- Boiler Volume Calculation

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- Installation of instantaneous water heater

- Preparation - Checking the Mains

- Location selection

- Wall mounting

- How to connect to the water supply

- Inclusion in the power supply

- Calculation of the main parameters of the boiler

- Volume and shape of the tank

- Heat exchanger power and length

- Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

- Instructions for connecting and starting the system

- Indirect heating boiler pros and cons

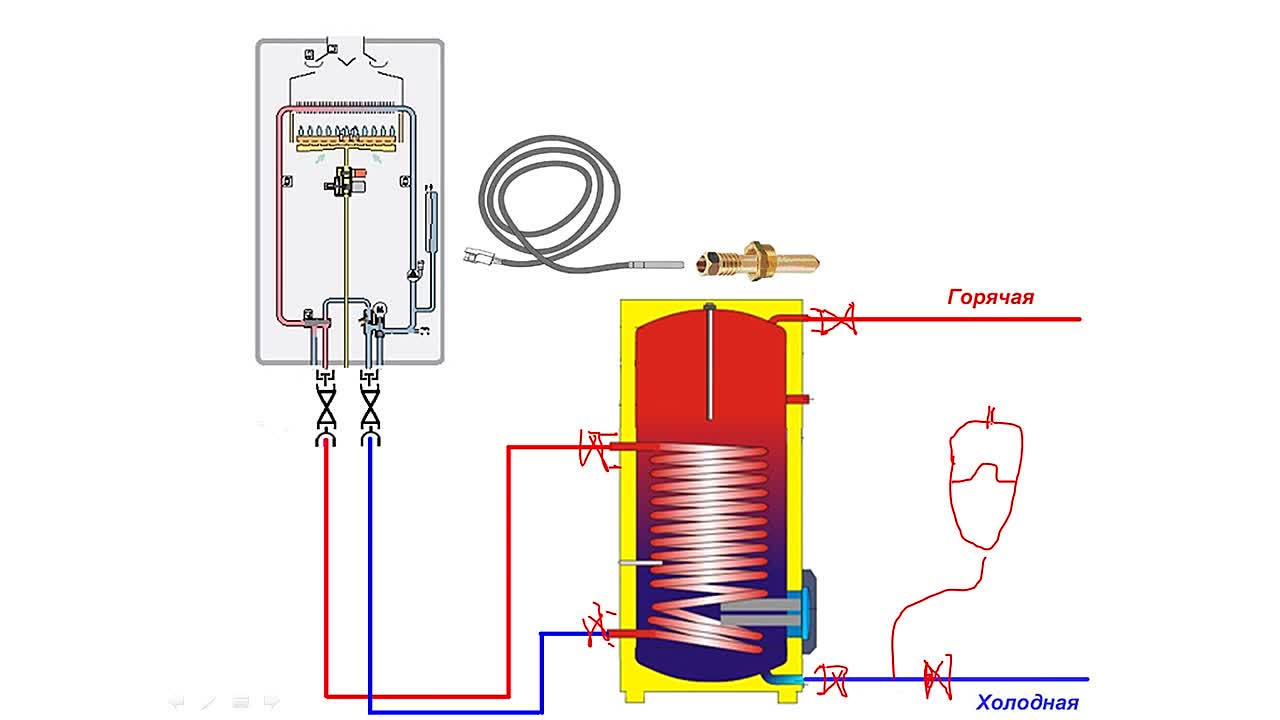

- Wiring diagram

- Possible mistakes

- Briefly about the main

- Do-it-yourself indirect heating boiler

- Power calculation

- Tank calculation

- Coil calculation

- Thermal insulation and assembly

- Conclusion

Boiler Volume Calculation

To calculate the volume of a container for heated water, you need to at least approximately understand the daily need for it. On average, one person spends about 60 liters of water per day, which means that an ordinary family of 3 people will need a boiler tank with a volume of about 200 liters.

But the next task will be more difficult - to calculate the diameter and length of the coil. These seemingly simple data are based on the temperature of the coolant in the coil, the speed of its movement, the material from which the coil is made.The volume of the tank is no less important - the larger it is, the larger the coil should be. On average, to heat 10 liters of water, it is necessary for the coil to produce one and a half kilowatts of heat. Usually it is made of copper or brass, taking a pipe about 2 cm in diameter. The length of the pipe will be calculated based on the required power using a special formula.

In this formula, the letter “P” denotes the power of the coil in kilowatts, “d” is the diameter of the coil pipe, ?T is the temperature difference between the water and the coolant in the coil in degrees Celsius. To make it clearer, we can give a simple example: there is a tank with a volume of 200 liters, the coil power for which must be at least 30 kW, a pipe with a diameter of 0.01 m (1 cm). The coolant in the coil has a temperature of 80 degrees, and the incoming water, on average, is about 15 degrees. Calculating the data using the formula, it turns out that the length of the pipes must be at least 15 m. To fit such a coil into the tank, it must be wound onto a template with a diameter of about 40 cm with a spiral. Ready! All the data is there to independently make an indirect heating boiler

What is an indirect heating boiler and what are they

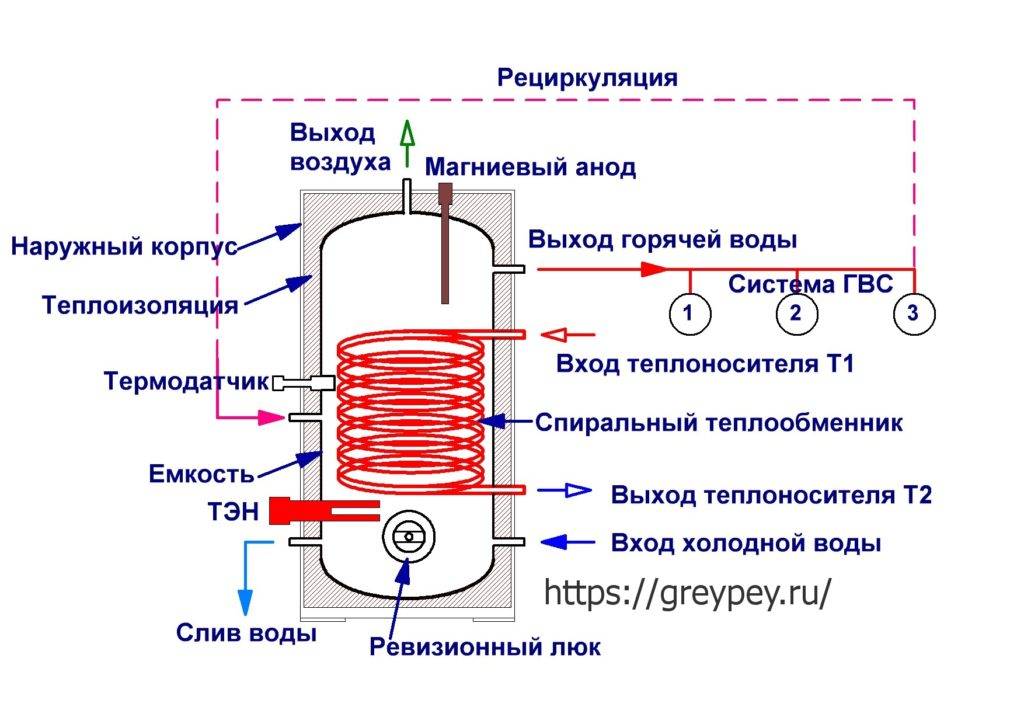

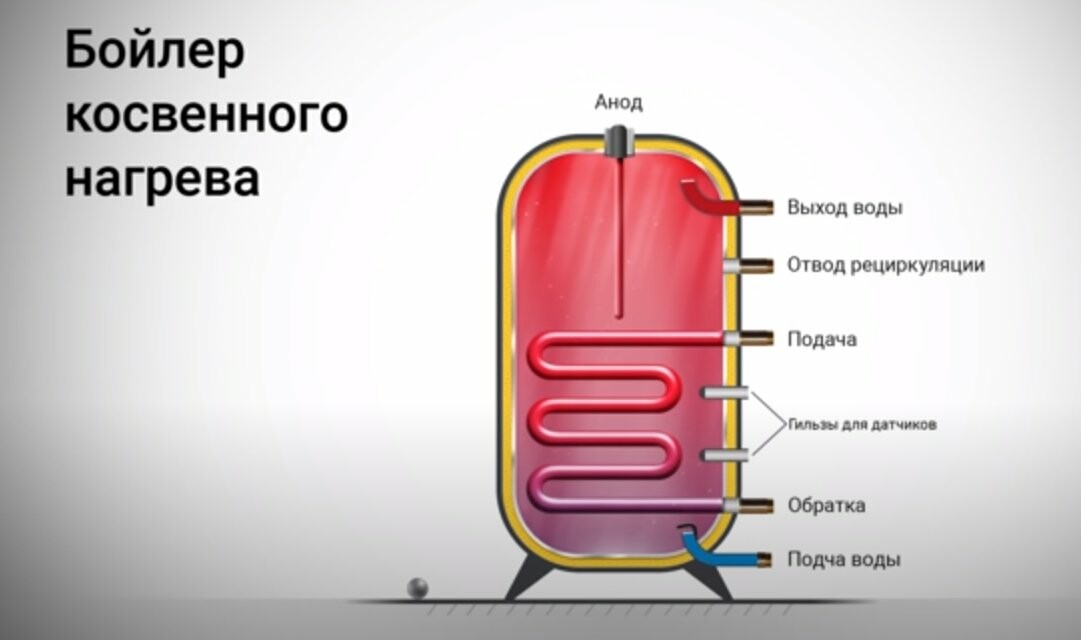

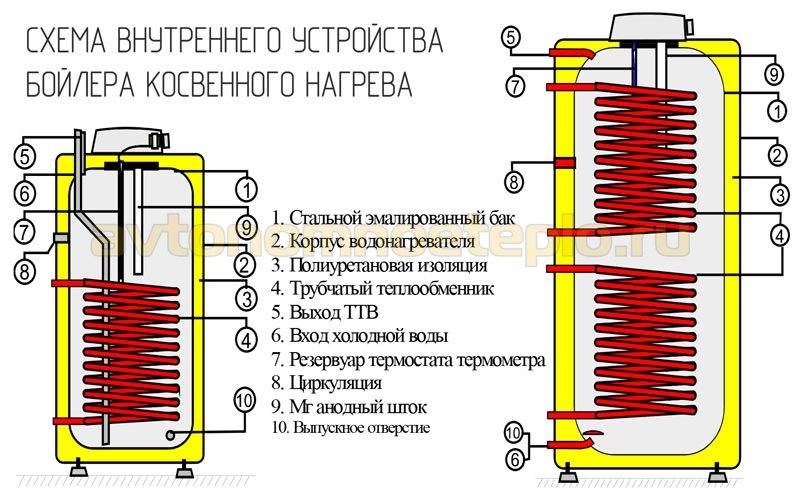

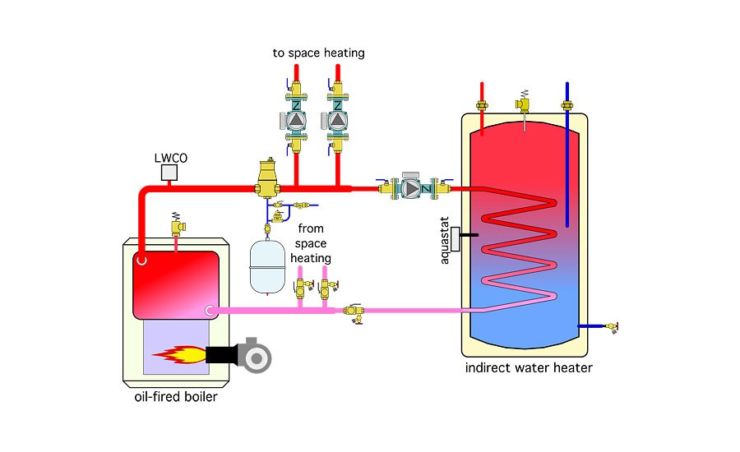

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating".The heated water is used for household needs as needed.

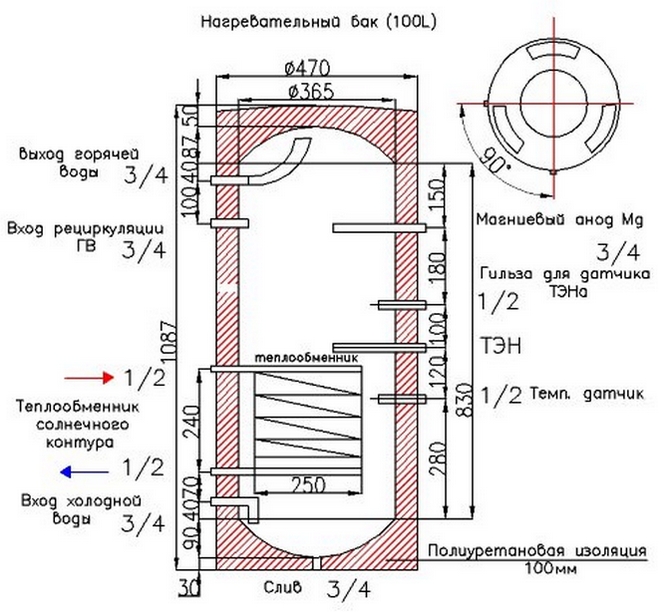

Indirect heating boiler device

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

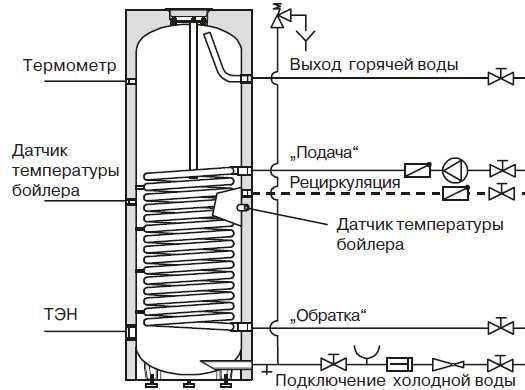

There are two types of indirect heating boilers: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet. Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

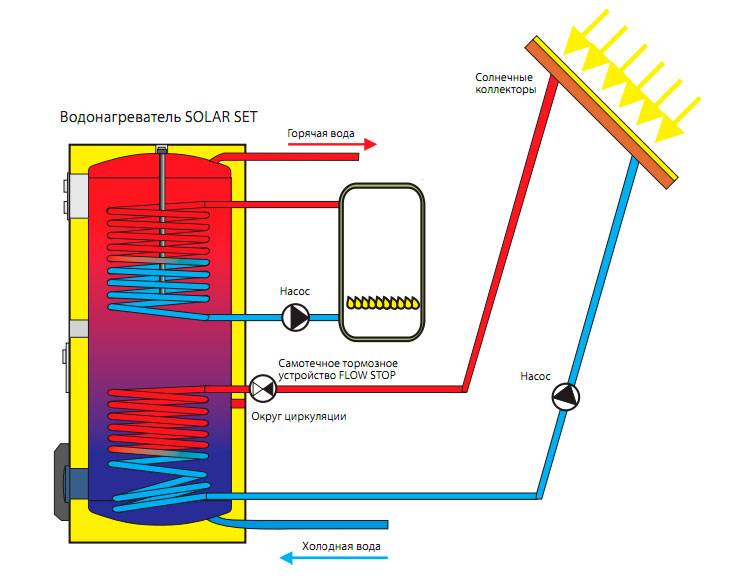

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil. So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element.The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task. If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

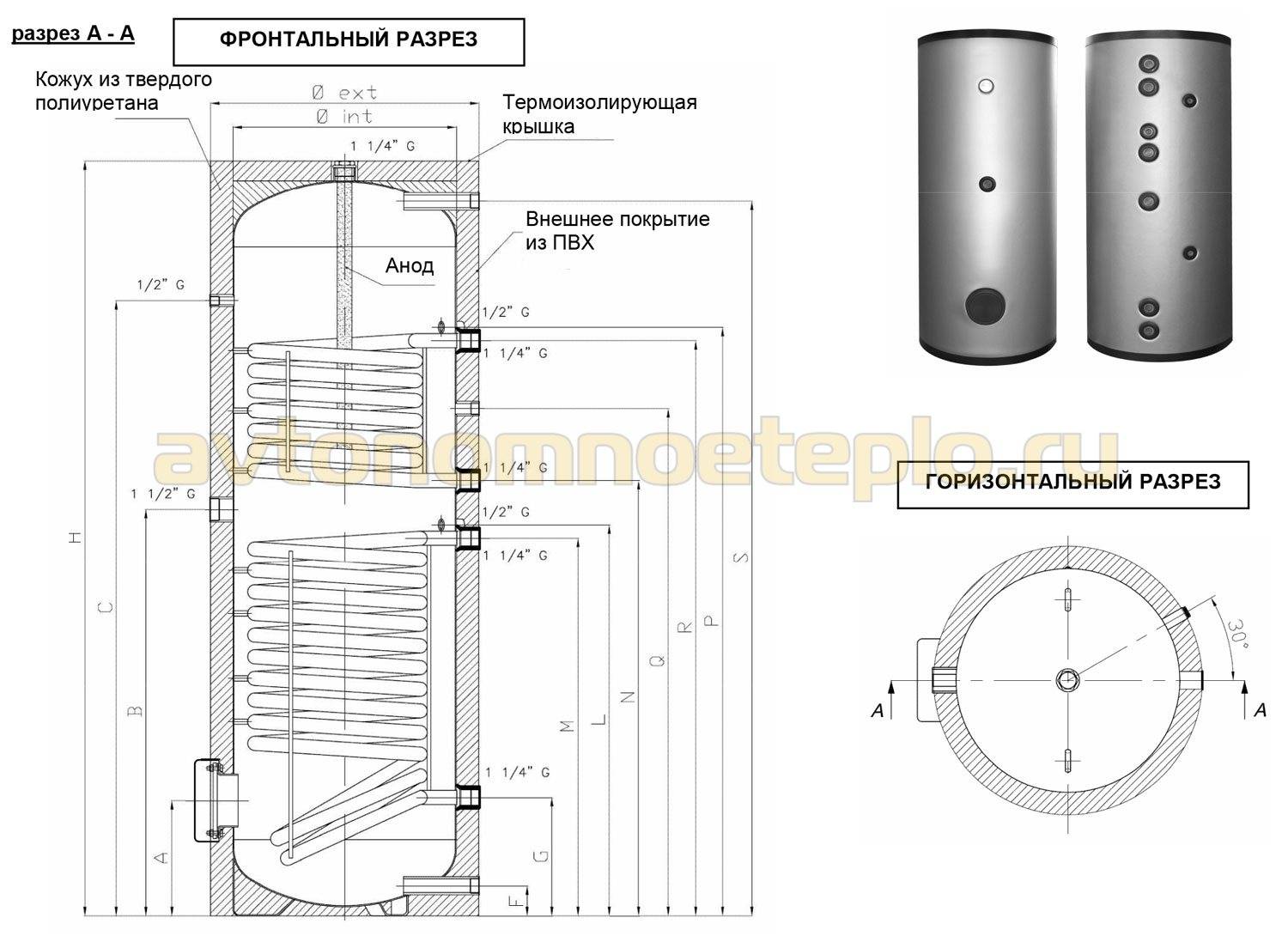

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder.In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better. On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

Installation of instantaneous water heater

Heating water in an instantaneous water heater, despite the simple principle of operation in residential areas, is used less frequently than the storage type. This is due to the fact that in order to quickly heat cold water, powerful heating elements from 3 to 27 kW are required, and not every intra-apartment electrical line can withstand such a load.

Preparation - Checking the Mains

Before deciding to install an instantaneous water heater, you should check the capabilities of the intra-house electrical network. Its required parameters are indicated in the passport for the water heater, and if they do not correspond to the actual data, the reconstruction of the house power supply line will be required.

To connect most instantaneous heaters, a stationary installation method is required, AC 220 V, 3-core copper cable, with a cross section of at least 3x2.5 mm and automatic protection of at least 30 A. The instantaneous water heater must also be connected to the grounding system .

Location selection

Non-pressure instantaneous water heaters, in general, are able to guarantee the operation of only one point of water intake, as a result, the question of selecting the installation area is not worth it.

It is placed instead of a mixer in the bathroom or kitchen. The choice of powerful pressure flowing heaters that serve several water points must be carefully carried out. As a rule, it is placed near the maximum water intake or riser.

Despite the fact that IP 24 and IP 25 modifications are structurally protected from direct water penetration, nevertheless, it is more reliable to place them in places where there is no threat of direct water ingress.

In addition, it should be borne in mind that devices that have a mechanical system for adjusting the pressure and temperature of hot water must be located at arm's length. Based on the above, installing a boiler in the bathroom will be the most preferable.

Wall mounting

Flow heaters do not have a lot of weight, their installation does not impose requirements similar to capacitive devices. Mounting on the wall of the building consists in drilling holes and fixing the heater using special brackets supplied in the kit.

The main conditions for a professional installation:

- The strength of the wall covering;

- perfect horizontal position.

If the heater is placed with an inclination, there will be a risk of air voids, which will lead to overheating of the heating element and failure of the water heater.

How to connect to the water supply

It is quite simple to tie a non-pressure flow heater. The connection is made with a flexible hose removed from the mixer to the fitting of the device.To do this, install a special gasket under the union nut and wrap it first by hand, and then with a little pressure with a wrench.

It is important to observe the rule that shut-off valves are not installed after the heater. The water must only be turned off by the heating device or faucet to which it is connected.

In a different scenario due to the lack of water movement, the heating element will overheat and fail.

Inclusion in the power supply

Small-sized non-pressure modifications of water heaters are mainly implemented with the necessary wire plug. In this regard, the inclusion is reduced to the fact that you need to insert the plug into an electrical outlet with grounding.

The electric heater is a powerful electrical appliance; it is forbidden to turn it on using various extension cords. Due to the huge electrical current, the contacts can overheat and cause a fire in the wiring.

Calculation of the main parameters of the boiler

Before proceeding with the search for material and directly manufacturing, it will be necessary to calculate the minimum volume of the tank and the working length of the heat exchanger.

Volume and shape of the tank

The volume of the water tank directly depends on the number of residents permanently residing at the place where the equipment is installed. It is believed that a person consumes up to 80 liters of water per day. For the calculated value, it is recommended to take 45-50 liters per person. If the norm is exceeded, the water in the tank will stagnate, which will certainly affect its quality.

The shape of the tank is selected taking into account the pressure force in the plumbing system. If the pressure is low, then homemade boilers with a square tank are allowed. At high pressure in the system, only equipment with a rounded bottom and top can be used.

Boilers with a storage tank of square and rectangular shape can only be used in water supply systems with low operating pressure

The fact is that increased pressure contributes to the occurrence of bending forces on the walls of the tank, so a square or rectangular tank can be deformed. A container with a round bottom is more resistant to deformation due to better streamlining.

Heat exchanger power and length

In vertical models of indirect heating, a copper coil is usually used as a heat exchanger, located between the inlet and outlet.

Boiler coil made of copper pipe

For self-production, it is best to use a copper pipe with a diameter of 10 mm. Such a product can be easily bent by hand without the use of any tool. When using a metal-plastic pipe, it should be borne in mind that the heating temperature of the coolant should not be more than 90 ° C, otherwise the pipe will deform and the joints will leak - this will lead to mixing of water in the tank.

The length of the pipe required for the manufacture of the coil is calculated by the formula L \u003d P / (3.14 ∙d ∙∆T), where:

- L is the length of the pipe (m);

- d is the pipe section (m);

- ∆Т is the temperature difference between hot and cold water (oC);

- P is the power of the heat exchanger for every 10 liters of water (kW).

According to experts, for every 10 liters of water there should be at least 1.5 kW of thermal energy. With this in mind, you can calculate the length of the pipe for the manufacture of the coil.

For example, we will calculate the material for the coil, which will be installed in a boiler with a capacity of 200 liters.The temperature of the cold water supplied to the tank will be 15 °C, and after heating it is necessary to obtain water with a temperature of 80 °C: L = 1.5 ∙20 / (3.14 ∙0.01 ∙65) ≈ 15 m.

Table: length of copper heat exchanger for boilers with a capacity of 50–200 liters

| Storage tank volume, l | Equipment power, kW | Heat exchanger length, m | Boiler tank diameter, m | Loop diameter, m | Number of turns |

| 200 | 30 | 15 | 0,5 | 0,4 | 12 |

| 150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

| 100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

| 50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

The number of turns of the coil depends on the method of bending and the distance between the elements. Usually the coil is positioned so that the distance between the coils and the walls of the tank is at least 10-12 cm. The distance between the coils should not be less than 5 cm. Calculated values for storage tanks of various volumes can be seen in the table above.

If an indirect type boiler must be equipped with a tubular electric heater, then the power is calculated based on the fact that a heating element with a power of at least 1.5 kW is required to quickly heat 50 liters of water. In addition, any combined boiler must be equipped with a thermostat.

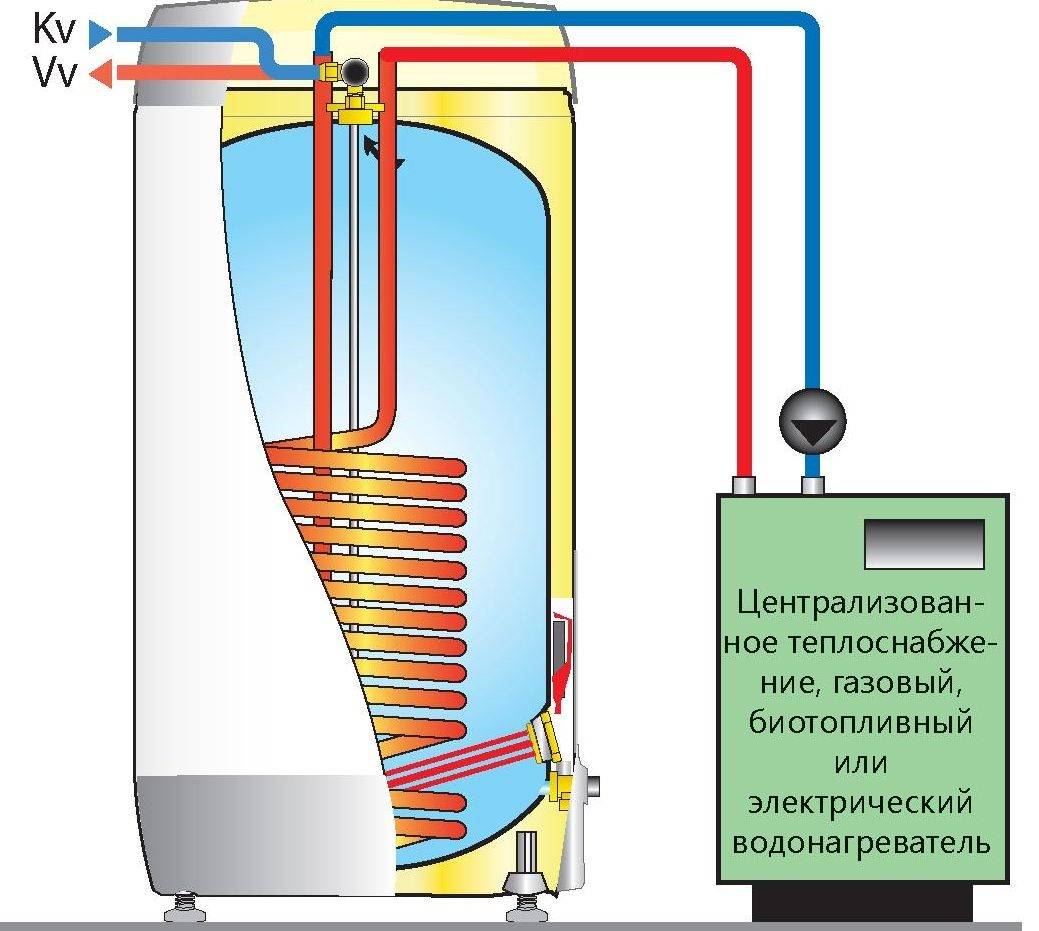

Instructions for connecting and starting the system

When preparing the boiler for operation, it is first connected to the heating system. It can be a network of a home autonomous boiler or a central highway. During the connection process, the lid of the water heater tank must be open. When all the pipes are connected to each other in the right order, open the shut-off valve of the return pipe to make sure that there are no leaks at the joints and the pipes themselves.

If no leaks are found, you can open the coolant supply valve to the coil.After the spiral warms up to normal temperature, the structure is once again inspected for leaks.

Indirect heating boiler pros and cons

The advantages of using an indirect heating boiler in the hot water system of a private house include:

- Comfort in use. DHW as in an apartment;

- Rapid heating of water (due to the fact that all 10-24 or even more kW of boiler energy are used);

- No scale in the system. Because heating is carried out through a heat exchanger, and its temperature does not exceed the boiling point of water. Of course, the problem is not completely solved, but its education is significantly reduced. Also, storage water heaters can be equipped with anodes made of various materials (aluminum, magnesium, titanium). Which also contributes to the resistance to corrosion of the tank itself and prevents the formation of scale.

- Possibility to organize a water recycling system. Hang towel warmers. No need to wait and drain a large amount of water until hot water flows. You can't do that on a double boiler.

- The ability to get a large amount of hot water, which is enough for all needs at the same time. With a double-circuit boiler, the flow of hot water is limited by the capacity of the boiler - its power. You can't wash dishes and use the shower at the same time. There will also be clear temperature fluctuations.

As always, there are cons:

- Naturally, the cost in relation to a double-circuit boiler is greater;

- Takes up a decent amount of space;

- Additional troubles for connecting and configuring the system;

- With a recirculation system, additional costs (faster cooling of the system, pump operation, etc.), which will lead to an increase in the DC in payment for energy carriers (gas, electricity);

- The system needs to be serviced regularly.

Wiring diagram

The connection of an indirect heating boiler to a single-circuit boiler of any type is carried out according to the same schemes: with or without priority. In the first case, the coolant, if necessary, changes the direction of movement and stops heating the house, and all the energy of the boiler is directed to heating. This method allows you to quickly heat a large volume of water.

At the same time, the heating of the house is suspended. But the boiler, unlike a double-circuit boiler, heats the water for a short time and the rooms do not have time to cool down.

Features of connecting an indirect heating boiler depend on the material of the pipes:

- polypropylene;

- metal-plastic;

- steel.

The easiest way is to connect the equipment to polypropylene communications that are not sewn into the walls. In this case, the master will have to cut the pipe, install tees, use couplings to connect the pipes going to the boiler.

To connect to hidden polypropylene communications, it is necessary to additionally install branch pipes leading to pipes in the walls.

There is no technology for hidden installation of a metal-plastic water supply system, so the connection will be identical to the connection of polypropylene open communications.

Properly installed indirect heating boiler

Connecting the boiler in the video:

When installing a water heater, it is necessary first of all to choose the right location in accordance with the requirements:

- Quick access to the connecting links of the water supply for quick repairs.

- Proximity of communications.

- The presence of a solid load-bearing wall for mounting wall models. In this case, the distance from the fasteners to the ceiling should be 15–20 cm.

Water heater placement options

When a place for equipment is found, it is necessary to select a boiler piping scheme. Connection with a three-way valve is very popular. The scheme allows you to connect several heat sources in parallel to one water heater.

With this connection, it is easy to regulate the temperature of the water in the boiler. For this, sensors are installed. When the liquid in the tank cools, they send a signal to the three-way valve, which shuts off the coolant supply to the heating system and directs it to the boiler. After heating the water, the valve works again, resuming the heating of the house.

When connecting distant water intake points, it is necessary to recirculate. This will help keep the temperature of the liquid in the pipes high. When the taps are opened, people will immediately receive hot water.

Connecting a boiler with recirculation

Connecting with recirculation in this video:

Possible mistakes

When connecting an indirect heating boiler, people make several common mistakes:

- The main mistake is the incorrect placement of the water heater in the house. Installed far from a heat source, the device requires laying pipes to it. This leads to an increase in costs. At the same time, the coolant going to the boiler cools down in the pipeline.

- Incorrect connection of the cold water outlet reduces the efficiency of the appliance. It is optimal to place the coolant inlet at the top of the device, and the outlet at the bottom.

To increase the life of the system, it is necessary to properly connect and then perform periodic maintenance of the equipment.

It is important to clean the pump and keep it in good working order. Option for proper placement and connection of the water heater

Option for the correct placement and connection of the water heater

Briefly about the main

An indirect heating boiler is an economical way to organize a hot water system at home. The equipment uses the energy of the heating boiler for heating, this does not lead to additional expenses.

The water heater is a durable equipment, so you should choose a quality installation. Best of all, stainless steel tanks with a brass coil showed themselves. They quickly heat water and are not afraid of corrosion.

Do-it-yourself indirect heating boiler

In order to make an indirect heating boiler with your own hands with high quality, first of all, you need to familiarize yourself with the device and the principle of operation of this unit.

It is much easier to make a boiler, having at hand a drawing indicating all overall dimensions, shape and location of all elements.

Drawing of an indirect heating boiler

Using the drawing and having all the necessary tools at hand, it will not be difficult to create the described design.

However, the success of the work will depend on the calculations, so it is very important to make them correctly.

Power calculation

This parameter depends on three indicators:

- circulation speed.

- The temperature of the water in the tank.

- Heat carrier temperature.

To calculate the power of the water heater, it is necessary to take the following parameters as the norm: a circulation pump of 1 atm., Which can distill 200 liters of liquid per hour, the highest coolant temperature is 85 ° C. This is the information without which you cannot get started.

Tank calculation

The area of the container for 120 liters is calculated by the formula:

S \u003d V / h \u003d 0.12 / 0.9 \u003d 0.133 sq.m.V is the volume of the container, measured in liters; H is the height. For models of famous brands, on average, it is 0.9 m.

Then, from the area of the base circle, you need to calculate the radius:

R = √S/π = √0.133/3.14 = 0.205 m = 20.5 cm

The diameter of the circle itself will be 41 cm.

And the last thing you need to know is the circumference:

L \u003d 2 * πr \u003d 2 * 3.14 * 0.205 \u003d 1.28 m

Having calculated all these parameters, you can start welding.

Stainless steel is difficult to cook and can only be dealt with using argon arc welding and alternating current.

Coil calculation

Most often it is made of copper, so you need to get a thin tube, 42 * 2.5 mm in size. 42 is the outer diameter, while the inner diameter in this case will be 37 mm.

First you need to calculate the length of the coil:

L= V/S= V/πR2 = 0.0044/3.14*0.01852 = 4 m

After that, you need to find out the length of one turn. Having determined it, it will be possible to find out the approximate diameter of the coil.

For example, take a coil with a radius of 15 cm.

L \u003d 2πR \u003d 2 * 3.14 * 15 \u003d 94.2 cm

As a result, 4 full turns are obtained.

Don't forget a supply of copper tubing about 20-30 cm long. It can be useful during the installation of the boiler.

To twist the coil, you need to use a log, its diameter should be less than that of the boiler tank. The free ends of the coil must be fixed at a right angle. 2 pieces of the coil, 6-8 cm each, should go beyond the limits of the tank.

Thermal insulation and assembly

Mounting foam, mineral wool, polyurethane, etc. can be used as thermal insulation.

On top of the applied thermal insulation for a better effect, the boiler can be “wrapped” with a thin sheet of metal or foil insulation.

With the independent manufacture of an indirect heating boiler, the assembly process includes the following steps:

- In the stainless steel tank, we make 3 holes with a diameter of 3/4″ and connect ball valves to them. The first faucet (in the lower part) is responsible for supplying water, the second (in the upper part) for water intake, the third one for draining water and maintaining pressure.

- We insert the coil and see how it became. We make holes in the walls of the tank for the ends of the coil and solder the threaded fittings. We solder threaded fittings to the ends of the coil. This is necessary to secure the coil in the tank.

- We check the tightness of the coil using a soapy solution and a compressor. We process the coil with a solution and block one hole, and supply air through the other.

- Close the boiler tank with a tight lid. It can be made from two sheets of steel and polyurethane (placed between them). Do not forget to weld the bezel and attach the handle.

- We warm the structure. We use glue, wire or other options for fixing the insulation.

- We check the boiler for leaks by connecting it to the water supply.

Conclusion

The rapid rise in the cost of energy resources is forcing many to create cheap alternative devices. Many build a water heater with their own hands and create comfort at minimal cost.

A water heater is a device designed to transform various types of energy into heat, which is then transferred to a coolant, which is water. The industry offers various options for such devices. The heat source in them can be electricity, gas, solid or diesel fuel. Along with this, alternative energy sources are becoming popular - the sun, wind.

All heating systems on the market are divided into two types:

The design of the first involves the use of a tank in which a certain temperature is maintained. When the tap is opened, cold water enters the sealed container, and hot water is squeezed out into the pipeline. Thus, in the middle of the tank there is always a certain amount of heated coolant. Storage units differ in their size and long-term heating of water. Their use is justified in systems with a large number of water intake points. Devices are produced with a tank volume from 10 to 200 liters.

Flow devices have a completely different principle of operation. In them, the water is heated only in the case of its circulation, that is, when the tap is opened. Their advantage is in small dimensions and easy installation. Of the significant drawbacks, there is a large power required for the rapid heating of water.

At the same time, if several water intake points are used at the same time, the tank will not be able to provide uniform heating and the temperature of the coolant will begin to change abruptly. In practice, it will take from 30 seconds to 2 minutes for water to flow from the tap at a normal temperature.

The heat carrier is heated using a gas burner located at the bottom of the tank, or an electric heating element (TEH). But there are also products that use a water or steam exchanger to maintain the temperature of the coolant.

In addition to the tank and heat source, the design of the storage device includes:

- 1. Temperature control device. This is a set of devices designed to maintain the set heating value. The most commonly used temperature sensors are connected to the electronics unit, which controls the on and off of the heating system.

- 2.Protection. To avoid the increase in pressure inside the tank, which occurs due to the expansion of heated water, various devices are used. It can be either an additional expansion tank or a safety valve. In addition, depending on the heating source, a complex of protective devices is used to prevent gas leakage and current breakdown to the case.

- 3. Trumpet. Two pipes are used in water heaters: one serves to supply a cold carrier, and the second to issue a hot one.

- 4. Check valve. This small device allows you to keep water in the tank, even if it is absent in the supply system. It allows the medium to flow in one direction and does not allow it to flow in the opposite direction.

Boilers can be closed and open type. The former are used in conjunction with a centralized water supply system, and the latter are designed to serve one water intake point by shutting off pipeline water not at the outlet, but at the inlet to the boiler. It is this water heater that is easiest to make with your own hands.