45 minutes after kindling, and these power values are 2-3 times greater than its real capabilities.

For reference:

- for a cozy room of 10 m² with a ceiling height of 2.5 m, 1 kW is required for heating;

- birch firewood (dry, moisture up to 14%) - 1 kg when burnt out, give 4 kW of energy.

Experts recommend choosing the power of metal structures by 10-15% more than indicated in the passport of the finished product, because laboratory indicators, as a rule, do not match the real ones under normal operating conditions.

The high power of the firebox allows, with the door closed, to heat the room faster and keep the temperature values in the smoldering mode longer. It is not recommended to use the maximum resource of the furnace for a long period of time, this will lead to its rapid wear.

The ability to supply the room with heat is provided not least by the dimensions of the model.

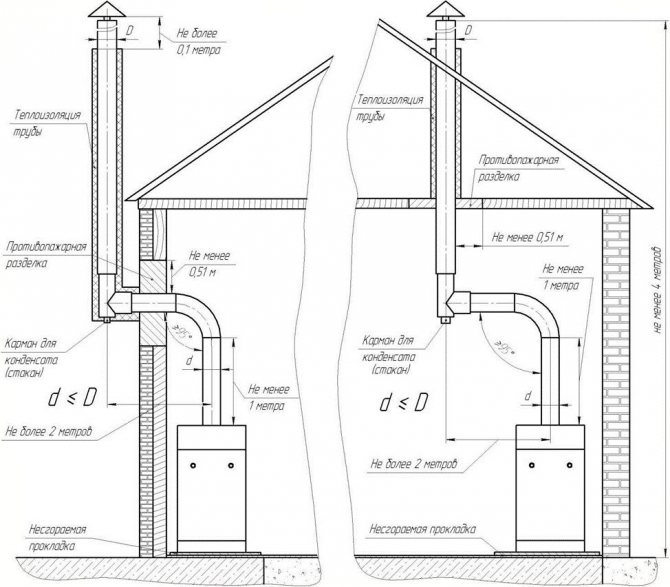

Errors in the installation of the chimney

Since it is not always possible to correctly install the stove in the house and lead the pipe through the wall, the most common installation errors should be considered in order to avoid them. Incorrect design robot is possible in such cases:

- Insufficient amount of insulation at the junction of elements. In this case, the pipe will overheat.

- The presence of joints in places where they pass through a wall or roof overhang. Such installation increases the risk of fire of a capital structure.

Video description

This video clearly shows an example of a violation of the rules for installing a sandwich chimney:

- The position of the pipe is not observed. It is installed strictly vertically. When insulating the main walls with foam plastic or mineral wool, long dowels are used to fasten the chimney.

- There is no ebb on the side slope of the roof. In this case, precipitation can get on the insulation and impair its function.

- Insufficient overall height of the vertical part. This error leads to poor traction.

Problems arise when using low-quality insulating material. Cheap insulation shrinks over time, so there is a possibility of local overheating of some parts of the chimney.

Expert advice

Before purchasing the necessary materials for arranging an external chimney, the power of the equipment is determined. It affects the diameter of the pipes. You can also use the following expert advice:

- if the heating equipment is equipped with forced draft, then it is not necessary to increase the vertical section of the structure, it is enough to bring out the horizontal pipe;

- too long horizontal section contributes to slowing down the smoke flow (the value should not exceed 1-1.5 m);

Rules for installing chimney pipes

Inspection holes are arranged not only on the outer part of the structure, but also on the inner horizontal element.

Service life of an outdoor chimney

The service life of the structure depends on the material of its manufacture and the correct installation. Ceramic pipes, if used correctly, will perform their function for up to 40 years. A brick chimney can be operated for more than 50 years. Stainless steel will have to be changed after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A quality sandwich system will last up to 20 years. Structures last longer if the heating equipment runs on gas or pellets.

Briefly about the main ...

Chimneys are single- and double-walled. According to the material of manufacture, metal, brick structures and structures made of sandwich pipes are distinguished. The last option is optimal for private houses. When installing the chimney, the rules for its placement in the room are observed. Its functionality, as well as the presence of traction in heating equipment, depends on the correct determination of the diameter and height of the structure.

The installation technology through a wooden and brick wall is the same, but there are some nuances: wood is more susceptible to ignition and requires maximum protection. During installation, fire regulations must be observed, as well as possible errors must be taken into account.

Making and installing a chimney with your own hands

Having decided to make a chimney with your own hands, first of all, you should:

- determine the material from which the structure will be made;

- complete a drawing and diagram of the future structure;

- calculate dimensions.

There is no universal building scheme for a smoke exhaust structure; it will be individual for each chimney, because. depends on a number of factors:

- features of the room where it is planned to install a fireplace, and the building as a whole;

- type of heating device;

- type of fuel used;

- selected building material (coefficient of its thermal expansion).

What materials are better to make

Initially, the choice of material is based on the type of fireplace used and only then on the aesthetics and personal preferences of the owner.

- A brick chimney is recommended for use only with solid fuel equipment.

- The symbiosis of a brick and a gas fireplace is not the best solution, because. the temperature of the processed combustion products of gas appliances is quite low. This leads to the formation of a large amount of condensate, which, entering into a chemical bond with the combustion products, destroys the brick structure. The same applies to liquid fuel, pyrolysis (gas generating) or pellet (automated solid fuel) fireplaces.

If brickwork is a prerequisite for you, you should make a sleeve (lining) of the chimney channel, i.e. install a single-layer stainless steel pipe inside, which is resistant to acidic environments. The advantage of a metal liner is that it can be inserted into the chimney even after the completion of construction work or during the reconstruction of an old mine. In this case, there must be a distance between the wall and the steel insert.

Drawing and diagrams

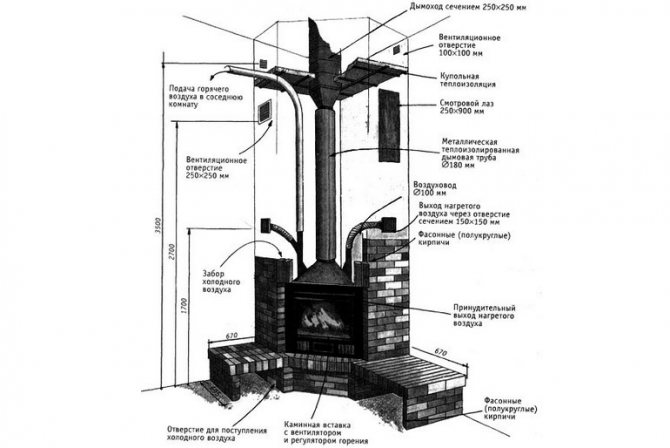

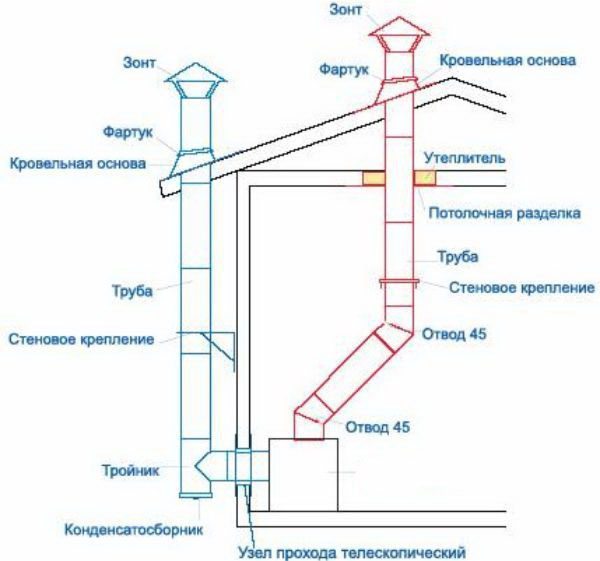

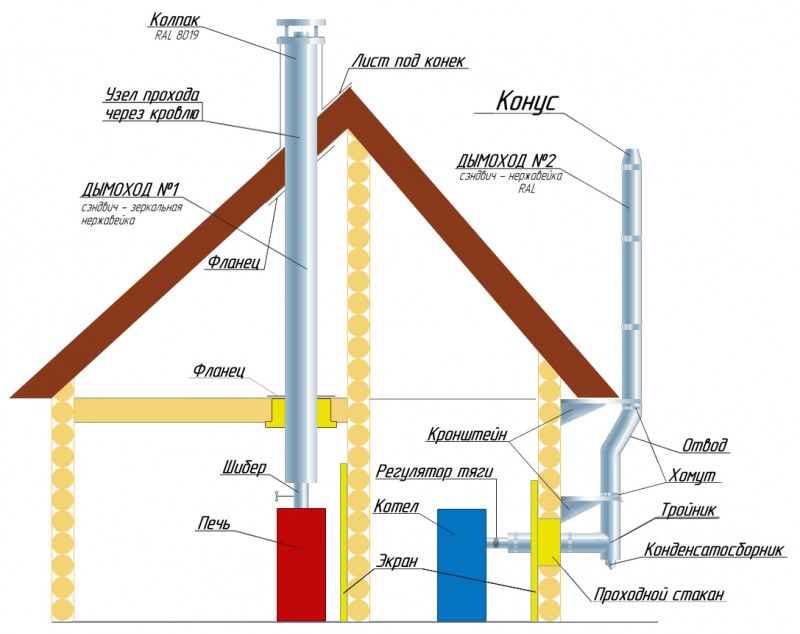

Scheme of the device of a metal sandwich chimney:

Drawing of a traditional brick chimney:

Scheme of a brick chimney with a steel / ceramic liner:

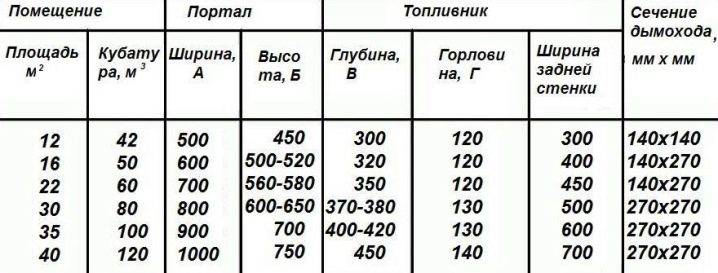

Size calculation

When carrying out design calculations, the required section and height of the pipes are determined. This takes into account:

- fireplace power;

- type of fuel;

- its location;

- climatic features of the region.

When the result obtained is lower than the height of the house, it is adjusted upwards, taking into account the regulatory standards for height (at least 5 meters) and the required level of elevation above the roof.

In addition, the following recommendations should be followed:

- the diameter of the flue duct must be equal to the diameter of the outlet pipe of the fireplace;

- the diameter of the chimney shaft with the simultaneous connection of two units to it is calculated for each separately and summed up;

- when rounding into a turn, the radius of this rounding should not exceed the cross section of the main contour.

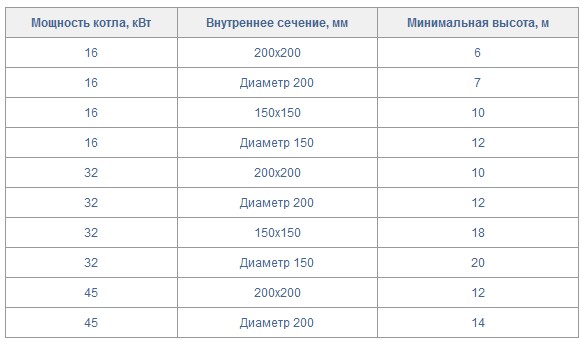

To determine the necessary parameters, knowing the power of the heating unit, you can use the table:

To maintain optimal heat transfer and circuit safety, the thickness of the pipeline walls is of no small importance. The following minimum values are set depending on the material type:

- for a brick structure - 12 cm;

- for concrete - 6 cm;

- for steel pipes - from 1 mm.

About offers on the market and general characteristics

At first glance, it may seem that chimneys for fireplaces are very diverse. In fact, there are only 3 proven directions and a couple of alternatives.

good old brick

Brick pipes are a classic, they are reliable, durable and look pretty solid, but it is advisable to build a brick chimney at the stage of building a house.

Brick pipe is reliable and durable.

Brick pipe is reliable and durable.

The average price of materials, excluding the cost of the foundation, fluctuates around 6-8 thousand rubles, this is provided that you lay the brick with your own hands. Plus, fireplace work is easier than laying stoves.

On the other hand, if you do everything right, then this fireplace chimney will safely live to the age of your grandchildren.

Proven stainless steel

About 20 years ago, double-circuit insulated stainless steel chimneys appeared. The design is simple - heat-resistant thermal insulation is stuffed between two pipes of different diameters, the thickness of the steel in them is 0.5-1.2 mm, the thing is reliable, the guarantee is given for 15-20 years, although it can stand longer.

The price of such pipes starts from about 1400 rubles. for 1 meter section and can reach up to 5000 rubles, but here you need to look at the steel grade:

- for high temperatures, grades from AISI 304 to AISI 321 are suitable; they withstand temperatures up to 700 ºС;

- grades from AISI 409 to AISI 430 are already designed for temperatures not exceeding 500 ºС.

Stainless steel pipes are assembled quickly and last a long time.

Stainless steel pipes are assembled quickly and last a long time.

If you have a fireplace with a closed firebox, then the temperature of the combustion products in the chimney will be higher. Firewood in open fireplaces gives a maximum of 400 ºС, and in closed 450-600 ºС. But if you load anthracite or coke into the furnace, then the temperature at the exit from the open furnace will be at least 500 ºС, in a closed furnace it can easily rise to 700 ºС.

Ceramics

A ceramic chimney is almost perfect, this material can withstand temperatures up to 1320 ºС, plus ceramics are absolutely indifferent to an acidic environment, it is not in vain that ceramic chimneys are used in hazardous industries with high temperatures.

Modular ceramic pipes are reliable, but expensive.

Modular ceramic pipes are reliable, but expensive.

There is only one problem - a set of such pipes for a chimney will cost you from 20 thousand rubles, plus add to this the cost of heat-resistant glue and the arrangement of a small foundation. But it’s quite simple to assemble such a constructor with your own hands, but more on that later.

Alternative for homemade

- Asbestos pipes. Such a chimney will cost a penny and it can be assembled in a couple of days, but the maximum for an asbestos-cement chimney is 300 ºС and it collapses instantly, it just bursts;

- A steel chimney (meaning ferrous metals) keeps the temperature well and is not expensive, but the problem is that the condensate that periodically falls inside any chimney duct is an acid-base "cocktail" and it corrodes iron very quickly;

- A cast iron fireplace chimney is a good alternative as about half of fireplace inserts are made of cast iron, but these chimneys are very heavy and usually installed inside a brick jacket, which means you have to fold the brick box first and then insert it into it. cast iron pipe.

Cast iron chimney is durable, but very heavy.

Cast iron chimney is durable, but very heavy.

A few words about calculations and standards

If you follow GOST 9817-95, then the size of the chimney for a stove or fireplace is calculated depending on the power of the unit, so for 1 kW of power there are 8 cm² in the cross section of the chimney;

There is not such an accurate, but simpler method of calculation: the diameter of the chimney for the fireplace is related to the area of the mirror of the fireplace insert as 1:10 (the mirror of the furnace is the front opening of the fireplace);

The size of the chimney pipe in height should not be less than 5 m;

It is also important how much the chimney pipe rises above the roof ridge, the level of thrust depends on this, the minimum parameters are shown in the diagram below, but in general, the higher the pipe rises above the ridge, the stronger the thrust will be;

The height of the pipe above the ridge is a very important parameter when building a chimney.

The height of the pipe above the ridge is a very important parameter when building a chimney. The configuration of steel chimneys can be different.

The configuration of steel chimneys can be different.

Brick fluffing scheme

How to properly lay out fluff?

Fluff is a significant increase in the outer sides of the pipe at the point where it intersects with the attic floor. Its function is to keep the wood floor from fire, as well as from excessive overheating.

The fluff width is a minimum layer of 1 brick.

It must be wrapped with a layer of thermal insulation, which is prepared in advance.

- To prepare a heat-insulating layer, the felt should be soaked in a clay solution.

- More fluff can be overlaid with asbestos sheets.

Experienced builders recommend:

- Spread the fluff in one and a half bricks, then it will not be necessary to wrap the fluff with thermal insulation. It should be remembered that such an action can be performed if they intend to heat the fireplace stove for no more than 3 hours.

- If the burning time of the hearth is more than 3 hours, the fluff should be laid out in 2 bricks, and the internal volume of the pipe must be maintained, which was before the expansion of the fluff.

Another fluff - a riser, is erected without expanding the pipe, to the roof. A hole is cut in the wood floor not only for the pipe, but also for the metal box.

The distance from each side of the pipe is 50 cm.

It is filled with refractory material, for example: sand, clay or expanded clay. In advance, metal rods are laid in the pipe, on which the box will hold.

There is another way to create fluff, it is done as follows:

- 30 cm before the wood floor, 6 mm thick rods are laid in the seam, protruding beyond the edge of the pipe by one and a half bricks.

- On the next row, the same rods are laid in the same direction.

- Perpendicular to them, the same wire is attached, with the same cross section, so a two-level grid is created.

- A plank formwork is installed under this wire. It is 40 cm wide and 10 cm high.

- Concrete of the M-350 brand is poured into the box, which can be kneaded independently.

Solution preparation

- This requires: one part of M-500 cement, two parts of sand (preferably coarse-grained) and three parts of crushed stone (the best option is chipped), (1:2:3).

- All this mass is mixed and filled with water, it is necessary to obtain a uniform consistency so that it is not liquid, otherwise the cement milk will flow through the cracks, and the solution will be fragile.

- This formwork is removed after 72 hours, and the concrete is kept without load for another 72 hours, periodically watering it with water.

- After aging for 6 days, a fluff brick is laid on this concrete base, tying it with a riser.

Remember that the expansion of the pipe is built in 7 rows, then the riser is laid out. The continuation of the pipe is erected three rows above the level of the roof, and then they begin to lay out the "otter". Create the lower part of the "otter", expanding it, half a brick to the sides.

Thus, the overhang of the sides made is increased in 4 directions. The riser expands by 10 cm, forming a small canopy.This expansion protects the roof from rain entering the attic.

It is important to observe the dressing between the bricks, especially in those places where the halves and quarters are located.

- Next, a head is laid out, which saves the pipe from destruction using the same technology as the fluff.

- A metal cap is installed on the head. It protects the inside of the pipe from atmospheric precipitation and improves draft in the fireplace.

If you want to plaster the pipe, then clean the surface of dust and foreign particles.

- Attach a plaster mesh to the outer part of the pipe - a solution is swept over it.

- The solution for plaster is lime-slag with the addition of cement.

The finished surface can be whitewashed to show cracks in the plastered pipe.

Placement methods

To think about the placement of the chimney, you need to think in advance where exactly it can be placed: on the wall, outside (external) or inside in a private house. On the street, the installation of a chimney is often carried out from a metal pipe, but we will talk about this a little later. By the way, remember what ceilings are installed in your house, what walls are made of, possibly combustible material, then there are some nuances associated with additional insulation, all this is money, and with proper work, and most importantly of high quality, not small enough.

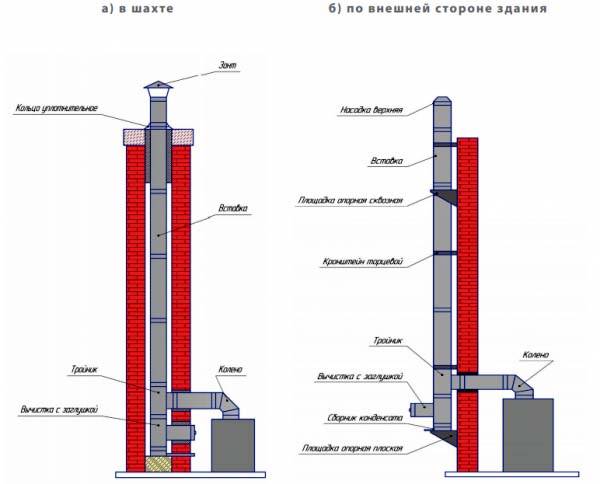

Ways to place the chimney: in the mine, on the outside of the building

Ways to place the chimney: in the mine, on the outside of the building

It is recommended to place the chimney on the warmer side of the site, at home

Pay attention to the nature of the output of the head, where exactly the technological output was provided. Consider such a scheme that the closer to the ridge, the lower the height of the chimney itself.

In addition, regardless of the type of placement, type of attachment and chimney, pay attention to the dimensions of the pipe itself, that is, the diameter

Remember, the diameter of the outlet channel of the boiler, stove, fireplace must match the chimney.

Where to start?

First of all, you have to create a chimney project: decide on the size, appearance and material. In order to understand exactly how to compose it, you can look on the Internet for a photo of a chimney project for a stove.

As mentioned earlier, it is important to choose the right basic dimensions, otherwise it will interfere with the quality work of the heater and affect the health of your family. Now you can decide on the appearance and structure of the chimney.

Depending on the location relative to the furnace, the following types are distinguished:

- Chimney coming directly from the stove.

- Chimney, located on one side of the heater.

- Chimney built into the wall.

Stainless steel chimneys

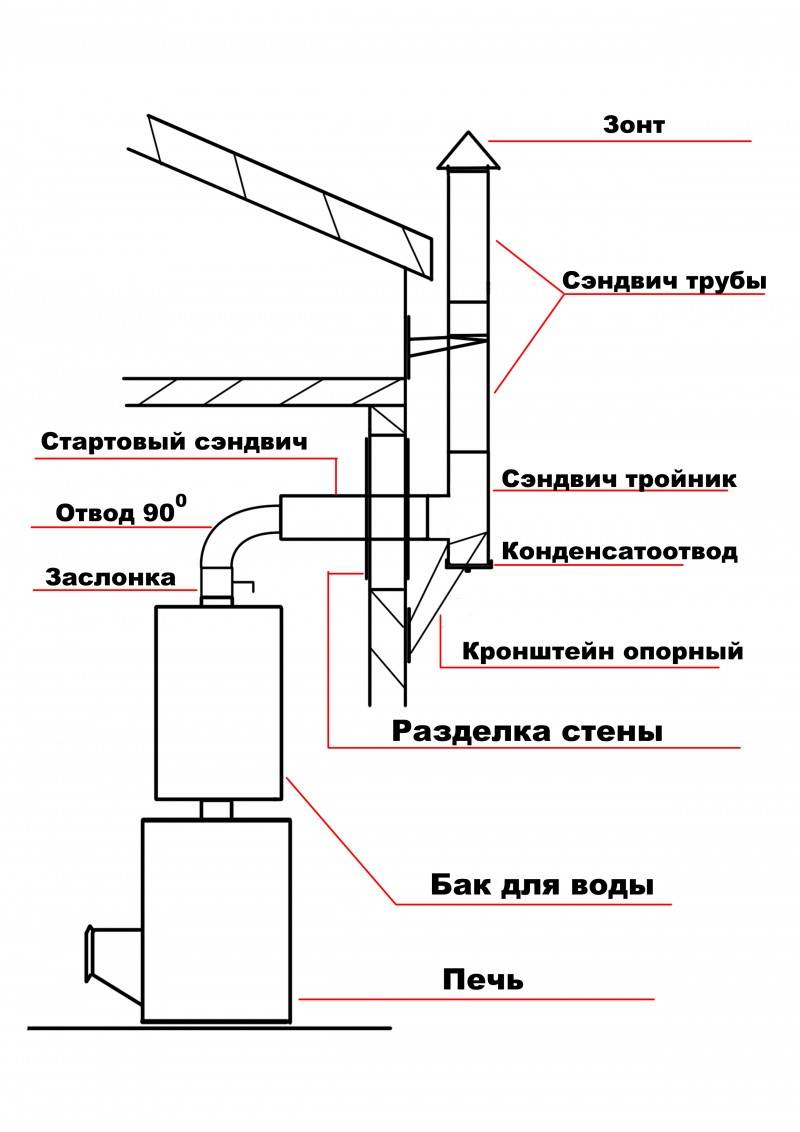

These pipes are made of stainless steel, and their thermal insulation is carried out using combustible materials.

Chimneys of this type can have different diameters and lengths. They often come with ceramic pipes, which are mounted inside steel ones.

A chimney made of galvanized steel is characterized by a number of advantages:

- due to their light weight, sandwich chimneys for fireplaces can be installed without a foundation (read: “Sandwich pipes for a chimney - installation”);

- it is possible to mount such a chimney even after the entire construction process is completed;

- stainless steel chimney is cheaper than block and ceramic chimneys;

- individual parts of the chimneys can be easily replaced if desired.

Information with a photo on the installation of pipes for a chimney made of stainless steel, if desired, can be found on our website.

Conclusions and useful video on the topic

What mistakes are most often made when installing stoves and chimneys to them:

How to lay brick chimneys:

How to make a stainless steel chimney:

Reliable chimney pipes can be made from different building materials. The choice of options is quite extensive. It is easiest to make a chimney from steel, and cheaper from brick.

But if you need the most durable and safe system for removing stove fumes, then ceramics is the undisputed leader here. It is expensive, but will last for decades. The main thing during the installation of all options is to comply with building and fire regulations.

After studying the material, there are incomprehensible moments and would like to find them out? Please leave your comments at the bottom of the article. Here you also have the opportunity to report interesting facts on the topic of the article or share your own experience with site visitors.